Patents

Literature

36results about How to "Ensure construction quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

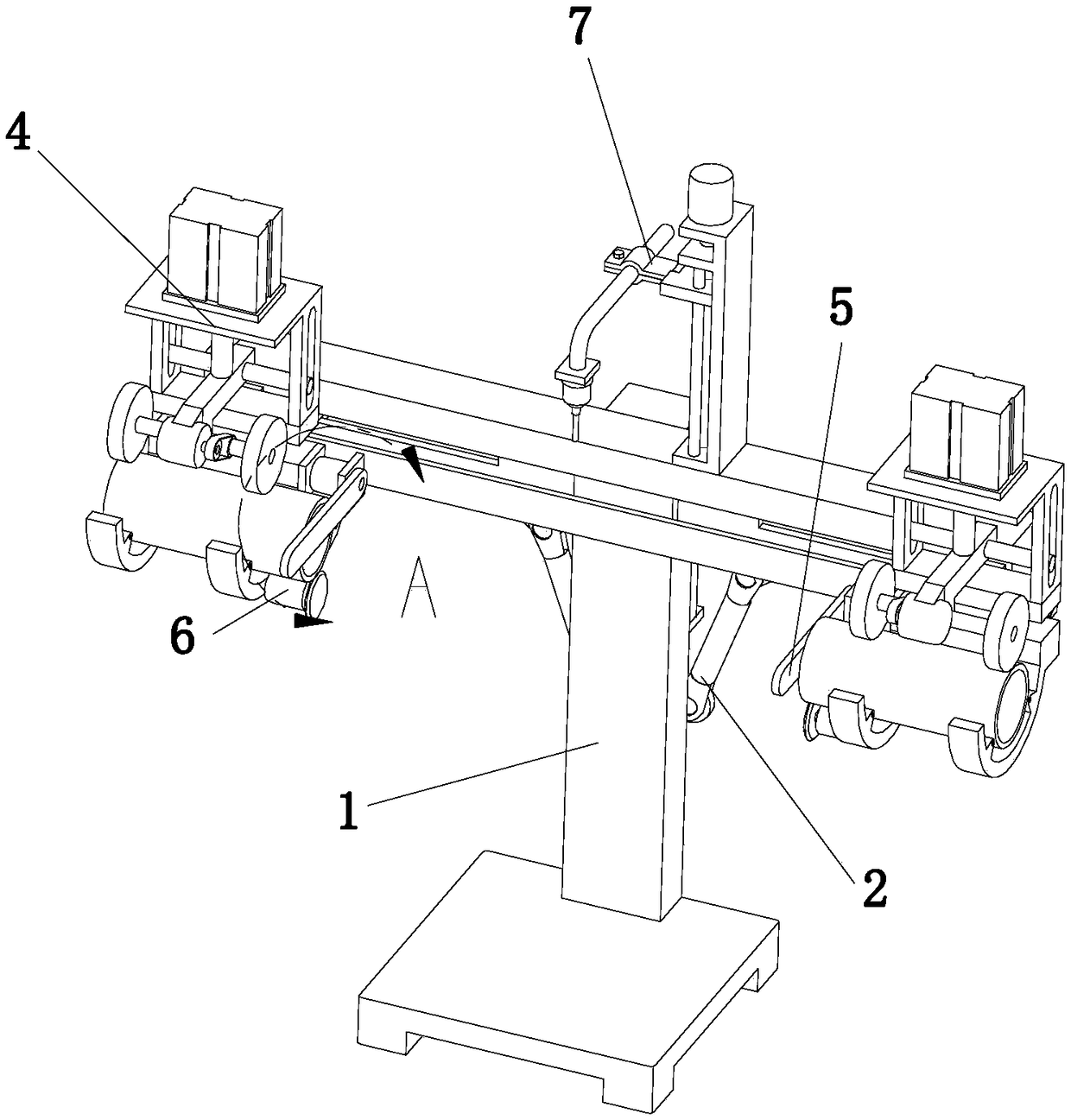

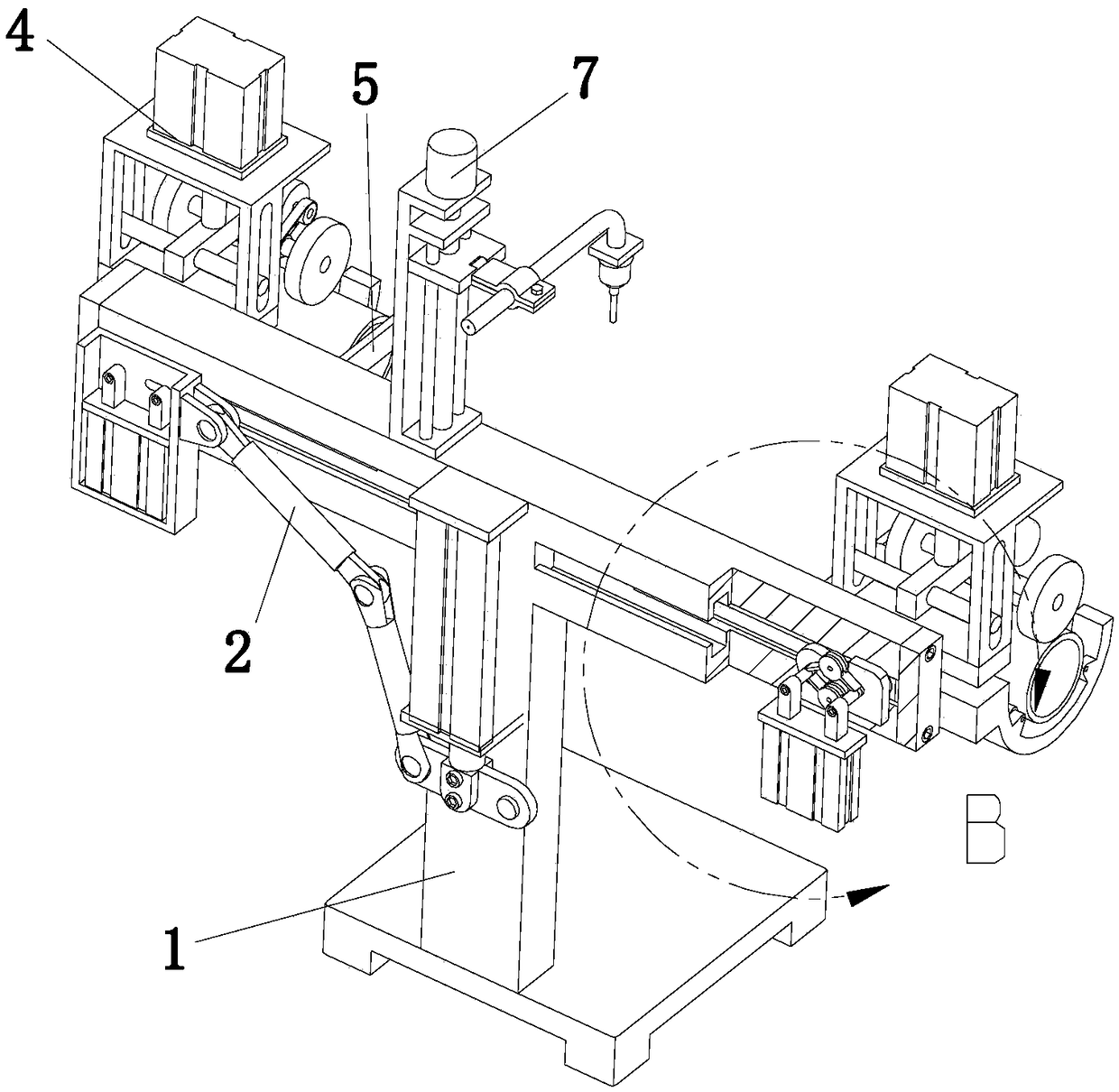

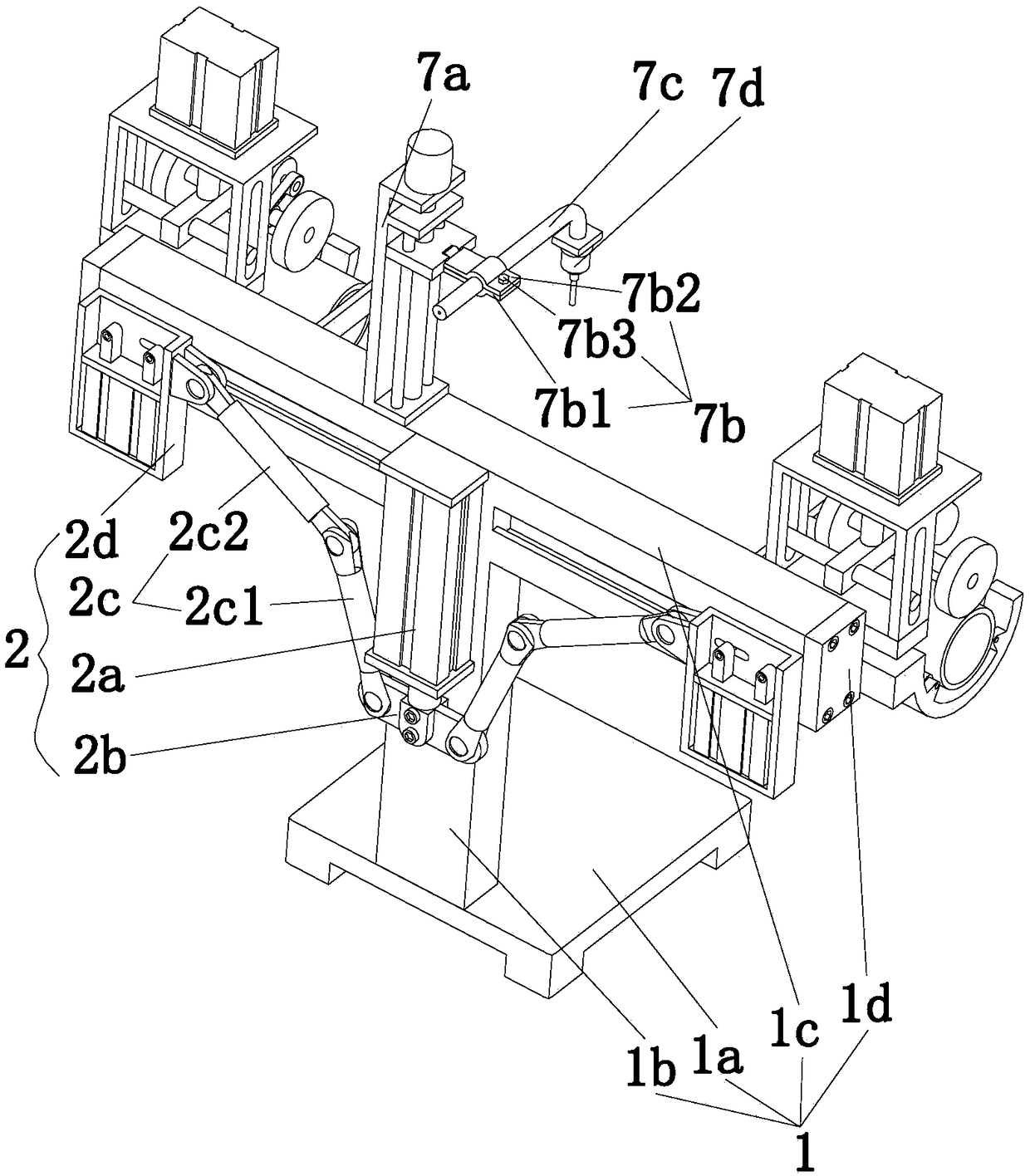

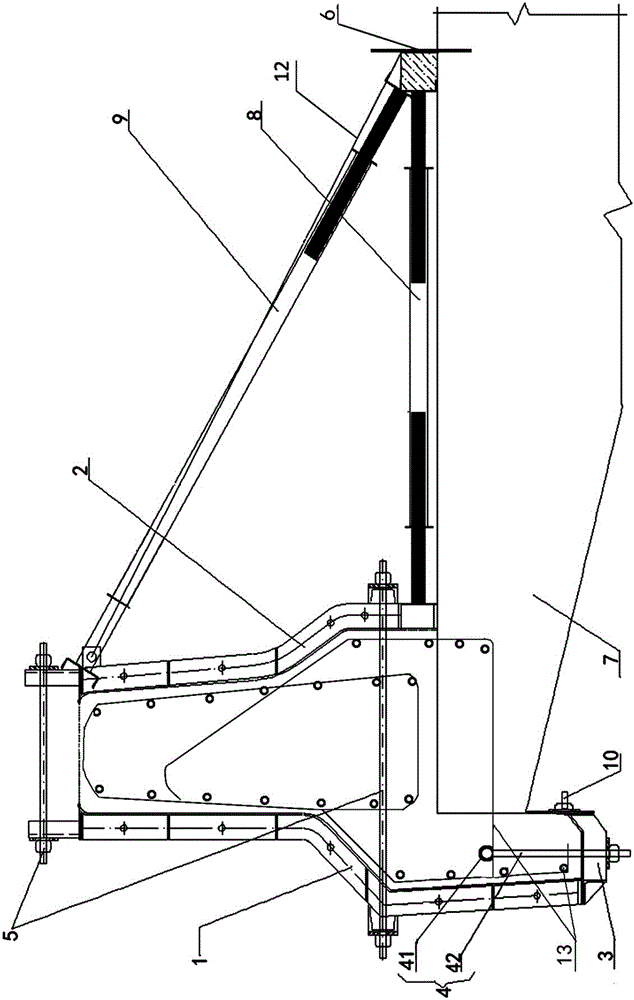

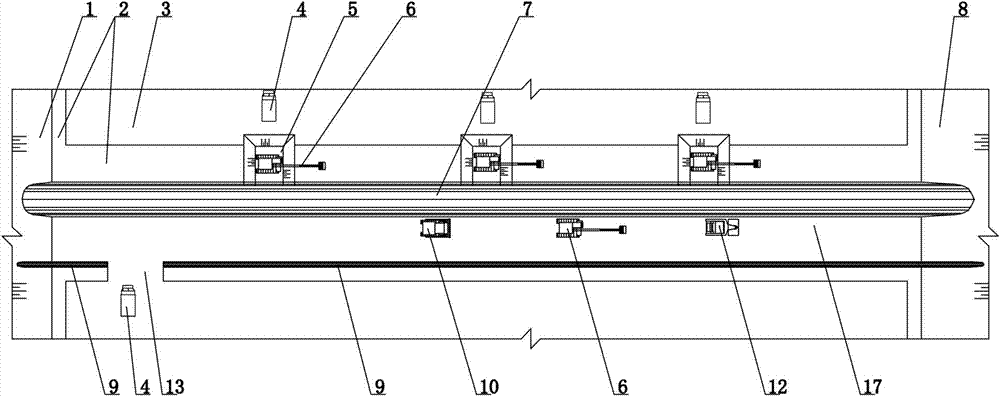

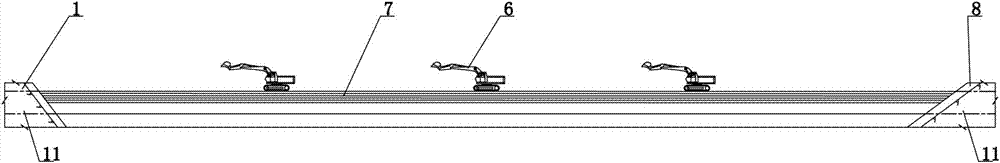

Pipe welding device for building construction

ActiveCN109465594ARealize automatic positioningAvoid partial solderingWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringPipe welding

The invention relates to the field of building construction equipment, in particular to a pipe welding device for building construction, comprising a T-shaped frame, a synchronous moving device, fixing devices, clamping devices, positioning devices, trimming devices and a welding device, wherein the synchronous moving device is arranged on the T-shaped frame, the fixing devices are arranged on both sides of the T-shaped frame and are connected with the synchronous moving device, the clamping devices are arranged on both sides of a beam guide rail, the clamping devices are connected with the fixing devices, and the fixing devices move to drive the clamping devices along the beam guide rail to do synchronized motion, the positioning devices are disposed on the sides of the two clamping devices near columns, the trimming devices are disposed on the sides of the clamping devices near the columns, and the welding device is installed above the middle of the beam guide rail. The invention canrealize the automatic welding of the pipe, realize the automatic alignment of the pipe welding part, can prevent the construction pipe material from being broken at the welded part during the rotation process, effectively reduce the labor intensity of the construction worker, and ensure the construction progress and the construction quality.

Owner:ZHEJIANG AOCHUAN HYDRAULIC

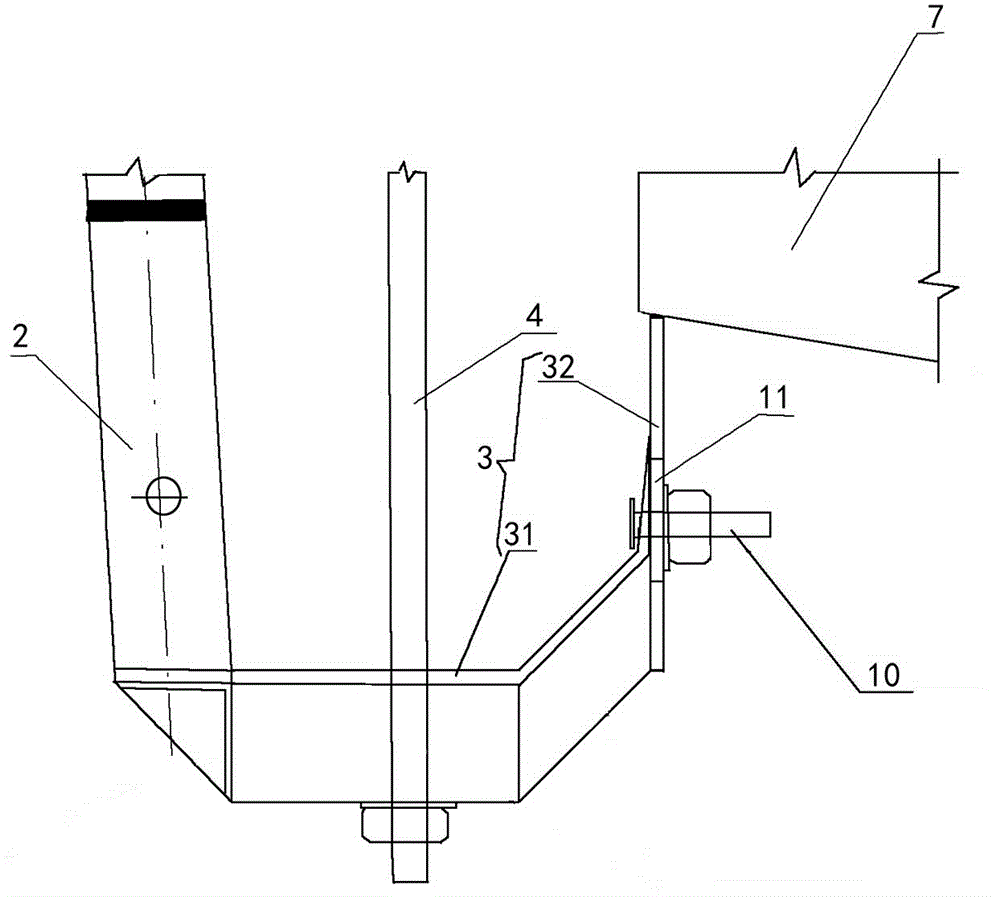

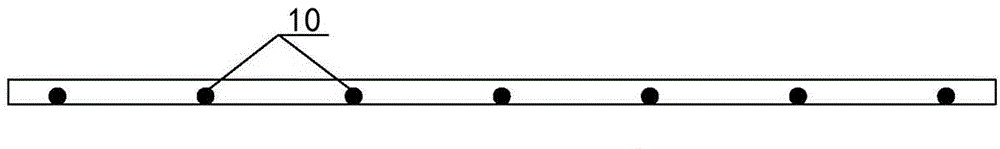

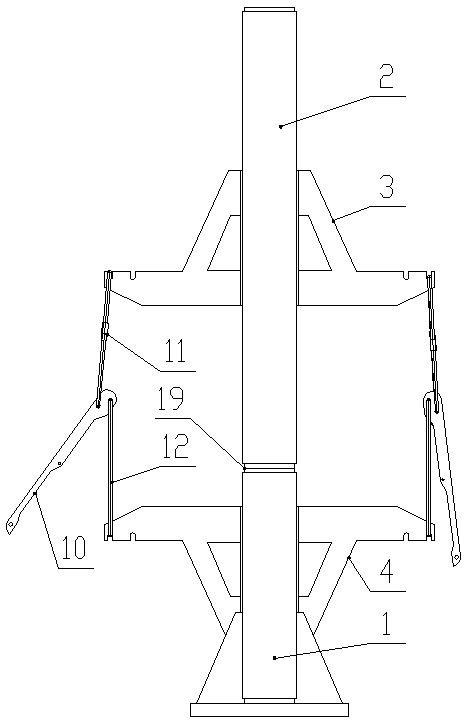

Special formwork for bridge integrated cast-in-situ anti-collision barrier and hanging plate and construction method thereof

ActiveCN103911951ASolve the problem that cannot guarantee smoothnessSolve the problem of no bracket fixationBridge erection/assemblySupporting systemRebar

Disclosed are a special formwork for a bridge integrated cast-in-situ anti-collision barrier and hanging plate and a construction method thereof. The formwork comprises an internal formwork, an external formwork and a base formwork; the internal formwork is fixed on a bridge edge plate through a supporting system; the external formwork which is hung on the external side is connected with the internal formwork through split bolts; one end of the base formwork is connected with the bottom of the external formwork and the other end is provided with a height adjustable vertical plate to be abut against the bottom surface of a bridge; the base formwork and arrangement achieved barrier internal reinforcement bars are fixedly welded through T-shaped hooks. A construction process comprises assembly, hoisting, fixation and connection of the formworks, height adjustment of the vertical plate, formwork integral quality testing and the like. According to the special formwork for the bridge integrated cast-in-situ anti-collision barrier and hanging plate, a detailed design is performed on the prior art, flexible adjustment of the formwork is achieved through the height adjustment vertical plate, support-free fixation of the bottom of the formwork is achieved through the T-shaped hooks, and accordingly preconditions are provided for integral effect formation of the anti-collision barrier and the hanging plate, the safety, the reasonability and the economic efficiency of the formwork are guaranteed, and the engineering construction quality and safety is effectively guaranteed.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP

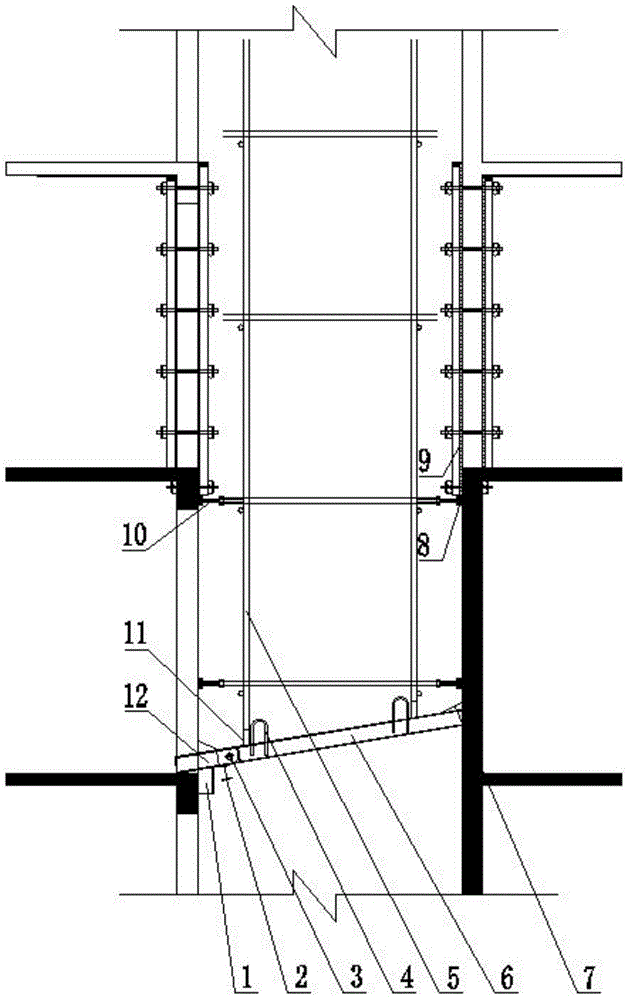

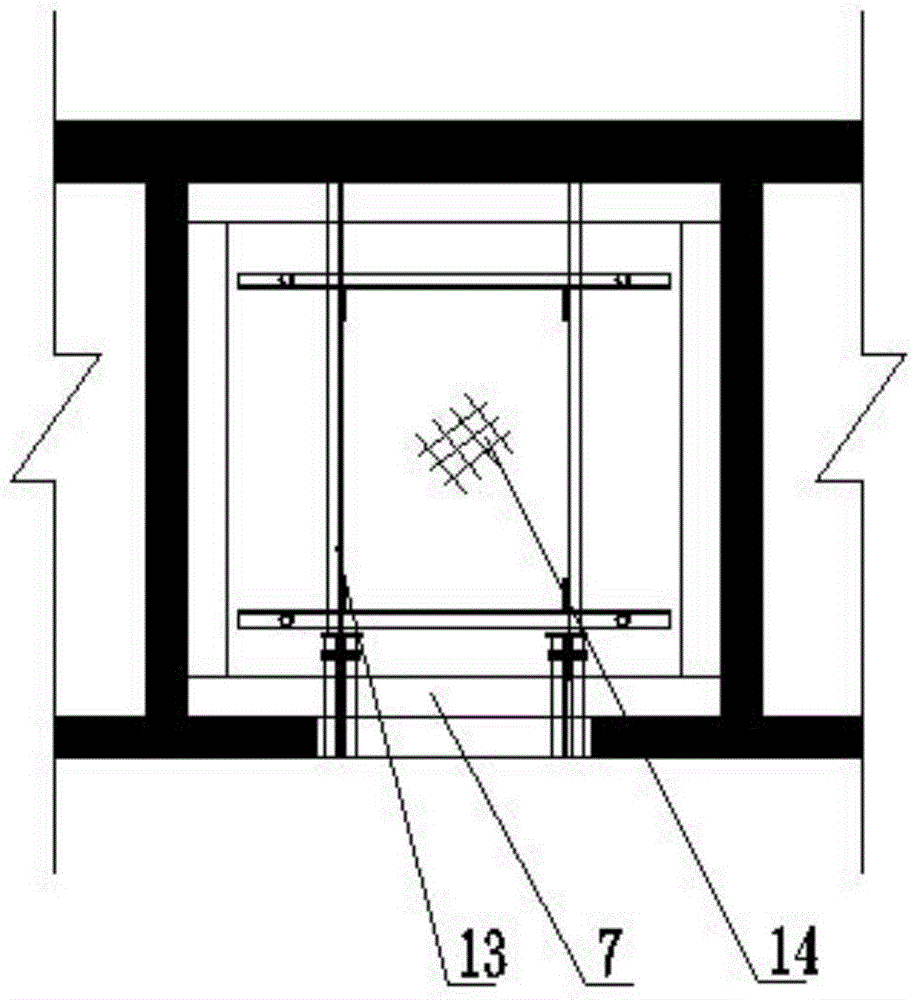

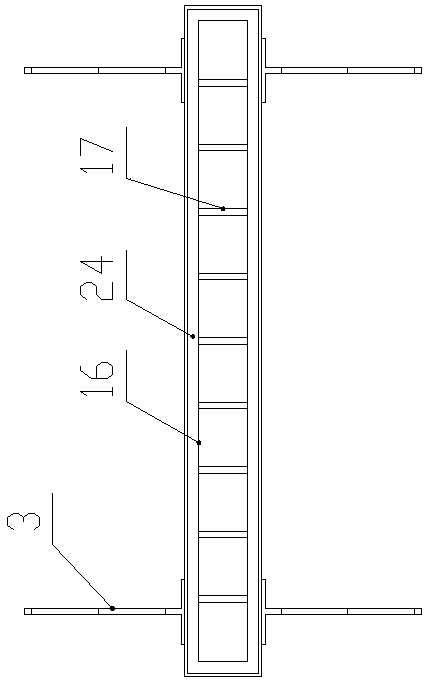

Construction method for high-rise reinforced concrete elevator shaft

InactiveCN104631822AQuick SetupLabor savingBuilding material handlingBuilding support scaffoldsFalseworkReinforced concrete

The invention relates to a construction method for a high-rise reinforced concrete elevator shaft. The construction method comprises the steps: step one, a movable platform is assembled; step two, the movable platform is lifted and installed in position by using a tower crane after completing construction of a first floor elevator shaft; step three, the movable platform which is lifted and installed in position is arranged in a tilted mode, a scaffold is vertically fixedly arranged on the tilted movable platform, an overturning lap beam is arranged on the wall of the elevator shaft in a lap joint mode, and the overturning lap beam is clamped by a limiting clamping plate; step four, the scaffold is fixed firmly; step five, a formwork of the elevator shaft is installed, and the formwork is erected on a horizontal-bar-positional continuous wood beam of the shaft wall; step six, concrete construction is carried out on the elevator shaft; step seven, the formwork of the elevator shaft is removed; step eight, the movable platform is installed in position; step nine, repeating the step four to eight until the construction of the high-rise reinforced concrete elevator shaft is completed. According to the construction method for the high-rise reinforced concrete elevator shaft, the construction method can be utilized repeatedly, the usage of the formwork is effectively reduced, the manpower input is lowered, the cross-operation of a formwork worker and a scaffolder is reduced, and the project cost is lowered.

Owner:MCC TIANGONG GROUP

Installing method of roof mast

The invention relates to an installing method of a roof mast. The method comprises the following steps: firstly, lifting up a whole steel tube assembly by a windlass; and stopping the windlass when the bottom of the steel tube assembly reaches a base of the lowest place; secondly, connecting a pair of hand-drive block stringers to an outermost layer of steel tube and lifting up or down the steel tube assembly in an alternative working manner in order to fine adjusting the height of the steel tube assembly till the outermost layer of the steel tube is arranged at the base of the lowest place and a base of the lower place, and then keeping the position of the steel tube assembly and welding and fixing the steel tube assembly; connecting the hand-drive block stringers to an innermost layer ofsteel tube in the steel tube assembly, lifting up the innermost layer of the steel tube in an alternative working manner, and stopping the lifting when the length of the sleeved part of the lower endof the innermost layer steel tube and the upper end of an inner layer steel tube sleeved on the innermost layer steel tube is ranged from 0.3-2 m, and then welding and fixing the innermost layer of the steel tube with the inner layer of steel tube; and finally, repeatedly lifting up and welding each remained section of steel tubes sleeved in the outermost layer of the steel tube, and then finishing the installation of the roof mast.

Owner:CHANGZHOU NO 1 CONSTR GRP

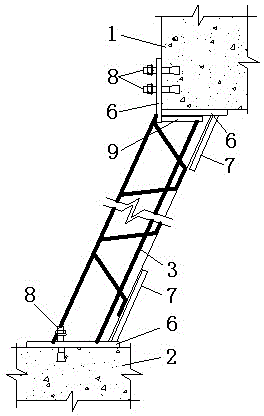

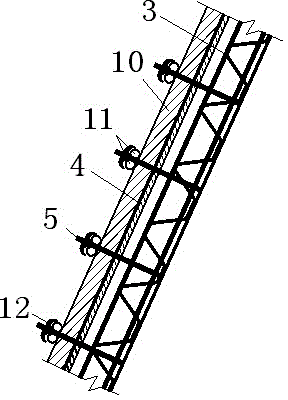

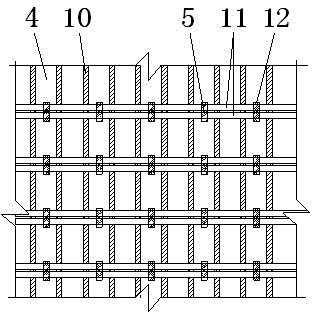

Ultra-thin steel truss inclined wall construction method and formwork structure

ActiveCN103603494ASolving the Difficulties in Supporting Inclined WallsEnsure safety and qualityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksMaterials processingRebar

The invention discloses an ultra-thin steel truss inclined wall construction method and structure. The ultra-thin steel truss inclined wall construction method is characterized in that a connecting member is fixed between a superstructure and a substructure; the outside of an inclined wall body utilizes a steel bar truss formwork as a supporting member, and two ends of the steel bar truss formwork are connected with the connecting member of the superstructure and the substructure to serve as the outer supporting formwork of the inclined wall body; the inside of the wall body utilizes an ordinary formwork; the ordinary formwork and the steel bar truss formwork are connected through a split bolt; the pouring of concrete utilizes self-compacting concrete. According to the ultra-thin steel truss inclined wall construction method and structure, the steel bar truss formwork serves as the support of the outside of the inclined wall body, and the inside of the inclined wall body still utilizes the ordinary formwork, so that the difficulty in the supporting of the inclined wall is overcome; the technology is simple, the field installation efficiency is high, the quality is reliable, the construction period is short, the labor intensity is low, and labor force can be arranged for performing construction simultaneously; materials can be processed in a material processing factory, field assembly can be performed directly, and the construction period is shortened; the construction quality meets design requirements.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

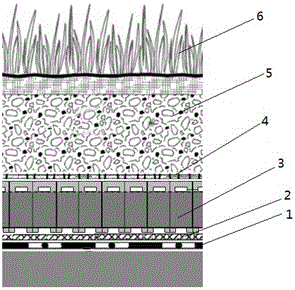

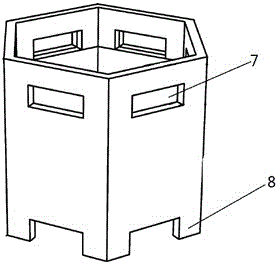

Technical method of green sponge roof modified on basis of grass planting plate

ActiveCN106013624ASimple construction processEasy to operateRoof improvementClimate change adaptationVegetationRoot isolation

The invention discloses a technical method of a green sponge roof modified on basis of a grass planting plate. The method comprises the following steps: laying a waterproof material on a roof; laying a root isolation material on the waterproof material; then laying an ecological grass planting plate, and laying an isolation filter material on a water drainage-storage water layer; burying planting soil on a filter layer; and seeding herbaceous plant seeds in the planting soil above the grass planting plate, watering, maintaining, completing the roof vegetation after an ecological colony is formed by herbaceous plants, and forming the green roof. The green roof technique is simple in construction process and easy in operation; the grass planting plate is used as the water drainage-storage layer and the plant planting basic surface, so that compared with the traditional green roof method adopting a coarse sand filter layer and a gravel (cobble and ceramic particles) drainage layer, the construction difficulty is much smaller, the construction stability is high, the construction quality and effect can be guaranteed, and the formed landscape is ecological and attractive.

Owner:SUZHOU UNIV

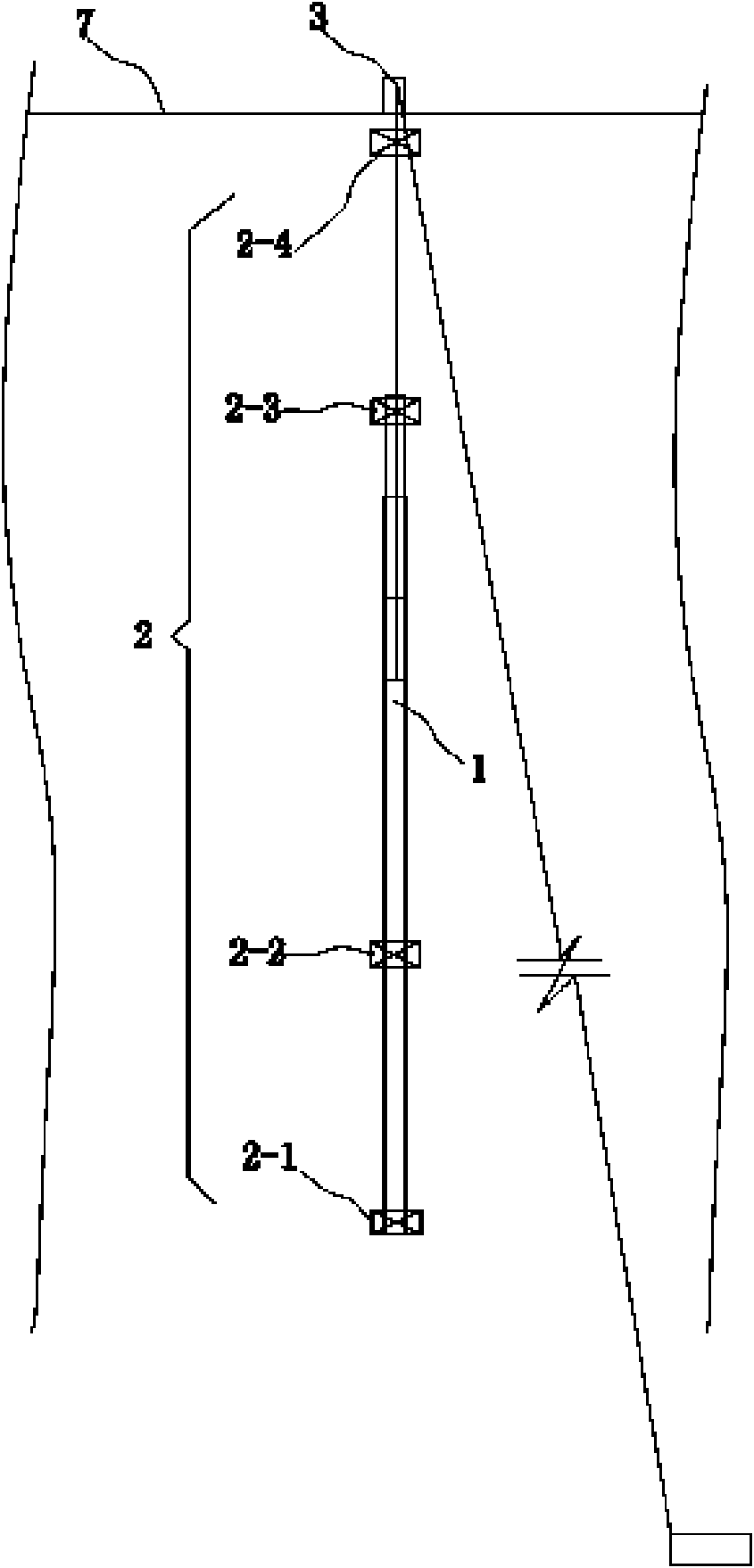

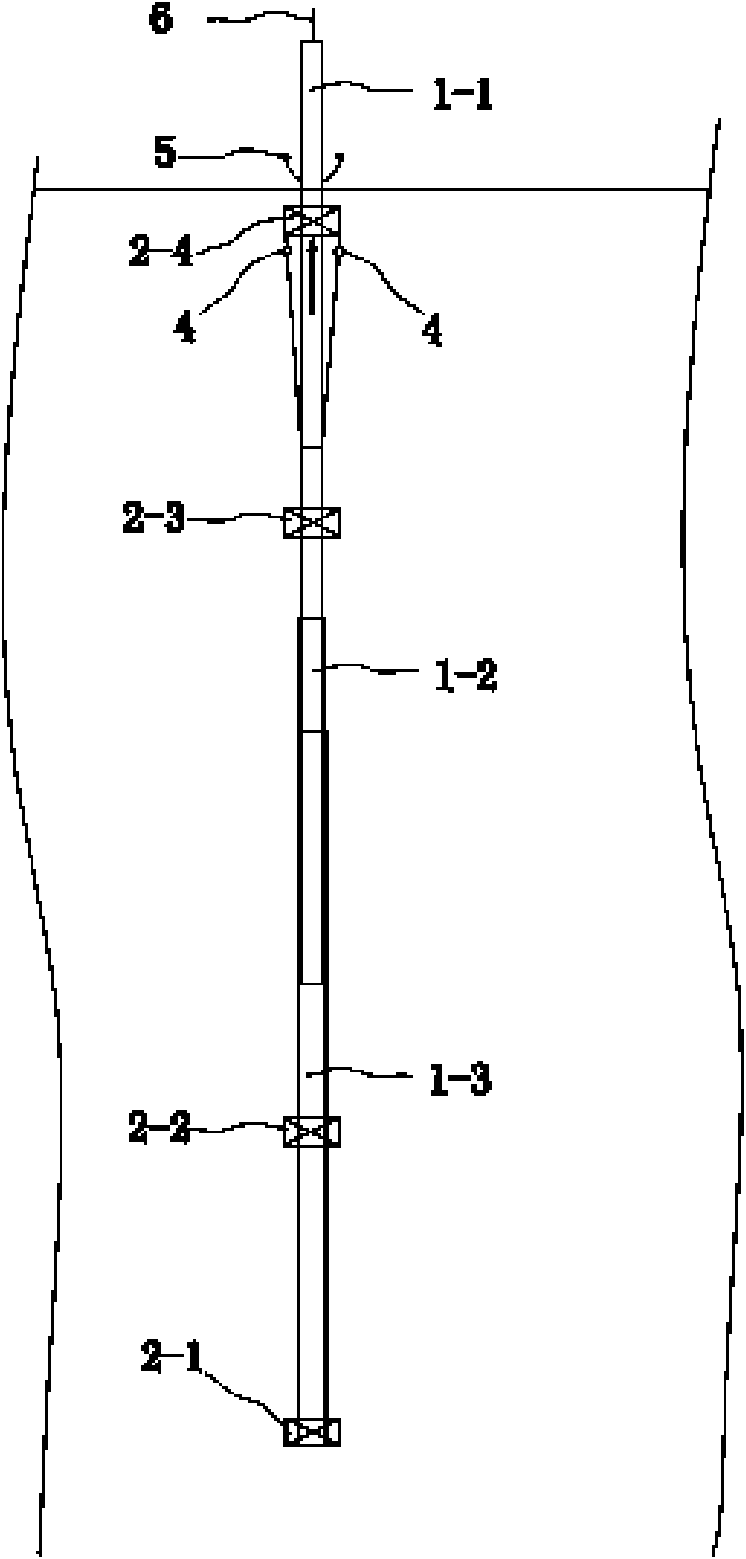

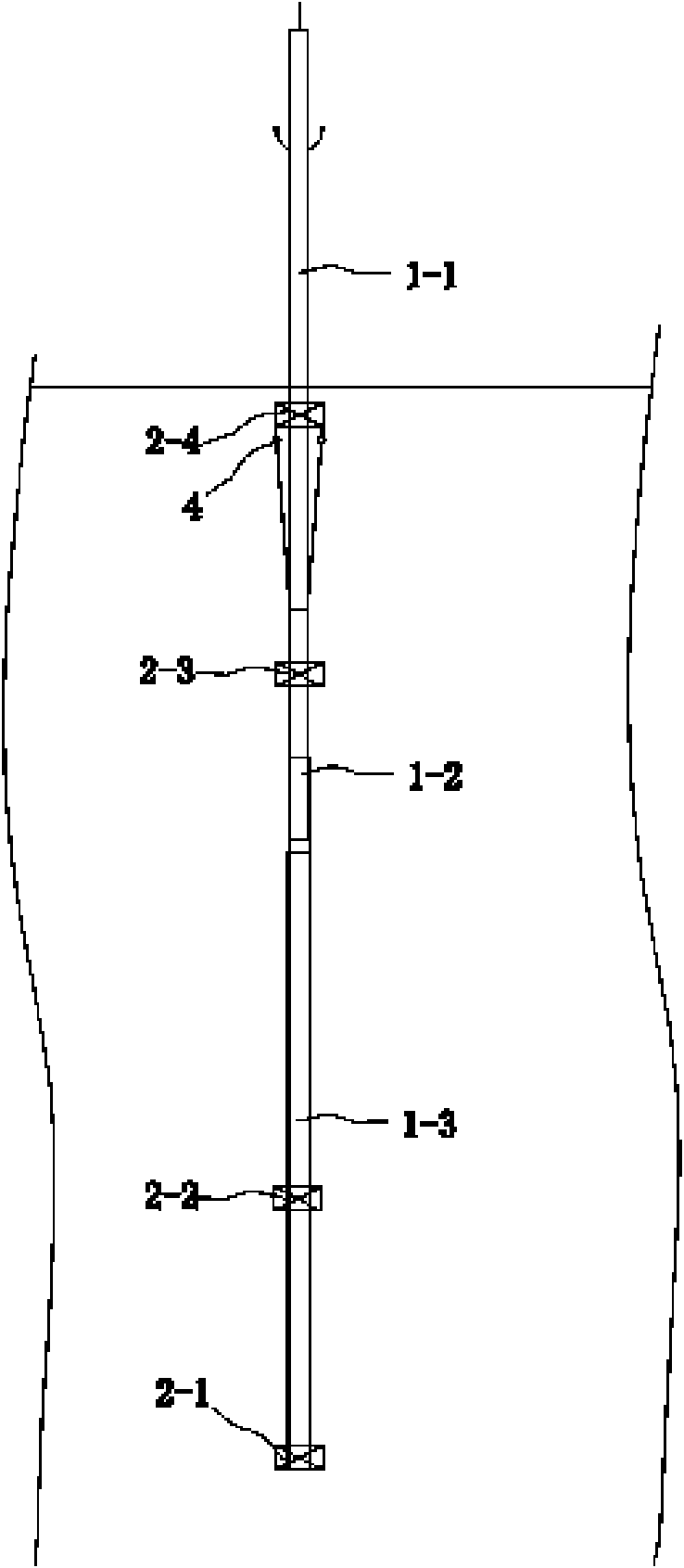

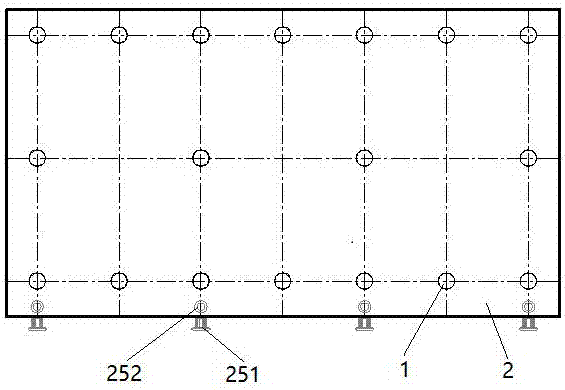

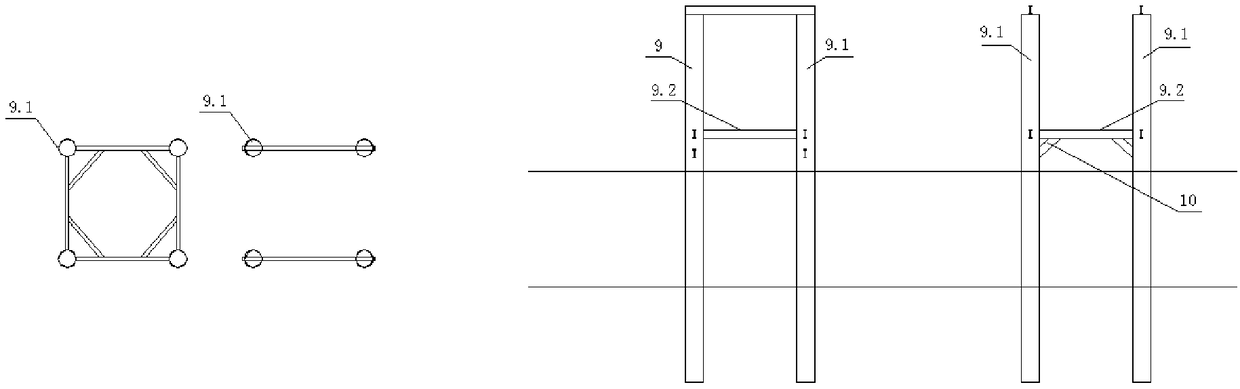

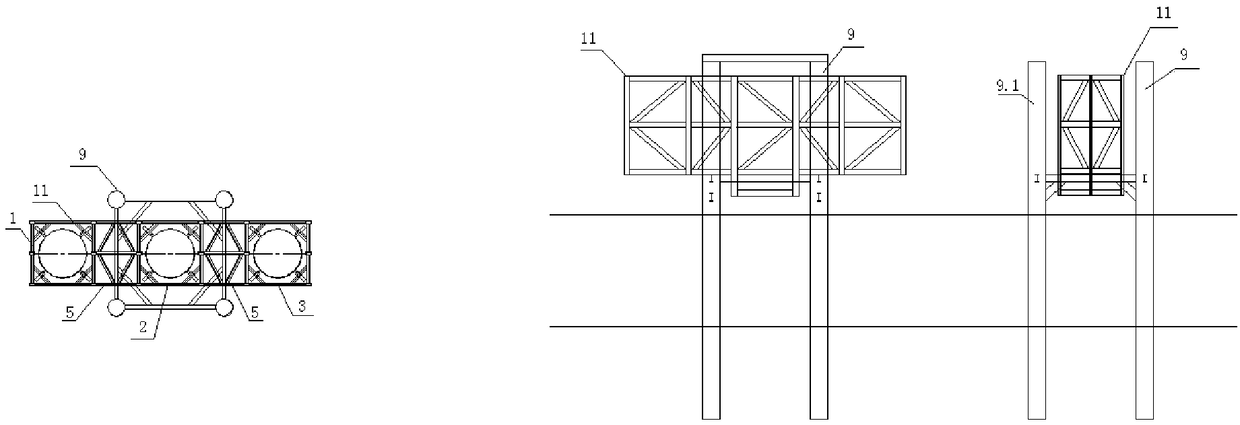

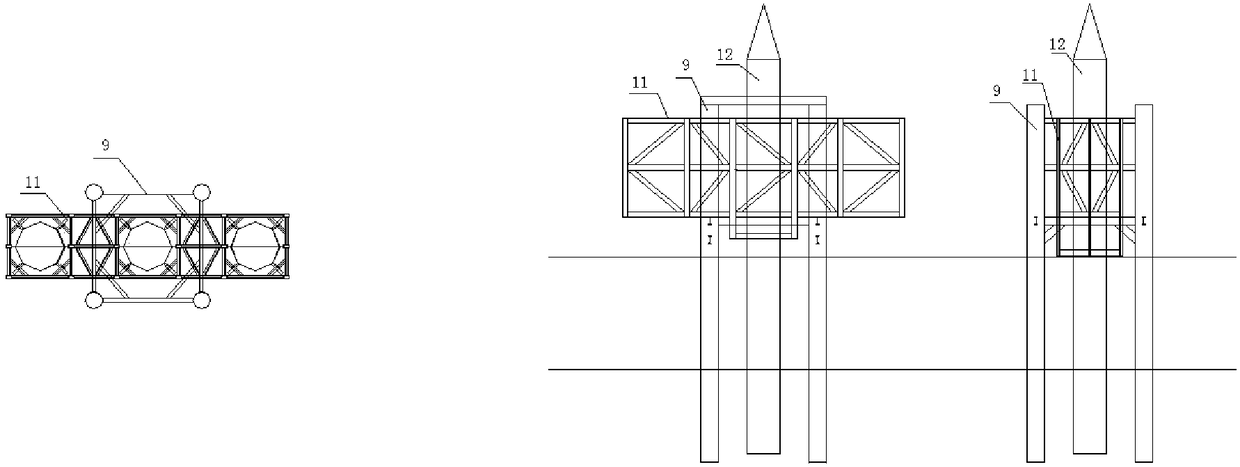

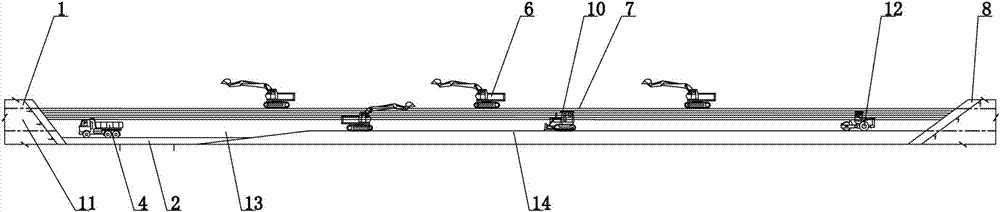

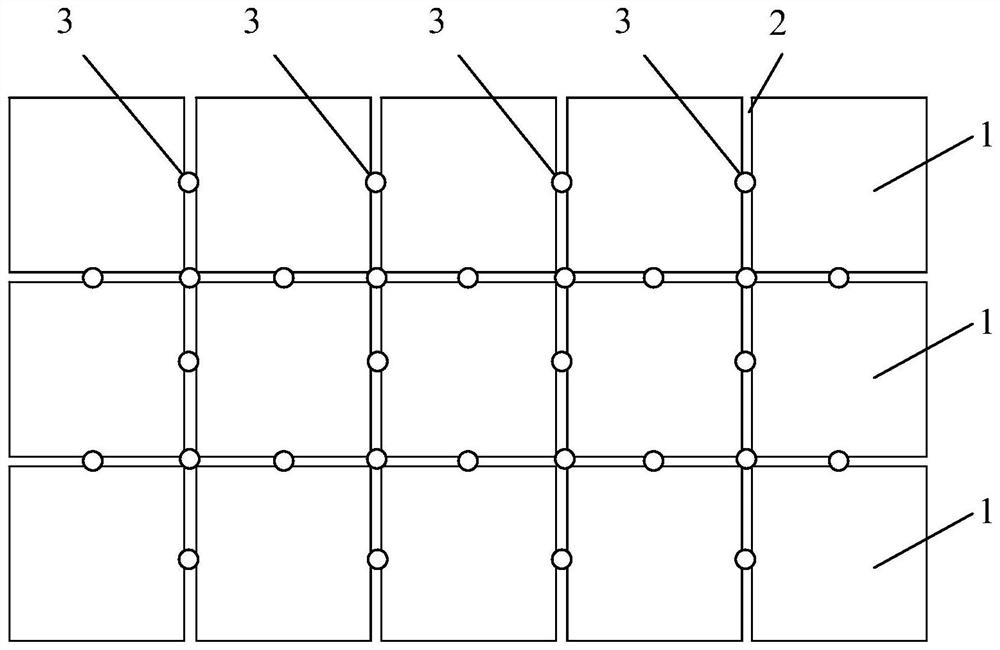

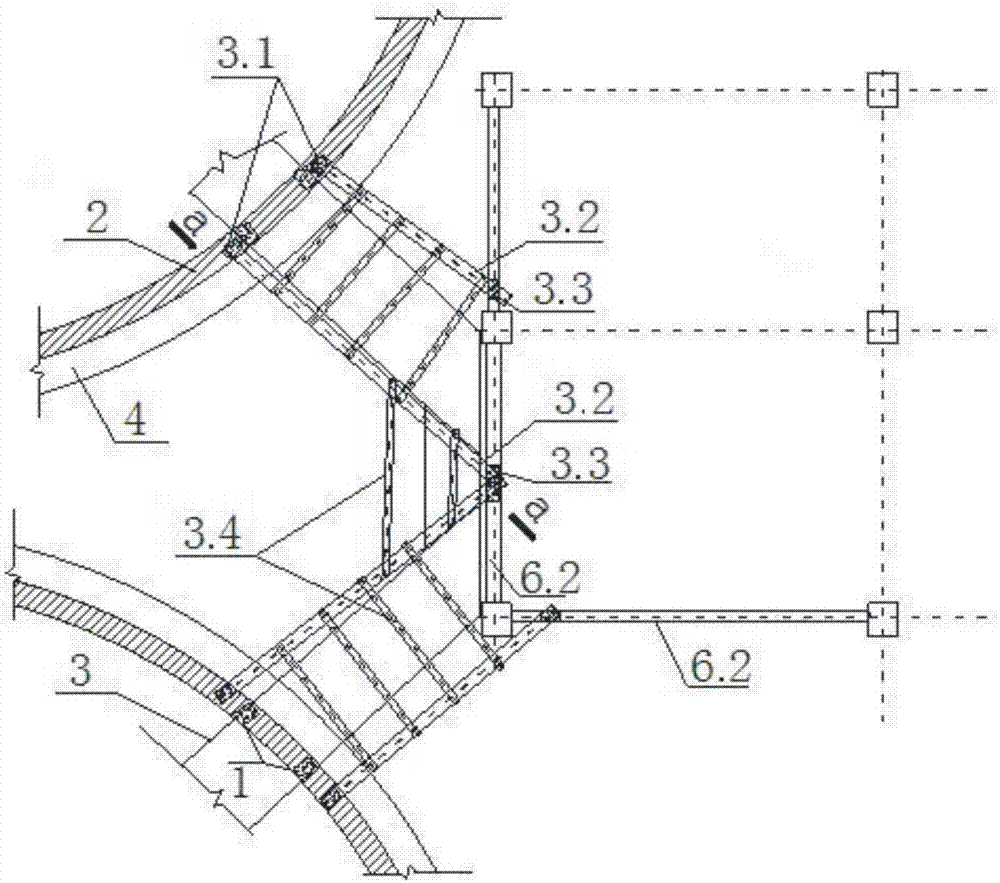

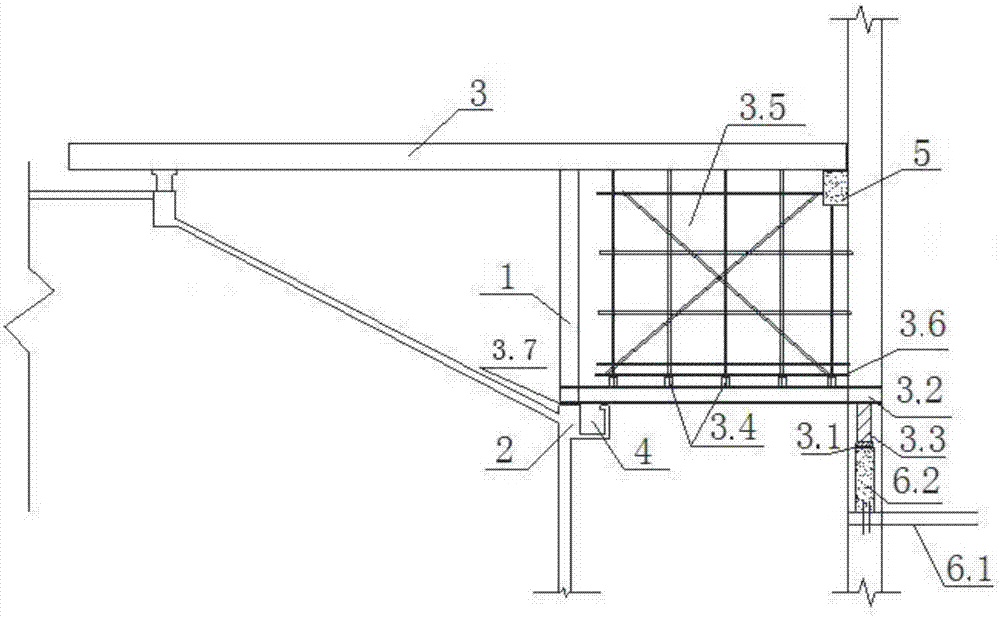

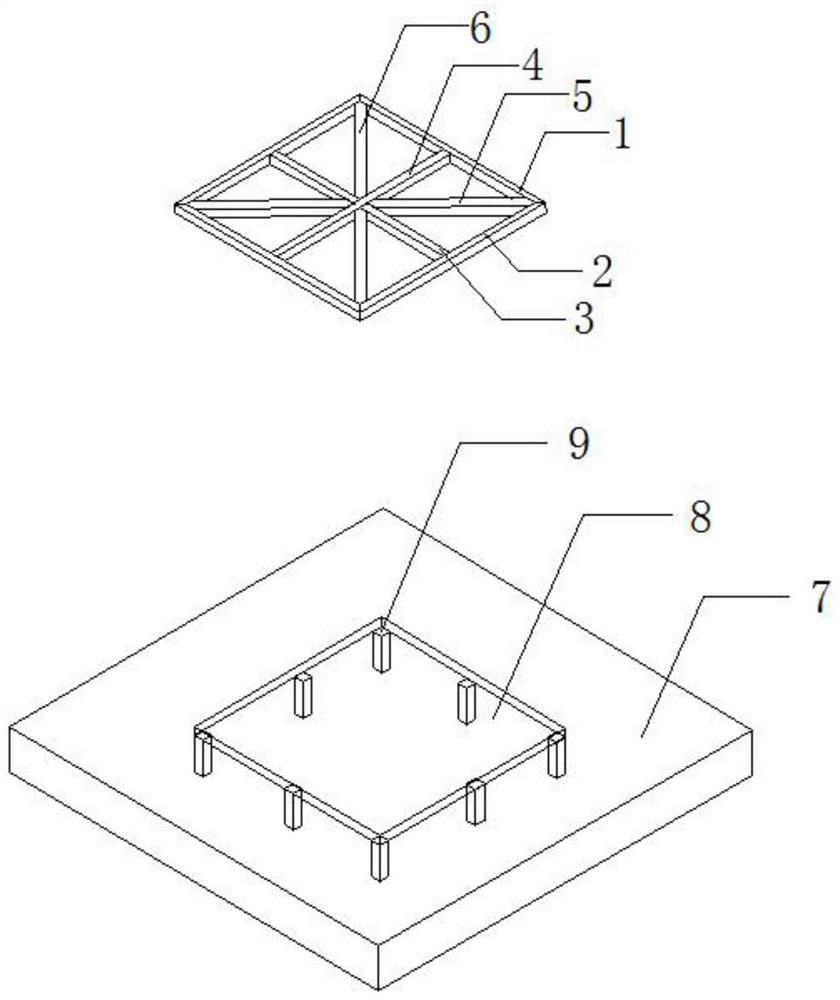

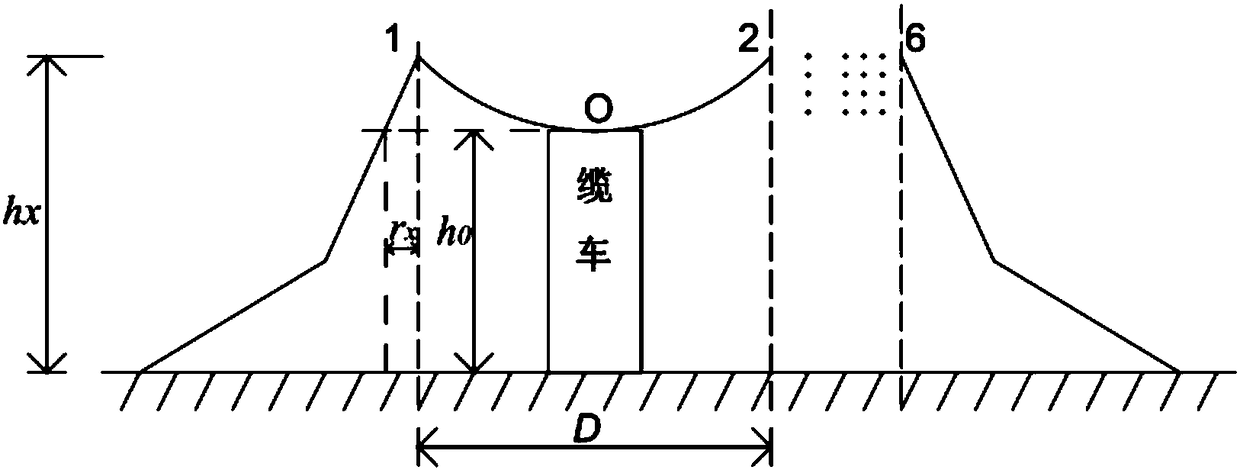

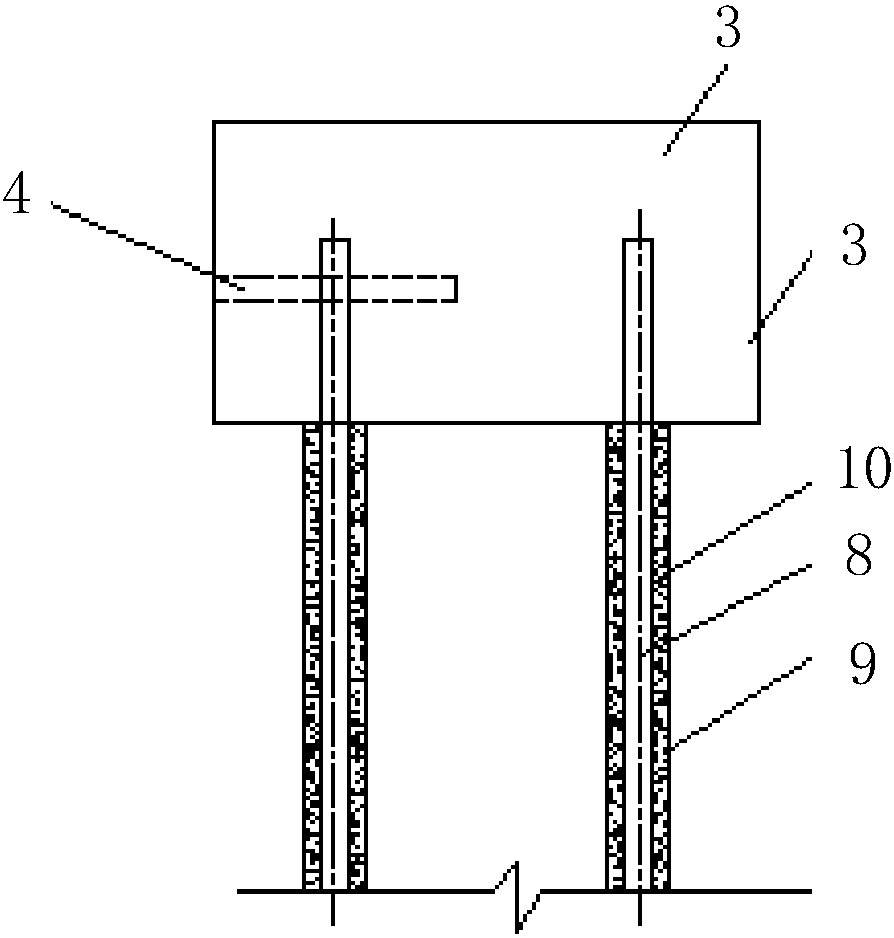

Modular assembly type pile foundation wharf structure system and construction method thereof

PendingCN107034842AReduce in quantityAvoid special dangerous construction operationsBreakwatersQuaysEngineeringGeneral assembly

The invention discloses a modular assembly type pile foundation wharf structure system. The system comprises pile foundations (1), modular upper structure portions (2) and pile foundation and modular upper structure portion connection joints (3). According to the technical scheme, the wharf total plane dimension: N*L(length)*B(width)m is directly divided to be the N upper structure portions (2), the N upper structure portions (2) are prefabricated and machined in a factory at first and then conveyed through a waterway to a site, and then general assembly and in-place installation are carried out. The invention discloses a construction method of the modular assembly type pile foundation wharf structure system. A large number of overwater special dangerous construction working procedures can be avoided, the number of on-site staff is reduced, the construction period is shortened, and the building efficiency is remarkably improved.

Owner:CCCC THIRD HARBOR CONSULTANTS

Large-diameter steel pile casing and three-frame type guide frame driving construction method

ActiveCN108193680AHigh positioning accuracyImprove vertical accuracyBulkheads/pilesCastingSelf weight

The invention discloses a large-diameter steel pile casing and three-frame type guide frame driving construction method. The method comprises the following steps that four auxiliary piles are driven in for placing a three-frame type guide frame, and connected through I-shaped steel; the three-frame type guide frame is placed to an auxiliary positioning steel pipe pile platform, and coordinates andperpendicularity are adjusted; steel pile castings sink due to the self weight; the steel pile castings on the two sides of the guide frame continue to be driven and are positioned, inserted and driven in the same ways as the first steel pile casting; locking connection between the guide frame and the auxiliary steel pipe piles and parallel connection of upper ports between the steel pipe piles are cut away, the guide frame is lifted up and rotated by 90 degrees and then placed down, and steel pile castings on the two sides in the longitudinal direction are driven in the same way; the guide frame is lifted and opened, and the auxiliary steel pipe piles are dismantled; two pieces of I45b type steel are welded to the top port of a middle guide port of the guide frame to be used as a bearingbeam, the middle guide port is placed down to the driven steel pile casting, the driven steel pile casting is used as a positioning base pile, and other steel pile castings are driven. The large-diameter steel pile casing and three-frame type guide frame driving construction method has the advantage of improving steel pile casting driving precision.

Owner:CCCC SHEC FIRST HIGHWAY ENG +2

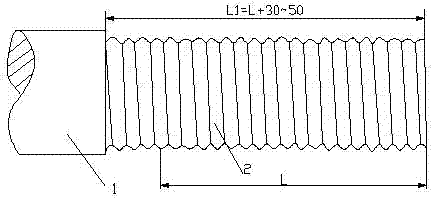

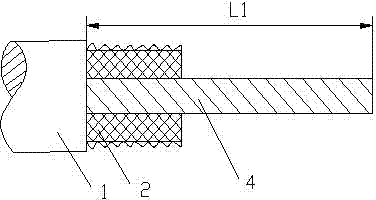

Installation technology of power cable aluminum alloy waterproof drawing head

ActiveCN104300479AEasy to weldLarge diameter variation rangeCable installations in underground tubesPower cableElectric cables

The invention discloses an installation technology of a power cable aluminum alloy waterproof drawing head. The installation technology is characterized by comprising the following steps: the end of the cable drawing head is processed; the drawing head is installed; confining pressure processing is carried out on the drawing head; a steel drawing head body is installed; a heat-shrinkable tubing is installed. Compared with a steel drawing head, an aluminum tube of the aluminum alloy drawing head and an aluminum jacket of the cable are more easily welded into a whole, an aluminum alloy welding welded joint can bear larger external force, the aluminum tube of the aluminum alloy drawing head allows the diameter changing scope of the aluminum jacket of the cable to be larger, the whole extrusion molding is adopted in the aluminum tube of the drawing head, strength is higher, organization is more compact, and the installation technology has the good waterproof and dampproof performance.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

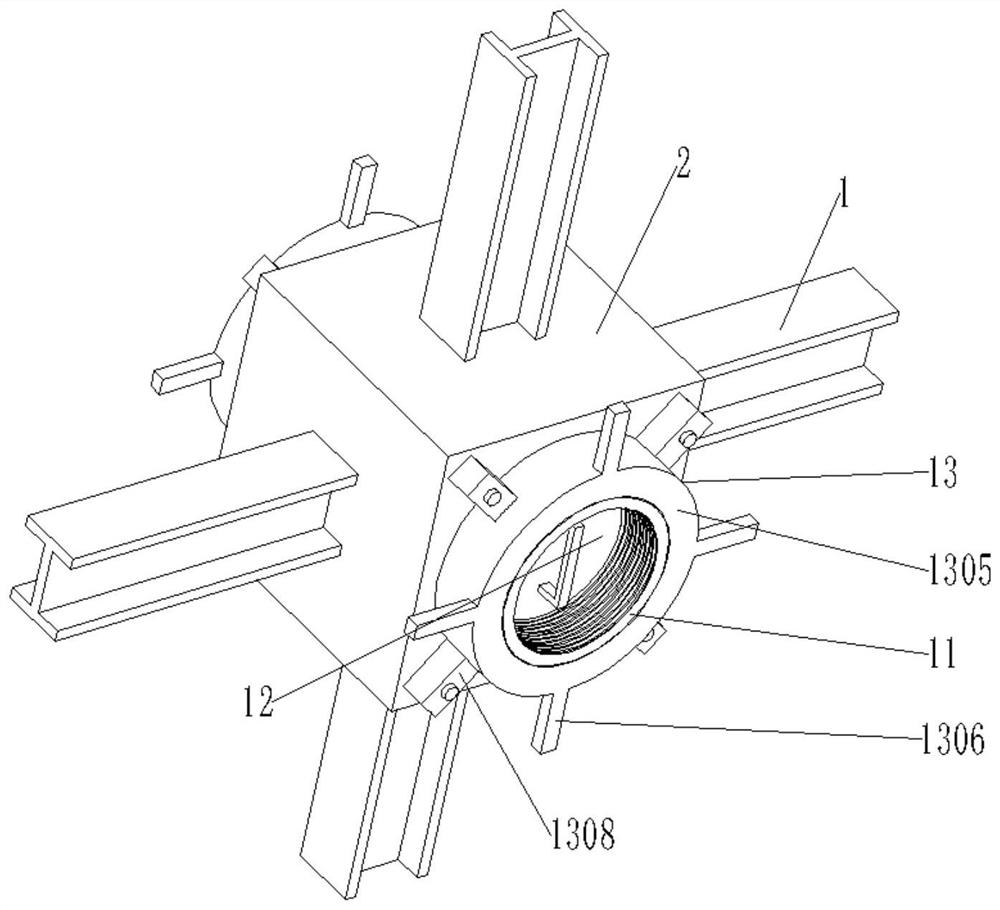

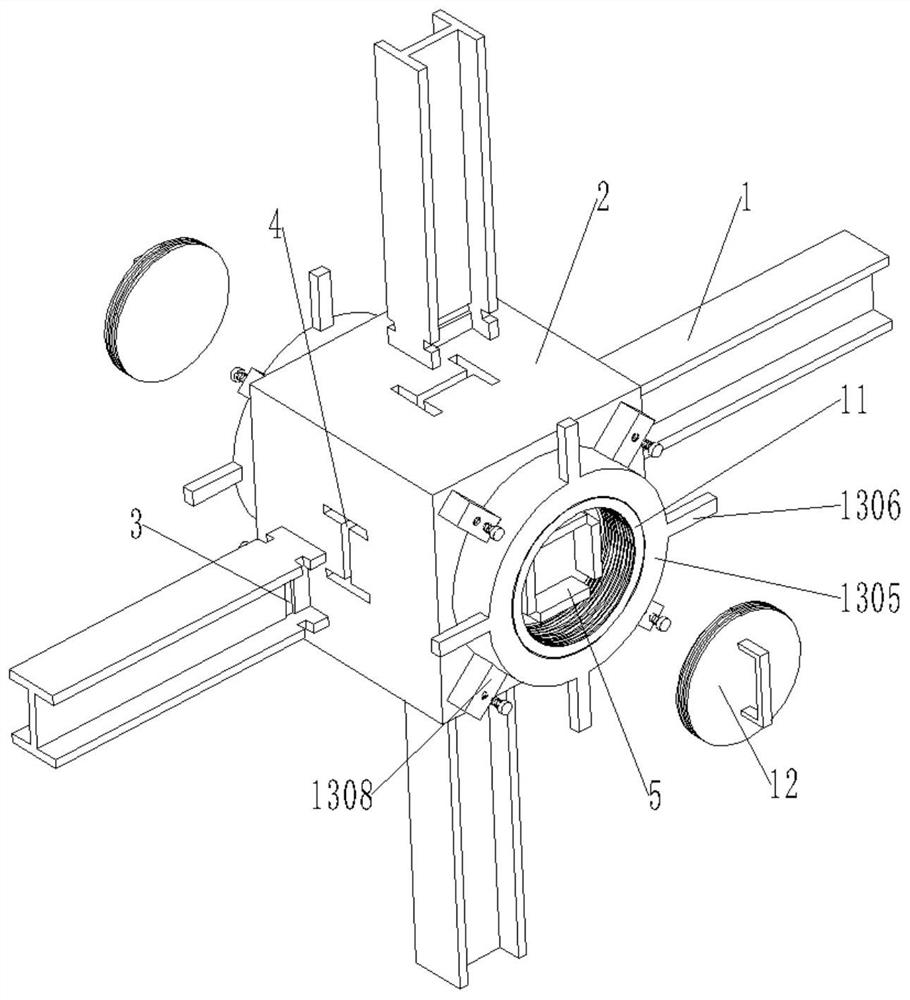

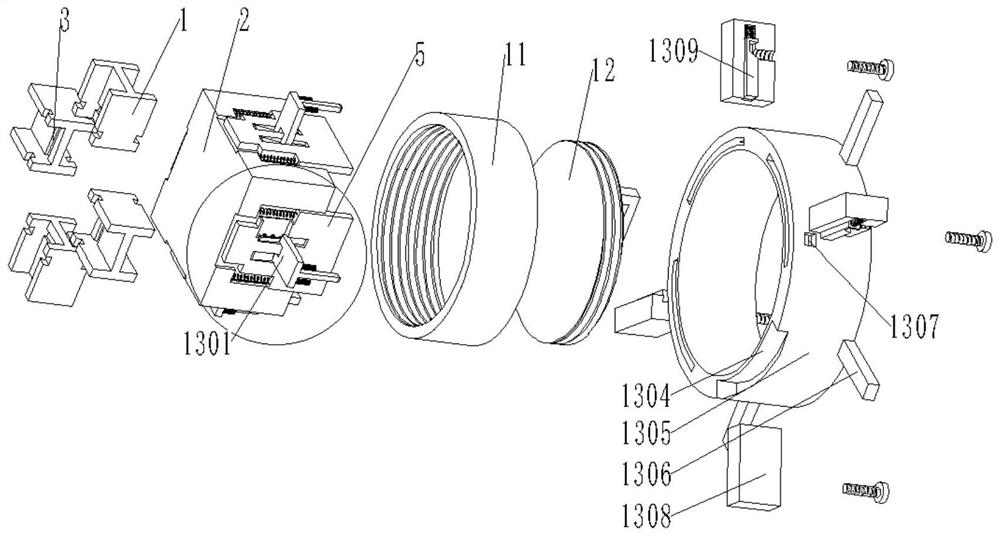

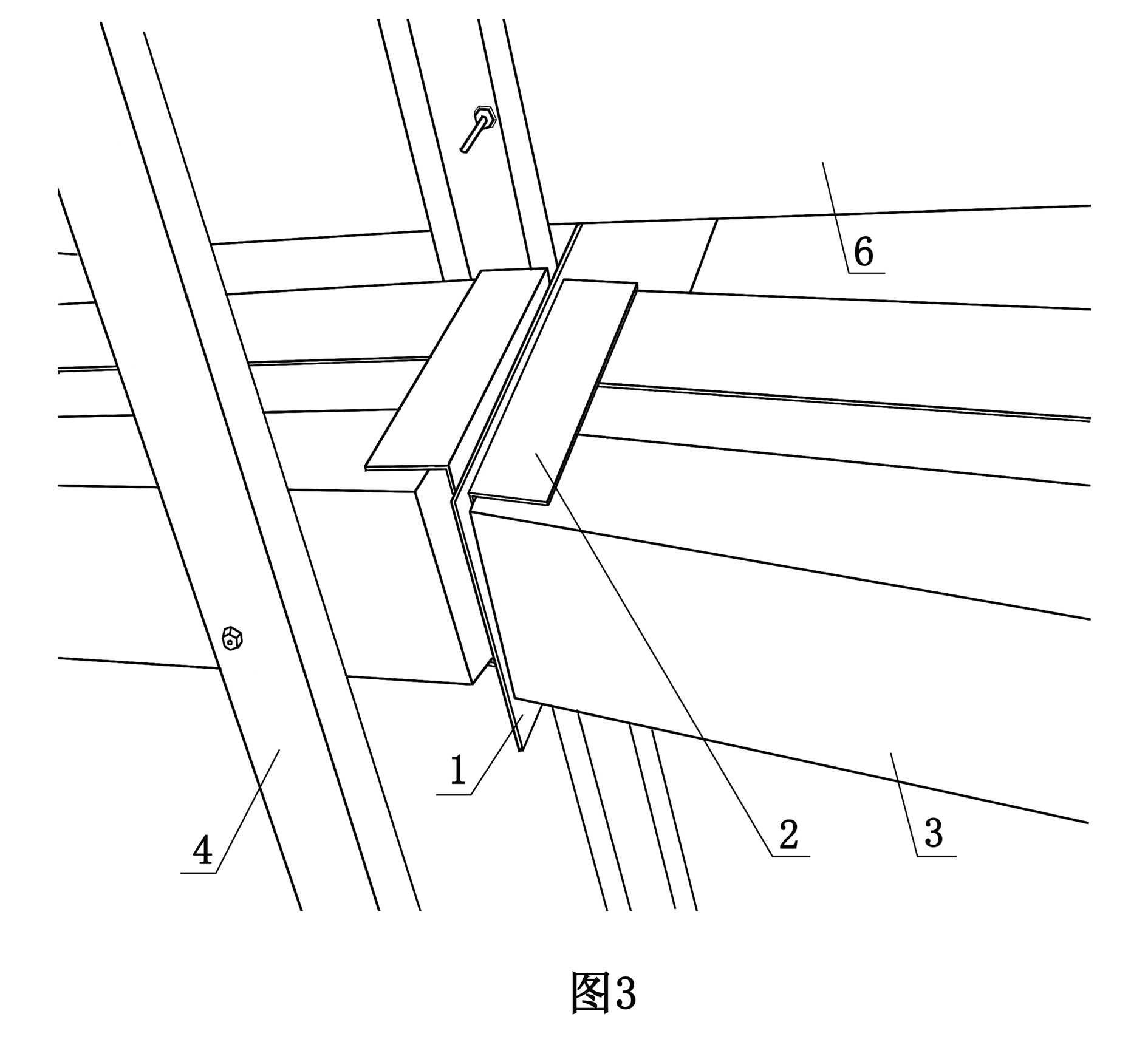

Connecting and mounting structure for steel frame building

ActiveCN111910779AEasy to buildFast constructionBuilding constructionsArchitectural engineeringSteel frame

The invention discloses a connecting and mounting structure for steel frame building. Locking clamping grooves formed in H-shaped steel plates are fixedly connected with a convex movable clamping plate arranged in a connecting square body in a clamped mode, the connecting square body is used for connecting and fixing, building construction of a steel structure is quite convenient and rapid, and the construction work efficiency is improved; connection strengthening and locking structures symmetrically arranged in the connection square body have a good strengthening auxiliary effect on connection and fixation of the H-shaped steel plates and the connection square body, then the firmness in steel framework connection construction is improved, the connection strength is improved, and the construction quality is guaranteed; and further, the connection strengthening and locking structures have a more stable connection strengthening function on the H-shaped steel plates and the connection square body, the stability of steel structure connection is guaranteed, and the construction quality is guaranteed.

Owner:FANGYUAN CONSTR GRP REAL ESTATE DEVT CO LTD

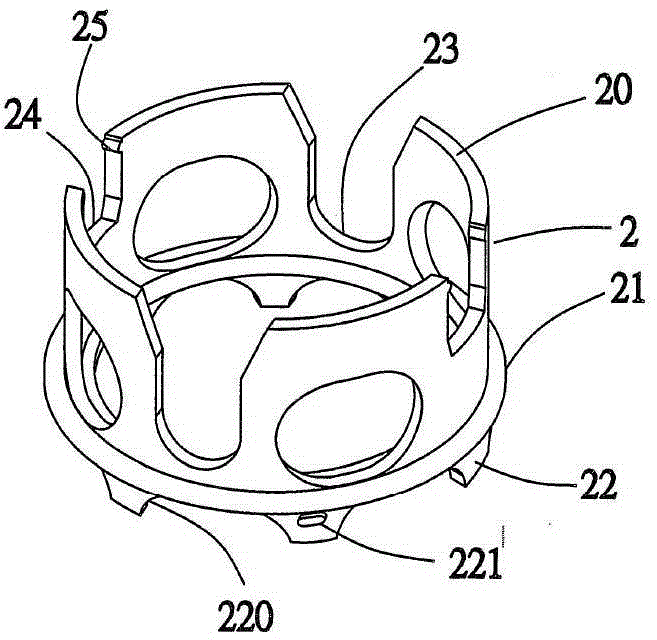

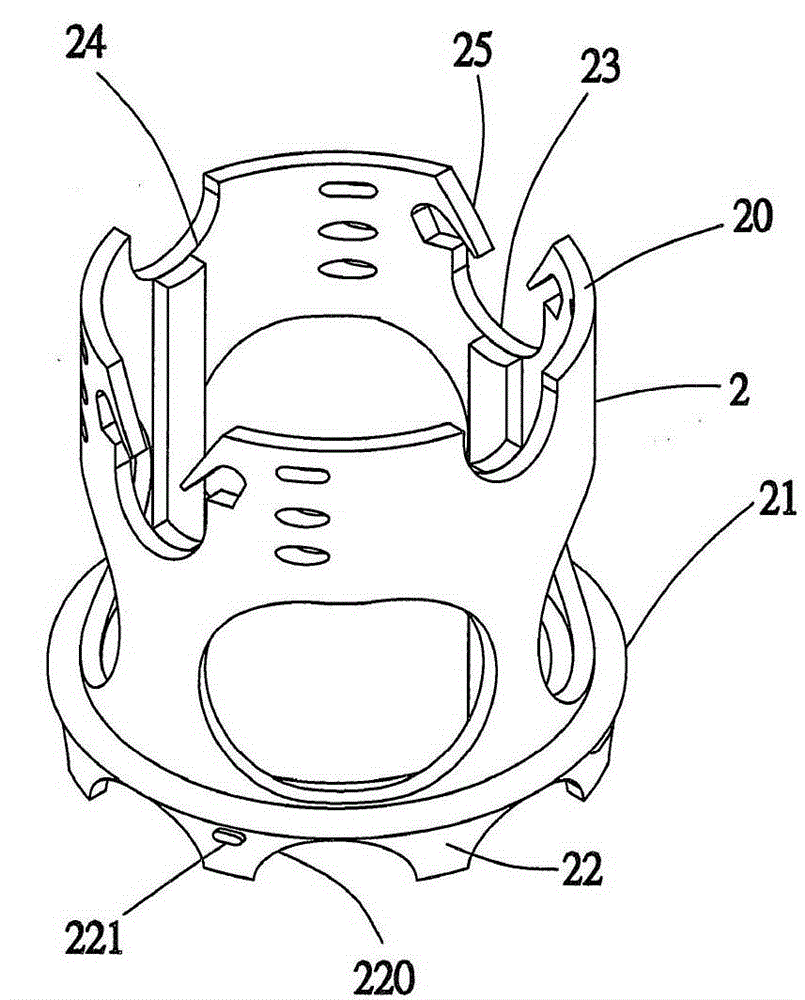

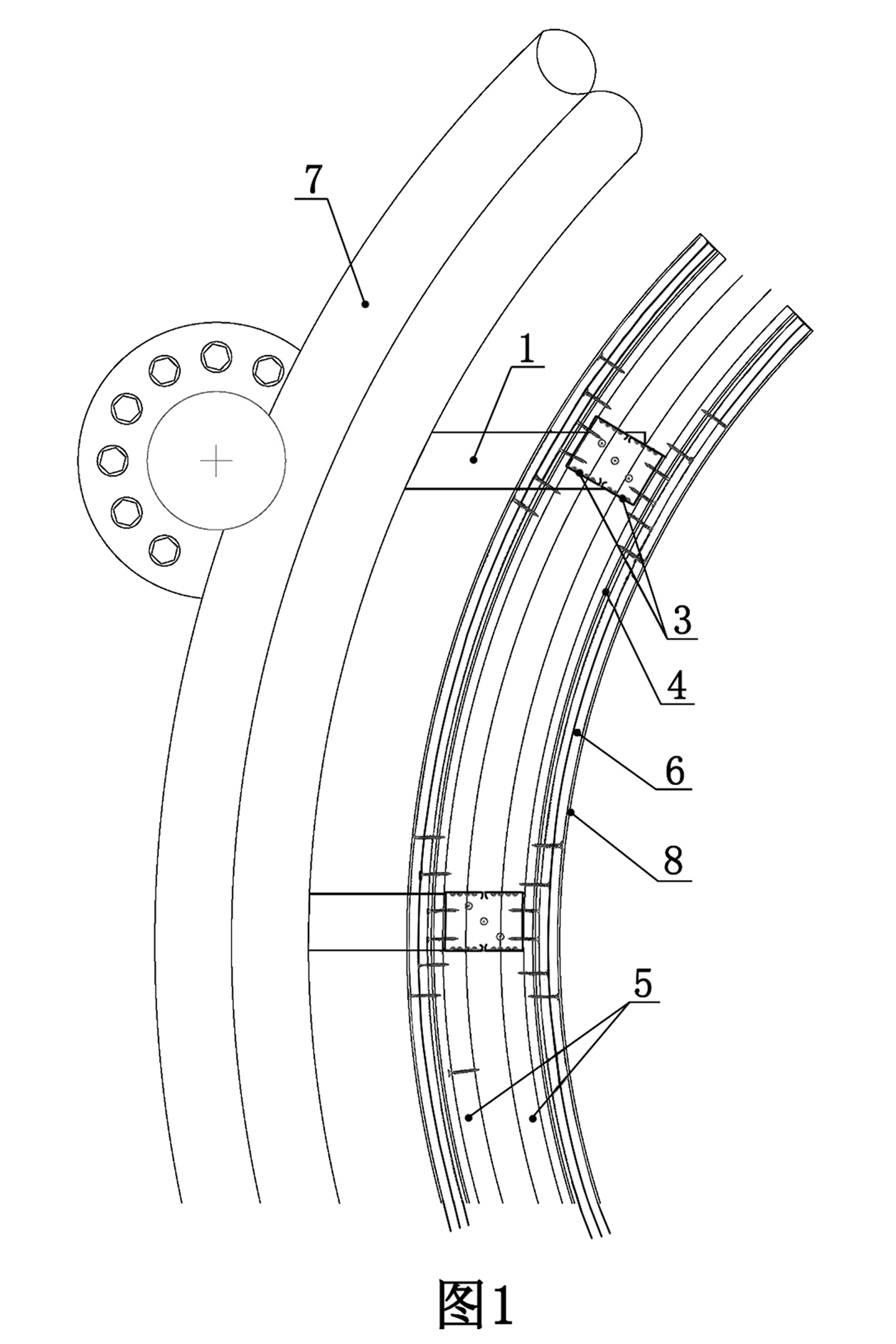

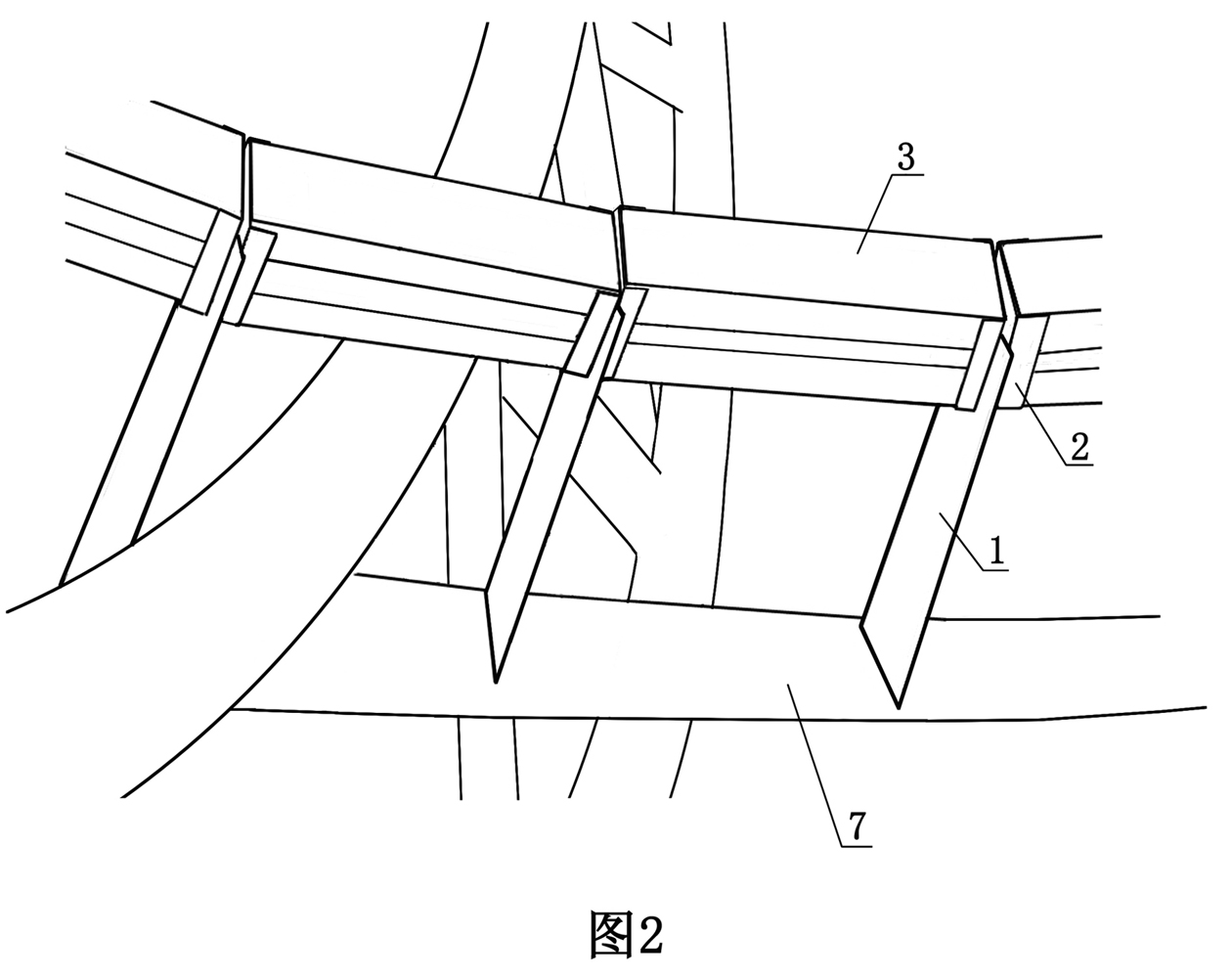

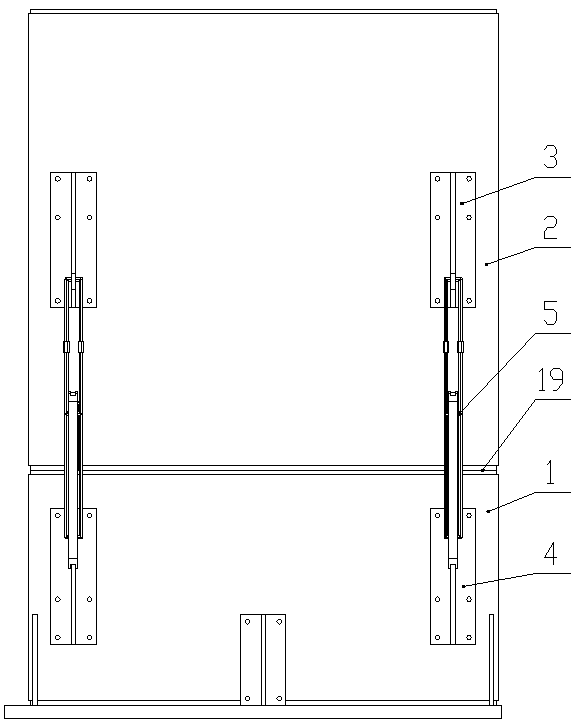

Portable assembled shield tunneling machine sleeper

ActiveCN104562870AEnsure construction qualityEnsure the scheduleMovable tracksSlagMaterial consumption

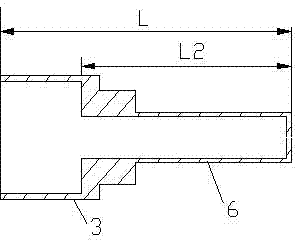

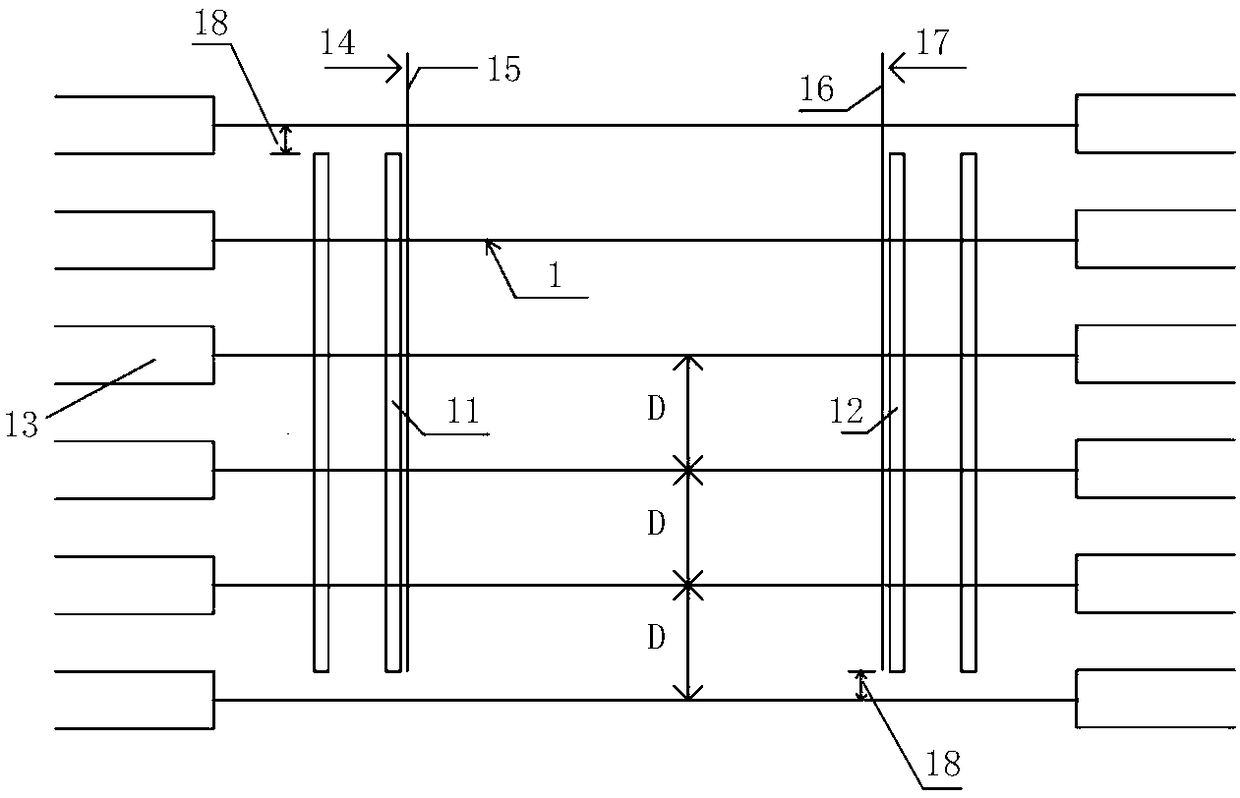

The invention discloses a portable assembled shield tunneling machine sleeper and solves the technical problems that an existing shield tunneling machine trolley sleeper is low in stability and is easy to deform. The sleeper comprises a motor vehicle channel steel sleeper beam (15); the top of the motor vehicle channel steel sleeper beam (15) is provided with two pairs of motor vehicle rail clamping grooves (18), pads are arranged between the left and right bottoms of the motor vehicle channel steel sleeper beam (15) and a first lining segment (2), lining segments of left and right sides of the motor vehicle channel steel sleeper beam (15) are provided with arc plates, and the arc plates are fixed to longitudinal segment connecting bolts through arc plate tail unit fixing sheets; shield tunneling machine trolley rail grooves are arranged on the tops of left and right vertical plates; the sides of the left and right vertical plates are movably connected to the sides of the motor vehicle channel steel sleeper beam (15) in a pressed manner. The shield tunneling machine trolley sleeper and a slag conveying motor vehicle sleeper can be assembled accurately and safely, the portable assembled shield tunneling machine sleeper can be assembled and disassembled in site particularly, and the sleeper material consumption is reduced.

Owner:CHINA RAILWAY 19TH BUREAU GRP RAIL TRANSIT ENG

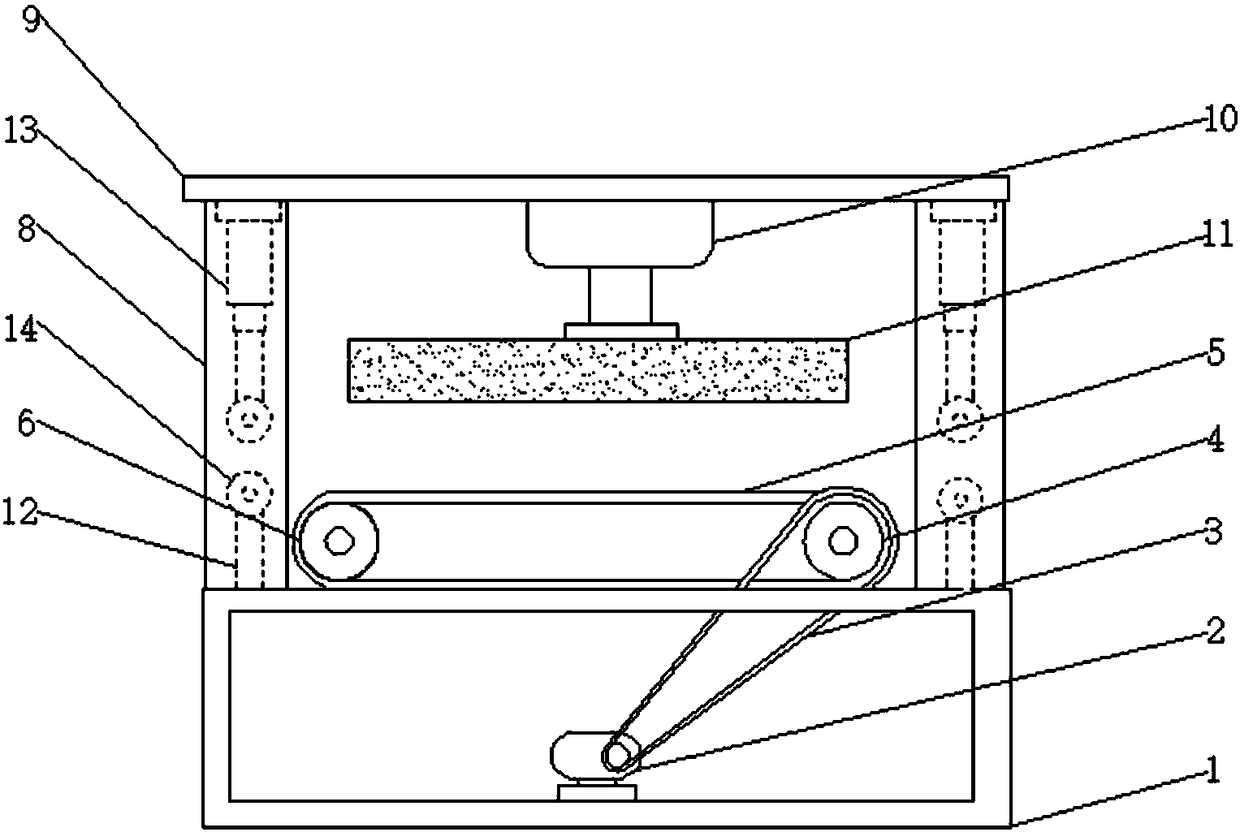

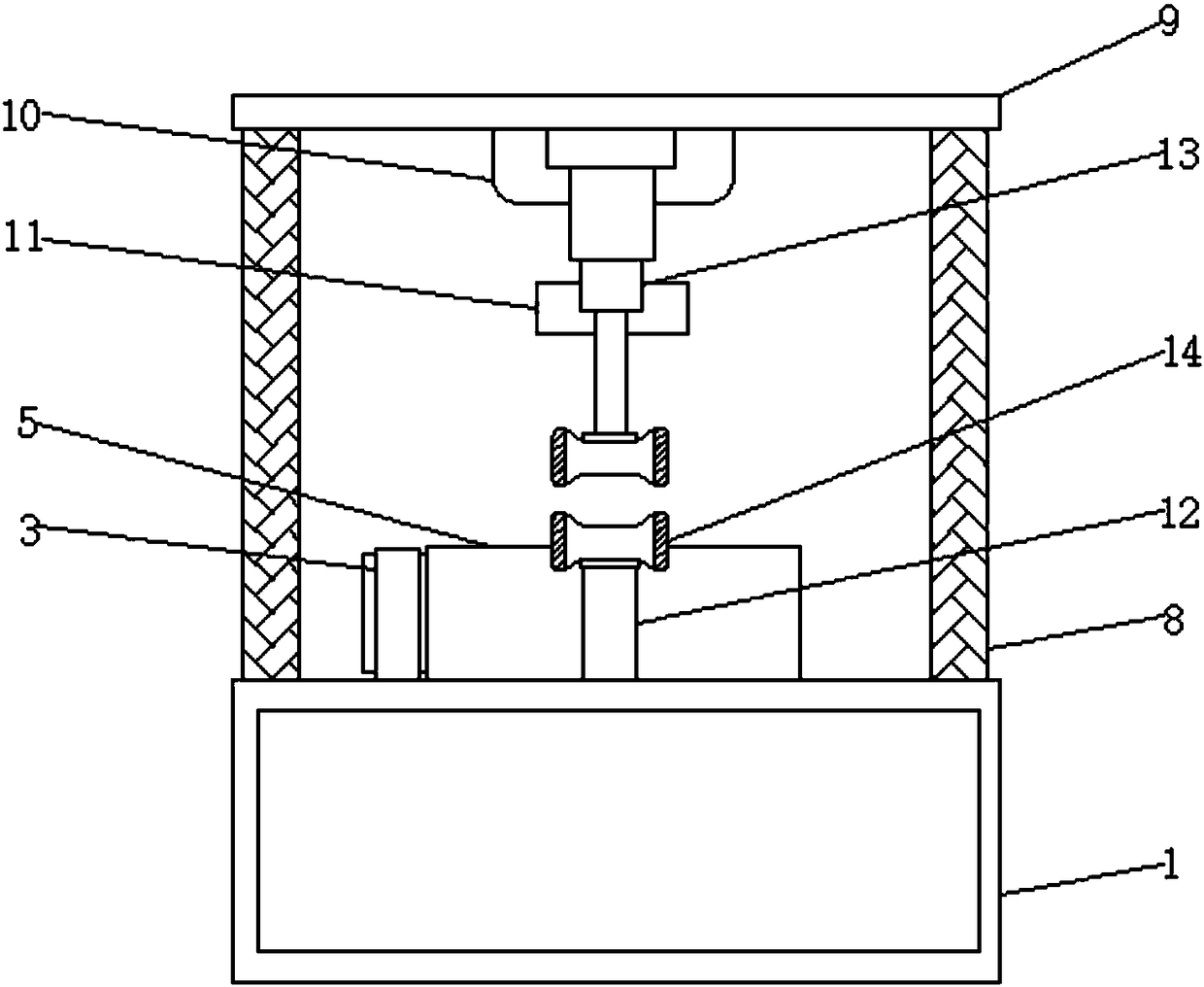

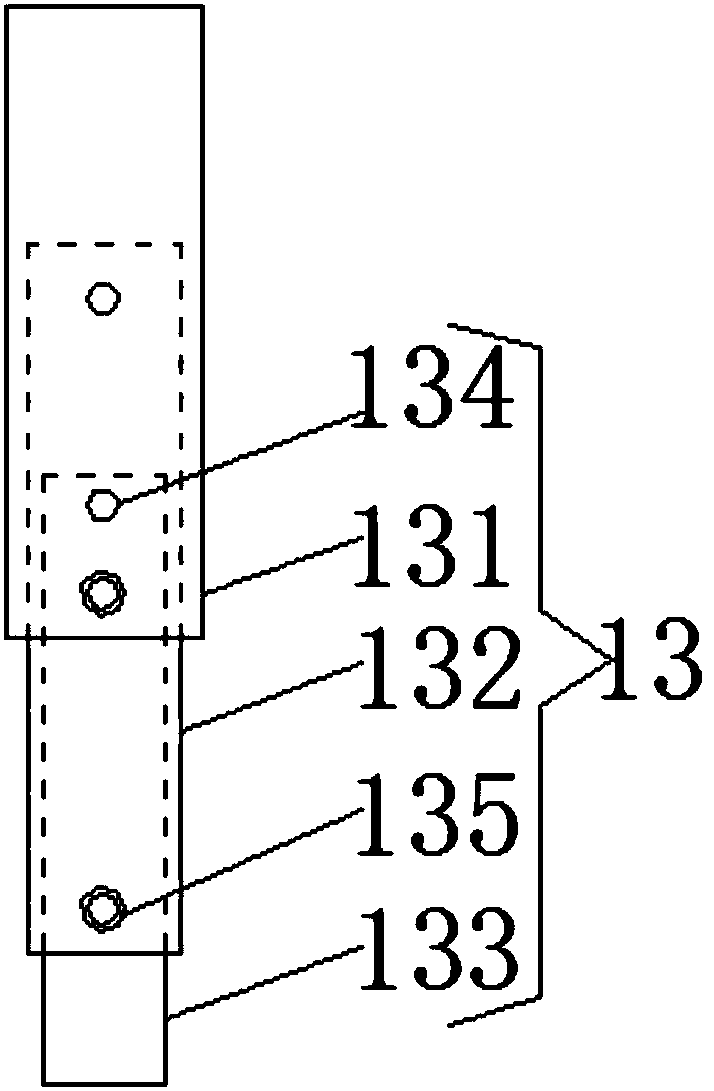

Cable conveyor

InactiveCN108599018AEasy to useLow failure rateApparatus for laying cablesPistonIndustrial engineering

The invention discloses a cable conveyor comprising a bottom box, wherein the bottom of an inner wall of the bottom box is fixedly connected with a motor, a rotating shaft of the motor is in transmission connection with a belt pulley through a belt, the belt pulley is in transmission connection with a crawler disk through an annular crawler, supporting columns are fixedly connected to both sides of the top of the bottom box, one end of each supporting column away from the bottom box is fixedly connected with a top plate, the bottom of the top plate is fixedly connected with a cylinder, and a clamping block is fixedly connected with one side of the cylinder away from the top plate through a piston. The cable conveyor adopts double-layer clamping to eradicate the problem that a clamped cabledeviates from or is extruded out from a clamping area in the prior art, thus ensuring the construction progress and quality, further improving the working efficiency, reducing the production cost andprolonging the service life of the machine, no abrasion damage is generated to the cable, and the cable conveyor has the advantages of being convenient to use, stable in operation and low in failurerate.

Owner:江苏伊居科技有限公司

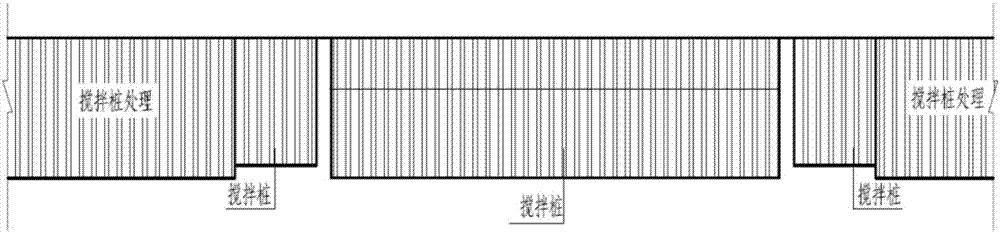

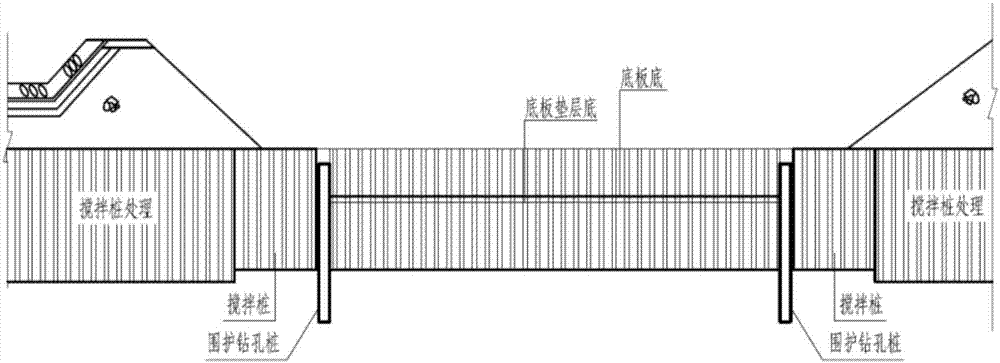

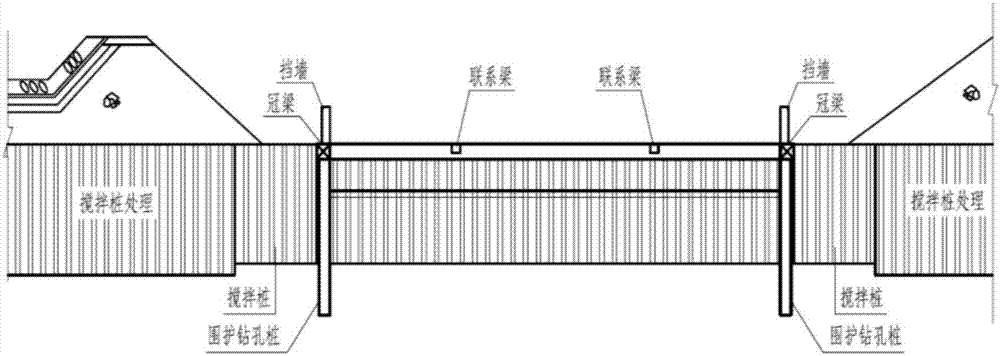

Construction structure and method for highway tunnel in coastal tidal area

ActiveCN107119716AEliminate tidal effectsEnsure construction qualityDamsArtificial islandsBuilding constructionCivil engineering

Owner:NINGBO COMM PLANNING INST CO LTD

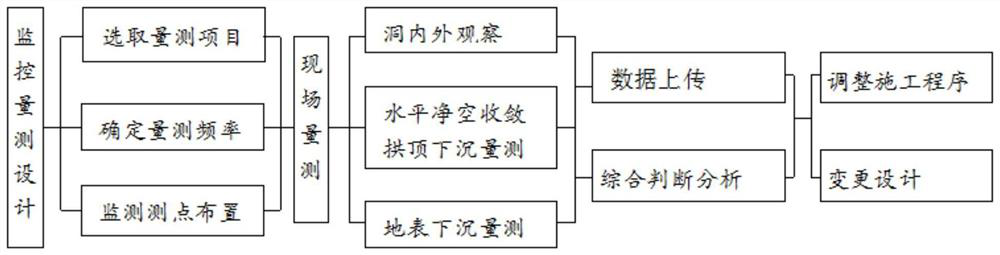

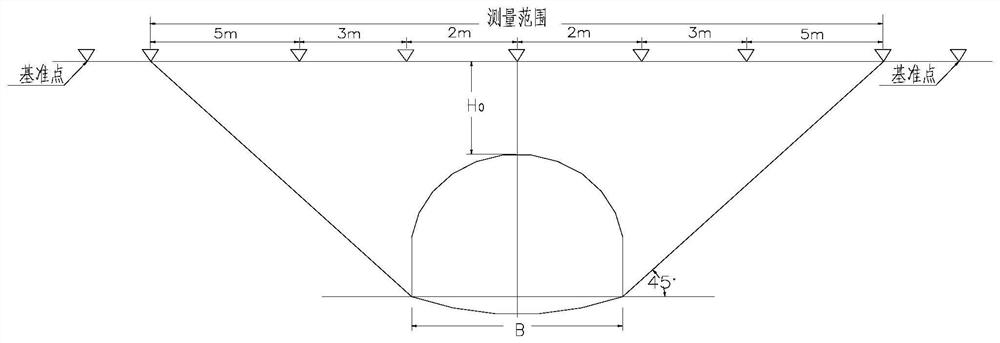

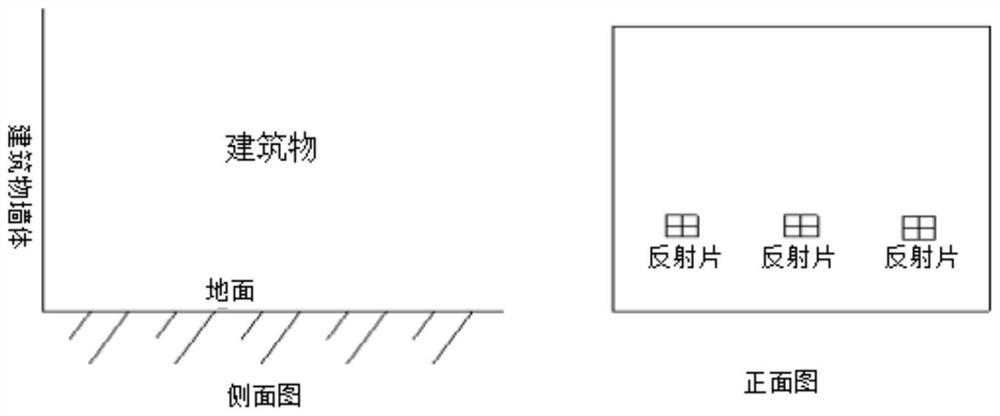

Earth surface monitoring method for shallow-buried underneath passing of a soft rock large deformation section tunnel through earth surface building

PendingCN113431016ASolve the problem of safe and fast constructionEnsure construction safetyIn situ soil foundationObservation pointClassical mechanics

The invention relates to the technical field of tunnel construction, in particular to an earth surface monitoring method for shallow-buried underneath passing of a soft rock large deformation section tunnel through an earth surface building. The method comprises the steps of observing in a hole and observing outside the hole, wherein observation in the hole comprises excavation surface observation and operated section observation, and observation outside the hole comprises observation of the ground building; measuring ground surface settlement and building settlement; arranging ground surface settlement observation points before tunnel excavation; enabling the distance from the tunnel center line to the farthest ground surface settlement observation point to greater than or equal to the sum of the tunnel burial depth and the tunnel excavation width; performing crown settlement measurement and convergence measurement; determining section spacing according to the surrounding rock level; and performing point distribution according to an excavation method, enabling the distribution height to be larger than each step, enabling a measuring point reflector plate to be aligned with the direction of a hole, and enabling measuring points to be exposed out of a primary support face. Through reasonable section arrangement, ground surface monitoring and ground surface building monitoring are added, so that monitoring data are more accurate and reliable, and the purposes of controlling settlement and accelerating construction are achieved.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

Method for filling bottom of gravelly soil core wall of stone dam

The invention discloses a method for filling the bottom of a gravelly soil core wall of a stone dam. The method includes steps of firstly, casting a concrete key wall on a first diaphragm wall, reserving a reserved passage for construction vehicles to enter on the concrete key wall; secondly, filling clay 2 meters thick in a gap area of the inner side and the outer side of the concrete key wall; thirdly, casting the concrete key wall to the top after the construction vehicles enter a filling roadway; and fourthly, forming a plurality of clay loading platforms on a downstream side of a concrete gallery by clay, throwing the clay into the filling roadway by a backacting shovel, paving, grinding and filling by layering until the clay in the filling roadway is all filled and then the construction vehicles can be driven out from the top. By the above steps, filling construction of the bottom of the gravelly soil core wall of the stone dam can be realized. By forming the filling roadway convenient for filling by the concrete key wall, flow of high-ductility clay is limited, and layering, grinding and paving of the construction vehicles in the filling roadway are facilitated. The method has the advantages of simplicity in construction, convenience and practicality, investment is saved and construction quality and speed are guaranteed.

Owner:中国葛洲坝集团第三工程有限公司

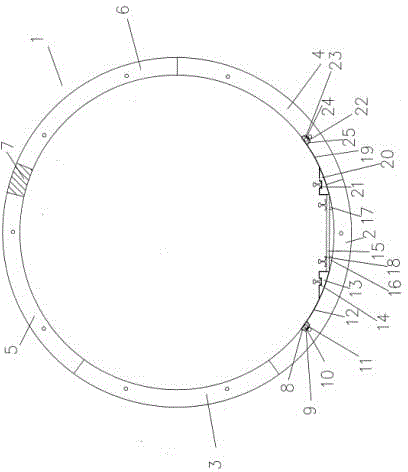

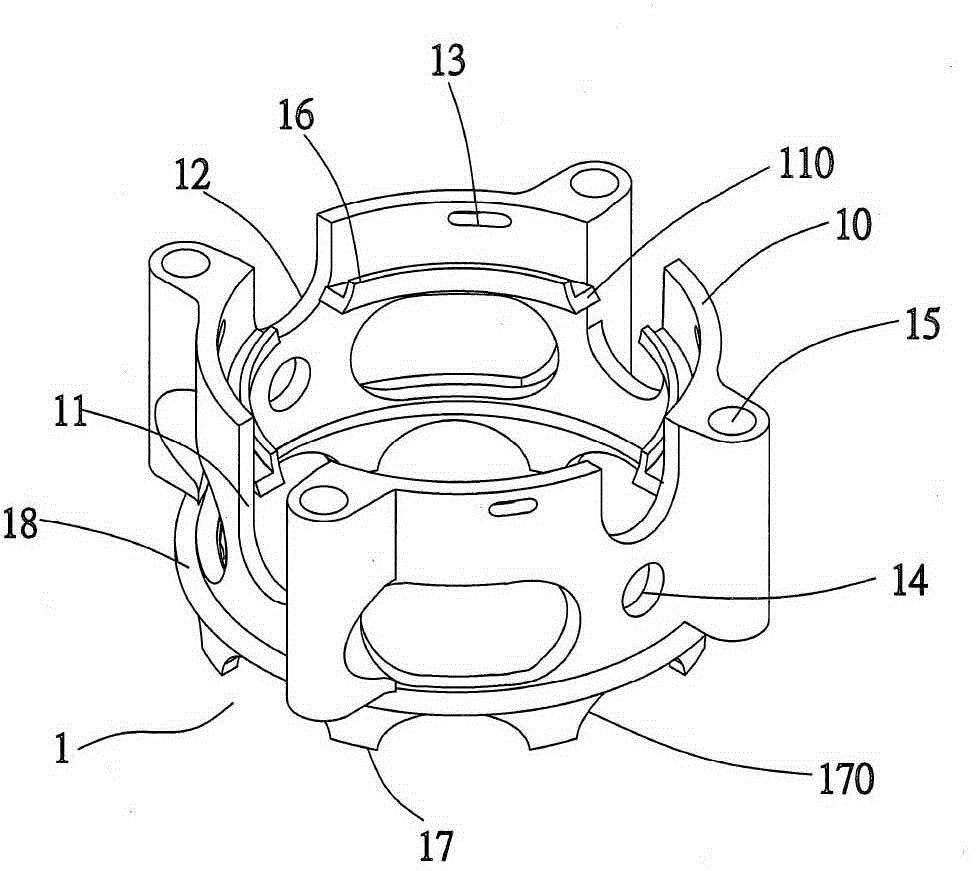

Reinforcing steel bar fixing device

The invention provides a reinforcing steel bar fixing device. The reinforcing steel bar fixing device can act on a plane and a slope according to the combined change of a single layer or multiple layers of reinforcing steel bars, the reinforcing steel bars cannot deflect in the cement grouting process, dampness can be prevented, and rusting of the reinforcing steel bars can be eradicated. The reinforcing steel bar fixing device mainly comprises a base which is a hollow cylinder with a porous face; the two ends of the base are bearing ends; a pair of deep trench grooves and a pair of shallow trench grooves are formed in the end edge of the upper bearing end in the axial direction; the reinforcing steel bars on the first layer are embedded in the grooves; the circumferential wall face of the base is provided with four hole trenches and one or more pairs of insertion hole seats; an inner ring trench groove is formed in the inner circumferential face of the base; a dampproof protruding ring is arranged on the circumferential wall face of the lower bearing end of the base; the upper bearing end is sleeved with and clamped to a set of extending bases at different heights; and the reinforcing steel bars on the second layer are arranged according to the required height. In addition, an M-shaped steel frame is arranged on any two insertion hole seats in the base in a striding manner, so that the purpose of rapid arrangement of the reinforcing steel bars is achieved.

Owner:TAIWAN SUBTEL TECH CO

Large pipe shed guide wall structure of underground excavation tunnel and construction method of large pipe shed guide wall structure

PendingCN113738399AEnsure construction qualityGuarantee the durationUnderground chambersTunnel liningStructural engineeringPipe

The invention provides a large pipe shed guide wall structure of an underground excavation tunnel and a construction method of the large pipe shed guide wall structure. The large pipe shed guide wall structure comprises a guide wall located outside an underground excavation tunnel portal, large pipe shed pre-buried sleeves arranged in the circumferential direction of the arch portion of the inner edge of the guide wall at intervals and longitudinally penetrate through the guide wall, and a large pipe shed constructed from the large pipe shed pre-buried sleeves to bed rock at the top of an underground excavation tunnel body, wherein the guide wall and a open-cut structure fender post are arranged in a nested mode, the width of the guide wall is equal to the diameter of the open-cut structure fender post, main ribs of the open-cut structure fender post are anchored and integrally cast to form a whole, the guide wall is supported on the open-cut structure fender post, and the open-cut structure fender post is fixedly fixed in a rock-soil layer below in an embedded mode. According to the large pipe shed guide wall structure of the underground excavation tunnel and the construction method, the large pipe shed guide wall structure is good in integrity, clear in force transmission path, space-saving, safe and reliable, the influence on the main body structure of a working well can be reduced by constructing the guide wall and the large pipe shed in advance, the large pipe shed guide wall structure of the underground excavation tunnel and the construction method can be used for arranging large pipe shed guide walls of subways, railways and municipal subsurface tunnels, and is high in practicability and good in generalizability.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

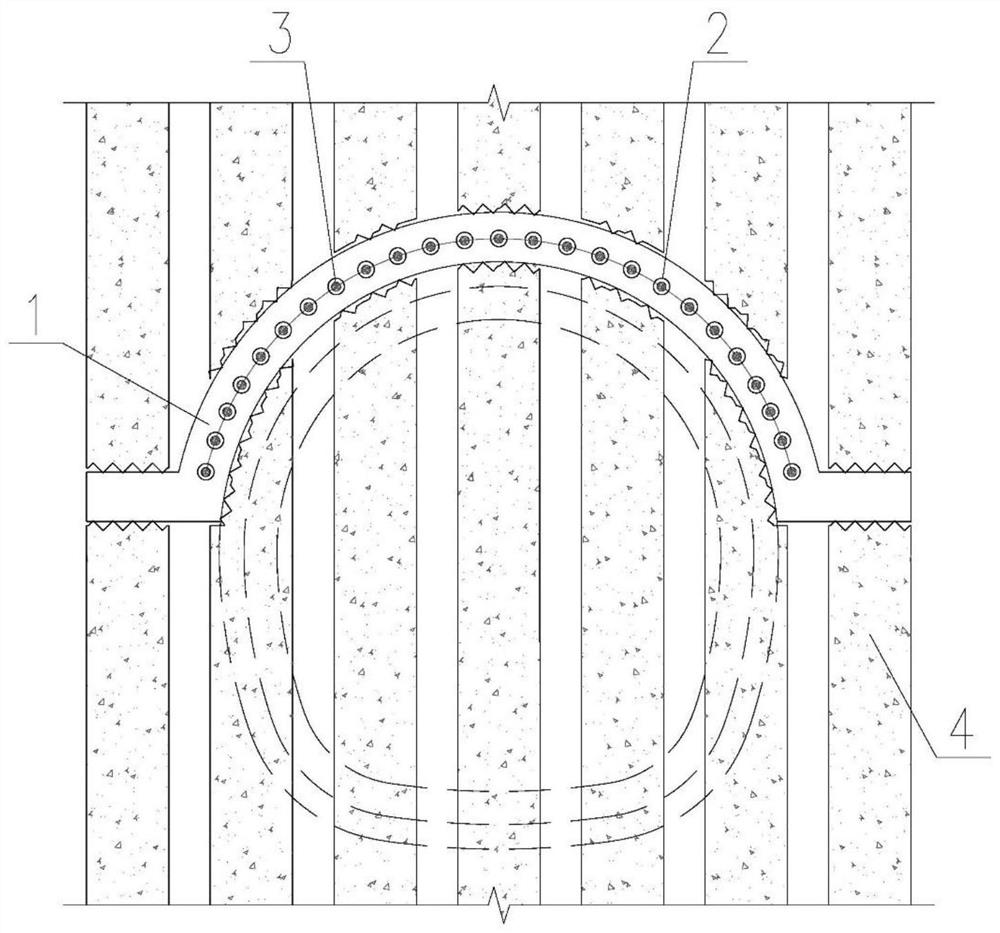

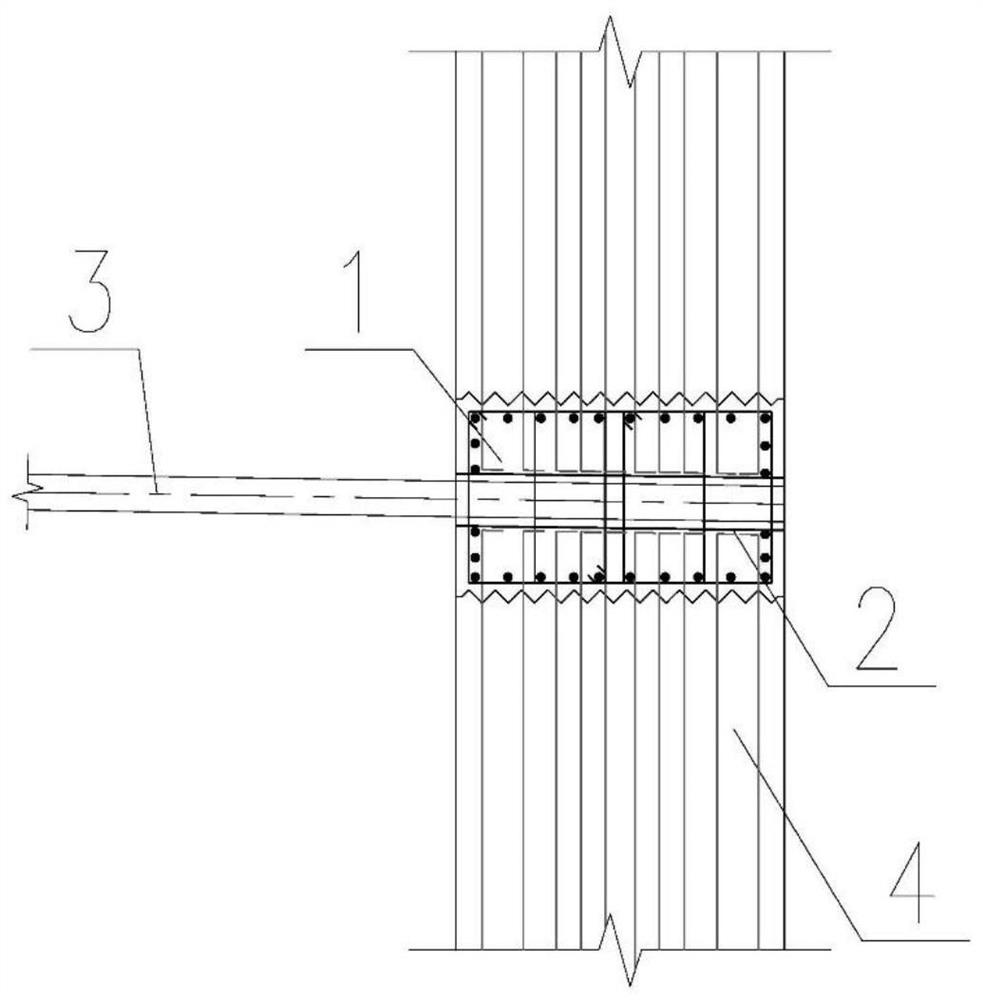

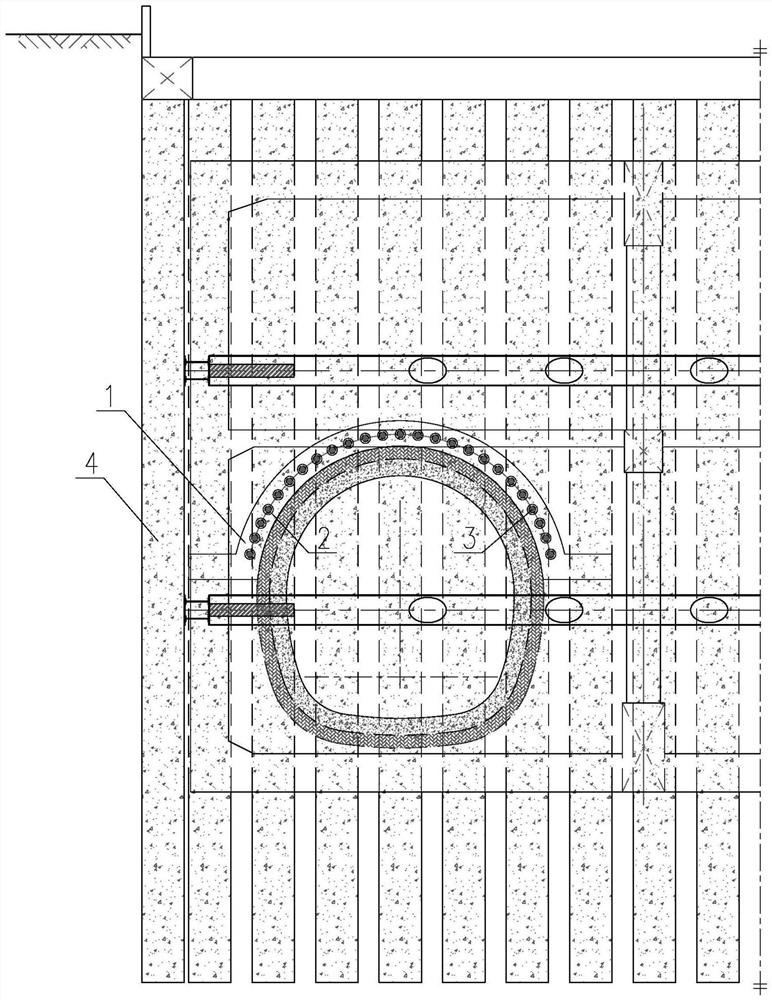

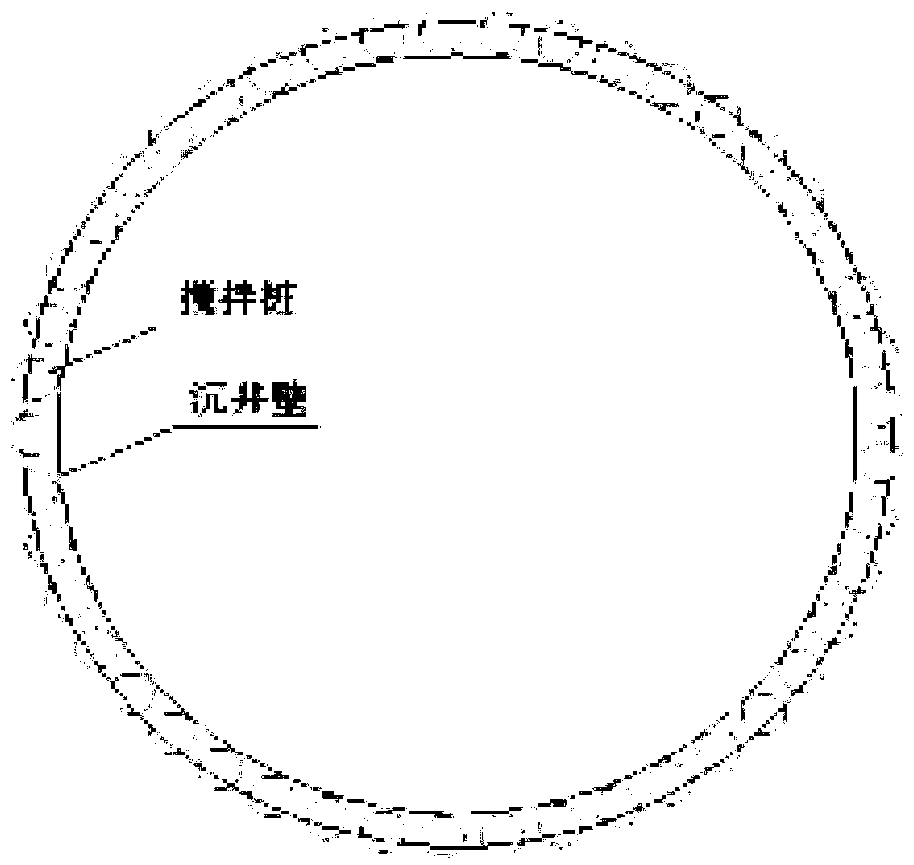

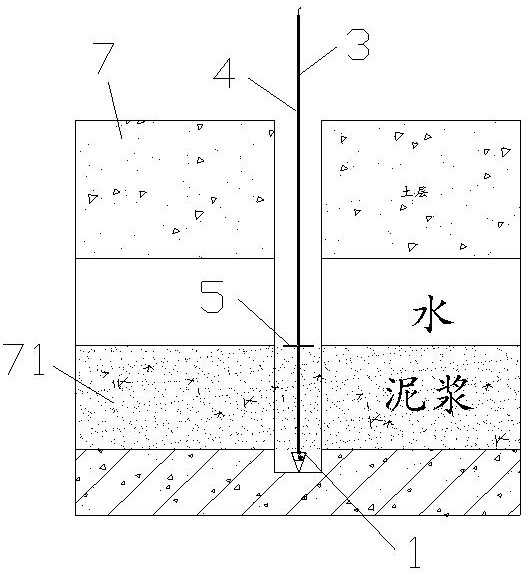

Construction method for open caisson on soft soil layer

InactiveCN109680703AUniform and controllable sinkingSink safetyCaissonsSoil horizonEnergy conservation

The invention discloses a construction method for an open caisson on a soft soil layer. According to the construction method, cement mixing piles are arranged at the bottom of the edge of the open caisson, drilling and grouting are carried out on the periphery of the open caisson before the open caisson is sunk, uniform and controllable self-sinking of the open caisson can be guaranteed along withthe fact that earthworks are excavated and transported out in the sinking process of the open caisson by adopting a drainage method, so that the problems of excess sinking and sudden sinking of the open caisson in the sinking process can be solved, when the open caisson sinks to the tops of the cement mixing piles, the mixing piles are uniformly broken at intervals layer by layer, large sand bagsare synchronously and uniformly arranged, unloading self-sinking is carried out by utilizing the sand bags filled with sands, namely sandboxes, and therefore safe and uniform controlled sinking of the open caisson can be realized, and sharp sinking and inclination of the open caisson can be prevented. The construction method for the open caisson on the soft soil layer has the advantages that a construction technology is convenient to use and reliable, materials are convenient to obtain, the construction process is safe and reliable, and therefore the problem that the safety quality risk is caused due to the fact that an open caisson is constructed in the soft soil layer can be solved in a targeted mode, the construction quality and safety of the open caisson are guaranteed, the construction cost is effectively lowered, and the method conforms to the national energy conservation and environment protection requirements.

Owner:广州市第三市政工程有限公司 +1

Large-space three-dimensional twisted gypsum board wall and construction method thereof

InactiveCN101881058AConforms to twisted smoothness requirementsFirmly connectedWallsHeat proofingThermal insulationKeel

The invention discloses a large-space three-dimensional distorted gypsum board wall and a construction method thereof. In the construction method, short flat steels for connecting a lightgage steel joist are welded at intervals along a traverse round rod and a longitudinal round rod of a three-dimensional twisted steel structure stand, and every two double L-shaped rotatable clamping plates are opposite and are respectively connected with the two faces of the short flat steel in a clamping way through bolts; main joists are horizontally connected between each two adjacent short flat steels by sections, assistant joists are vertically connected with all the main joists arranged horizontally, the main joists and the assistant joists are connected horizontally and vertically to form a double-layer grid structure of which the grids are filled with thermal insulation materials, and the front and the back sides of the double-layer grid structure are provided with gypsum boards of which the outer facades are brushed with paint. The invention has simple and convenient construction, fast speed and low requirements on construction operation and can be used for the construction of background walls or wall structures in large size exhibitory and public buildings.

Owner:CHINA STATE DECORATION GRP

Construction process for special-shaped concrete tower column of asymmetric cable-stayed bridge

PendingCN113802468AImprove construction accuracyEnsure construction efficiencyCable-stayed bridgeBridge structural detailsArchitectural engineeringTower

The invention discloses a construction process for a special-shaped concrete tower column of an asymmetric cable-stayed bridge, the construction process comprises the following steps: step 1, tower base construction: a main tower base is in the form of a prismatic table which is inwards inclined by 45 degrees, a support template pouring concrete construction process is adopted for construction, and a customized steel template with the thickness of 8mm is adopted as a tower base template; the construction process has the beneficial effects that the processes of pouring, climbing, curing and the like in each construction stage of the special-shaped concrete tower column of the asymmetric cable-stayed bridge are strictly controlled before and after construction, so that the construction precision of the special-shaped concrete tower column of the asymmetric cable-stayed bridge is improved; the bending moment phenomenon caused by overlarge self weight or construction load capacity of the tower bridge is effectively avoided, the tower column root is prevented from being fractured due to large tension, meanwhile, the stability of the main tower can further avoid the phenomenon that the design value of the finished bridge root exceeds the standard due to the fact that the side pressure stress exceeds the standard, and the construction efficiency and quality of the special-shaped concrete tower column of the asymmetric cable-stayed bridge are greatly improved and ensured.

Owner:中天交通建设投资集团有限公司 +1

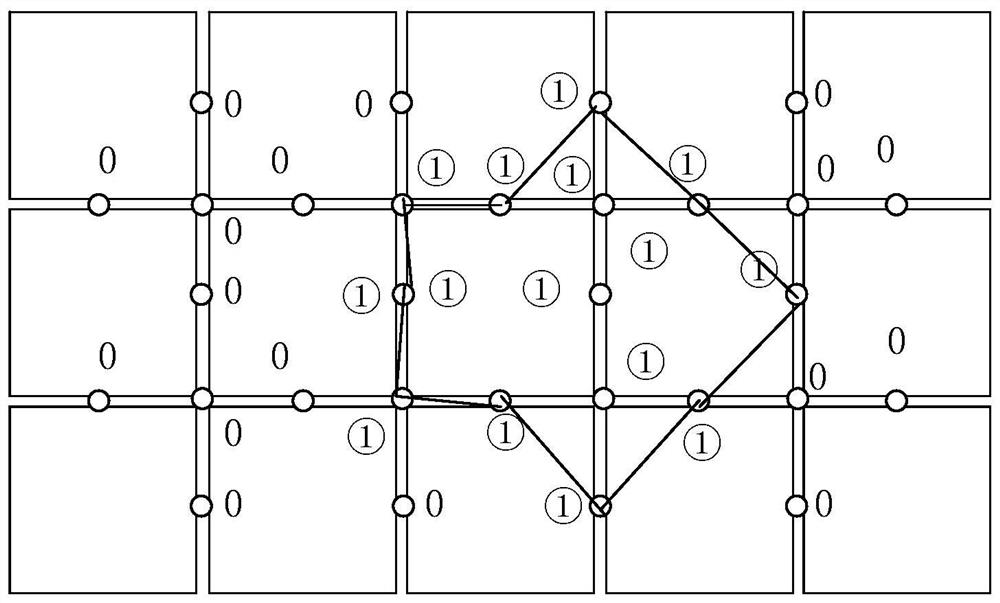

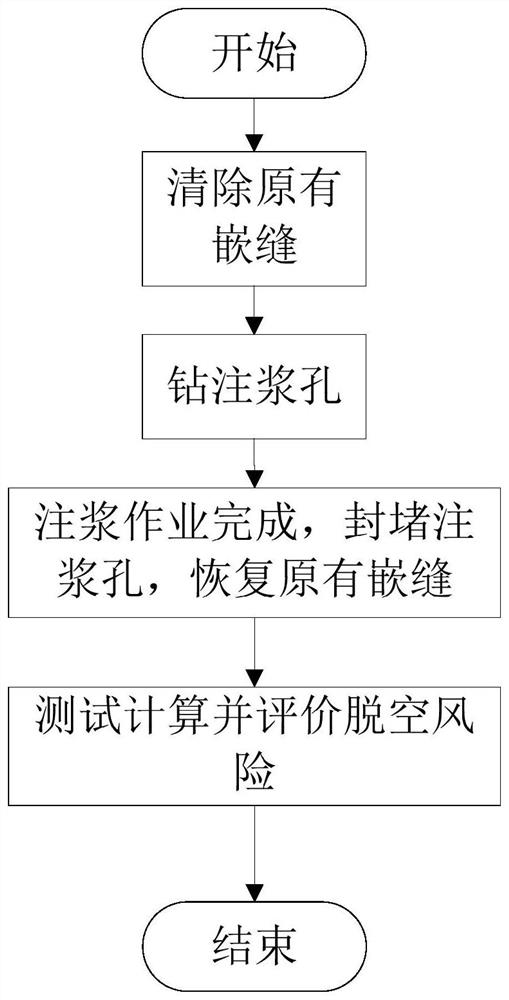

Cement concrete pavement slab edge concealed grouting and void risk evaluation method

ActiveCN114293450AStructural integrityQuantify the degree of risk of shortfallSolid waste managementRoads maintainenceStructural engineeringCement paste

The invention discloses a cement concrete pavement slab edge concealed grouting and void risk evaluation method. The method comprises the steps of determining a grouting area, forming a hidden drill hole, grouting in the hidden drill hole, marking, blocking the hidden drill hole, obtaining the maximum envelope area of a void area, determining the maximum grouting depth, obtaining the actual grouting amount, obtaining the grouting depth of a unit area, obtaining a void threat index, evaluating the void risk of the grouting area and the like. The method has the advantages that 1) the implementation is simple; the existing airport pavement grouting process is innovated, and the construction quality and the grouting effect can be ensured. (2) the concealment is strong; holes are drilled in the joint positions of the pavement, and pavement caulking is used for covering after hole sealing, so that the complete performance of the pavement structure can be guaranteed. And 3) the void risk evaluation is accurate. The maximum depth and the average grouting depth of the iron oxide-containing cement paste tested by the ground penetrating radar are creatively proposed and synthesized, and the risk degree of plate bottom void can be effectively quantified and evaluated.

Owner:TIANJIN CAUC-ZHONGJING TECH LTD CO

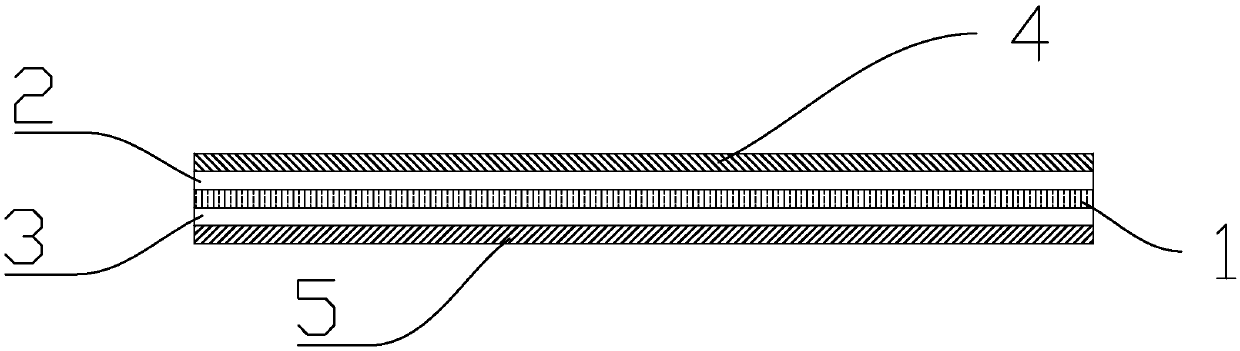

Single-sided high-temperature-resistant impervious three-cloth-two-membrane type composite geo-membrane

PendingCN107696660AReduce or eliminate damageHigh Right Angle Tear StrengthSynthetic resin layered productsGeotextilesPolyesterFiber

The invention relates to a single-sided high-temperature-resistant impervious three-cloth-two-membrane type composite geo-membrane. The invention aims to provide the single-sided high-temperature-resistant impervious three-cloth-two-membrane type composite geo-membrane so as to reduce or eliminate damage to an internal structure due to external water temperature, external water pressure, air pressure and the like, and then the construction safety and quality can be ensured. According to the technical scheme of the invention, the single-sided high-temperature-resistant impervious three-cloth-two-membrane type composite geo-membrane is characterized by being composed of two geo-membrane layers, two geotechnical cloth layers and a polytetrafluoroethylene high-temperature cloth layer. The composite geo-membrane has polyester filament geotechnical cloth, a high density polyethylene geo-membrane and the polytetrafluoroethylene high-temperature cloth are sequentially attached to one side of the polyester filament geotechnical cloth, and an ethylene / vinyl acetate copolymer geo-membrane and a polyester staple fiber needle-punched geotextile are sequentially attached to the other side of thepolyester filament geotechnical cloth. The invention is applicable to the single-sided high-temperature-resistant impervious three-cloth-two-membrane type composite geo-membrane.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Construction method for upper and lower layer vertical connection of fabricated steel-concrete combined pipes

ActiveCN111140010AImprove construction efficiencyEasy to press and operateBuilding material handlingArchitectural engineeringStructural engineering

A construction method for upper and lower layer vertical connection of fabricated steel-concrete combined pipes comprises the following steps that (1) temporary positioning devices are installed; (2)a tower crane is used to hoist upper-layer steel-concrete combined pipes to lower-layer steel-concrete combined pipes which have been fixed firmly and makes the upper-layer steel-concrete combined pipes and the lower-layer steel-concrete combined pipes basically correspond up and down; (3) the temporary positioning devices are operated to integrally and fixedly connect the upper-layer steel-concrete combined pipes and the lower-layer steel-concrete combined pipes; (4) the temporary positioning devices are finely adjusted through spanners; (5) the lower ends of the upper-layer steel-concrete combined pipes and the upper ends of the lower-layer steel-concrete combined pipes are welded at butt-joint rectangular annular slits; and (6) the temporary positioning devices are removed. According tothe construction method, operation is convenient, a large amount of time is saved for the tower crane to do other hoisting operations, and the construction progress is accelerated; the upper-layer steel-concrete combined pipes are positioned in a press-positioning way, which is convenient and rapid; and fine adjustment can be made so as to ensure perpendicularity and construction quality.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

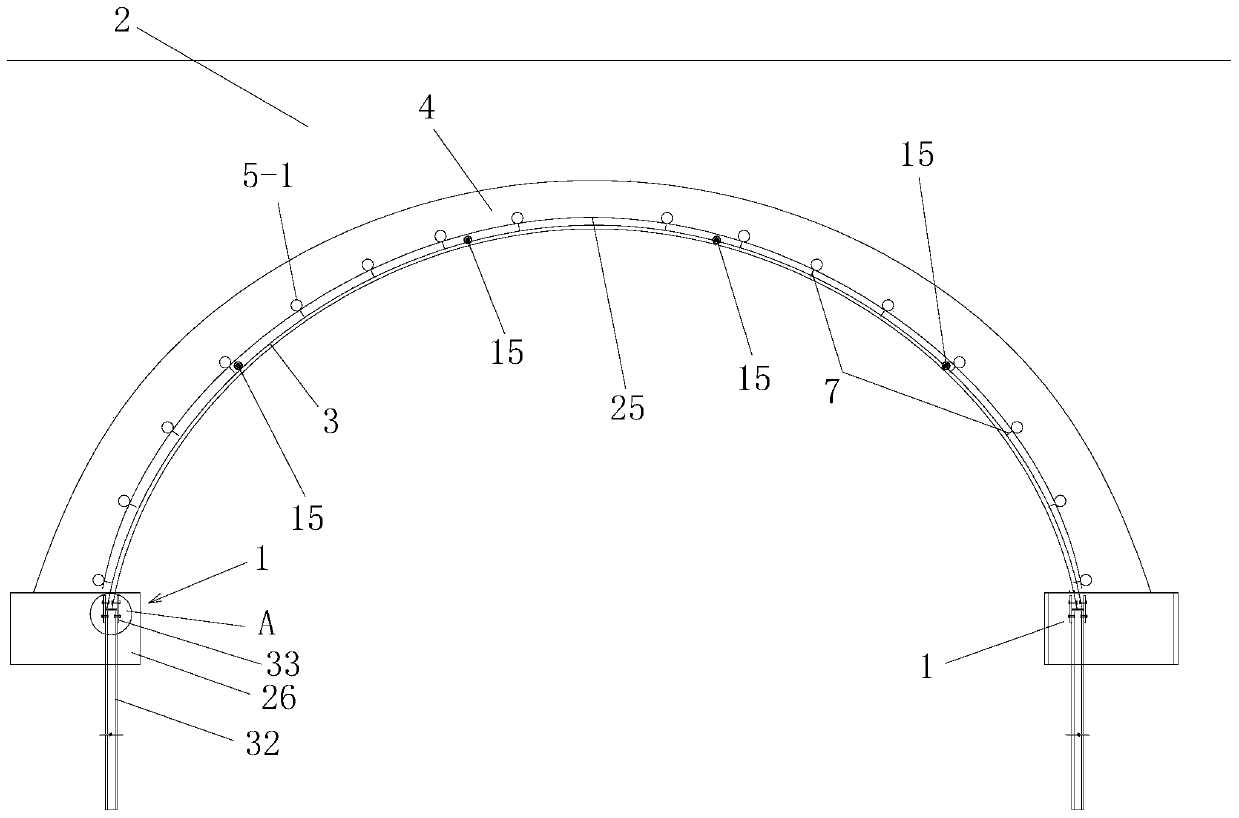

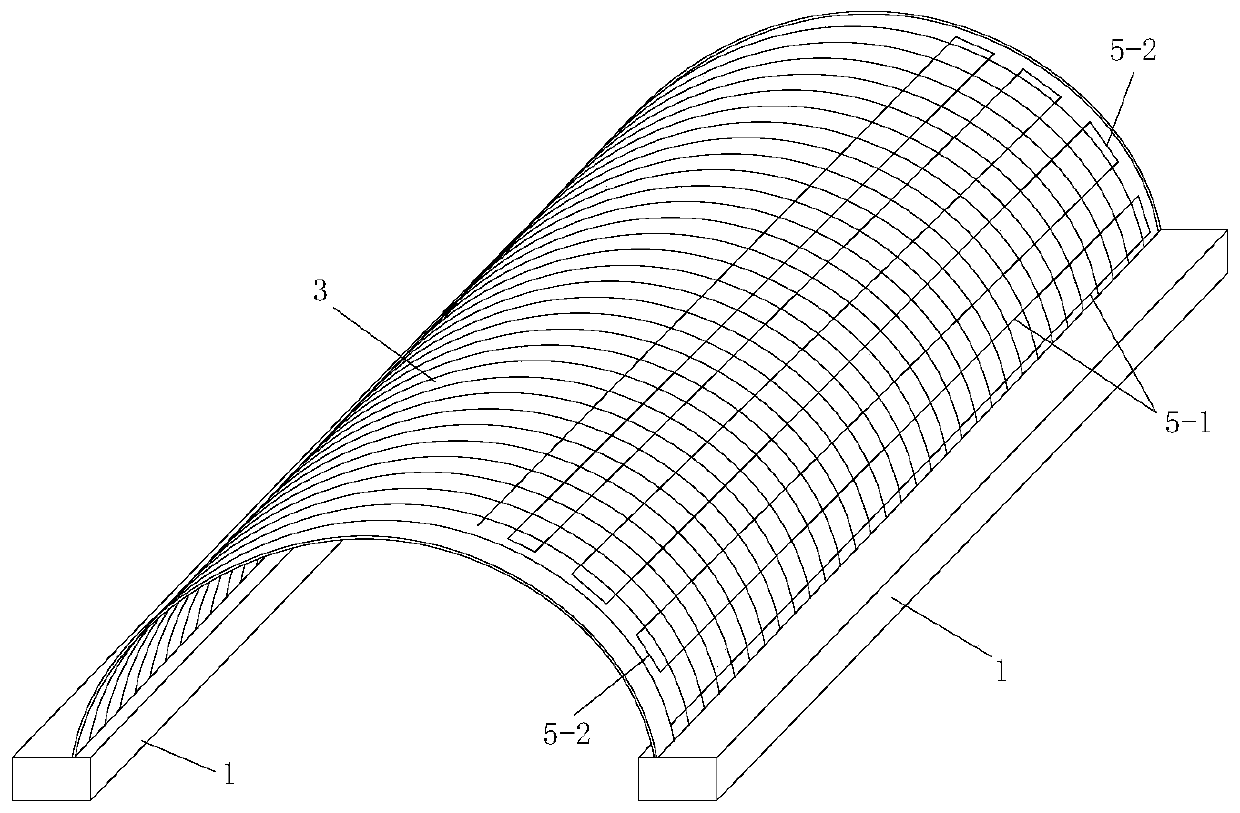

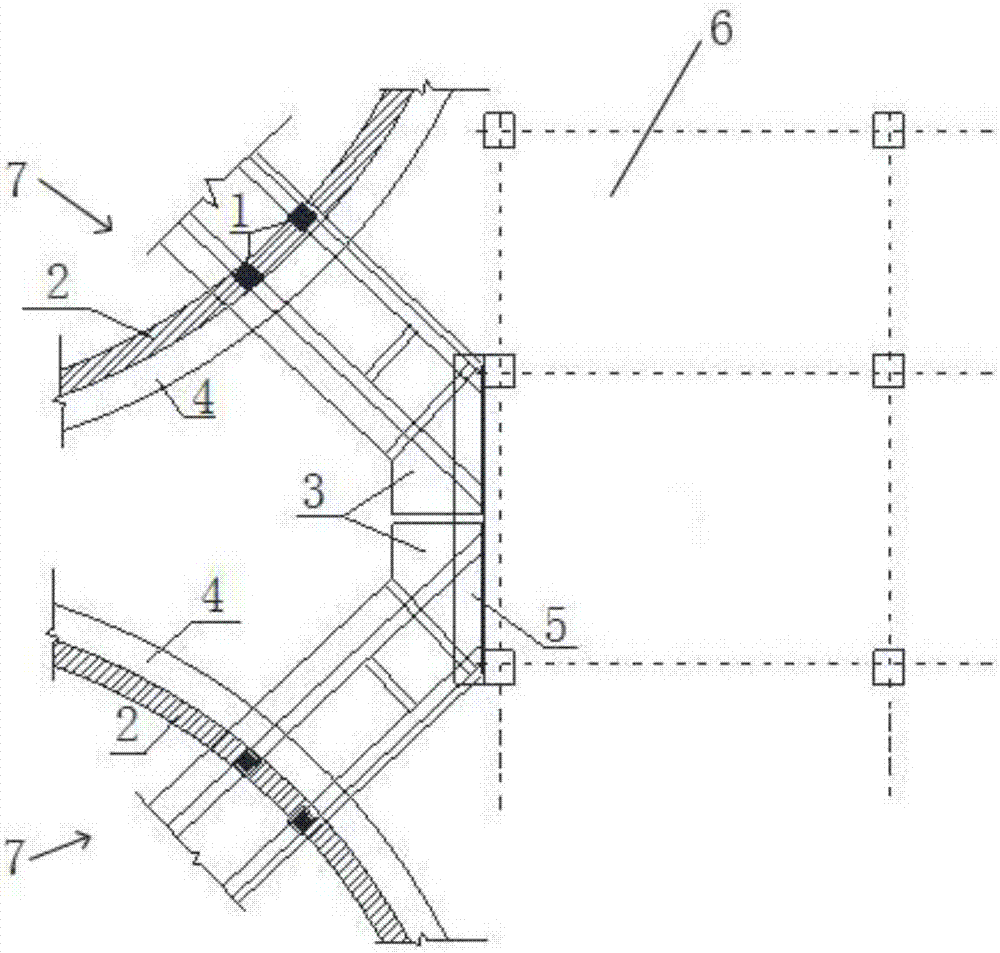

Soil covering corrugated steel plate bridge construction method

ActiveCN111101446AThe method steps are simpleReasonable designBridge structural detailsFoundation engineeringPre stressArchitectural engineering

Owner:ZHENGPING ROAD & BRIDGE CONSTR CO LTD +4

Granary top overhead section concrete construction platform and construction method

InactiveCN107965133AStable forceEnsure construction qualityBuilding support scaffoldsSupporting systemSupport point

The invention relates to a granary top overhead section concrete construction platform and a construction method. The construction platform comprises a constructional column arranged on a concrete wall plate of a support platform, a first steel embedded part is pre-embedded on the constructional column, steel short columns are welded to the upper portion of the steel embedded part, and a second steel embedded part is pre-embedded at the support point of a granary top ring beam; the construction platform further comprises multiple main steel beams and secondary steel beams which are arranged horizontally, one ends of the main steel beams are fixed to the steel short columns, the other ends of the main steel beams are fixed to the second steel embedded part, the multiple main steel beams areconnected through the vertical secondary steel beams, a slidewalk is laid on the surfaces of the secondary steel beams, and a steel pipe fixing frame is fixed to the upper portion of the slidewalk. Accordingly, the number of supporting steel pipes can be greatly reduced, the construction time is shortened, different elevation surfaces are constructed to be the same supporting plane, and the steelplatform and the steel pipe supporting system can carry the load better.

Owner:CHINA FIRST METALLURGICAL GROUP

Concrete floor slab descending area slab surface shaping support construction method

PendingCN114541741AEnsure construction qualityEnsure perceptionClimate change adaptationForms/shuttering/falseworksFloor slabArchitectural engineering

The invention discloses a concrete floor slab descending area slab surface shaping supporting construction method, and belongs to the technical field of building construction. The method comprises the following steps that firstly, transverse rods are manufactured, then longitudinal rods are manufactured, and the outer sides of the transverse rods and the outer sides of the manufactured longitudinal rods are placed according to the section size of a floor descending area of a floor; secondly, an inner longitudinal rod is manufactured, and the inner longitudinal rod is placed in the middle of the inner side of the transverse rod and is welded and fixed; thirdly, an inner transverse rod is manufactured, and the inner transverse rod and the inner longitudinal rod are placed in the middle of the inner side of the longitudinal rod; fourthly, an inclined supporting rod A and an inclined supporting rod B are manufactured, and the inclined supporting rod A and the inclined supporting rod B are placed in the diagonal direction of the transverse rod and the longitudinal rod; fifthly, cushion blocks are placed on the inner side of the plate descending area one by one; and sixthly, concrete is poured, formed, cured and then dismantled. The device can be quickly mounted and dismounted, is convenient to construct, can be repeatedly used, saves time and labor, and effectively saves the cost.

Owner:CHINA MCC17 GRP

Arrangement method and system of anti-thunder skynet of hydropower station hoisting equipment

PendingCN108306244AReliable lightning protectionEnsure safetyInstallation of lighting conductorsWinchSea level

The invention discloses an arrangement method and system of an anti-thunder skynet of hydropower station hoisting equipment. Multiple GJ-50 lightning conductors are adopted for covering the operationrange of all hoisting equipment. The lightning conductors are arranged in parallel, are parallel to traction ropes of the hoisting equipment and are perpendicular to main / secondary vehicle of the hoisting equipment; the lowest height above sea level protected by the lightning conductors is higher that of the main / secondary vehicle of the hoisting equipment, so that the skynet can cover the operation range of the hoisting equipment. The lightning conductors, and the lightning conductors and circular steel are connected and fixed by rope clamps, and circular steel and grounding flat steel are welded; when the lightning conductors are mounted across a river, the lightning conductors are bundled and fixed by steel wires and then pulled down by a winch; and after the lightning conductors are pulled to the opposite bank, the lightning conductors are pulled to positions corresponding to anchoring piles by hemp ropes, and the lightning conductors are fixed. The arrangement method and system have the obvious advantages of reliable anti-thunder effect, high popularization degree, short construction period and low erection cost.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD

Construction method for reducing frost heave pressure during jacking pipe freezing

InactiveCN107761711AEasy to operateEnsure construction qualitySoil preservationAbsorbent materialFrost heaving

The invention discloses a construction method for reducing the frost heave pressure during jacking pipe freezing. When a frozen pipeline is manufactured, a polymer absorbent material is injected intothe pipe wall of the frozen pipeline; when freezing equipment is mounted, the polymer absorbent material is evenly smeared on the freezing equipment; and during jacking pipe freezing construction, after freezing, the moisture of surrounding soil can be absorbed, so that the soil around a jacking pipe is compacted more densely.

Owner:CHINA MCC17 GRP

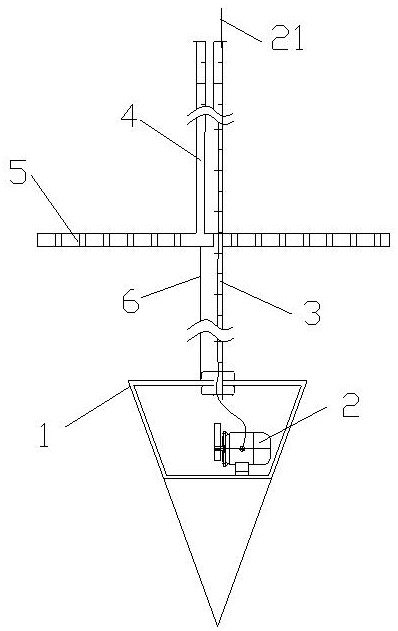

Device for measuring depth of slurry in cast-in-place pile

PendingCN114232699AEnsure construction qualityEnsure hole qualityFoundation testingBulkheads/pilesMeasurement deviceEngineering

The invention discloses a device for measuring the depth of slurry in a cast-in-place pile, and the device comprises a hollow conical vibrator, a vibration motor, a first telescoping calibrated scale, a second telescoping calibrated scale, a floating disc with holes, and a telescoping traction rope. The vibration motor is disposed in the inner cavity of the conical vibrator, the first telescoping calibrated scale is vertically disposed on the top surface of the conical vibrator, and the second telescoping calibrated scale is disposed on the top surface of the conical vibrator. The floating disc with holes penetrates through the first telescopic graduated scale and ascends and descends along the first telescopic graduated scale, the second telescopic graduated scale is arranged on the top face of the floating disc with holes and is parallel to the first telescopic graduated scale, and the two ends of the telescopic traction rope are connected with the bottom face of the floating disc with holes and the top face of the conical vibrator respectively. The device overcomes the defects of traditional mud depth measurement, the depth of mud is calculated through the density buoyancy of power, water and mud, the device has the advantages of being efficient, scientific and accurate, and construction and hole forming quality of cast-in-place pile drilling are ensured.

Owner:CHINA MCC20 GRP CORP

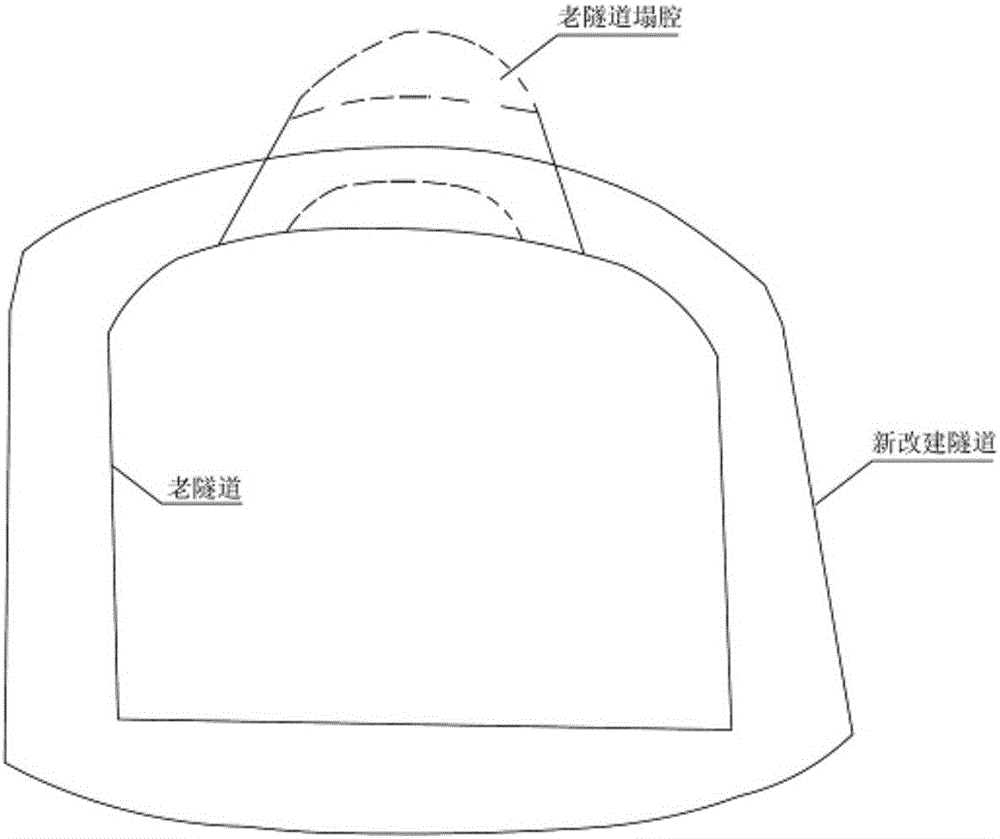

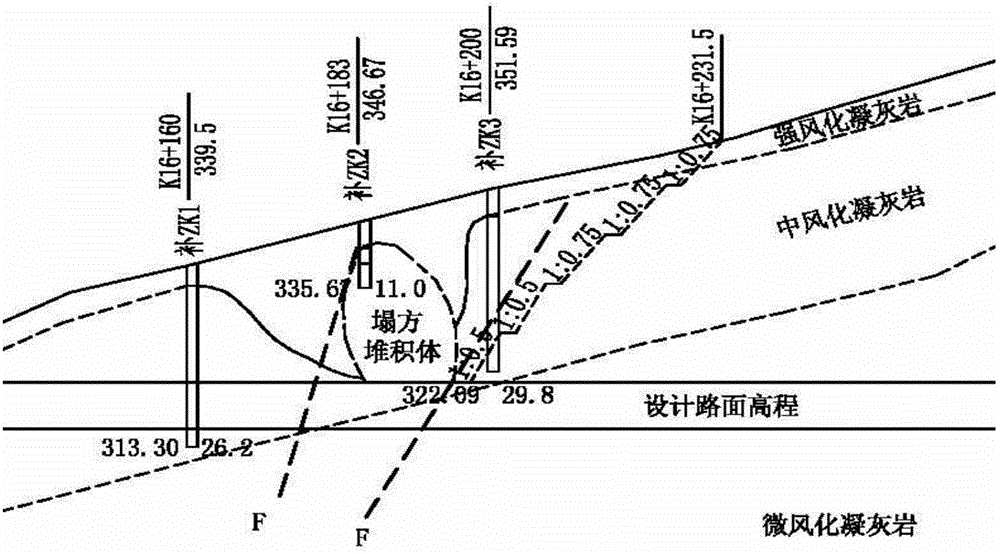

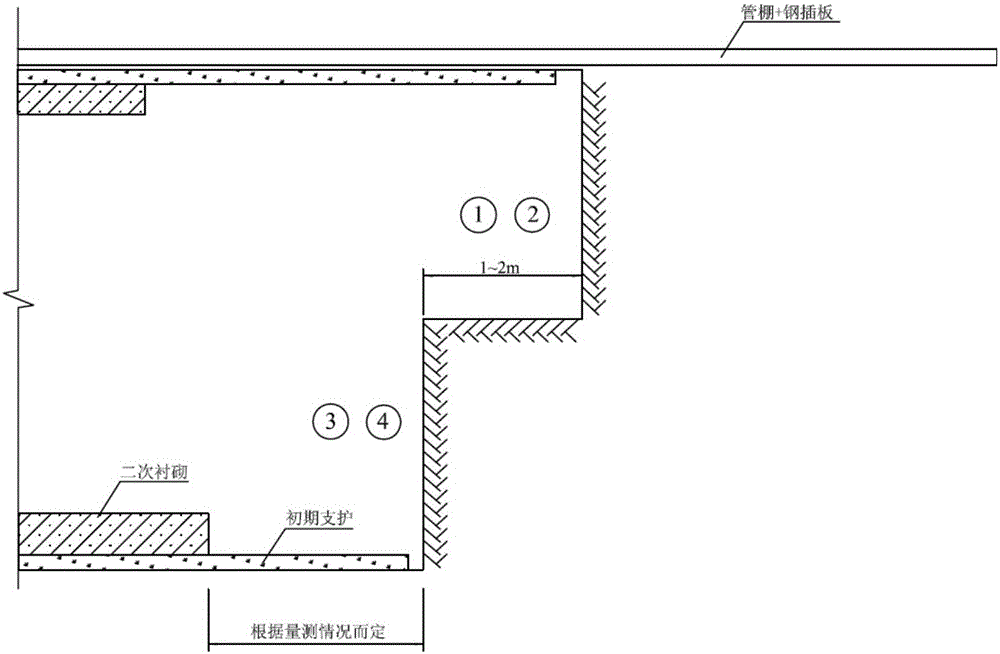

A mountain tunnel reconstruction expanding excavation construction method

ActiveCN105952464AEnsure construction safetyEnsure construction qualityUnderground chambersTunnel liningDetonationCollapsed cavity

The invention provides a mountain tunnel reconstruction expanding excavation construction method. The method comprises the steps of performing expanding excavation support and construction according to tunnel construction standard requirements at sections without collapse cavities of a tunnel; performing detonation at sections with collapse cavities of the tunnel directly if the collapse cavities are smaller than a newly-constructed tunnel profile, and performing expanding excavation support and construction according to the tunnel construction standard requirements; if collapse cavities of the tunnel are larger than the newly-constructed tunnel profile, performing the following substeps on the sections with the collapse cavities of the tunnel: forming shed frames through pipe shed support and plate insertion for support in the sections of the tunnel, filling the collapse cavities outside the newly-constructed tunnel profile with light materials, and performing expanding excavation construction on the sections of the tunnel by using an improved expanding excavation support method. Compared with the prior art, the method directly analyzes tunnel collapse cavity construction risks by using the energy method, founds a macroscopic qualitative control method, formulates an implementation scheme, performs strict control, prevents adverse acting force and energy from transferring to or working intensively on weak parts of a structure, facilitates control of construction risks and guarantees engineering construction safety and quality.

Owner:NINGBO COMM PLANNING INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com