Installation technology of power cable aluminum alloy waterproof drawing head

A technology of power cable and installation technology, which is applied in the field of installation technology of aluminum alloy waterproof pulling head of power cable, which can solve the problems of affecting the quality of cable use, water ingress of high-voltage cables, cracking and falling off of lead seals, etc., so as to ensure the construction and use of cable laying Quality, avoid environmental pollution, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The installation process of the aluminum alloy waterproof pulling head of the power cable of the present invention comprises the following steps:

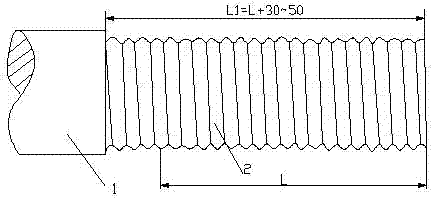

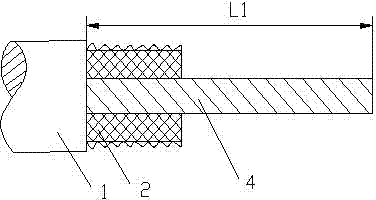

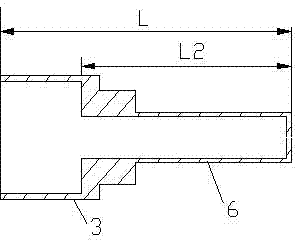

[0048] Step a: Cable puller end treatment

[0049] Properly adjust the cable reel according to the position of the cable end on the cable reel. When installing, the cable end and the pulling head should be installed in a horizontal position to ensure safe installation of the pulling head. Straighten the cable end, determine the delivery length of the cable, and use a vernier caliper to add 30 to 50 mm from the delivery cable length L as the cutting length L1, such as Figure 1a and Figure 1b shown. Use a utility knife to peel off the outer sheath of the cable with a cutting length of L1, and use a cloth strip dipped in acetone to clean the asphalt and other impurities on the surface of the aluminum sheath 2. When stripping the outer sheath, care should be taken not to damage the aluminum sheath 2 of the cable. Use a verni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com