Soil covering corrugated steel plate bridge construction method

A technology of corrugated steel plates and construction methods, which is applied to bridges, arch bridges, bridge parts, etc., can solve problems such as complex processes, unreliability, and insufficient longitudinal rigidity, and achieve the effects of simple method steps, guaranteed grouting effects, and guaranteed construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

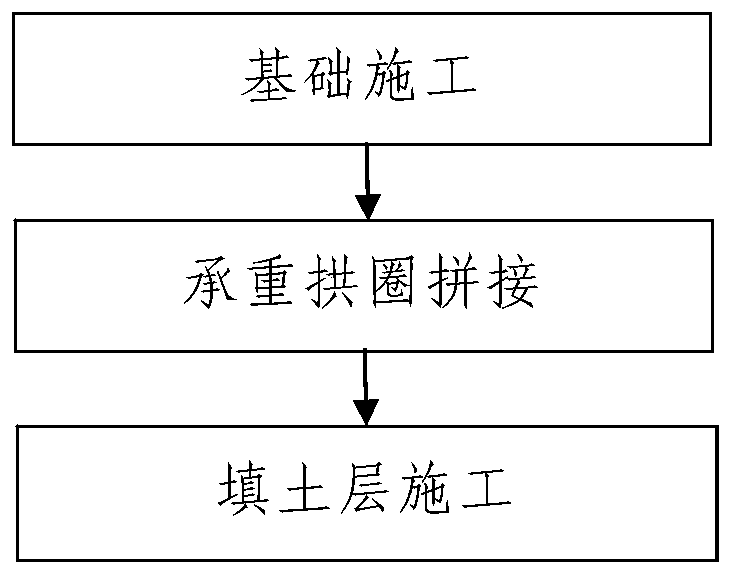

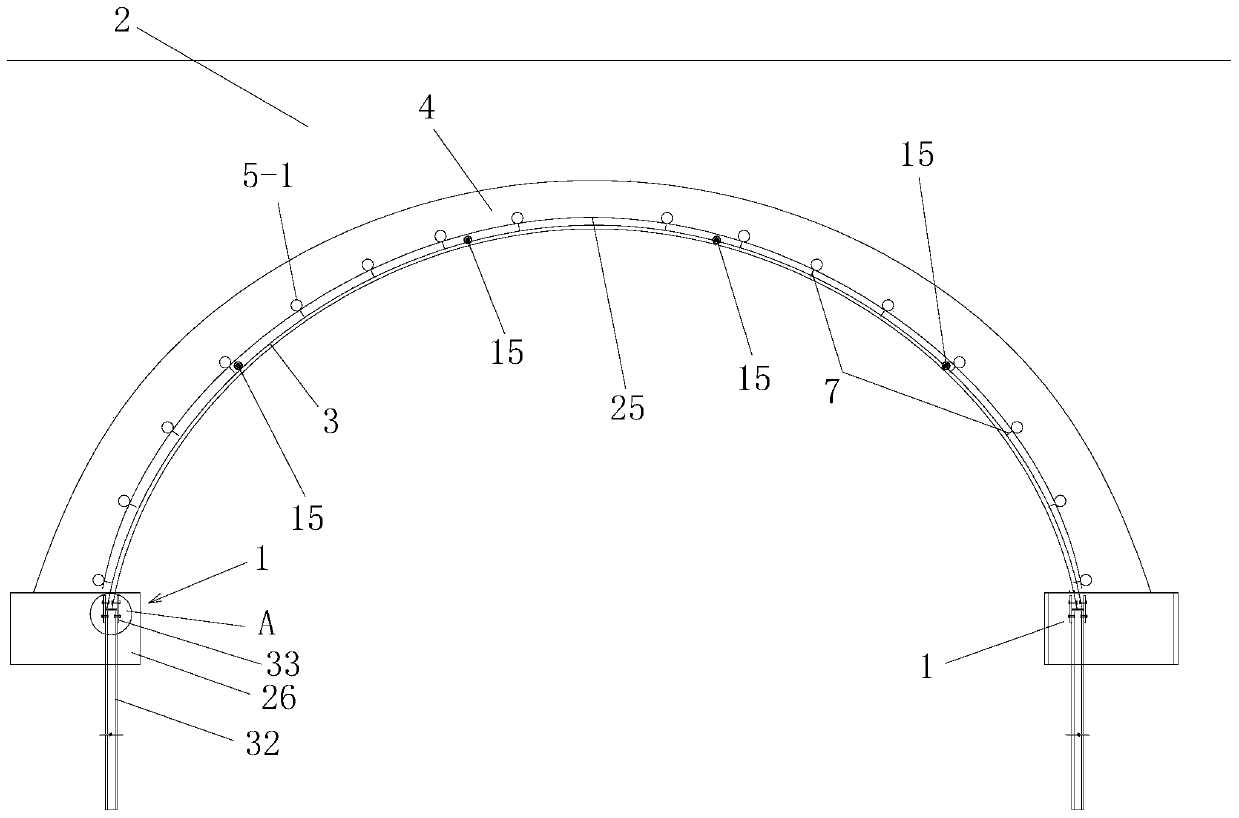

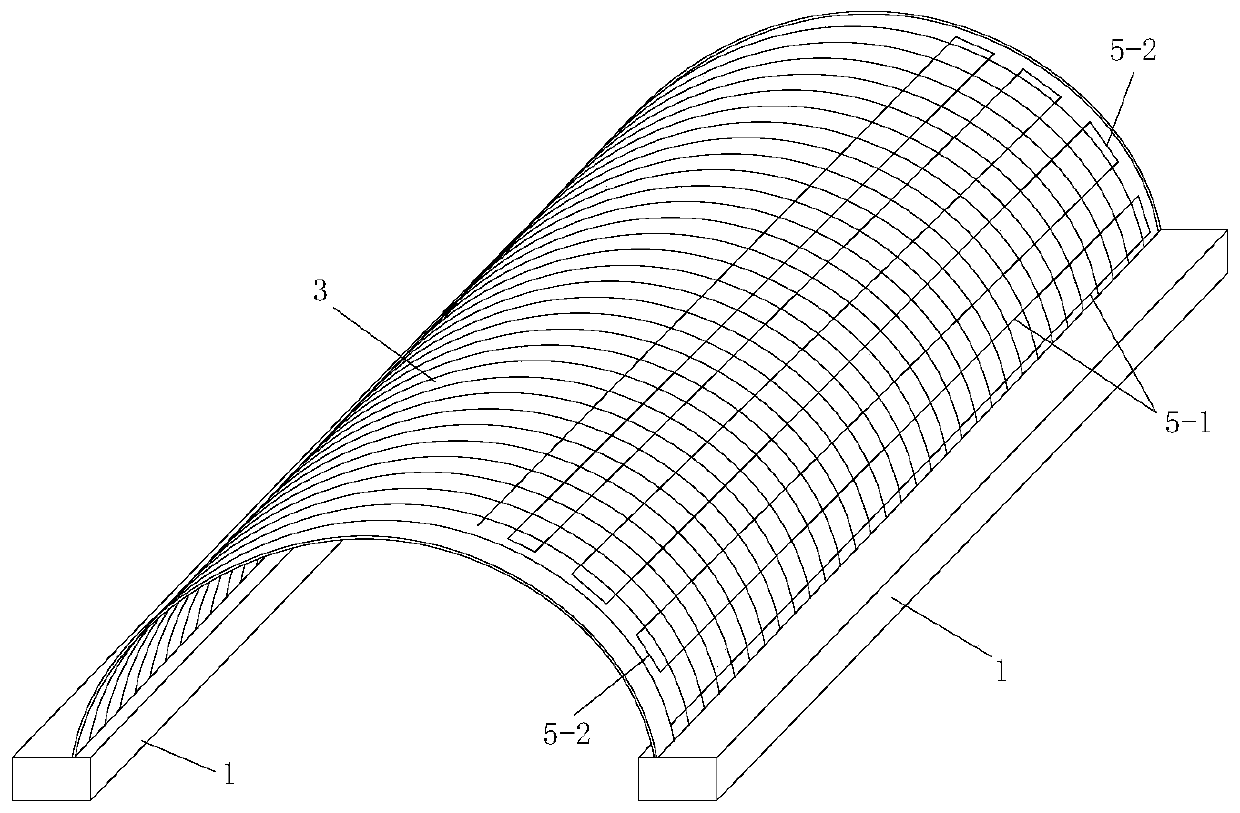

[0100] Such as figure 1 A construction method of a corrugated steel plate bridge covered with soil is shown, combined with figure 2 , image 3 , Figure 4 , Figure 5 and Figure 12 , the constructed soil-covered corrugated steel plate bridge includes a main arch and a filling layer 2 covering the outside of the main arch; structure;

[0101] to combine Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 and Figure 21 , the load-bearing arch ring 3 is spliced by m arch ring splicing segments 11, wherein m is a positive integer and m≥4, the transverse bridge width of the load-bearing arch ring 3 is greater than 50m; the m arch rings are spliced The sections 11 are arranged on the same horizontal straight line from left to right along the transverse bridge direction, and the cross-sectional structure and size of the m arch ring splicing sections 11 are all the same; each of the arch ring splicing sections 11 is arranged horiz...

Embodiment 2

[0290] Such as Figure 22 As shown, in this embodiment, the difference from Embodiment 1 is: m=6. During actual construction, the value of m can be adjusted accordingly according to specific needs. Four arch ring splicing sections 11 in the load-bearing arch ring 3 are respectively the left end splicing section, the second splicing section, the third splicing section and the right end splicing section from left to right.

[0291] In this embodiment, the rest of the method steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com