Construction method for high-rise reinforced concrete elevator shaft

A reinforced concrete and construction method technology, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of prolonging the construction period, difficulty in ensuring safety protection, and increasing costs, so as to save labor, The effect of shortening the construction period and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0025] A kind of high-rise reinforced concrete elevator shaft construction method, the steps of its construction method are:

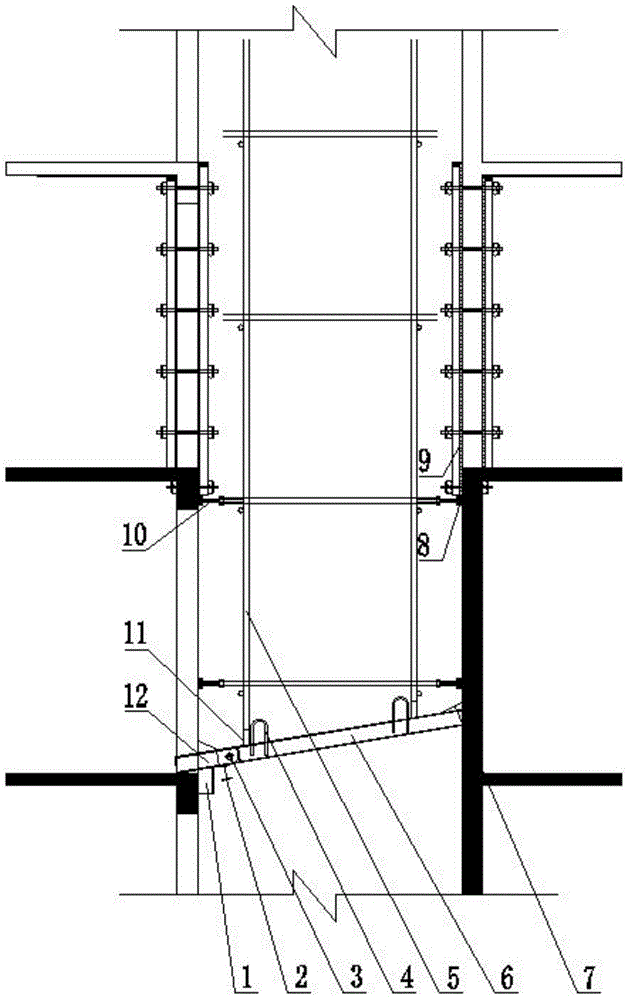

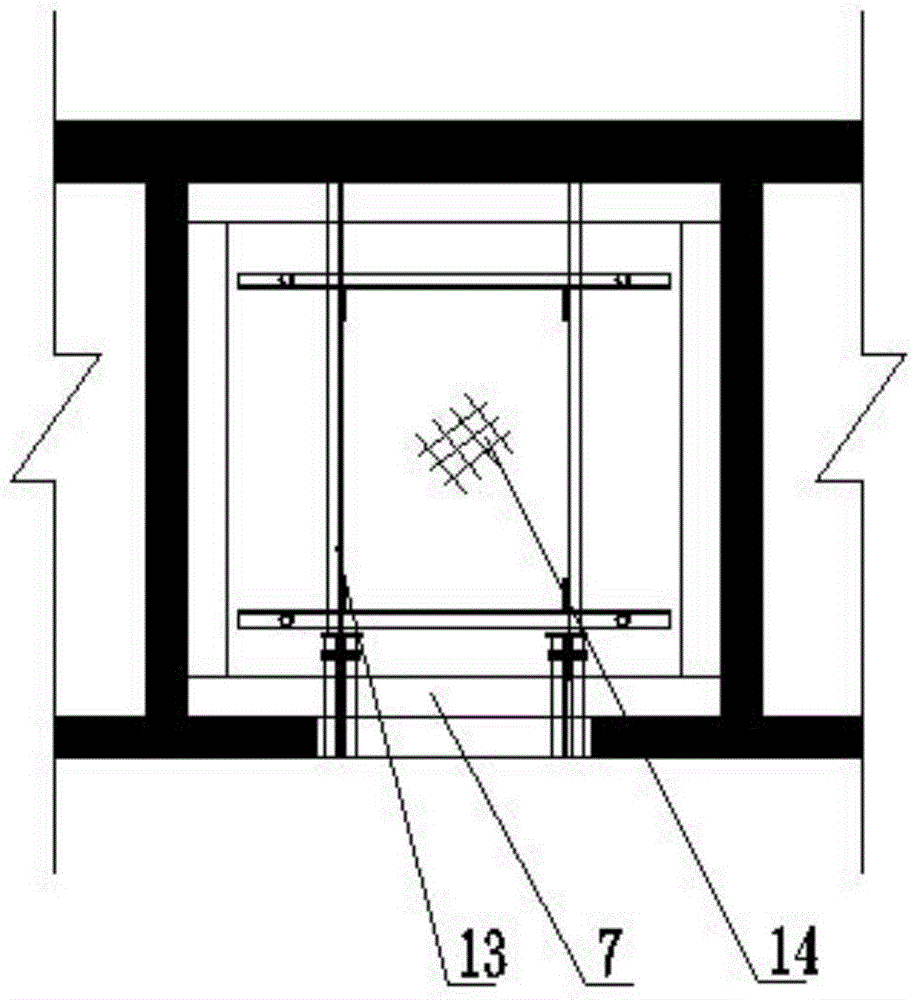

[0026] (1) Assembling the movable platform: the movable platform includes platform main beam 6, platform secondary beam 13, platform checkered steel plate 14, overturned lap beam 12, and two parallel platform main beams and two parallel platform secondary beams are vertically fixed to each other. Beam frame, platform checkered steel plates are arranged on the beam frame to form a platform, and suspension rings 4 are installed on the platform. The overturning lap beam is installed on one end of the platform through the rotation of the rotating shaft 3, and the limit clamp plate 1 is installed under the overturning lap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com