Granary top overhead section concrete construction platform and construction method

A construction platform and concrete technology, which is applied in the direction of scaffolding for building structure support, building structure support, building structure support, etc., can solve the problems of uncontrollable frame settlement, unguaranteed quality, and many unsafe factors, so as to shorten the construction period , Reduce the use of steel pipes and reduce the effect of erection height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

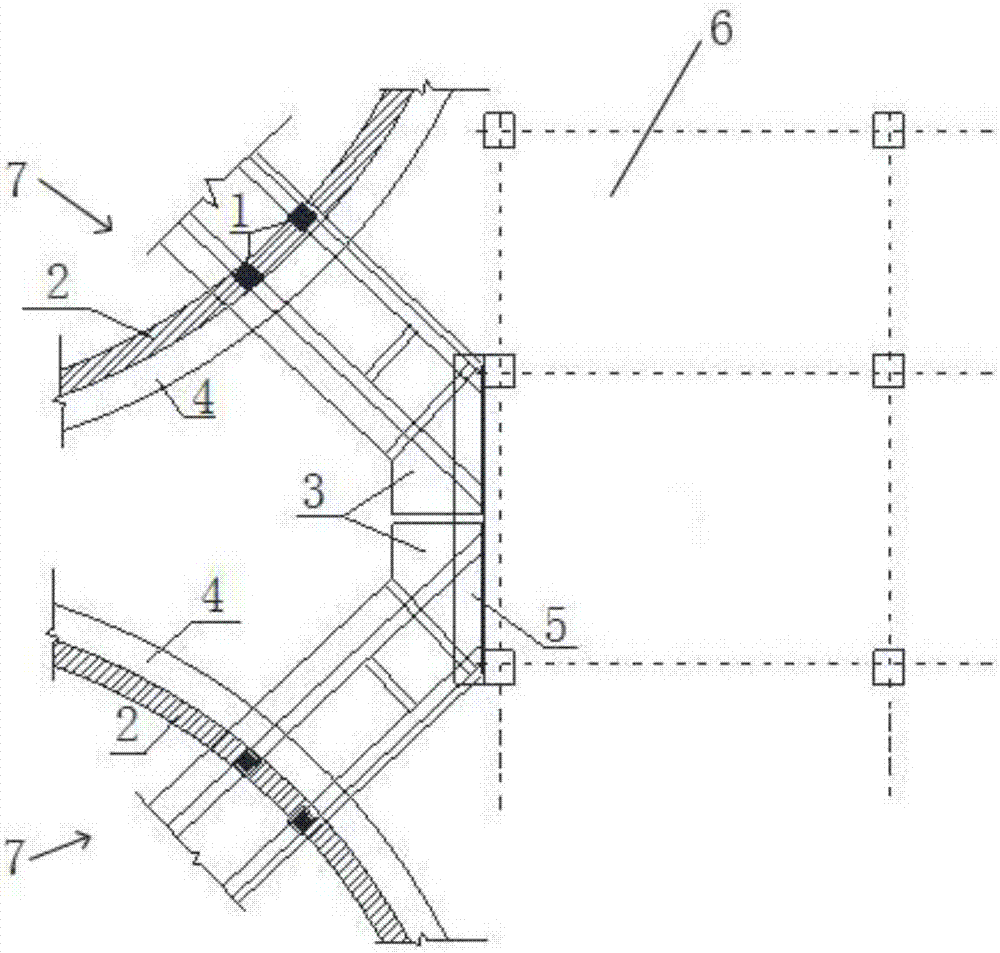

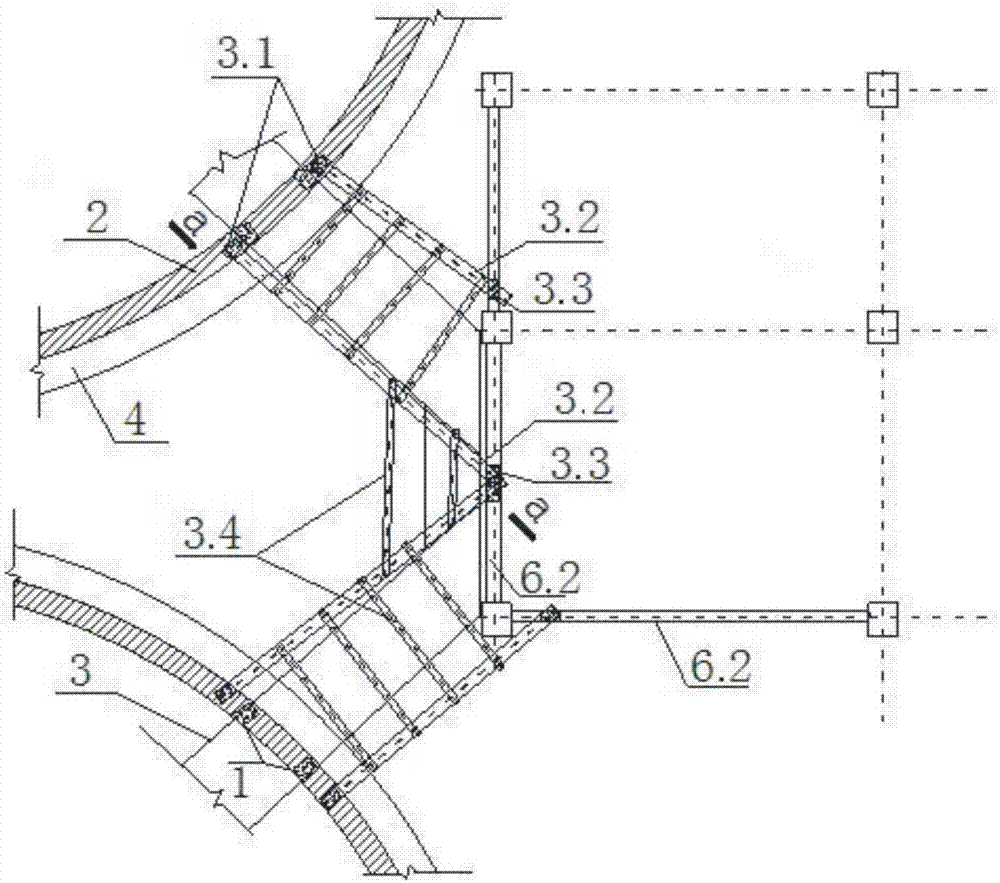

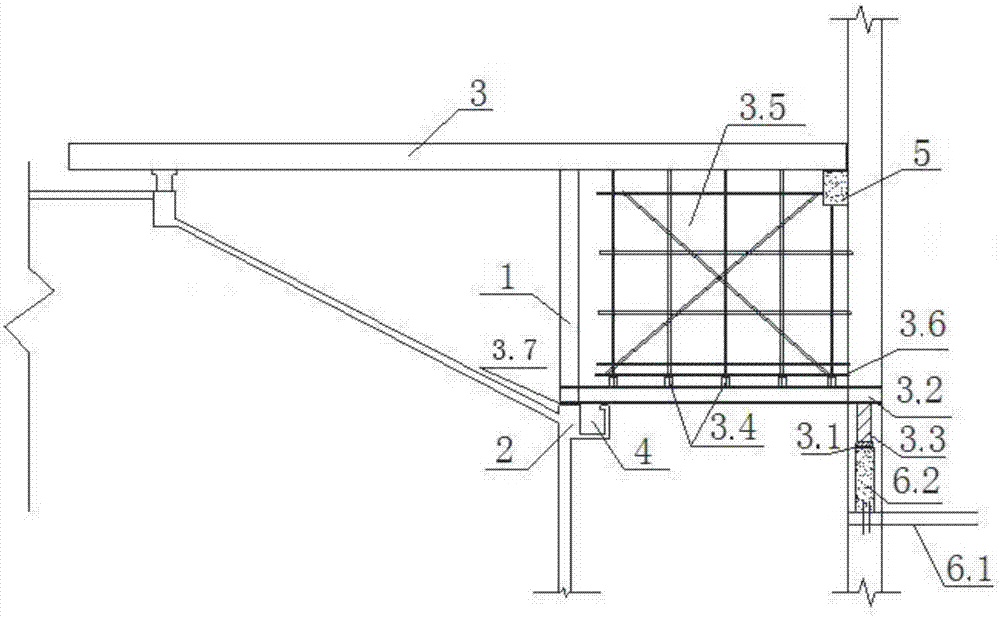

[0025] Such as Figure 1-3 As shown, the concrete construction platform of the overhead section on the top of the granary of the present invention is arranged between the shallow round warehouse 7 and the lifting tower 6 for the construction of the corridor platform 3 . The corridor platform 3 connects the top of the shallow round warehouse 7 and the corbel beam 5 of the lifting tower, and a short column 1 is arranged between the corridor platform 3 and the main steel beam 3.2.

[0026] The top of the shallow round warehouse 7 is provided with a roof ring beam 2 , the inside of the lifting tower 6 is provided with a support platform 6.1 , and the outer side of the warehouse roof ring beam 2 is provided with a gutter 4 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com