Patents

Literature

244results about How to "Magnetically stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

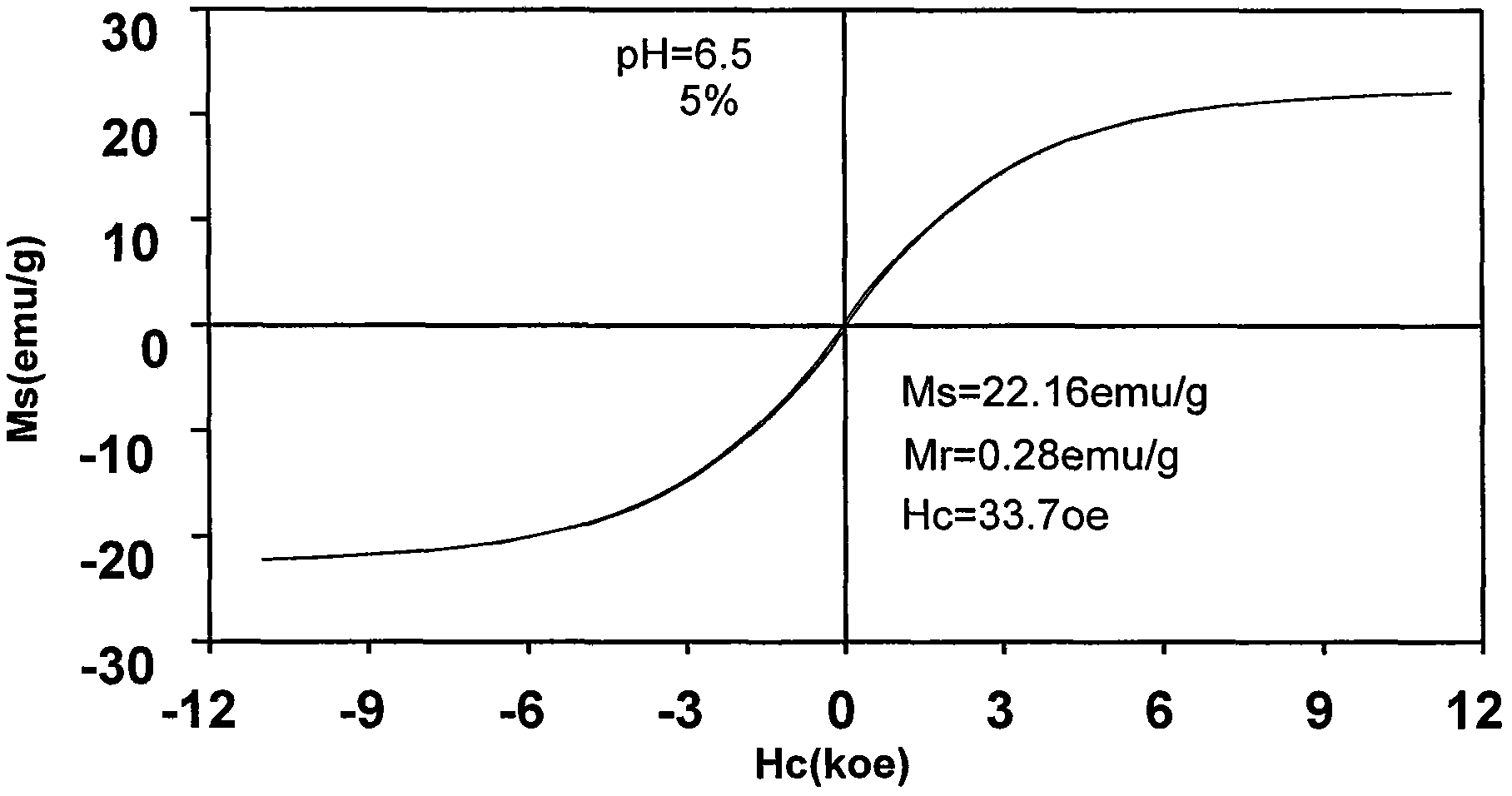

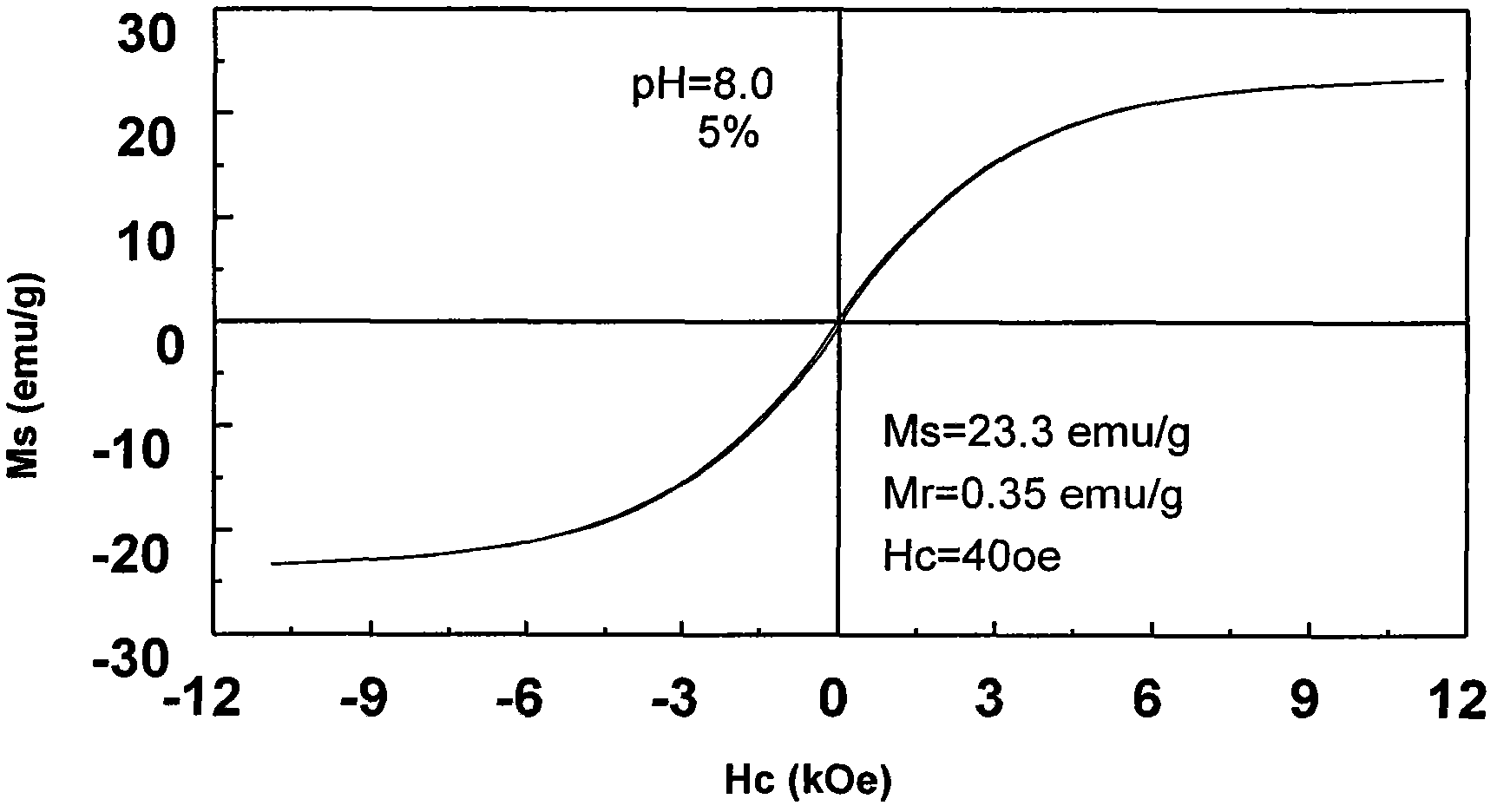

Super paramagnetic ferric oxide composite nanometre particle preparation method

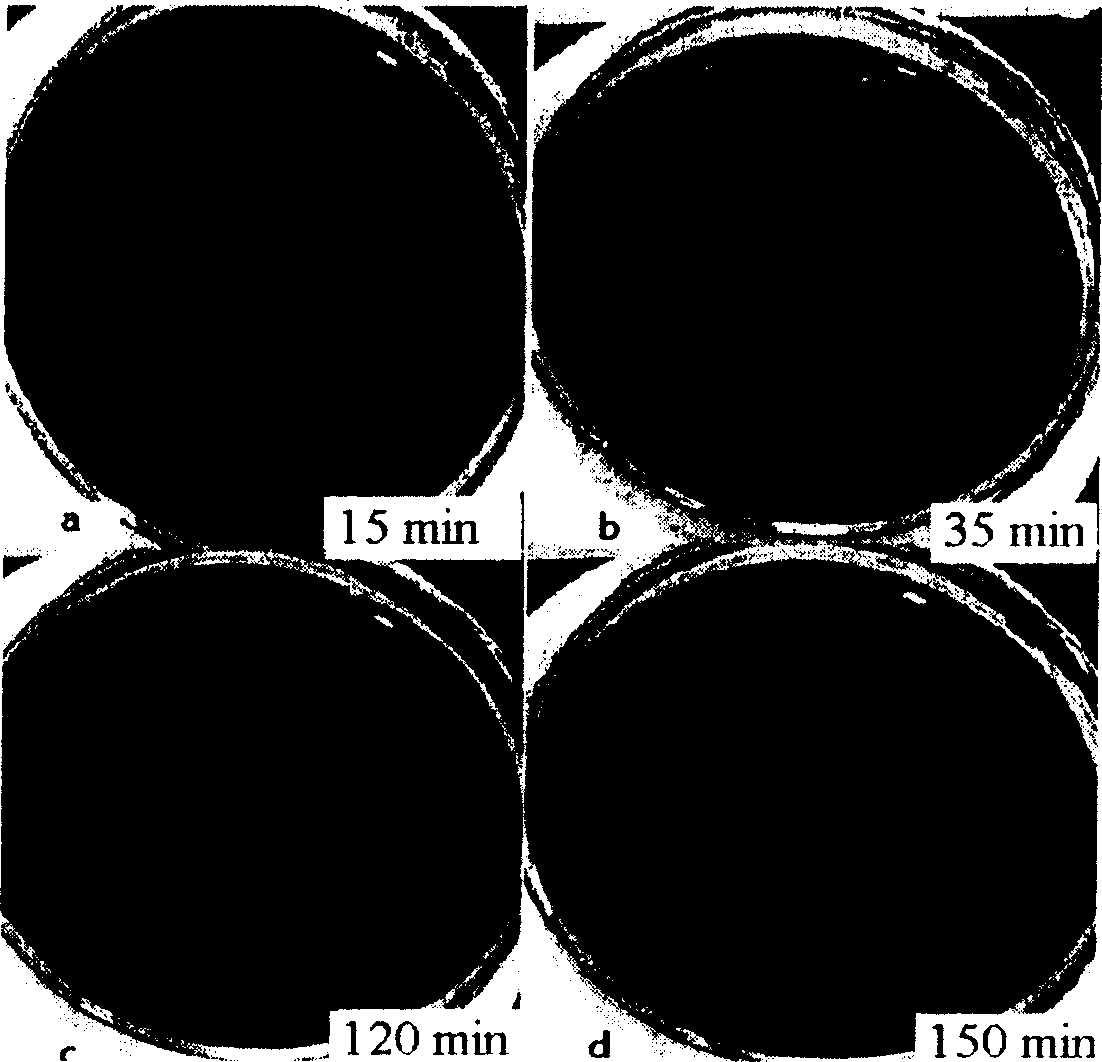

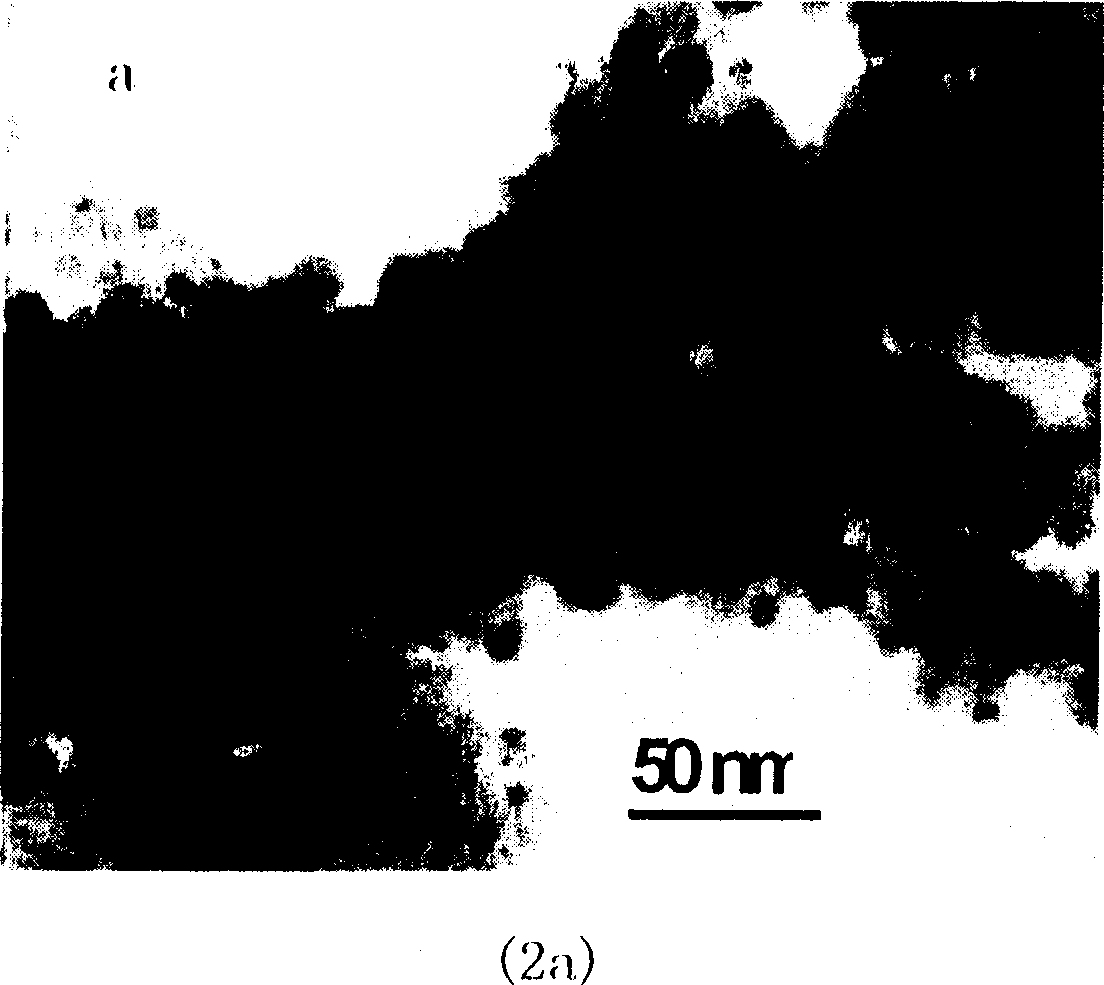

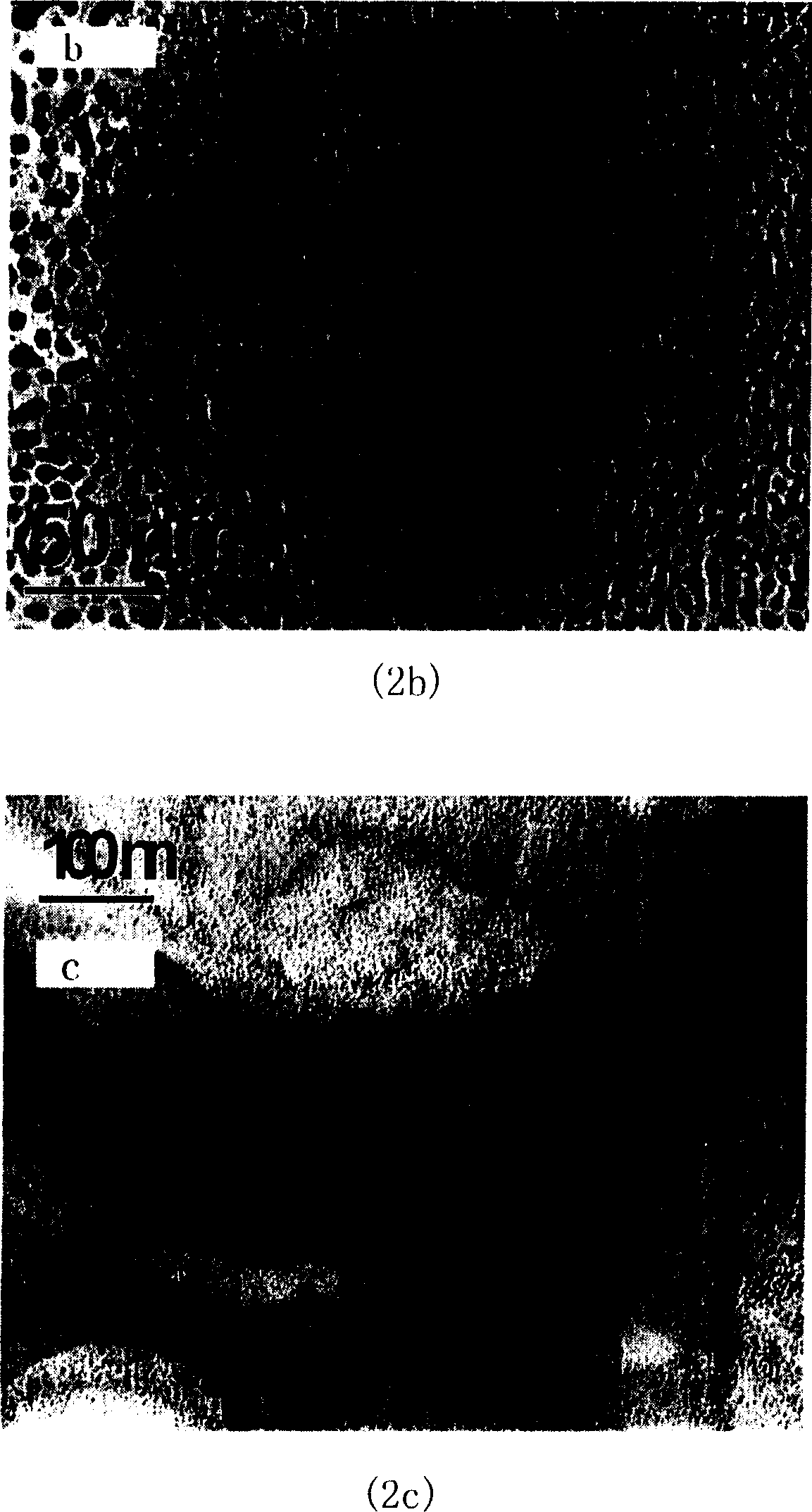

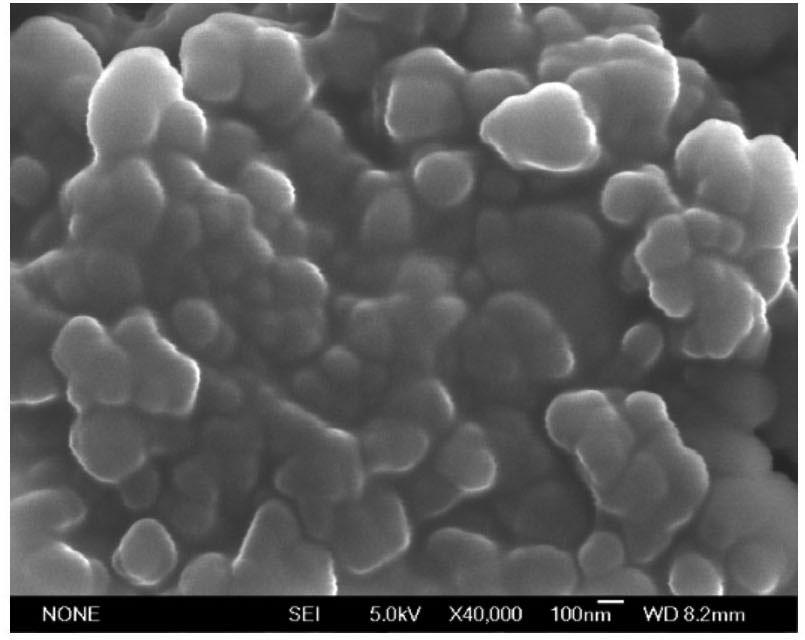

InactiveCN1736881AReduce nucleationReduced growth rateNanostructure manufactureFerric oxidesSal ammoniacNanoparticle

The invention discloses a preparation method for composite nano particcle of superparamagnetic ferric oxide. Wherein, adding ammonia and sodium citrate synchronously and speed controlled to make ions of Fe3+ and Fe2+ coprecipitate and form Fe3O4 nano particle with water-phase dispersion surface adsorbed by citric acid radical that can be substituted by multi chemical functional group on basic condition as crystal seed for sodium citrate-goden chloric acid reduction reaction and form SPION nano particle.

Owner:HUAZHONG UNIV OF SCI & TECH

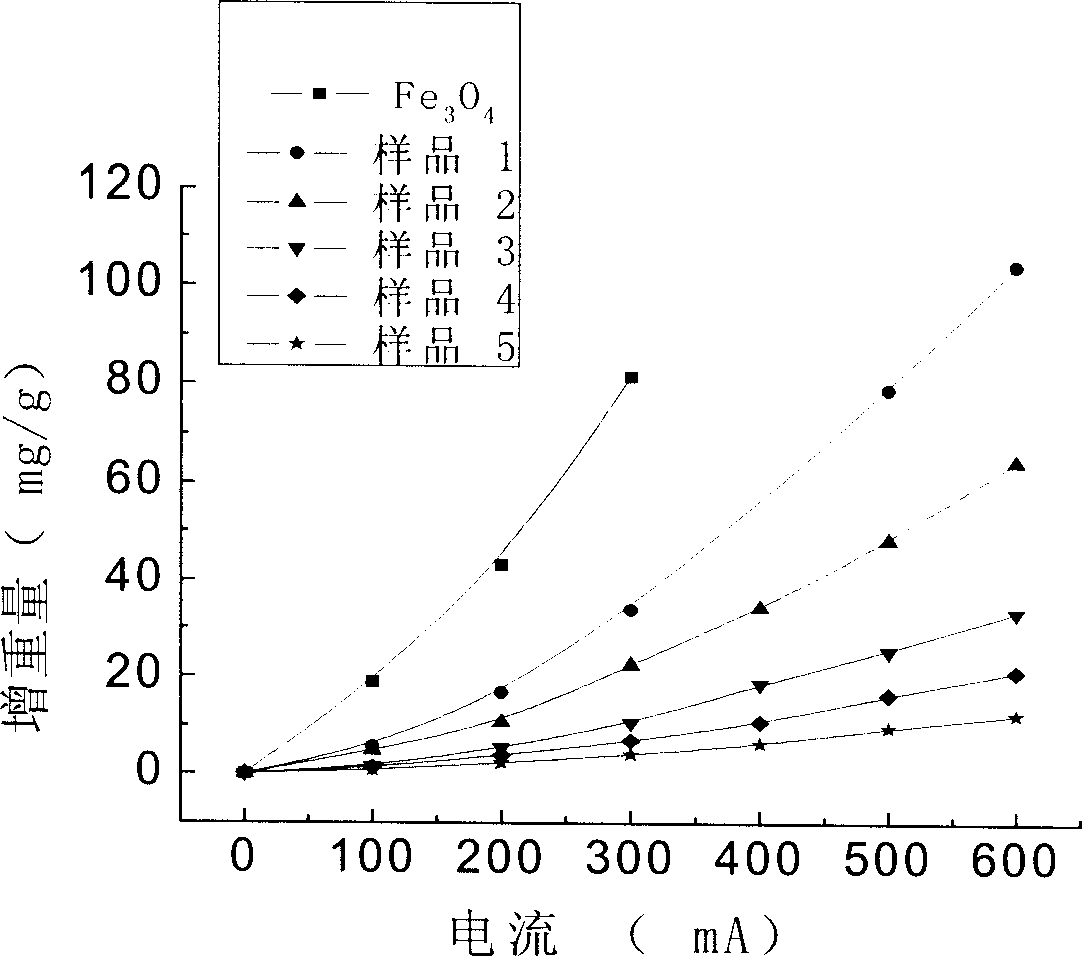

Method for preparing magnetic active carbon composite material for water processing

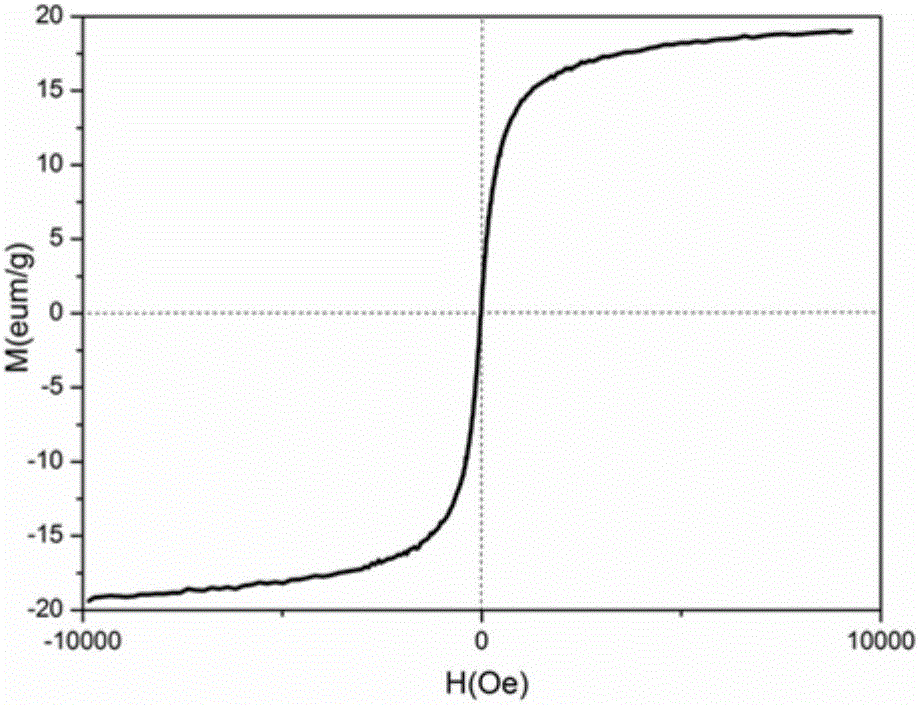

InactiveCN101502789APreserve the open cell structureImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionMagnetite NanoparticlesHigh pressure

The invention provides a method for preparing a magnetic active carbon composite material for water treatment in the technical field of environmental purification. The method comprises the following steps: mixing active carbon and corresponding metal salt solution, and generating magnetic nano granules in pore canals of the active carbon in situ by using the characteristics of instantaneous high temperature, high pressure, high cooling speed and the like generated by ultrasonic waves; and filtering and drying the obtained compound, and treating the compound at high temperature to form the magnetic active carbon composite material, wherein the magnetic material accounts for 15 to 50 percent in the whole material in terms of weight percentage, and the active carbon material accounts for 85 to 50 percent. The invention provides a new method for generating magnetic nano particles in the pore canals of the active carbon; and the prepared magnetic active carbon keeps larger specific surface area, reserves the open pore canals from the active carbon, removes organic substances and inorganic heavy metal ions in water treatment, and is easy for magnetic separation and convenient to recover.

Owner:SHANGHAI JIAO TONG UNIV

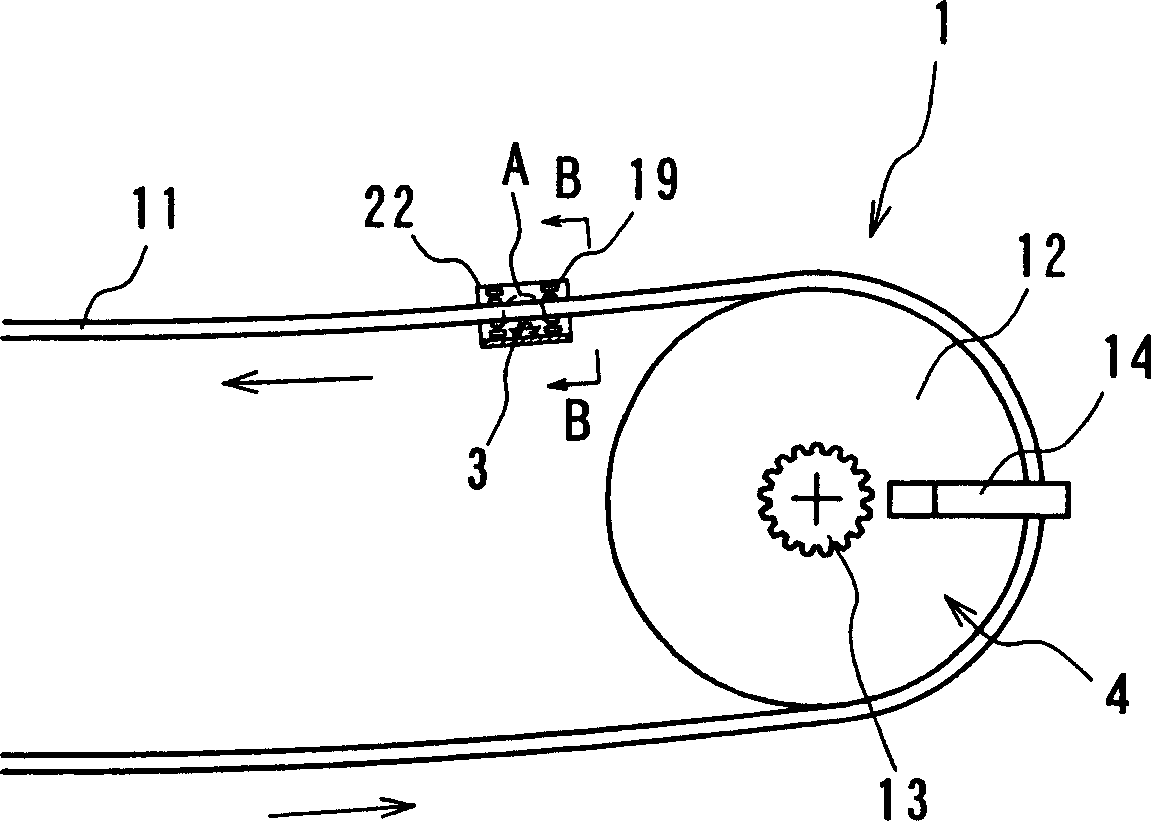

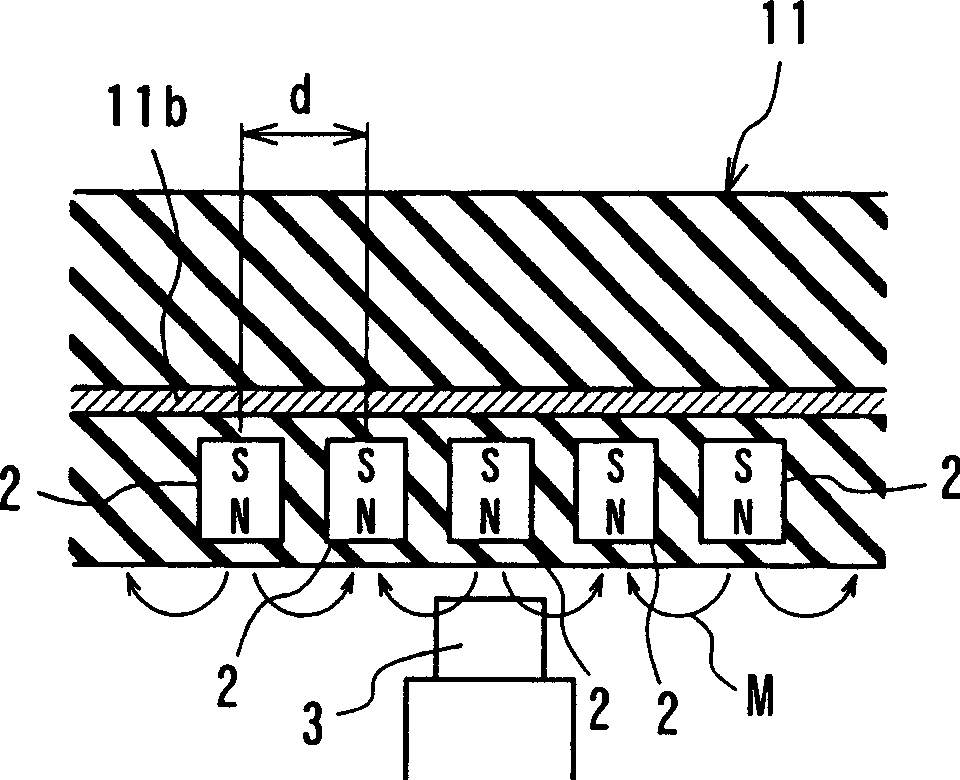

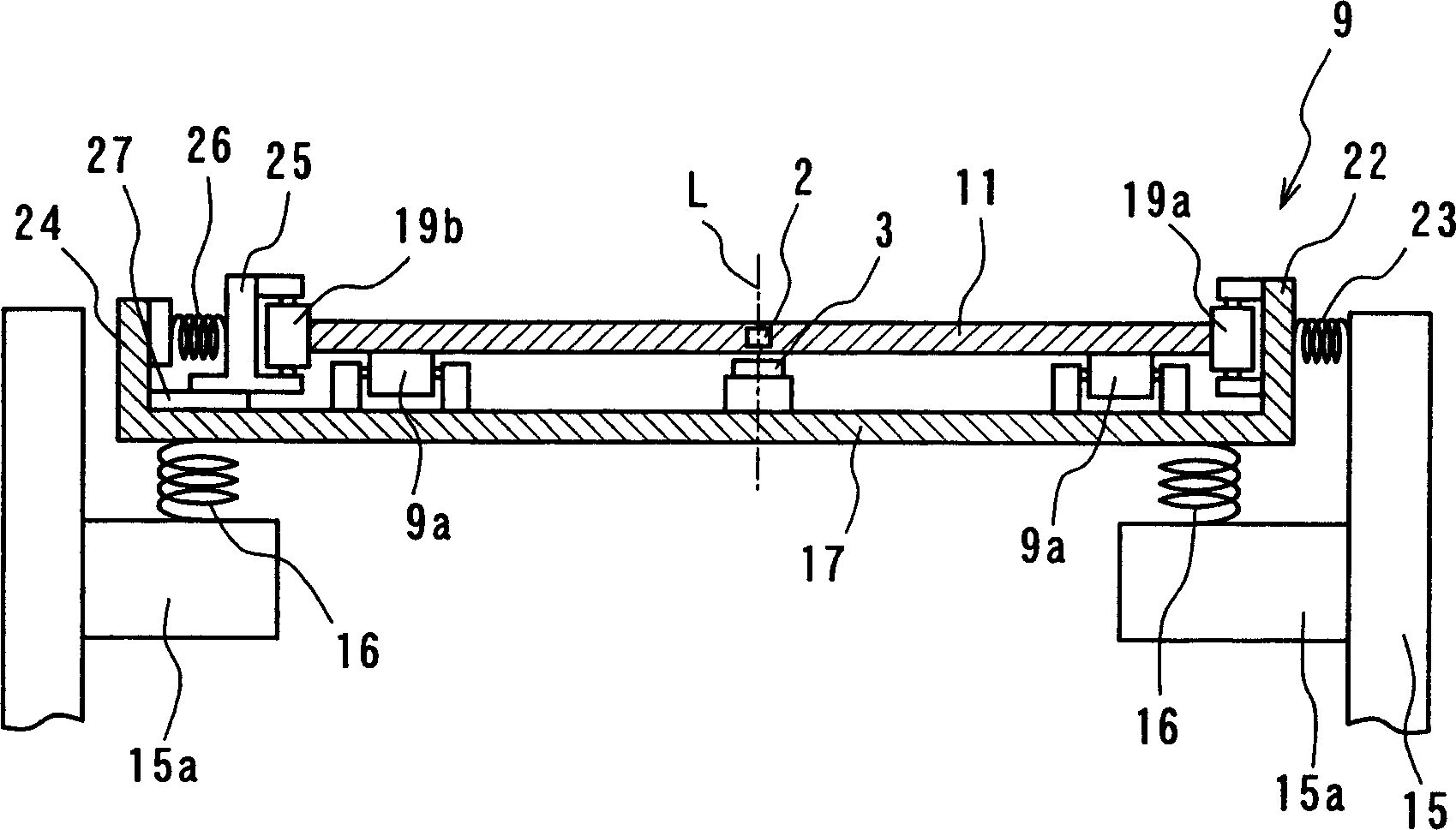

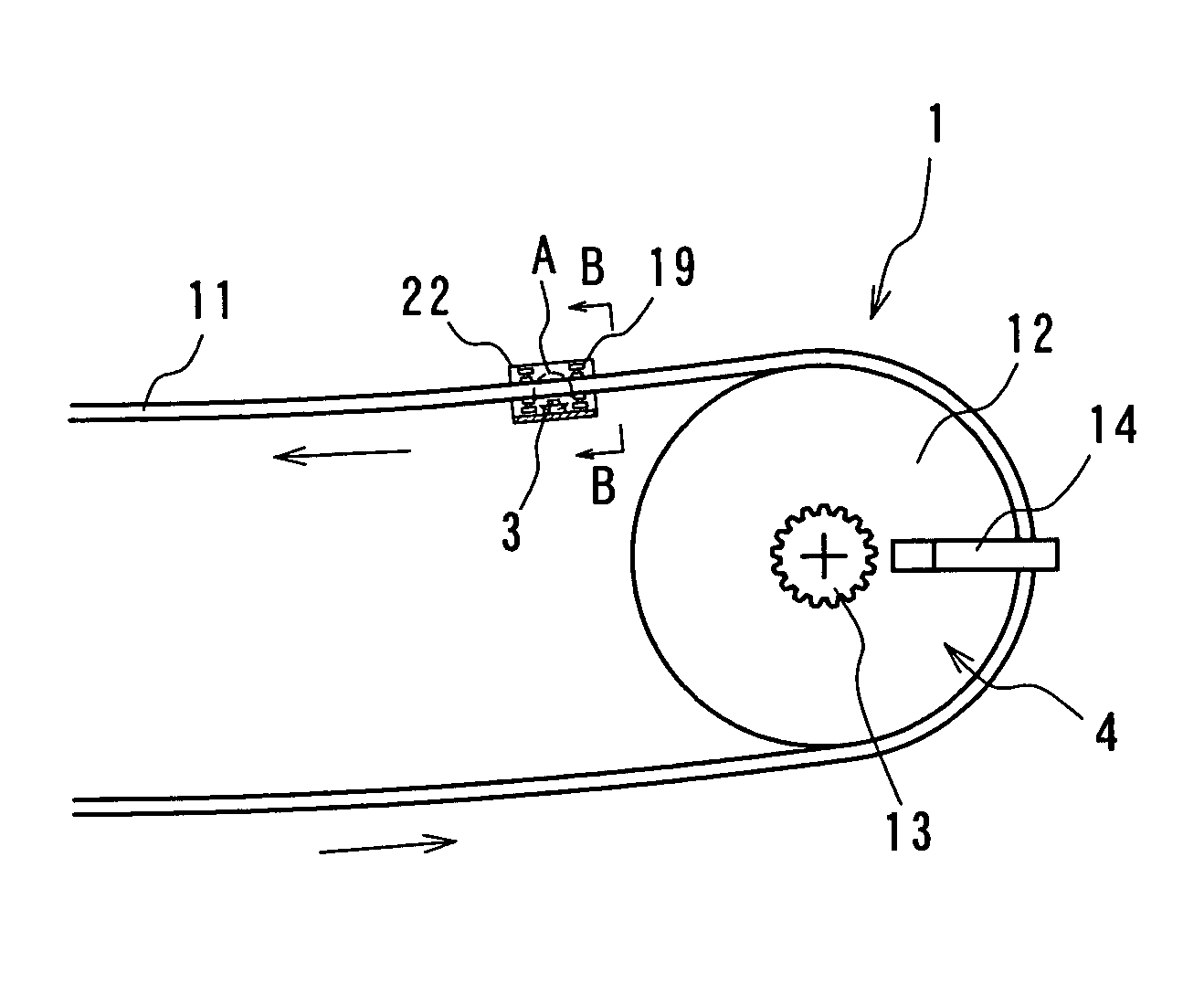

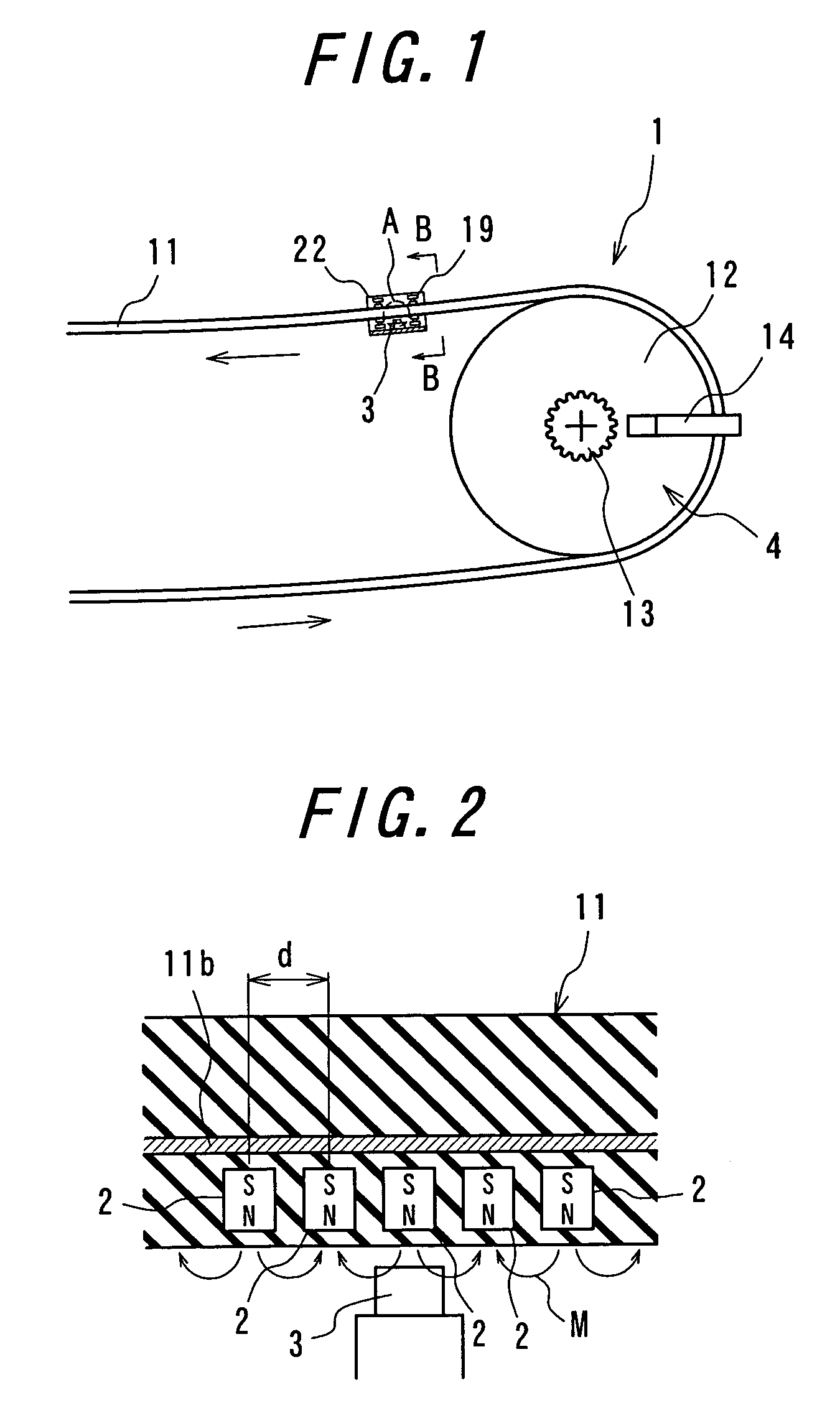

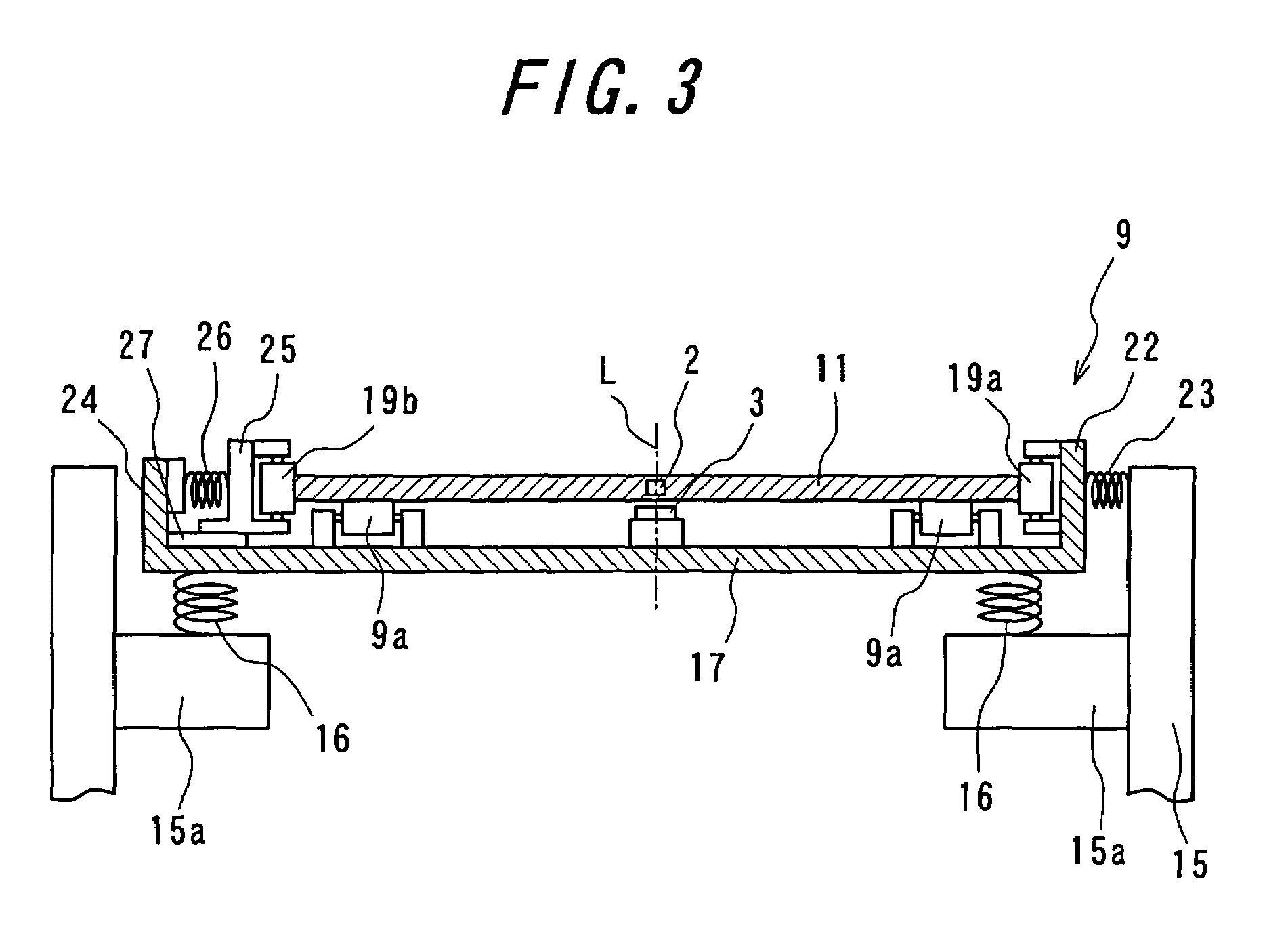

Method and device for measuring conveyor belt elongation, method and device for measuring conveyor belt wear extent, method and device for measuring conveyor belt temperature, rubber magnet sheet, and

InactiveCN1835881AShort lifeAccurate elongationConveyorsThermometers using electric/magnetic elementsConveyor beltInternal temperature

Methods and devices for measuring elongation, wear, and internal temperature of a conveyor belt to catch signs of conveyor belt failure such as breakage by detecting a magnetic field from a magnetic body by using a magnesium sensor, as well as a rubber magnet sheet as a magnetic body and a method of producing the sheet, the rubber magnet sheet being able to be used while it is embedded in the conveyor belt. To measure elongation of a running conveyor belt ( 11 ), a magnetic field of a magnetic body ( 2 ) embedded in the belt ( 11 ) is detected by a magnetism sensor ( 3 ) fixed to the earth, and elongation of the belt ( 11 ) is calculated from temporal variation of the detected magnetic field.

Owner:BRIDGESTONE CORP

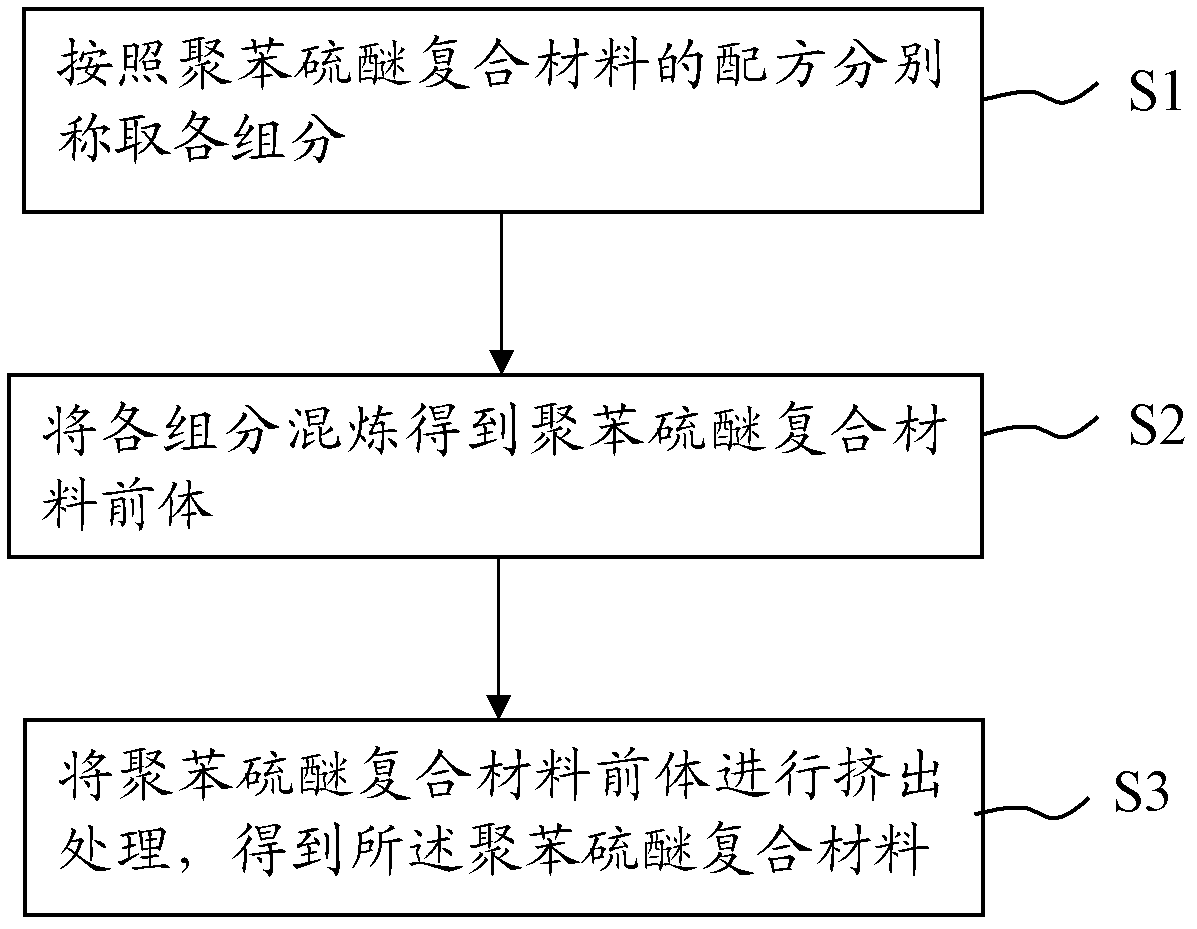

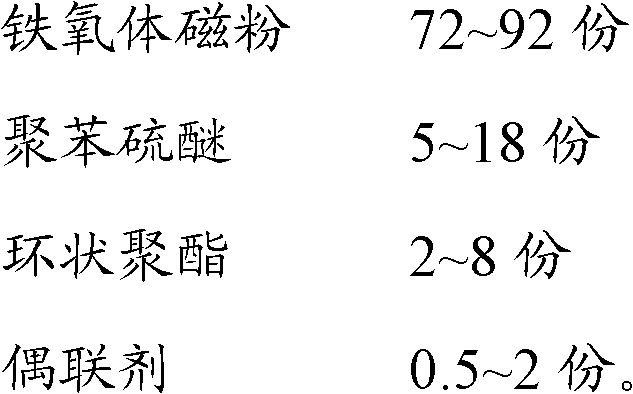

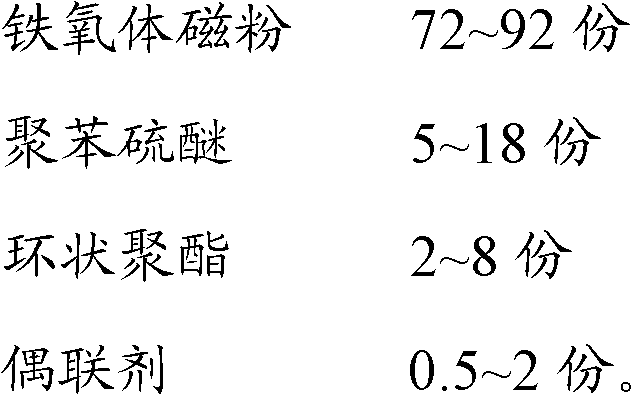

Polyphenylene sulfide composite material and preparation method thereof

InactiveCN102181156AImprove processing fluidityImprove mechanical propertiesPolyesterMechanical property

The invention discloses a polyphenylene sulfide composite material and a preparation method thereof. The polyphenylene sulfide composite material comprises the following formula components in part by weight: 72 to 92 parts of ferrite magnetic powder, 5 to 18 parts of polyphenylene sulfide, 2 to 8 parts of cyclic polyester and 0.5 to 2 parts of coupling agent. By interaction of the components in aproper content range in the extrusion process, the polyphenylene sulfide composite material has good processing flow property and mechanical performance and stable magnetic performance. The product can be obtained by mixing and extruding the components according to the formula in the preparation method of the polyphenylene sulfide composite material; and the preparation method is simple in process, low in cost, low in equipment requirement and suitable for industrialized production.

Owner:SHENZHEN KEJU NEW MATERIAL

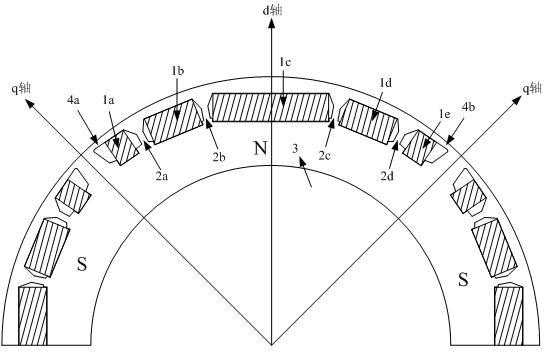

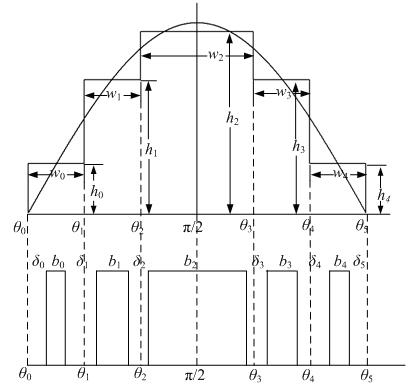

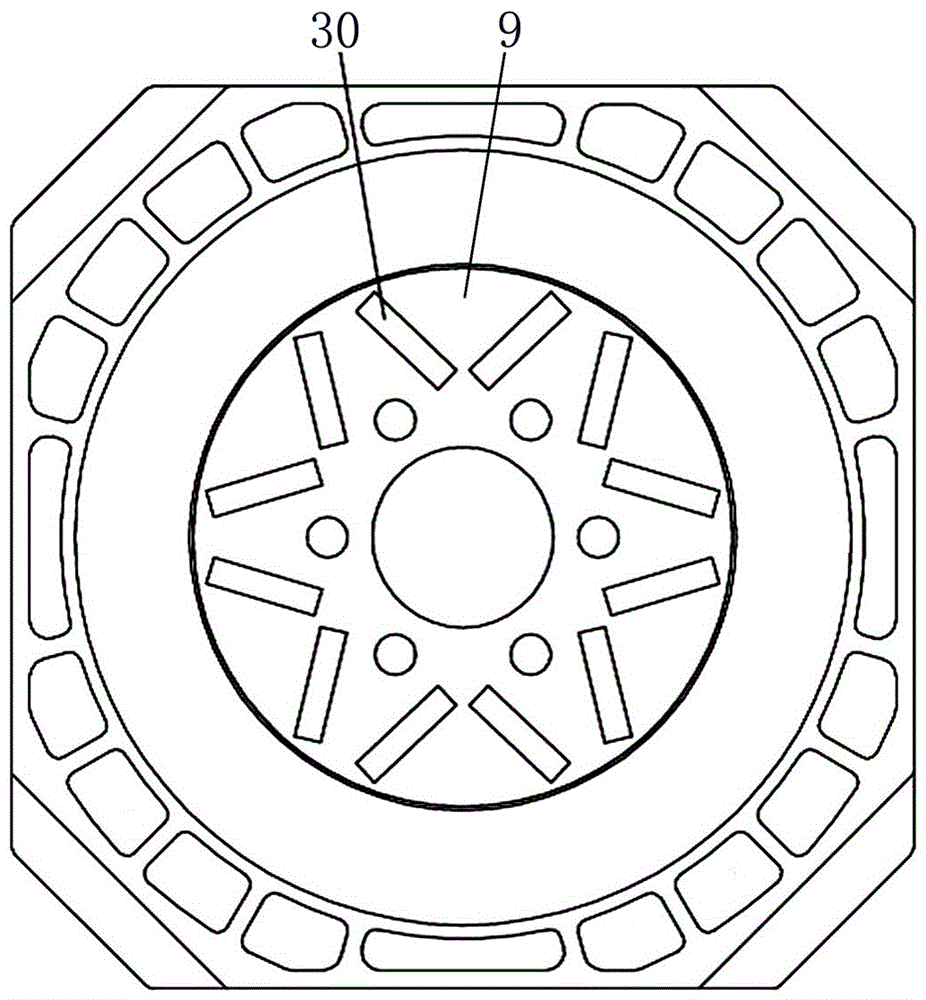

Rotor of built-in permanent magnet motor and magnetic steel structural parameter determining method thereof

InactiveCN102157998AHigh mechanical strengthIncrease stiffnessMagnetic circuit rotating partsElectric machinePermanent magnet motor

The invention relates to a rotor of a high-quality and high-speed built-in permanent magnet motor and a magnetic steel structural parameter determining method thereof. In the invention, the whole section magnetic steel of each electrode of the rotor of a conventional built-in permanent magnet motor is divided into multiple sections of magnetic steel which have the same polarity and different widths; the multiple sections of the magnetic steel are respectively arranged in a rotor core; and reinforcing ribs with the function of magnetic isolation are arranged among the multiple sections of the magnetic steel. By reasonably modulating and determining the width and distribution of each section of the magnetic steel, the air gap magnetic density waveform approaches sine distribution; harmonic components are reduced to the greatest extent; the eddy current loss of the magnetic steel and the torque pulsation of the motor are simultaneously reduced; and the electromagnetic performance of the motor is enhanced. Furthermore, the multiple sections of the magnetic steel are arranged in the circumference along the rotor; the highest rotating speed of the safe operation of the rotor is greatly enhanced on machinery; the radial thickness which is needed by the magnetic circuit of the rotor is obviously reduced on the structure; the rotational inertia and weight of the rotor are reduced; the dynamic response of the motor is improved; and the requirements of a high-speed driving system on the performance of the motor are met.

Owner:SHANGHAI UNIV

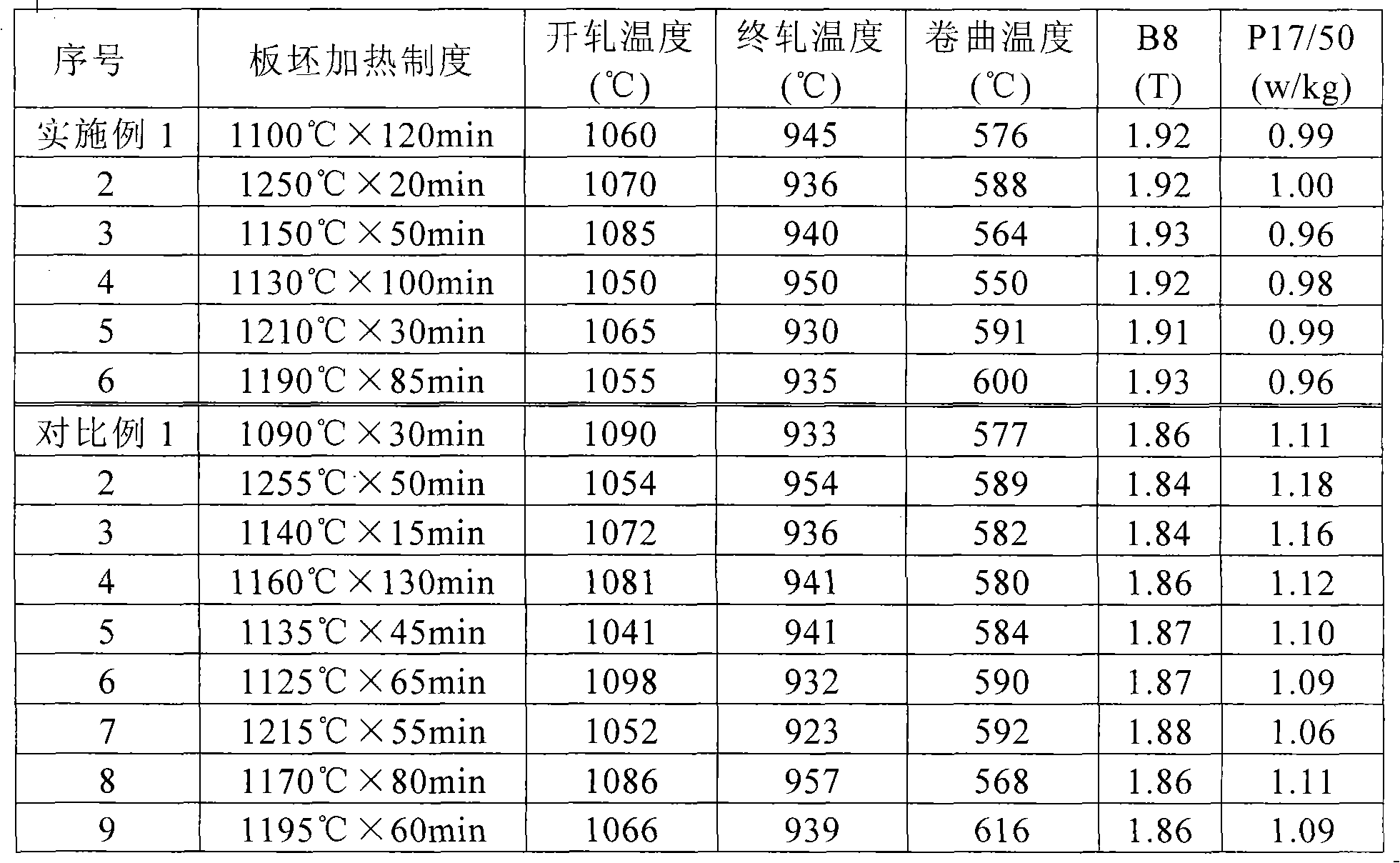

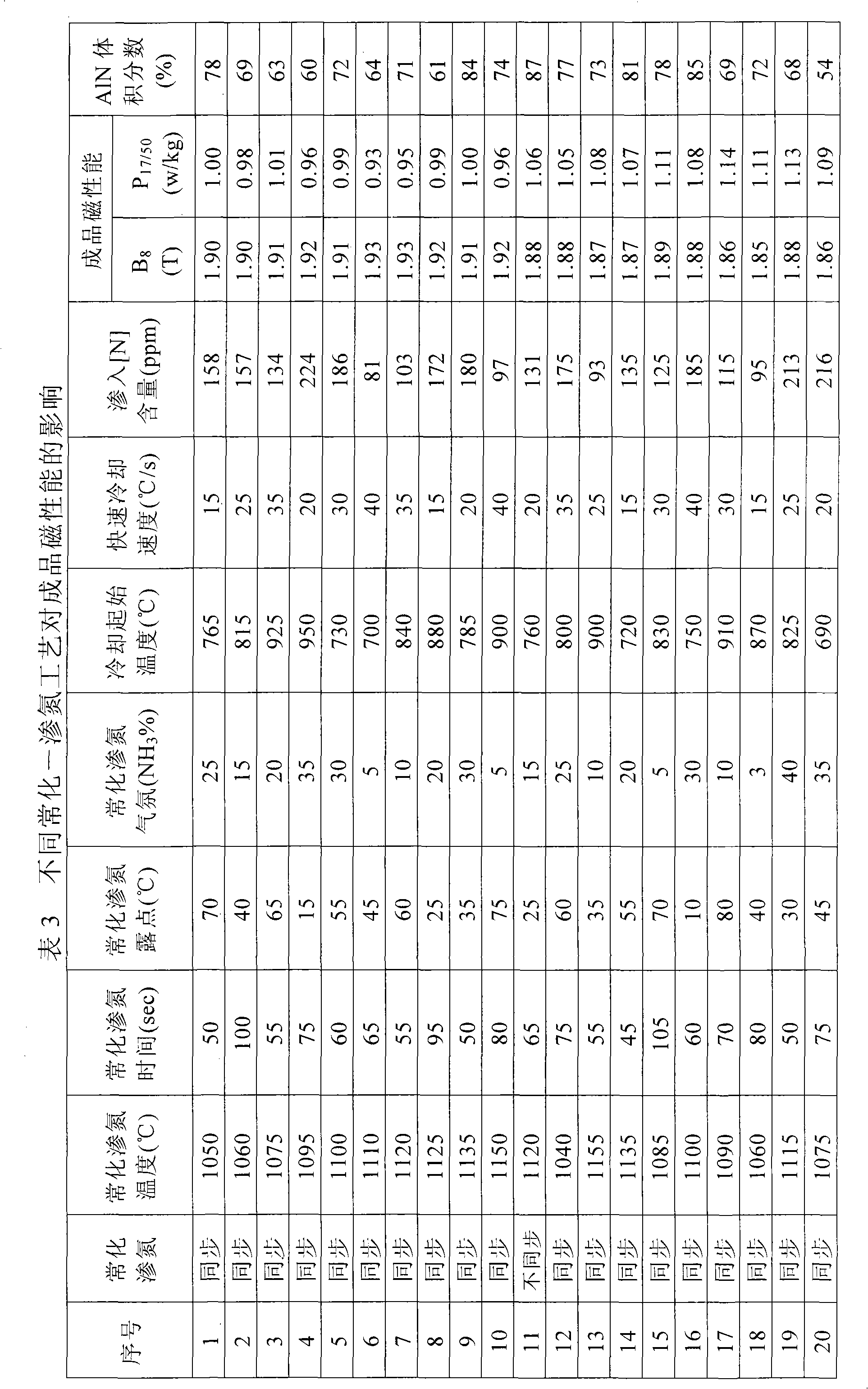

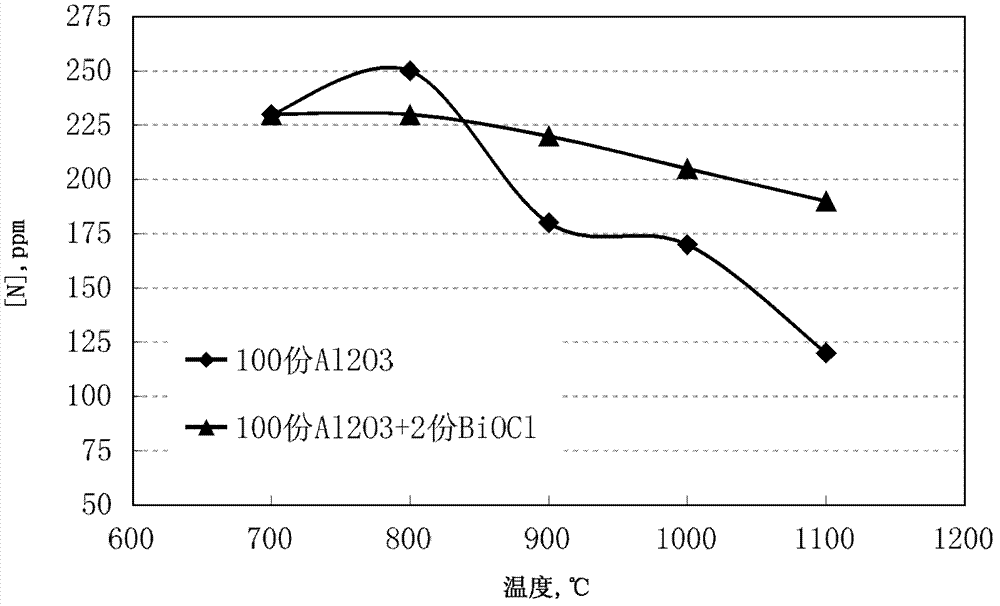

Production method of high magnetic induction oriented silicon steel

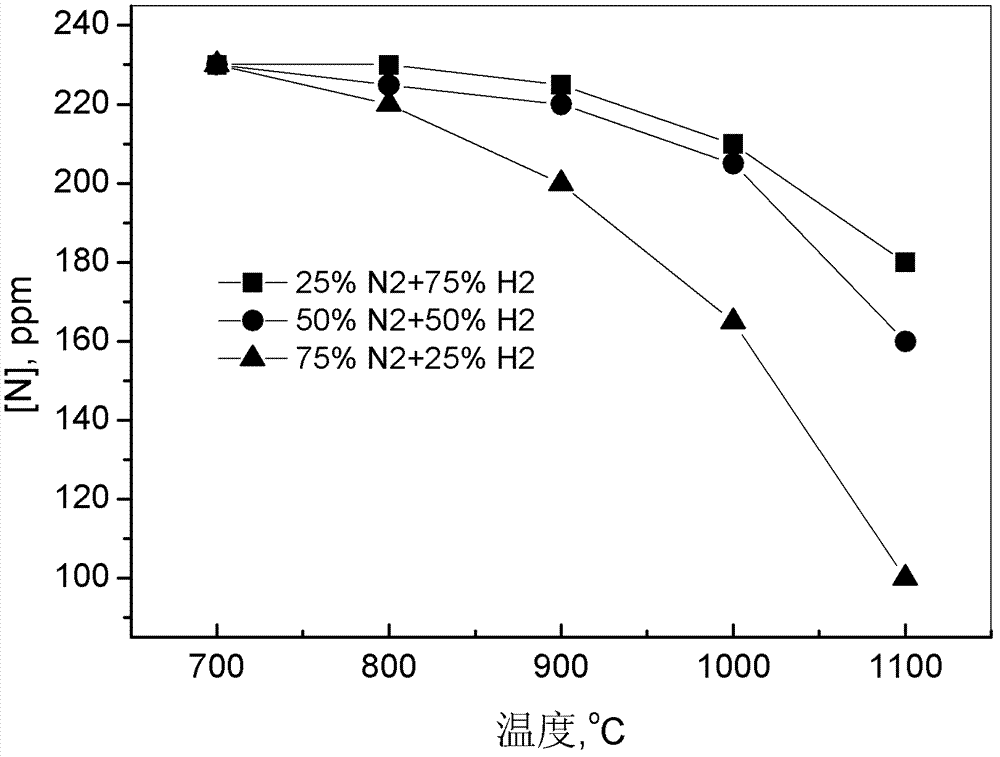

ActiveCN101845582AIncrease contentPrevent transverse crackingSolid state diffusion coatingSiliconAtmosphere

The invention relates to a production method of high magnetic induction oriented silicon steel, comprising the steps of smelting, continuous casting, hot rolling, normalization, decarbonization and annealing, MgO coating, high-temperature annealing and insulation coating, wherein the normalization comprises the steps that: normalization is carried out on a hot rolling plate, nitridation is finished synchronously, the temperature of normalization and nitridation is 1050-1150 DEG C, the atmosphere is 5-35% NH3 (volume percentage), and the balance of gas is N2; after the normalization and nitridation, the N content nitrided into the hot rolling plate is 60-250ppm; and normalization cooling is carried out, the initial temperature of fast cooling is 700-950 DEG C, and the fast cooling speed with the temperature of being reduced to 550 DEG C is 15-40 DEG C / sec. The production method solves the problem of difficult nitridation in the decarbonization procedure when a low-temperature plate blank heating technology is used for producing the high magnetic induction oriented silicon steel, carries out synchronous nitridation on the hot rolling plate in the normalization procedure, and leads the following procedure of decarbonization and annealing techniques to be simplified and easily controlled, thus not only being capable of obtaining a high magnetic induction oriented silicon steel product with excellent performance and simultaneously leading the production cost to be reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing high magnetic induction grain-oriented silicon steel

The invention relates to a method for producing high magnetic induction grain-oriented silicon steel, and belongs to the technical field of silicon steel production. The process comprises the following steps of: smelting, refining, and performing continuous casting to obtain a casting blank; performing hot rolling; normalizing, namely performing normalizing annealing and cooling; performing cold rolling at one time, wherein the cold rolling reduction ratio is 85 to 90 percent; nitriding by using a nitriding medium, namely dry NH3 at the temperature of between 600 and 740 DEG C for 5 to 40 seconds; decarburizing at the temperature of between 750 and 850 DEG C for 60 to 360 seconds, wherein the dew-point temperature is 25 DEG C; and annealing at a high temperature, and coating a stress coating. The method has the advantages that: a plate blank low-temperature heating process of nitriding at the temperature of between 600 and 740 DEG C and decarburizing annealing is adopted, the nitriding of a steel plate is not influenced by an oxidation film, the steel plate is uniformly nitrided, and efficiency is high; by controlling the nitriding and decarburizing processes, an appropriate amount of effective (Al, Si) N inhibitor is formed, and high magnetic property is achieved; and nitriding is performed at a low temperature, so energy consumption is low, and production cost is reduced.

Owner:SHOUGANG CORPORATION

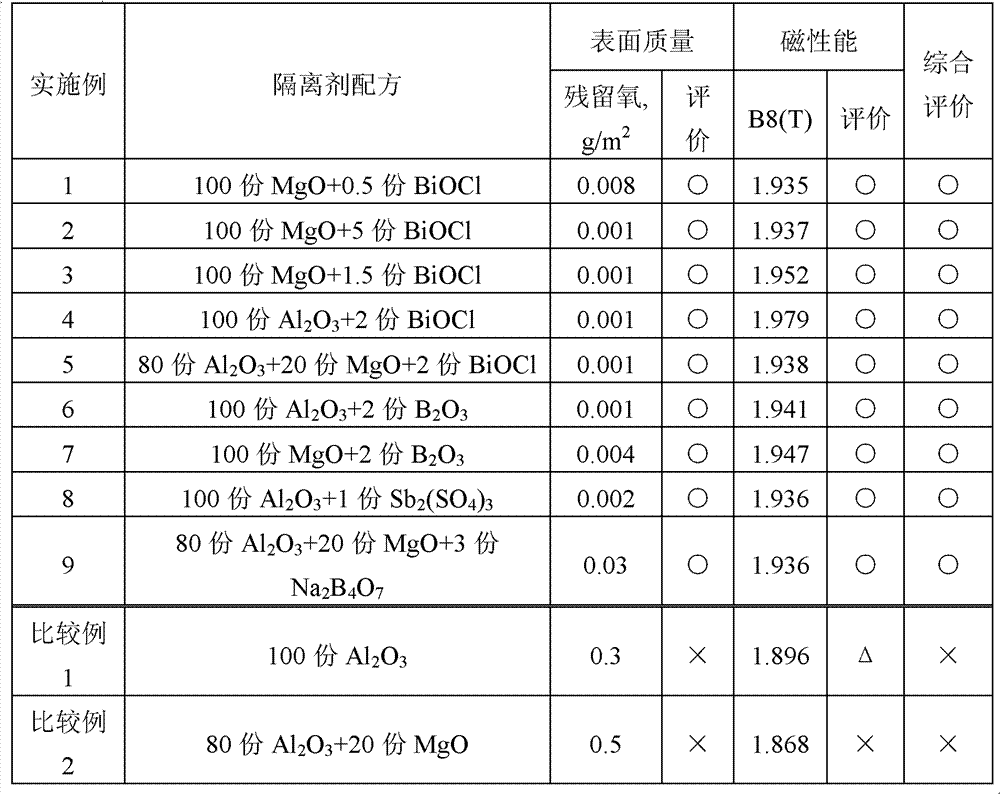

Glass-film-free oriented silicon steel manufacture method and annealing isolation agent

ActiveCN102952931AGuaranteed decarbonization efficiencyImprove nitriding efficiencyNitrogen gasOxide

The invention discloses a glass-film-free oriented silicon steel manufacture method. The method comprises the following steps of: (1) smelting; (2) hot rolling and normalizing; (3) cold rolling; (4) decarburization and nitriding, wherein a cold-rolled sheet is subjected to decarburization annealing treatment in wet N2+H2 protective gas at 800 to 860 DEG C, and oxidation energy is controlled within 0.16 to 0.40; carbon in the steel sheet can be reduced to below 30ppm by the decarburization annealing treatment while an oxide layer mainly containing SiO2 is formed on the surface of the steel sheet, and the single-side oxygen content of the steel sheet is controlled to below 0.7g / m<2>; and continuous nitriding treatment is carried out on the steel sheet in ammonia-contained N2+H2 protective gas with oxidation energy of 0.05 to 0.15 to control the nitrogen content of the steel sheet within 180ppm to 280ppm; (5) application of an isolation agent; (6) high-temperature annealing and temperature rising and maintenance, wherein the steel sheet is heated to 1150 to 1250 DEG C in dry N2+H2 mixed atmosphere containing 50% to 90% of N2 and H2, is maintained at the 1150 to 1250 DEG C in pure hydrogen atmosphere for above 15 hours; and (7) coating of an insulation coating, stretching, leveling and annealing, thus obtaining the grain-oriented silicon steel product with an excellent magnetic property.

Owner:BAOSHAN IRON & STEEL CO LTD

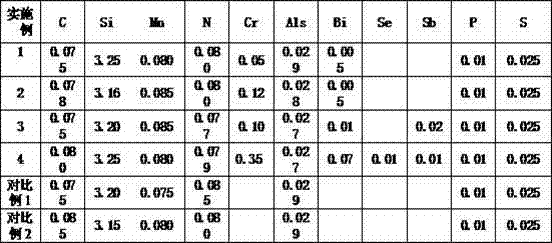

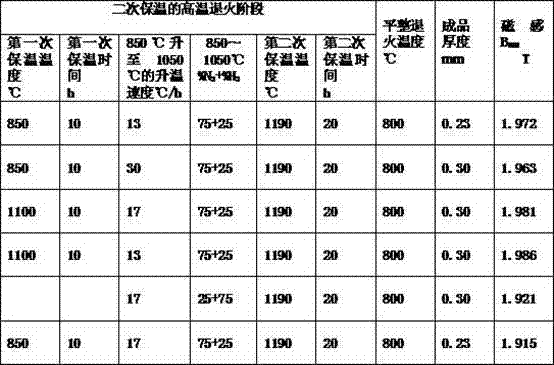

High-magnetic strength oriented silicon steel and production method thereof

The invention discloses high-magnetic strength oriented silicon steel, comprising the following components by weight percent: 0.055-0.095% of C, 2.95-3.25% of Si, 0.050-0.090% of Mn, no more than 0.01% of P, 0.010-0.025% of S, 0.006-0.010% of N, 0.05-0.5% of Cr, 0.020-0.030% of Als, 0.002-0.1% of Bi, 0.01-0.06% of Se and 0.01-0.06% of Sb. The production method comprises the following production steps: heating a casting blank; rolling, processing at normal temperature; conventionally rolling into the product by adopting a primary cold rolling method or a secondary rolling method containing intermediate annealing; decarbonizing and annealing; coating a parting compound of taking magnesium oxide as a main ingredient; annealing at high temperature by adopting secondary heat preservation, carrying out heat preservation at 800-1100 DEG C for 5-20 hours, and at 1170-1220 DEG C for 5-25 hours in a full-hydrogen atmosphere; stretching and flatly annealing; coating an insulating layer on the surface of a steel plate. The magnetic induction strength B800 of the oriented silicon steel is not lower than 1.95T by independently adding or compositely adding Sb, Se and Bi grain-boundary segregation elements, and the magnetic property is stable.

Owner:武汉钢铁有限公司

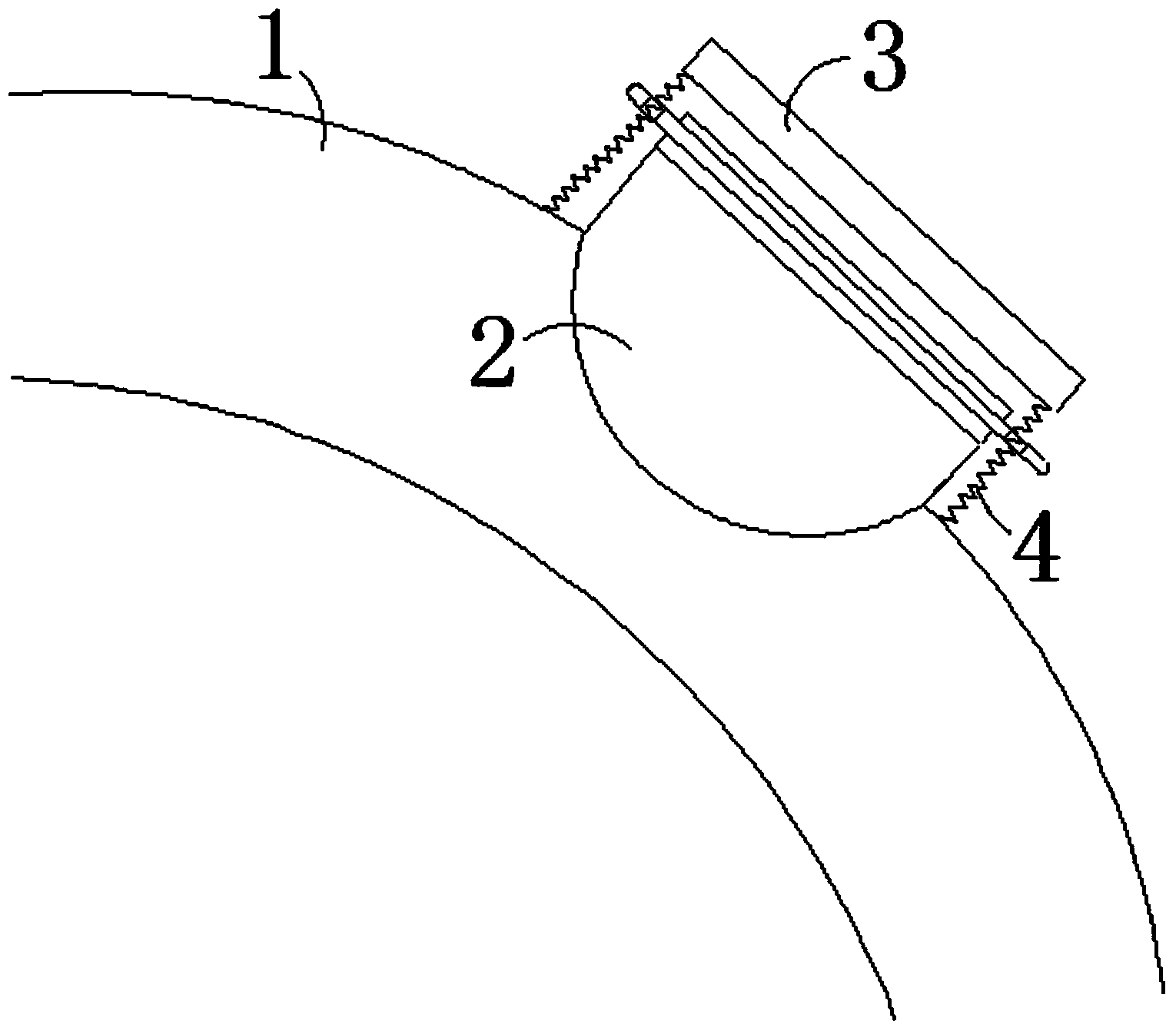

Method and device for measuring conveyor belt elongation, method and device for measuring conveyor belt wear extent, method and device for measuring conveyor belt temperature, rubber magnet sheet, and method of producing rubber magnet sheet

ActiveUS7347317B2Improve accuracyEnhanced magnetic forceConveyorsThermometers using electric/magnetic elementsConveyor beltInternal temperature

Methods and devices for measuring elongation, wear, and internal temperature of a conveyor belt to catch signs of conveyor belt failure such as breakage by detecting a magnetic field from a magnetic body by using a magnesium sensor, as well as a rubber magnet sheet as a magnetic body and a method of producing the sheet, the rubber magnet sheet being able to be used while it is embedded in the conveyor belt. To measure elongation of a running conveyor belt (11), a magnetic field of a magnetic body (2) embedded in the belt (11) is detected by a magnetism sensor (3) fixed to the earth, and elongation of the belt (11) is calculated from temporal variation of the detected magnetic field.

Owner:BRIDGESTONE CORP

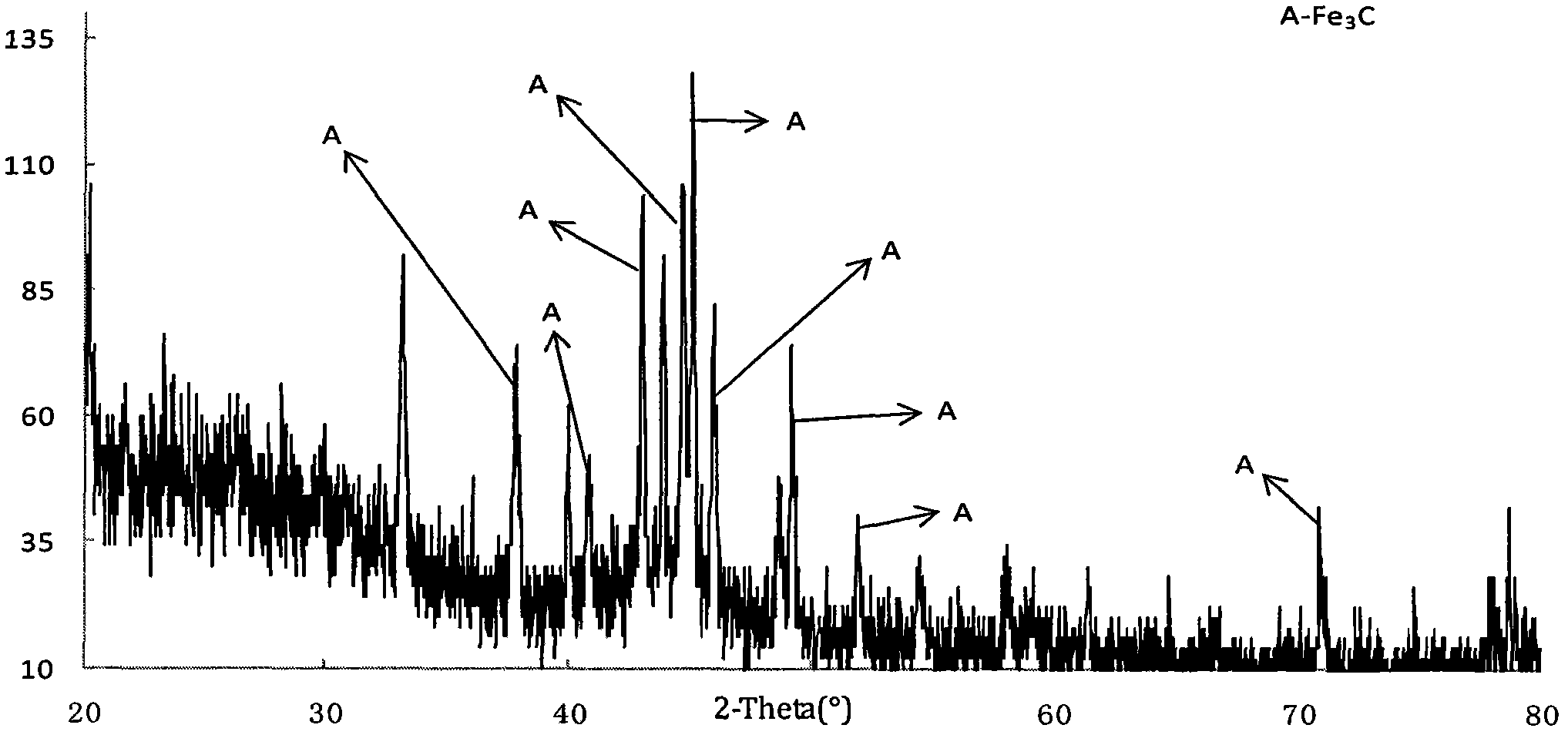

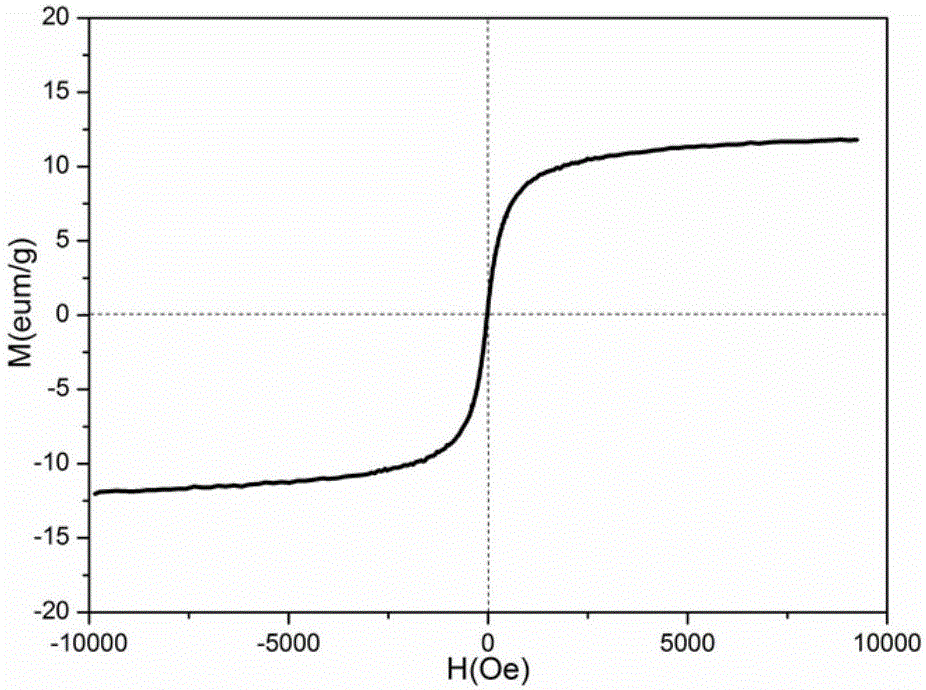

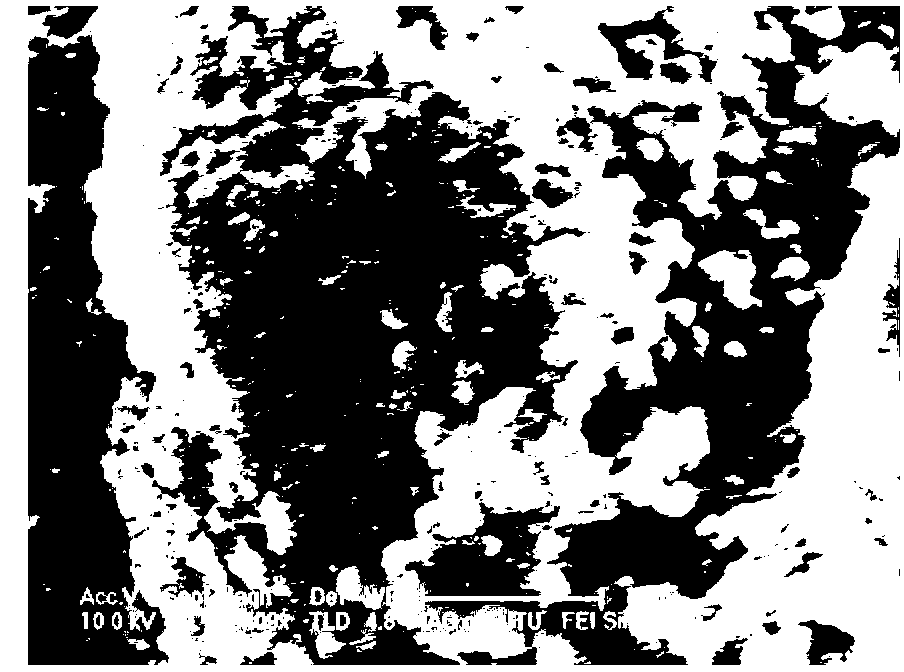

Preparation method of coal-based magnetic activated carbon and coal-based magnetic activated carbon

InactiveCN101972629AEasy to separate and recycleIncrease the areaOther chemical processesMagnetic materialsFerric hydroxideCarbonization

The invention relates to a preparation method of coal-based magnetic activated carbon and the coal-based magnetic activated carbon. The preparation method of the coal-based magnetic activated carbon comprises the following steps of: placing deashing coal dust and dodecyl sodium sulfate into a ferric chloride solution, sufficiently mixing, and then standing for adsorption; then adding ammonia water and a sodium hydroxide solution or a potassium hydroxide solution, sufficiently stirring, and then standing for transforming ferric chloride into ferric hydroxide; filtering and drying solid-phase materials to obtain a mixture of deashing coal and the ferric hydroxide, i.e. a precursor of the coal-based magnetic activated carbon; sufficiently mixing the precursor with activating agents, i.e. potassium hydroxide or sodium hydroxide, adding distilled water to stir into paste, and warming for carbonization under the protection of nitrogen; and heating and activating under the protection of the nitrogen. The obtained coal-based magnetic activated carbon has difficult blockage of pores because a magnet exists in a state of Fe3C, thereby having higher saturation and magnetization intensity and larger specific surface area. The invention has the advantages of extensive source of coal raw materials, low cost, simple preparation process and easy separation and recovery of the coal-based magnetic activated carbon.

Owner:CHONGQING UNIV

Preparation method and application of modified charcoal adsorbent based on lanthanum ferrite

InactiveCN106362688AAvoid pollutionLow costOther chemical processesAlkali metal oxides/hydroxidesPhosphate ionSorbent

The invention discloses a preparation method and application of a modified charcoal adsorbent based on lanthanum ferrite. The preparation method comprises the following steps: S1, preparing charcoal; S2, performing modification treatment; and S3, performing finished product treatment. According to the method, low-cost and sufficient-source crop straws are adopted as a raw material; by virtue of a chemical coprecipitation method, the surface of the charcoal obtained by pyrolysis of the straws is modified with the lanthanum ferrite, so that the modified charcoal adsorbent has a favorable removal effect on pollution by phosphate anions in a water body, especially low-concentration phosphorus; furthermore, the adsorbent is favorable and stable in magnetism and convenient to recycle; in addition, the preparation method is simple to operate and high in preparation yield, and has potential application prospect in the field of inorganic wastewater treatment.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

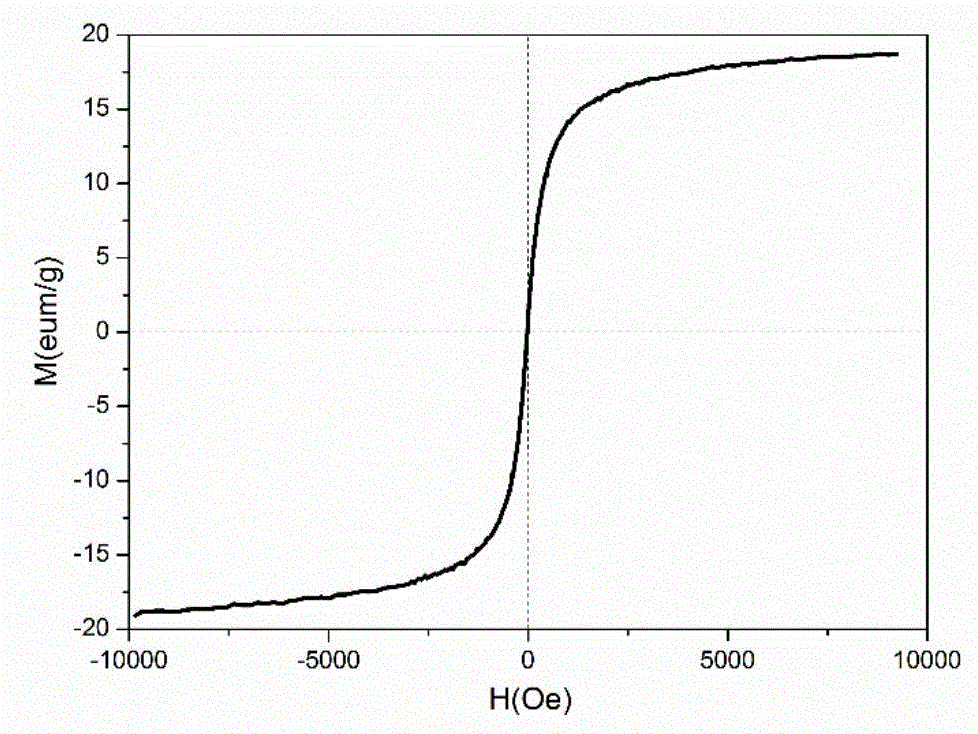

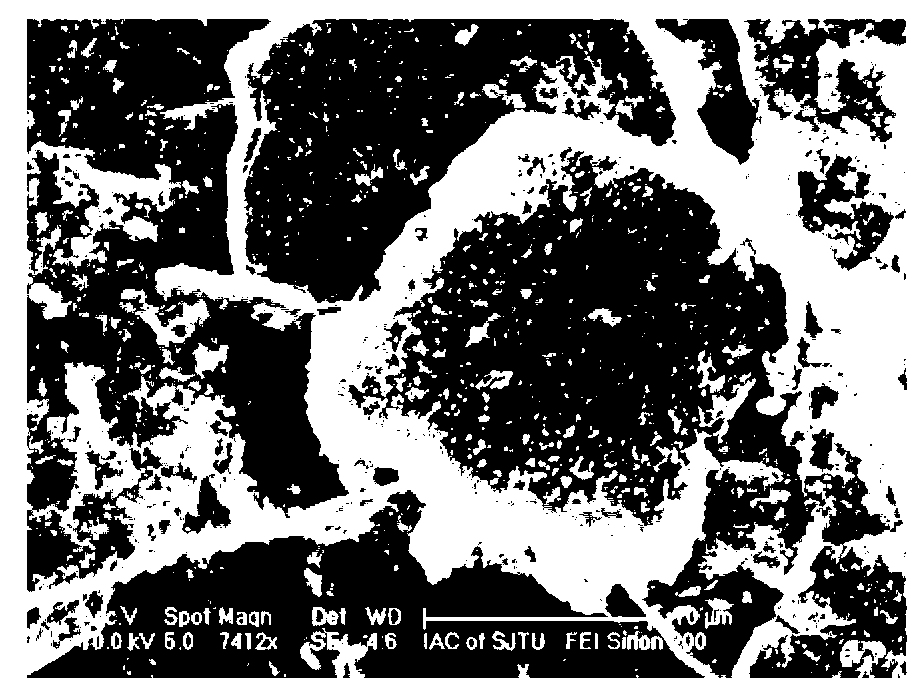

Magnetic carbon-based iron oxide compound material and preparation method thereof

ActiveCN103280577AHigh degree of crystallizationStrong loadCell electrodesWater/sewage treatment by magnetic/electric fieldsMagnetic carbonIron oxide

The invention discloses a magnetic carbon-based iron oxide compound material and a preparation method of the magnetic carbon-based iron oxide compound material. Particularly, the invention discloses a prepraation method of the magnetic carbon-based iron oxide compound material. The preparation method comprises the following steps of: (a) providing a mixture comprising a carbon-based precursor, elemental iron and a solvent; and (b) carrying out heating reaction on the mixture in the step (a), thus obtaining the carbon-based iron oxide compound material. The method has the advantages that materials are common and are easily available, and the process is simple, safe and effective and the like. The obtained compound material has stable magnetism, and is wide in application.

Owner:SHANGHAI JIAO TONG UNIV

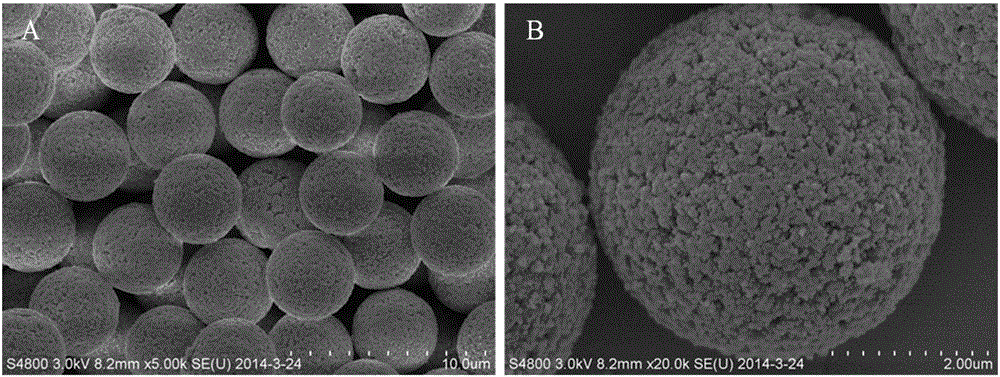

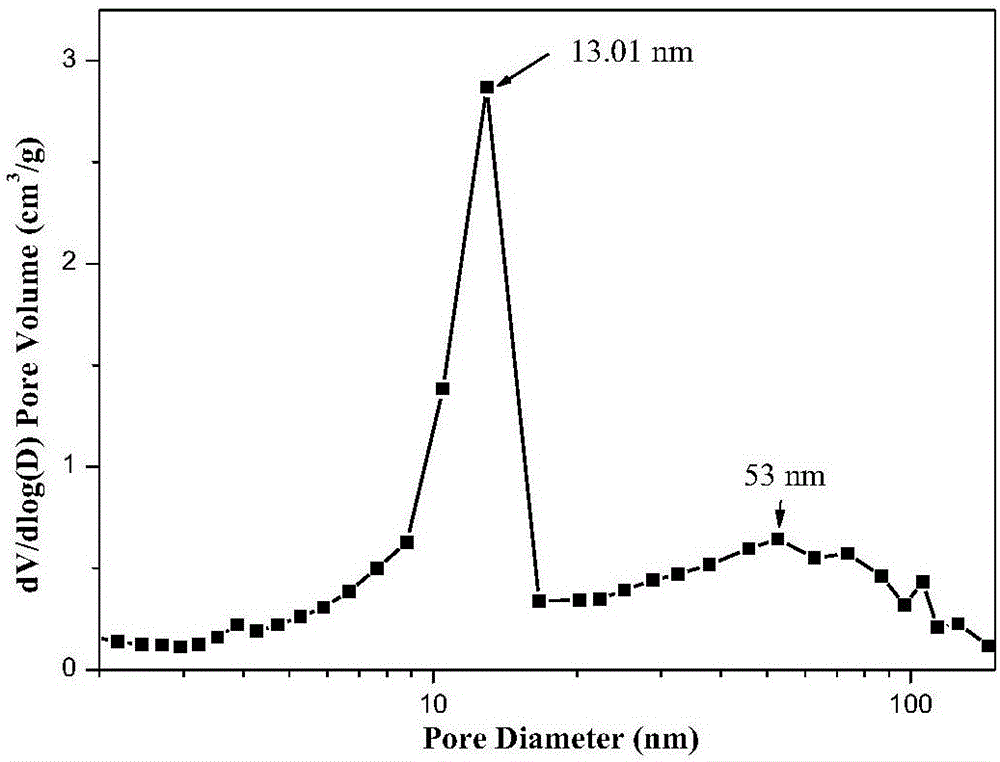

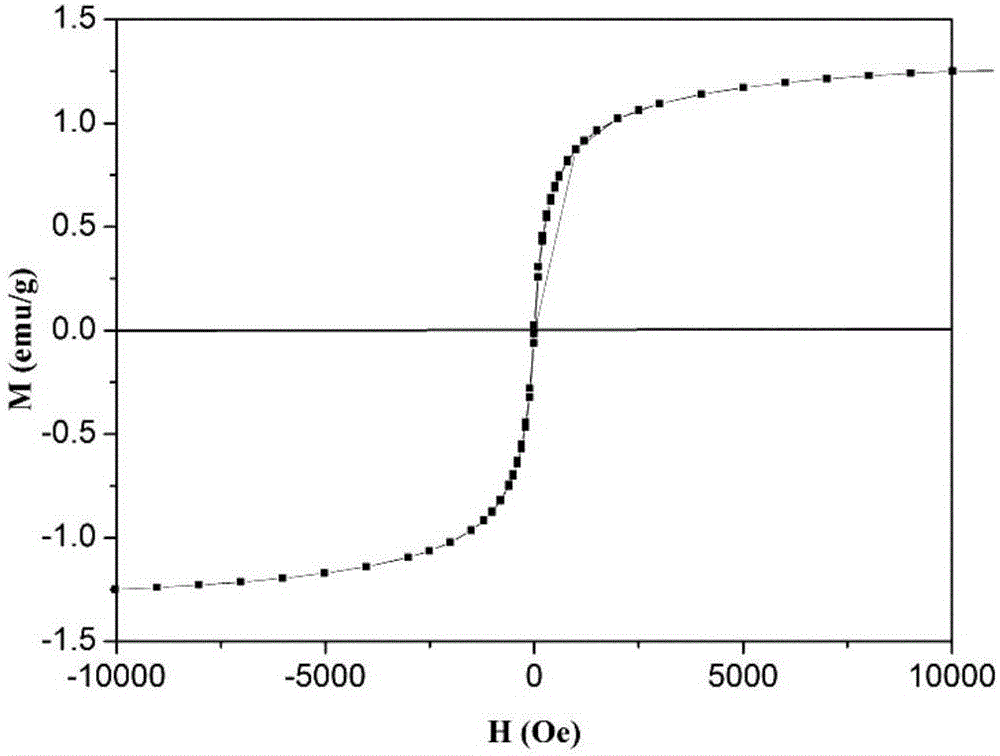

Monodisperse magnetic porous silicon dioxide pellet and preparing method thereof

InactiveCN106710773AMagnetically stableControllable particle sizeSilicaInorganic material magnetismMicrosphereMagnetite Nanoparticles

The invention discloses a monodisperse magnetic porous silicon dioxide pellet and a preparing method thereof. The preparing method of the monodisperse porous silicon dioxide pellet comprises the steps of utilizing a monodisperse magnetic porous macromolecule pellet as a template, generating in situ a magnetic Fe3O4 particle and sol-gelation of a silicon source and using a Fe3O4 particle to oxidize gamma-Fe2O3, forming a magnetic macromolecule-silicon dioxide composite pellet, and then removing the macromolecule template after calcination to obtain the monodisperse magnetic porous silicon dioxide pellet. The preparing method of the monodisperse magnetic porous silicon dioxide pellet is simple in process and easy to operate, and the prepared monodisperse magnetic porous silicon dioxide pellet has the advantages of being homogenous in particle size, controllable in particle diameter and pore diameter, connective in pore, simple in method of introducing magnetic nanoparticles, stable in magnetism and the like.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Soft magnetic ferrite material containing magnesium, nickel and zinc element as well as manufacturing method thereof

InactiveCN101354941AHigh initial permeabilityMagnetically stableInorganic material magnetismCopper oxideInductor

The invention discloses a soft magnetic ferrite material containing magnesium element, nickel element and zinc element, which comprises the following compositions in mol portion: 60 to 66 mol percent of ferric oxide Fe2O3, 7 to 10 mol percent of nickel oxide NiO, 7 to 10 mol percent of magnesia MgO, 10 to 15 mol percent of zinc oxide ZnO and 3 to 6 mol percent of copper oxide CuO. The manufacturing method comprises the following steps of the processing of raw material, batching, primary ball milling, drying, pulverization or sifting, preburning, secondary batching, secondary ball milling, secondary drying and secondary pulverization or sifting, in a preburning condition, the soft magnetic ferrite material is presynthesized in an air furnace at a temperature of between 800 and 900 DEG C. The prepared soft magnetic ferrite material has the initial magnetic conductivity of about 100, stable magnetic performance and low production cost when the soft magnetic ferrite material is used to produce a laminated sheet type inductor.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +3

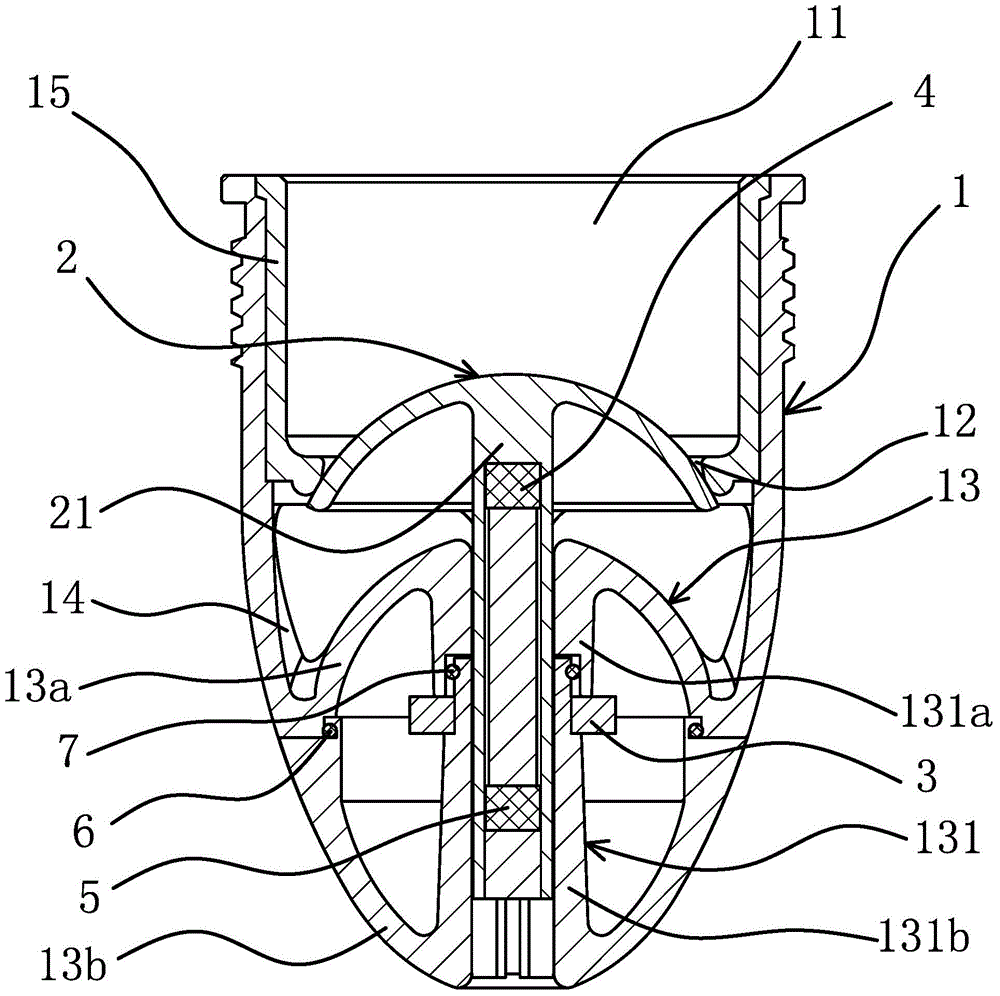

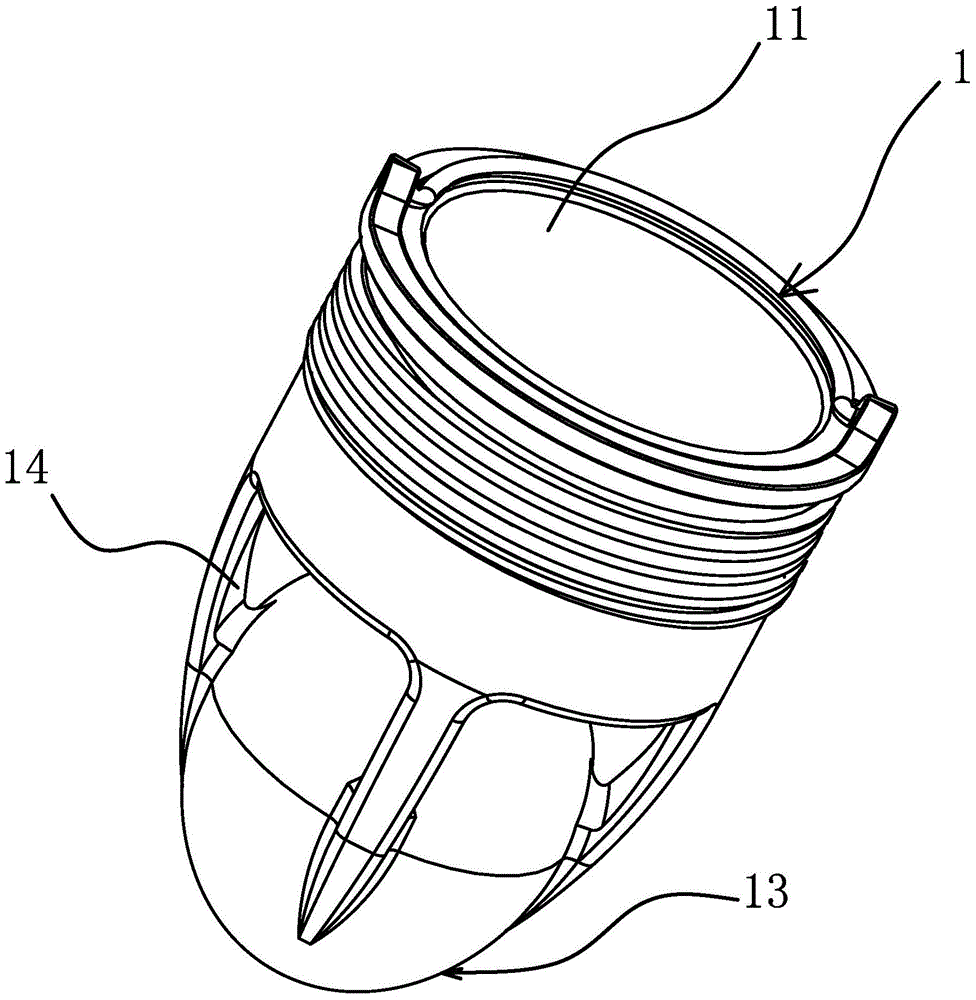

A magnetic levitation floor drain core

ActiveCN104863246BMagnetically stableWon't add weightSewerage structuresDomestic plumbingEngineeringMagnetic levitation

The invention provides a magnetic levitation floor drain core, belongs to the technical field of fixing construction, and aims to solve the technical problem of high failure possibility of the automatic sealing performance of the conventional floor drain. The magnetic levitation floor drain core comprises a core body and a sealing cover, wherein a water inlet is formed in the upper end of the core body; a water outlet is formed in the lower end of the core body; a magnet II is arranged in the sealing cover; a housing with a sealed inner chamber is fixed at the lower end of the core body; a magnet I is fixed in the inner chamber of the housing and below the magnet II; the sealing cover is arranged between the water outlet and the housing; the sealing cover is tightly clung to the water outlet under the action of the repulsive force between the magnet I and the magnet II, so as to be sealed. Through the adoption of the magnetic levitation floor drain core, the automatic sealing performance of the floor drain can be kept effective for a long time.

Owner:吕家杰

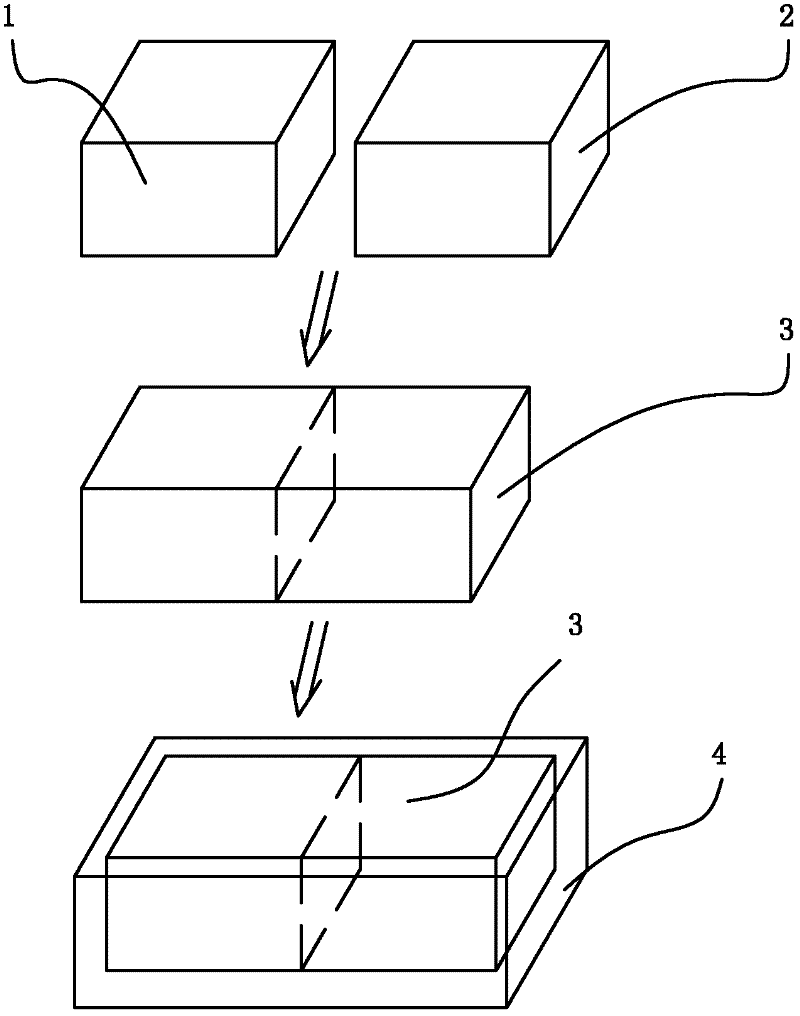

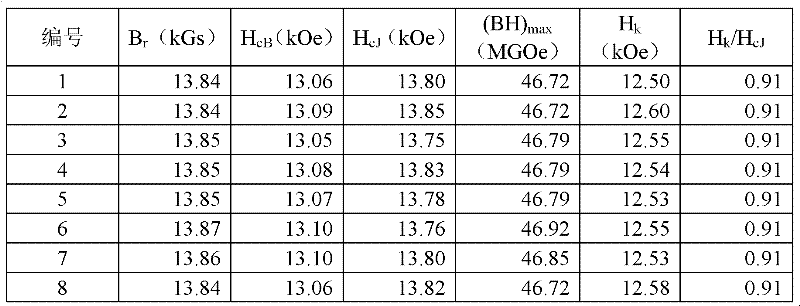

Method for preparing bulk sintered Nd-Fe-B permanent magnet material

ActiveCN102233428AHigh precisionMagnetic properties are stableInorganic material magnetismVacuum furnaceMicrometer

The invention discloses a method for preparing a bulk sintered Nd-Fe-B permanent magnet material. The method comprises the following steps of: preparing fine powder with the average particle size of 2.9 to 3.3 micrometers from raw materials which are prepared according to a required formula; adding the fine powder into a metal die cavity of a molding pressing machine; and arranging a molding magnetic field to ensure that the fine powder is prepared into a patch raw blank in a compression molding way under an electromagnetic induction oriented magnetic field. The method is characterized by comprising the following steps of: selecting at least two patch raw blanks; selecting the joint surfaces of the patch raw blanks on the premise of ensuring the consistent orientation of all patch raw blanks; clearing Nd-Fe-B attached powder on the joint surfaces of all the patch raw blanks; performing butt joint on all the patch raw blanks; putting the butt-jointed raw blanks into a die box made of rubber; performing vacuum encapsulation on the die box; keeping the pressure of an encapsulation body under the isostatic pressure of 180 to 220MPa for 8 to 13 seconds; taking the butt-jointed raw blank combination body out; transferring into a sintering basin; and sintering in a vacuum furnace to form a compact bulk Nd-Fe-B blank body. The invention has the advantages that: the bulk sintered Nd-Fe-B permanent magnet material can be produced by the conventional universal equipment, and has high precision, stable magnetic performance and low preparation cost.

Owner:NINGBO YUNSHENG +2

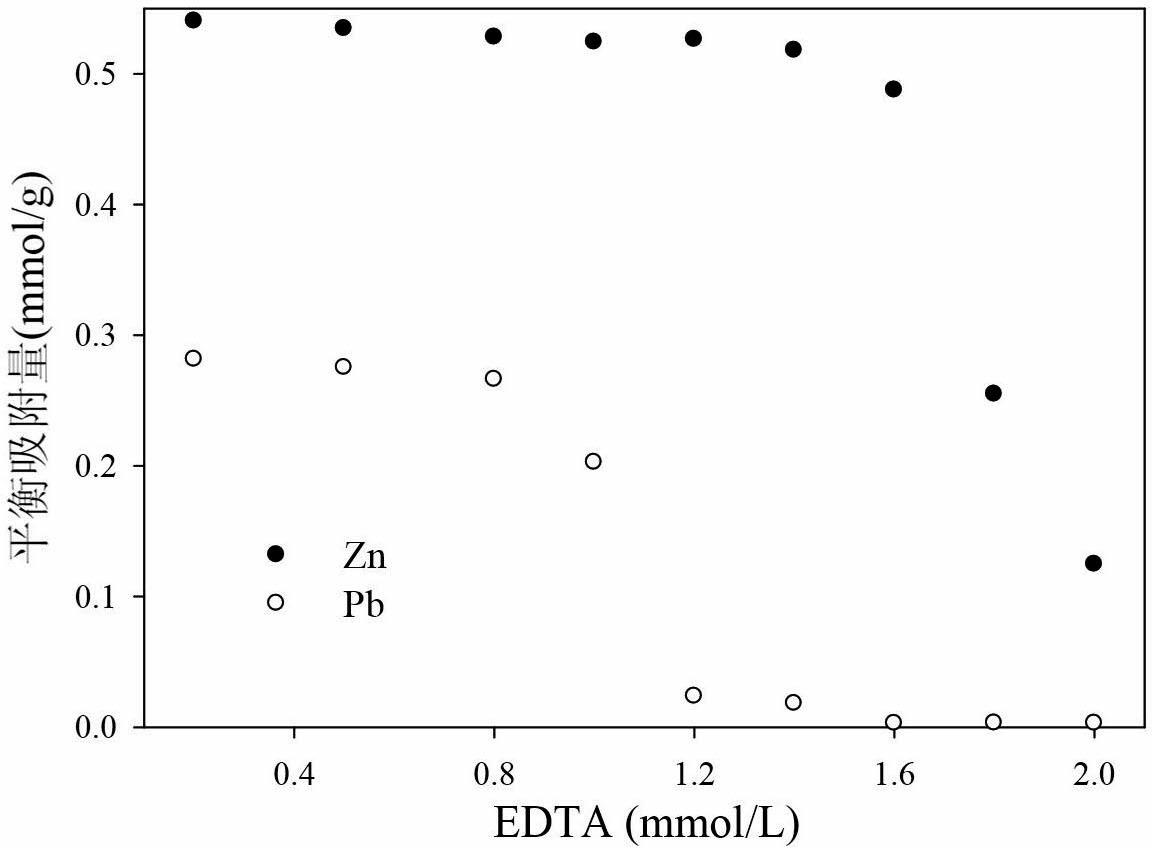

Imido magnetic nano-adsorbent as well as preparation method and application thereof

InactiveCN102327768AStable performanceEasy to separateOther chemical processesWater contaminantsStrong acidsPoly ethylene

Owner:HUNAN UNIV

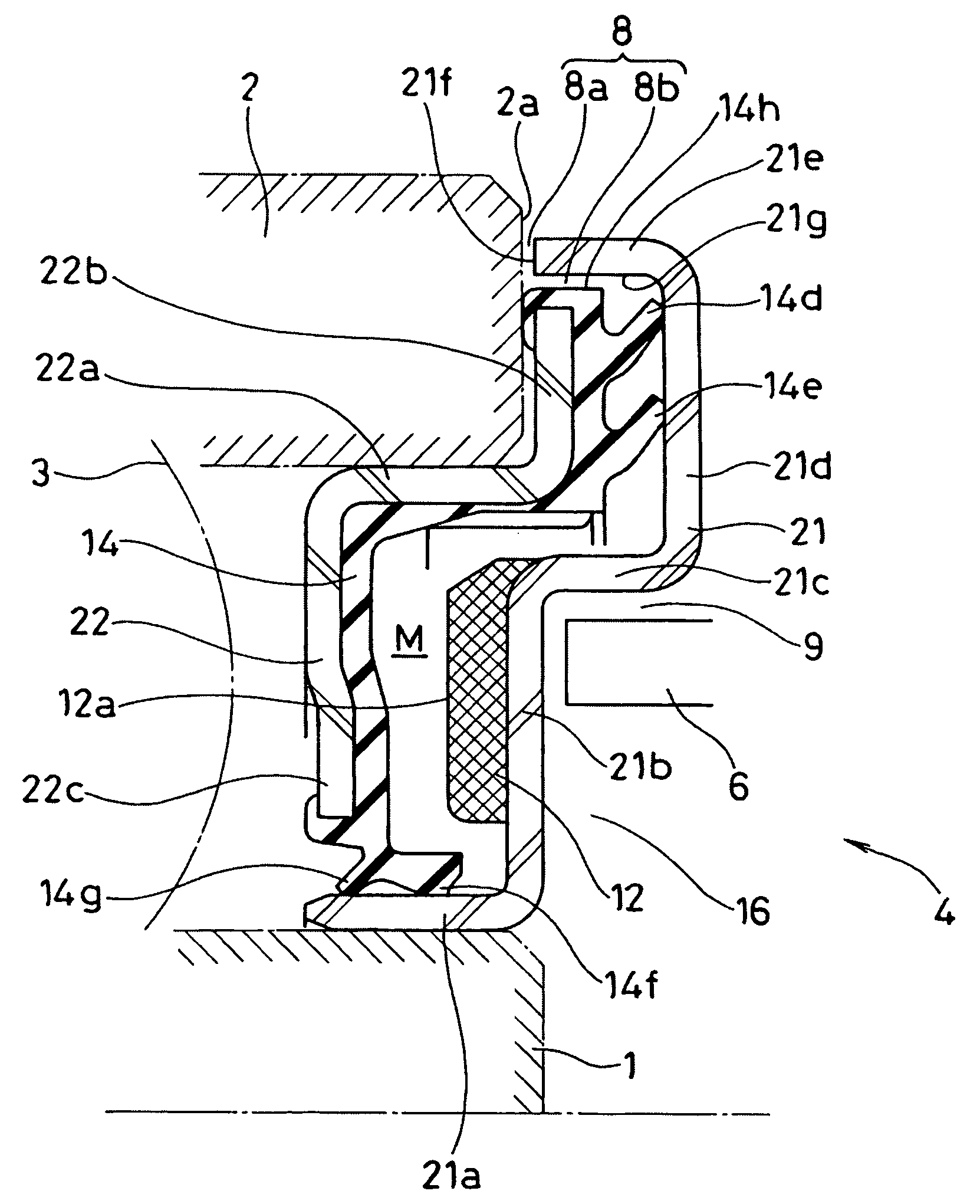

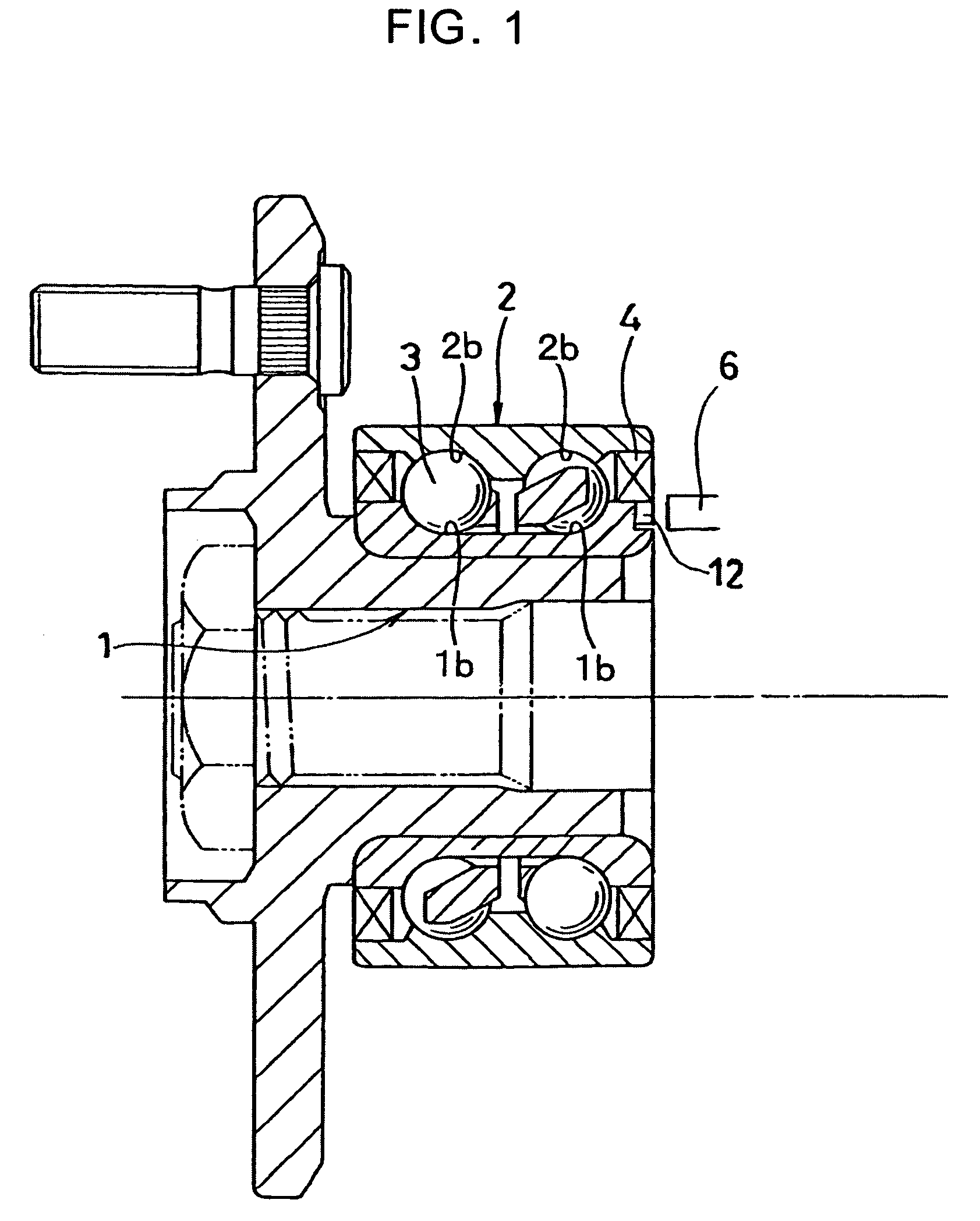

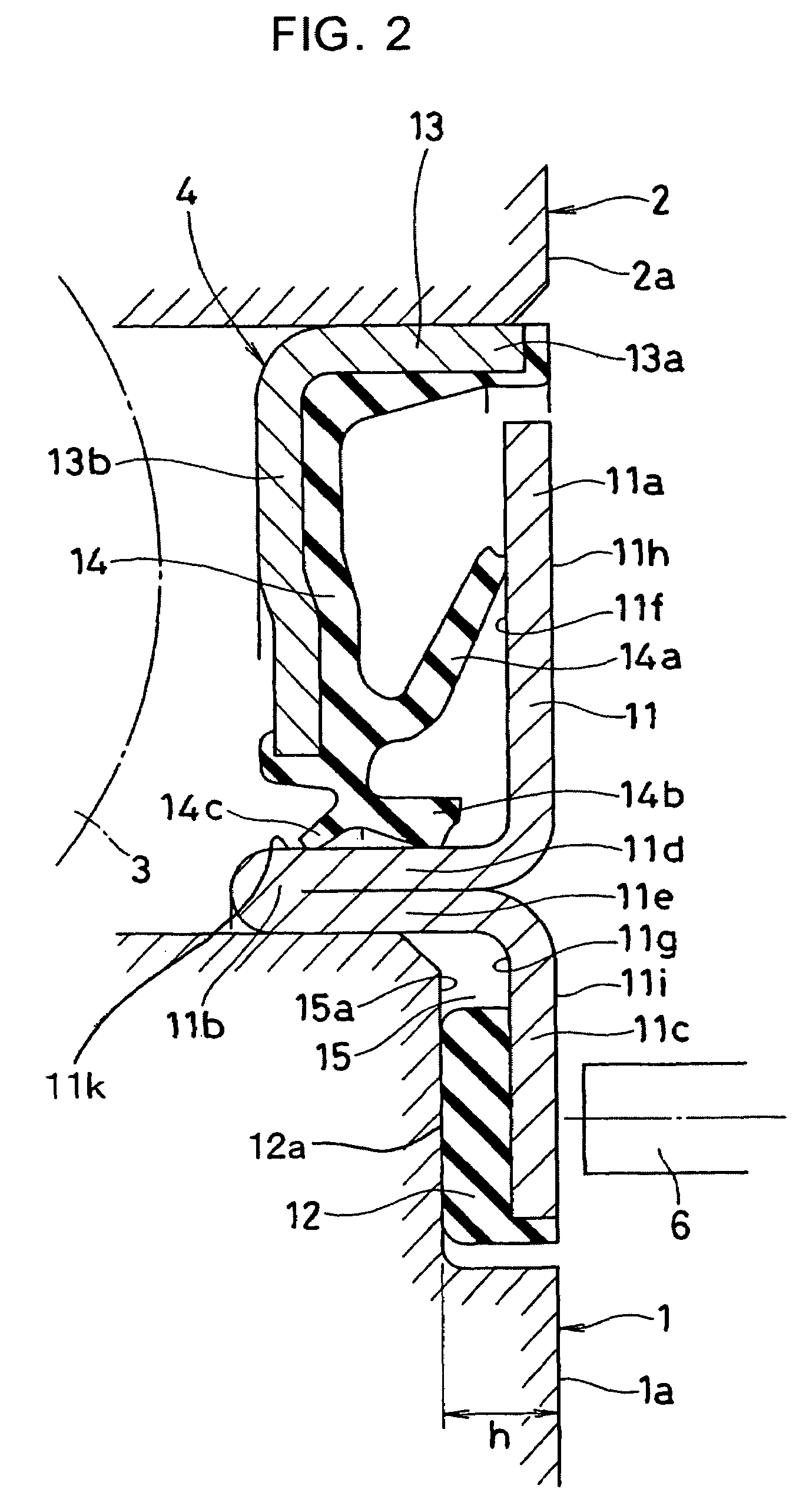

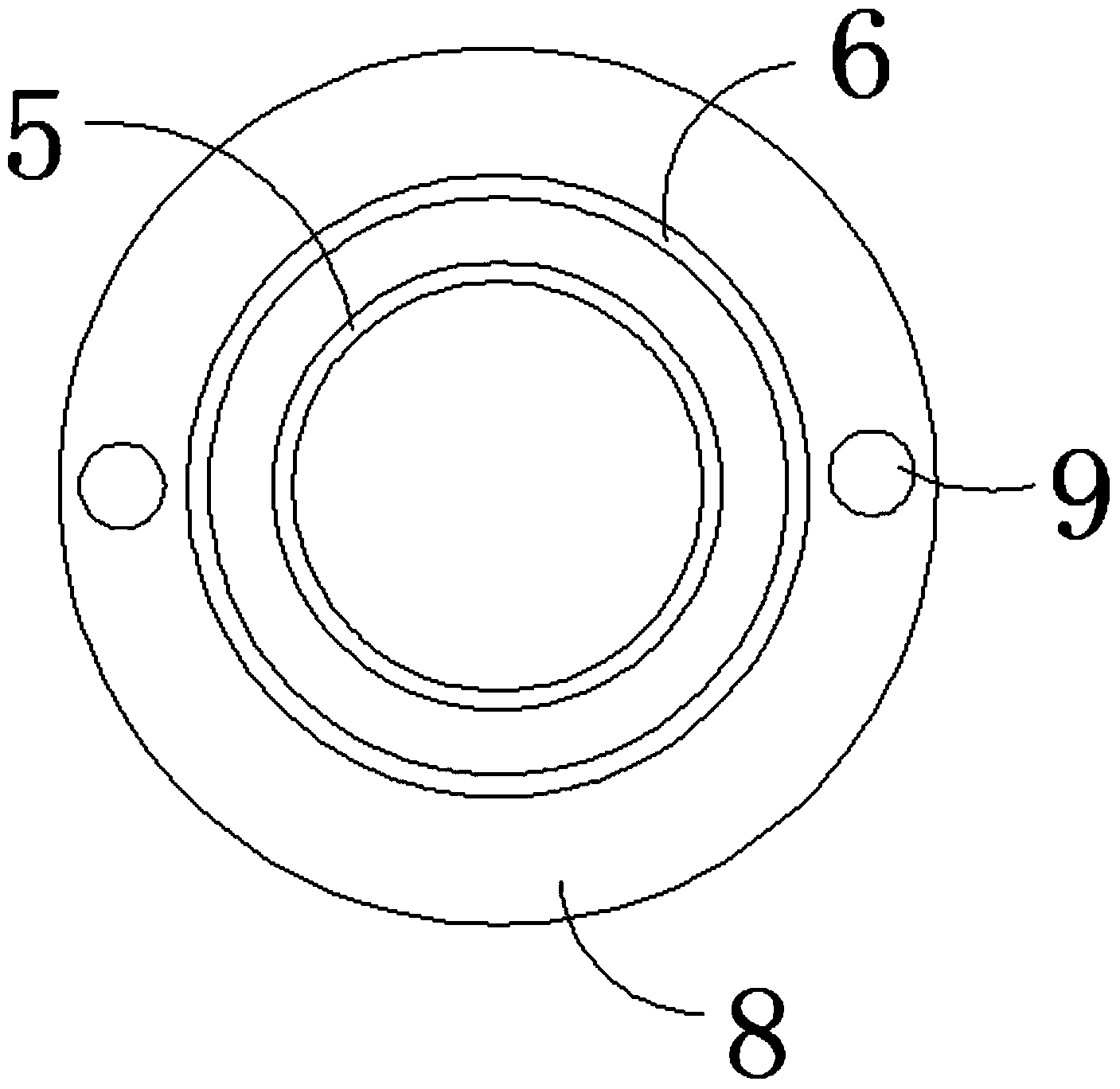

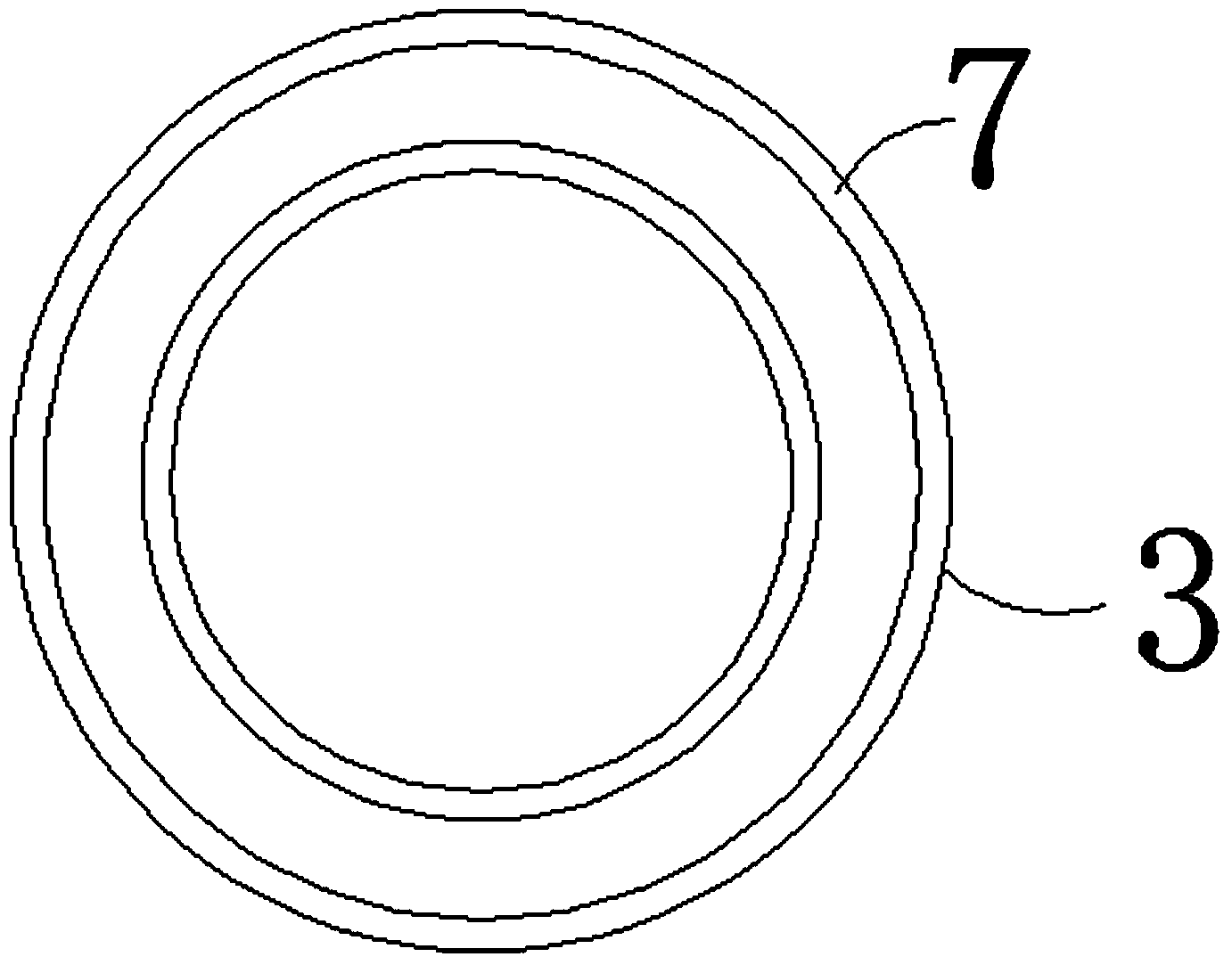

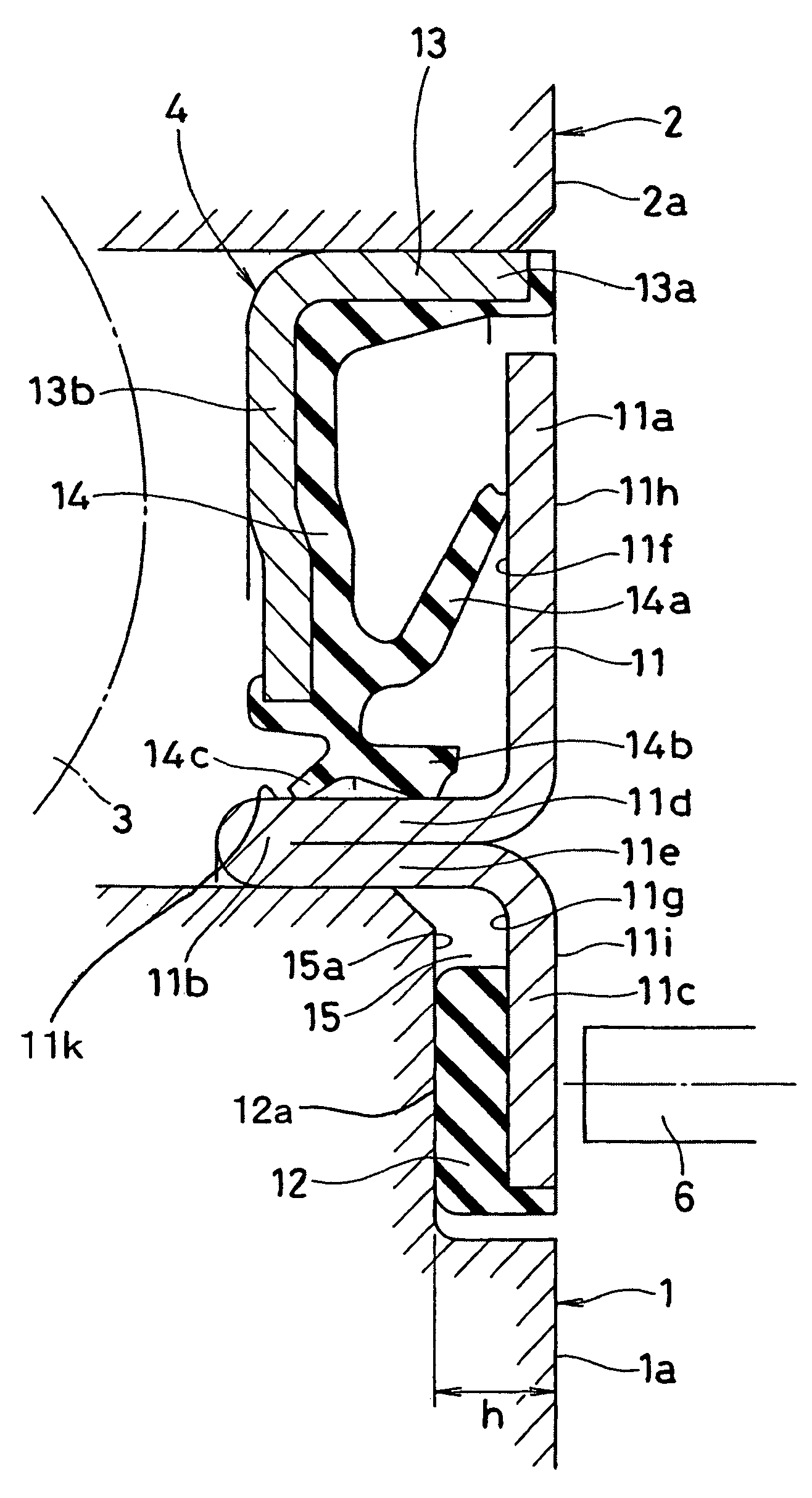

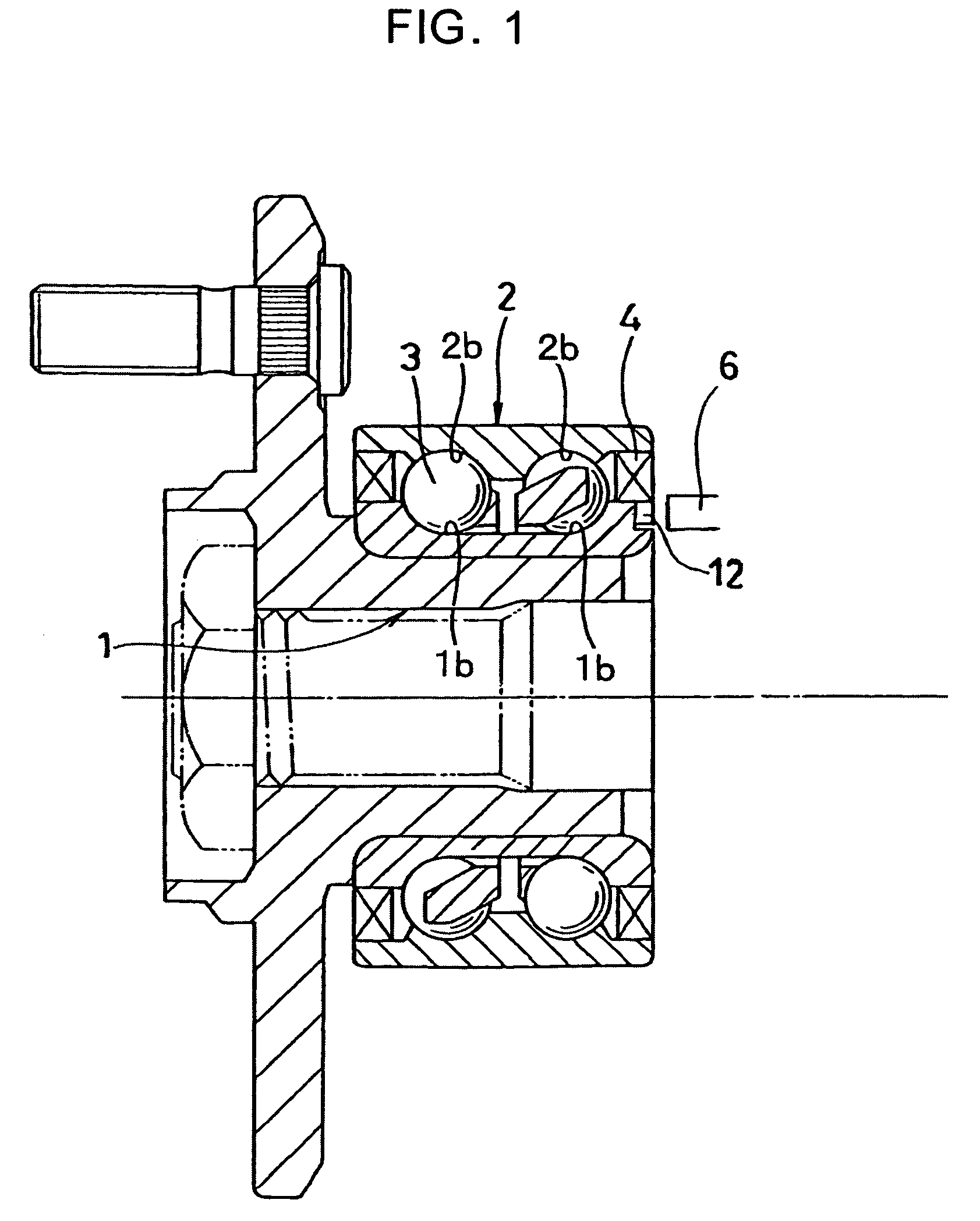

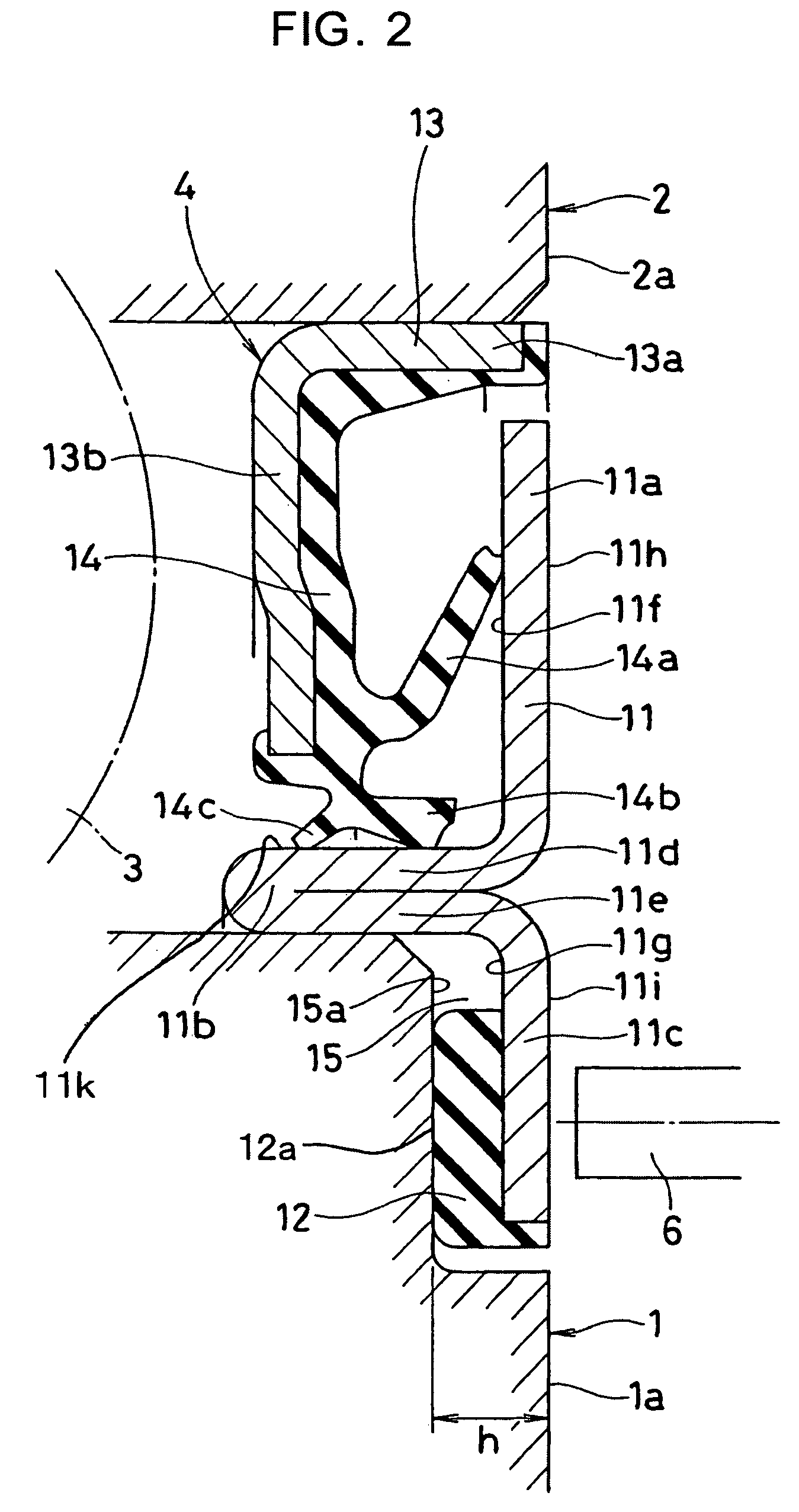

Sealing device

InactiveUS7675212B2Magnetically stableSynchronous generatorsEngine sealsEngineeringMechanical engineering

A sealing device in which a magnetic encoder is protected so as to improve detecting precision and reliability, without increasing the number of parts and assembling time and without enlarging a setting space, the sealing device is structured such that a detected portion is arranged in the sealed fluid side of an annular member. A first annular member fitted to a shaft is formed with an axial direction portion and diametrical direction portions extending in the inward and outward diametrical directions from the axial direction portion. One of the diametrical direction portions supports the detected portion in the sealed fluid side. A seal lip is in slidable contact with the other diametrical direction portion for sealing, and the seal portion is formed with the seal lip and the micro space.

Owner:NOK CORP

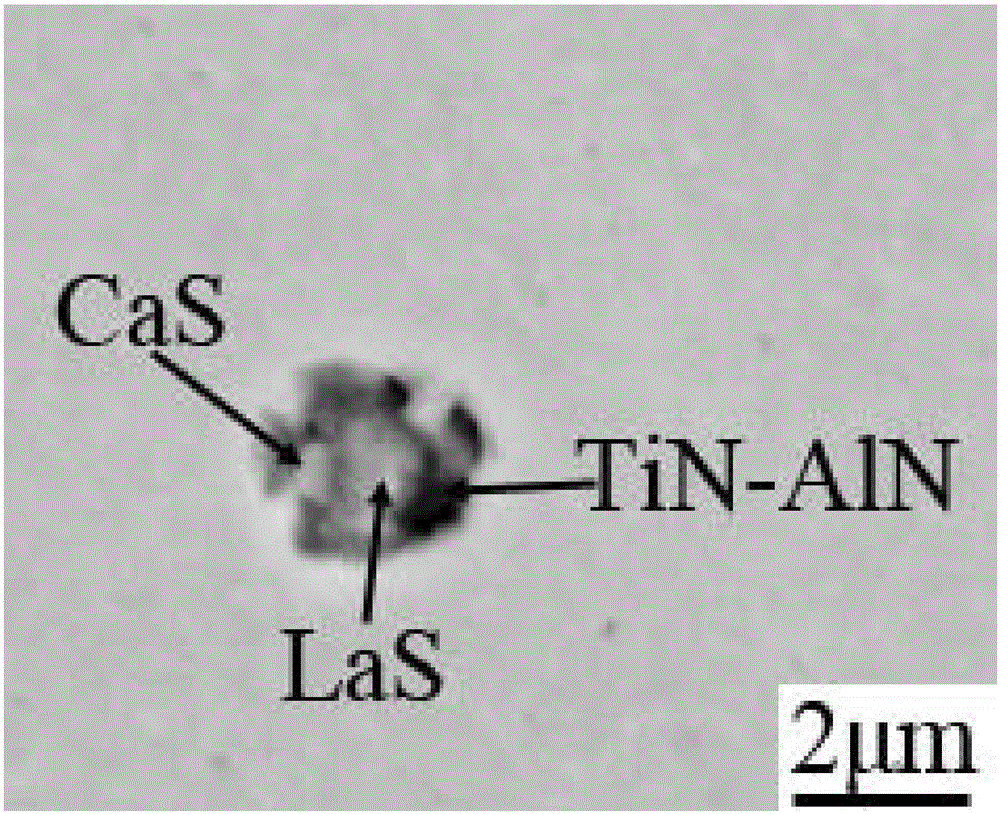

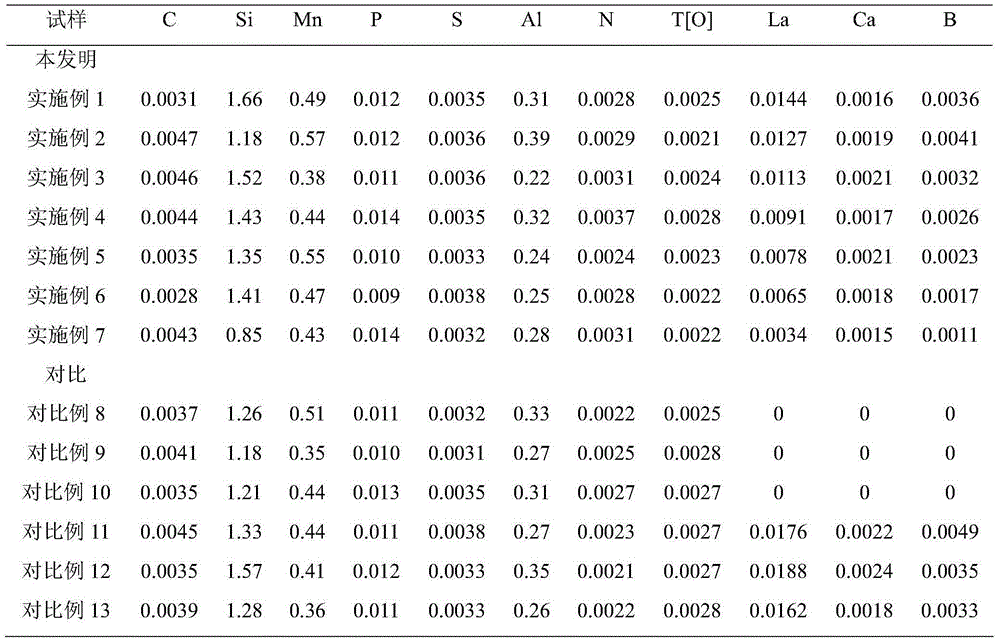

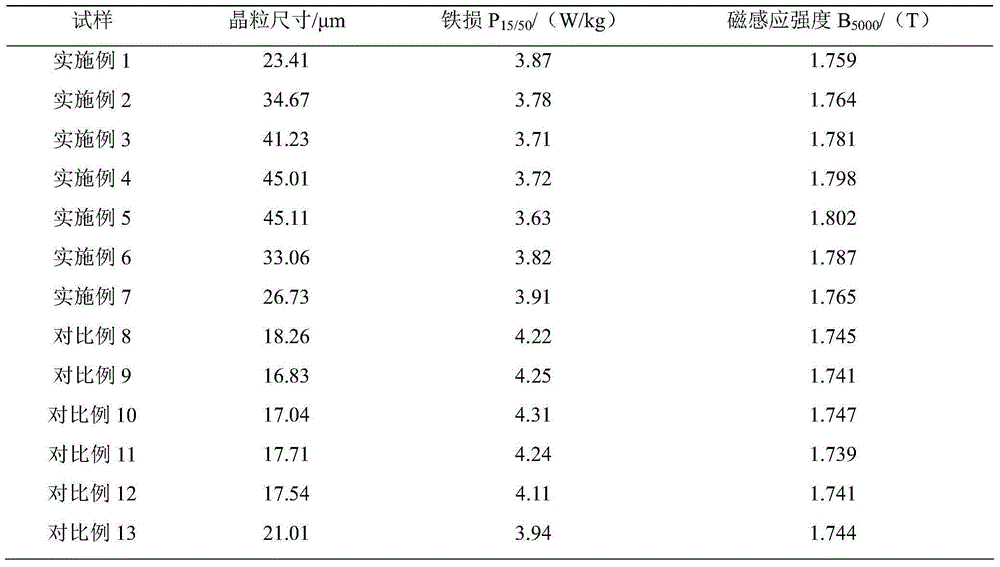

Method for preparing compound element processed non-oriented silicon steel for high-efficiency motor

The invention discloses a method for preparing compound element processed non-oriented silicon steel for a high-efficiency motor and belongs to the technical field of electrical steel. A non-oriented electrical steel casting blank into which a certain amount of Ca, a certain amount of La and a certain amount of B are added serves as the raw material, smelting, forging, hot rolling, normalizing, acid pickling, primary cold rolling, intermediate annealing, secondary cold rolling and finished product annealing are conducted in sequence, the temperature and time of finished product annealing are controlled to be 900-940 DEG C and 3-5 min respectively, and the non-oriented silicon steel product, which is low in iron loss and high in magnetic strength, for the high-efficiency motor is obtained finally. The final magnetic performance of the product is that when a steel plate is 0.5 mm thick, P15 / 50=3.6-3.9 W / kg, and B5000=1.76-1.80 T. The steel belt finished product can be widely applied to large and medium motor manufacturing as well as variable-frequency air conditioner compressor manufacturing.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Explosion protection device of smelting furnace

ActiveCN104390479ADisadvantages affecting normal operationNot easy to misplaceFurnace componentsExplosion protectionEngineering

The invention relates to an explosion protection device of a smelting furnace. The explosion protection device comprises a pipeline with a corner, wherein one end of the pipeline is communicated with a furnace chamber passage, and the other end of the pipeline is communicated with a smoke exhaust passage; the pipeline is provided with an explosion protection opening; the upper end of the explosion protection opening is provided with an explosion protection cover; elastic devices are arranged on the two sides of the explosion protection opening; the lower ends of the two elastic devices are fixedly connected with the pipeline, and the upper ends of the elastic devices are fixedly connected with the explosion protection cover; the edge of the upper end of the explosion protection opening is provided with a circle of seal ring; a first magnetic ring is arranged on the circle on the outer side of the seal ring; the explosion protection cover is provided with a second magnetic ring; the second magnetic ring is positioned in the corresponding upper space of the first magnetic ring. Compared with the prior art, the explosion protection device has the advantages of simple structure, stable operation, capability of automatically closing the smelting furnace and good sealing property.

Owner:响水德丰金属材料有限公司

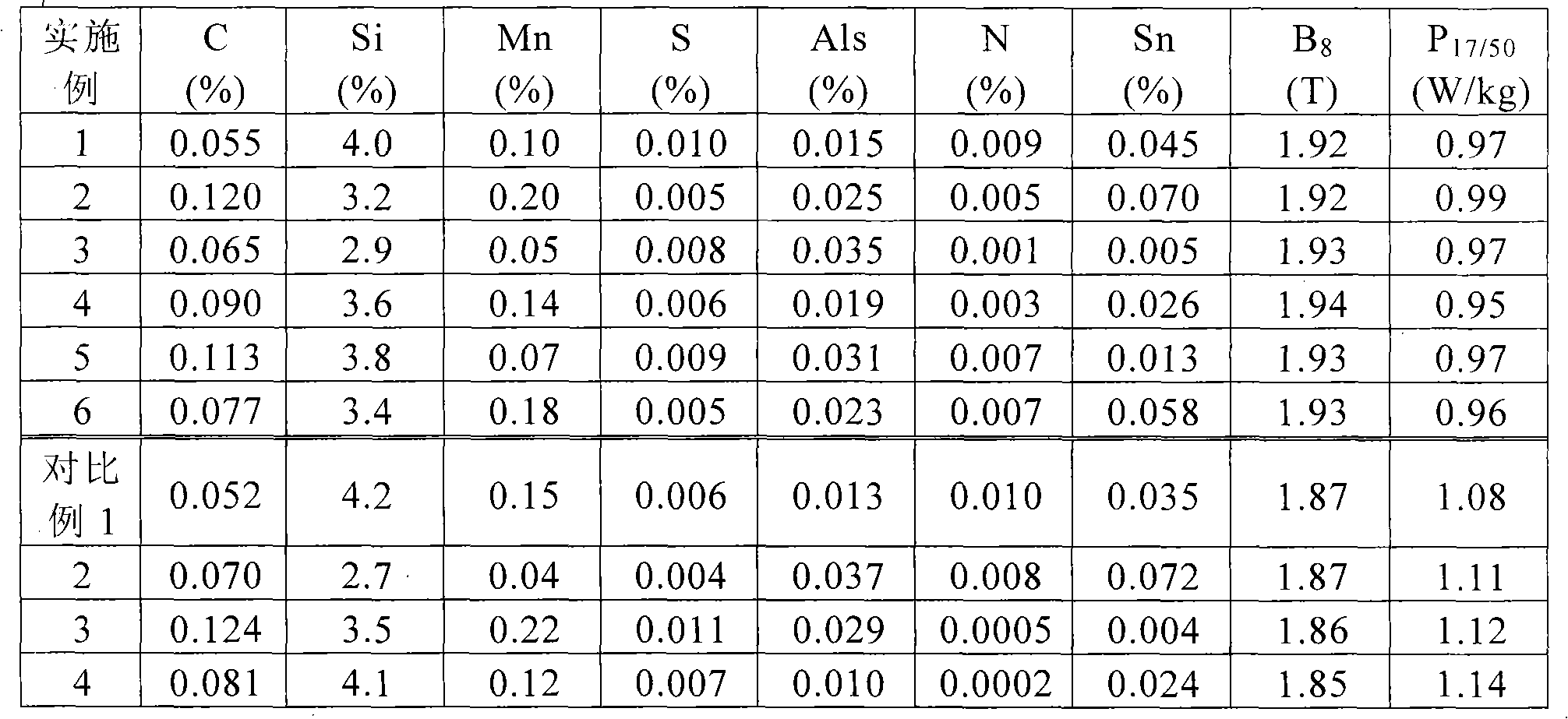

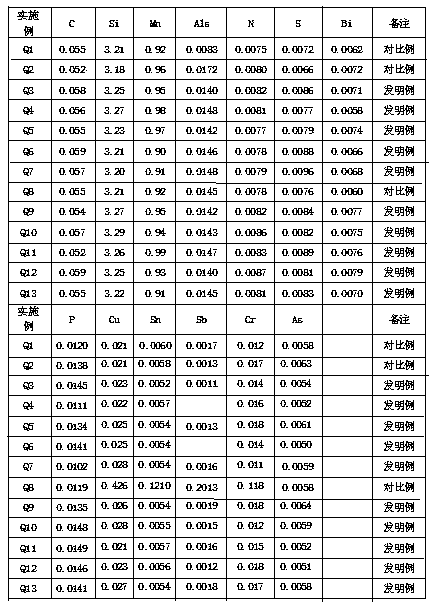

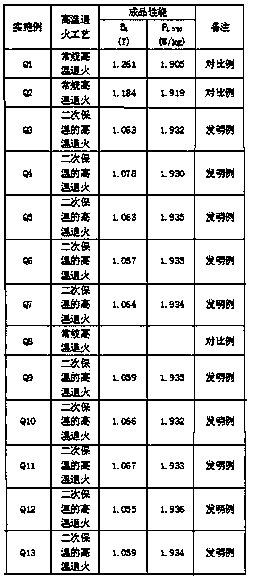

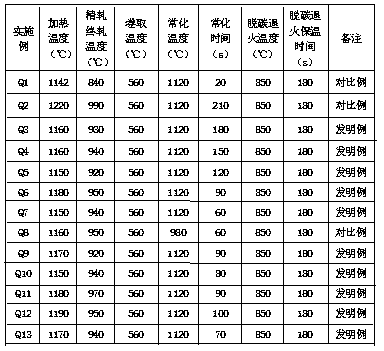

Economy high magnetic induction grain-oriented silicon steel and production method thereof

Economy high magnetic induction grain-oriented silicon steel comprises the following components according to weight percent: 0.015 to 0.095 percent of C, 2.80 to 3.60 percent of Si, 0.010 to 0.015 percent of Als, 0.0050 to 0.0100 percent of N, 0.010 to 1.00 percent of Mn, 0.0030 to 0.0150 percent of S, 0.0015 to 0.100 percent of Bi, as well as P, Cu, Sn, Sb, Cr and Ar, of which the sum is no morethan 0.80 percent; a production method comprises the following steps: smelting and continuously casting to form a blank; heating the blank; carrying out segmented hot rolling; reeling; normalizing; carrying out one-step cold rolling after acid pickling; carrying out decarburizing annealing; coating a high temperature annealing isolation agent; carrying out high temperature annealing with secondaryheat insulation; stretching and smoothing, and coating an insulating coating. According to the invention, under a condition of not carrying out nitriding, steel plate magnetic induction intensity B800 is not lower than 1.930T, iron loss P17 / 50 is smaller than or equal to 1.08W / k, the magnetic performance is stable, and the cost is lowered by 5 percent or more by compared with that in the prior art.

Owner:武汉钢铁有限公司

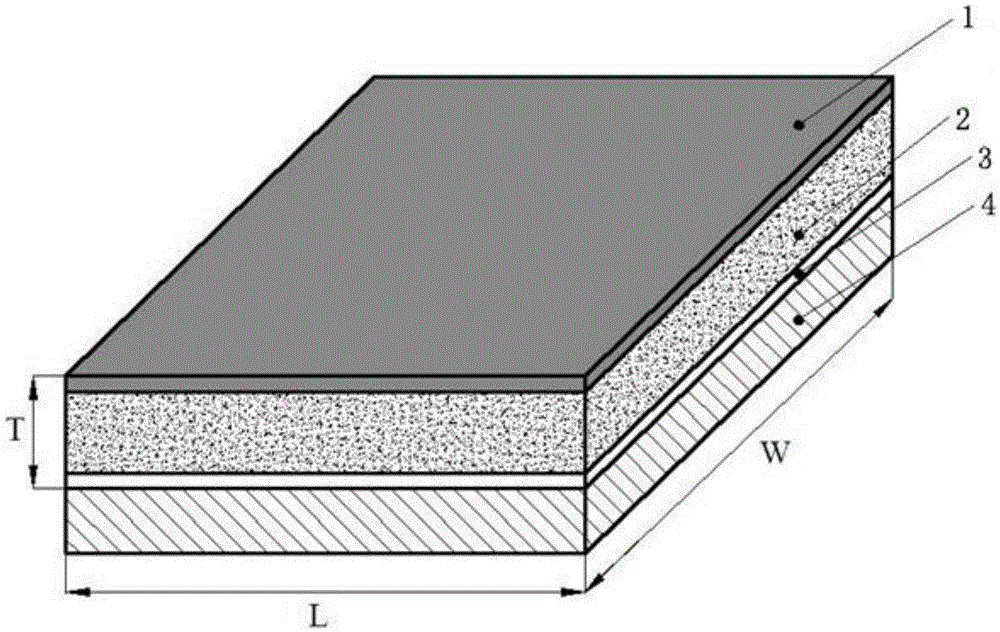

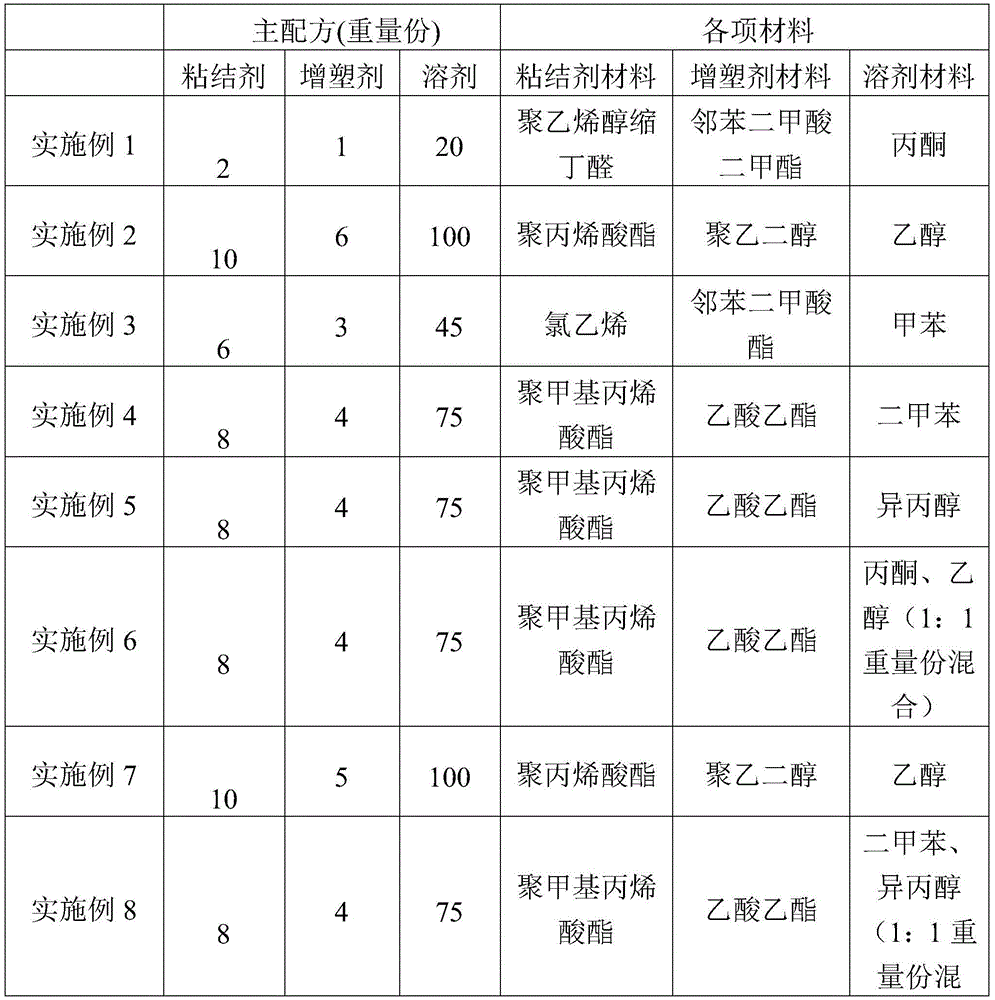

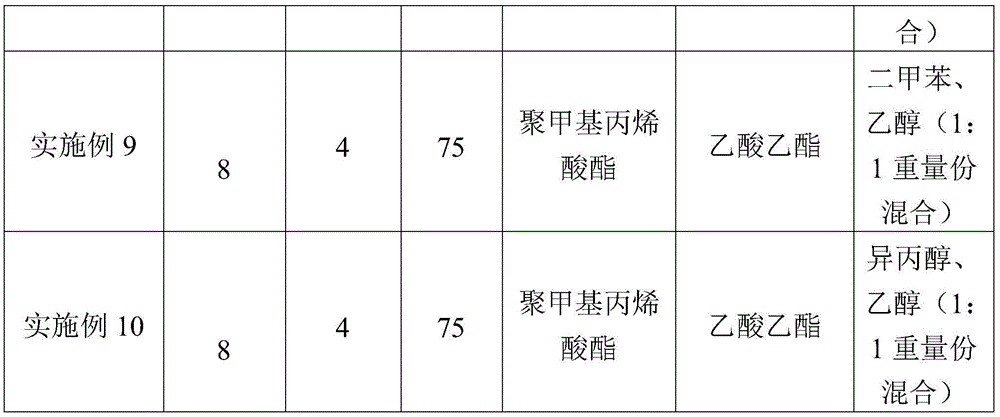

Ferrite sheet and preparation method

ActiveCN105644060AImprove the ability to gather electromagnetic signals to pass throughIncrease reading and writing distanceLaminationLamination apparatusPlasticizerFerrite powder

The invention discloses a ferrite sheet. The ferrite sheet comprises the following components in parts by weight (counted by 100 parts of NiCuZn ferrite powder): 2-8 parts of a binding agent, 1-6 parts of a plasticizer and 20-100 parts of a solvent. The invention further discloses a preparation method of the ferrite sheet. According to the ferrite sheet prepared by virtue of the preparation method, under the frequency of 13.56MHz, the complex permeability real part mu' is 140-200, the complex permeability imaginary part mu'' is 1-6, and the thickness is 30-120 microns; the ferrite sheet has certain flexibility; by increasing the magnetic conductivity mu' of the ferrite sheet, the magnetic field intensity reduced due to the decrease of the thickness is compensated, and the capacity of the ferrite sheet for gathering electromagnetic signals is improved, so that the read-write distance of an NFC mobile phone is improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

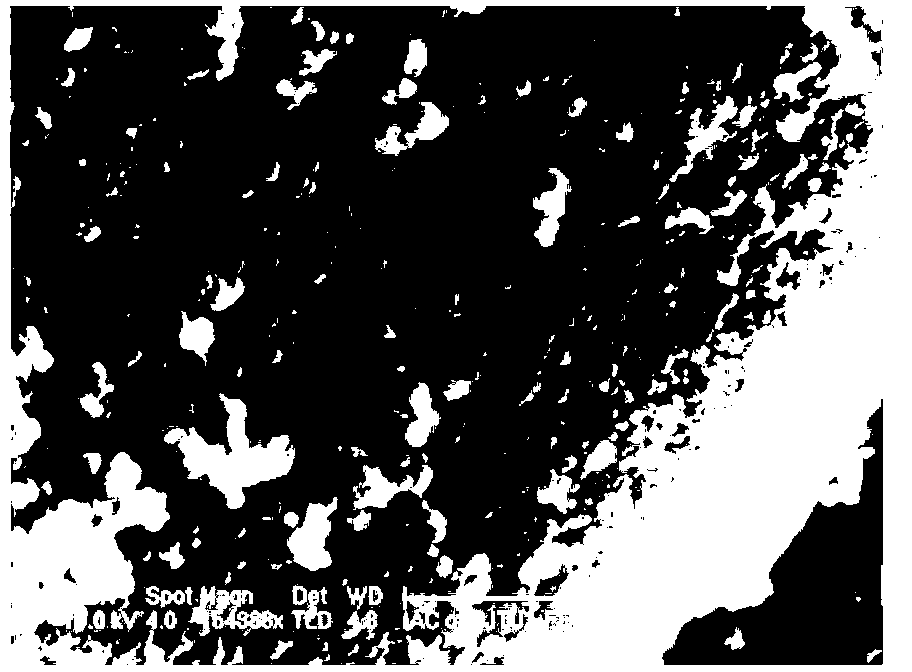

Magnetic active carbon and preparation method thereof

InactiveCN104028221ASufficient magnetic strengthMagnetically stableOther chemical processesActivated carbonMetallurgy

The invention discloses magnetic active carbon and a preparation method thereof. The magnetic active carbon comprises the following raw materials in parts by weight: 20-30 parts of cow dung, 10-20 parts of sludge, 60-80 parts of crop straw, 20-40 parts of coal powder and 20-30 parts of magnetic materials. The preparation method comprises the following steps: cleaning, filtering and drying the cow dung and the sludge; weighing and mixing the raw materials in parts by weight, soaking the raw materials by using a KOH solution, and then washing by using distilled water until the raw materials are neutral; performing two-step microwave treatment on the treated raw materials, cooling to room temperature after activation is finished, and then taking out an activated product; washing the activated product which is taken out by using the distilled water, adding a hydrochloric acid solution, heating, and re-washing the treated activated product by using the distilled water until the treated activated product is neutral to obtain a semi-finished active carbon; and drying and grinding to obtain the active carbon. The prepared magnetic active carbon is sufficient in magnetic strength and stable in magnetic performance, has the advantages of high specific surface area, good adsorption performance and the like, and is low in cost and suitable for industrial production; the raw materials of the magnetic active carbon can be widely obtained.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

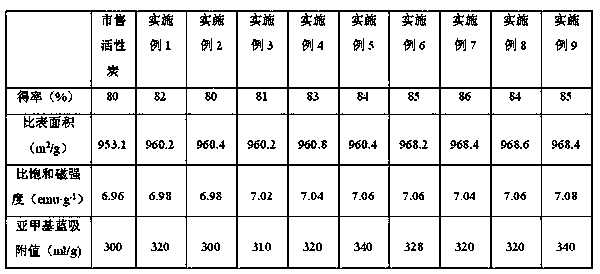

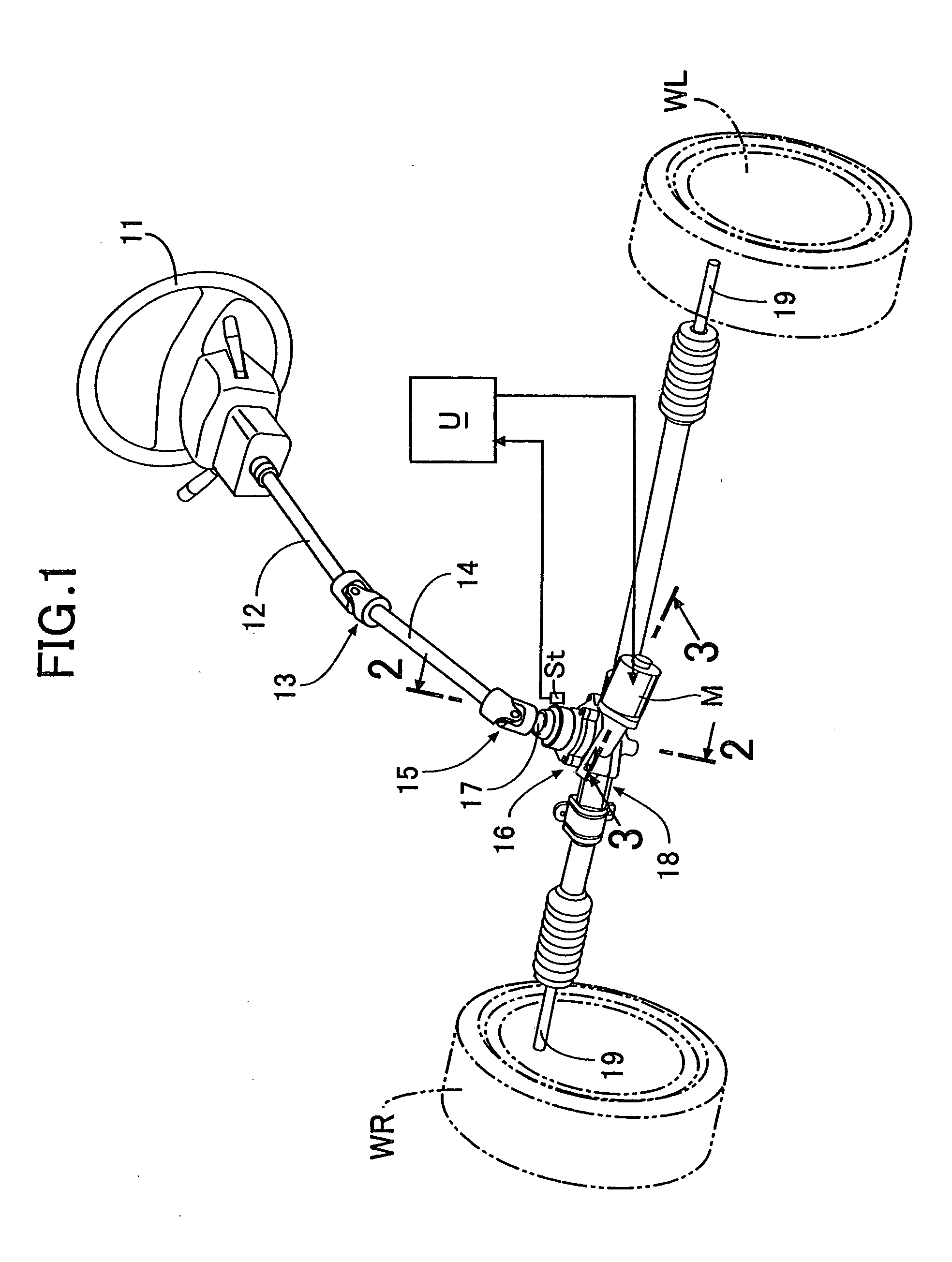

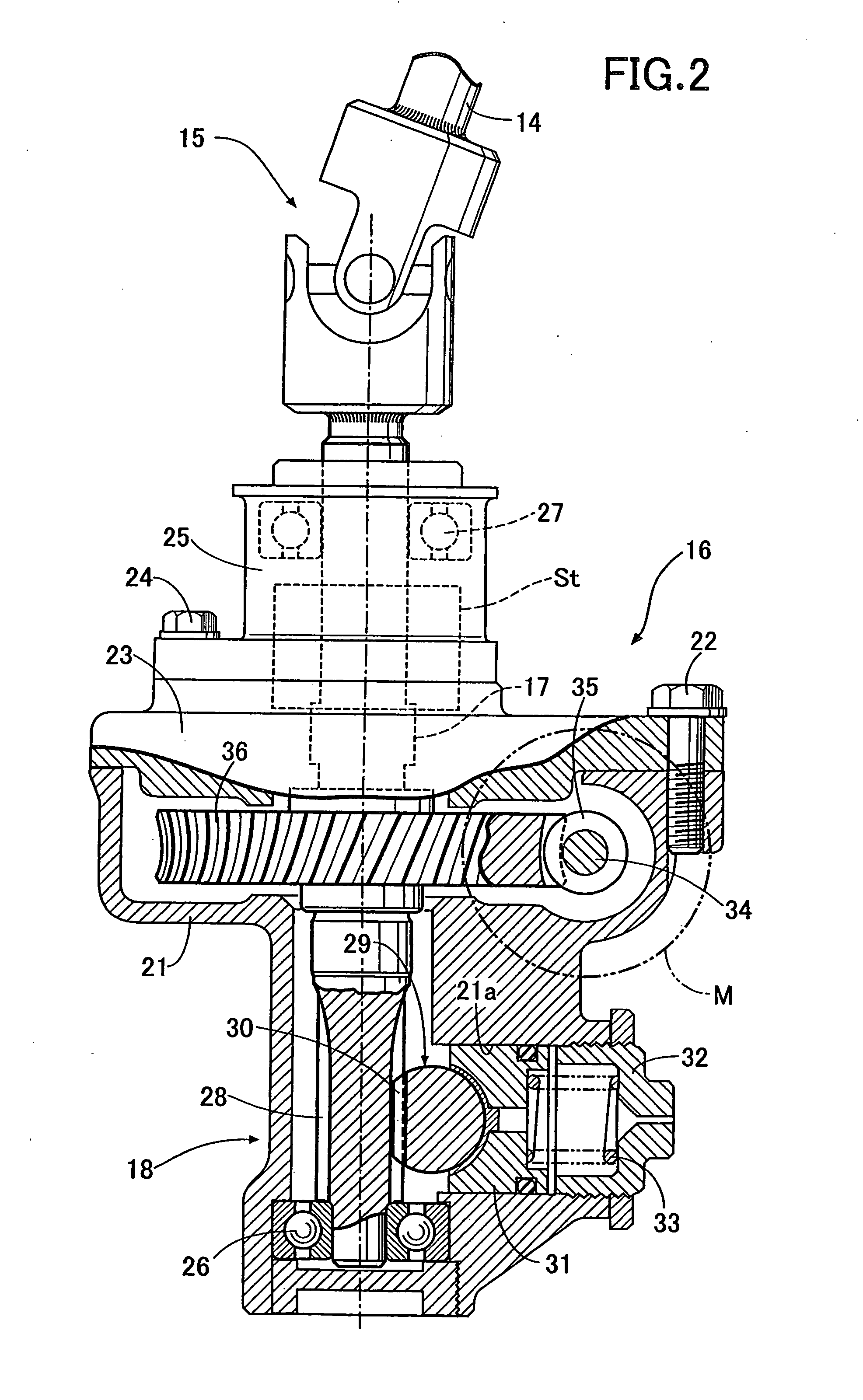

Motor rotation angle detection device

InactiveUS20090107756A1Improve accuracyMagnetically stableUsing electrical meansElectrical steeringEngineeringRotary transformer

A motor rotation angle detection device, comprising a resolver which detects a rotation angle of a motor generating an assist torque for steering road wheels. The resolver includes an annular rotor disposed inside an annular stator with an air gap interposed in between an outer circumferential surface of the rotor and an inner circumferential surface of the stator, so that the stator and the rotor are rotatable relative to each other, wherein a rotor supporting member is connected to a rotary shaft of the motor, and the rotor extends out from an axial end portion of the rotor supporting member so as to surround an outer periphery of the rotary shaft. With the such a motor rotation angle detection device, it is possible to stabilize the magnetic permeability of the rotor, and accordingly to increase an accuracy with which the rotation angle of the motor is detected.

Owner:HONDA MOTOR CO LTD

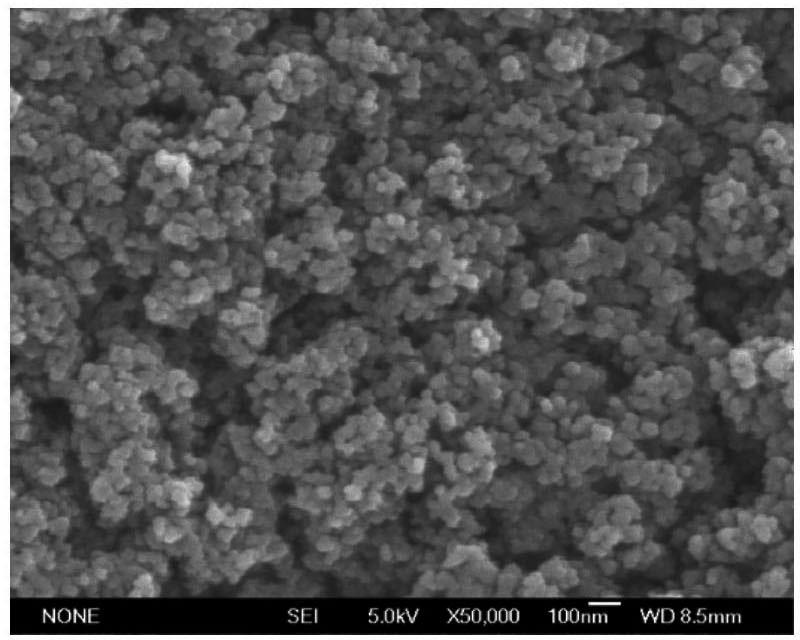

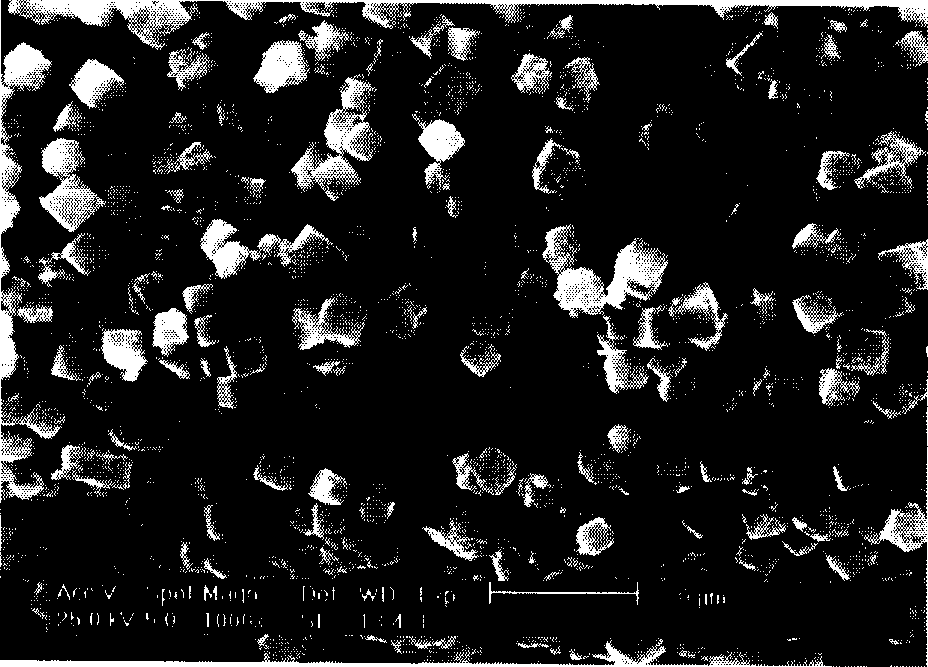

4A type zeolite molecular sieve and its preparation method

InactiveCN1868876AIncrease magnetic susceptibilityUniform particlesCrystalline aluminosilicate zeolitesSal ammoniacMolecular sieve

A 4A zeolite molecular sieve with a certain magnetism and carrying Fe contained compound on its surface is a granular one containing Fe (3.55-9.70 mass%). Its preparing process includes such steps as synthesizing 4A zeolite molecular sieve, preparing Fe ion solution and aqueous solution of NH4, and magnetically modifying the 4A zeolite molecular sieve by chemical deposition method.

Owner:HEBEI UNIV OF TECH

Sealing device

InactiveUS20070024273A1Without increaseMagnetically stableSynchronous generatorsEngine sealsMan-hourEngineering

To provide a sealing device in which a magnetic encoder can be protected so as to improve detecting precision and reliability, without increasing the number of parts and assembling man-hour and without enlarging a setting space, the sealing device is structured such that a detected portion is arranged in the sealed fluid side of an annular member, a first annular member fitted to a shaft is formed with an axial direction portion and diametrical direction portions extending in the inward and outward diametrical directions from the axial direction portion, one of the diametrical direction portions supports the detected portion in the sealed fluid side, a seal lip is in slidably contact with the other diametrical direction portion for sealing, and the seal portion is formed with the seal lip and the micro space.

Owner:NOK CORP

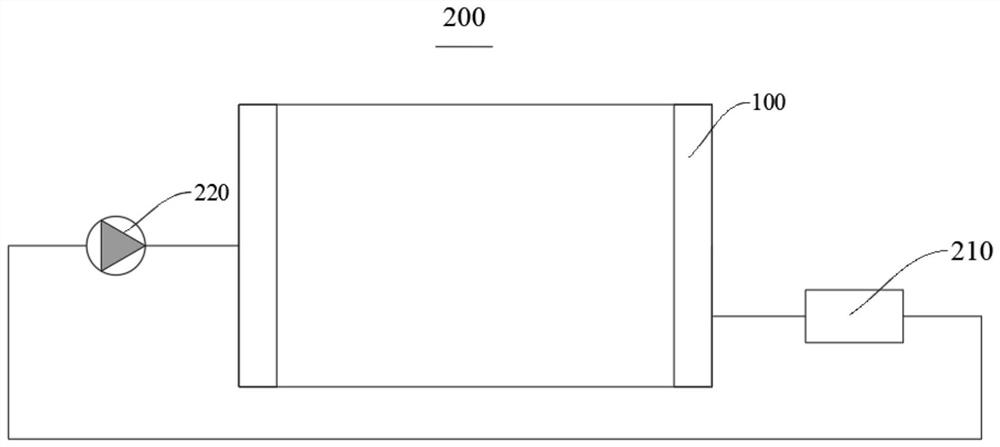

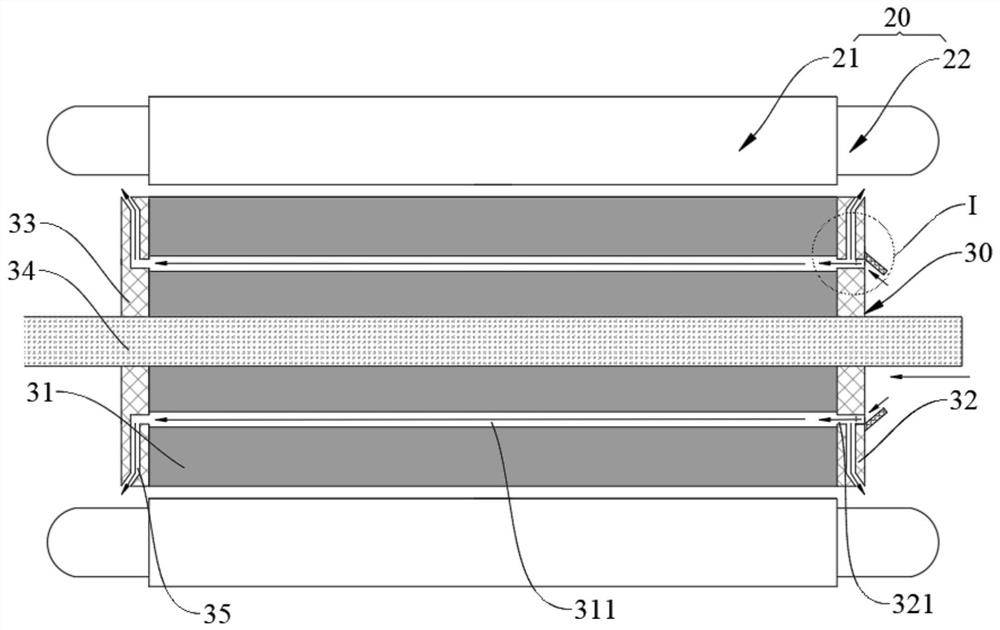

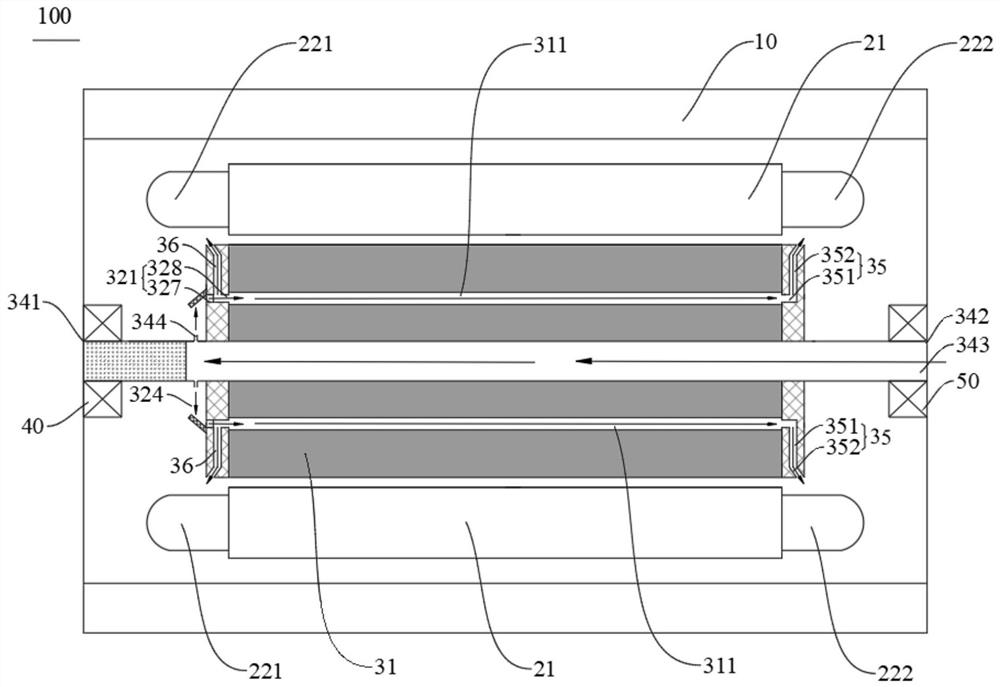

Motor, motor cooling system and electric vehicle

ActiveCN111884428AImprove cooling effectAdequate heat dissipationMagnetic circuit rotating partsElectric propulsion mountingElectric machineElectric cars

The invention provides a motor, a motor cooling system and an electric vehicle. The motor comprises a rotor, and the rotor comprises a rotor iron core, a first end cover and a second end cover, wherein the first end cover and the second end cover are connected to the two ends of the rotor iron core respectively; the first end cover is provided with a liquid inlet flow channel, the rotor iron coreis provided with a liquid passing flow channel, the first end cover or the second end cover is provided with a liquid outlet flow channel, the liquid inlet flow channel is communicated with the liquidpassing flow channel and the space outside the rotor, and the liquid outlet flow channel is communicated with the liquid passing flow channel and the space outside the rotor. An outlet of the liquidoutlet flow channel faces the stator winding, and the liquid inlet flow channel, the liquid passing flow channel and the liquid outlet flow channel form a rotor flow channel for cooling liquid to flowthrough. According to the technical scheme, the processing cost can be reduced on the basis of ensuring the heat dissipation reliability of the rotor of the motor.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

Multifunctional tourmaline health-care material and preparation method thereof

The invention relates to a multifunctional tourmaline health-care material and a preparation method thereof, and relates to a health-care composite material and a preparation method thereof, which solve the problem of single function in the conventional health-care material. The multifunctional tourmaline health-care material is prepared from iron tourmaline powder, neodymium iron boron powder, titanium dioxide powder, cerium oxide powder, a bonder, a coupling agent and a lubricating agent. The method comprises the following steps of: mixing the iron tourmaline powder, the neodymium iron boron powder, the titanium dioxide powder, the cerium oxide powder, the bonder, the coupling agent and the lubricating agent uniformly, pressing the mixture to form parison, and curing and magnetizing to prepare the multifunctional tourmaline health-care material. The multifunctional tourmaline health-care material also can be prepared from the iron tourmaline powder, the neodymium iron boron powder, the titanium dioxide powder, the cerium oxide powder and viscose fiber slurry, and the method comprises the following steps of: adding the iron tourmaline powder, the neodymium iron boron powder, the titanium dioxide powder and the cerium oxide powder into the viscose fiber slurry, mixing uniformly, and after performing wire drawing, spinning and weaving, magnetizing to prepare the multifunctional tourmaline health-care material. The multifunctional tourmaline health-care material releases negative ions, far infrared rays, magnetic fields and microcurrent, and can be used for preparing health-care products.

Owner:哈尔滨韩都电气石纳米科技发展集团有限公司

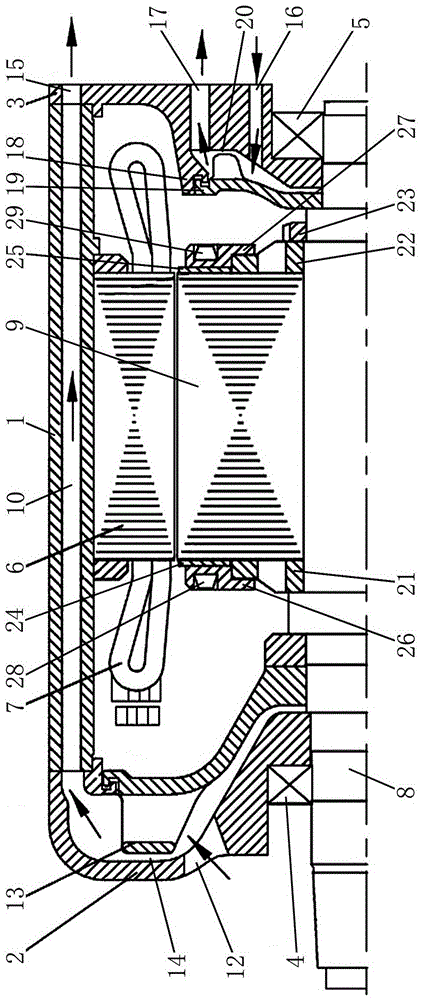

Fully enclosed self-ventilation permanent magnet motor

InactiveCN106208584ARealize circulating coolingImprove cooling effectMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsPermanent magnet motorEngineering

The invention relates to permanent magnet motors, in particular to a fully enclosed self-ventilation permanent magnet motor. The fully enclosed self-ventilation permanent magnet motor provided by the invention solves the problems of poor cooling performance, limited application range, large dissipation, low efficiency, poor operation reliability, complex structure and large volume of the existing permanent magnet motors. The fully enclosed self-ventilation permanent magnet motor comprises an engine base, a front end cover, a rear end cover, a front bearing, a rear bearing, a stator structure and a rotor structure; an axial main air inlet hole, a main ventilation gap, an axial ventilation hole and an axial main air outlet hole constitute a main cooling air path structure together; an axial auxiliary air inlet hole, an auxiliary ventilation gap and an axial auxiliary air outlet hole constitute an auxiliary cooling air path structure together; and the rotor structure further comprises a front rotor pressure ring, a rear rotor pressure ring, a round nut, a front permanent magnet baffle, a rear permanent magnet baffle, a front permanent magnet baffle pressure ring, a rear permanent magnet baffle pressure ring, a front balancing block and a rear balancing block. The fully enclosed self-ventilation permanent magnet motor provided by the invention is suitable for various fields.

Owner:CRRC YONGJI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com