Magnetic active carbon and preparation method thereof

A magnetic activated carbon and activated carbon technology, applied in the field of activated carbon, can solve the problems of difficult activated carbon recovery, etc., and achieve the effect of good adsorption performance, high specific surface area, and wide range of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

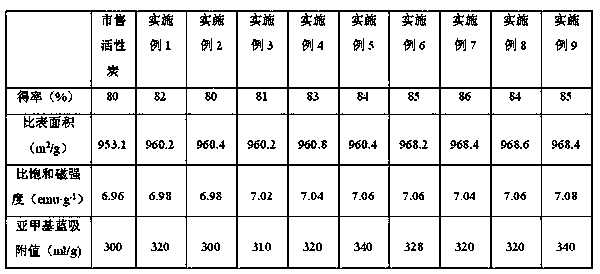

Examples

Embodiment 1

[0020] A magnetic activated carbon comprises the following raw materials in parts by weight: 20 parts of cow dung, 10 parts of sludge, 60 parts of crop straw, 20 parts of coal powder, and 20 parts of iron powder core.

[0021] A preparation method of magnetic activated carbon, comprising the following steps:

[0022] (1) Clean, filter and dry the cow dung and sludge first, weigh and mix the raw materials according to the parts by weight, soak the raw materials in KOH solution for 1 day, and then rinse them with distilled water until neutral;

[0023] (2) Put the raw materials treated in step (1) in a jade crucible, and then put the jade crucible into a microwave oven for two-step microwave treatment. The power of the first microwave treatment is 600W, and the activation time is 12 minutes. The power of microwave treatment is 800W, and the activation treatment is 5 minutes. After the activation is completed, cool to room temperature and take it out;

[0024] (3) Rinse the remo...

Embodiment 2

[0027] A magnetic activated carbon comprises the following raw materials in parts by weight: 20 parts of cow dung, 10 parts of sludge, 60 parts of crop straw, 20 parts of coal powder, and 20 parts of iron powder core.

[0028] A preparation method of magnetic activated carbon, comprising the following steps:

[0029] (1) Clean, filter and dry the cow dung and sludge first, weigh and mix the raw materials according to the parts by weight, soak the raw materials in KOH solution for 2 days, and then rinse them with distilled water until neutral;

[0030] (2) Put the raw materials treated in step (1) in a jade crucible, and then put the jade crucible into a microwave oven for two-step microwave treatment. The power of the first microwave treatment is 700W, and the activation time is 13 minutes. The power of microwave treatment is 850W, and the activation treatment is 6 minutes. After the activation is completed, cool to room temperature and take it out;

[0031] (3) Rinse the rem...

Embodiment 3

[0034] A magnetic activated carbon comprises the following raw materials in parts by weight: 20 parts of cow dung, 10 parts of sludge, 60 parts of crop straw, 20 parts of coal powder, and 20 parts of iron powder core.

[0035] A preparation method of magnetic activated carbon, comprising the following steps:

[0036] (1) Clean, filter and dry the cow dung and sludge first, weigh and mix the raw materials according to the parts by weight, soak the raw materials in KOH solution for 3 days, and then rinse them with distilled water until neutral;

[0037] (2) Put the raw materials processed in step (1) in a jade crucible, and then put the jade crucible into a microwave oven for two-step microwave treatment. The power of the first microwave treatment is 800W, and the activation time is 15 minutes. The power of microwave treatment is 900W, and the activation treatment is 10 minutes. After the activation is completed, cool to room temperature and take it out;

[0038] (3) Rinse the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com