Method for preparing bulk sintered Nd-Fe-B permanent magnet material

A permanent magnet material, NdFeB technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of easy dislocation cost, poor dimensional accuracy, etc., and achieve the effect of promoting splicing, high precision and stable magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

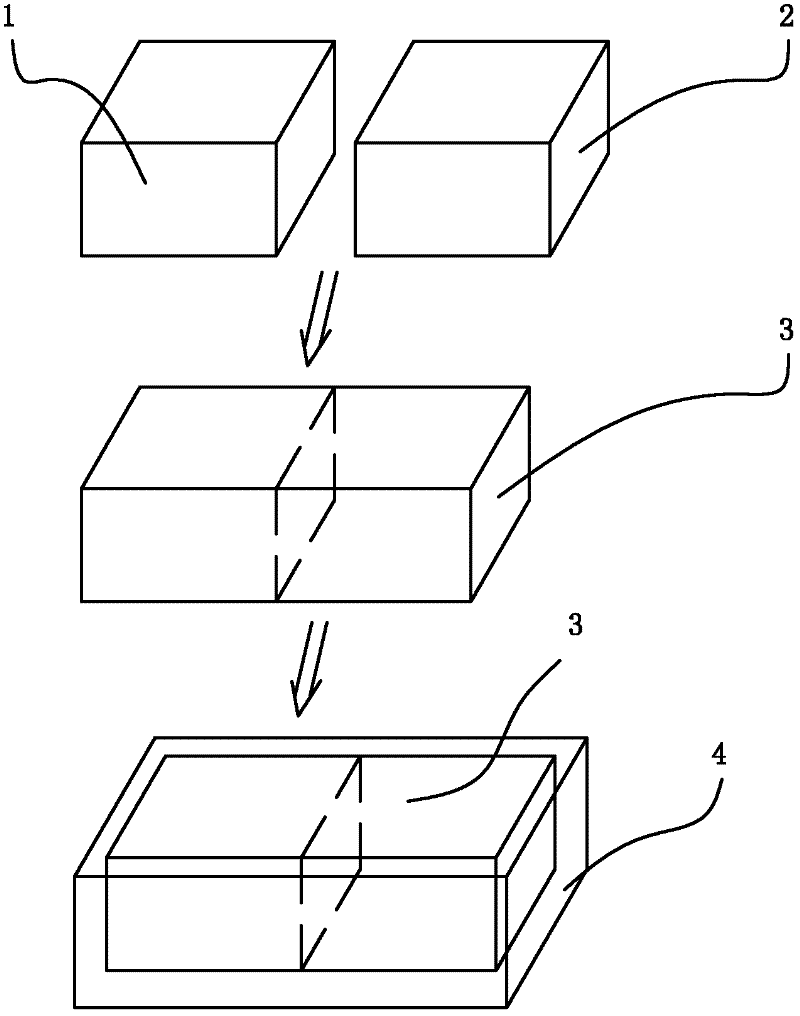

Method used

Image

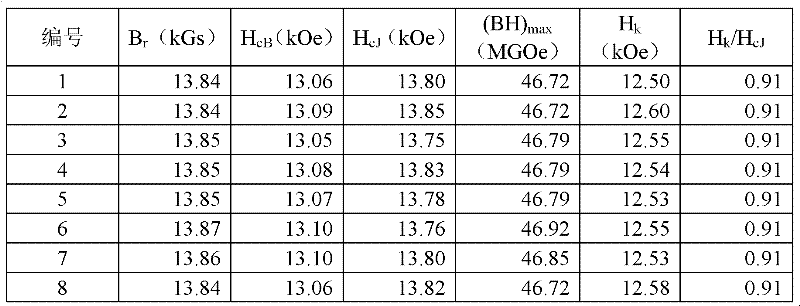

Examples

Embodiment 1

[0018] Raw materials such as metallic neodymium, praseodymium neodymium, dysprosium iron, pure iron, ferroboron, copper metal, aluminum and ferroniobium are mixed according to the required formula and put into a vacuum electromagnetic induction furnace to melt and cast them into quick-setting sheets at 1400℃~1500℃. The thickness is 0.2-0.6mm, and then the quick-setting tablet is hydrogen-crushed in a hydrogen crushing furnace to make a coarse powder, and the particle size is 0.1-3mm. Coarse powder is accelerated by 0.6-0.7Mpa high-pressure gas in the jet milling equipment, and collides with each other to form fine powder with an average particle size of 3.1 μm.

[0019] In an ordinary sintered NdFeB molding press, set the molding magnetic field to 1.4T, weigh 1629g of the above fine powder, pour the fine powder into a metal mold with a cavity cross-section of 63.5×105.0mm, and place the fine powder under the electromagnetic induction orientation magnetic field Pressed into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com