Patents

Literature

867results about How to "Quick docking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

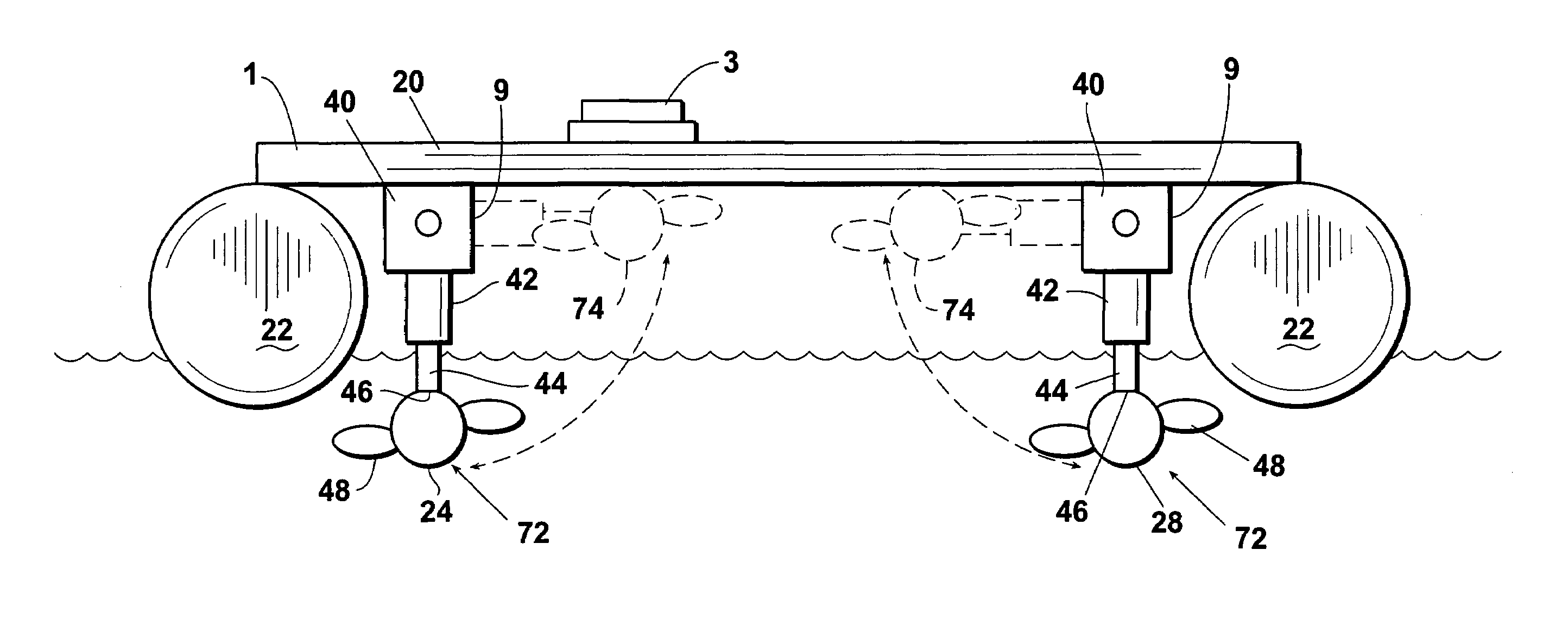

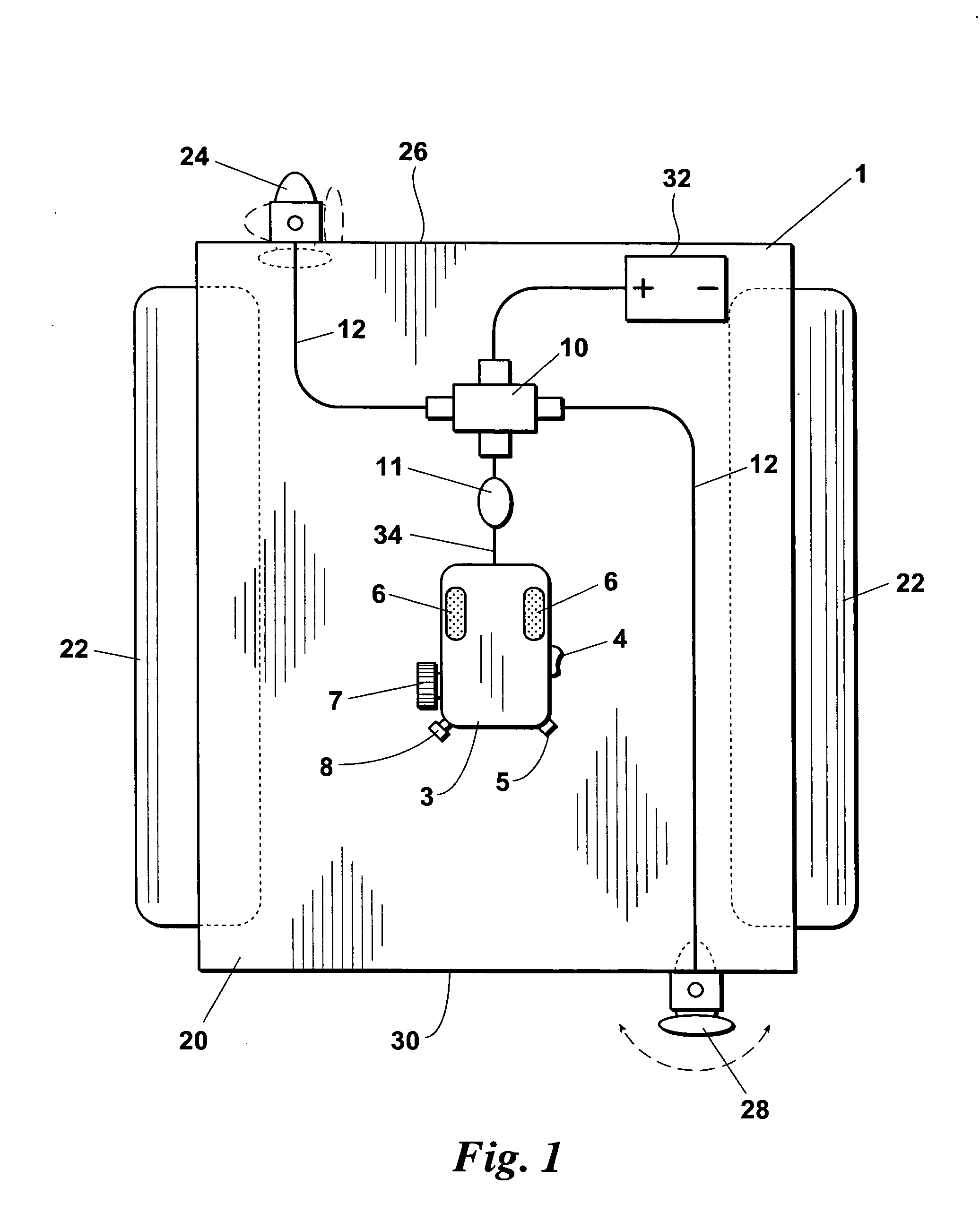

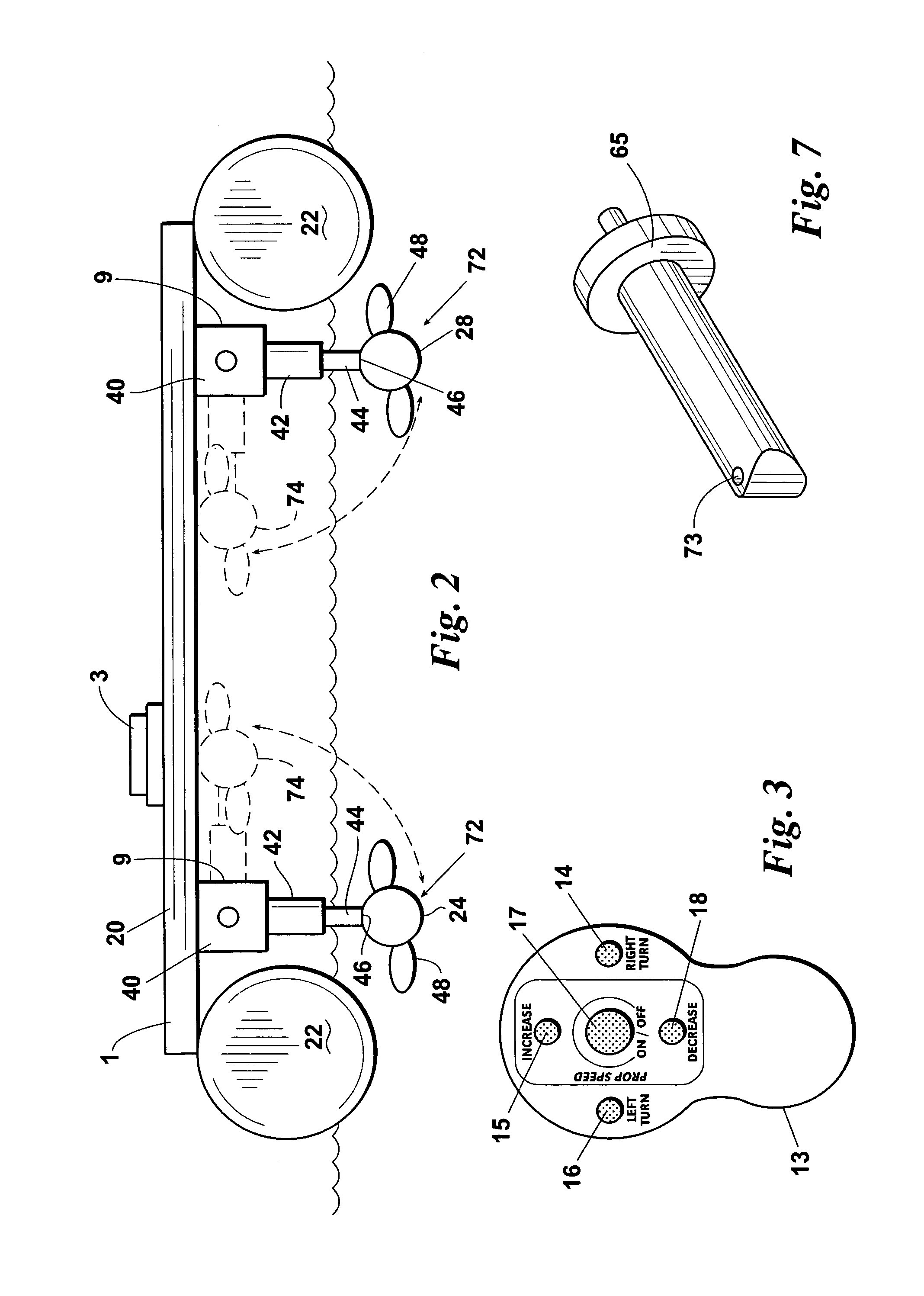

Watercraft docking system and propulsion assembly

ActiveUS7150662B1Highly maneuverableHighly versatileSpeed controllerPropulsion power plantsSteering columnOperating point

An improved docking system for a watercraft and a propulsion assembly therefor wherein the docking system comprises a plurality of the propulsion assemblies and wherein each propulsion assembly includes a motor and propeller assembly provided on the distal end of a steering column and each of the propulsion assemblies is attachable in an operating position such that the motor and propeller assembly thereof will extend into the water and can be turned for steering the watercraft.

Owner:BRUNSWICK CORPORATION

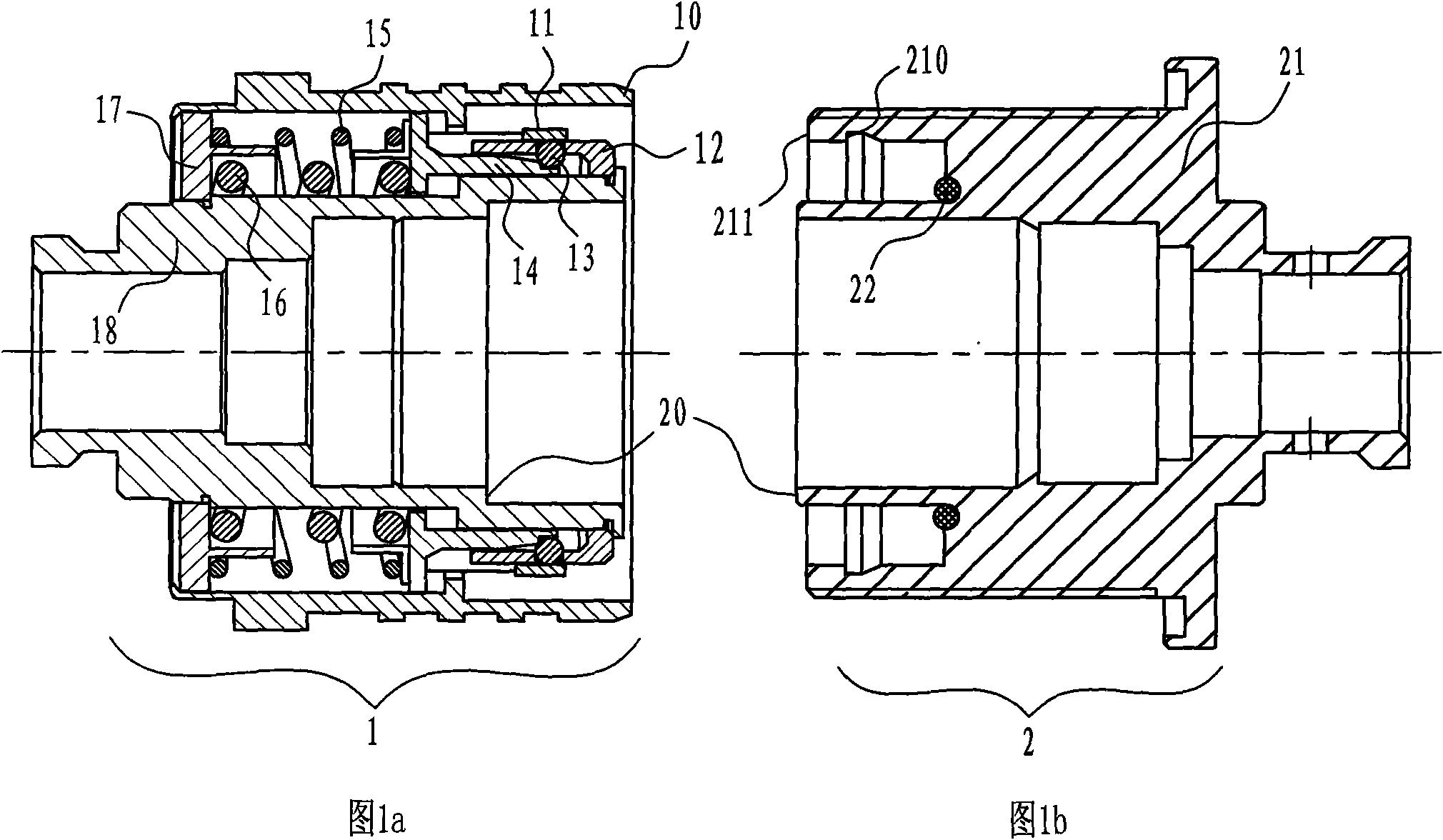

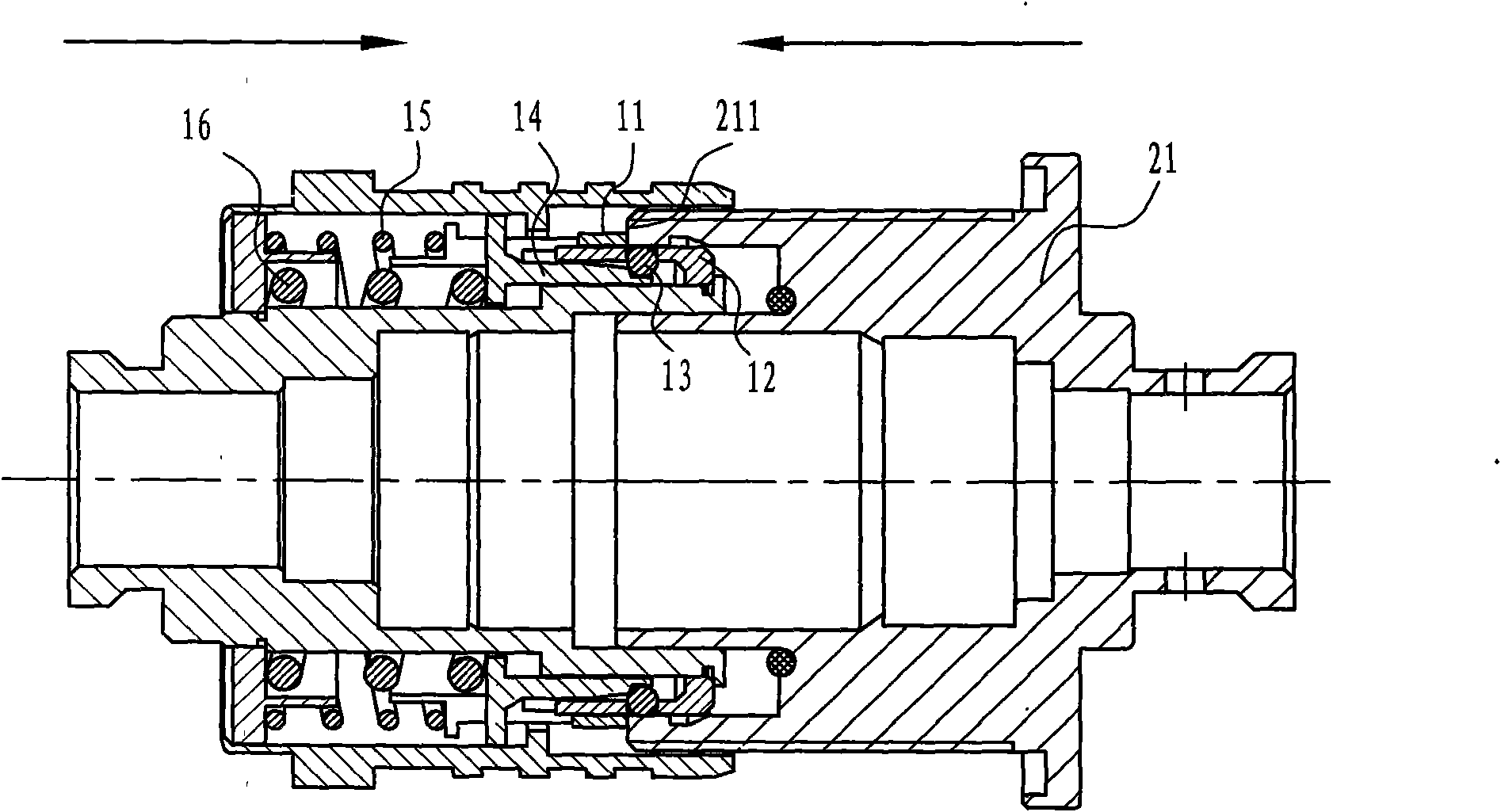

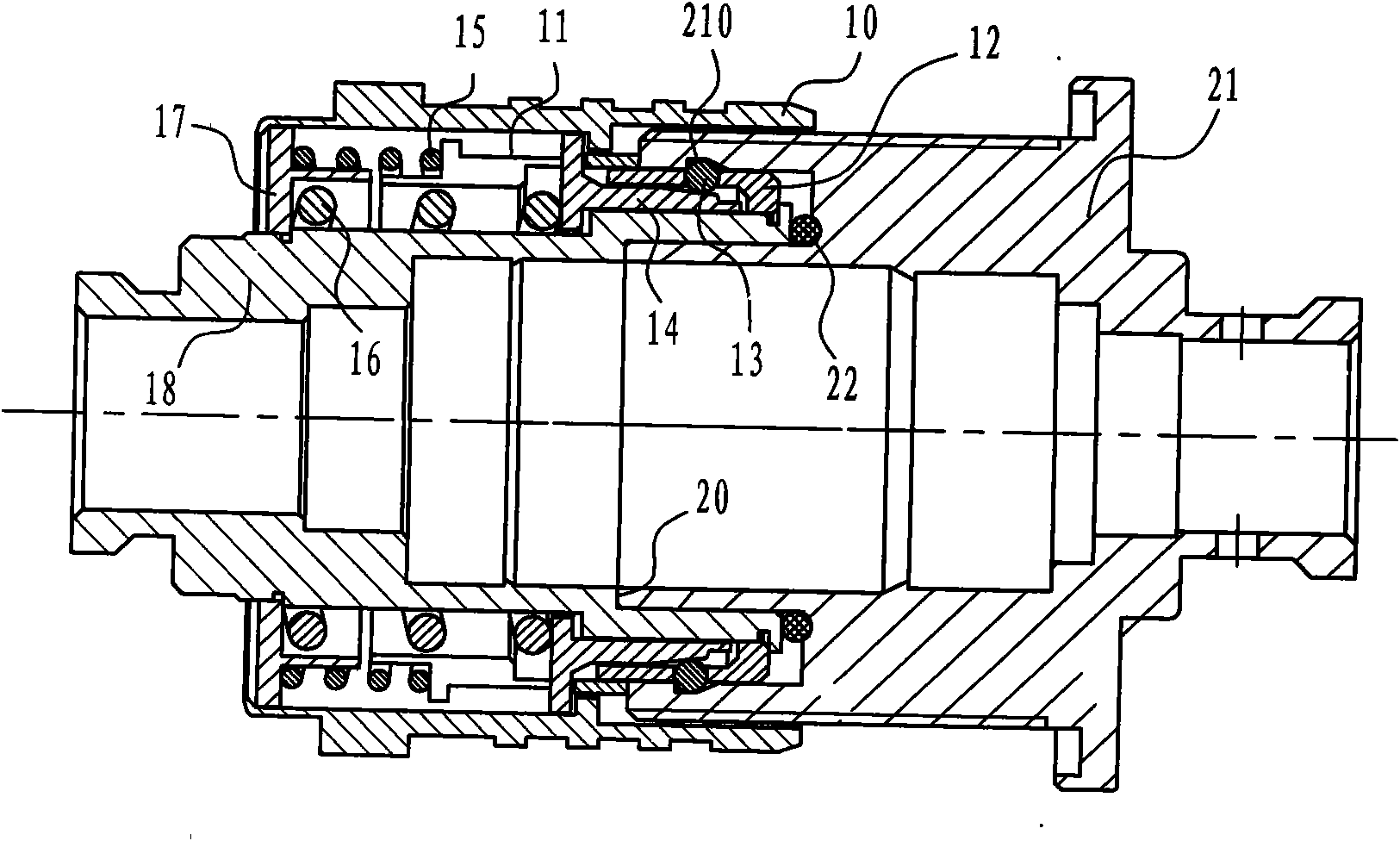

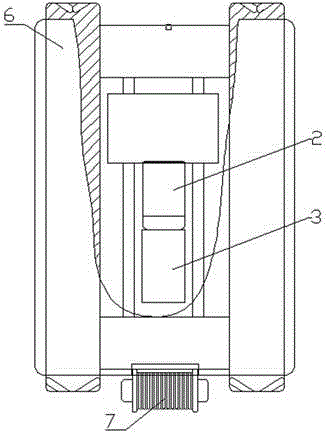

High power radio frequency connector capable of quickly locking and separating

InactiveCN101656381AReliable lockingGreat Interface RetentionCoupling device detailsTwo-part coupling devicesElectrical conductorButt joint

The present invention relates to a high power radio frequency connector capable of quickly locking and separating, a plug comprises a fixing ring, a collar, a sheath, a back-up ring, a large spring, asmall spring, a thread sleeve and a housing, the back-up ring is pressed and arranged on the housing, the thread sleeve connects the plug integrally, locking steel balls are evenly distributed in a circumferential hole of the fixing ring, outer side contacts with the sheath, and inner side contacts a bevel A on the collar, the large spring is mounted on inner side of the back-up ring, and the small spring is mounted on outer side of the back-up ring, the pre-pressure of the large spring is higher than that of the small spring, the sheath presses the locking steel balls in the fixing ring under press of the large spring and the small spring, a part pressing the locking steel balls at front end of the collar comprises the bevel A and a bevel B, and grooves are provided at front end of the butt joint interface of the socket. The invention has advantages of small butt joint locking force and separation unlock force, rapid butt joint and locking; large interface maintenance force, convenient locking and separation, high reliability, excellent mechanical and electrical property.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

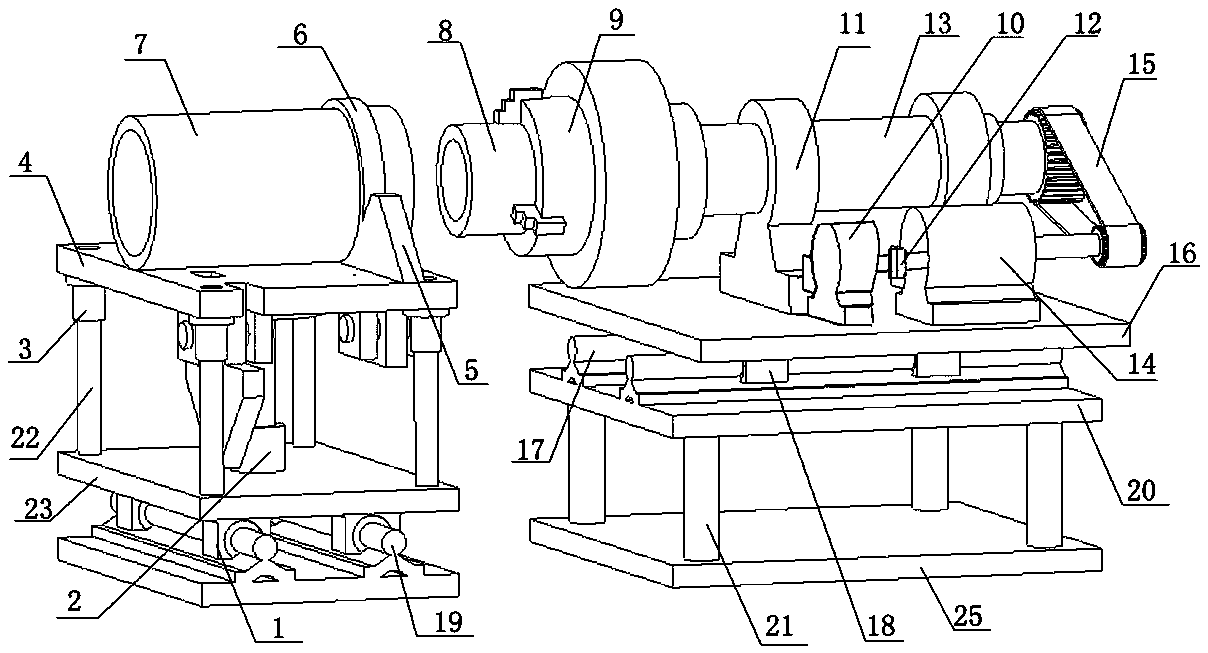

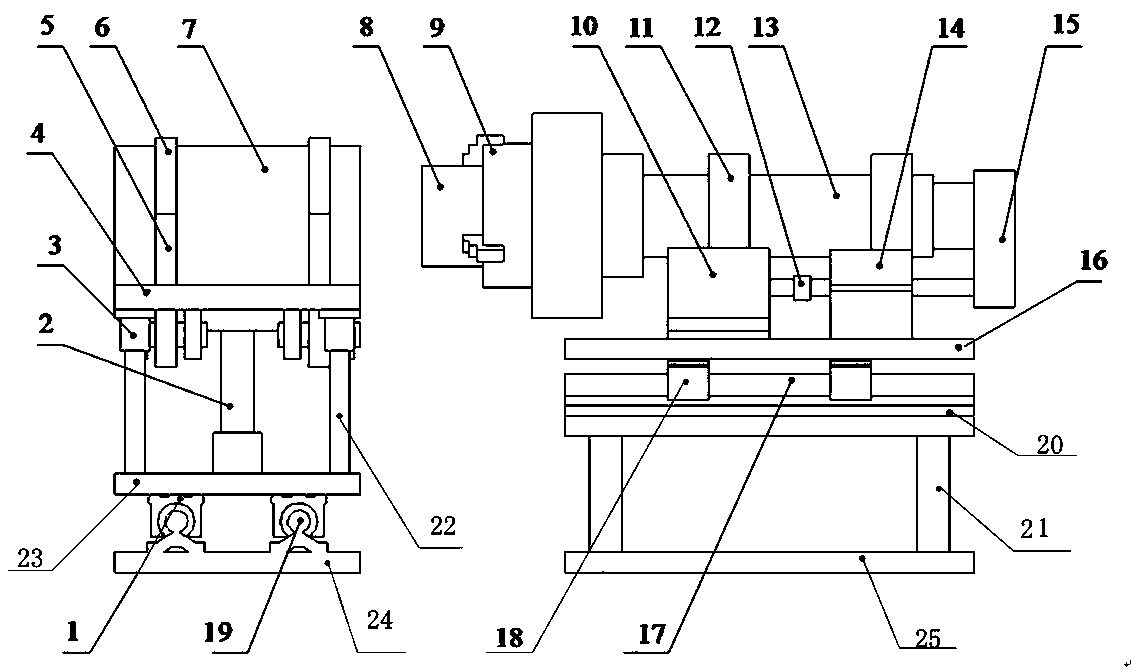

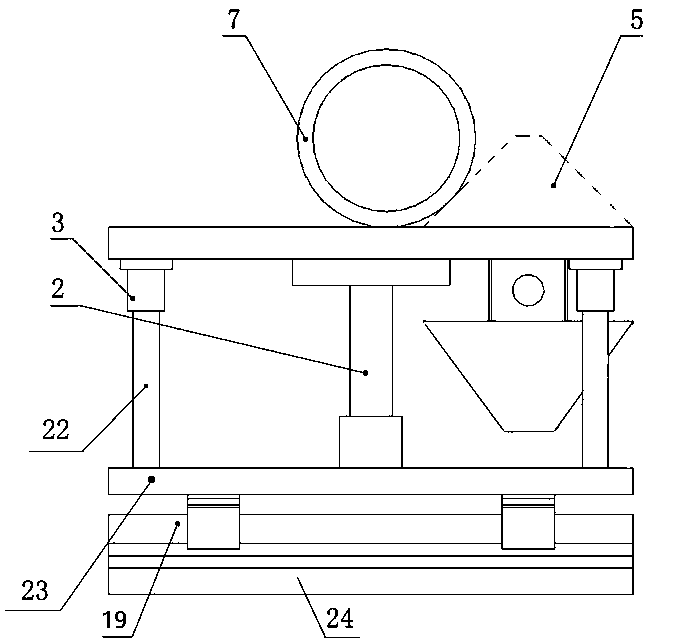

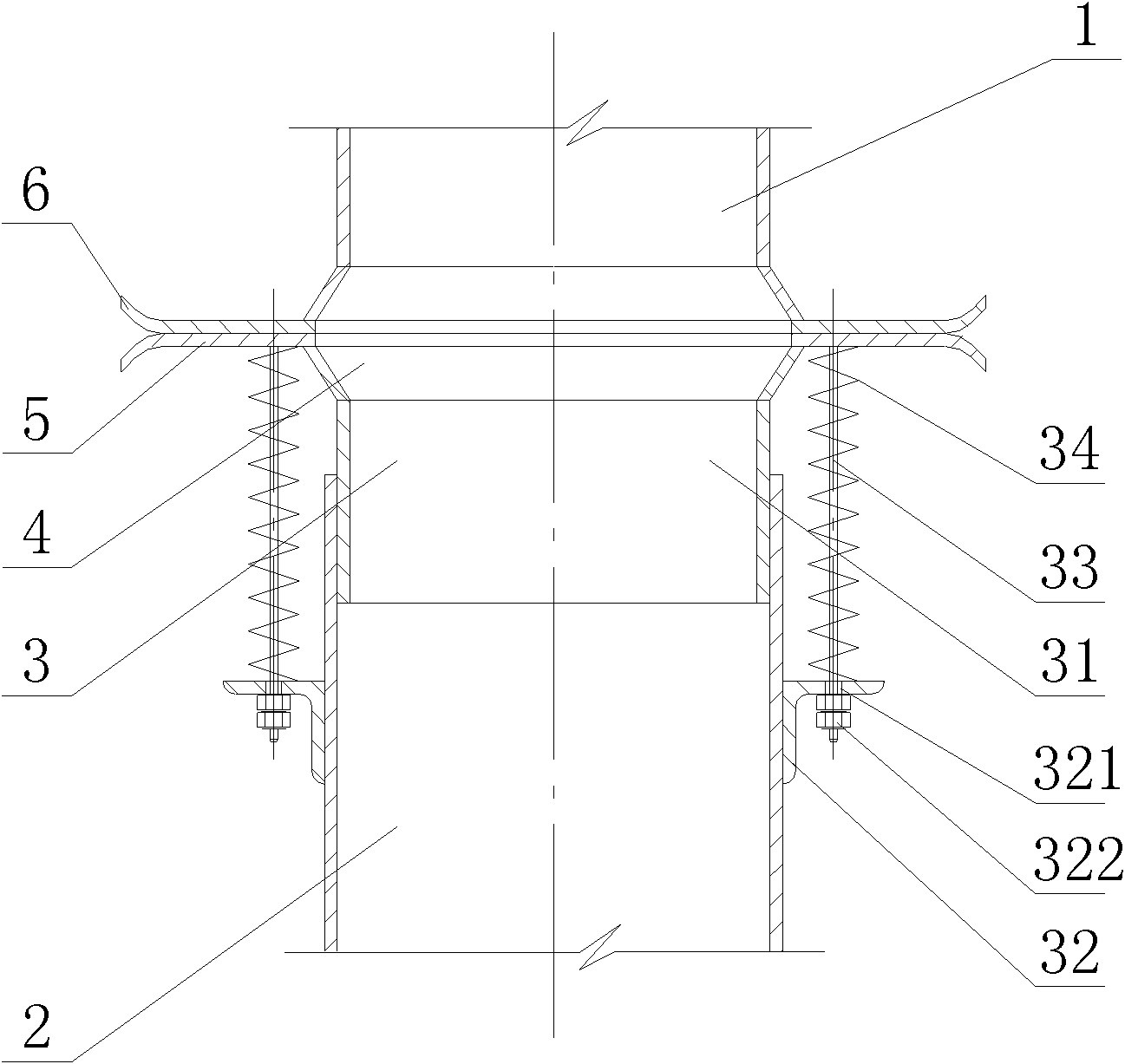

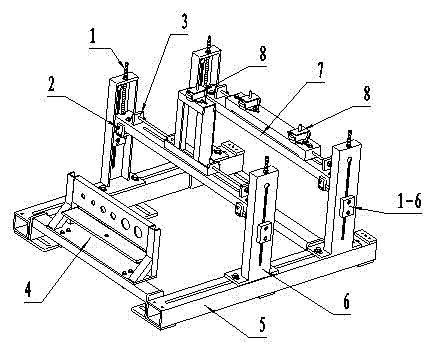

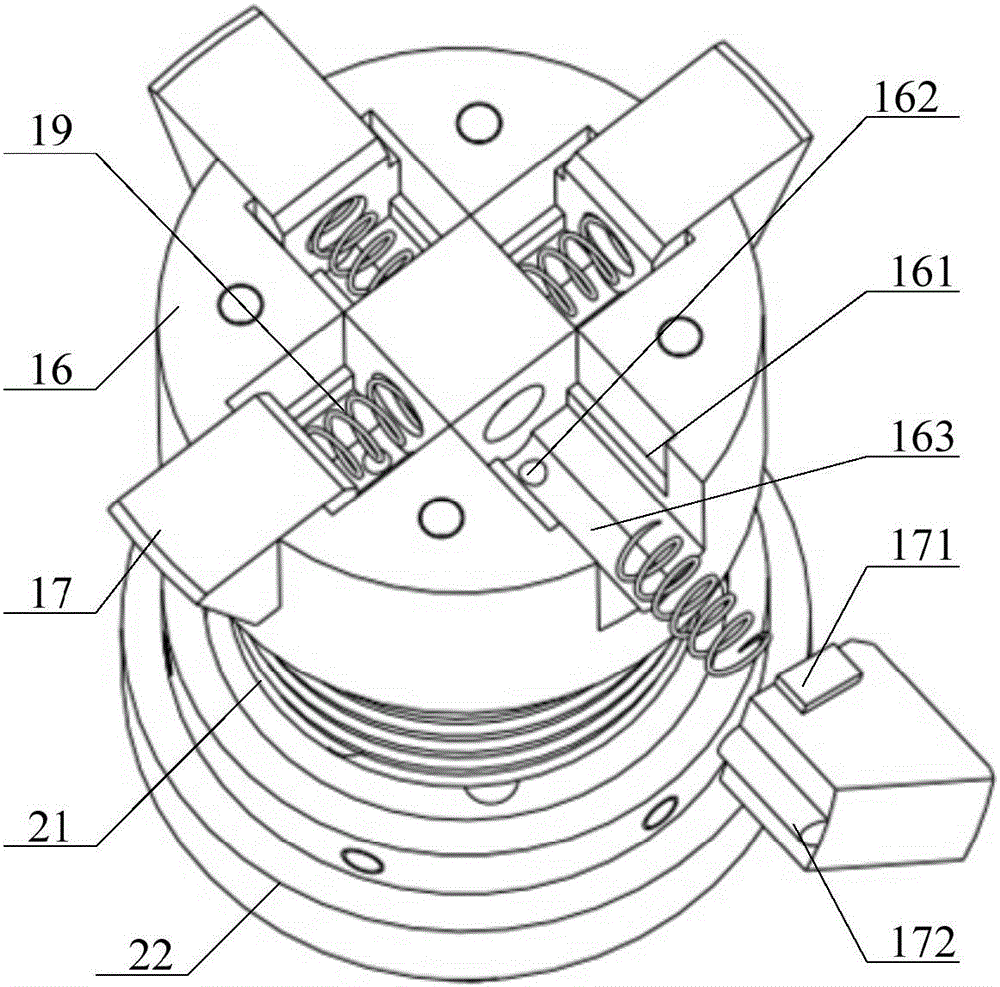

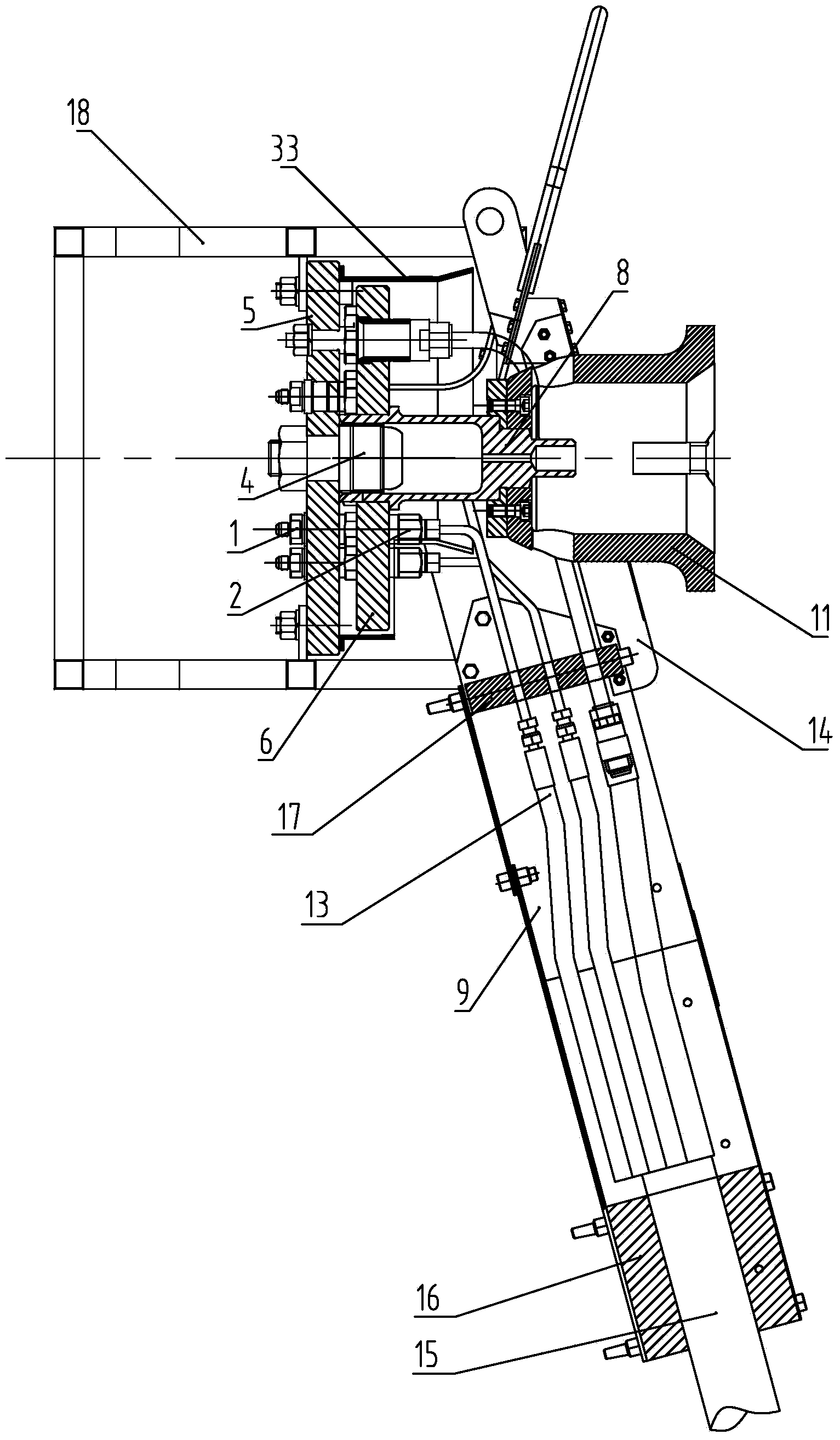

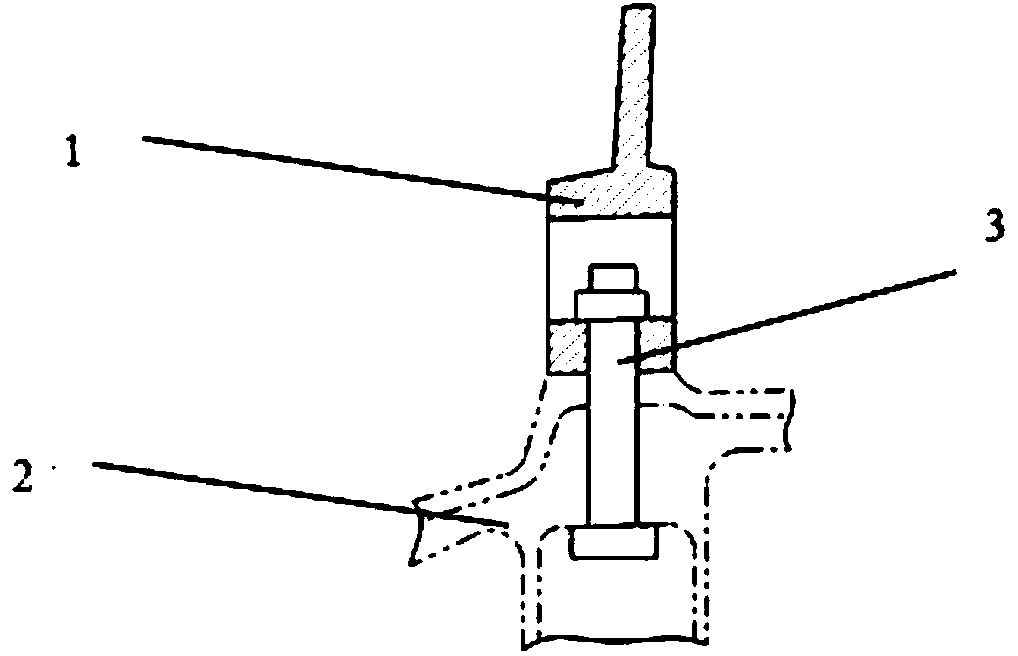

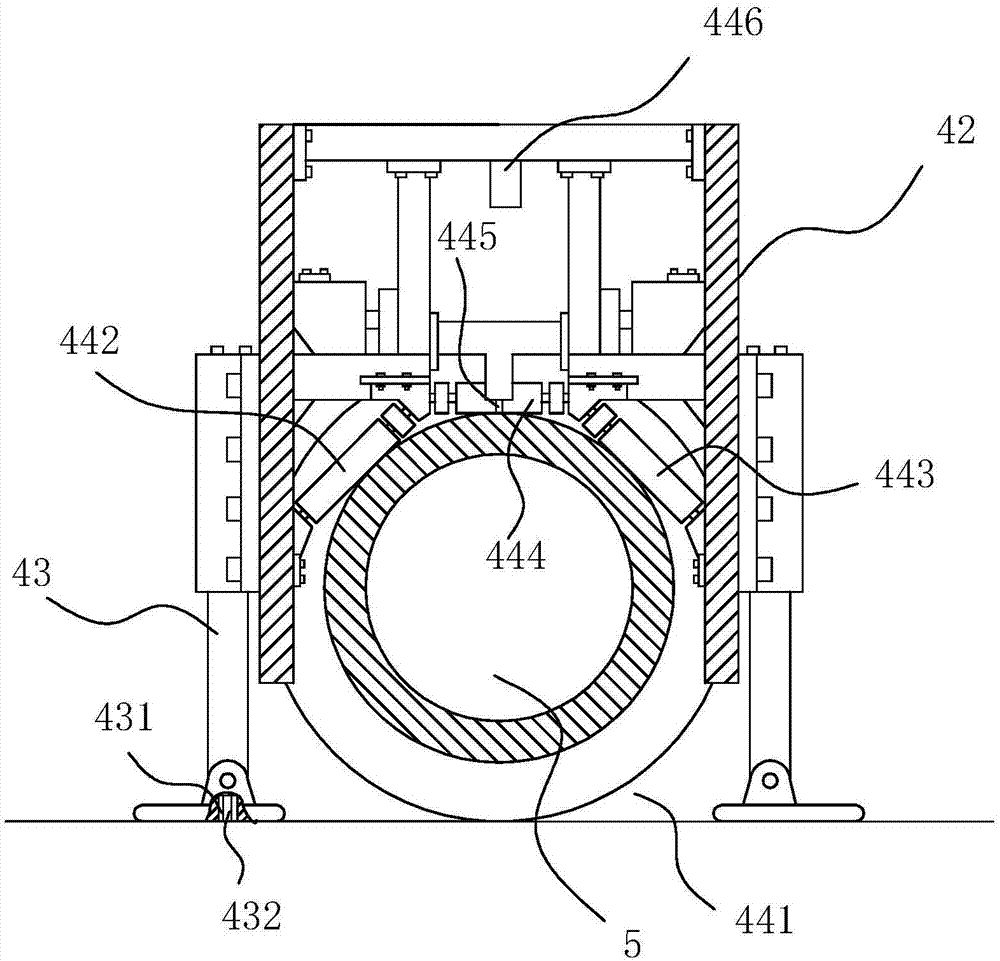

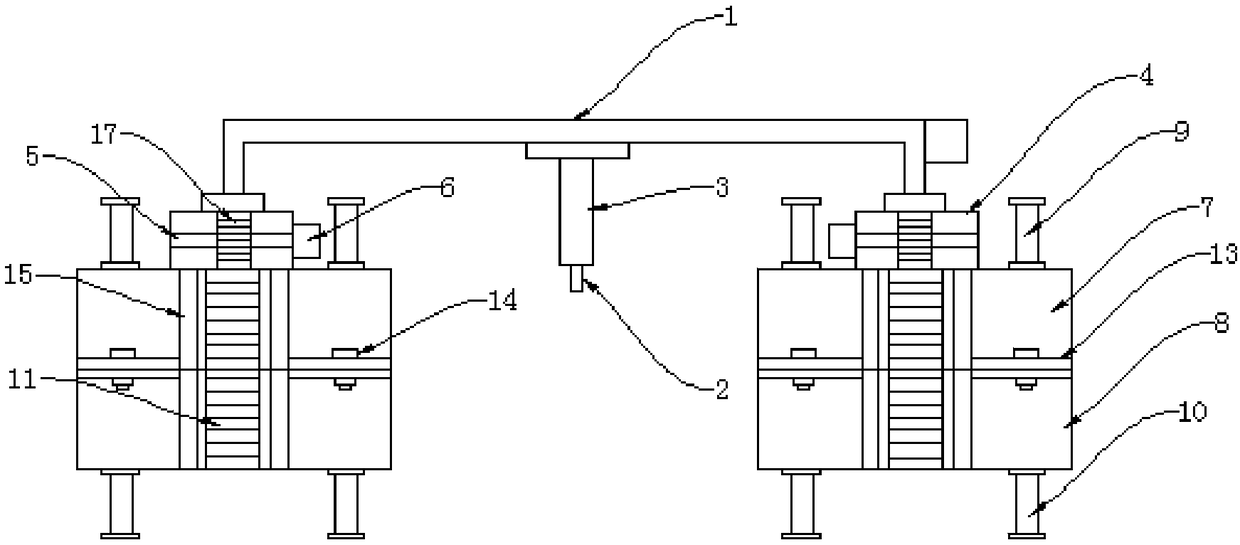

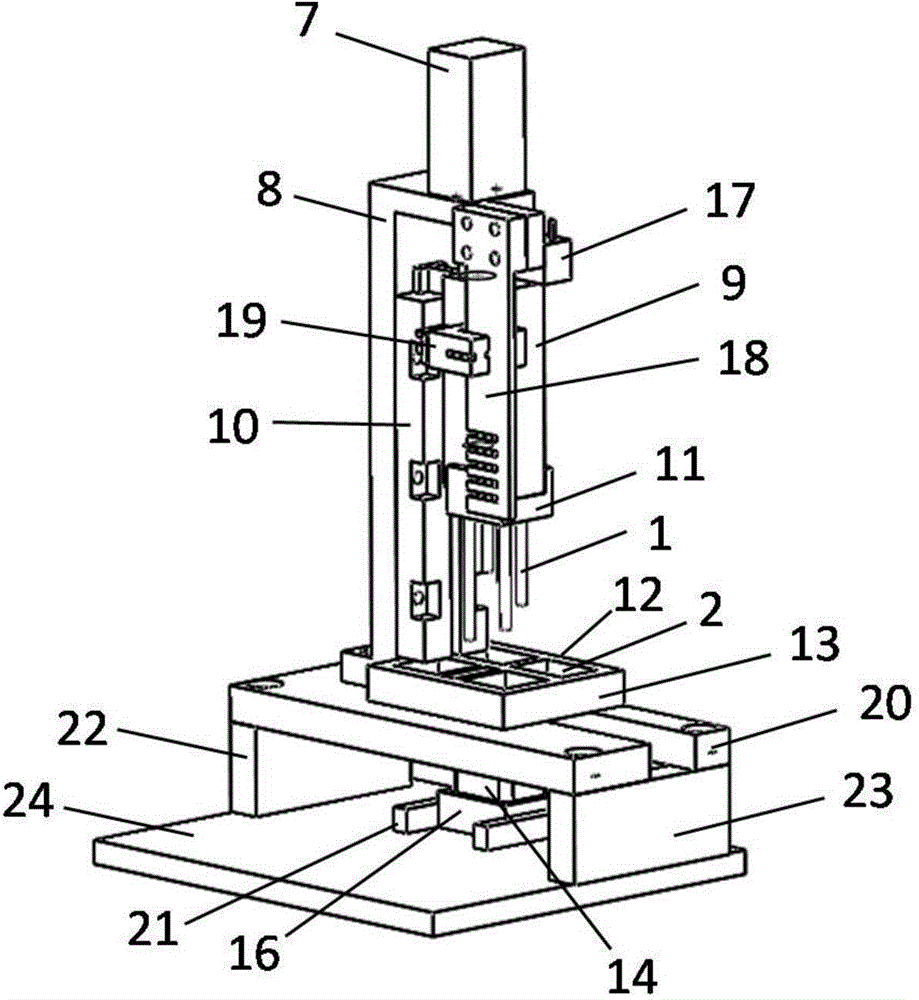

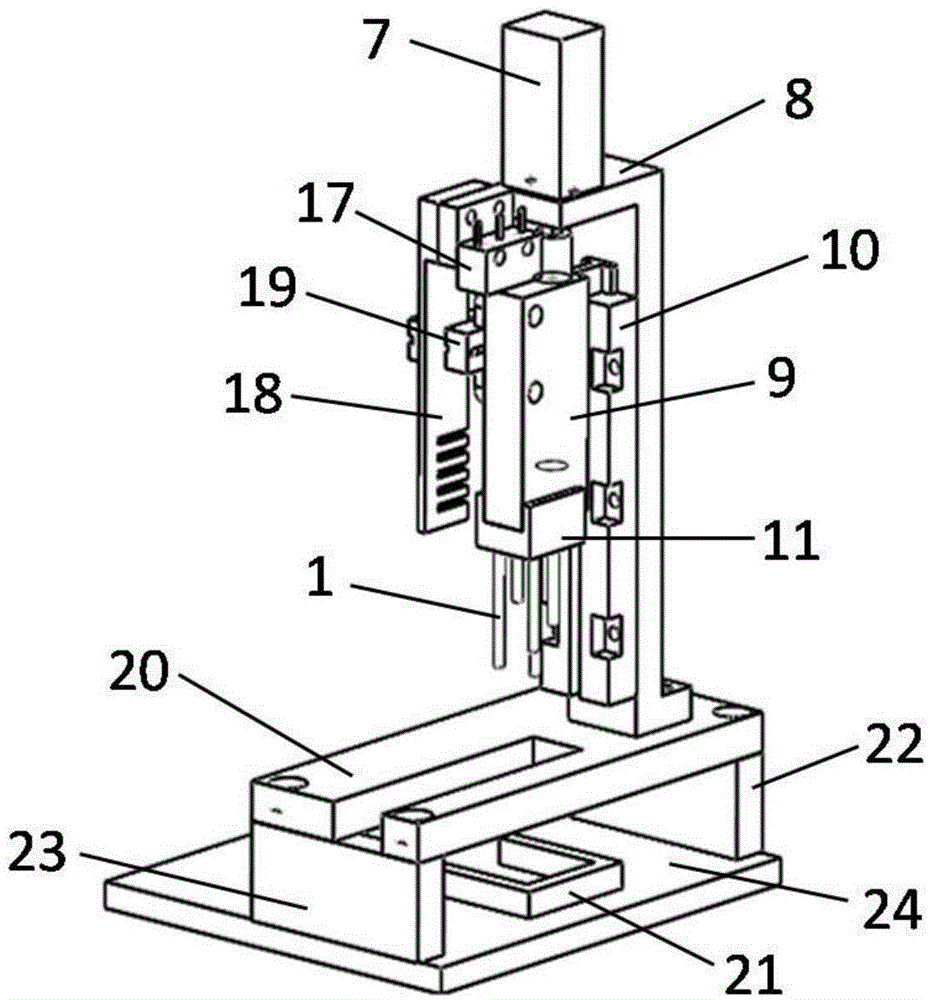

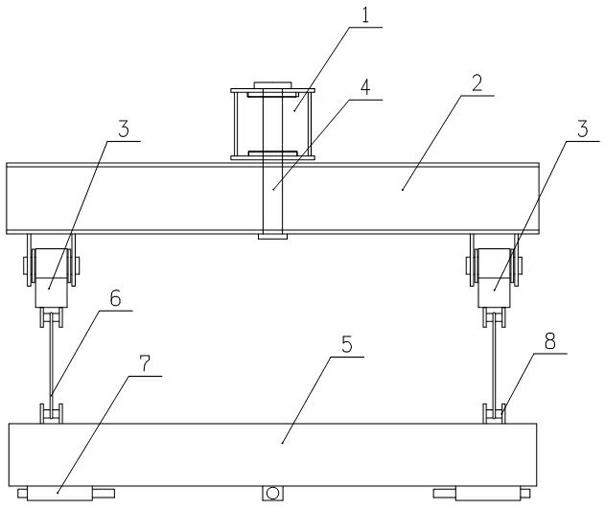

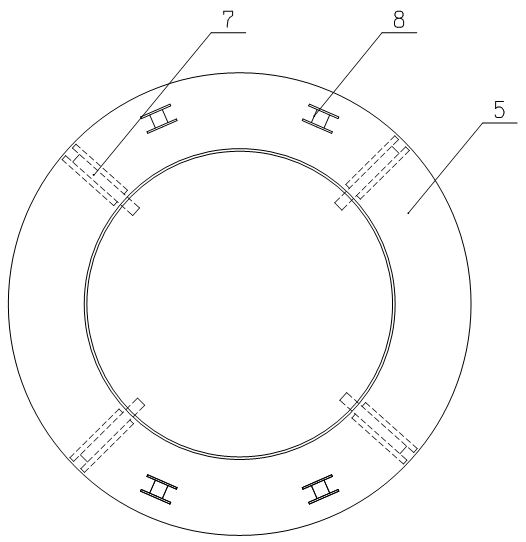

Self-adaptation flexible assembling device for hydraulic cylinder head body

InactiveCN109015468AFast and accurate vertical liftingQuick dockingWork holdersMetal working apparatusHydraulic cylinderCylinder head

The invention relates to the technical field of automatic machine assembling, in particular to a self-adaptation flexible assembling device for a hydraulic cylinder head body. The technical problem ofassembling of a cylinder barrel and a cylinder head body of a large multistage hydraulic cylinder is solved. The self-adaptation flexible assembling device comprises a cylinder barrel flexible clamping platform and a cylinder head body flexible clamping platform which are independent from each other and need to be used in cooperation with each other. The cylinder barrel flexible clamping platformis used for fixing a cylinder barrel, and the cylinder barrel flexible clamping platform can do perpendicular lifting motion and horizontal motion in the radial direction of the cylinder barrel. Thecylinder head body flexible clamping platform is used for fixing a cylinder head body, the cylinder head body flexible clamping platform can do horizontal motion along the axis of the cylinder barrel,the cylinder head body flexible clamping platform drives the cylinder head body to move towards the cylinder barrel and rotate synchronously, and finally the cylinder head body and the cylinder barrel can be assembled through thread connection. By means of the self-adaptation flexible assembling device, the historic problems that operation is complex, the assembling efficiency is low, the surface, making contact with a lifting clamp, of the cylinder barrel is likely to be damaged, and even the cylinder barrel is disengaged in the traditional cylinder barrel and cylinder head body assembling process can be effectively solved.

Owner:SHANXI UNIV

Distributed ecological intelligent internet pension service system

InactiveCN106204396AIntegrated service for safe and healthy lifeOptimize the integrated service of healthy lifeData processing applicationsControl layerThe Internet

A distributed ecological intelligent internet pension service system comprises a government-level multi-department unified command and supervision layer, a region-level central management and control layer, a community-level service guarantee layer and a user terminal function layer. The user terminal function layer acquires user health basic data and sends the data to the region-level central management and control layer; the region-level central management and control layer receives the data and community comprehensive service guarantee service configuration information, builds a user database according to the information, generates region user group reports and distributes the reports to corresponding organizations; the government-level multi-department unified command and supervision layer sends related decisions and instructions to the region-level central management and control layer. The distributed ecological intelligent internet pension service system is an intelligent service system based on the internet of things, the internet and pension, and has the advantages of data standardization, structure networking, system self-evolution, operation disintermediation, high information security degree and the like.

Owner:南京青云智锋科技发展有限公司

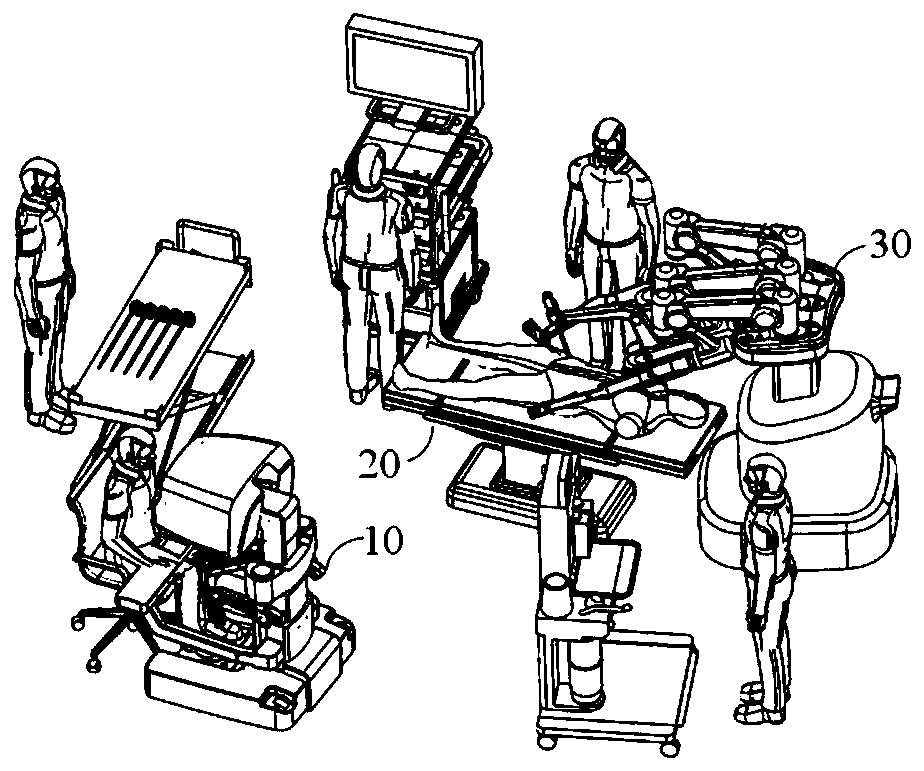

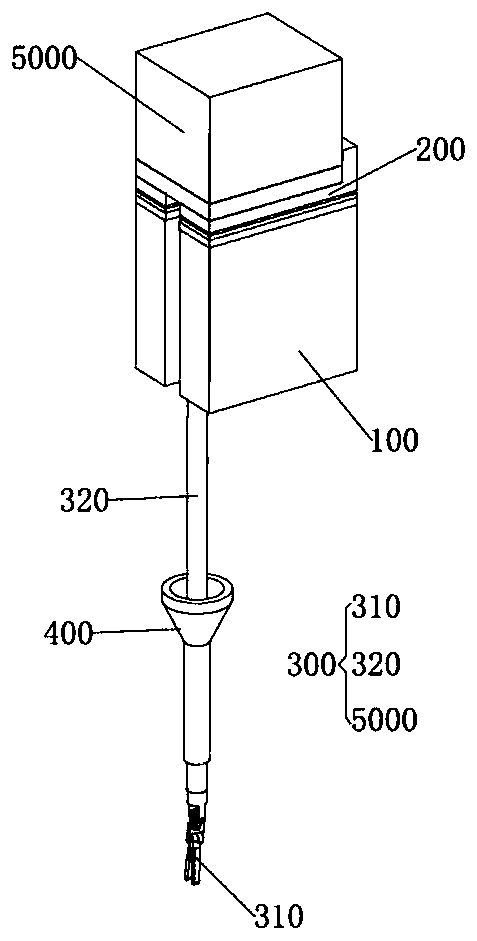

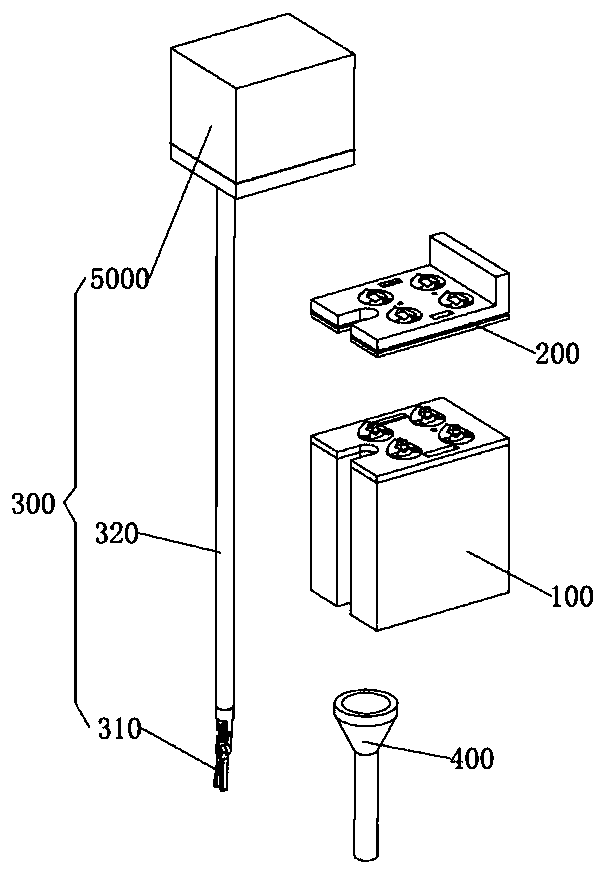

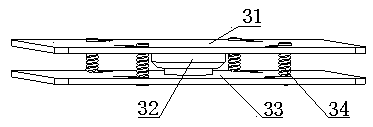

Transmission assembly, driving assembly, sterile assembly, instrument box assembly, operative instrument system, and operative robot

ActiveCN110464467AAvoidance of Joint Failure SituationsQuick dockingSurgical furnitureDiagnosticsCouplingOperative instrument

The invention relates to a transmission assembly, a driving assembly, a sterile assembly, an instrument box assembly, an operative instrument system, and an operative robot. Guiding faces are arrangedon a transmission disc constituting the transmission assembly, thus jointing parts can be accurately positioned and jointed through the guiding faces, thus quick and accurate jointing of the operative instrument system is achieved, the coupling failure phenomenon is avoided, and safety and effectiveness of the operative robot are improved.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

Goods logistics control method and goods logistics control system

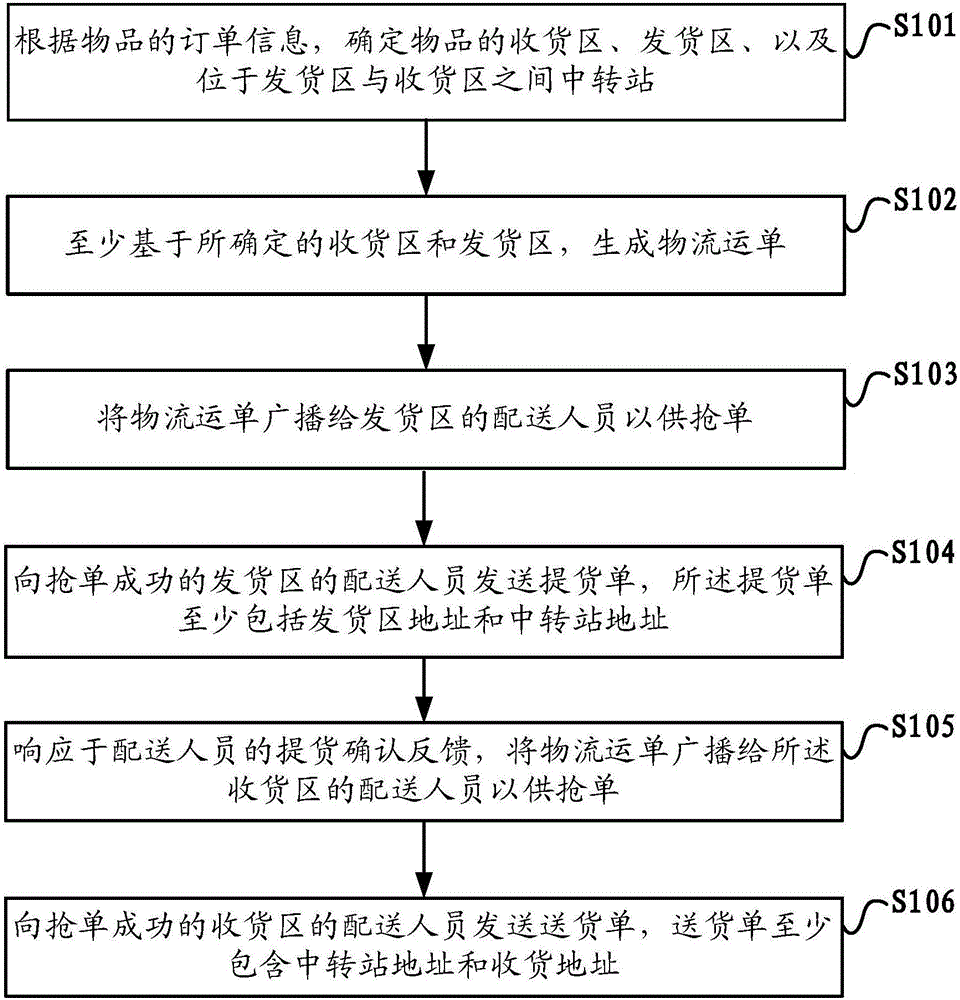

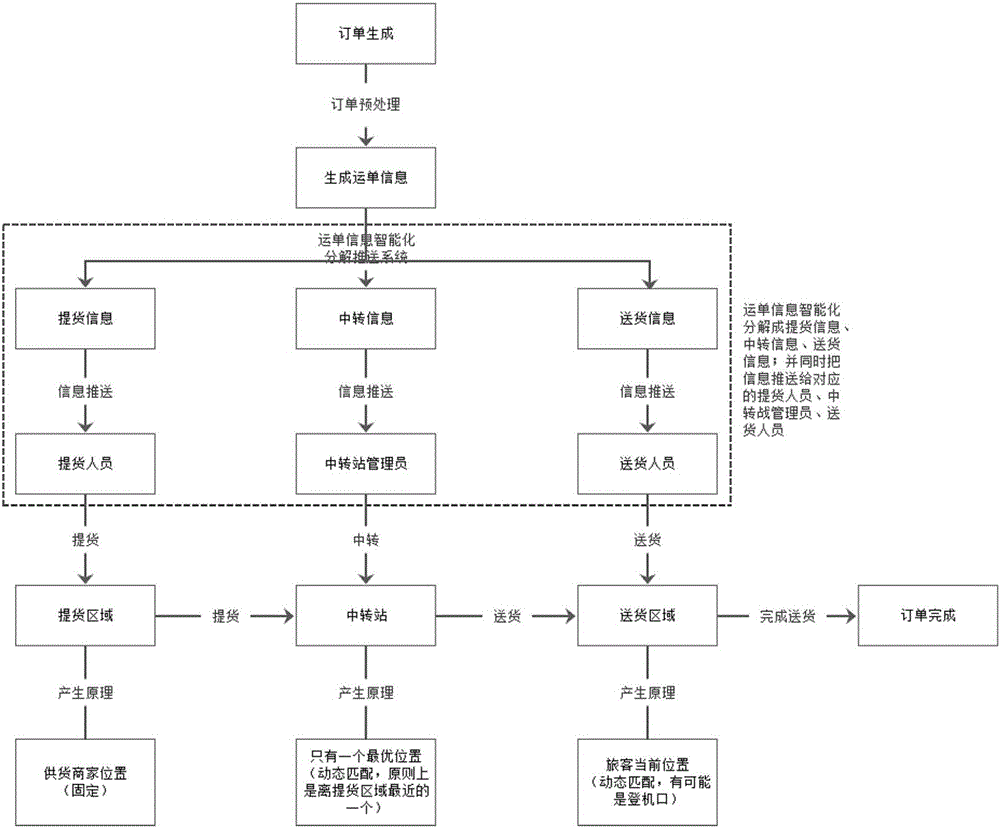

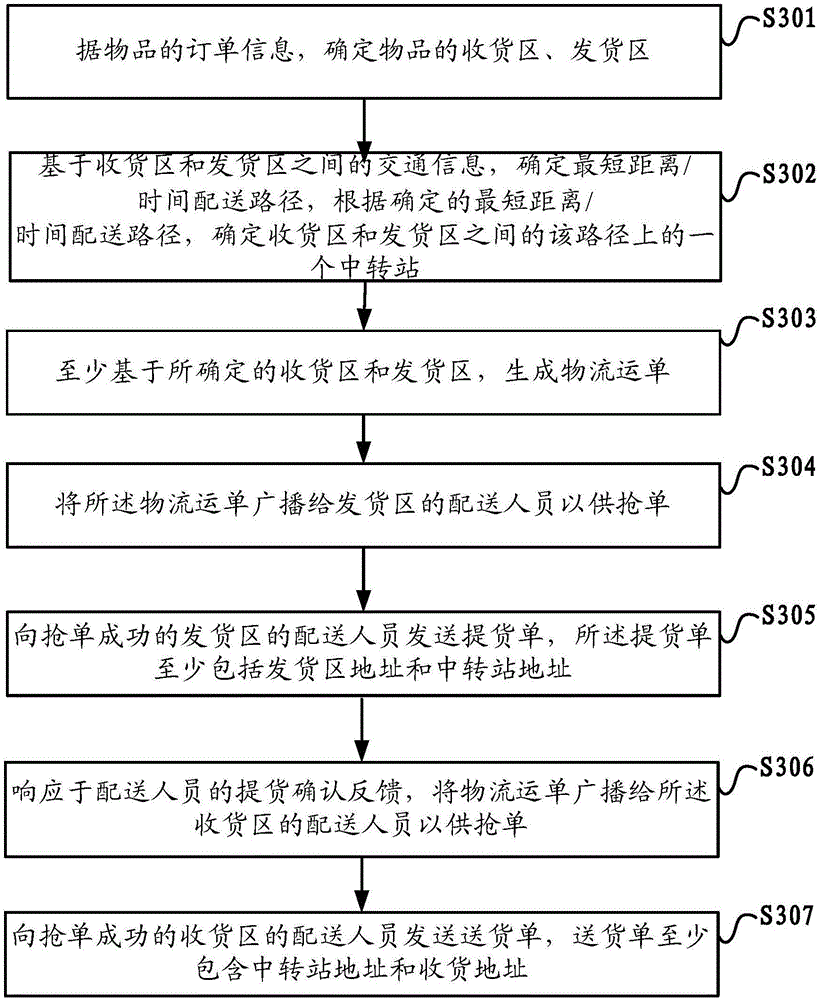

InactiveCN106651242AOrderly and efficient logisticsIncrease delivery speedBuying/selling/leasing transactionsLogisticsLogistics managementControl system

The embodiments of the invention provide a goods logistics control method and a goods logistics control system. The method comprises the following steps: determining the receiving area, the shipping area and the transit station between the receiving area and the shipping area of goods according to the order information of the goods; generating a logistics waybill at least based on the receiving area and the shipping area determined; broadcasting the logistics waybill to deliverymen in the shipping area for waybill grabbing; sending a pickup order to the deliveryman grabbing the waybill in the shipping area; and in response to the delivery confirmation feedback of the deliveryman, broadcasting the logistics waybill to deliverymen in the receiving area for waybill grabbing, and sending a delivery order to the deliveryman grabbing the waybill in the receiving area. Through the method and the system provided by the invention, flexible and efficient operation in each region of goods delivery is realized. The functional division of deliverymen is made clear by means of waybill grabbing. The shipping area and the receiving area of cross-area goods are quickly connected through the transit station. The speed of goods delivery is improved greatly. Ordered and efficient circulation of goods is realized.

Owner:CHIGOO INTERACTIVE TECH

Device for jointing dust removing air pipes of movable discharging carriage, dust removing system and method for jointing air pipes

The invention discloses a device for jointing dust removing air pipes of a movable discharging carriage, which comprises a fixed jointing pipe fixed on a main air pipe in a factory, and a movable jointing pipe arranged on the movable discharging carriage. The jointing ends of at least one of the two kinds of jointing pipes are provided with elastic flexible sections, and the two kinds of jointing pipes are mutually pressed and closely contacted through the elastic flexible sections when the two kinds of jointing pipes are jointed. The device has the advantages of simple structure, capability of avoiding jointing gaps, no air drafting pressure loss, good dust removing effects, and improvement on operational environment of workers. The invention also discloses a dust removing system of the movable discharging carriage, and the system is provided with the device for jointing the dust removing air pipes of the movable discharging carriage. The invention also discloses a method for jointing the dust removing air pipes of the movable discharging carriage. According to the method, the jointing is realized by using the device for jointing the dust removing air pipes of the movable discharging carriage, the movable discharging carriage drives to a discharging point during jointing, and the movable jointing pipe and the fixed jointing pipe are mutually pressed so as to form sealing by using elasticity of the elastic flexible sections.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

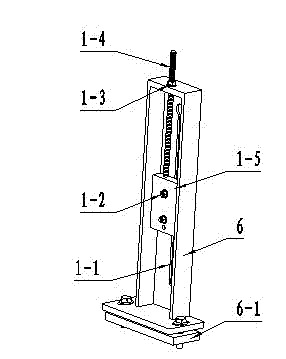

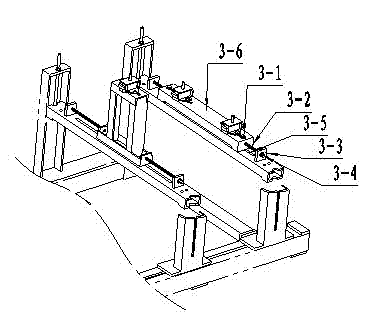

Quick centering device for engine pedestal test

The invention provides a quick centering device for an engine pedestal test, which is used for quickly centering the crankshaft flywheel end of an engine to a main shaft of a dynamometer. The quick centering device comprises a base, a supporting frame, a beam and a quick plug panel, wherein the supporting frame comprises four groups of vertical supports which are all assembled to the base; an up-down adjusting mechanism is arranged on the vertical support in each group; beams are arranged between each two opposite groups of vertical supports; the up-down adjusting mechanisms are assembled to the beams; a front-back adjusting mechanism is arranged on each beam; rubber engine support seats are fixedly arranged on the front-back adjusting mechanisms; and a fine left-right adjusting mechanism is also arranged at the front and rear ends of each beam. The quick centering device allows the centering adjustment on the crankshaft flywheel end of the engine and the main shaft of the dynamometer in the engine pedestal test to be easy, is high in adjustment precision, eliminates the shortcomings of the conventional centering way of beating through a heavy object such as an iron hammer, avoids the waste of a pedestal resource when the centering operation is performed in a laboratory, and can realize quick butt-joint of water channels, oil channels and sensor lines and improve the working efficiency.

Owner:BAODING WEIYI AUTOMOBILE CO LTD

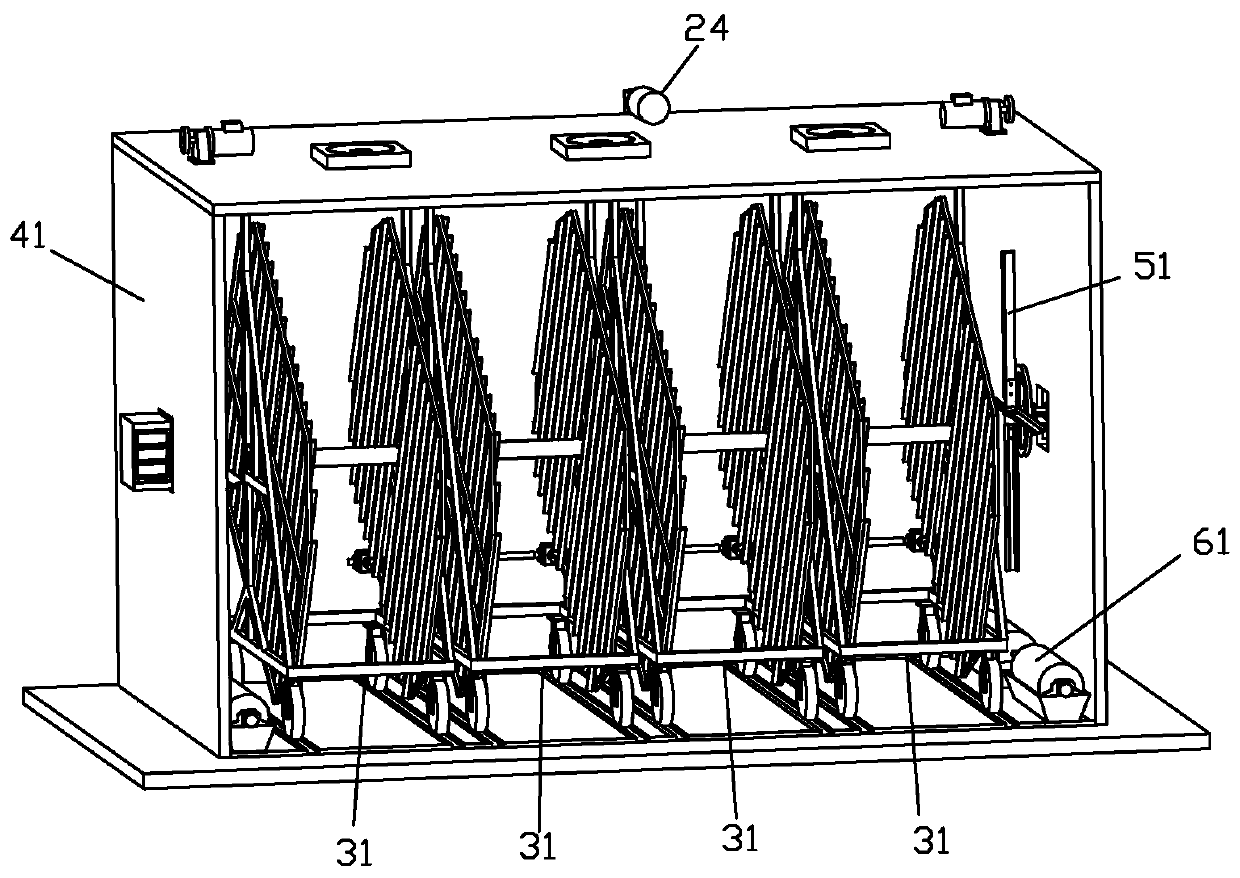

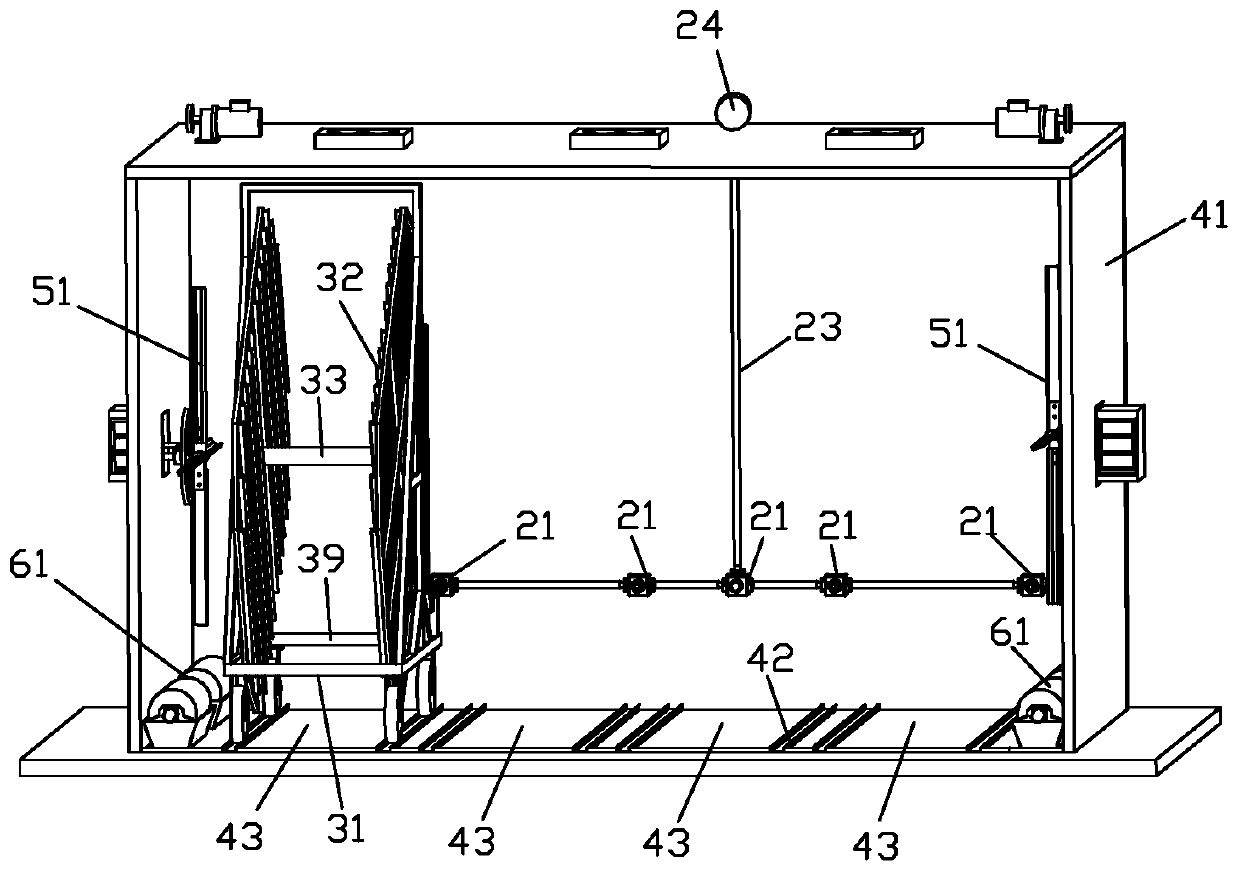

Movable egg car hatcher

The invention discloses a movable egg car hatcher which comprises an incubator, a hatching adjustment system, at least one egg rack, at least one movable egg car, a power source and a transmission shaft component. The egg racks are erected on the corresponding movable egg cars in a suspended manner through rotating spindles, transmission mechanisms are arranged on the movable egg cars, parking spaces corresponding to the movable egg cars are arranged in the incubator, both the transmission shaft component and the power source are fixedly mounted on the incubator, the power source is connectedwith an input shaft of the transmission shaft component, the transmission shaft component is provided with output shafts corresponding to the parking spaces, a fixed butt joint part is arranged at theend of each output shaft, a butt joint shaft connected with the transmission mechanism of each movable egg car is arranged on each movable egg car, and a movable butt joint part is arranged at the end of each butt joint shaft. The movable egg car hatcher is reasonable in structure and simple to operate.

Owner:佛山市任氏机械科技有限公司

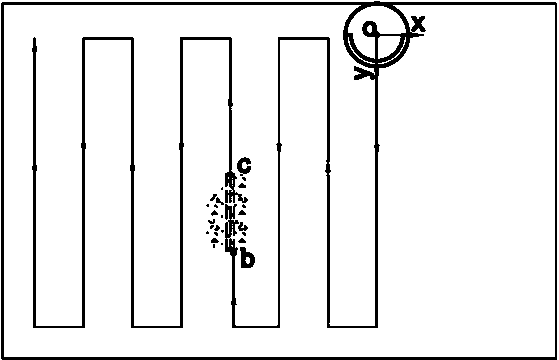

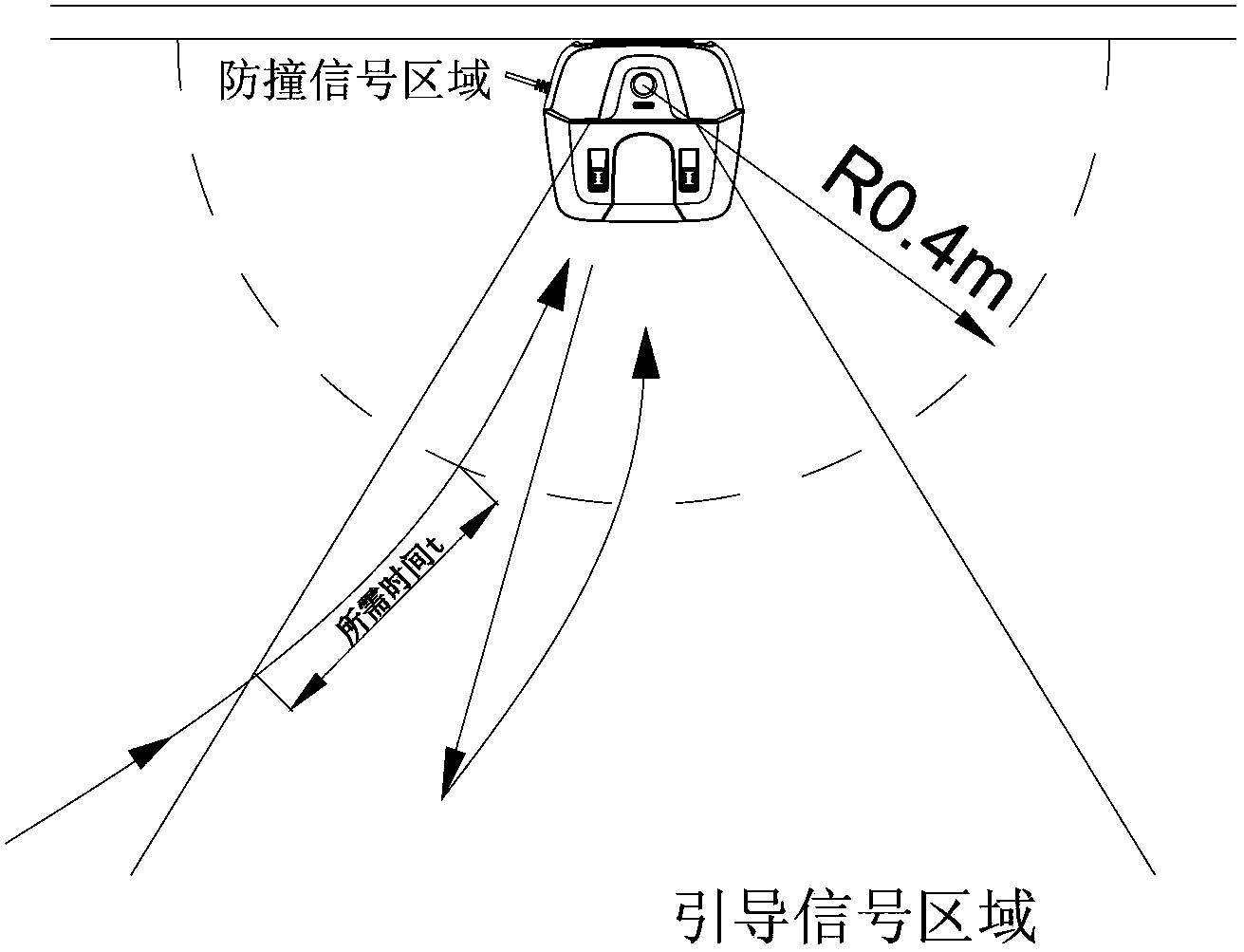

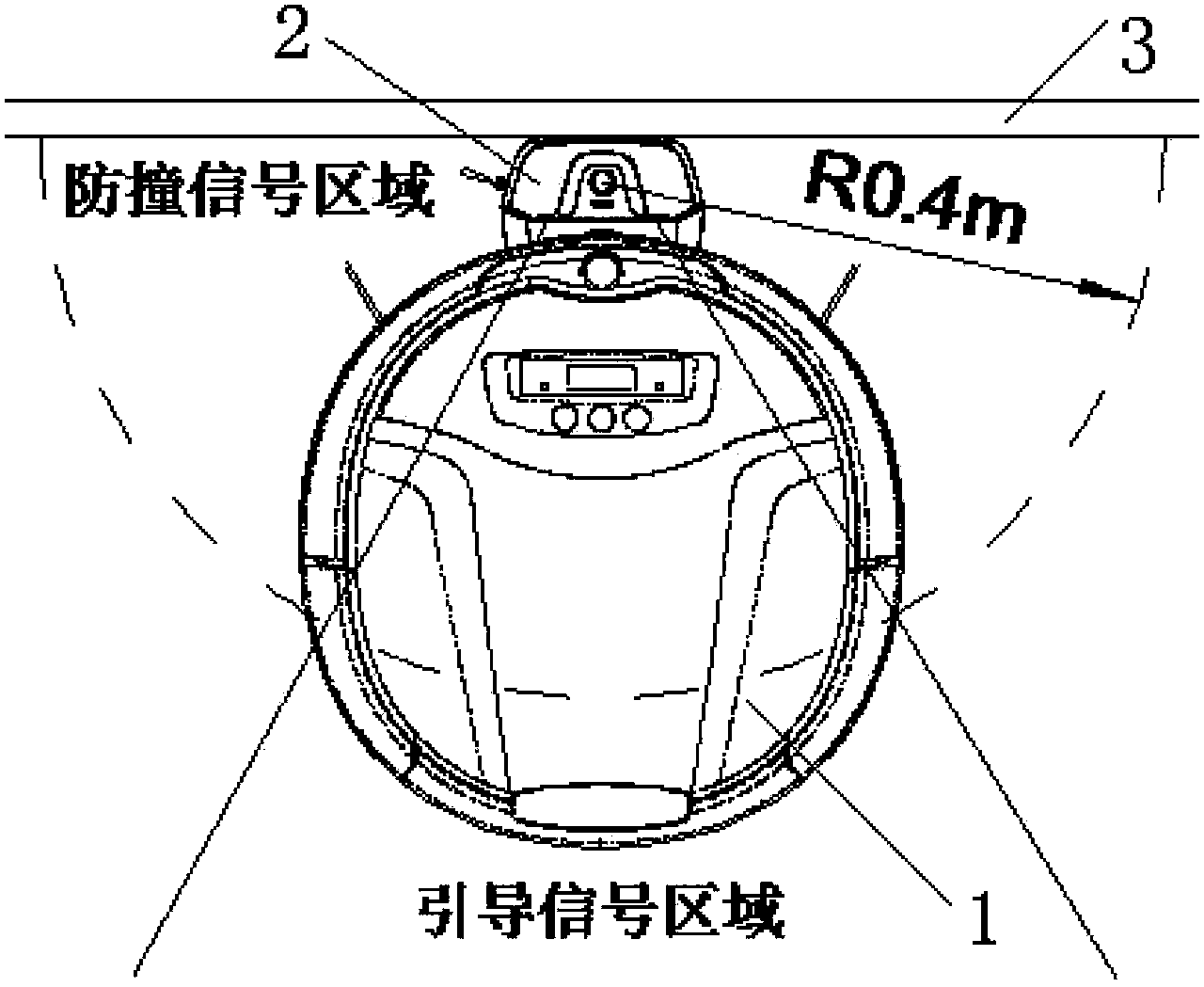

Method for optimizing butt-joint position of robot type dust collector in charging and returning process

ActiveCN103356136AImprove work efficiencyQuick dockingElectric equipment installationTime differenceButt joint

The invention discloses a method for optimizing a butt-joint position of a robot type dust collector in a charging and returning process. The method comprises the following steps that a charge seat for charging the robot type dust collector transmits an anti-collision signal about a semicircular signal area and a guiding signal about a sector-shaped signal area outside; when the robot returns and charges, the time difference t when the robot receives the guiding signal and the anti-collision signal is less than or equal to 10s, so that the robot backs up for a distance d and resets a butt-joint program; and if the t is larger than 10s, the butt joint is carried out according to the normal situation. According to the method for optimizing the butt-joint position of the robot type dust collector in the charging and returning process, which is disclosed by the invention, the position of the robot type dust collector is regulated according to the time difference when the robot type dust collector in the returning and charging process receives the guiding signal and the anti-collision signal, so that the dust collector can quickly finish the charge and return operation and the working efficiency of the dust collector is improved.

Owner:KINGCLEAN ELECTRIC

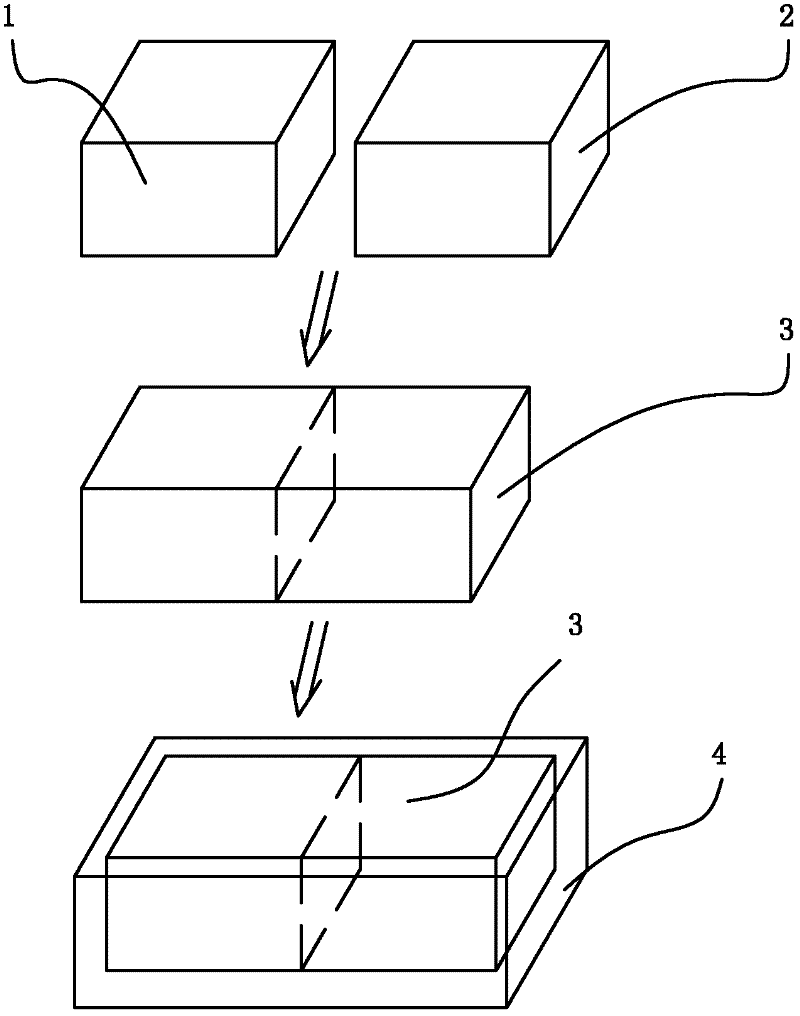

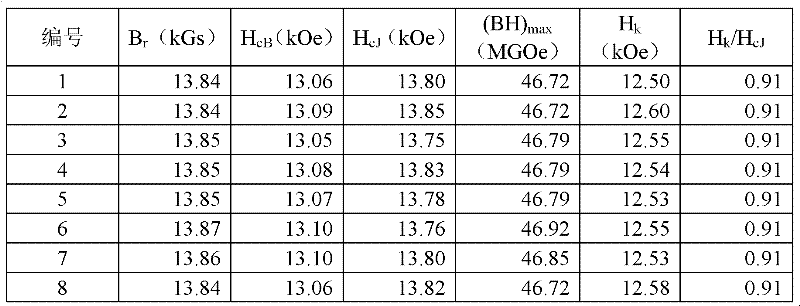

Method for preparing bulk sintered Nd-Fe-B permanent magnet material

ActiveCN102233428AHigh precisionMagnetic properties are stableInorganic material magnetismVacuum furnaceMicrometer

The invention discloses a method for preparing a bulk sintered Nd-Fe-B permanent magnet material. The method comprises the following steps of: preparing fine powder with the average particle size of 2.9 to 3.3 micrometers from raw materials which are prepared according to a required formula; adding the fine powder into a metal die cavity of a molding pressing machine; and arranging a molding magnetic field to ensure that the fine powder is prepared into a patch raw blank in a compression molding way under an electromagnetic induction oriented magnetic field. The method is characterized by comprising the following steps of: selecting at least two patch raw blanks; selecting the joint surfaces of the patch raw blanks on the premise of ensuring the consistent orientation of all patch raw blanks; clearing Nd-Fe-B attached powder on the joint surfaces of all the patch raw blanks; performing butt joint on all the patch raw blanks; putting the butt-jointed raw blanks into a die box made of rubber; performing vacuum encapsulation on the die box; keeping the pressure of an encapsulation body under the isostatic pressure of 180 to 220MPa for 8 to 13 seconds; taking the butt-jointed raw blank combination body out; transferring into a sintering basin; and sintering in a vacuum furnace to form a compact bulk Nd-Fe-B blank body. The invention has the advantages that: the bulk sintered Nd-Fe-B permanent magnet material can be produced by the conventional universal equipment, and has high precision, stable magnetic performance and low preparation cost.

Owner:NINGBO YUNSHENG +2

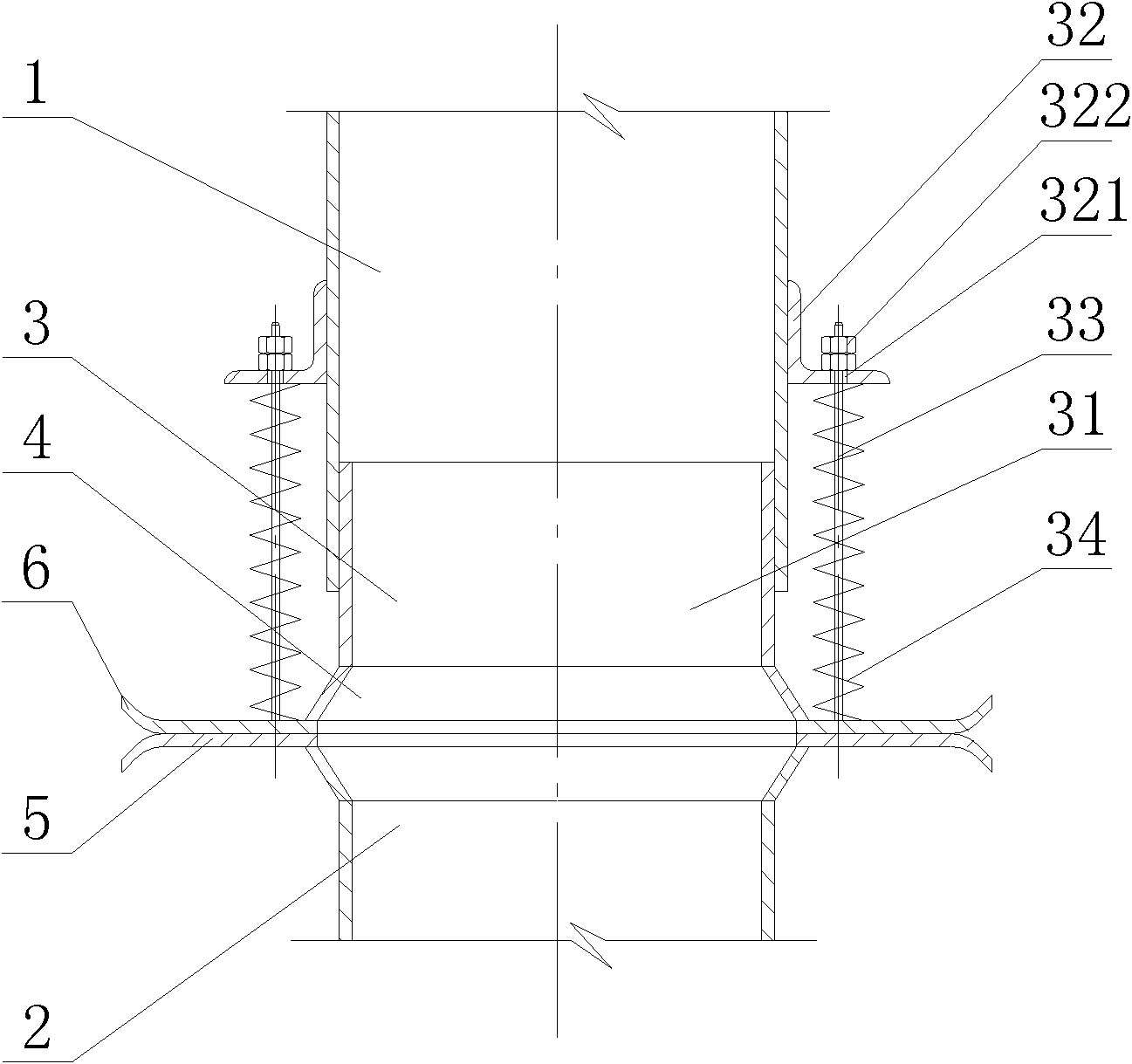

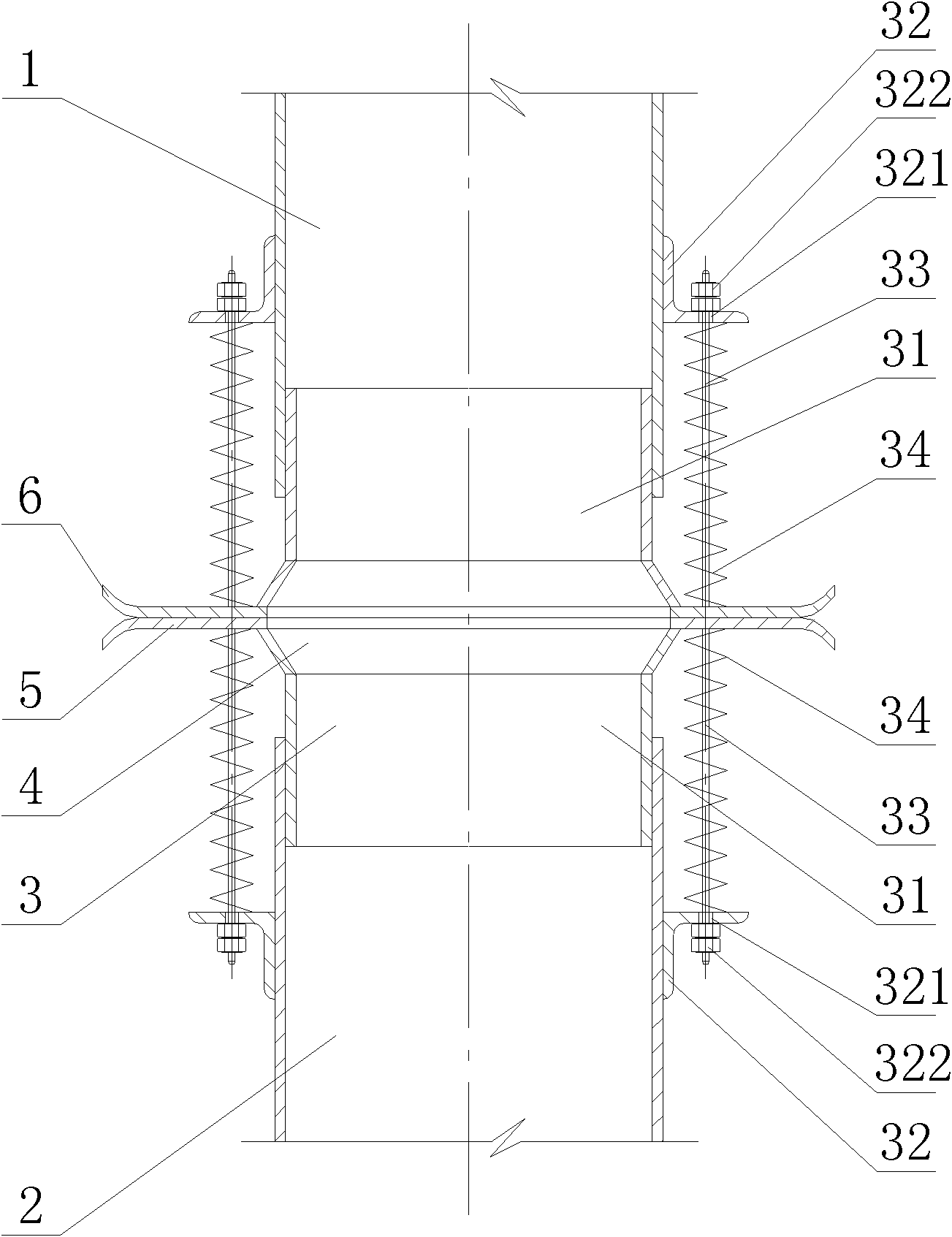

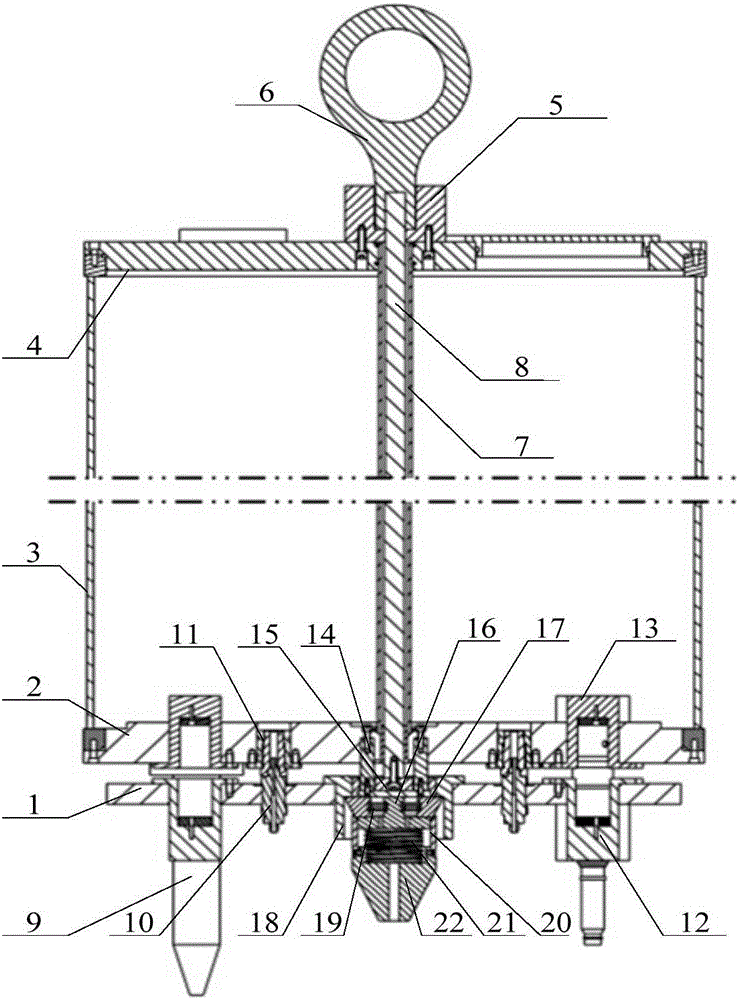

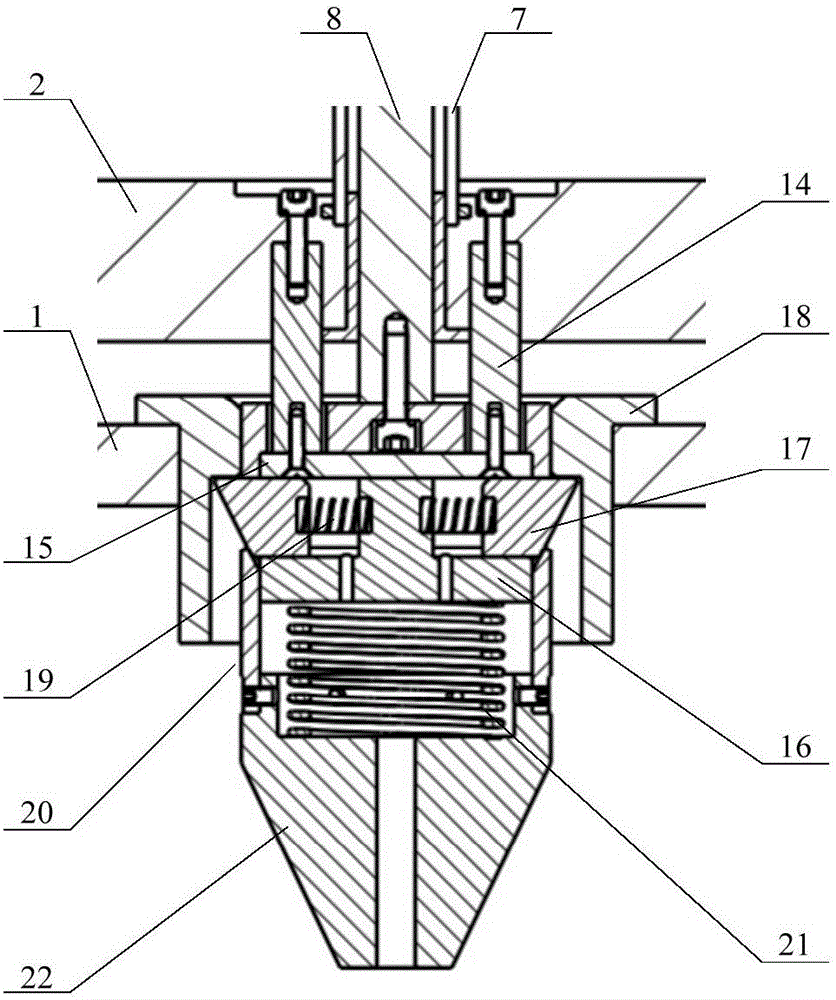

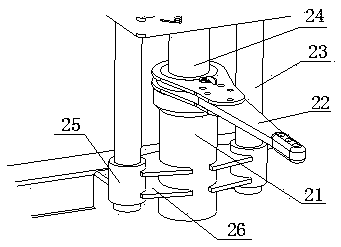

Spring type automatic locking device for underwater control module

ActiveCN106275330ASolve the problem of frequent stuckSolve the problems of low transmission efficiency and poor stabilityUnderwater equipmentUnderwaterButt joint

The invention provides a spring type automatic locking device for an underwater control module. The spring type automatic locking device mainly comprises a ring, a guide sleeve, a center shaft, a support column, an inner locking sleeve, a fixed cover, a lock core, a sliding block, a locking spring, a return spring an outer locking sleeve and a guide head and is used for butt joint, locking and unlocking of an upper connection disc and a lower connection disc of the underwater control module. After butt joint, the ring is released, automatic locking is achieved under the action of the locking spring and the return spring, and thus breakover of the underwater control module with electric and liquid functional elements and the like of underwater production equipment in an inserting-connecting mode is achieved, and the positions of all the functional elements are kept fixed. When the underwater control module needs maintenance and replacement, automatic unlocking can be achieved by pulling the ring directly through a manipulator on an ROV. The difficult technical problems of too long consumed time and difficult locking of the operation process when locking and unlocking are conducted by a torque tool through the ROV. The spring type automatic locking device is compact in inner structure and suitable for operation in a deepwater environment, and the butt joint, locking and unlocking efficiency is improved significantly.

Owner:HARBIN ENG UNIV

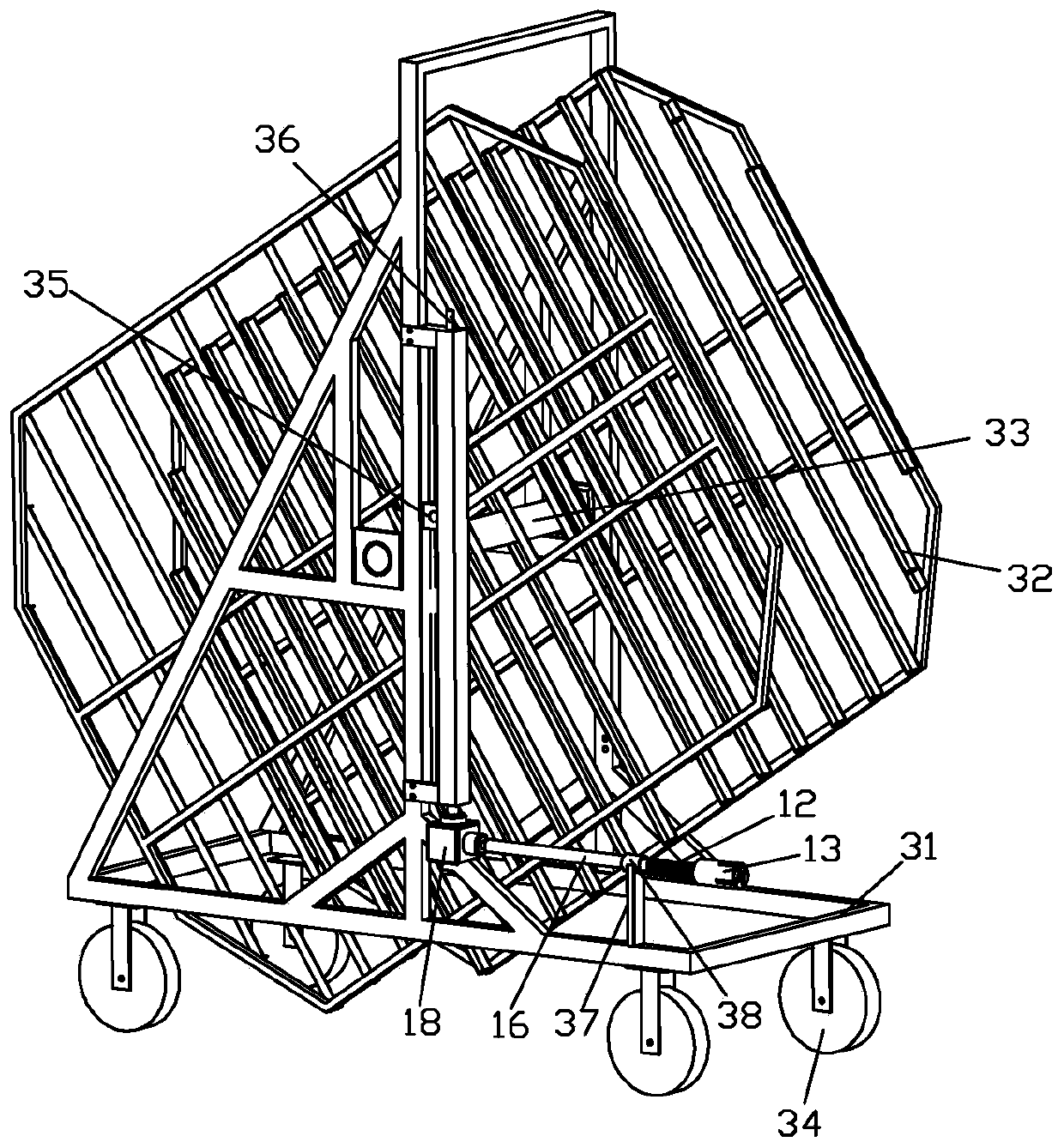

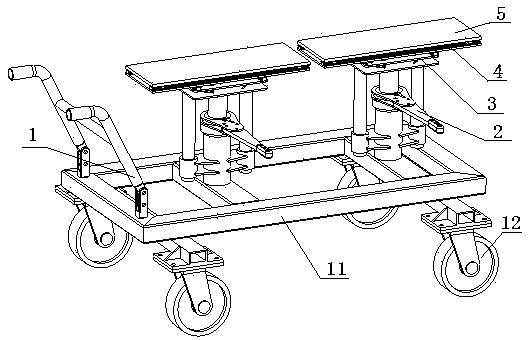

Multi-degree-of-freedom missile bay section butt joint device

The invention discloses a multi-degree-of-freedom missile bay section butt joint device. The multi-degree-of-freedom missile bay section butt joint device comprises a vehicle body and a butt joint system. The vehicle body comprises a vehicle frame and wheels. The wheels are installed under the vehicle frame. The butt joint system is installed on the vehicle frame and comprises lifting mechanisms, posture adjustment mechanisms, feeding mechanisms and supporting mechanisms. The lifting mechanisms used for lifting missile bay sections are fixed to the vehicle frame. The lifting mechanisms are sleeved with one ends of the posture adjustment mechanisms, and the other ends of the posture adjustment mechanisms are connected with the feeding mechanisms. The supporting mechanisms are installed on the feeding mechanisms. According to the multi-degree-of-freedom missile bay section butt joint device, the advantages of a hoisting butt joint mechanism and the advantages of a lead screw and nut butt joint mechanism are combined; a flexible butt joint form is adopted, and adjustment of the butt joint postures of the missile bay sections is achieved through ball hinge assemblies and limiting assemblies; operation is flexible and easy, and butt joint can be achieved rapidly, safely and reliably; in addition, the structure is simple, and the manufacturing cost is low; the butt joint system is installed on the vehicle frame, thereby being suitable for being transferred from one site to another site.

Owner:JIANGXI HONGDU AVIATION IND GRP

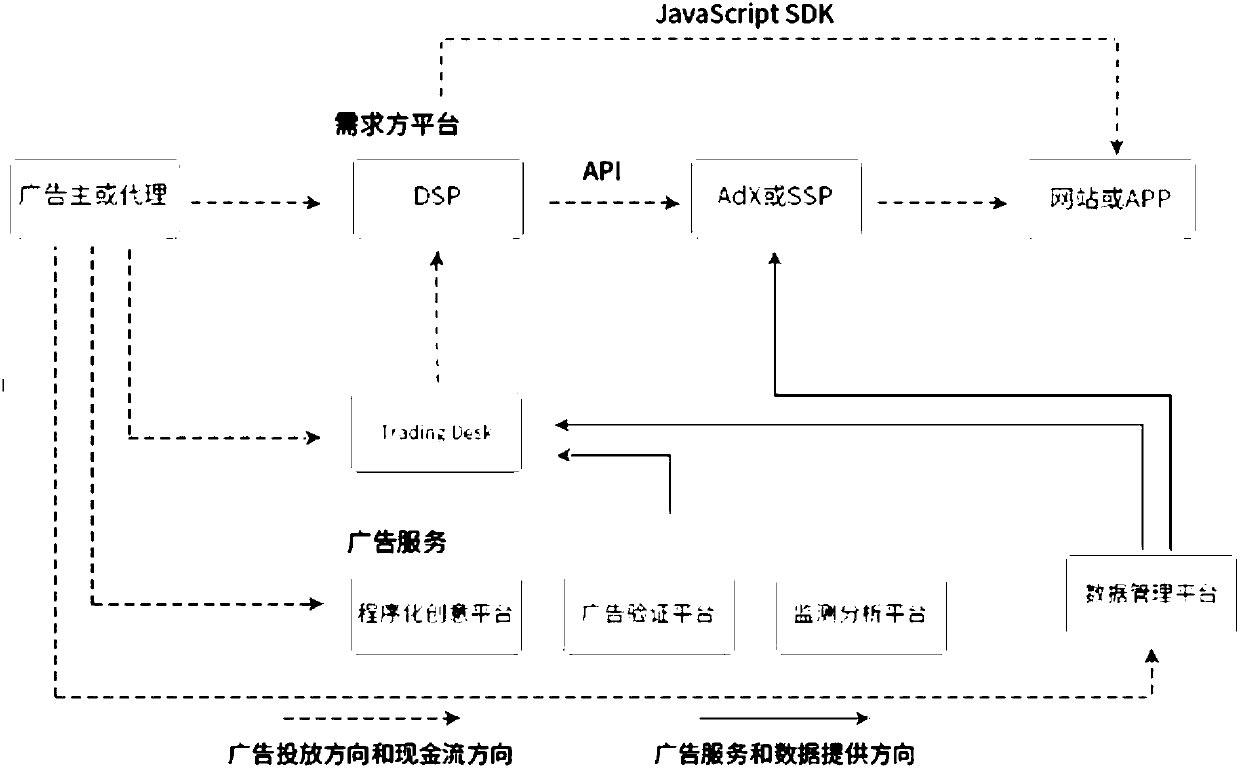

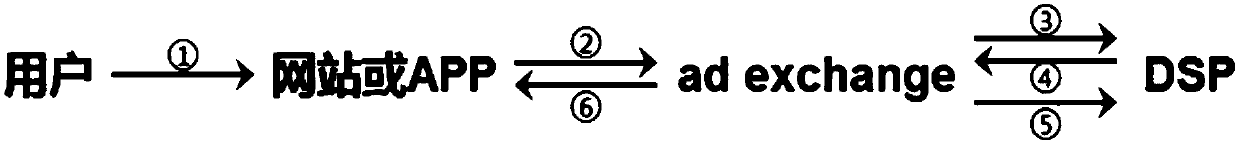

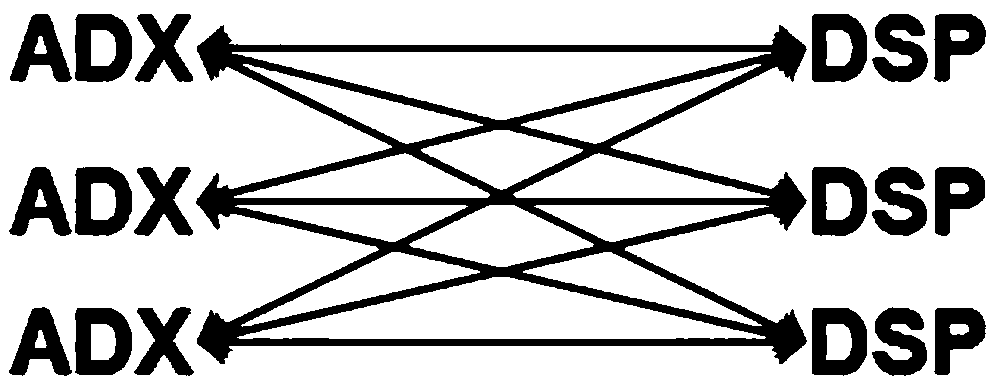

Butting mode reconstructing programmed advertisement ecological chain

ActiveCN108053252ALow costDecrease in bid responseAdvertisementsTransmissionThe InternetComputer science

The invention relates to the technical field of the internet, and discloses a butting mode reconstructing a programmed advertisement ecological chain. The butting mode includes the following steps: ADX receives an advertisement putting request; ADX organizes bidding, and sends a bidding request to BidEx; BidEx forwards the bidding request to DSPs that satisfy screening conditions; the DSPs judge whether to bid after receiving the bidding request, and returning bidding response to BidEx within specified time; BidEx performs internal bidding on a bidding scheme returned by the DSPs, and returning a plurality of bidding schemes to ADX; ADX performs auction according to bidding response of the DSPs, and sends a winning notification to BidEx; BidEx receives the winning notification from ADX, and sends WinNotice to the DSP that bids successfully; and ADX returns a winning advertisement to a media side. The programmed advertisement butting mode provided by the invention has the characteristics of transparency, efficiency, intelligence and stability, improves butting speed, and reducing butting cost.

Owner:广州舜飞信息科技有限公司

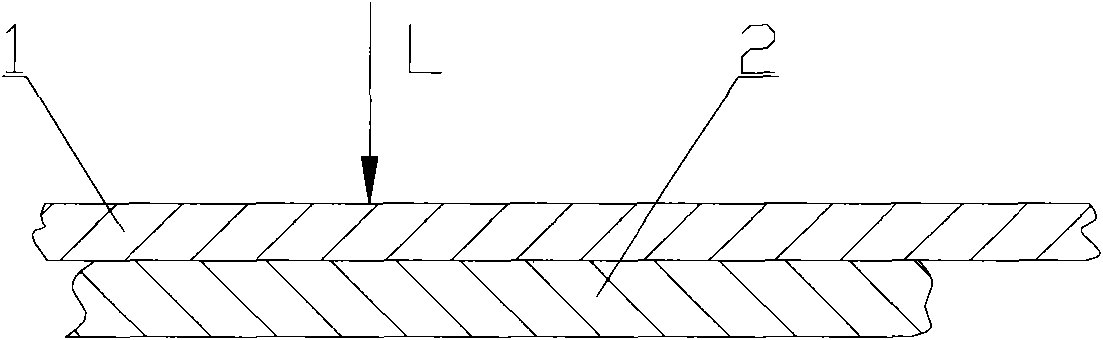

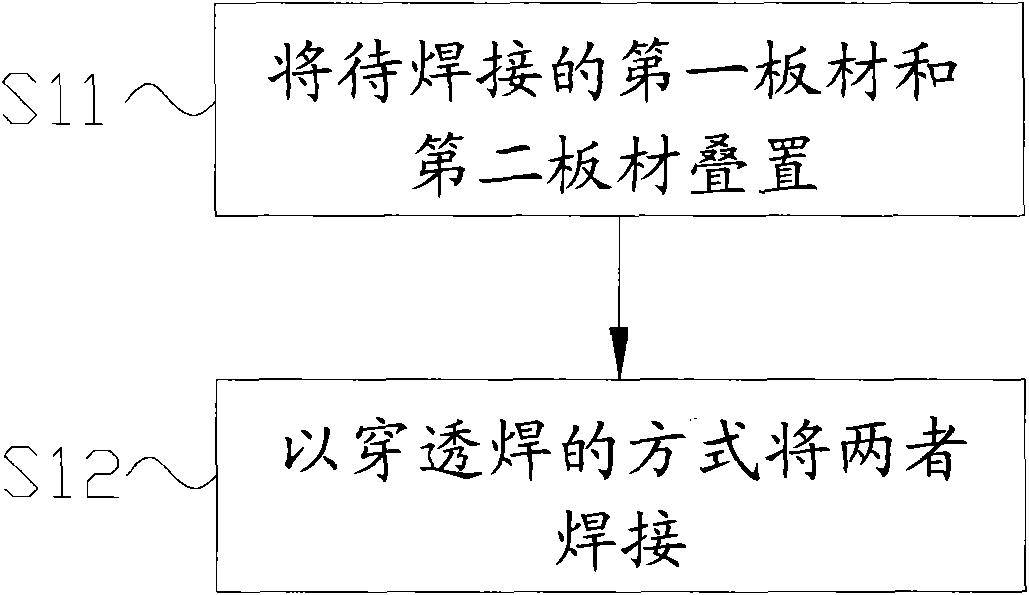

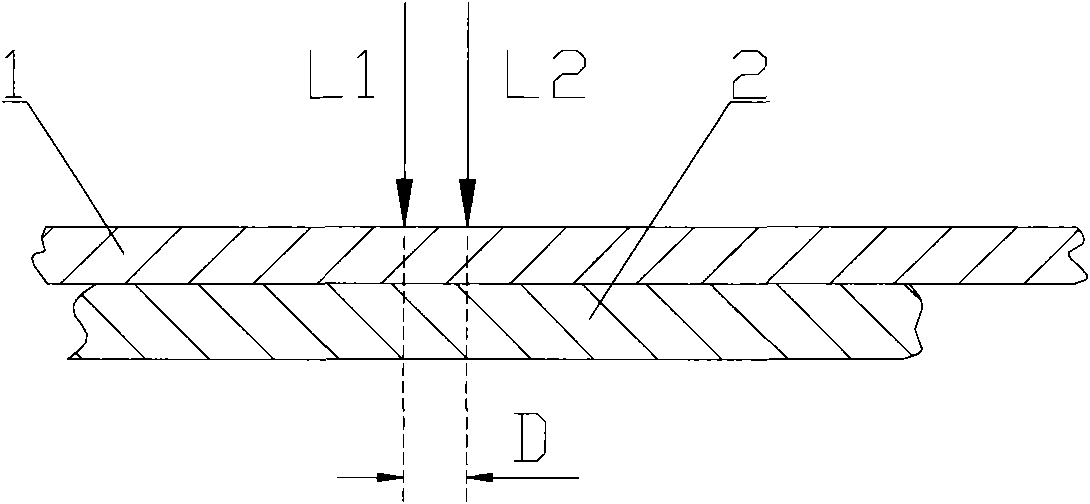

Method for welding plate material of seat of vehicle by laser

ActiveCN101676060AImprove welding effectWelding width widenedWelding/soldering/cutting articlesMetal working apparatusAbsorption rateWeld seam

The invention discloses a method for welding a plate material of a seat of a vehicle by laser, which comprises primary welding and secondary welding which is carried out by the afterheat of the primary welding. The welding seams of the primary welding and the secondary welding are close and have the same extension direction. In the process of the primary welding, a position close to the welding seam of the primary welding is heated, and the temperature of the position is greatly enhanced; then, the secondary welding is carried out on the position with the enhanced temperature, the laser absorption rate of the secondary welding is greatly enhanced, and the welding effect of the secondary welding is surely enhanced obviously. Furthermore, the welding width of the welding operation is remarkably widened due to the existence of the two close welding seams, and the welding effect is further enhanced.

Owner:HUBEI AVIATION PRECISION MASCH TECH CO LTD

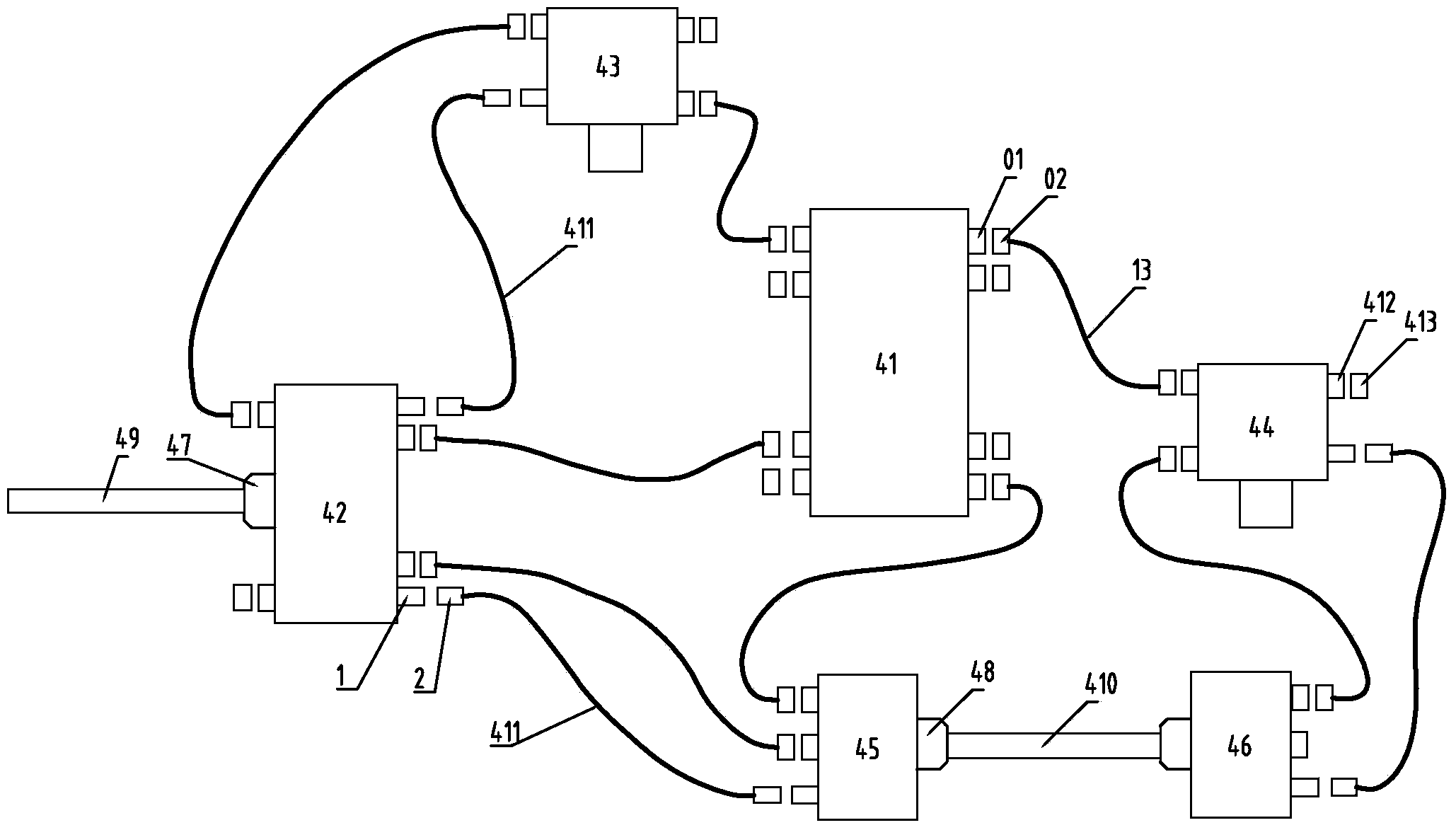

Deep water pipeline multi-circuit bridging system and testing and installing method thereof

The invention discloses a deep water pipeline multi-circuit bridging system and a testing and installing method thereof. The deep water pipeline multi-circuit bridging system comprises a seabed manifold, an underwater electric distribution assembly, a first underwater Christmas tree, a second underwater Christmas tree, a first underwater umbilical cable terminal and a second underwater umbilical cable terminal, wherein the seabed manifold, the underwater electric distribution assembly, the first underwater Christmas tree, the second underwater Christmas tree, the first underwater umbilical cable terminal and the second underwater umbilical cable terminal are connected through a hydraulic bridging wire and a water and gas injection pipeline. The hydraulic bridging wire comprises male connector terminals and female connector terminals matched with the male connector terminals. The testing and installing method of the deep water pipeline multi-circuit bridging system includes the following steps that a leakage test and a flushing test are performed on the male connector terminals and the female connector terminals, after the tests are finished, the water and gas injection pipeline and the hydraulic bridging wire are moved underwater, and the water and gas injection pipeline and the hydraulic bridging wire are installed between underwater equipment respectively through the ROV operation. According to the deep water pipeline multi-circuit bridging system and the testing and installing method thereof, fast connecting and disconnecting between the underwater equipment can be achieved, it is ensured that all key parts and moving portions can be recycled, and the stopping and connecting states of an ROV can be safe and reliable.

Owner:CHONGQING QIANWEI SCI & TECH GRP

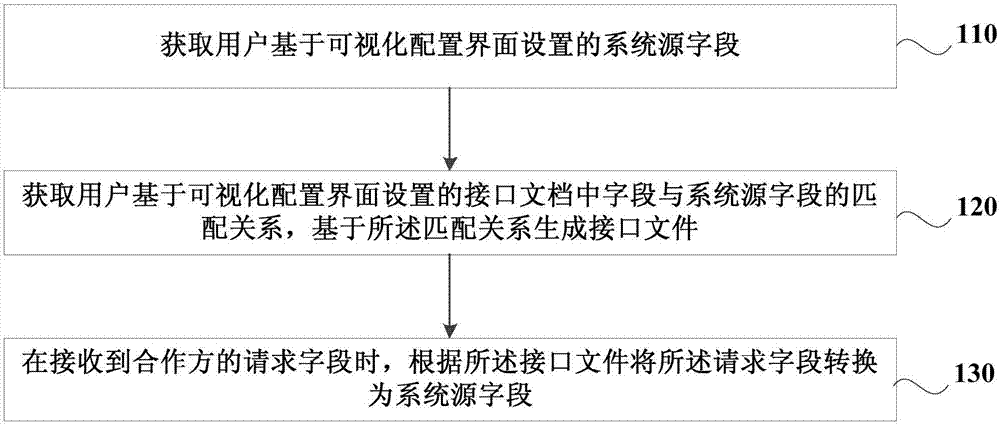

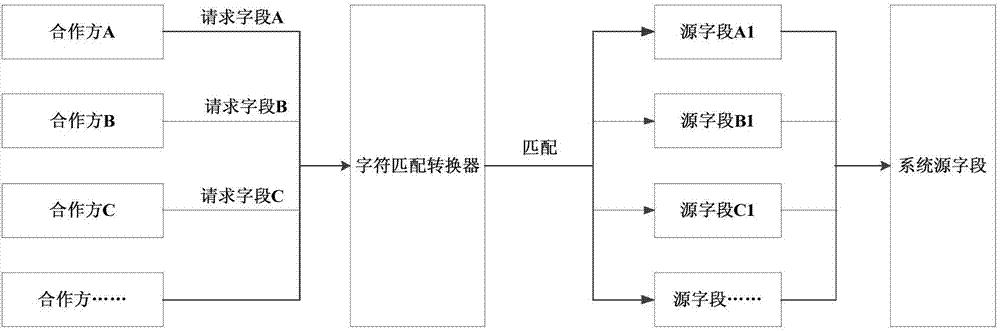

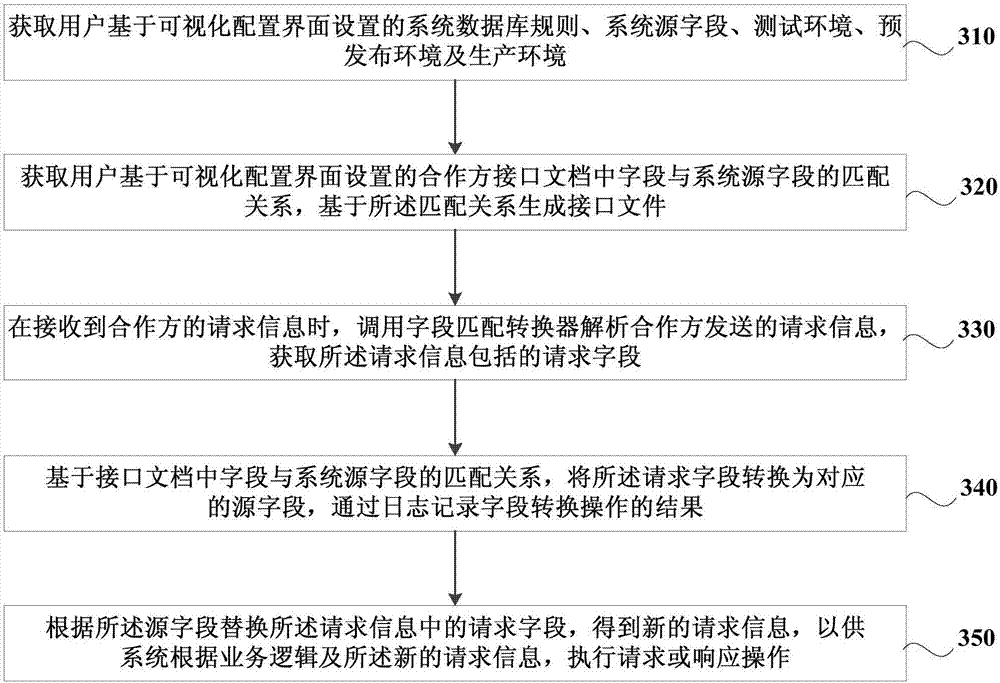

Interface conversion method, interface converter, storage medium and electronic terminal

InactiveCN107463409AReduce maintenance costsQuick dockingProgram loading/initiatingSource fieldComputer science

Embodiments of the present invention disclose an interface conversion method, an interface converter, a storage medium, and an electronic terminal. The method comprises: obtaining a system source field set by a user based on a visual configuration interface; obtaining a matching relationship between a field in an interface document set by the user based on the visual configuration interface and the system source field, and generating an interface file based on the matching relationship; and when receiving a request field from a cooperating party, converting the request field into the system source field according to the interface file for the system to perform a request or response operation according to the business logic. By virtue of the technical scheme of the embodiments of the present invention, the cooperating party can be quickly connected without any modification to the code of the business system so as to realize the seamless connection with the cooperating party; and at the same time, the interface management of the cooperating party is carried out based on the visual configuration interface, the interface maintenance operation process is simplified, and the interface maintenance costs of multiple cooperation parties are reduced.

Owner:SHENZHEN LEXIN SOFTWARE TECH CO LTD

Mobile terminal system based on augmented reality and LBS function

InactiveCN103810356AReduce sizeQuick responseLocation information based serviceSpecial data processing applicationsGraphicsComputer terminal

The invention discloses a mobile terminal system based on the augmented reality and the LBS function. The mobile terminal system based on the augmented reality and the LBS function is characterized in that a PC or a workstation serves as a system operation platform in the development and application of the AR all the time mainly because the PC and the workstation have the strong computing power and the graphic display capacity; according to the AR, a client terminal and a server are used for undertaking the calculating task and the processing task respectively, processing of a rendering part and processing of a display part are transplanted into a mobile terminal, the system augments a target by recognizing the target observed by a user, initial recognition of the target is performed by the server, an initial recognition result is sent to the client terminal, and accurate recognition and rendering display of the target are achieved at the client terminal. The mobile terminal system has the advantages of high efficiency, universality, implementation, stability, flexibility and the like.

Owner:DALIAN LITIAN SCI & TECH

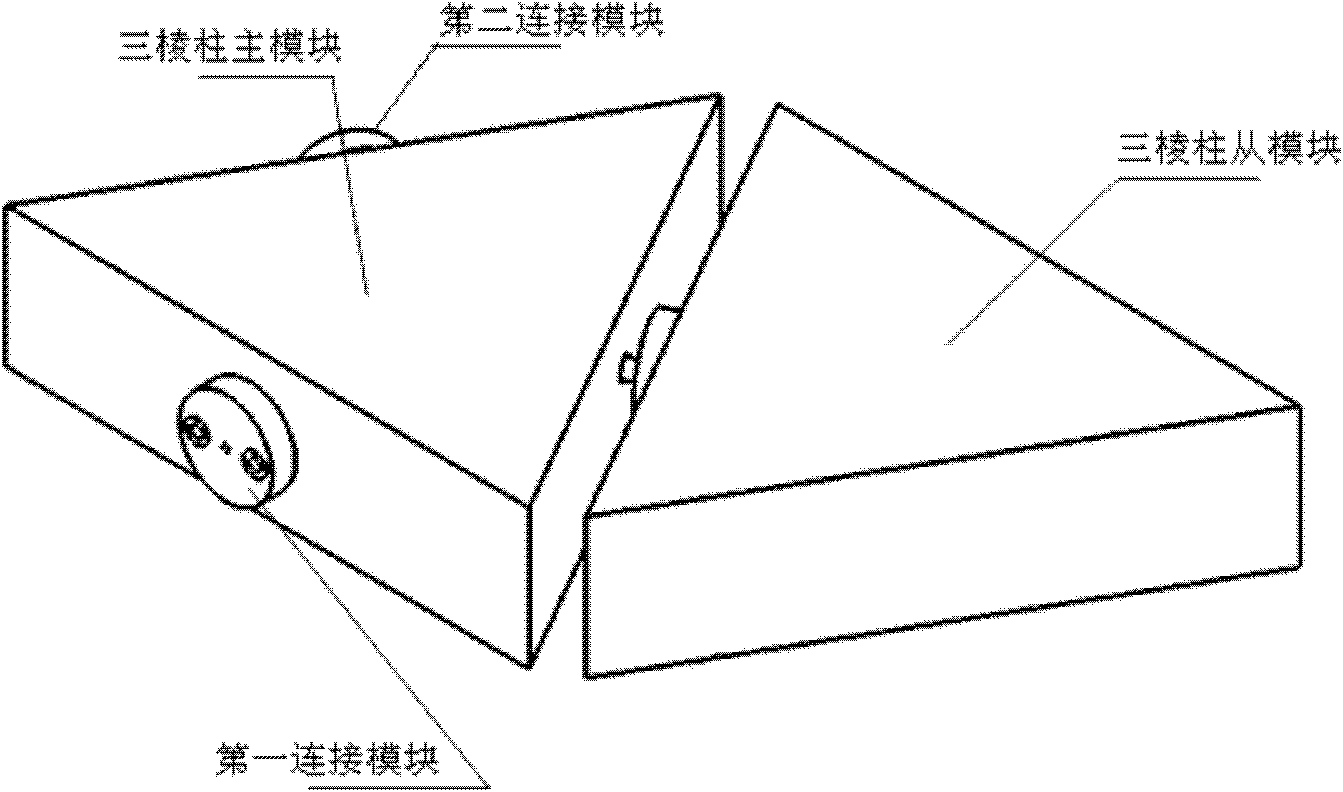

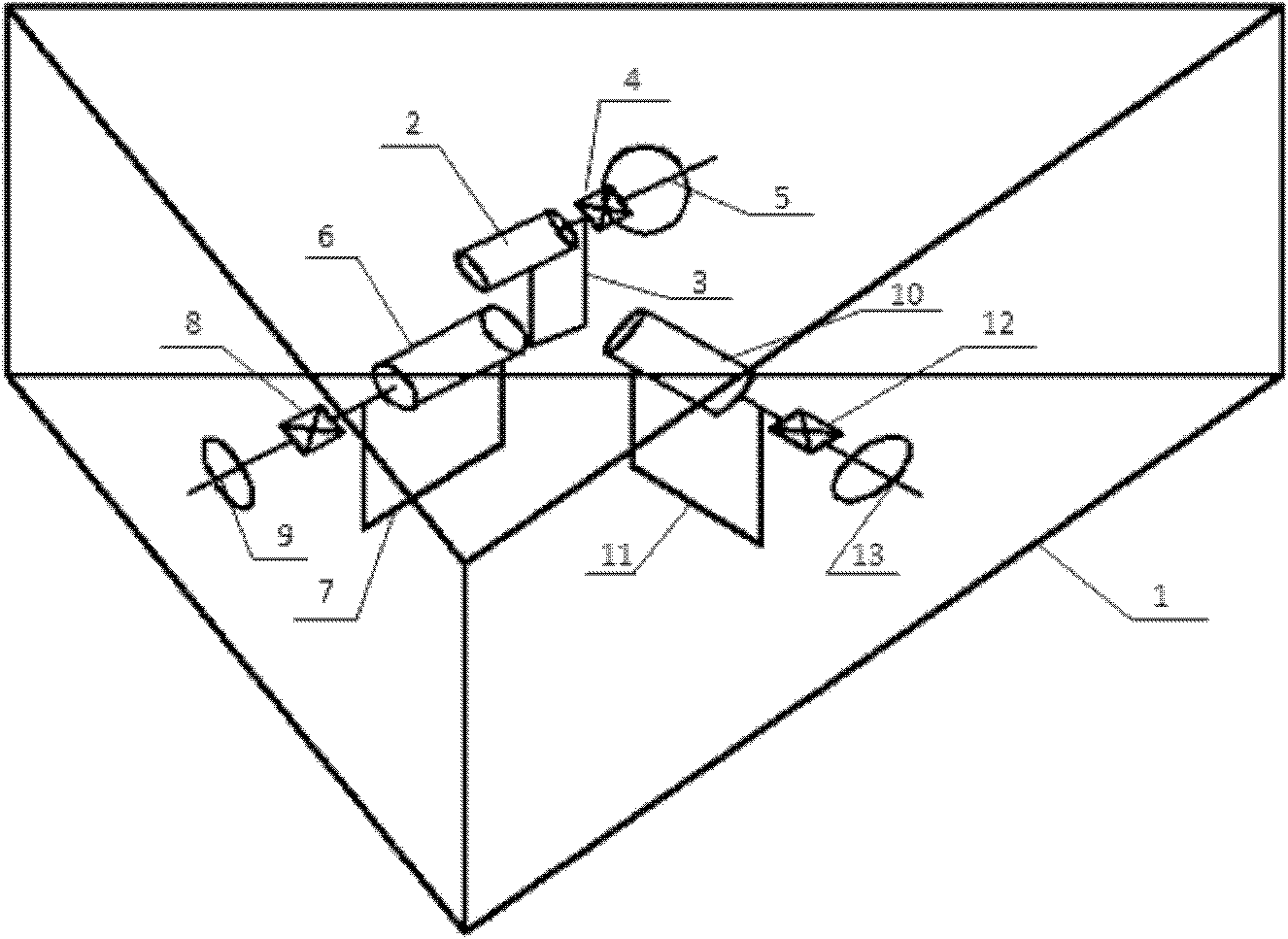

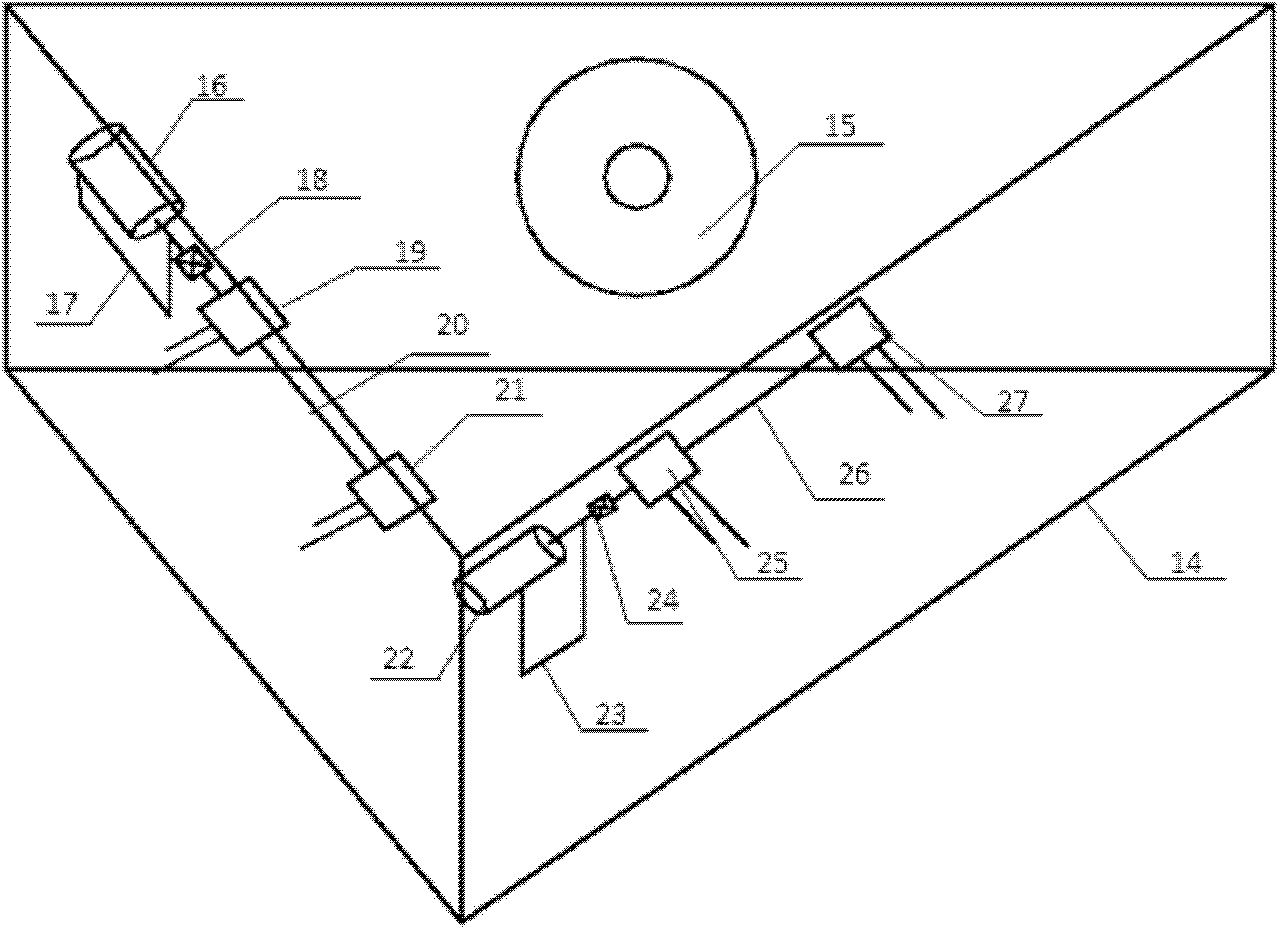

Master-slave modular robot

The invention provides a master-slave modular robot in the technical field of electromechanical engineering, which comprises a plurality of robot units. Each robot unit is connected with four adjacent robot units respectively and comprises a triangular-prism master module, a triangular-prism slave module and two connecting modules, wherein one side face of the triangular-prism master module is fixedly connected with one side face of the triangular-prism slave module; the other side faces of the triangular-prism master module are connected with a connecting module; and the other two side faces of the triangular-prism slave module are connected with the connecting modules of adjacent robot units. The connecting modules used in the invention can rapidly realize reliable connection of the modules; and rapid assembly, replacement, maintenance and functional expansion of different robot modules can be realized by modularizing the robot modules, so the manufacturing cost is remarkably lowered.

Owner:SHANGHAI JIAO TONG UNIV

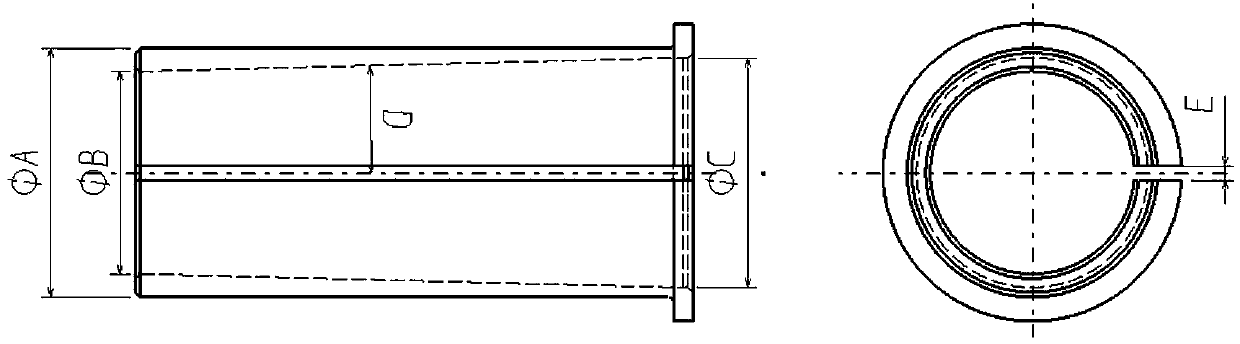

Design method for vertical tail docking structure

InactiveCN103625631AMeet the use requirementsReduce the amount of connection processingAircraft stabilisationFuselagesMaintainabilityEngineering

The invention provides a design method for a vertical tail docking structure. The design method is characterized in that an amount of single lug joints are respectively arranged at the root of a vertical tail at two sides of a course, a same amount of double lug joints are correspondingly arranged at a docking structure of the vertical tail, the diameters of holes in the single lug joints are equal to those of holes in the corresponding double lug joints, the axes of the holes are coaxial, bushes are pressed into docking through holes of the single lug joints and the double lug joints, and the single lug joints and the double lug joints are fixedly connected in a bolt connection mode. According to the invention, docking between the box section of a vertical tail composite material and fuselage lugs is realized in multi-point docking manner, so connection processing amount is reduced, connection workload is reduced, docking weight is lowered down, assembling workload is decreased, rapid docking between the vertical tail and a fuselage is realized, and connection of a few points enables the purpose of docking to be achieved and requirements on usage of an airplane to be met; thus, a development period is shortened, production cost is reduced, and maintainability and replaceability of a product are improved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

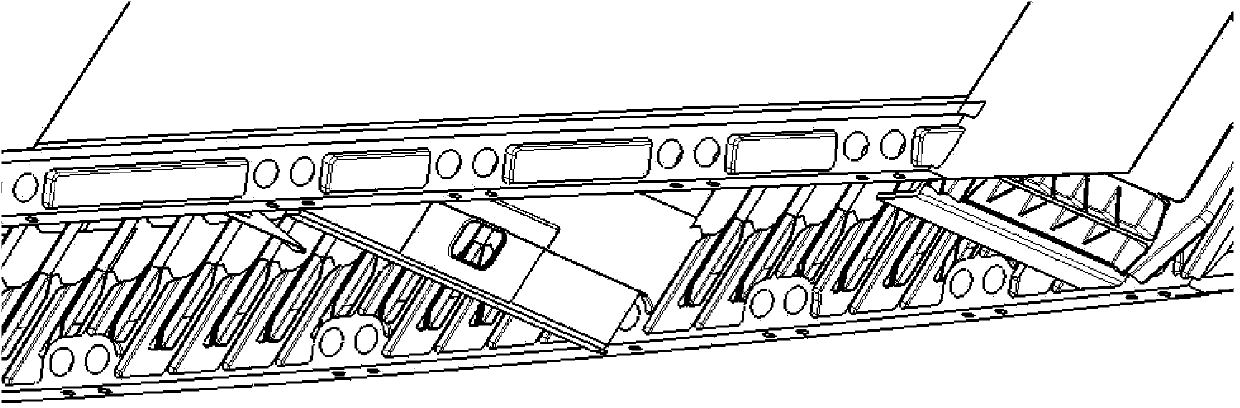

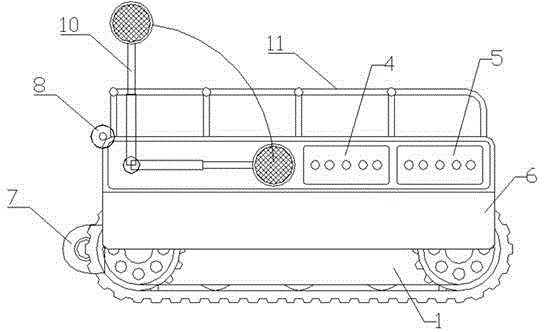

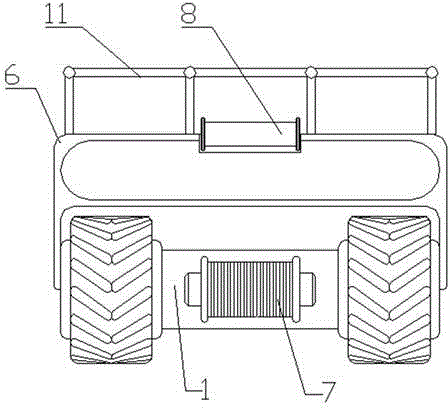

Caterpillar type electric overhaul vehicle

InactiveCN104787135AConvenient for night workStable and reliable placementEndless track vehiclesApparatus for overhead lines/cablesAutomotive engineeringElectric generator

A caterpillar type electric overhaul vehicle comprises a caterpillar type chassis. A power system and a vehicle travel auxiliary system are installed on the caterpillar type chassis. The power system is connected with a caterpillar walking system of the caterpillar type chassis. An electric generator and a hydraulic pump are installed on the caterpillar type chassis and connected with the power system. The output end of the electric generator is connected with a power output quick port and operation board. The output end of the hydraulic pump is connected with a hydraulic output quick port and operation board. A load supporting shell is arranged above the caterpillar type chassis. The power output quick port and operation board and the hydraulic output quick port and operation board are installed on the load supporting shell. A hydraulic winch is arranged on the caterpillar type chassis and installed at the end of the caterpillar type chassis. A goods dragging steering disc for facilitating steel rope motion of the hydraulic winch is arranged at the portion, above the hydraulic winch, of the load supporting shell.

Owner:贵州送变电有限责任公司

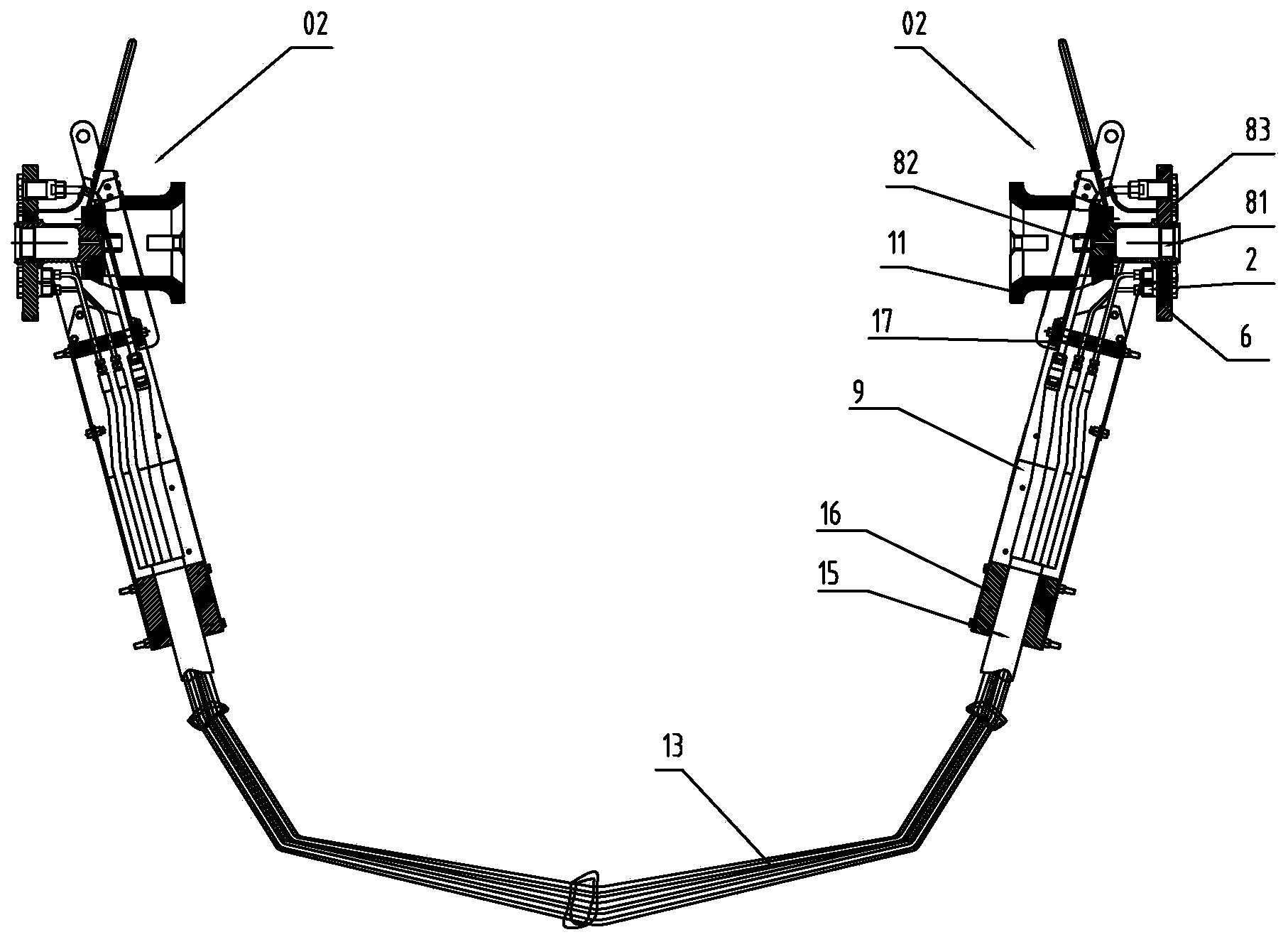

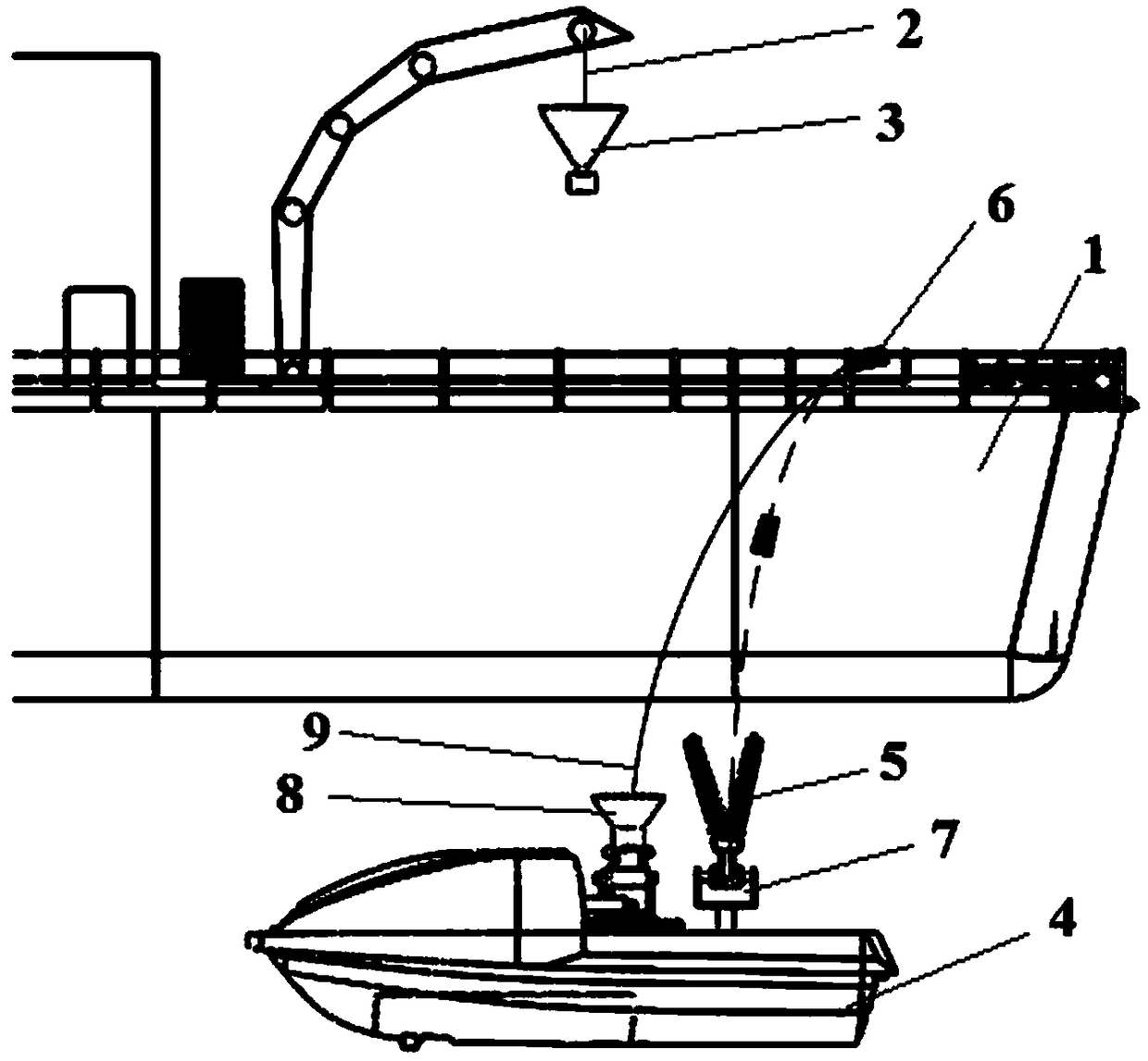

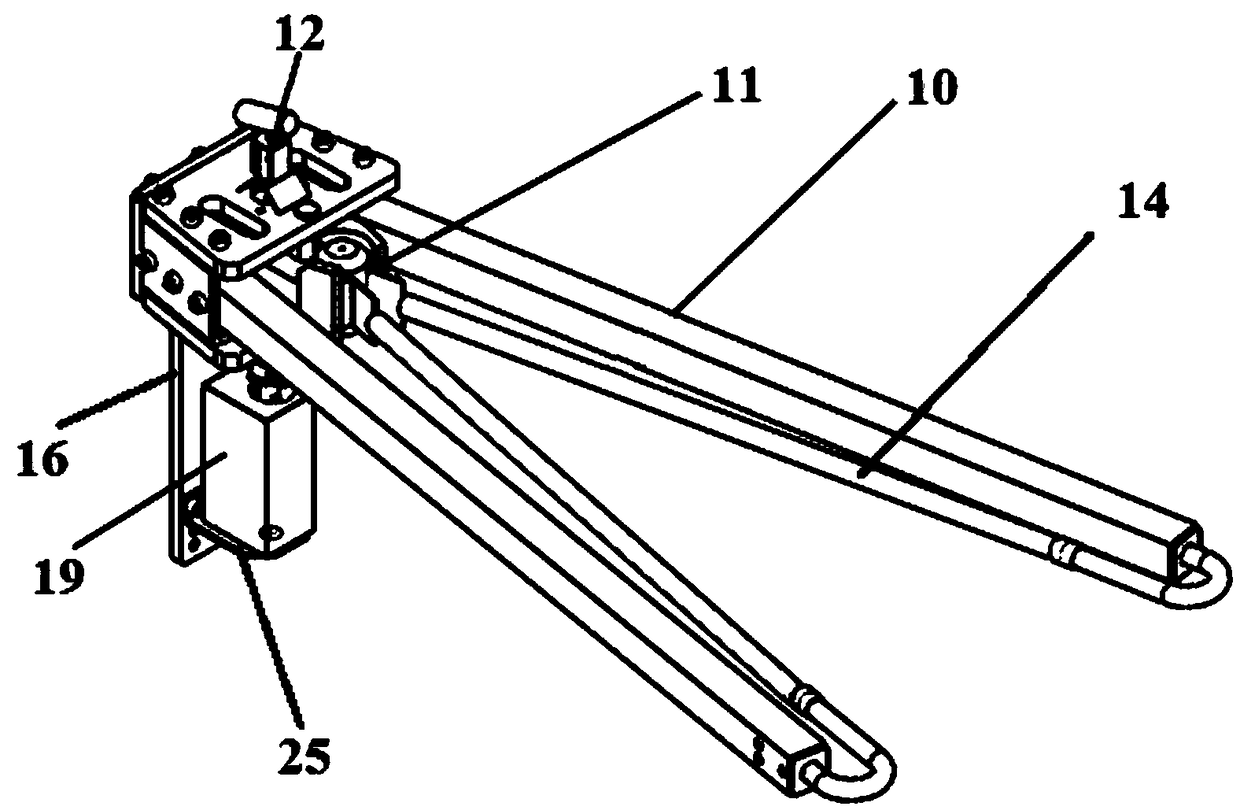

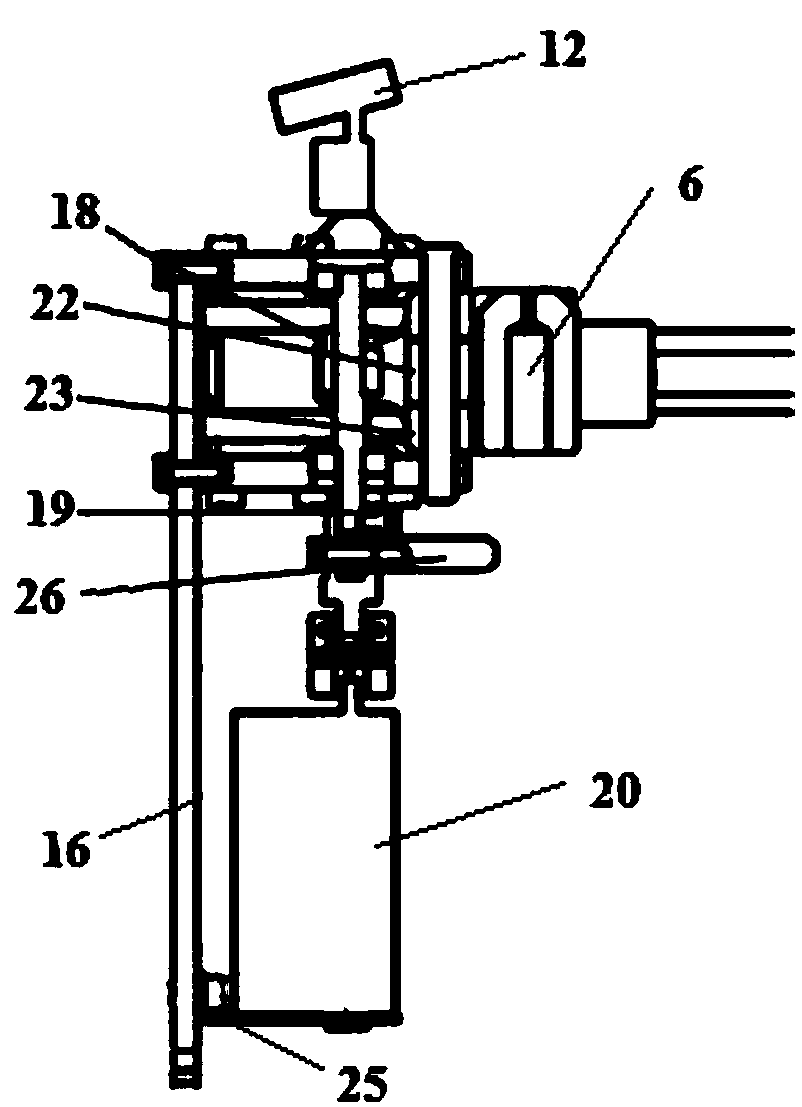

Unmanned ship arrangement and recovery system

ActiveCN108163149AImprove deployment and recovery efficiencyQuick dockingDavitsHoisting/lowering gearButt jointMarine engineering

The invention discloses an unmanned ship arrangement and recovery system which comprises a butt joint connected with a sling of a mother ship and further comprises an ejection mechanism, an ejection head, a cloud deck mechanism, a butt-joint mechanism and a pulling line which are mounted on an unmanned ship. The ejection mechanism is mounted on the cloud deck mechanism, and the cloud deck mechanism is used for adjusting the ejection angle of the ejection mechanism. One end of the pulling line is fixedly connected with the ejection mechanism, and the other end of the pulling line is connected with the ejection head. The pulling line is used for guiding the butt joint to be embedded into the butt-joint mechanism, and the ejection mechanism is used for ejecting the ejection head to the mastership. The butt-joint mechanism is used for fixing the butt joint to fix the unmanned ship to the sling. The unmanned ship arrangement and recovery system can improve the arrangement and recovery efficiency of the unmanned ship.

Owner:SHANGHAI UNIV

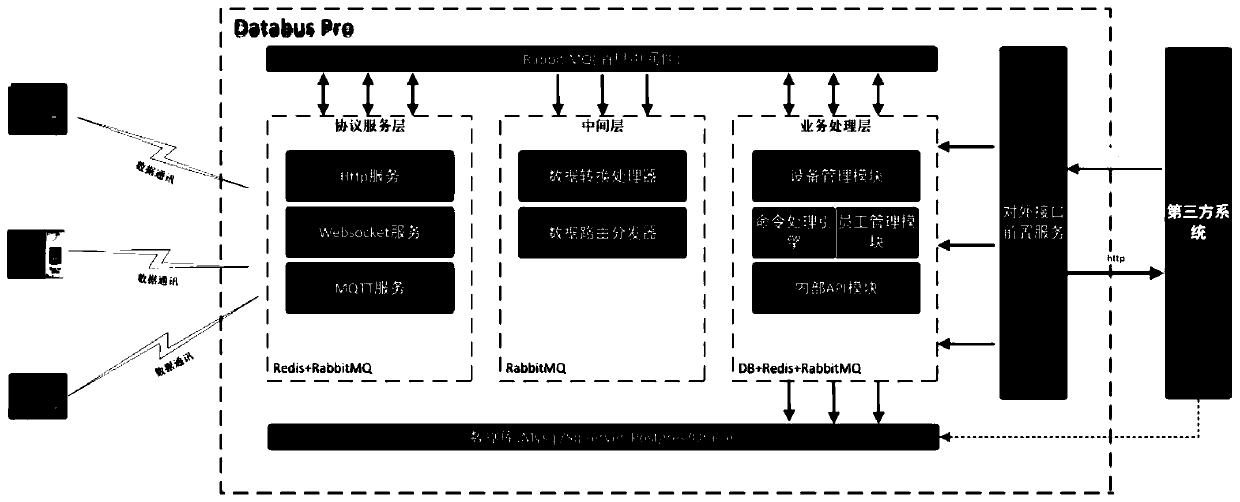

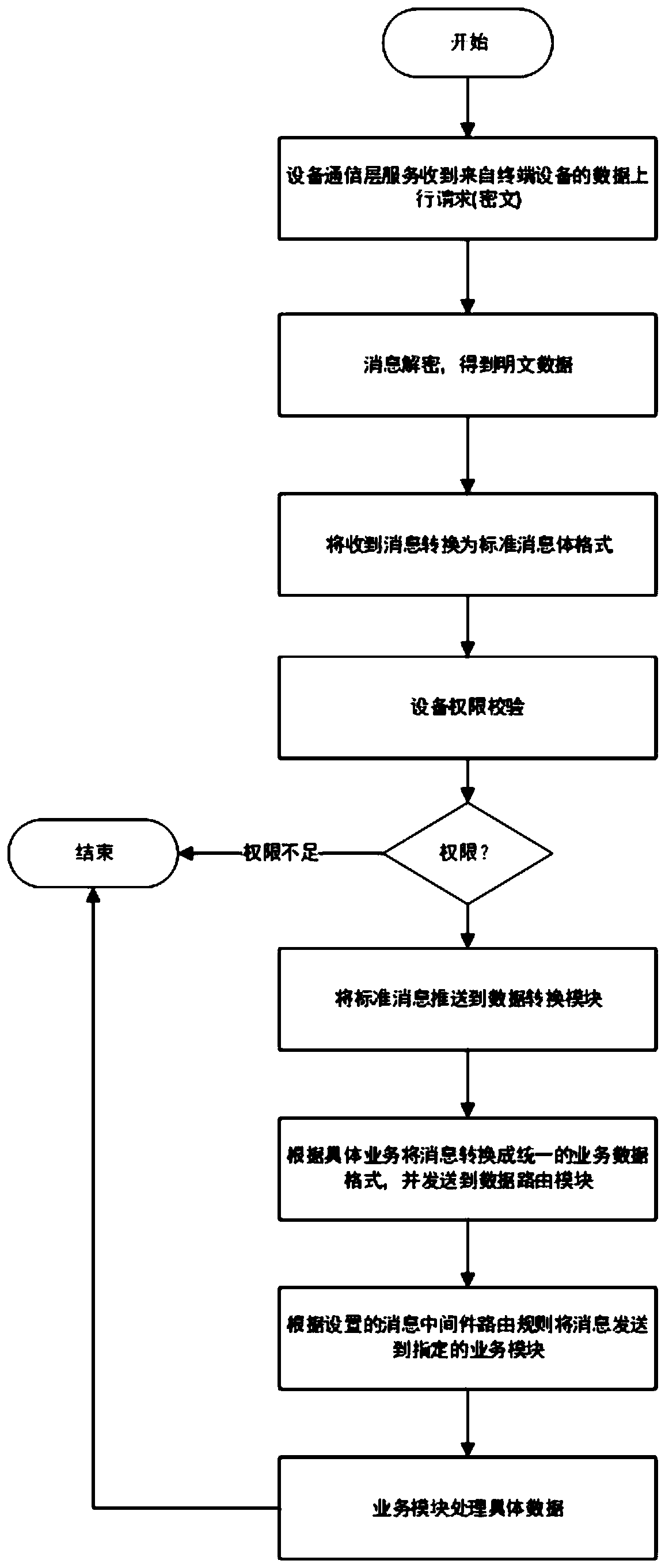

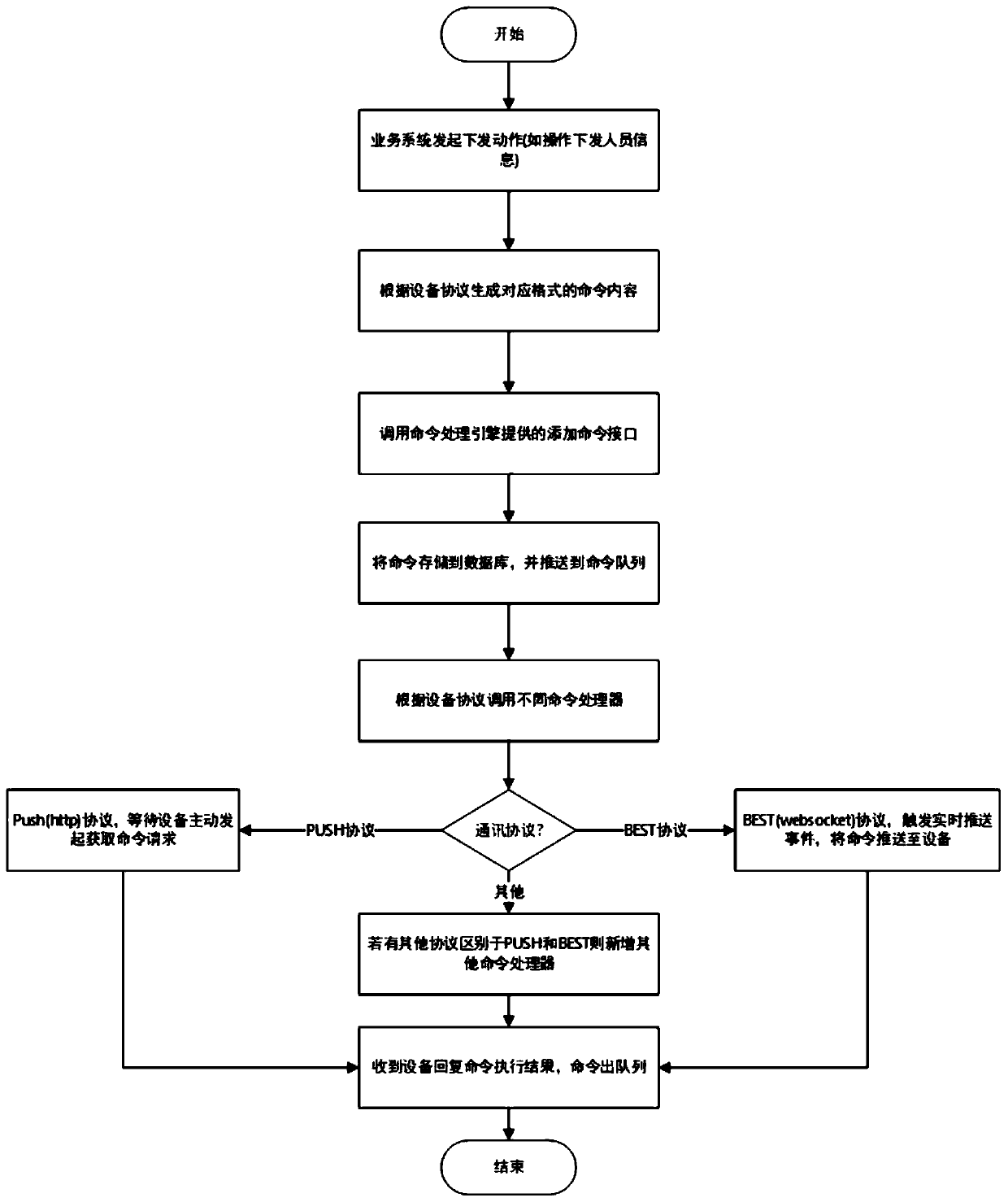

Server device supporting multi-protocol distributed high-concurrency communication and a communication method

The invention discloses a server device supporting multi-protocol distributed high-concurrency communication and a communication method. The server device comprises a device communication layer, an intermediate layer, a service processing layer and message middleware, the equipment communication layer is provided with a plurality of protocol services and is used for receiving data requests of different protocols, decrypting the data requests, converting the data requests into standard message bodies and verifying equipment authority; the intermediate layer is used for converting the standard message body into unified service data according to the service type and dynamically distributing routing rules; the service processing layer is provided with a plurality of service modules which are respectively used for processing corresponding service data; the message middleware is used for performing data interaction among the equipment communication layer, the intermediate layer and the service processing layer. A modular development mode is adopted, specific modular design and distinct layers are provided, secondary high modularization is further carried out in different layers, clusterand distributed deployment is supported, the whole frame can be transversely and longitudinally expanded infinitely according to needs, and the server side can bear communication of more than millionsof devices.

Owner:XIAMEN ZKTECO BIOMETRIC IDENTIFICATION TECHNOLOGY CO LTD

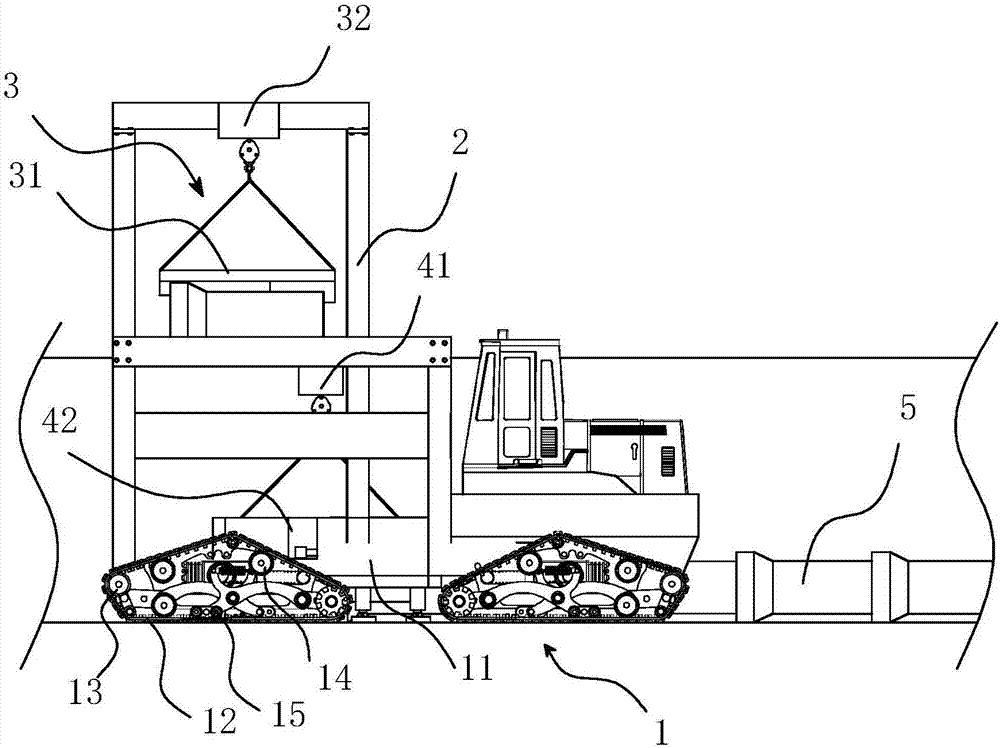

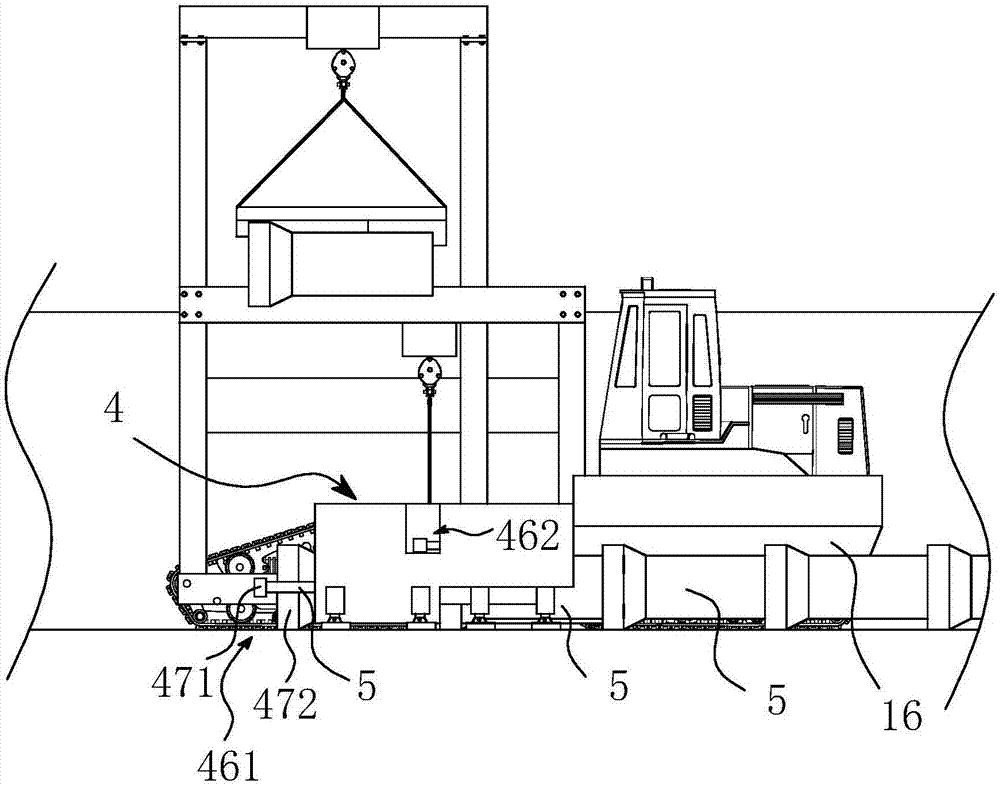

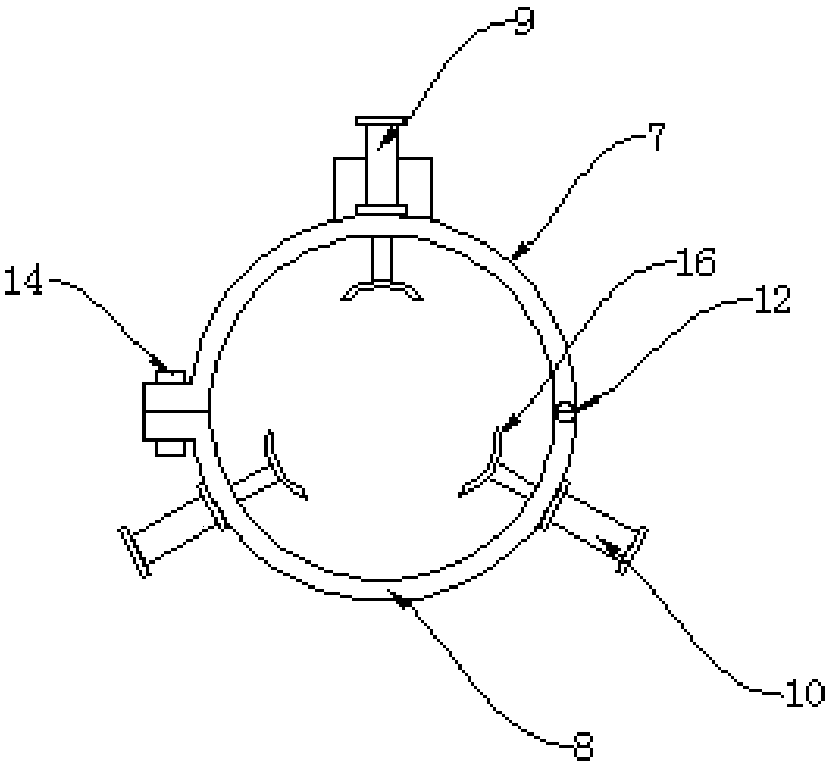

Automatic pipe laying device

ActiveCN107387870AAvoid breakageAvoid offsetPipe laying and repairLoad-engaging elementsMechanical engineeringHydraulic pressure

The invention discloses an automatic pipe laying device which is characterized in that the automatic pipe laying device comprises a positioning pipe laying device and a pipe hoisting device, the positioning pipe laying device comprises a positioning traveling crane, a device support, hydraulic pressure supporting legs and a rear-end positioning mechanism, the hydraulic pressure supporting legs are fixed on two sides of the device support, a rear-end positioning space is formed in the device support and used for covering a pipe body from top to bottom, the rear-end positioning mechanism comprises a rear-end left side pipe, a rear-end right side pipe and a rear-end middle side pipe which are rotatably mounted in the rear-end positioning space, a front-end positioning space is formed in the device support and used for carrying falling pipe bodies, guide plates are obliquely fixed on two sides of the front-end positioning space, a front-end positioning mechanism comprises a front-end left side pipe, a front-end right side pipe, a front-end pushing mechanism, a left side pipe driving mechanism and a right side pipe driving mechanism, the left side pipe driving mechanism is used for unfolding the front-end left side pipe, and the right side pipe driving mechanism is used for unfolding the front-end right side pipe. According to the automatic pipe laying device, rapid positioning can be achieved, abutting joint is convenient and rapid, opening efficiency is improved, and potential safety hazards are avoided.

Owner:黄山云天建筑工程有限公司

Rapid automatic pipeline welding machine

PendingCN108080876AQuick dockingSmall footprintWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLower half

The invention provides a rapid automatic pipeline welding machine. The rapid automatic pipeline welding machine comprises a cross beam and clamping and fixing assemblies arranged at the two ends of the cross beam; a screw and nut pair is arranged on the lower surface of the cross beam in the axial direction, a nut is connected with a spraying gun clamping part which is arranged vertically and downwards, each clamping and fixing assembly comprises a motor fixing base and a clamping sleeve, horizontal rotating shafts are arranged in the motor fixing bases, the surfaces of the rotating shafts aresleeved with first gears, the rotating shafts are driven by motors arranged outside the motor fixing bases, each clamping sleeve is composed of an upper half arc pipe and a lower half arc pipe whichform a round pipe, the outer surfaces of each upper half arc pipe and the corresponding lower half arc pipe are provided with racks matched with the first gears, the racks on the outer surfaces of theupper half arc pipes and the lower half arc pipes are arranged along the circumference of the round pipes formed by the upper half arc pipes and the lower half arc pipes. According to the welding machine, due to arrangement of an air cylinder and a propelling assembly, the machine adapts to welding of pipelines with any pipe diameters.

Owner:MCC TIANGONG TIANJIN EQUIP MFG

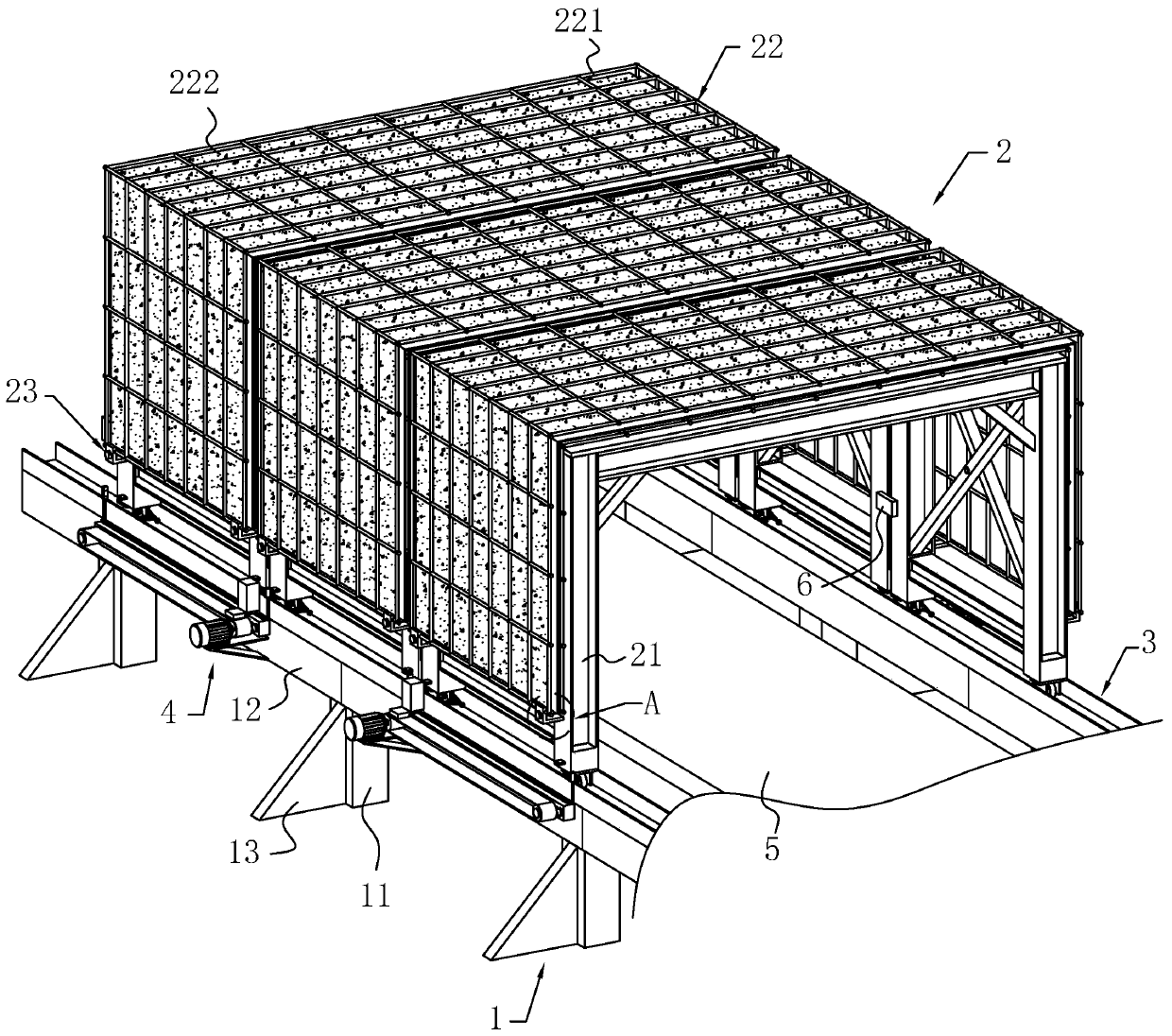

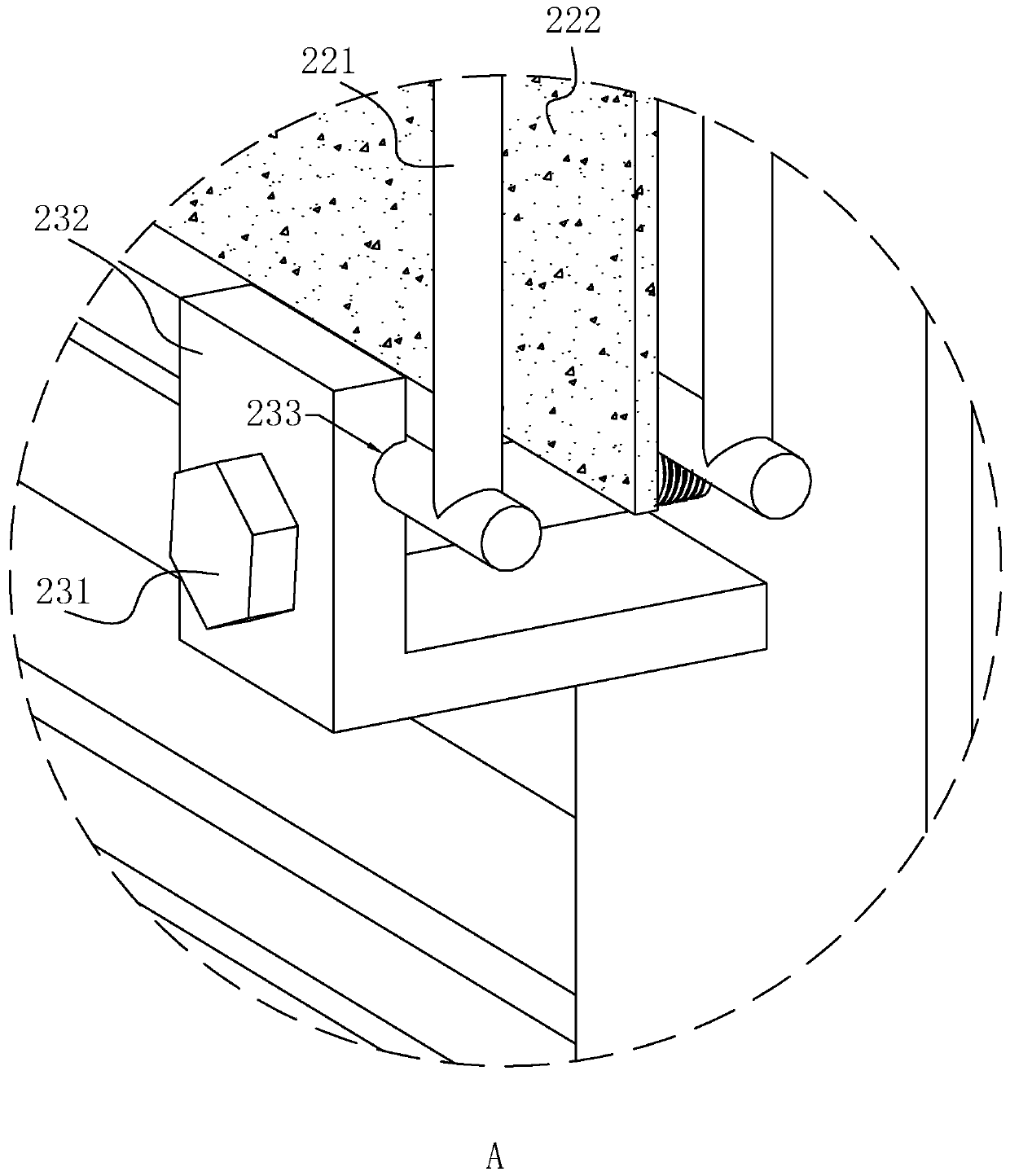

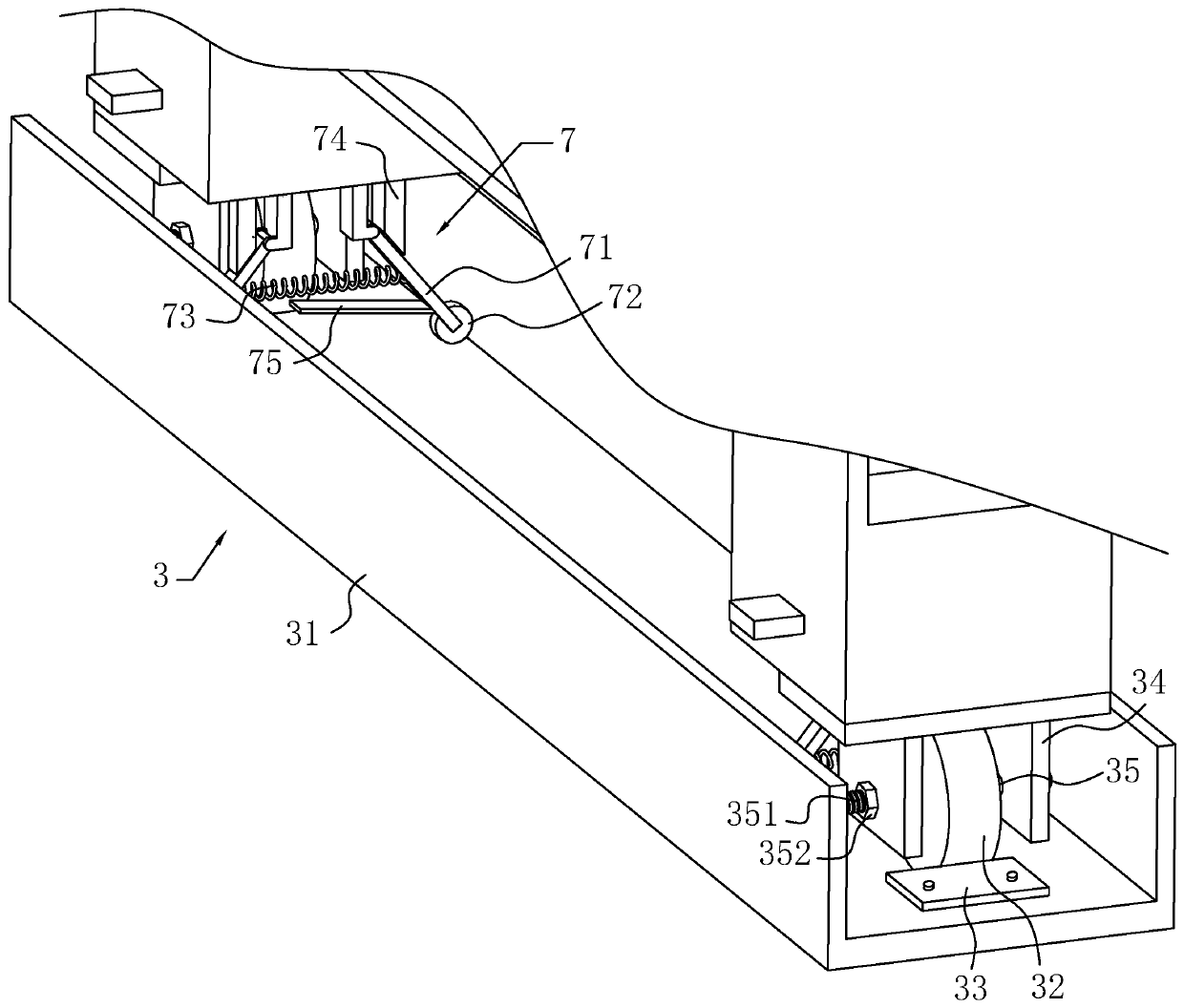

Upper-span existing line construction safety protection device and construction method thereof

ActiveCN109944451AQuick dockingEasy to assemble and disassembleBuilding material handlingEngineeringPulley

The invention provides an upper-span existing line construction safety protection device and a construction method thereof, and relates to the technical field of upper-span existing line construction.The protection device comprises a base assembly, a plurality of groups of protection assemblies and a first fixing piece, wherein the base assemblies are respectively arranged on two sides of an existing line; a plurality of groups of protection assemblies are bridged and arranged on two groups of base assemblies; the first fixing piece is used for fixing two adjacent groups of protection assemblies; a sliding assembly is arranged between the base assembly and each group of protection assemblies; each group of sliding assembly comprises a slide rail arranged on each group of base assembly; aplurality of pulleys are rotationally arranged at the bottom end of each protection assembly and can slide along the slide rail; and an anti-slip block is arranged on the slide rail and is used for fixing the pulleys. When in use, the base assemblies are buried on the two sides of the existing line, the sliding rails are arranged on the base assemblies, the protection assemblies in each group arearranged in sequence, the protection assemblies are hoisted and arranged on the sliding rails by a crane, and the multiple groups of protection assemblies are pushed to be spliced and fixed in sequence. The upper-span existing line construction safety protection device and the construction method thereof have the advantages of convenient disassembly and assembly and labor-saving.

Owner:中交二公局第五工程有限公司

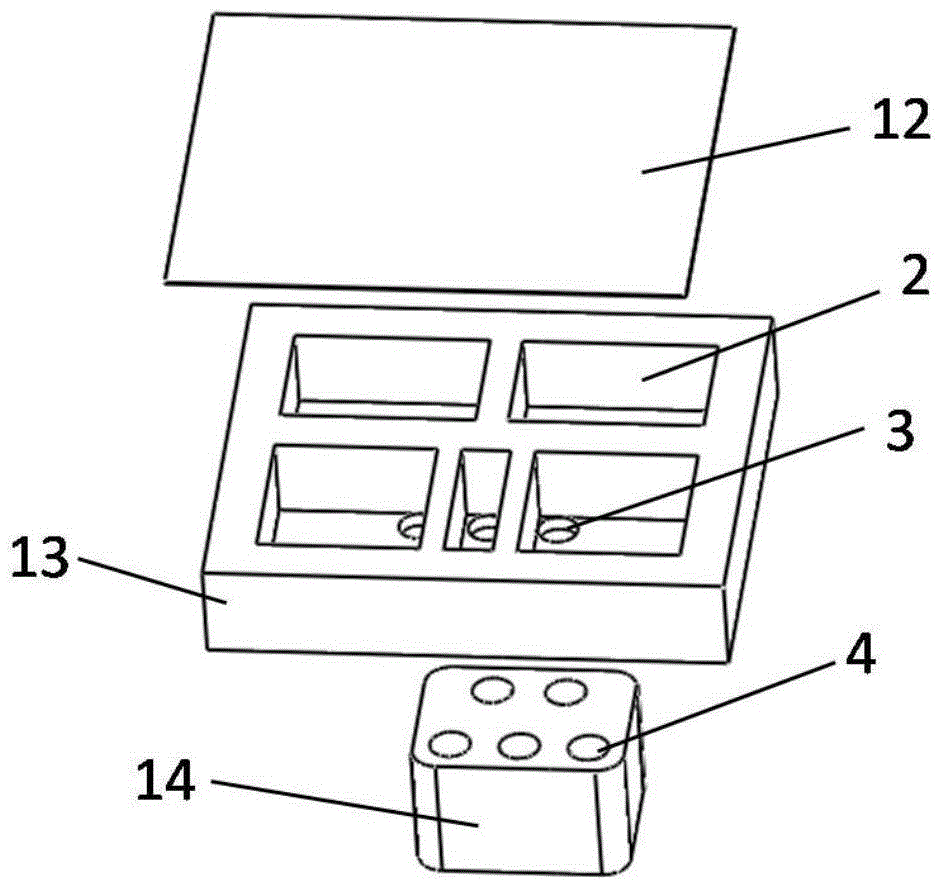

Micro-fluidic chip detecting reaction device with reagent storage function

Provided is a micro-fluidic chip detecting reaction device with a reagent storage function. The detecting reaction device comprises a micro-fluidic chip and a driving device; long-term storage, fast release, reagent driving and detecting reacting of a dry reaction reagent and a wet reaction reagent are achieved through cooperation of the micro-fluidic chip and the driving device, and finally POCT type on-site fast detection is achieved. The micro-fluidic chip comprises a reagent storage module and a detecting reaction module; the reagent storage module comprises a cover plate, a storage structure plate and a connecting structure plate; the detecting reaction module comprises a reactor; before detection, half of the reactor is embedded into a groove of a chip locating base, then the reagent storage module is placed on a chip butt joint base, and the reagent storage module is moved under guidance of a square guide rail to be in fast butt joint with the detecting reaction module. Thus, the two modules of the chip are fast assembled, and the micro-fluidic chip and the driving device are mutually positioned and fixed.

Owner:BEIJING UNIV OF CHEM TECH +1

Shoe making method by uploading two-dimensional plane photo by network and establishing three-dimensional foot model

InactiveCN105469441AQuick dockingFree shooting location3D modellingInternet networkDimensional modeling

The invention provides a shoe making method by uploading a two-dimensional plane photo by a network and establishing a three-dimensional foot model. The method comprises: a three-dimensional foot model is established by a computer; a shoe tree is matched or made according to the three-dimensional foot model; and then a shoe is made based on the three-dimensional foot model or the shoe tree. During a photo shooting process, an absolute fixed value reference substance is arranged at a foot position; and for the photo image, data are uploaded by a self-timer and an internet network or data are kept at a shoe making site. Only one piece of imaging equipment is needed and the shooting angle of the imaging equipment is not fixed; and the shooting equipment includes a mobile phone and the like. The shooting sites are not restricted and the operation becomes convenient. The photo image is uploaded by the internet to generate shoe tree data from the manufacturer or make a shoe tree meeting individual data so as to carry out shoe making.

Owner:NANJING JIAODU HEALTH TECH

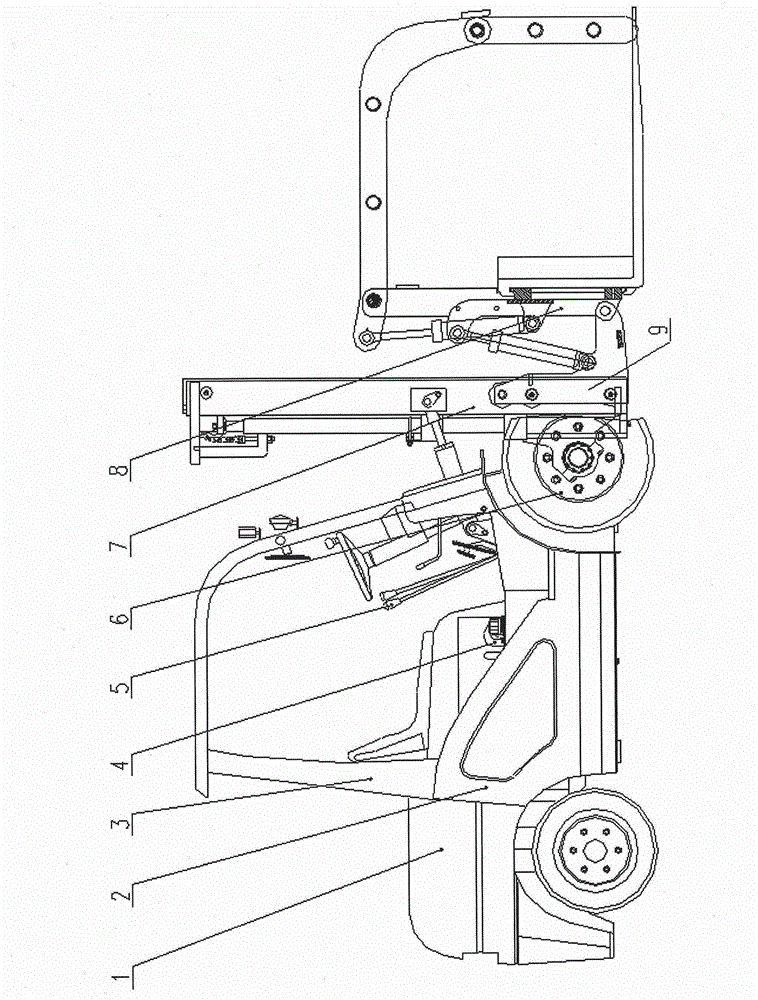

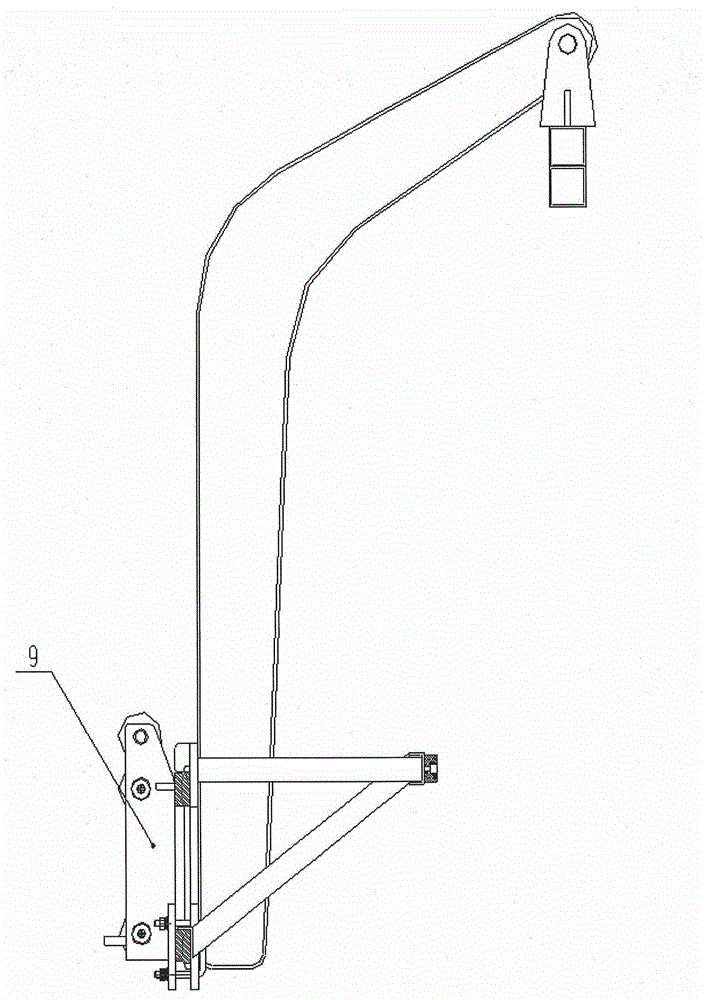

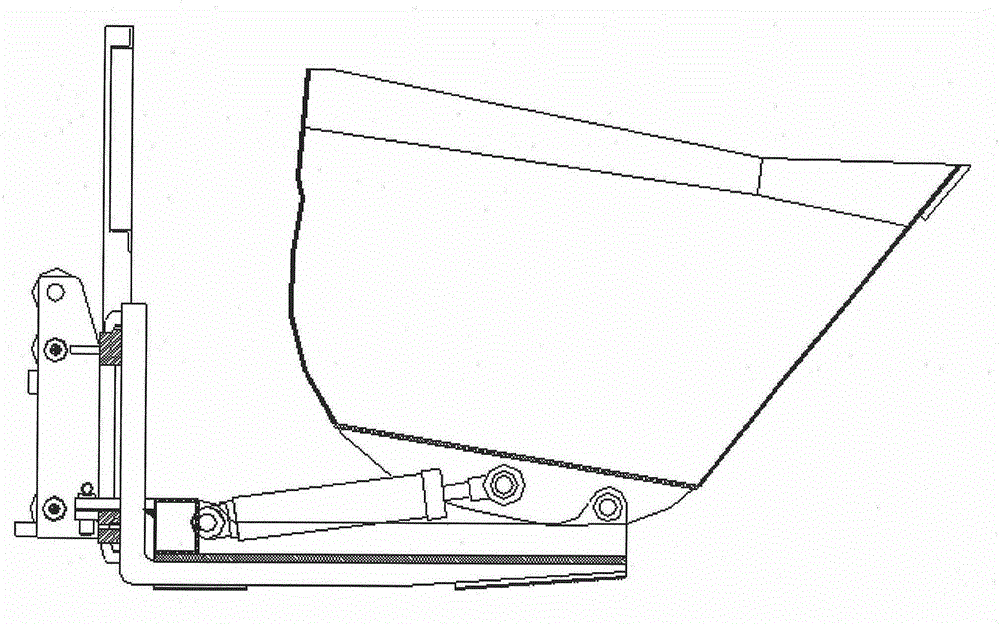

Multi-functional attachment forklift

The invention provide a multi-functional attachment forklift, which relates to a hoisting machinery field and comprises a balance weight, a rack, a door frame, a goods folk frame, a top protection frame, a hydraulic system, a walking power system and a manipulation control system of a forklift, wherein the multi-functional attachment forklift is characterized in that the multi-functional attachment forklift also comprises a functional module with different functions; and the attachment functional module can be mounted in a guide groove inside the door frame in a hanging way and the attachment functional module can also be directly mounted on the goods fork frame. According to the invention, with the different use requirements of the forklift attachments, each attachment functional module can complete various tasks like pushing and pulling, holding and clamping, shoveling and delivering, stacking and hoisting; each attachment functional module can be jointed with the whole forklift rapidly to form a complete task performance unit; and personalized carrying work can be performed.

Owner:ANHUI XINGHUA FORKELEVATOR

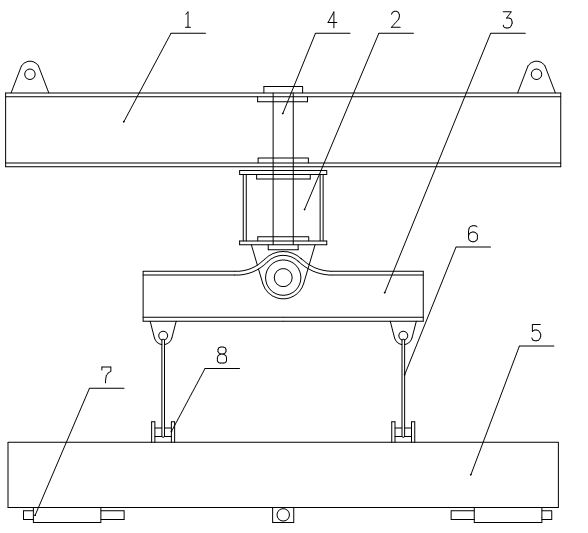

Reinforcement cage lifting device

The invention discloses a reinforcement cage lifting device, which comprises an upper beam, a middle beam, lower beams and an annular beam for connecting a reinforcement cage, wherein the two ends of the upper beam are fixed with a lifting lug for connecting a crane respectively; the middle beam is hinged to the center of the upper beam through a connecting shaft vertically inserted into the middle beam; the lower beams are hinged to the two ends of the middle beam through pin shafts horizontally inserted into the centers of the lower beams respectively; and the annular beam is horizontally suspended on the lower beams by corresponding suspenders. When in use, the reinforcement cage lifting device connects the reinforcement cage to the annular beam in a suspension way, and when the reinforcement cage is jointed, can conveniently drive the reinforcement cage to horizontally rotate, flexibly regulate the vertical angel of the reinforcement cage and ensure the verticality of the reinforcement cage in a jointing process to easily and rapidly finish the jointing of the reinforcement cage, increase the jointing speed of the reinforcement cage and improve the jointing quality of the reinforcement cage by hinging fit among the upper, middle and lower beams, thereby ensuring the progress and quality of pile foundation construction.

Owner:HENAN MINE CRANE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com