Deep water pipeline multi-circuit bridging system and testing and installing method thereof

A multi-circuit and pipeline technology, which is applied in the directions of surveying, earthwork drilling, mining fluid, etc., can solve the problems of cumbersome connection, inconvenient operation, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present invention will be further described below in conjunction with the drawings and embodiments:

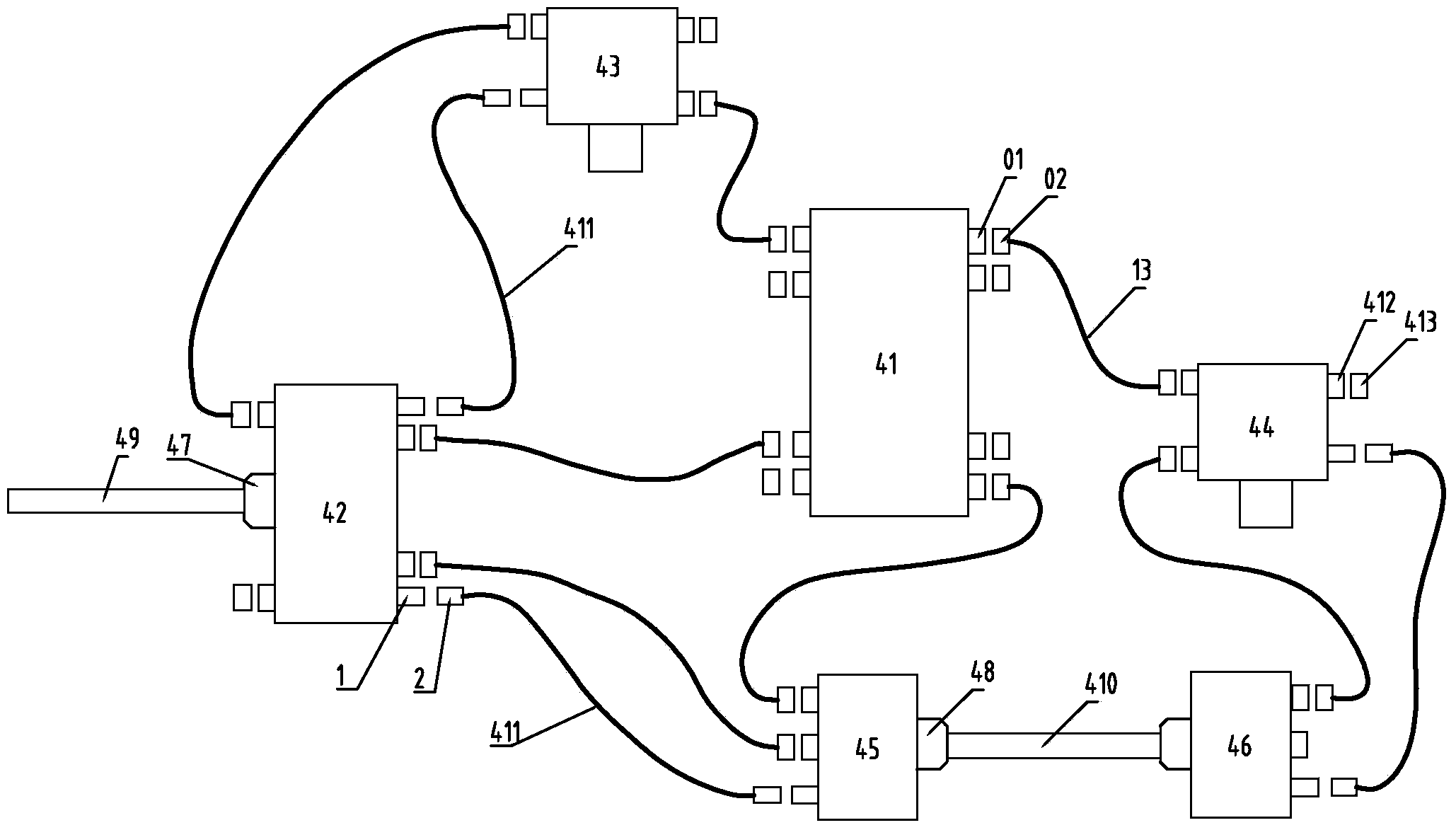

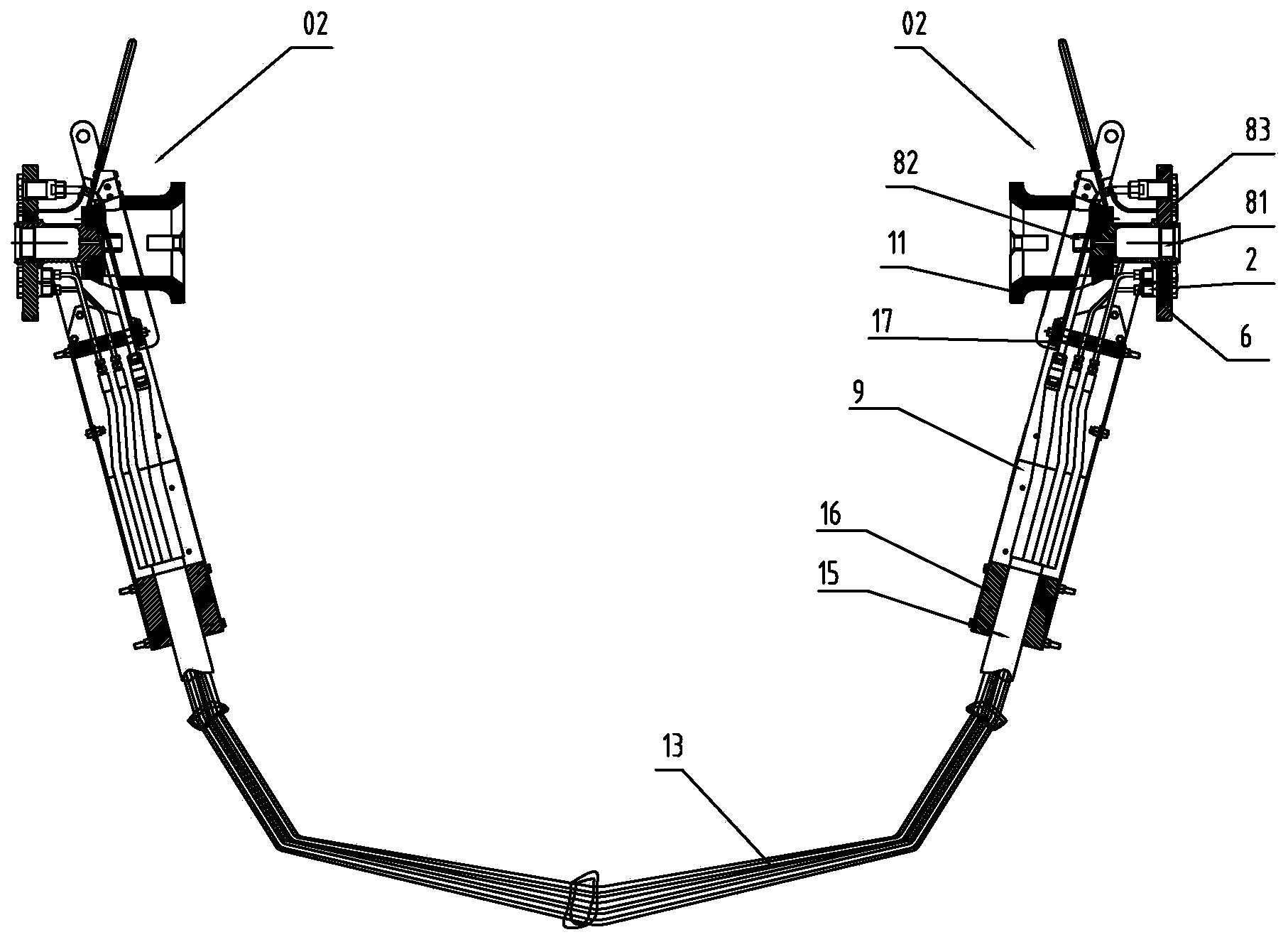

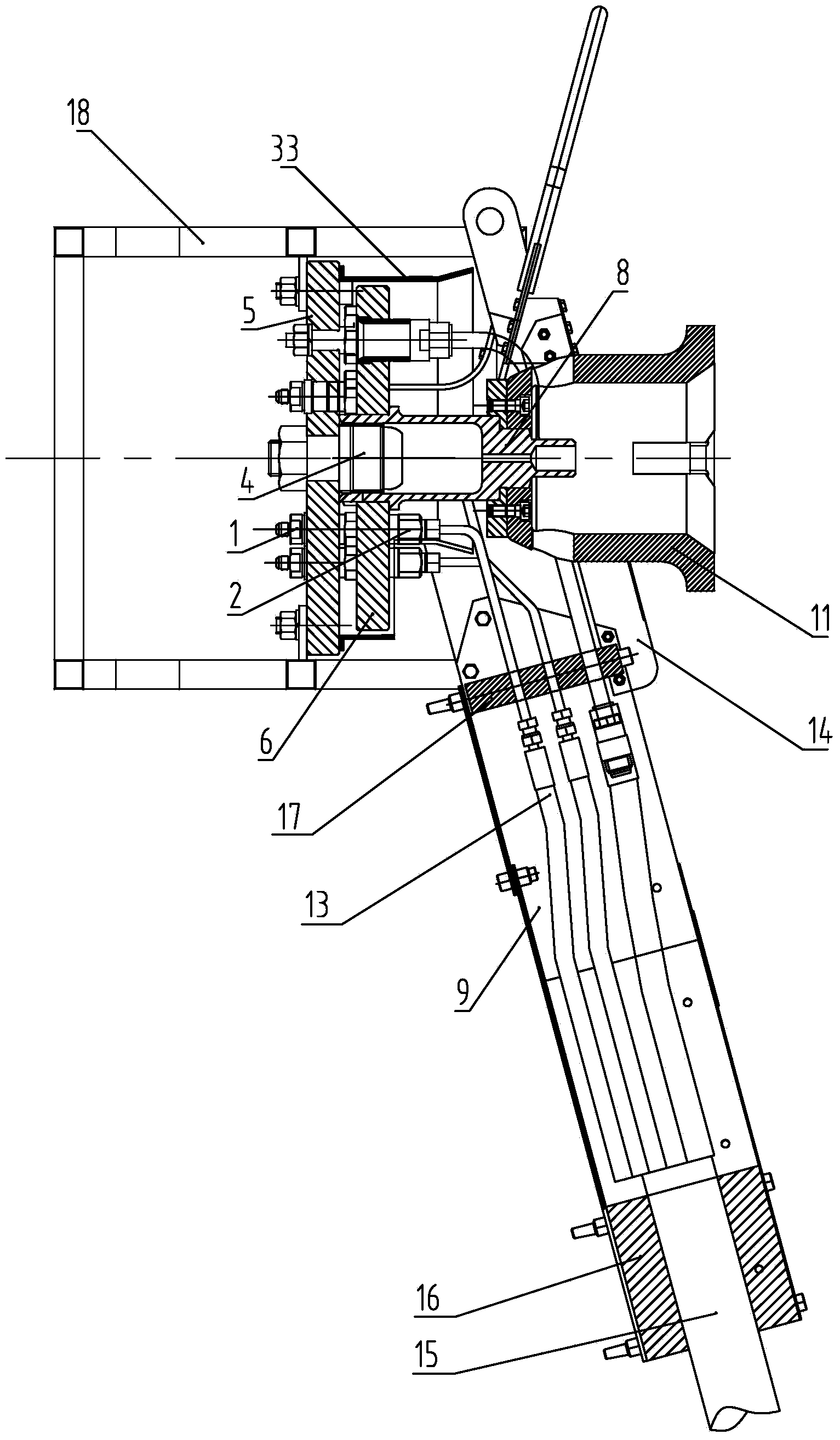

[0097] Such as figure 1 And to Picture 8 As shown, a deep-water pipeline multi-circuit bridging system includes a submarine manifold 41, an underwater electrical distribution assembly 42, a first underwater christmas tree 43, a second underwater christmas tree 44, and a first underwater umbilical cable terminal 45 and the second underwater umbilical cable terminal 46 six devices, the submarine manifold 41 is equipped with four male connector terminals 01 and four docking connectors 412, and each of the docking connectors 412 is close to each male connector terminal. 01. Three male connector terminals 01, three docking connectors 412, two male connectors 1 and an underwater umbilical cable interface 47 are installed on the underwater electrical distribution assembly 42, and the first underwater christmas tree 43 Two male connector terminals 01, one docking connector 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com