Quick centering device for engine pedestal test

An engine stand and centering device technology, which is applied in the direction of engine testing, measuring device, machine/structural component testing, etc., can solve problems such as difficulty in ensuring adjustment accuracy, complicated operation steps, and difficulty in finding interference problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

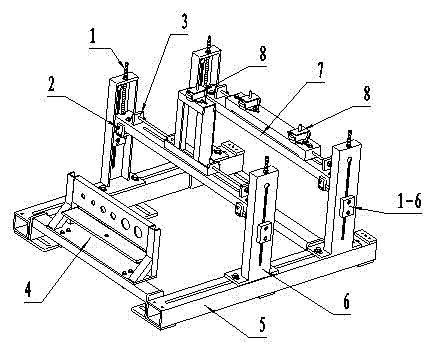

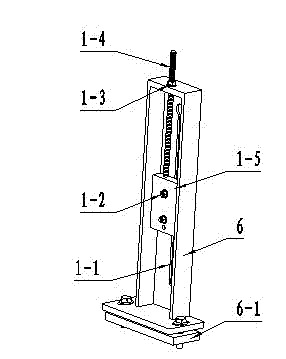

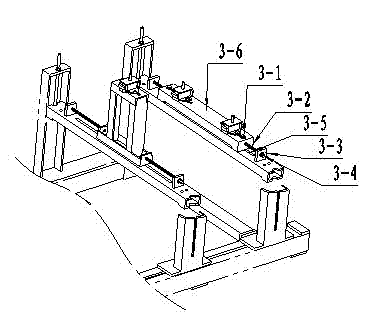

[0022] Referring to Fig. 1, the present invention comprises base 5, support frame 6, crossbeam 7 and quick plug panel 4, and described support frame 6 is made up of four groups of vertical supports, and they are all fitted with base 5, and each group of vertical supports An up and down adjustment mechanism 1 is provided, and a crossbeam 7 is arranged between the two sets of vertical supports. The up and down adjustment mechanism 1 is assembled with the crossbeam 7. The front and rear adjustment mechanisms 3 are fixed on the front and rear adjustment mechanisms 3 on the crossbeam 7. The engine support rubber seat 8 is installed, and the left and right fine adjustment mechanisms 2 are also provided at the front and rear ends of the beam 7 .

[0023] See Figure 1, Figure 5 , the base 5 of the present invention is composed of a base beam 5-4 and a base longitudinal beam 5-5, the base beam 5-4 includes two parts arranged left and right, wherein the left base beam is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com