Design method for vertical tail docking structure

A technology of structural design and vertical tail, applied to aircraft parts, aircraft control, fuselage, etc., to achieve the effect of shortening the development cycle, reducing assembly workload, and reducing docking weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

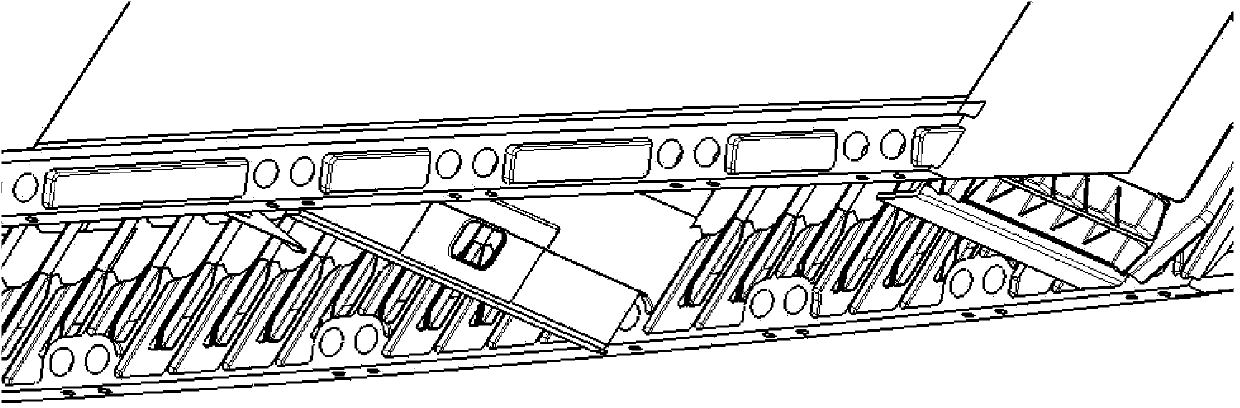

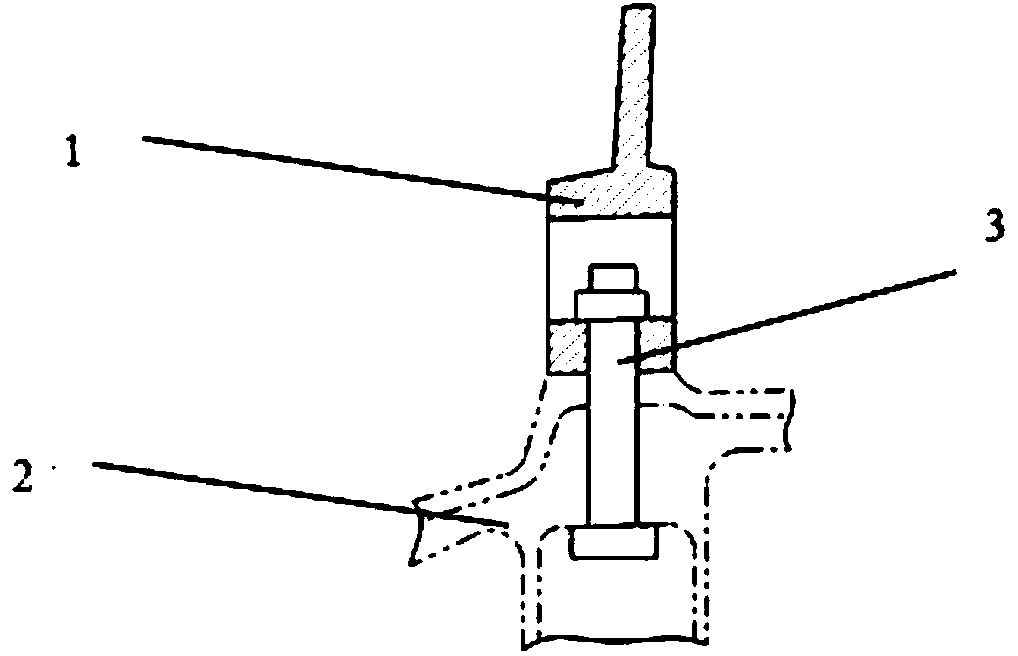

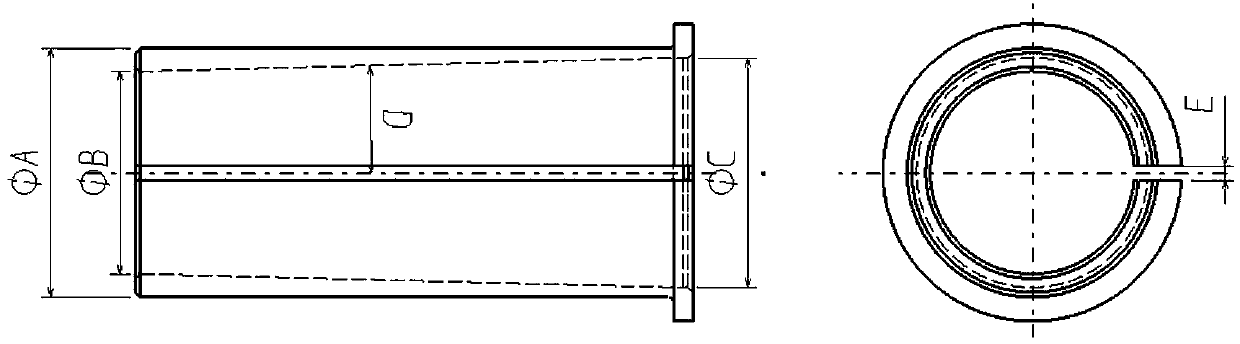

[0021] attached Figure 5 , 6 , 7, the present invention mainly includes a vertical tail panel 1, a structure 2 docked with the vertical tail, a docking structure 3, a docking structure 4, a butt bolt group 5, a vertical tail beam 6, and a tie rod assembly 7. The vertical tail wall plate 1 is a composite material structure, and the structural form is a composite material stiffened plate with a single ear joint; the structure 2 docked with the vertical tail is a metal structure, and the structural form is a double ear joint, which corresponds to a single ear joint; the docking structure 3 (joint bolt group 5) is a metal composite structure, including tapered slit bushings, tapered bolts, adjusting gaskets, etc.; butt joint structure 4 (tie rod 7) is a metal composite structure, and its structural length is adjustable; the vertical tail beam 6 is composite material an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com