Patents

Literature

227results about How to "Reduced assembly effort" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-cost technologically-molded carbon fiber composite material subway vehicle body and manufacturing method thereof

InactiveCN107214977AImprove sound insulationReduce in quantityDomestic articlesHoneycombFibrous composites

The invention discloses a low-cost technologically-molded carbon fiber composite material subway vehicle body and a manufacturing method thereof. The subway vehicle body comprises a carbon fiber outer covering, a carbon fiber inner covering, and a sandwich layer paved between the carbon fiber outer covering and the carbon fiber inner covering. The invention also discloses a manufacturing method of the carbon fiber composite material subway vehicle body, which comprises the following steps: (1) paving and adhering carbon fiber fabric prepregs, carrying out OOA technological molding on carbon fiber outer covering; (2) paving honeycombs, foams and pre-modled pre-embedded parts on the carbon fiber outer covering to be used as the sandwich layer, and carrying out OOA technological molding on the sandwich layer; (3) paving and adhering the the carbon fiber fabric prepregs on the sandwich layer, and carrying out OOA technological molding on the carbon fiber inner covering, i.e. integration on the vehicle body. According to the low-cost technologically-molded carbon fiber composite material subway vehicle body and a manufacturing method thereof disclosed by the invention, the weight of the subway vehicle body is effectively reduced, the aim of the lightweight of the vehicle body is fulfilled, the energy consumption of the vehicle body is reduced, and the service life of the vehicle body is prolonged; moreover, by adopting the OOA molding technology with low cost, the cost of the molded carbon fiber composite material subway vehicle body is greatly reduced.

Owner:HENGSHEN

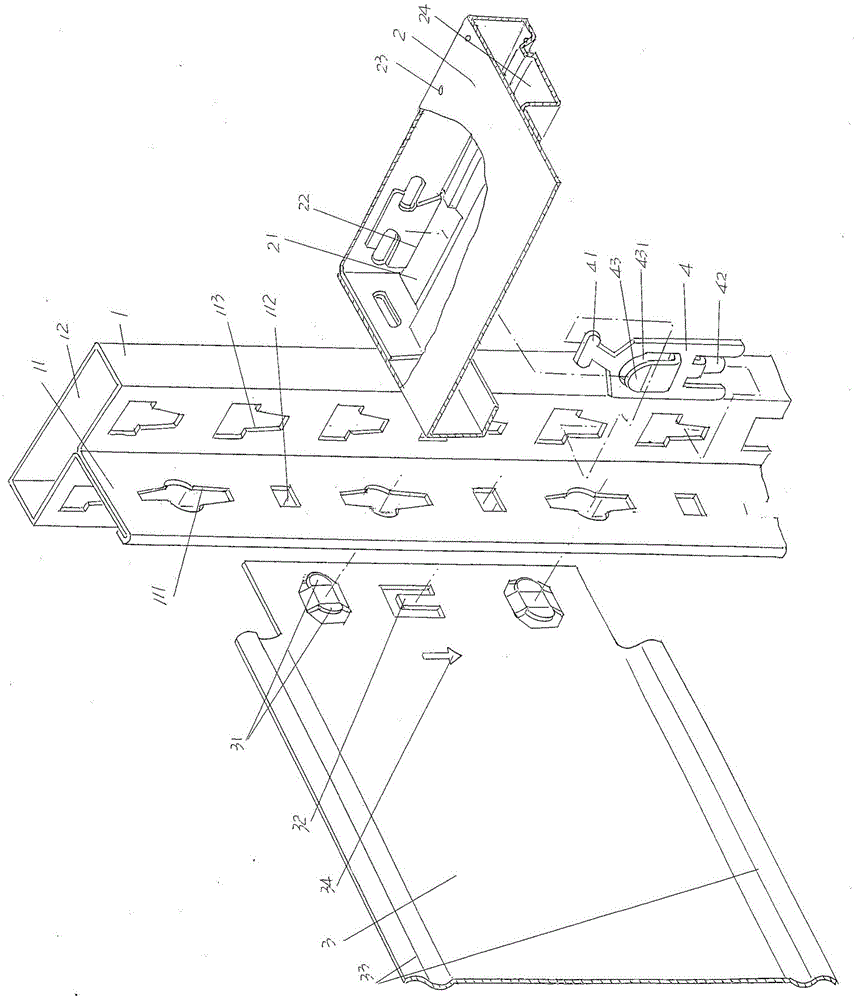

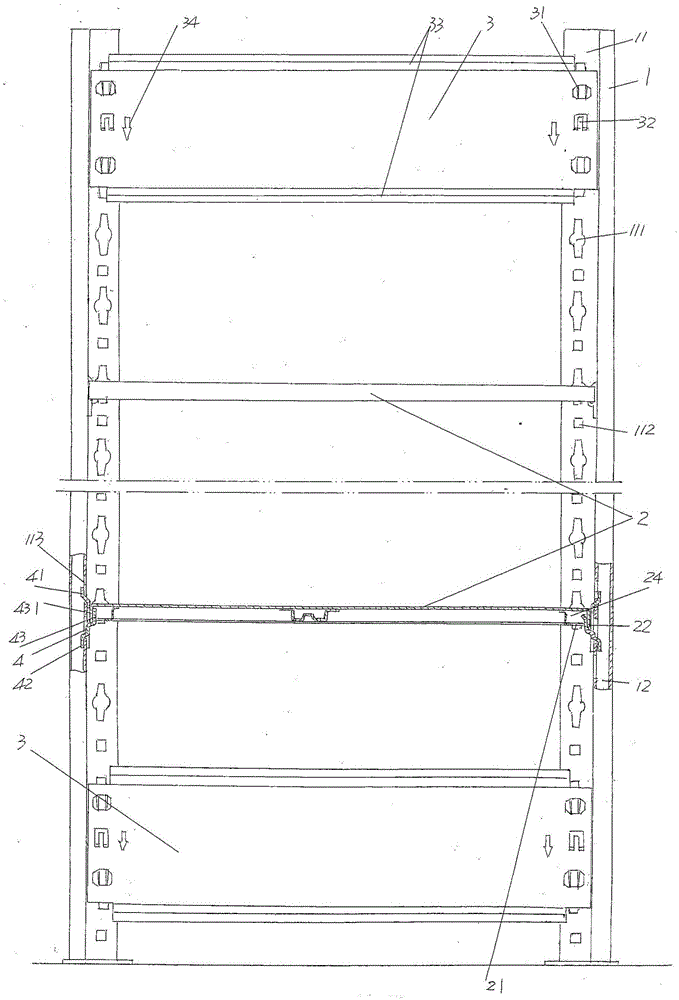

Assembled goods shelf

InactiveCN105640094AReduced manufacturing and assembly effortSave resourcesFurniture partsEngineering

The invention discloses an assembled goods shelf, and belongs to the technical field of commercial facilities. The assembled goods shelf comprises stand columns which are arranged face to face, carrying plates which are correspondingly arranged among the stand columns and stand column supporting cross beams. The assembled goods shelf is characterized in that carrying plate hitching legs arranged on the stand columns are further included, a cross beam hanging plate is arranged in the middle of the side, facing the corresponding stand column supporting cross beam, of each stand column, the cross beam hanging plates are provided with cross beam fin positioning holes and cross beam locking piece positioning holes, the sides, facing the stand column supporting cross beams, of the stand columns are provided with carrying plate hitching leg embedded holes, the left end and the right end of each stand column supporting cross beam are provided with a pair of cross beam fins and a pair of cross beam locking pieces respectively, a pair of the cross beam fins and the corresponding cross beam hanging plate are locked at the positions corresponding to the cross beam fin positioning holes, and the cross beam locking pieces and the corresponding cross beam hanging plate are locked at the positions corresponding to the cross beam locking piece positioning holes; each carrying plate hitching leg is connected between every two adjacent carrying plate hitching leg embedded holes formed in the stand columns, and the front ends and the back ends of the carrying plates in the short-edge direction are matched with the carrying plate hitching legs in an embedded mode. Accordingly, the manufacturing and assembling workload is reduced, resources are saved, and the assembling speed is increased.

Owner:常熟市尚湖镇鼎艺超市货架厂

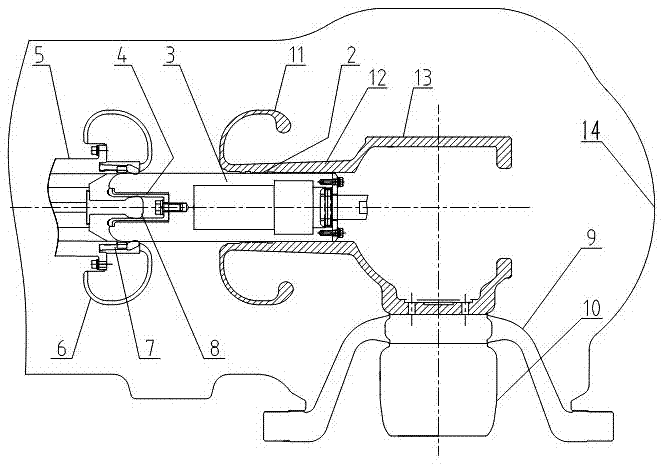

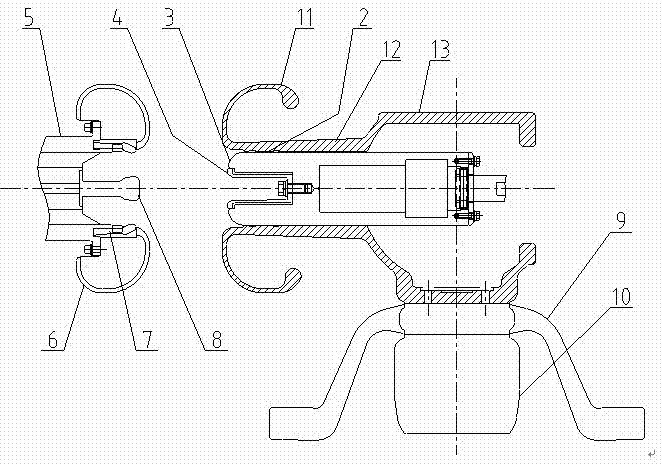

Isolation switch and conductor thereof

ActiveCN105448578AGuaranteed temperature riseSimple structureHigh-tension/heavy-dress switchesContacts enclosures/screensElectrical conductorEngineering

The invention discloses an isolation switch and a conductor thereof. The conductor of the isolation switch comprises a main conductor; the head of the main conductor is integratedly provided with an annular housing-shaped head part shielding structure for sleeving the outer circumference of a moving contact or a static contact; the head part shielding structure is coaxial with a main conductor; a rotating bus is a rotating body of a curve which is bent along an arc track from the head part of the main conductor; through the combination of the traditional isolation switch conductor and the shielding housing, the surface area is increased through the head part shielding structure, and the current conduction is realized; the head part shielding structure can perform shielding on the head part of the main conductor and uniformly isolates the power plant inside the switch; in the meantime, the integration design of head part shielding structure on the head part of the main conductor eliminates the bolt connection between the traditional conductor and the shielding housing, and reduces the kinds and amount of the parts inside the isolation switch. The compact structure design of the conductor enables the isolation switch to be simple and easy to disassemble.

Owner:HENAN PINGZHI HIGH VOLTAGE SWITCHGEAR +2

Design method for vertical tail docking structure

InactiveCN103625631AMeet the use requirementsReduce the amount of connection processingAircraft stabilisationFuselagesMaintainabilityEngineering

The invention provides a design method for a vertical tail docking structure. The design method is characterized in that an amount of single lug joints are respectively arranged at the root of a vertical tail at two sides of a course, a same amount of double lug joints are correspondingly arranged at a docking structure of the vertical tail, the diameters of holes in the single lug joints are equal to those of holes in the corresponding double lug joints, the axes of the holes are coaxial, bushes are pressed into docking through holes of the single lug joints and the double lug joints, and the single lug joints and the double lug joints are fixedly connected in a bolt connection mode. According to the invention, docking between the box section of a vertical tail composite material and fuselage lugs is realized in multi-point docking manner, so connection processing amount is reduced, connection workload is reduced, docking weight is lowered down, assembling workload is decreased, rapid docking between the vertical tail and a fuselage is realized, and connection of a few points enables the purpose of docking to be achieved and requirements on usage of an airplane to be met; thus, a development period is shortened, production cost is reduced, and maintainability and replaceability of a product are improved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

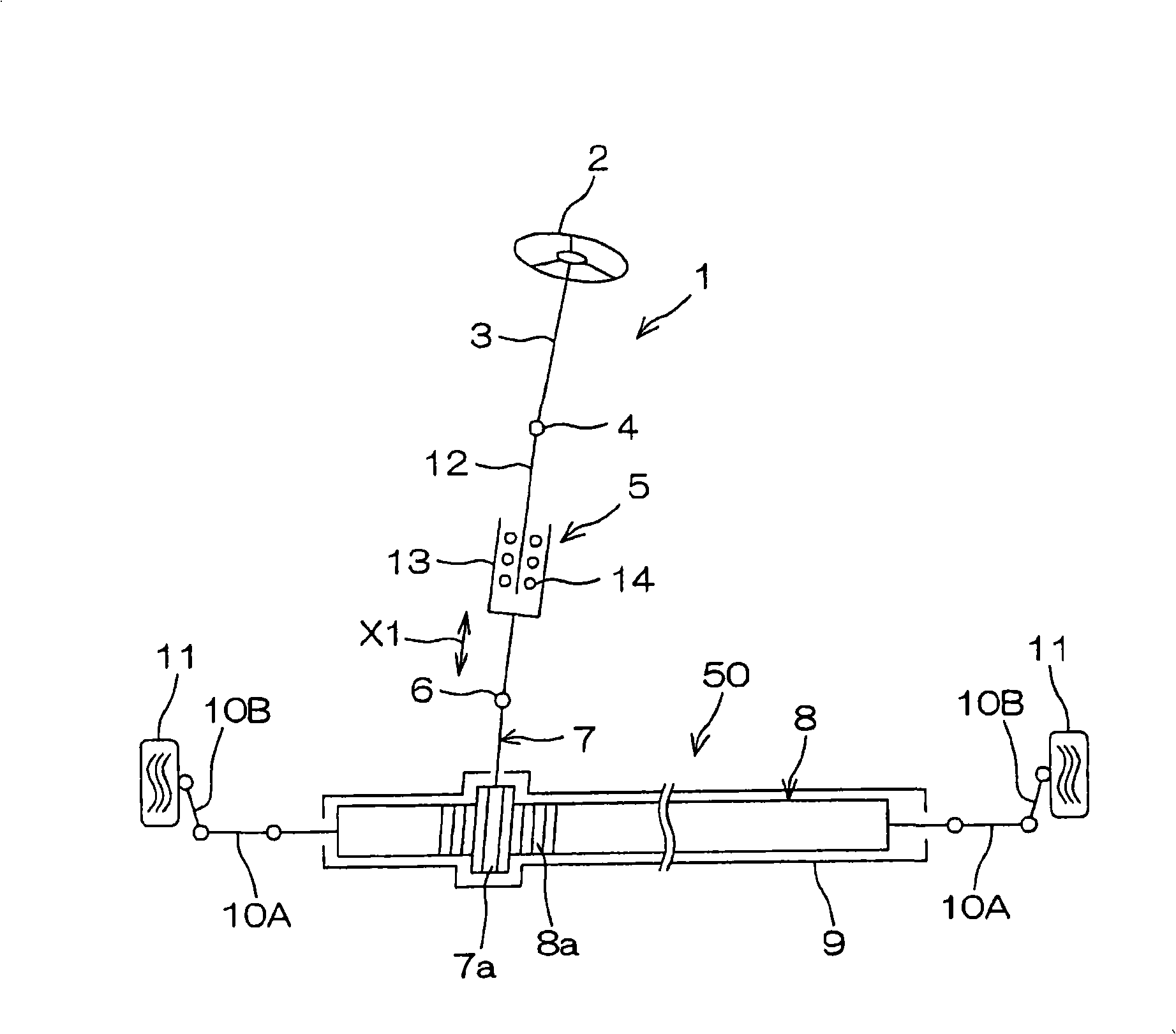

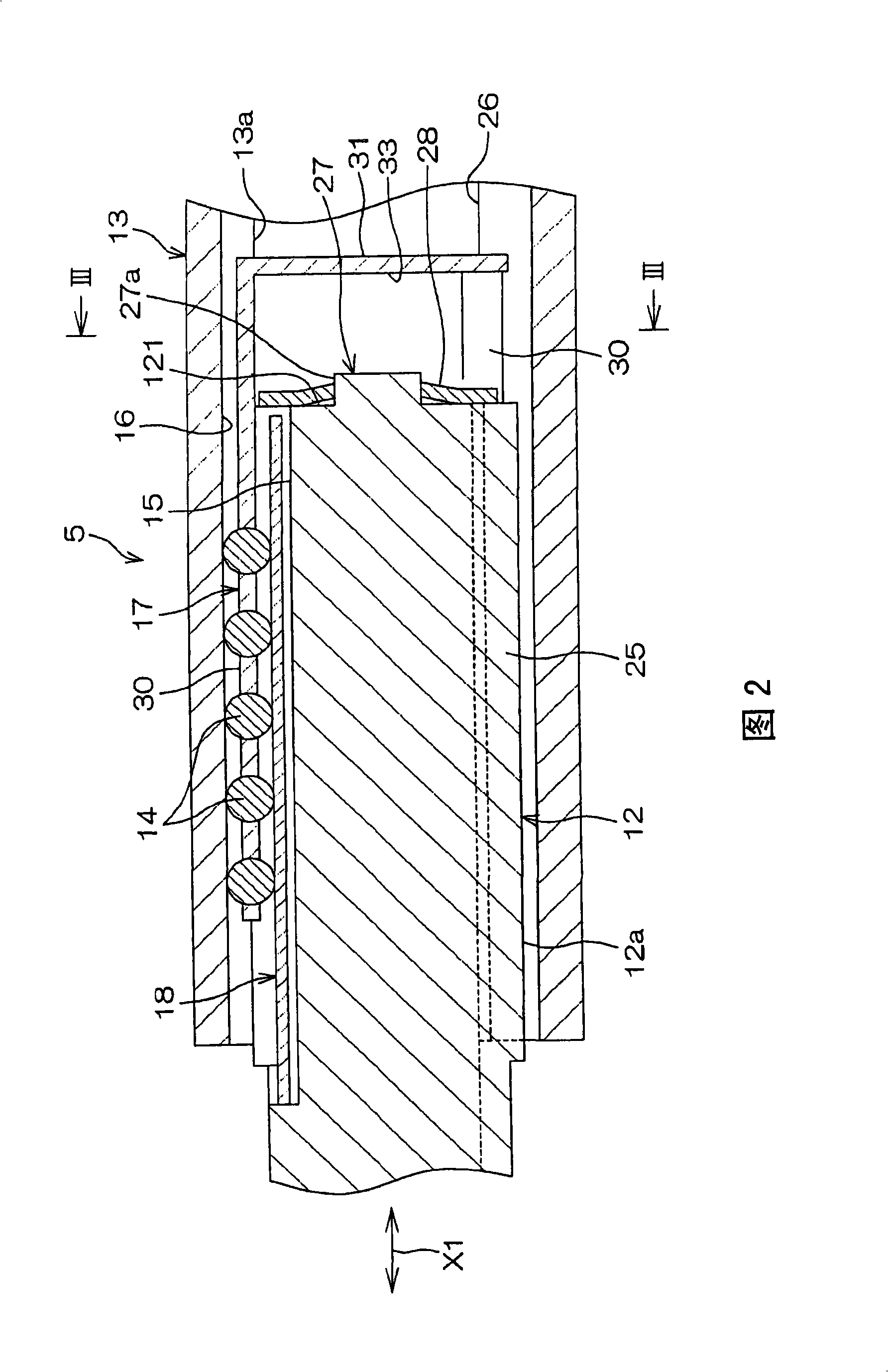

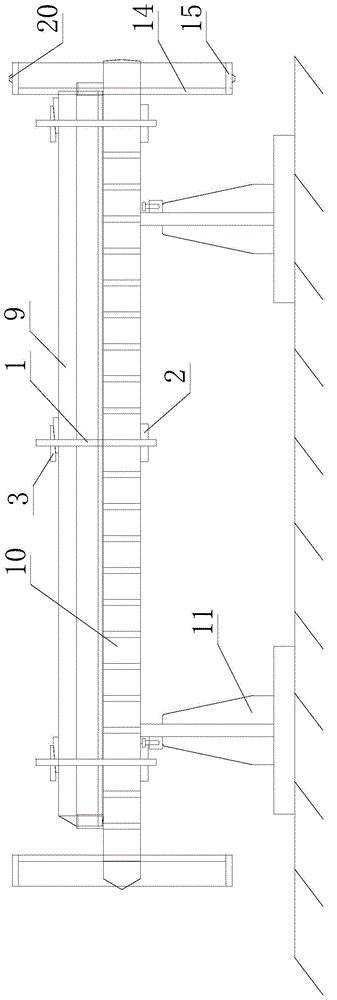

Telescopable shaft and steering device for vehicle

InactiveCN101258335ASimple structureReduced assembly effortYielding couplingLinear bearingsEngineeringMechanical engineering

Owner:JTEKT CORP +1

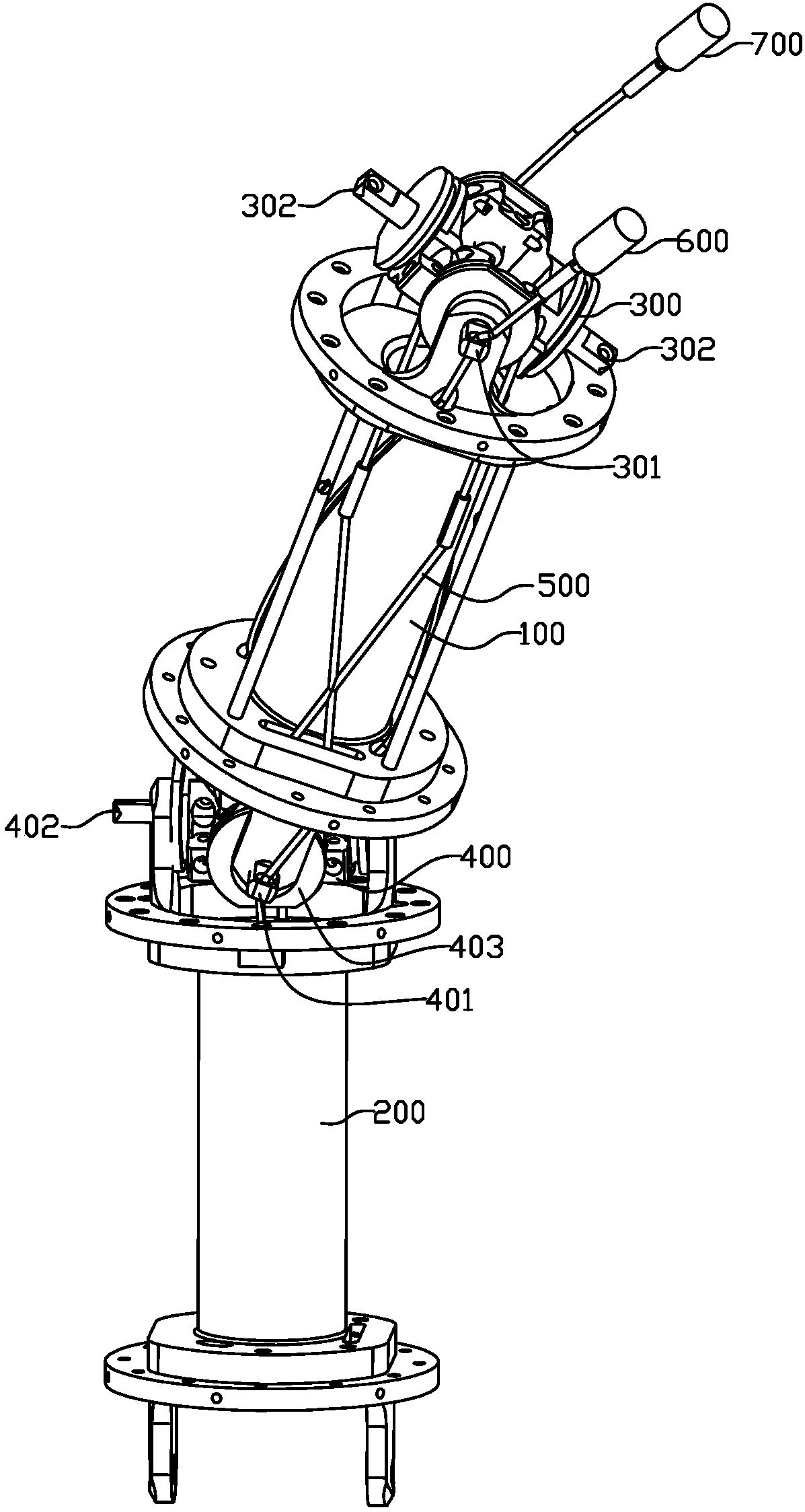

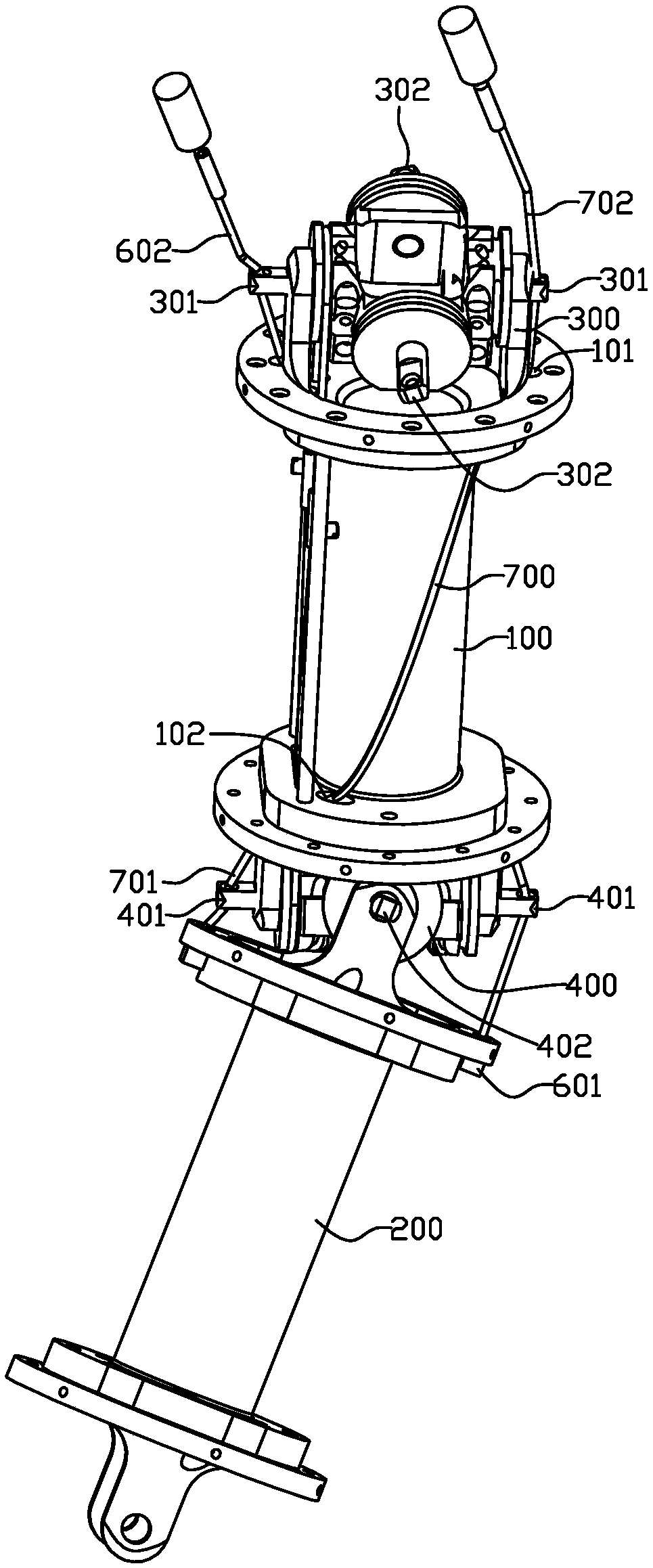

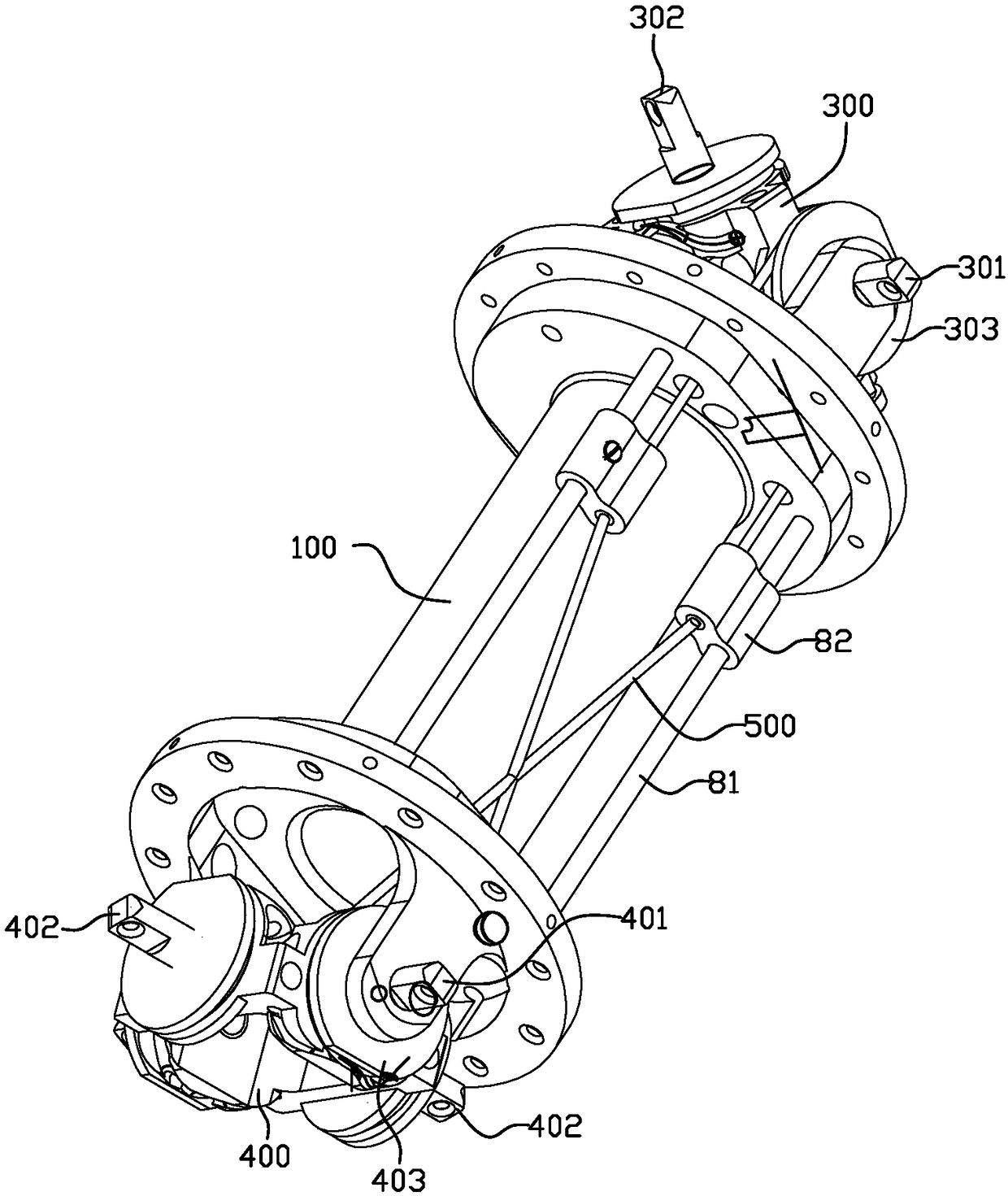

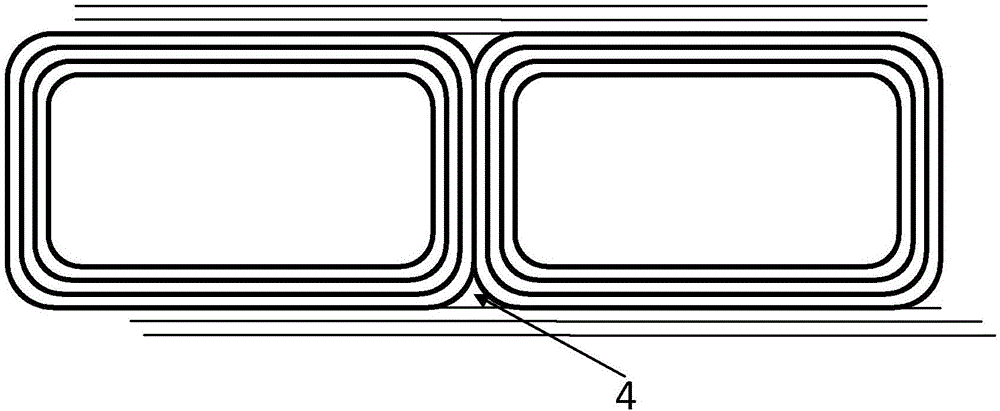

Two-freedom-degree linkage joint section and flexible mechanical arm

ActiveCN108555959AShorten the lengthReduced assembly effortJointsArmsEngineeringMechanical engineering

The invention discloses a two-freedom-degree linkage joint section and a flexible mechanical arm. The joint section comprises a first arm section, a second arm section, a first connecting part, a second connecting part, a short linkage rope, a first long linkage rope and a second long linkage rope. The head end of the first arm section is connected with the first connecting part in a rotating manner. The tail end of the first arm section and the head end of the second connecting part are both connected with the second connecting part in a rotating manner. The rotating direction of the first arm section and the rotating direction of the second arm section are perpendicular to each other. The short linkage rope is connected with the same side of the first connecting part and the second connecting part. The tail end of the first long linkage rope and the second arm section are fixed. The head end of the first long linkage rope is located on the opposite side of the tail end after wound around the first arm section from the exterior of the first arm section. The first long linkage rope and the second long linkage rope are symmetrical about the axis of the first arm section. The joint section is conductive to reducing the assembling workload of the mechanical arm, and the assembling efficiency is improved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

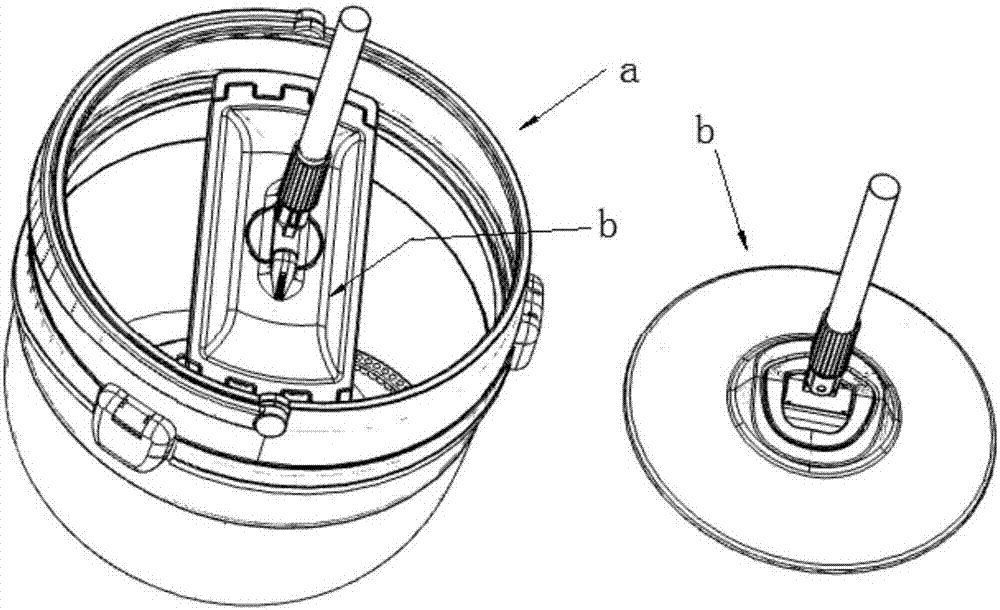

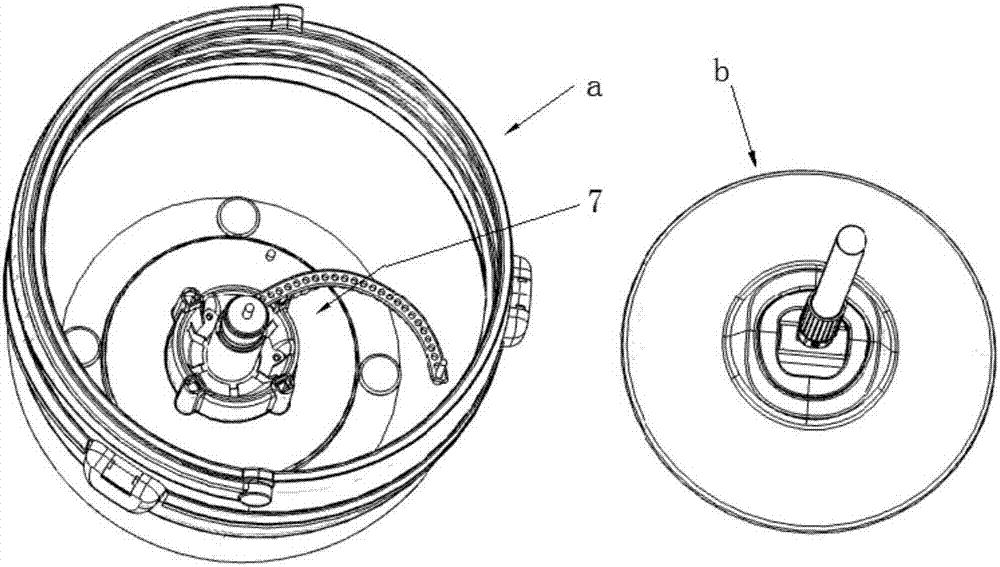

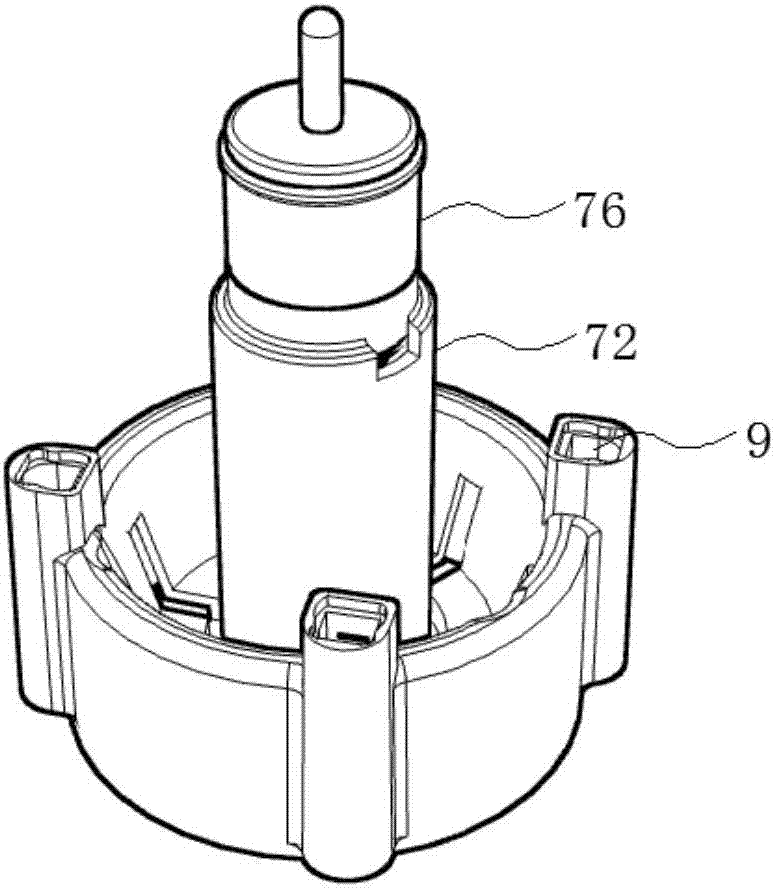

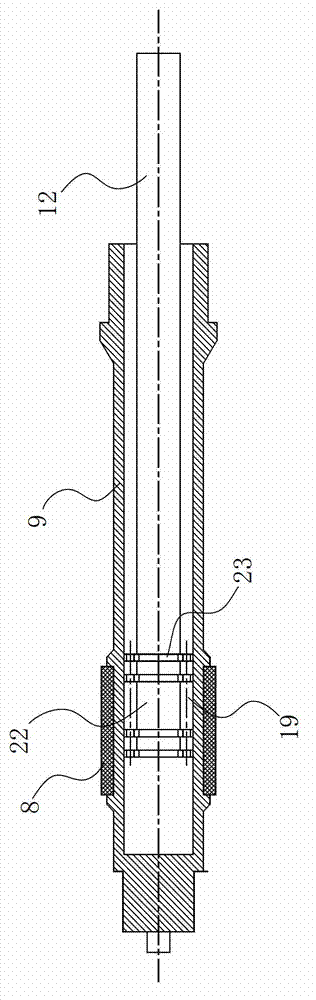

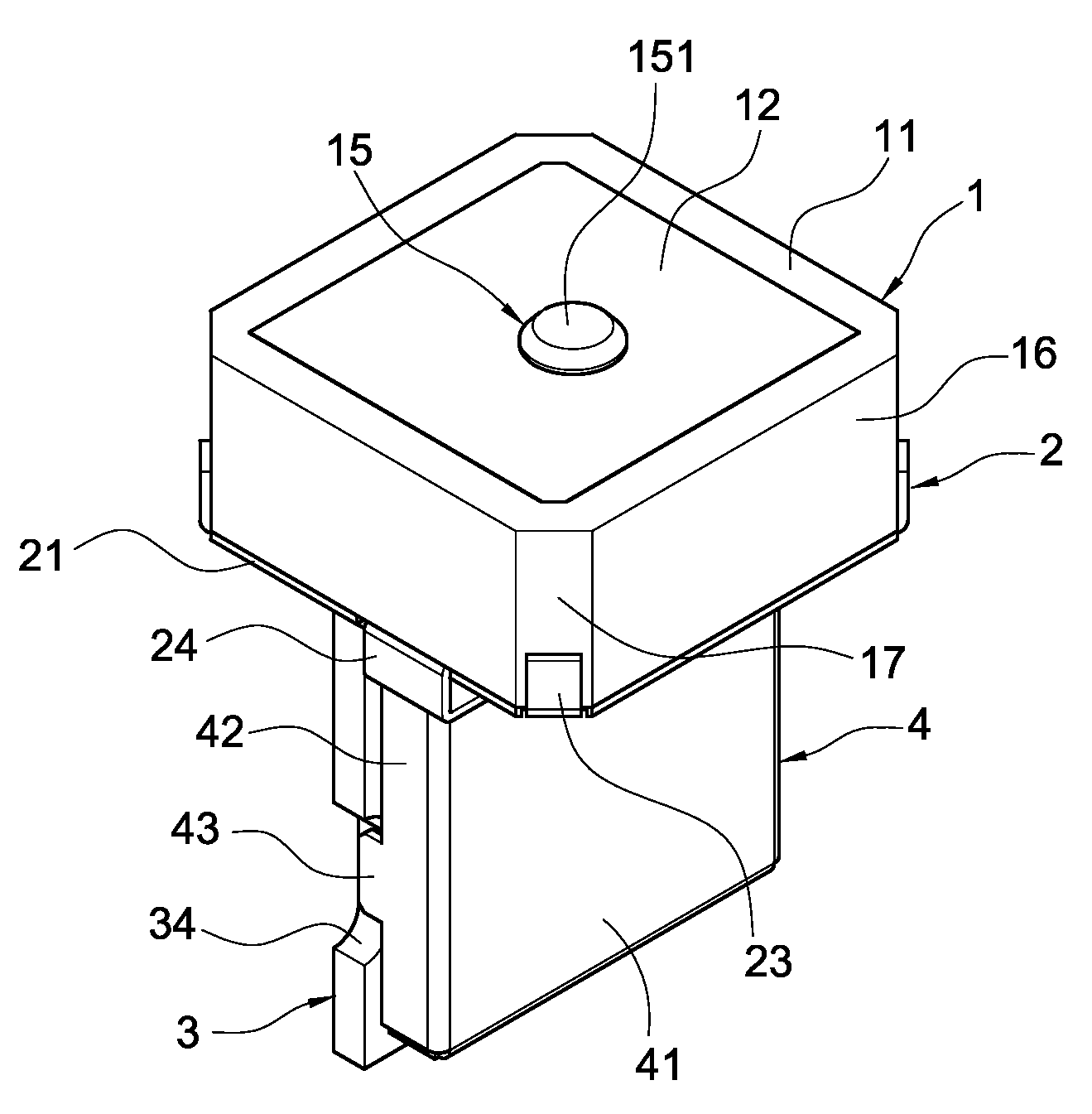

Cleaning tool

ActiveCN107997708ASimple structureEasy to manufactureCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a cleaning tool. The cleaning tool comprises a mop bucket and a mop. The mop comprises a mop rod, a bottom board and a rotation joint. The mop rod comprises an outer rod body and an inner rod body. The rotation joint comprises a first rotation part and a second rotation part. The bottom of the mop bucket is provided with a lifting mechanism. The lifting mechanism comprisesa fixing column fixed at the bottom of the mop bucket, a moving tube and a positioning rod. The moving tube is sheathed outside the fixing column. The positioning rod passes through the moving tube and is inserted in an inserting hole at the center of the fixing column, and the positioning rod is rotated relative to the fixing column. The lifting structure of the cleaning tool is simplified, and the operation is convenient, so the washing and dewatering functions of the mop are combined and coaxially performed, and the volume of the mop bucket can be reduced. The locking structure of the mop rod is simplified, and the angle between the mop rod and a faceplate can be conveniently adjusted and positioned. The locking structure is suitable for the mop or other cleaning tools with the similardemand. In addition, wiping cloth is effectively fixed on a bottom plate of the mop through a fixing claw by the lower faceplate, so the service life of the mop is prolonged.

Owner:HEBEI JIESHIBAO DAILY PLASTIC PROD CO LTD

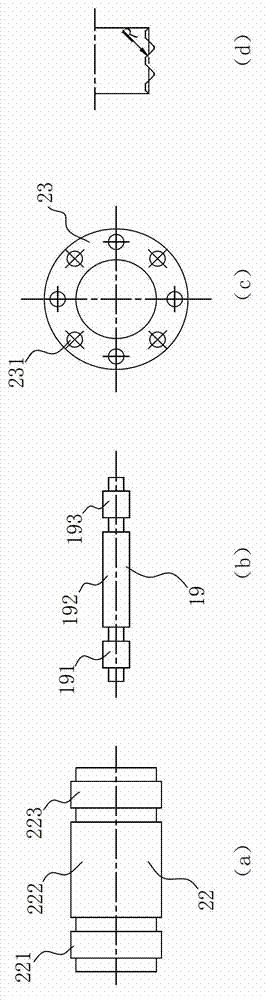

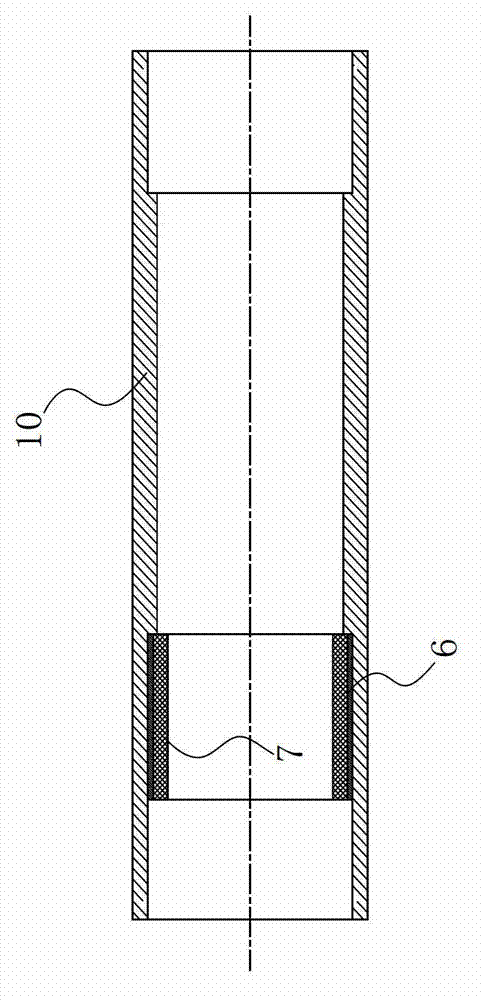

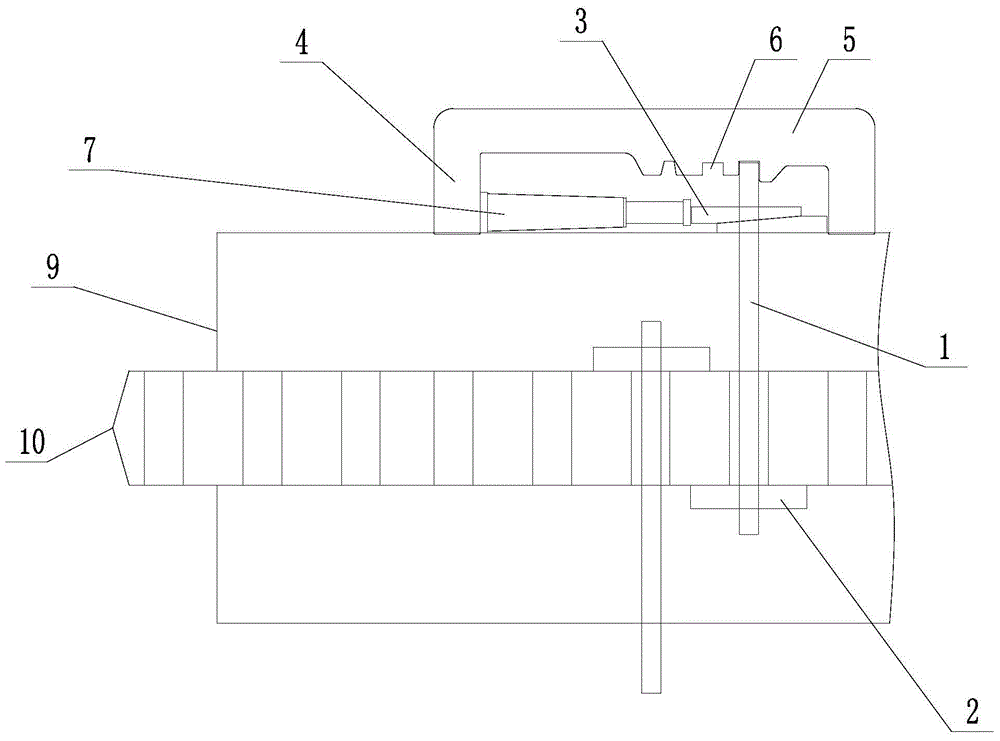

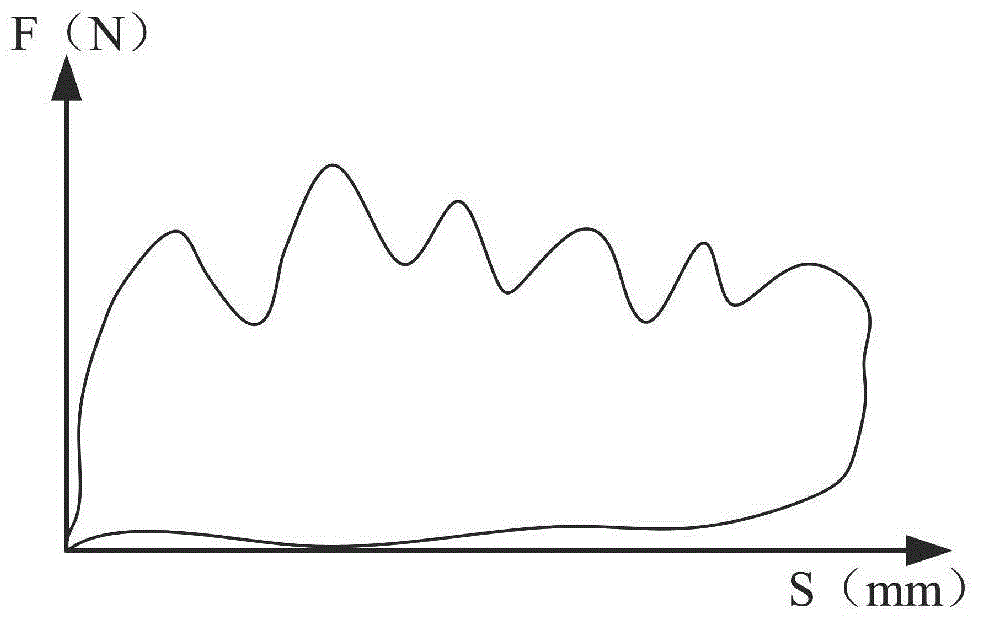

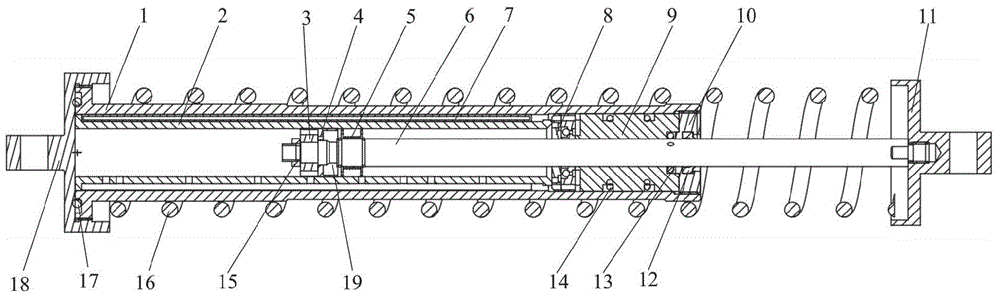

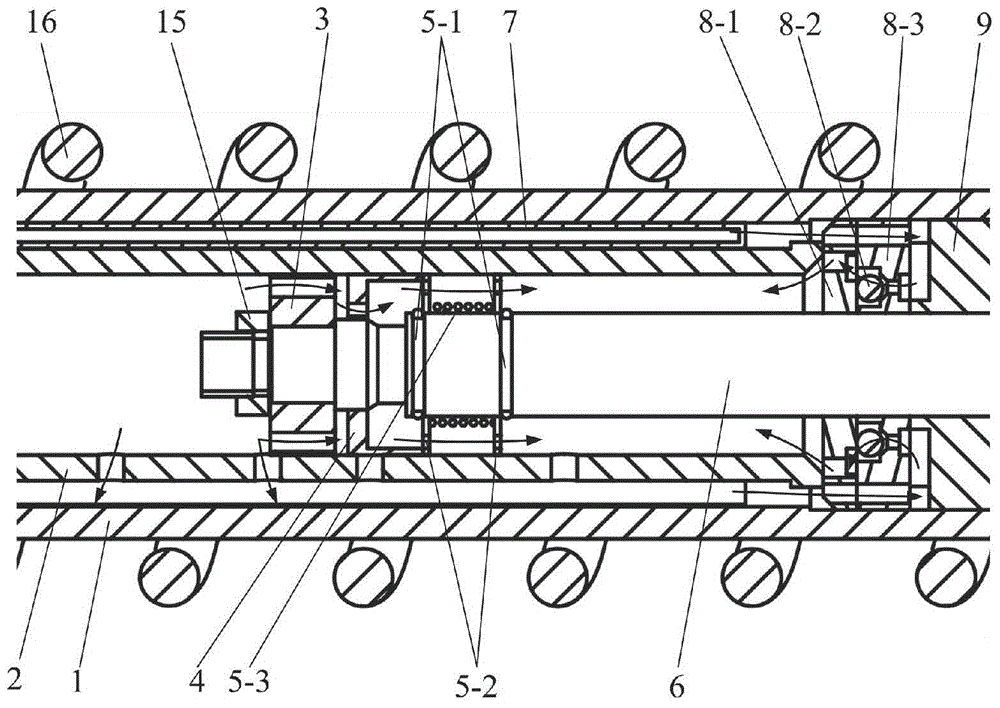

Mechanical and electrical integration linear driving device

ActiveCN103199649AReduced assembly effortReduce processing difficultyMechanical energy handlingElectric machineCylinder block

The invention relates to a linear driving device and aims to provide a mechanical and electrical integration linear driving device which is reliable in performance, simple in structure, convenient to assemble, and cost-saving. The mechanical and electrical integration linear driving device comprises an output shaft, a lead screw pair and a cylinder body, wherein the output shaft is connected with the lead screw pair, a stator module is fixed inside the cylinder body, a lead screw nut of the lead screw pair is of a long cylinder shape, and a rotor module which is matched with the stator module is fixed outside the lead screw nut. The stator module of a motor is designed on the lead screw nut of the lead screw pair, namely the motor stator module and the lead screw nut are regarded as a whole to form a stator of the motor, the motor stator is placed inside the linear driving device, namely the motor stator module and the cylinder body are regarded as a whole to form a rotor of the motor, and therefore mechanical and electrical integration of the linear driving device is achieved. The mechanical and electrical integration linear driving device has the advantages of being reliable in performance, simple in structure, convenient to assemble and cost-saving.

Owner:成都瑞迪智驱科技股份有限公司

Modularized planar antenna structure

ActiveUS20080231519A1Low costReduced assembly effortSimultaneous aerial operationsAntenna supports/mountingsCircularly polarized antennaElectromagnetic interference

A modularized planar antenna structure includes an antenna unit, a connection unit, a circuit board and a cover. The modularized planar antenna structure connects the antenna unit and circuit board. The antenna unit includes a signal feeder electrically connected the circuit board at end thereof such that the antenna unit is vertical to the circuit board. The cover is assembled to the circuit to protect the circuit board from electromagnetic interference or strike of external article. When the antenna structure is assembled to a main circuit board of an electronic device, the circuit board can be directly assembled to the main circuit board of an electronic device and the circular-polarized antenna unit points toward zenith direction to receive satellite signal.

Owner:CIROCOMM TECH CORP

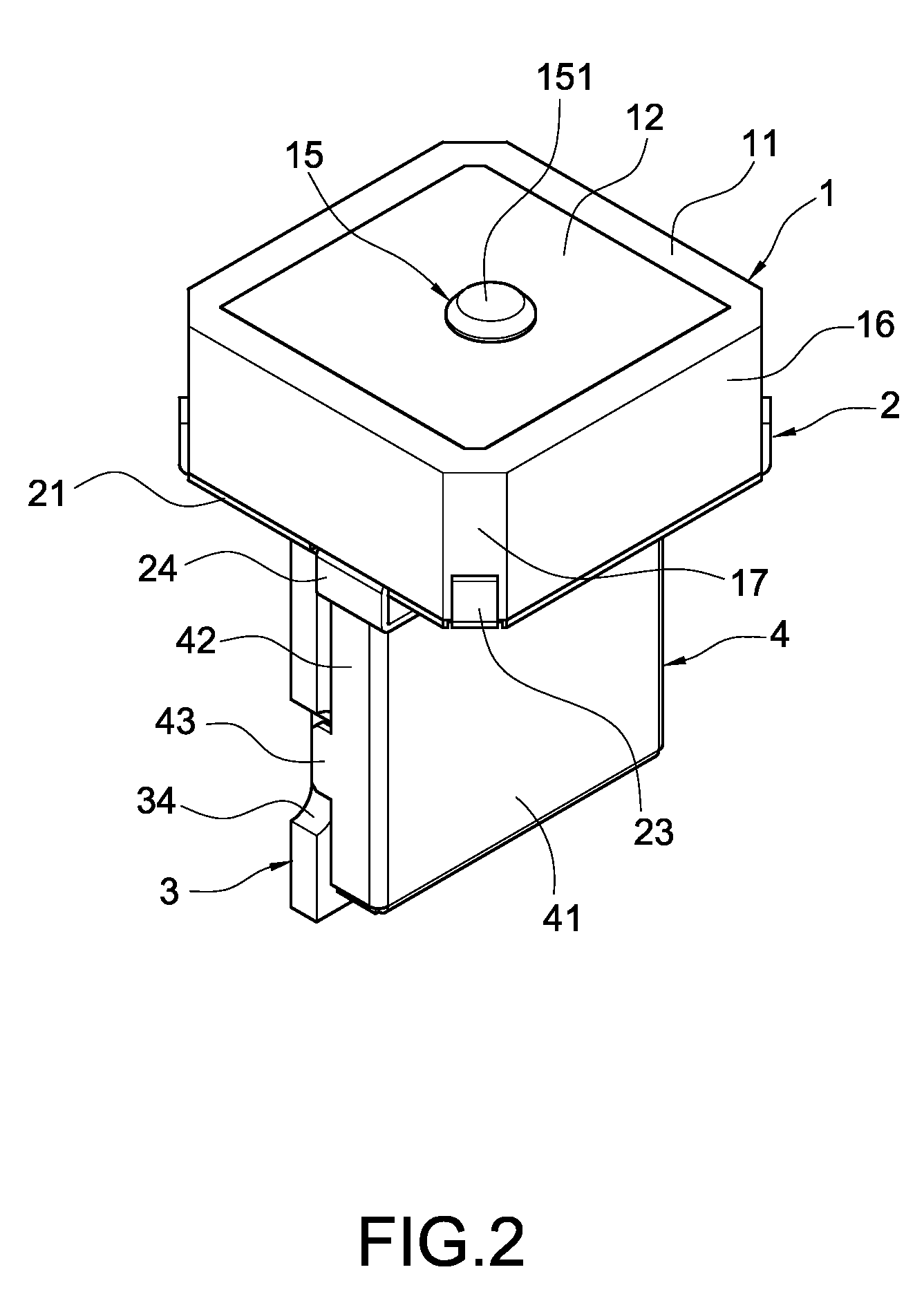

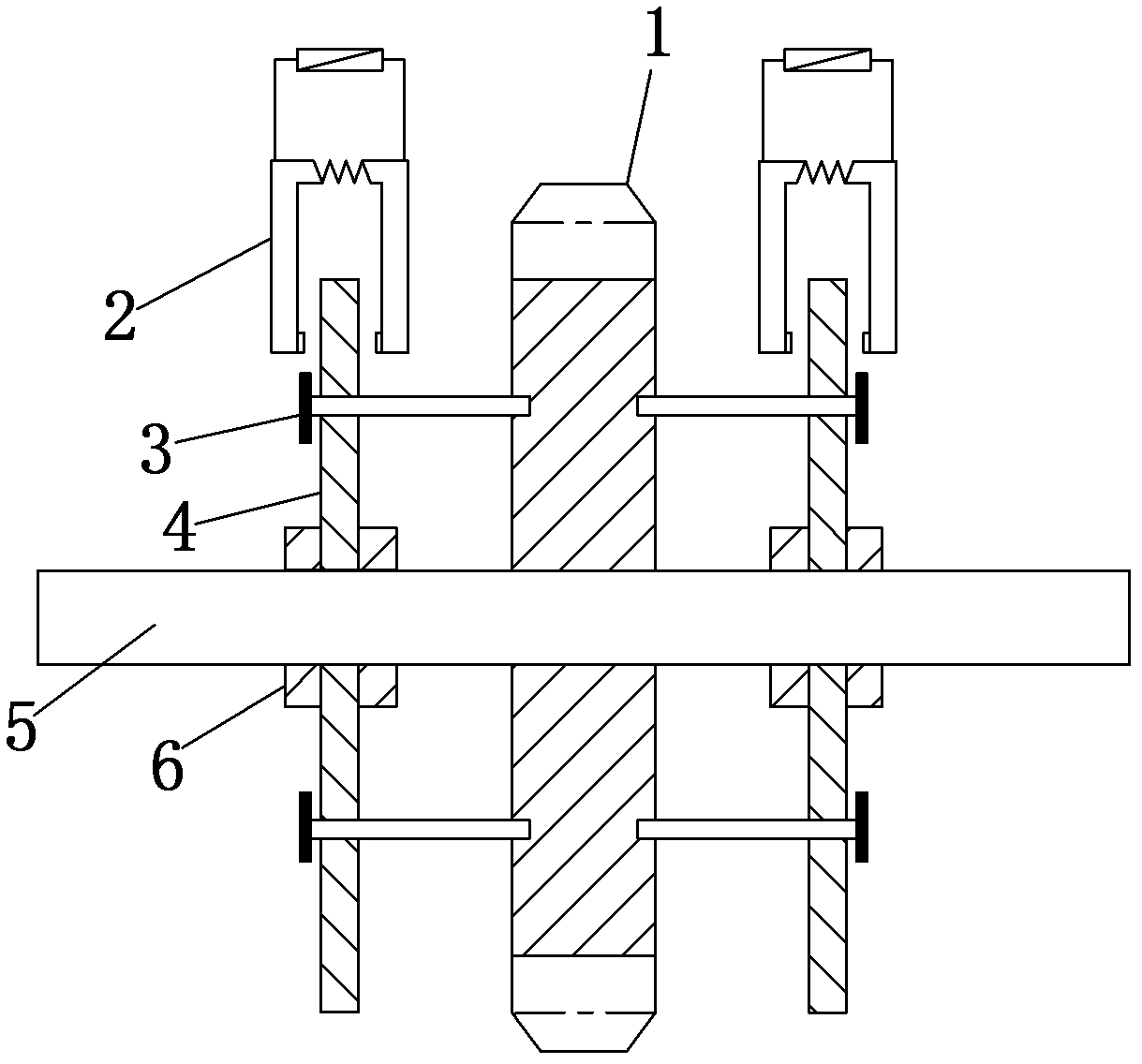

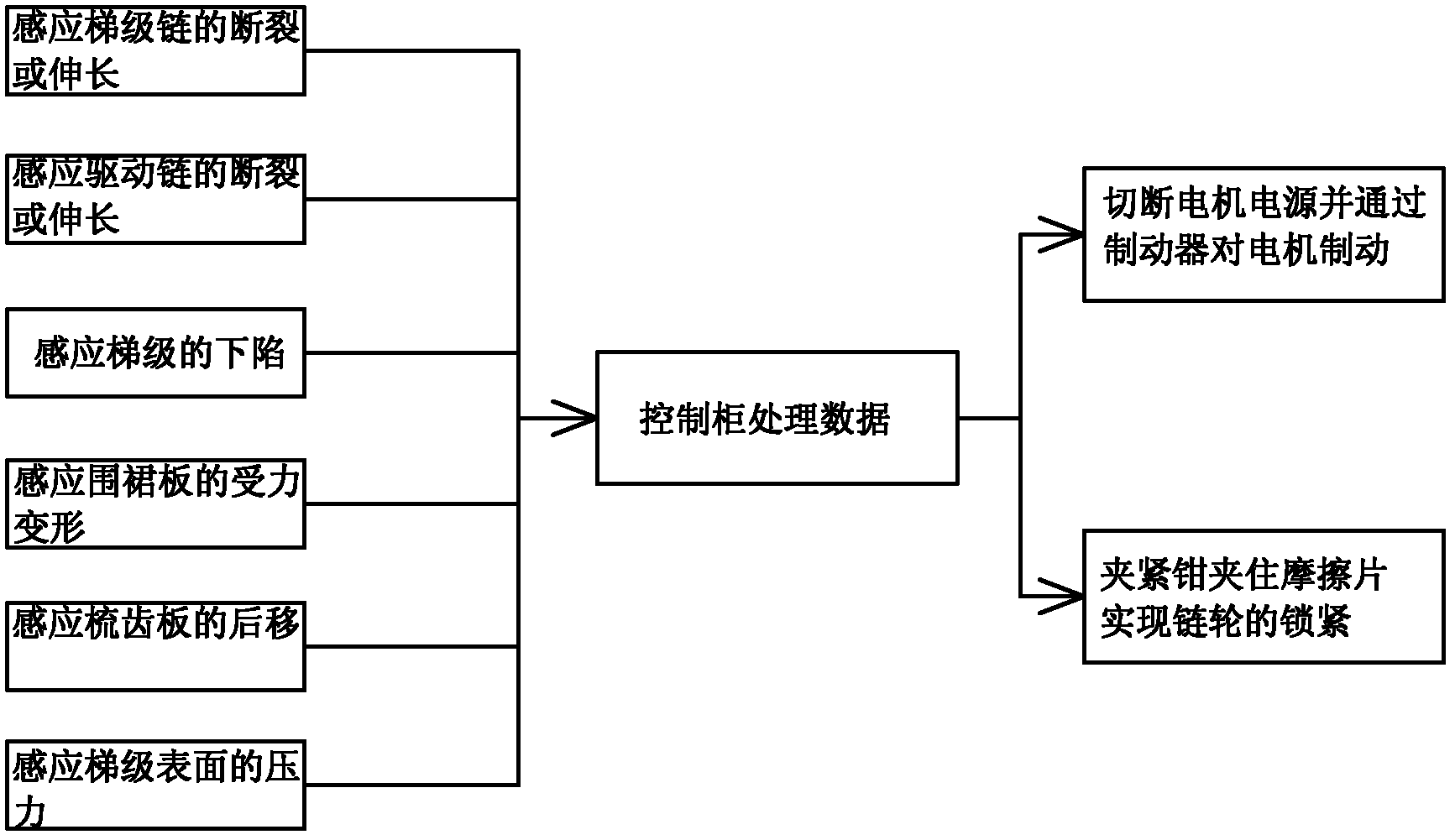

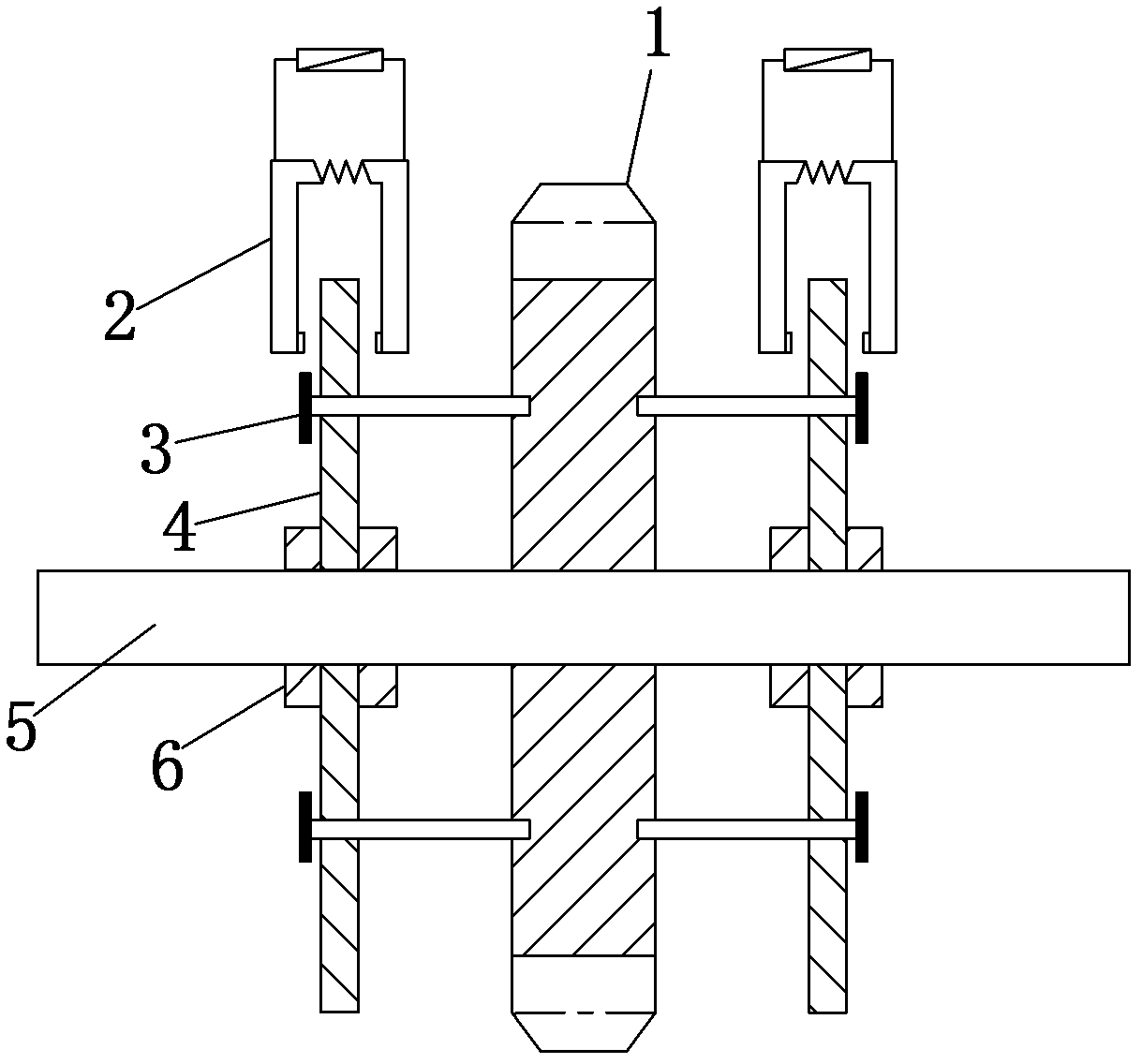

Safety braking method of automatic escalator and device

The invention discloses a safety braking method of an automatic escalator, which is characterized by comprising the following steps of: adopting a sensor to detect the abnormal condition of the automatic escalator and / or passengers, transmitting feedback signals of the sensor to a control cabinet to cut off a power supply of a motor for braking, and carrying out locked braking on a chain wheel connected with the motor. In the invention, a double-braking mode is adopted for the occurring abnormal condition of the automatic escalator and the passengers, so that the inverse operation of the escalator is avoided and the safety of the passengers is ensured.

Owner:王锡林

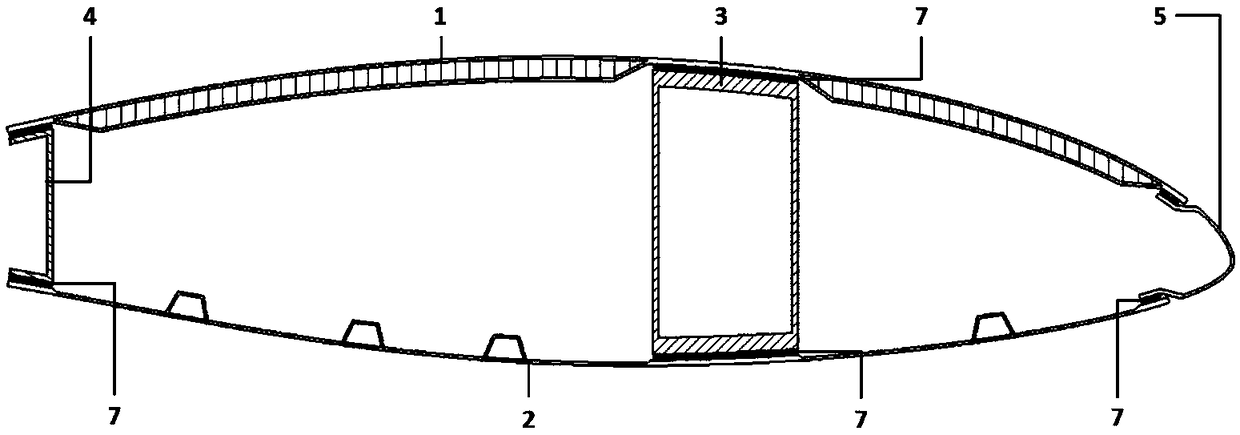

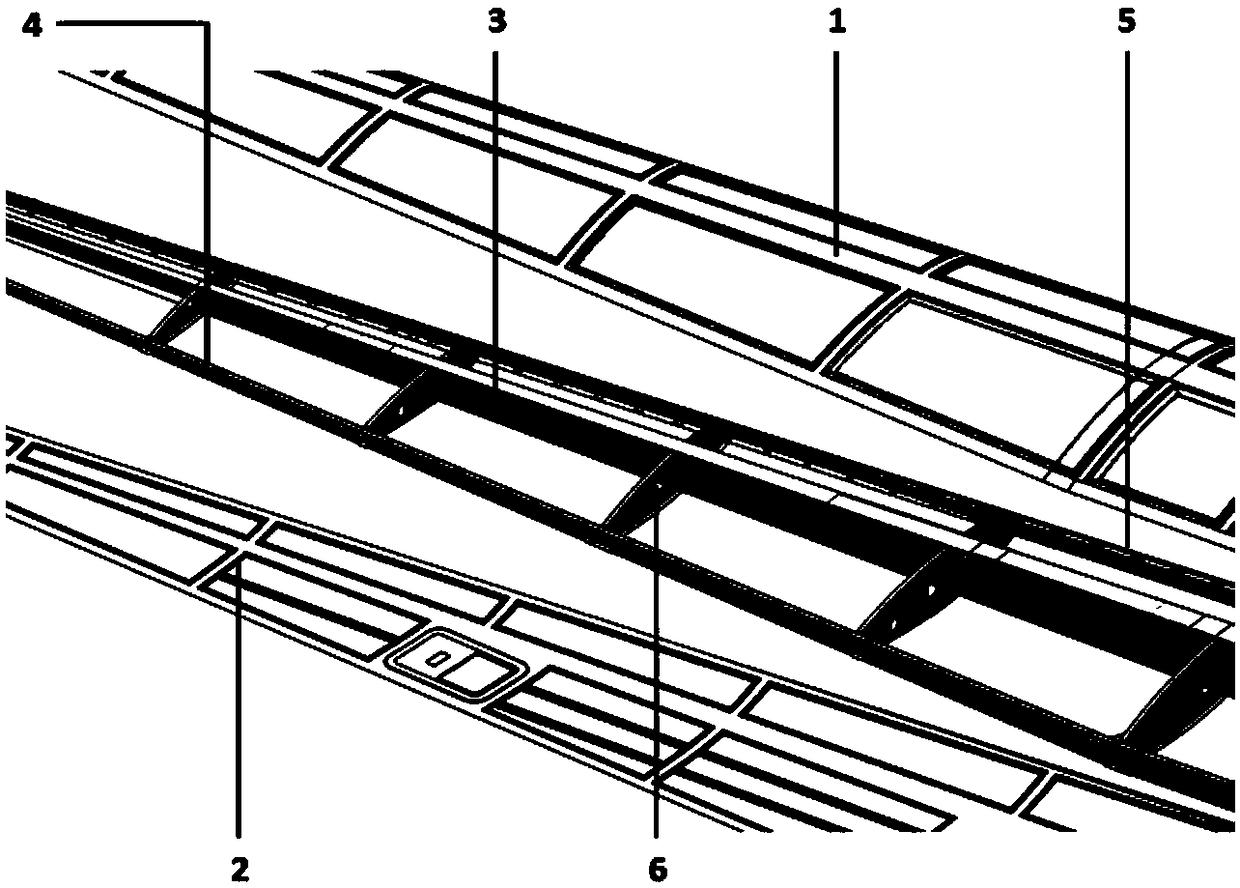

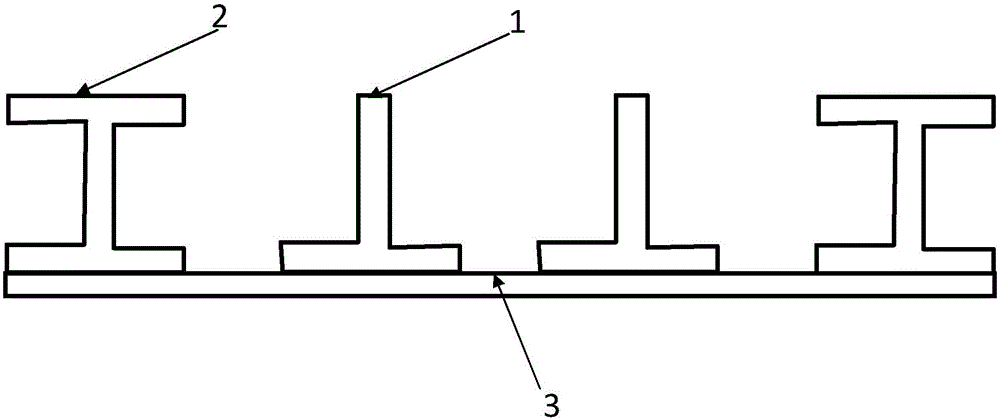

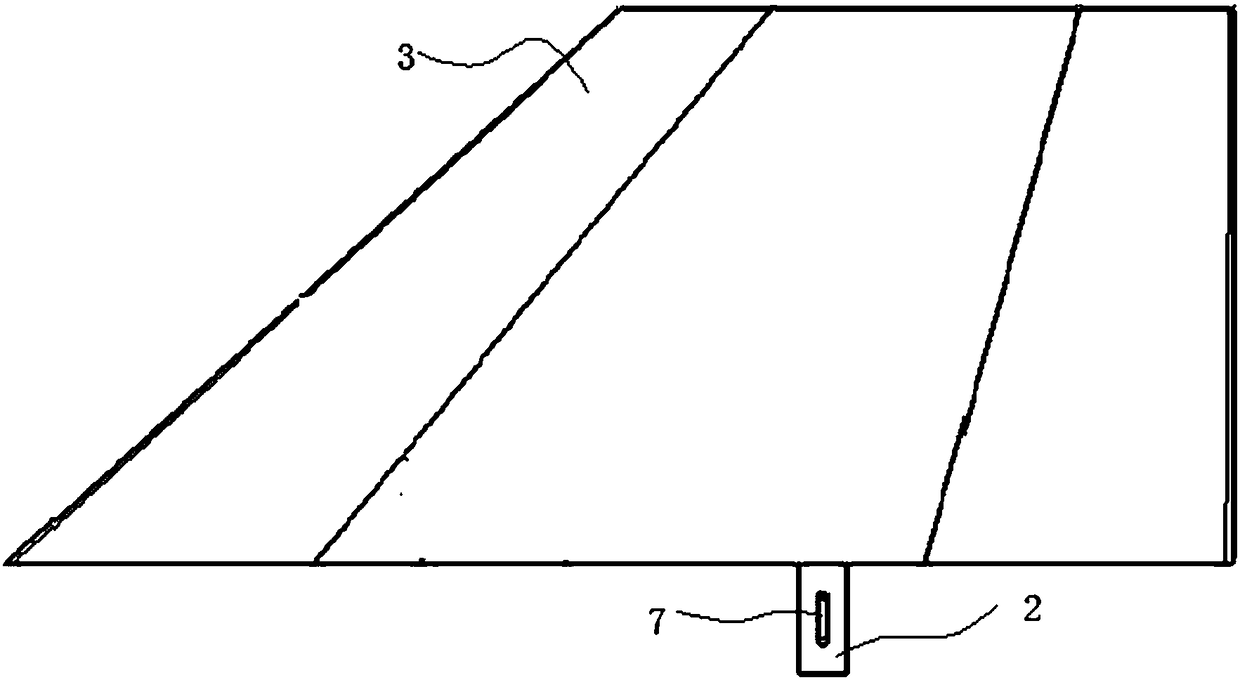

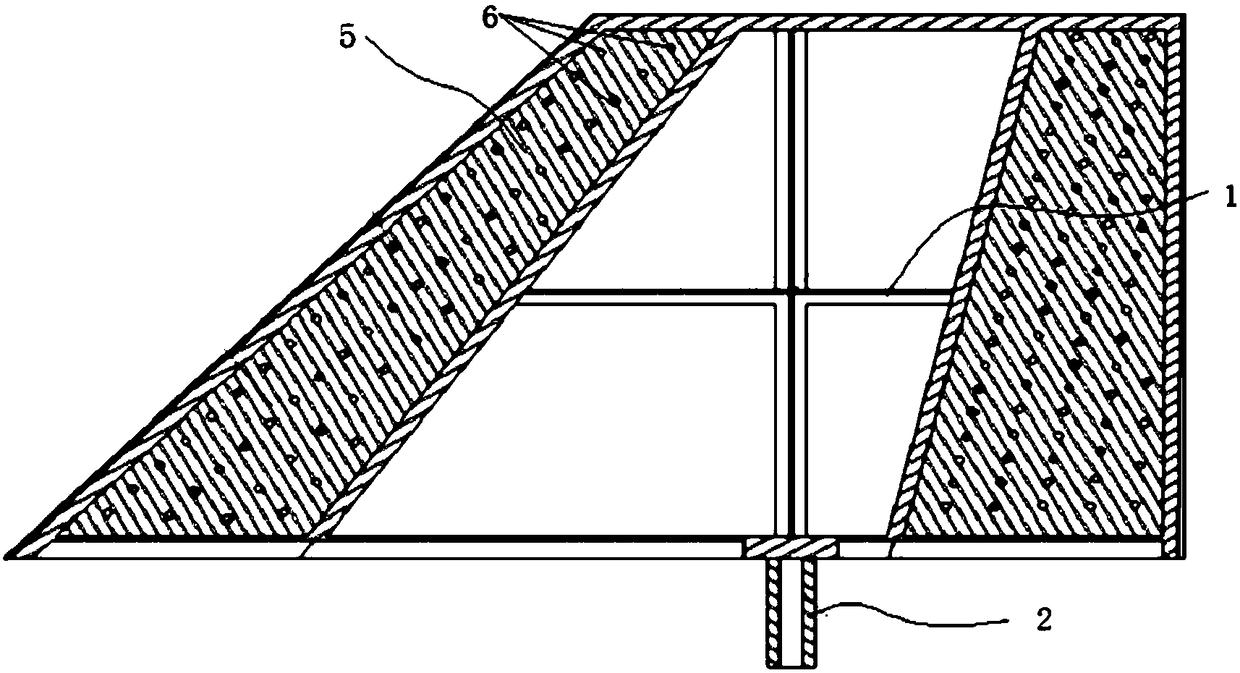

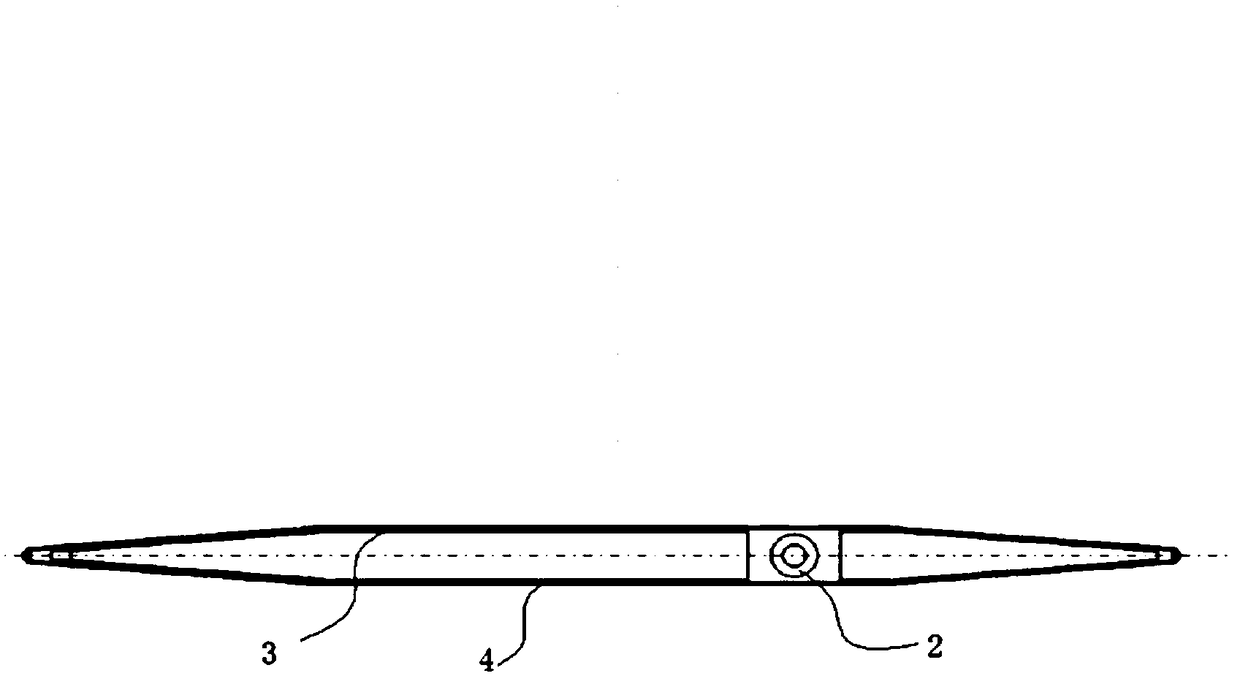

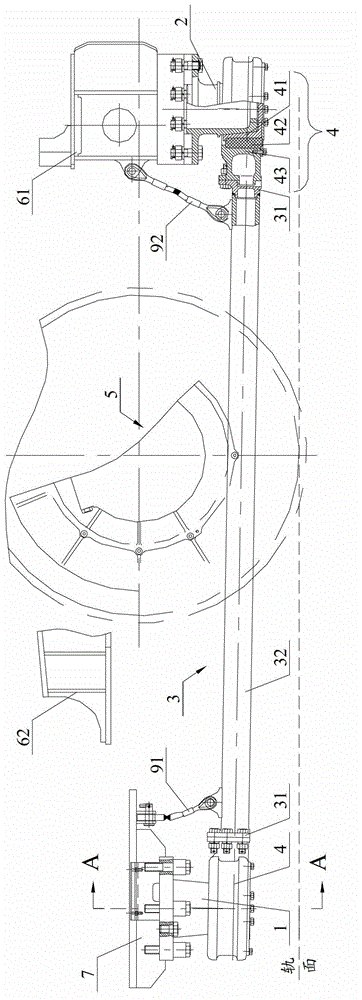

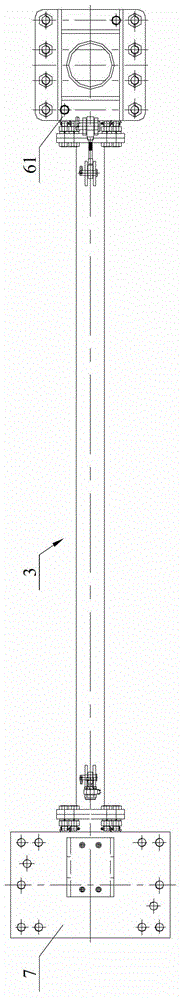

Main wing surface structure of large aspect ratio wing

The invention relates to a main wing surface structure of large aspect ratio wing, and belongs to the field of aviation. The main wing surface structure with the large aspect ratio comprises a honeycomb sandwich upper wall panel 1, a cap type reinforced lower wall panel 2, a box type main beam 3, a rear wall 4, a leading edge skin 5, a wing rib 6 and an adhesive 7. The honeycomb sandwich upper wall panel 1 is of a sandwich structure co-cured by carbon fiber composite inner and outer panels and a lightweight paper honeycomb. The cap-type reinforced lower wall panel 2 is of a cap type reinforcedstructure integrally cured by a carbon fiber composite skin and a foam core. The box type main beam 3 is of an integrated structure co-cured by adhering carbon fiber composite materials. The rear wall 4, the leading edge skin 5 and the wing rib 6 are of a carbon fiber composite press plate structure. The adhesive 7 is a room temperature curing paste adhesive. According to the respective bearing characteristics, each component adopts the corresponding structural form, which fully exerts the weight loss advantage of the composite material, and effectively solves the contradiction between the high load bearing and the light weight of the main wing surface structure of large aspect ratio wing.

Owner:中航(成都)无人机系统股份有限公司

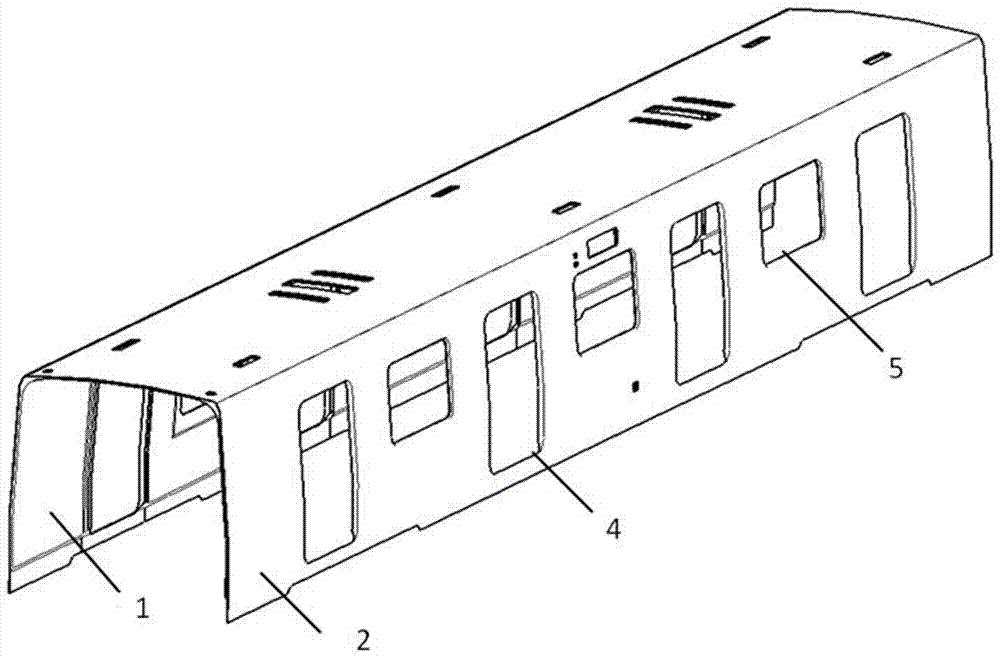

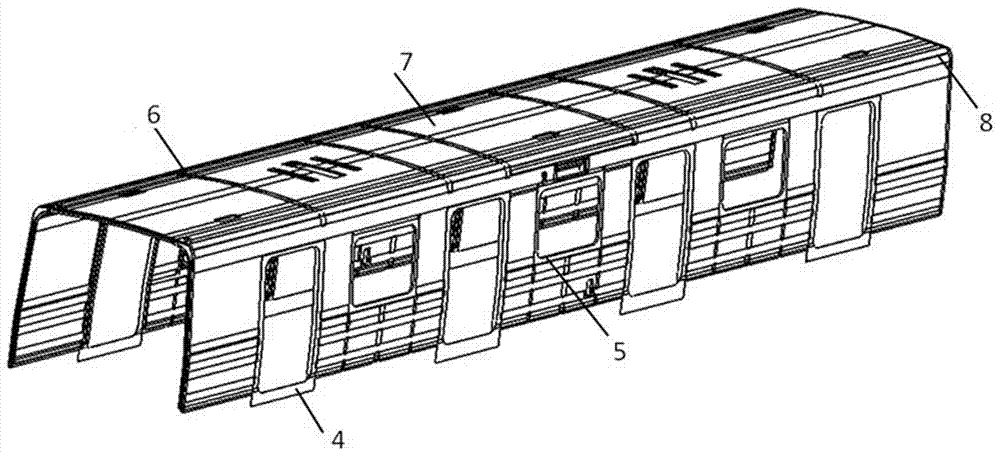

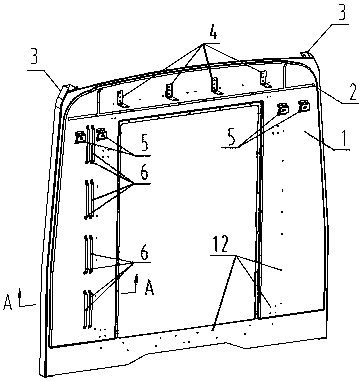

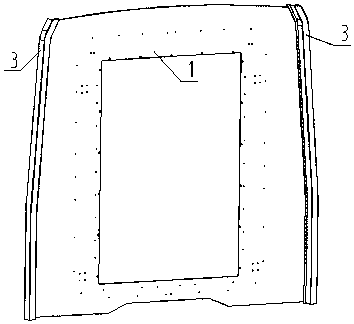

Carbon fiber composite end wall structure for subway

InactiveCN107792103AHigh specific strengthObvious weight loss effectAxle-box lubricationRailway bodiesAdhesiveHoneycomb

The invention provides a carbon fiber composite material end wall structure for subway, which includes an end wall interlayer structure, a grounding copper bar, a drainage pipe, a wiring trough installation hanger, an electrical cabinet installation seat and a cable tie rod. The end wall interlayer structure includes an integral reinforcement frame, Honeycomb sandwich core, end wall inserts, inner skin and outer skin, the overall reinforcement frame, honeycomb sandwich core, and end wall inserts are all built between the inner skin and outer skin, and the overall reinforcement frame adopts an integrated hat-shaped structure , the two sides of the overall reinforced frame are respectively provided with honeycomb sandwich, the end wall inserts are set in the honeycomb sandwich, the end wall inserts are provided with threaded holes, and the grounding copper bar is connected to the inner skin of the end wall sandwich structure by glue riveting The upper part of the side; this kind of carbon fiber composite material end wall structure for subway can give full play to the characteristics of high specific strength and large specific modulus of carbon fiber composite materials, and the effect of weight reduction is outstanding; the integrated design simplifies the redundant traditional welding structure , reduce the assembly workload.

Owner:HENGSHEN

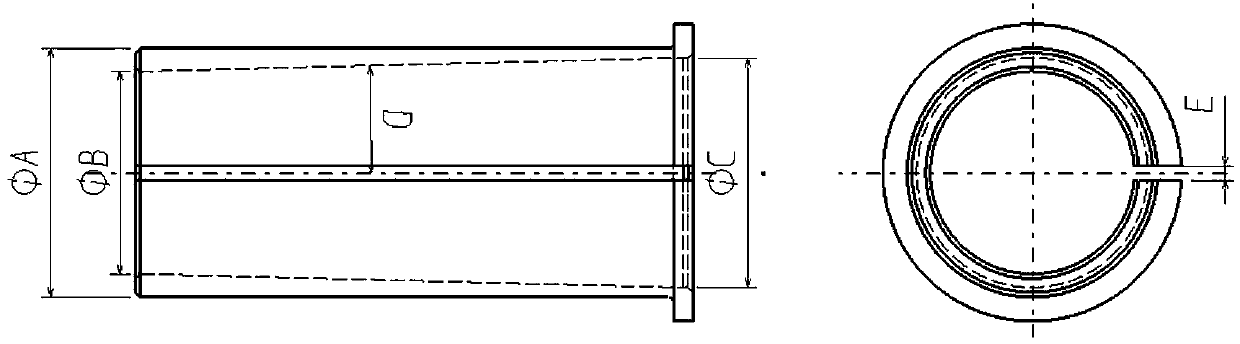

Process method for assembling and welding pile leg of ocean platform

InactiveCN105057857AWelding quality is easy to controlDimensional accuracy is easy to controlArc welding apparatusProduction lineEngineering

The invention discloses a process method for assembling and welding a pile leg of an ocean platform. According to the method, the production speed is high, and the percent of pass of products is high. A pile leg assembly is composed of a rack and two semicircular pipes. Coming cargo examination should be carried out on the rack and the semicircular pipes carefully, and the rack and the semicircular pipes are installed through a tool. The rack is turned over through a turnover device. The assembled pile leg examined to be qualified is lifted to an electric heating furnace stage trolley, conveyed into a furnace and heated, wherein the temperature ranges from 150 DEG C to 200 DEG C. The temperature in a hearth should be kept even. The heated pile leg is placed on the ground. Two welding joints are in the horizontal state. Manual welding rods are used for backing welding. Welding is performed on the pile leg by four welding workers from the middle position. The two sides are simultaneously and symmetrically welded. After welding is finished, the pile leg is turned over and welded continuously. After the welding joints are backed for 1 to 2 layers, the pile leg is lifted to roller carriers on a submerged arc welding production line and then formally welded. The welded pile leg is conveyed into a thermal treatment furnace, the heating temperature ranges from 200 DEG C to 280 DEG C and maintained for 2 to 3 hours, and then the pile leg is delivered out of the thermal treatment furnace.

Owner:张家港润通海洋工程科技有限公司

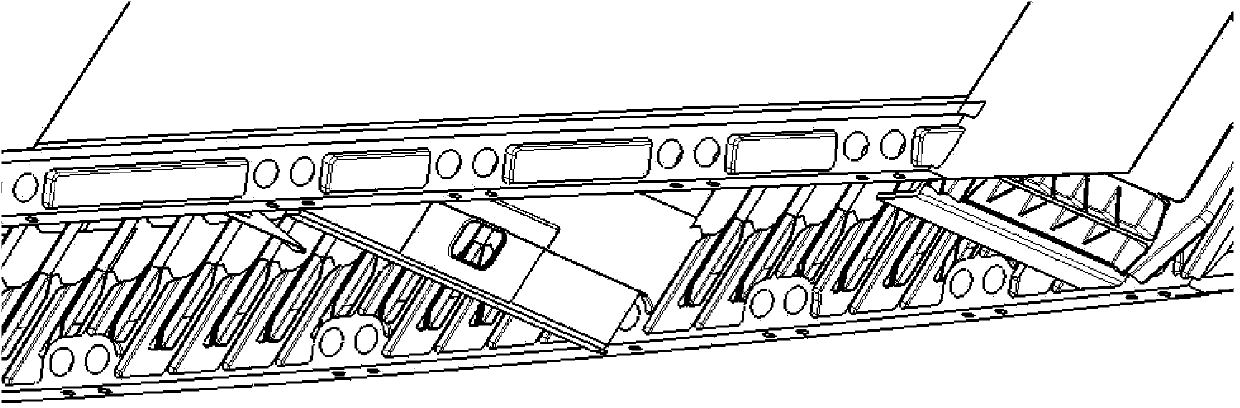

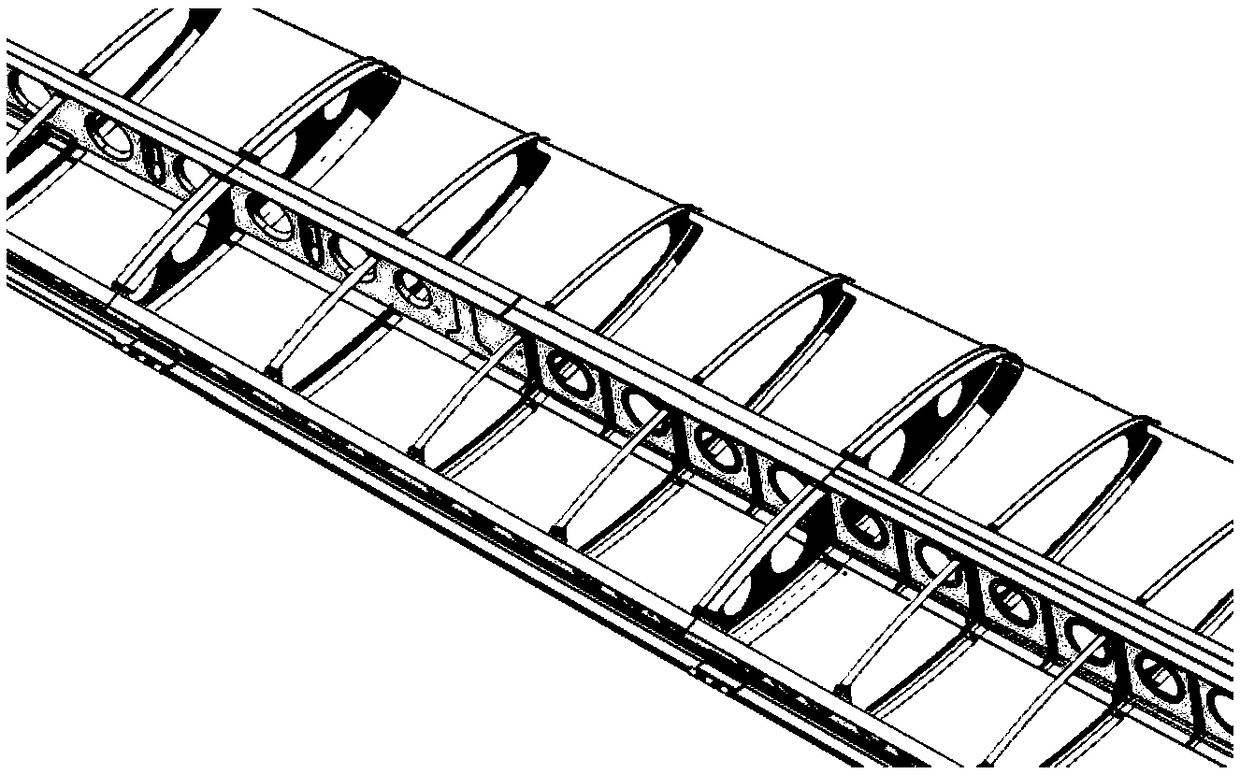

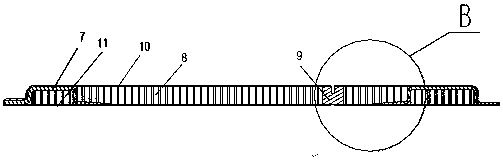

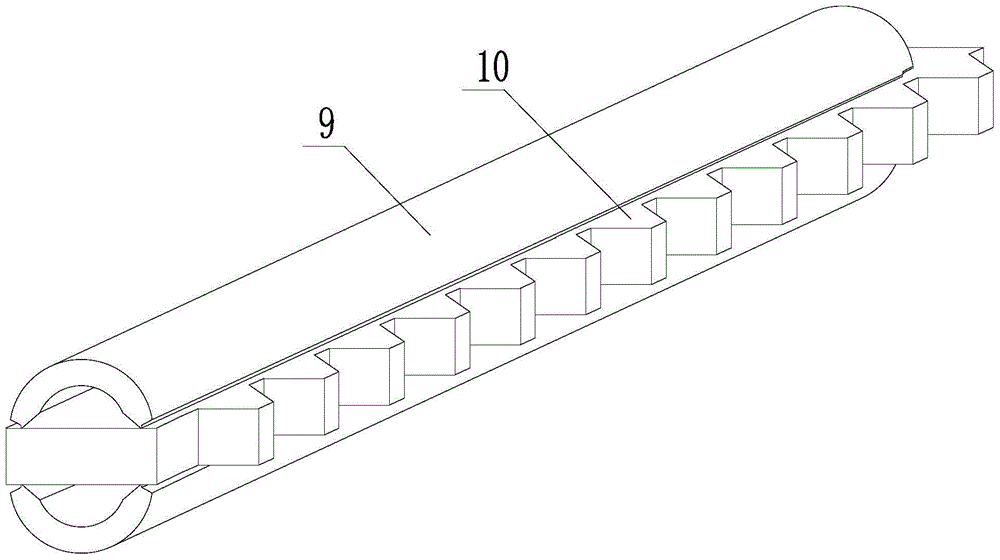

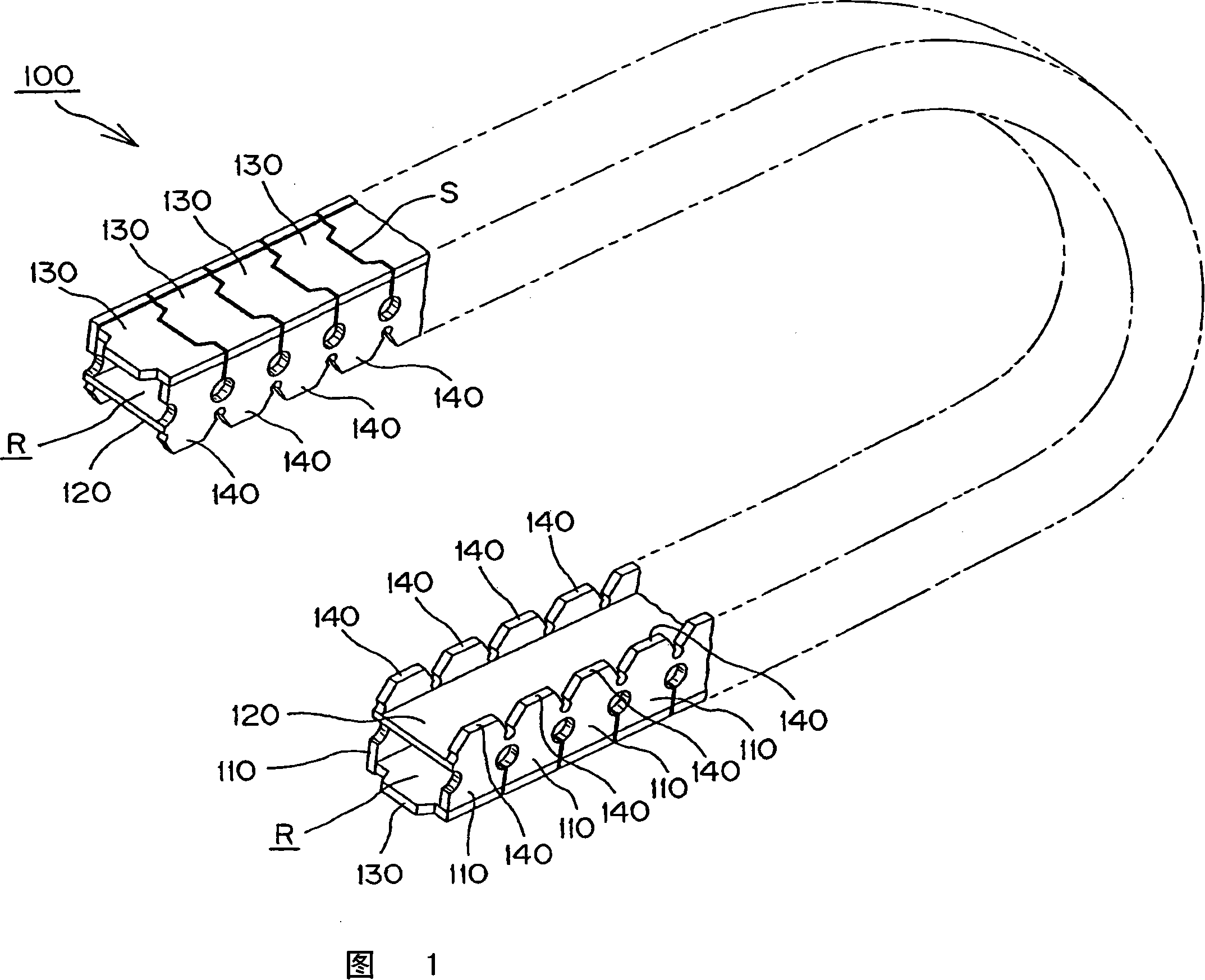

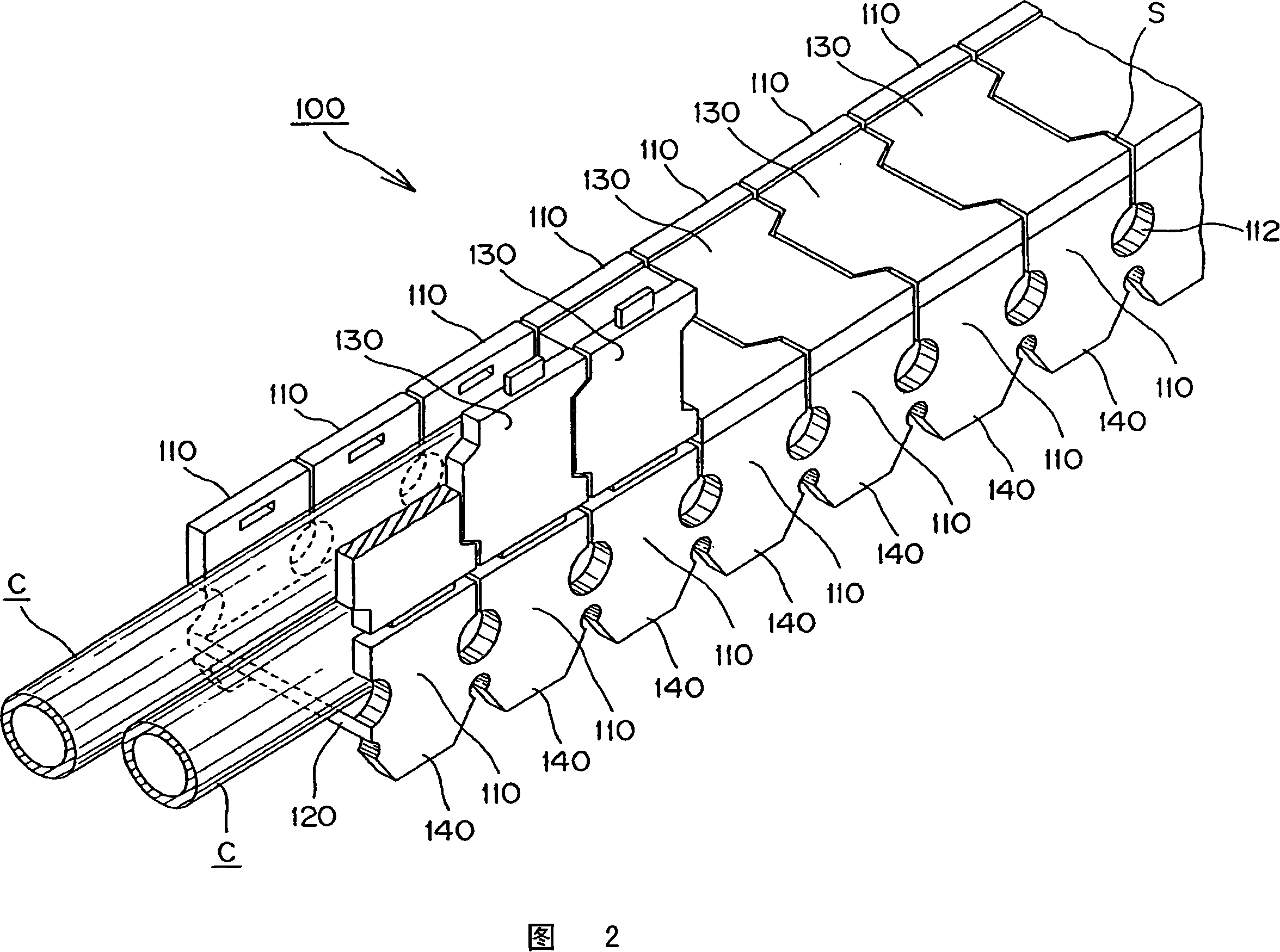

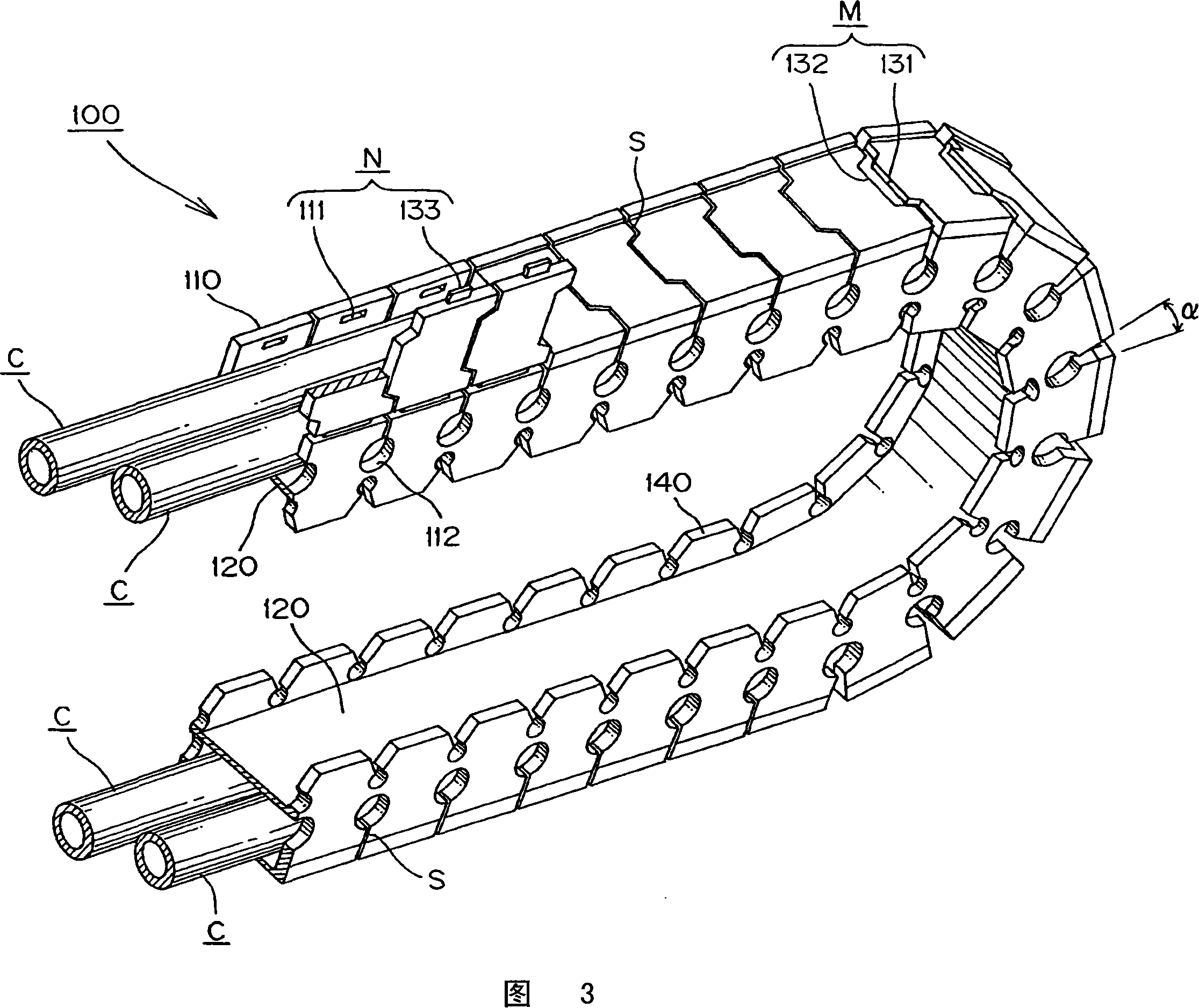

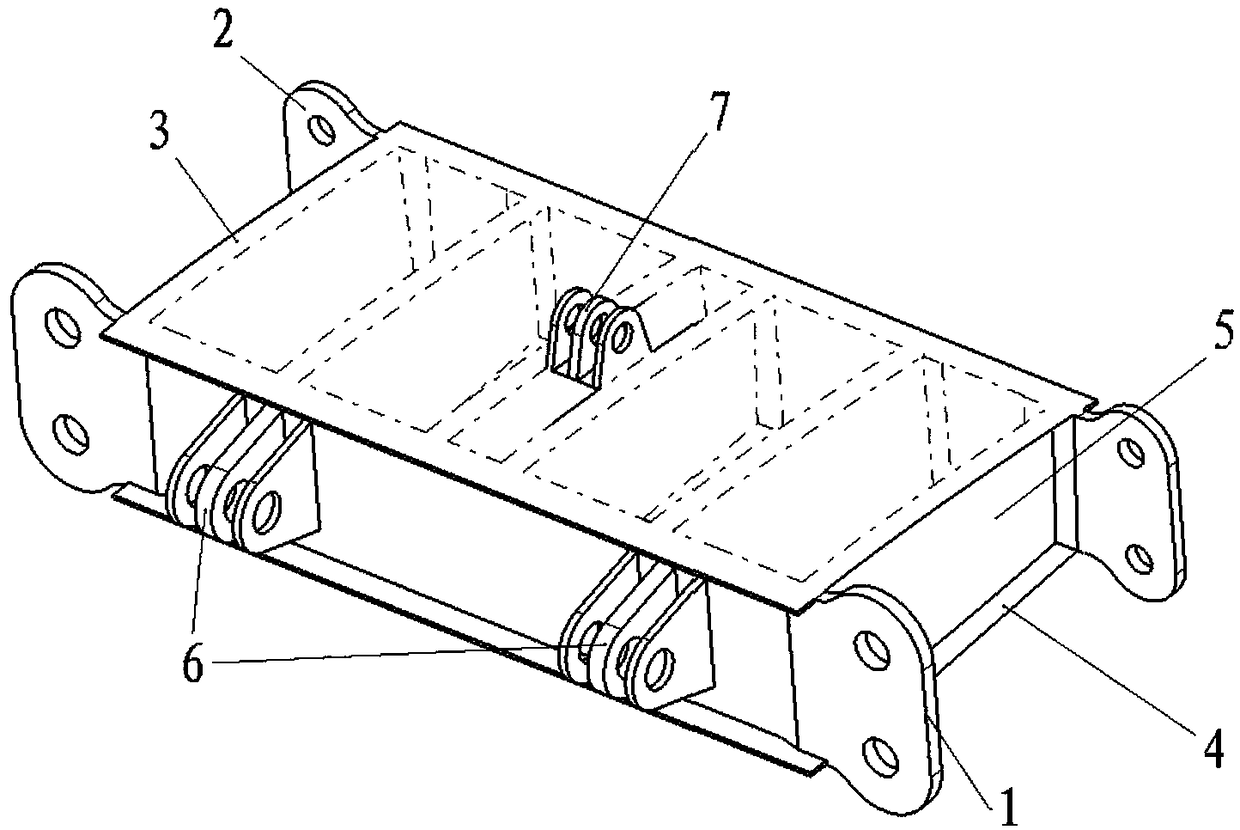

Cable protection guiding apparatus

ActiveCN101141055AEasy maintenanceEasy to operateHauling chainsHoisting chainsEngineeringSynthetic resin

The present invention provides a cable or the like protection and guide device which accommodates a cable or the like while allowing for examination of the cable. Smooth linear and flexional movement is achieved while not compromising the form stability of the cable accommodation space. Partial or local wear is suppressed. The device is made of a synthetic resin and accommodates a cable in a rectangular cable accommodating space. The accommodating space is surrounded by the outer circumferential wall portion, which is openable, a pair of side wall portions, and an inner circumferential wall portion. Inserting protrusion mechanisms, engagement mechanisms, slits, opening windows and flexion restricting piece portions contribute to the stability and usefulness of the device.

Owner:TSUBAKIMOTO CHAIN CO

Small unmanned plane undercarriage buffer

InactiveCN104895995AIncrease the damping factorCurb reboundSpringsShock absorbersAviationUpper joint

A small unmanned plane undercarriage buffer relates to the field of aviation aircrafts and solves problems of low buffering efficiency, easy bounce, low reliability of a present flat spring type buffer. The small unmanned plane undercarriage buffer comprises an external cylinder, a first spring on the external cylinder, an internal cylinder having a damping hole, an air sac between the external cylinder and the internal cylinder; an upper joint, a lower joint, a piston rod extending into the internal cylinder, a piston, a damping plate, a pressure-limiting valve, a check valve, a guide sleeve and a locking cover, wherein the piston rod is orderly covered with the piston, the damping plate and the pressure-limiting plate; the piston rod is orderly covered with the check valve, the guide sleeve and the locking cover; the check valve, the guide sleeve and the locking cover are all disposed in the external cylinder; an internal-external cylinder annular oil storage cavity is formed between the internal cylinder and the external cylinder; the damping plate axially moves along the piston rod; the pressure-limiting plate limits maximum damping force to a preset valve during compression stroke; after the locking cover is tightly screwed, the guide sleeve, the check valve and the internal cylinder are axially pressed to the lower joint; the check valve controls communication between the internal-external cylinder annular oil storage cavity and a right cavity of the internal cylinder; and two ends of a first spring are respectively pressed against the upper and lower joints. The small unmanned plane undercarriage buffer possesses high buffering efficiency, uneasy bounce, stable performance and great reliability.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

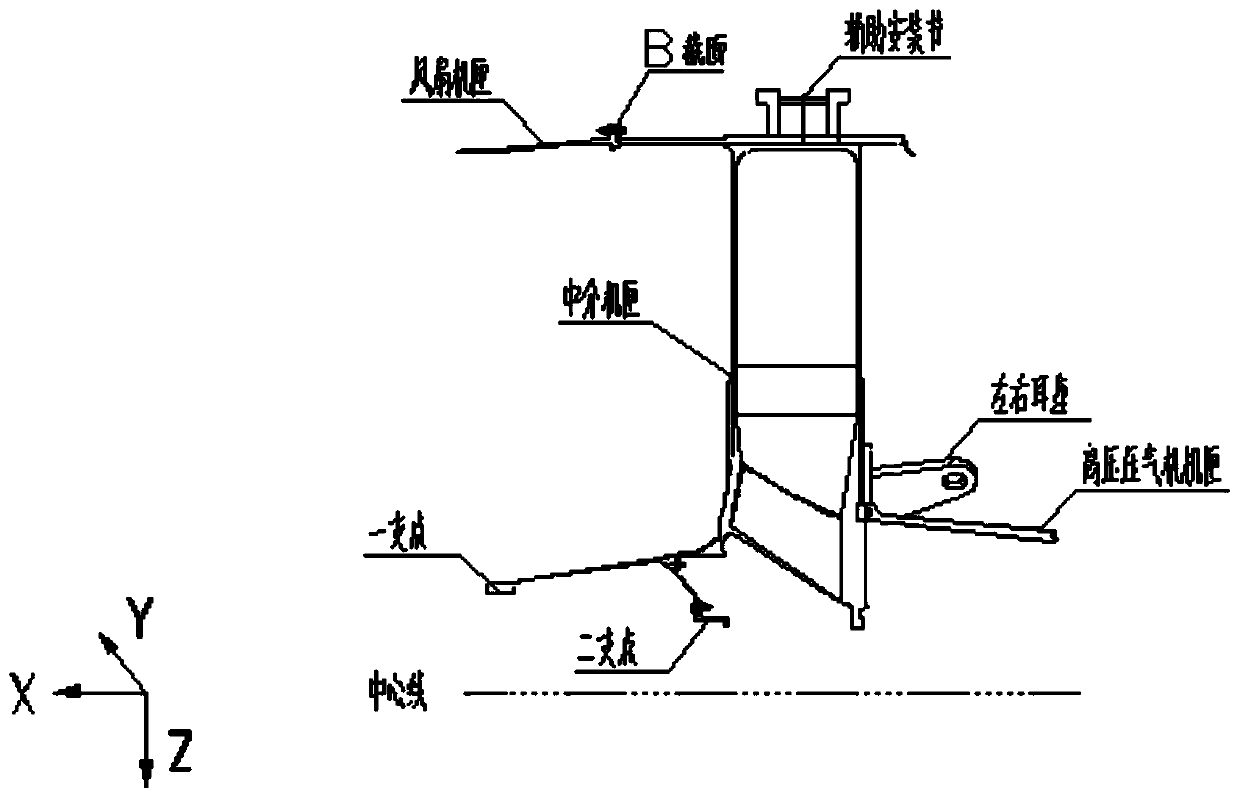

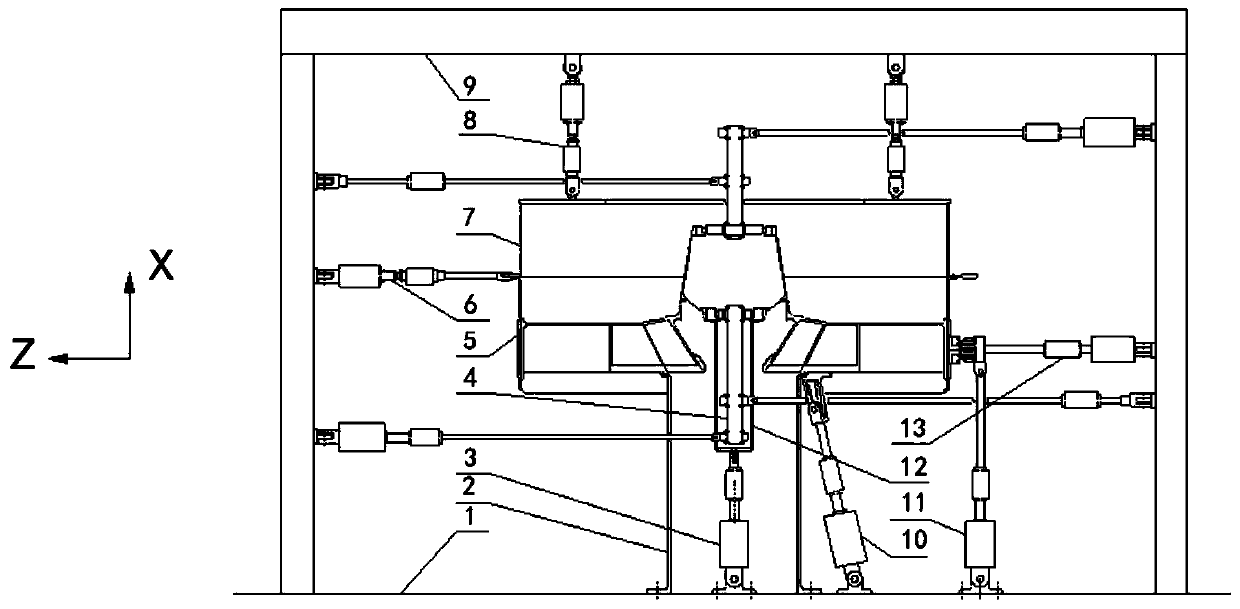

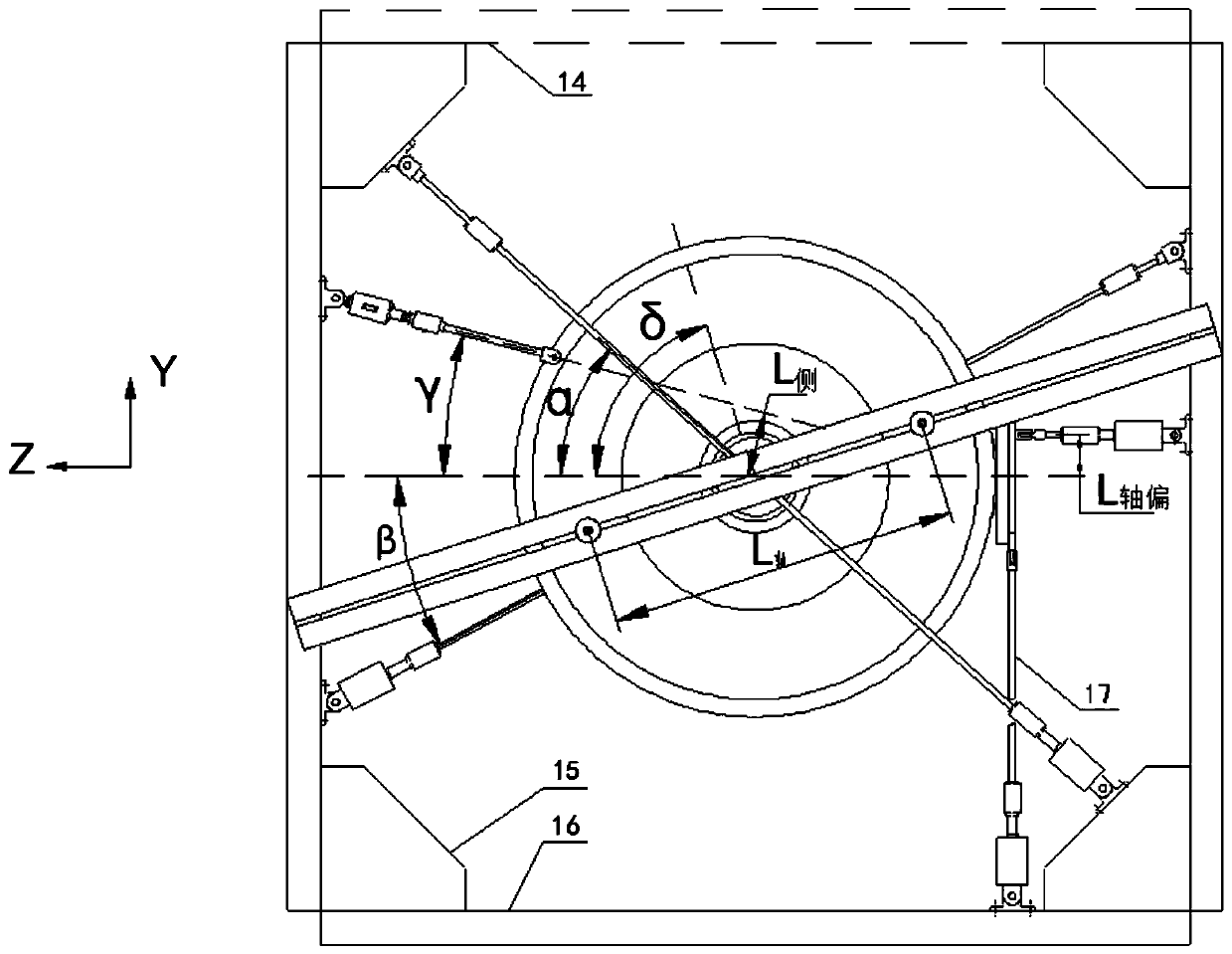

Strength test device for intermediate case of aeroengine with large bypass ratio

The invention belongs to the field of aviation test devices, and particularly relates to a strength test device for an intermediate case of an aeroengine with a large bypass ratio. The strength test device comprises an intermediate case test piece, a bearing assembly, a simulation case and a loading assembly, wherein an auxiliary installation joint, a B-section installation edge, a main installation joint lug set, a first support point and a second support point are arranged at an outer side of the intermediate case test piece, a bottom end of a triangular vertical post of the bearing assemblyis fixedly arranged on a foundation platform, a bearing beam and a bearing wall are arranged on the triangular vertical post, a top-end cross beam is arrange on the bearing beam and / or the triangularvertical beam and / or the bearing wall, a bottom end of a simulation high-pressure compressor case is arranged on the foundation platform, a top end is connected with a bottom end of the intermediatecase test piece, a bottom end of a simulation fan case is in bolt connection with the B-section installation edge, the loading assembly is arranged on the bearing assembly and is used for loading thetwo support points of the intermediate case test piece, a B section, the main installation joint lug seat and the auxiliary installation joint. By the strength test device, the workload can be reduced, and the strength test device is high in universality.

Owner:AECC SHENYANG ENGINE RES INST

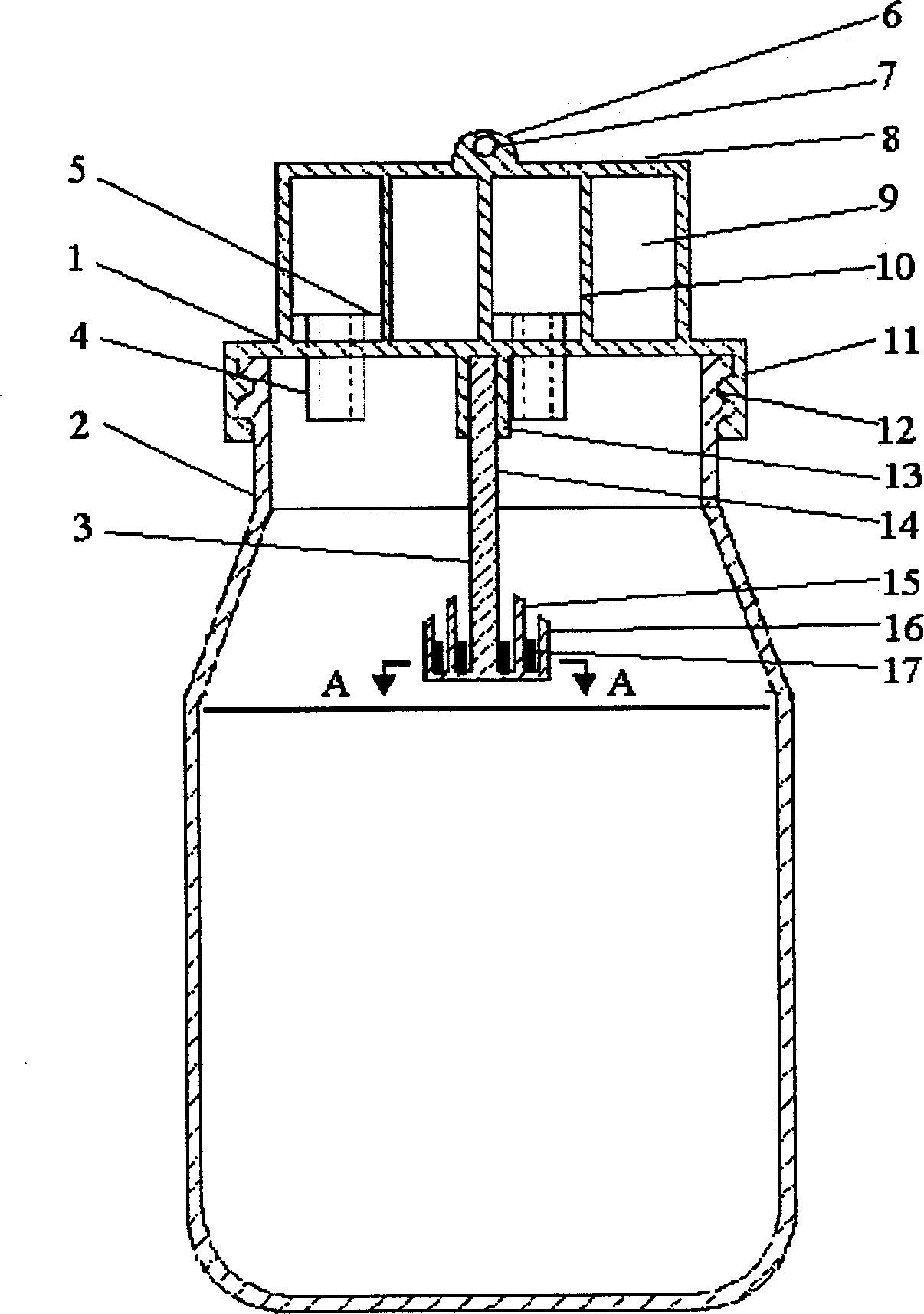

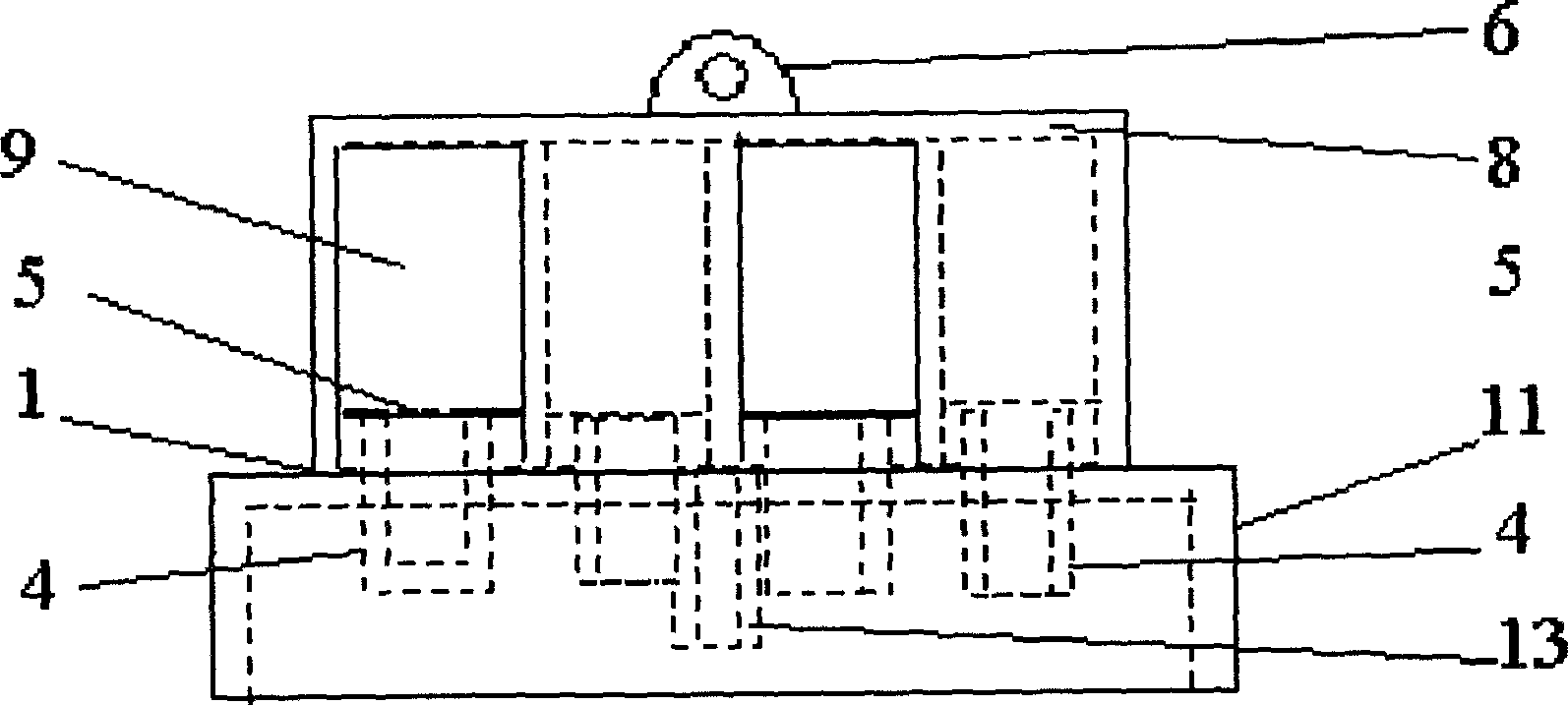

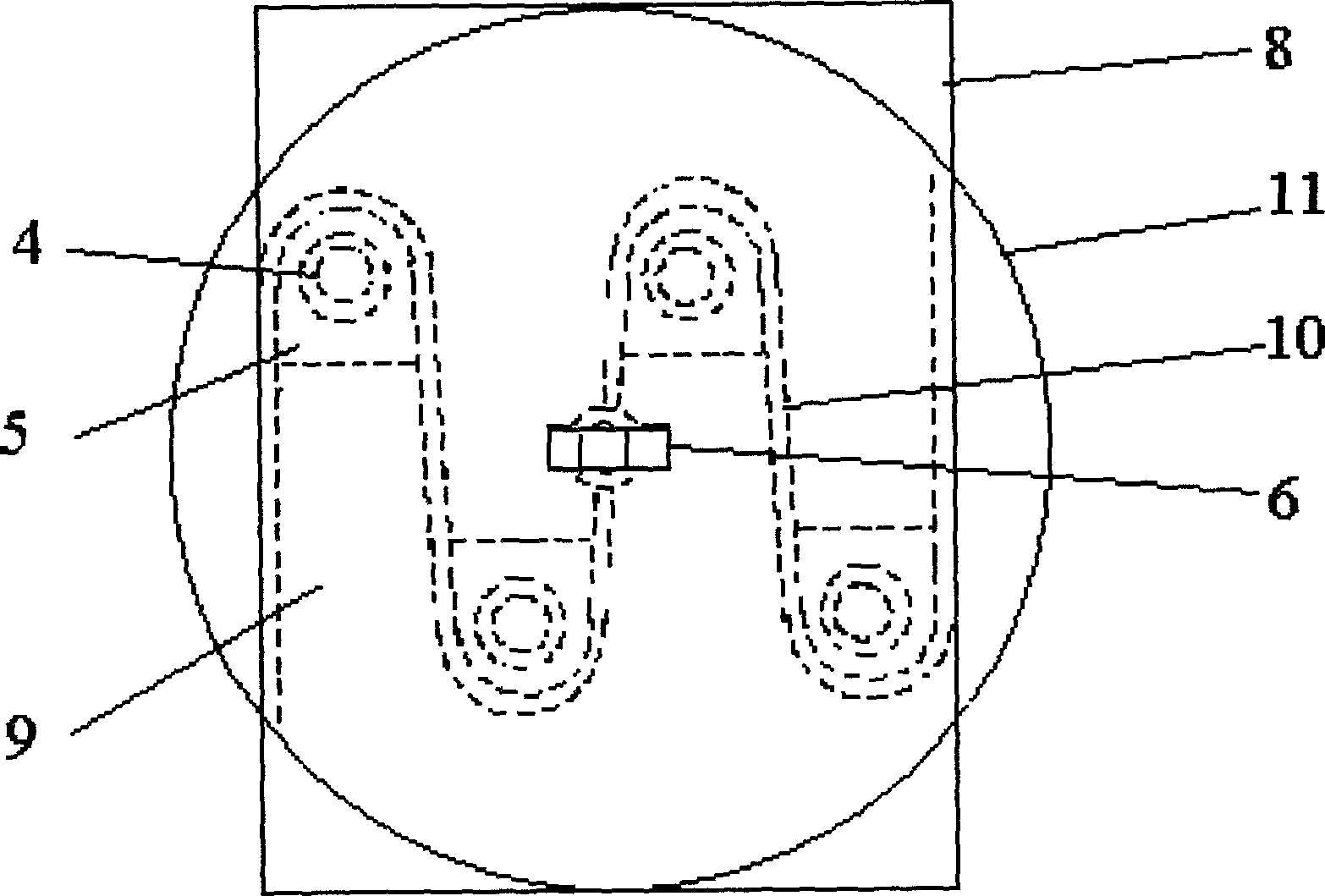

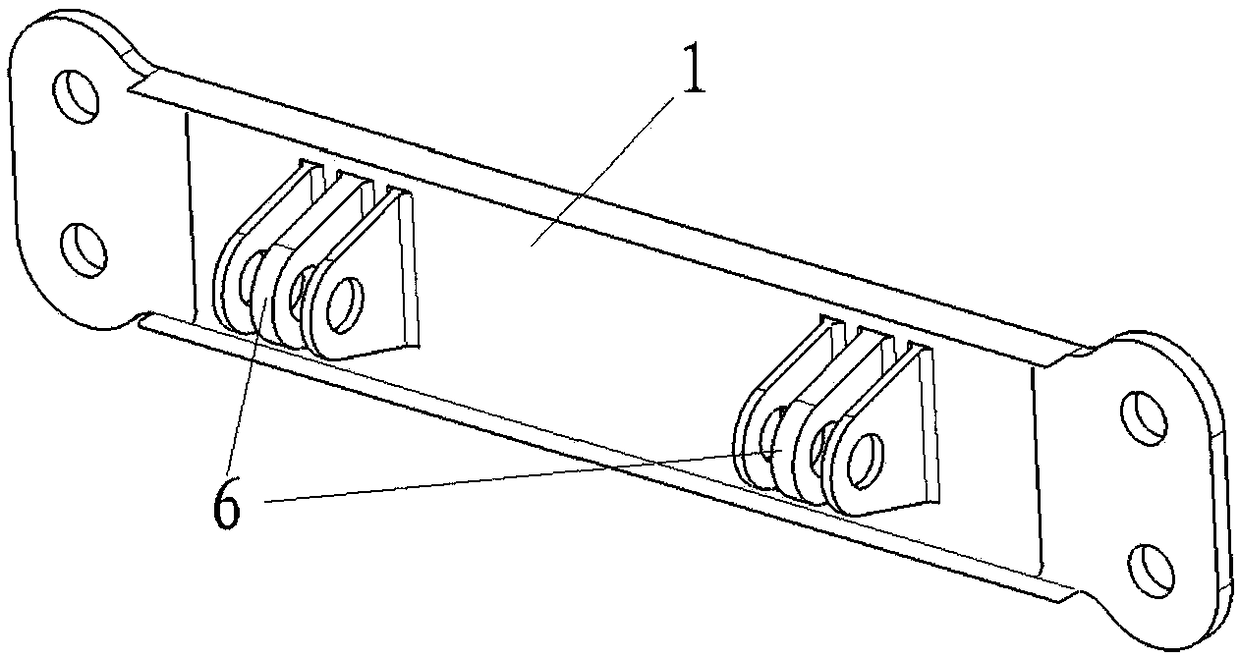

Drosophila melanogaster trapper

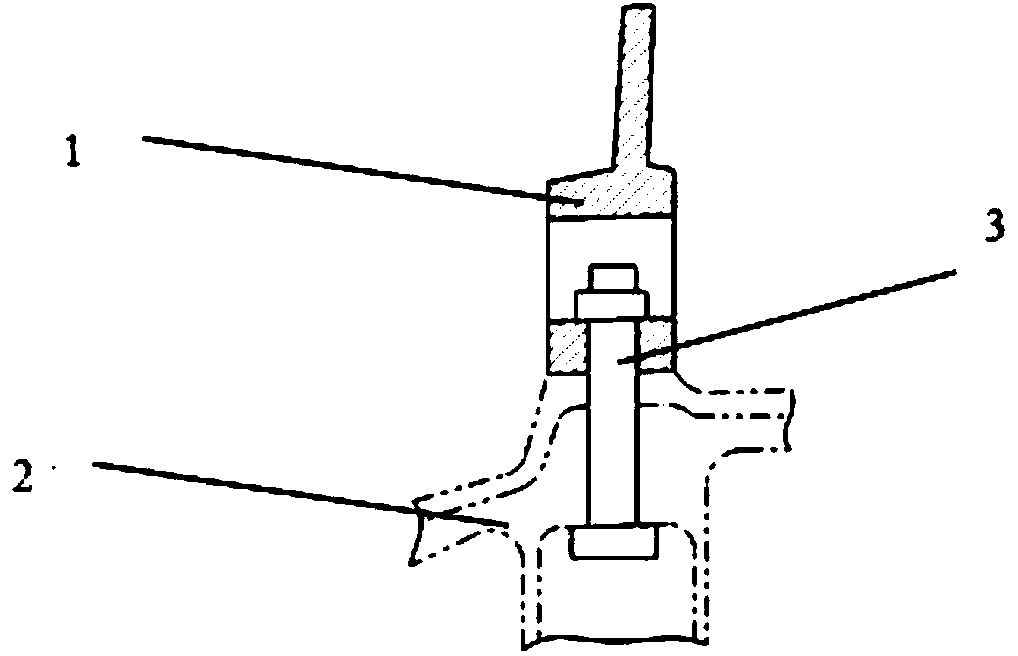

InactiveCN1666607AReduce part count and production complexityReduce mold count and material usageInsect catchers and killersAgainst vector-borne diseasesEngineeringInsect

The invention discloses a fruit fly trapper which relates to the means for killing pest, comprising bottle cap 1, bottle body 2 and means of attractant. Said bottle cap 1 comprises a semi-closed channel 9 with a horizontal open, a transfusion bottle ear 6, and a cover base 11 with a vertical channel and several channels as entrance for pest, to be an integral body which can be injected molding in one shot by common mold. Considering the biological characteristics of pest and the requirements of producing fruit fly trapper, the invention has fewer elements between 50-80 %, less investment of producing molds between 40-70 %, and more production efficiency between 100-300 % contrasting to prior trappers that have similar function of preventing escape.

Owner:刘觉滨

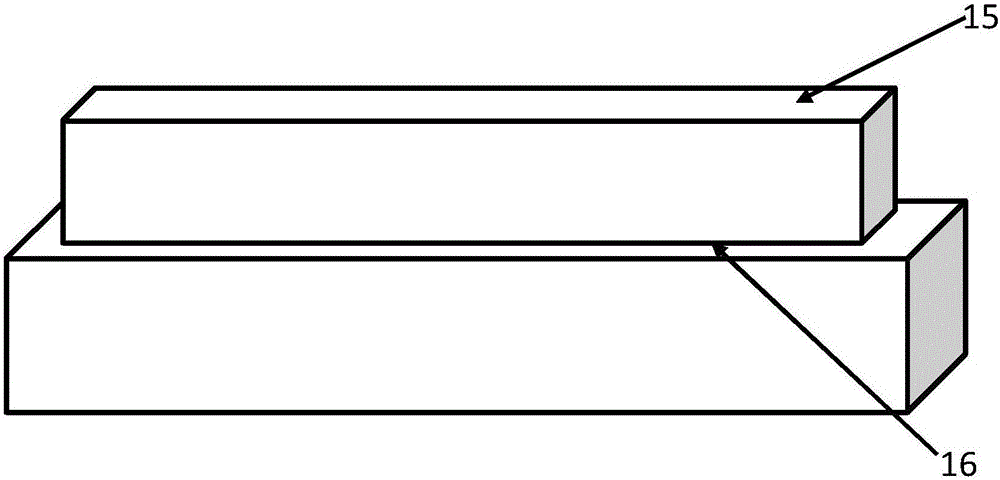

VARI (Vacuum Assistant Resin Infused) integral moulding clear dimension composite material ribbed structure manufacturing method

The invention discloses a VARI (Vacuum Assistant Resin Infused) integral moulding clear dimension composite material ribbed structure manufacturing method. The manufacturing method comprises the following steps: manufacturing an envelope prefabricated body by adopting an envelope moulding steel mould; manufacturing C-shaped ribs and I-beam prefabricated bodies by adopting wood substituted prefabricated body moulds; then, paving a drainage net and de-moulding cloth at the lower part of the manufactured envelope prefabricated body; assembling the manufactured C-shaped ribs and the manufactured I-beam prefabricated bodies onto the envelope moulding steel mould with the envelope together with a core mould; and finally, performing resin importing and resin curing on an overall composite material ribbed structure in a curing oven. The composite material ribbed structure manufactured by the manufacturing method is of a clear size integral structure; subsequent processing is not required; the assembling workload is reduced; point connection of screw connection and rivet connection is avoided; the rigidity and the strength of the overall structure are improved; in addition, the processes of prepreg storing and autoclave curing are eliminated by adopting a VARI process; the cost is lower compared with the conventional autoclave process.

Owner:HENGSHEN

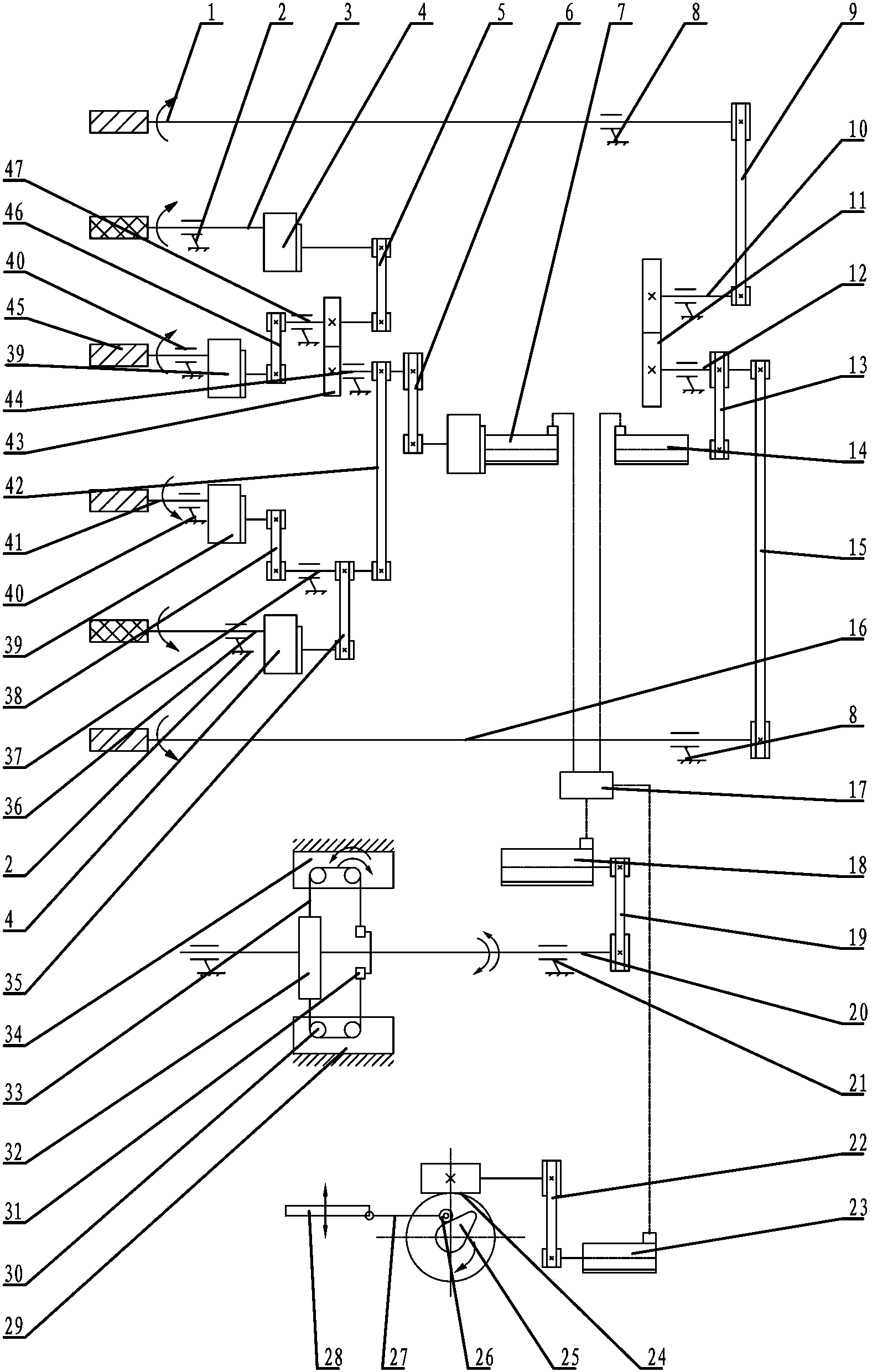

Fuel nozzle testing platform

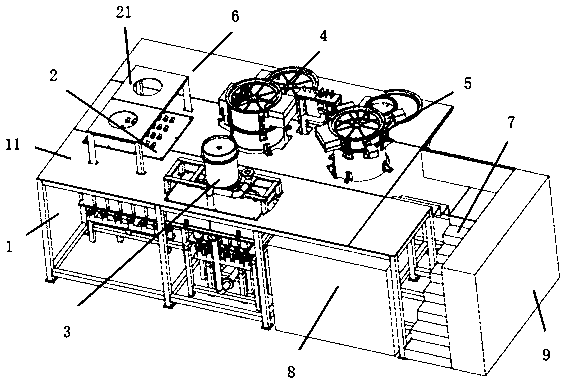

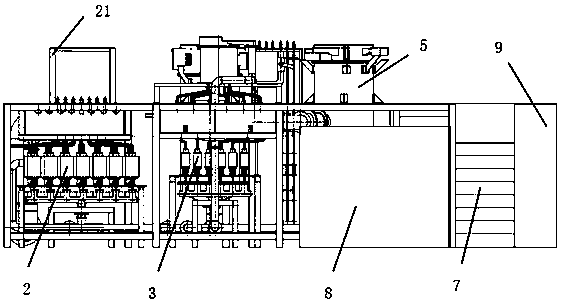

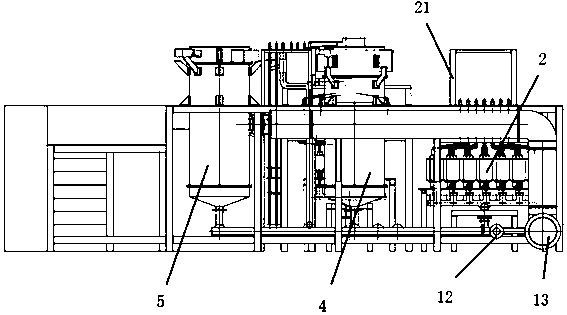

PendingCN109387373ACompact layoutExquisite designGas-turbine engine testingJet-propulsion engine testingAviationSpray cone

The invention belongs to the technical field of an aeroengine, and discloses a fuel nozzle testing platform. The fuel nozzle testing platform comprises a stand with a floor, a trunk pipe testing device which penetrates through the floor, a maldistribution degree testing device, a spraying cone angle manual measuring device and an automatic measuring device. The trunk pipe testing device and the maldistribution degree testing device are vertically arranged. The spraying cone angle manual measuring device and the automatic measuring device are parallelly arranged next to the long side of the rectangular floor. The trunk pipe testing device, the maldistribution degree testing device, the spraying cone angle manual measuring device and the automatic measuring device form a U-shaped path. The width of the U-shaped path is 700-900mm. The maldistribution degree testing device, the spraying cone angle manual measuring device and the automatic measuring device respectively comprise a testing clamp for mounting a single nozzle clamp or a trunk pipe nozzle clamp. The floor is provided with a plane rack which extends at the long side of the spraying cone angle manual measuring device and is used for placing a changed testing clamp. The side surface of the stand is provided with a lifting mechanism for climbing the floor by an operator.

Owner:中科航空动力(株洲)装备制造研究院有限公司

Horizontal tail wing box of helicopter

The invention relates to the field of surface pressure measurement of rotor blades of helicopters, and relates to a horizontal tail wing box of a helicopter. The horizontal tail wing box comprises a front beam, a rear beam and two reinforcing ribs formed by performing laminating on carbon fiber fabric and forming a framework of the horizontal tail wing box of the helicopter, an upper skin and a lower skin formed by performing laminating on the carbon fiber fabric and used for forming a complete wing box body, and an upper connector and a front connector formed by performing laminating on the carbon fiber fabric. The horizontal tail wing box is small in weight, and simple to assemble, and as the front connector, the front beam and the rib adopt integrated design, the upper connector and a rib web adopt integrated design, the power transmission route is direct, the configuration is simple, and the horizontal tail wing box is convenient to manufacture.

Owner:CHINA HELICOPTER RES & DEV INST

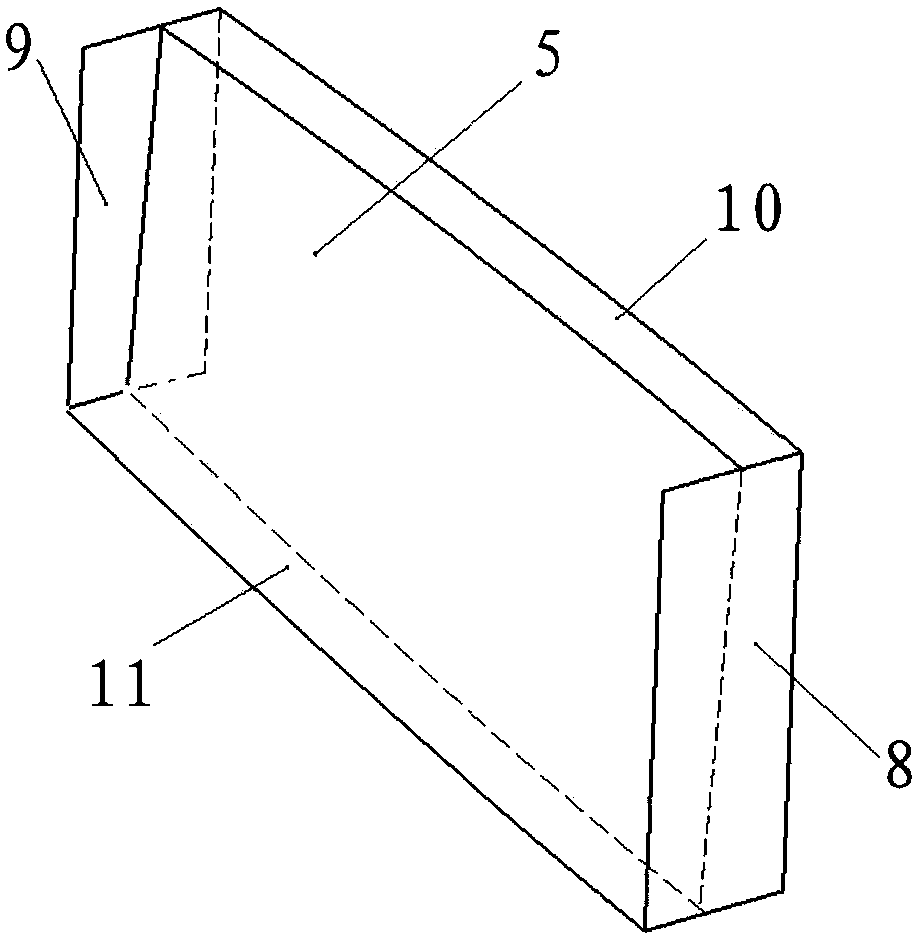

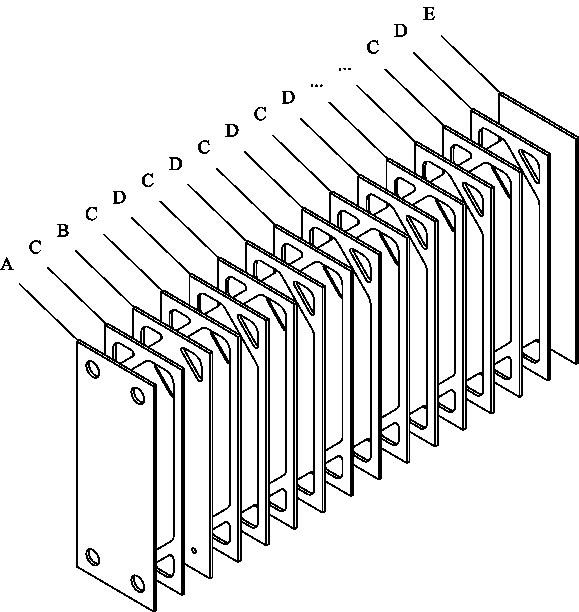

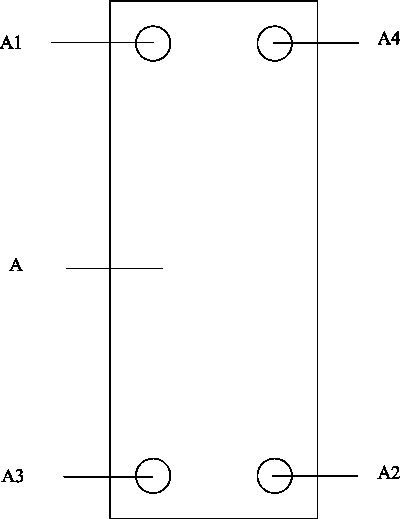

Micro heat exchanger with small hole throttling function

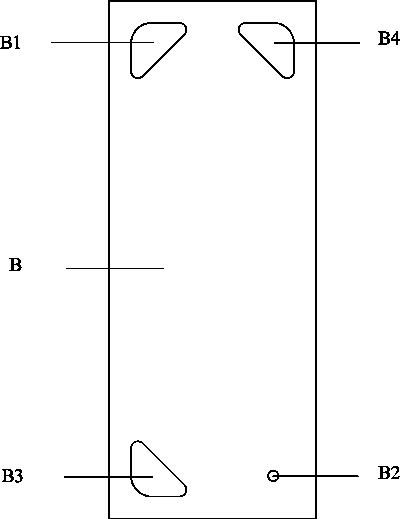

InactiveCN103759560ACompact structureReduce volumeLaminated elementsStationary plate conduit assembliesEngineeringPhase change

The invention provides a micro heat exchanger with a small hole throttling function. The micro heat exchanger can serve as an evaporator or a condenser and is a solid formed by laminating five different kinds of etching plates in a certain sequence and welding the etching plates through vacuum diffusion welding. The micro heat exchanger comprises an interface plate A, a refrigerating fluid throttling plate B, one or more fluid heat exchange plates C, one or more refrigerating fluid heat exchanger plates D and a blind plate E. A small throttling hole is formed in the refrigerating fluid throttling plate B, throttling depressurization can be performed on refrigerating fluid when the refrigerating fluid flows through the small hole, throttling and phase-change heat exchanging of the refrigerating fluid can be achieved through one device, throttling elements such as capillary tubes, throttling short tubes and the like are eliminated, and quantity of external connection tubes and welding points is reduced. The micro heat exchanger with the small hole throttling function is compact in structure, small in size and capable of reducing volume and mass of the system when applied to a micro vapor compression refrigerating system.

Owner:MICROCOOL TECH

Rocket lightweight efficient full-motion air rudder and manufacturing method thereof

InactiveCN108372936AImprove bearing efficiencyImprove versatilityCosmonautic vehiclesLayered productsResin-Based CompositeRocket

The invention relates to a rocket lightweight efficient full-motion air rudder and a manufacturing method thereof. The rocket lightweight efficient full-motion air rudder comprises an air rudder bodywhich comprises a framework and a rudderpost connected with the framework, the left side of the framework is provided with a left skin, and the right side of the framework is provided with a right skin. Reinforcing parts are arranged in a foam interlayer between the left skin and the right skin. By adoption of a carbon fiber resin based composite material and arrangement of the reinforcing parts in the foam interlayer between the left skin and the right skin, bearing efficiency of a rudder surface structure is remarkably improved. By assembly of the framework, the rudderpost, reinforcing rods,the foam interlayer, the left skin and the right skin through a secondary curing process after independent forming, consumption of fastening parts for component connection is avoided, and accordinglyworkload in assembly is relieved.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

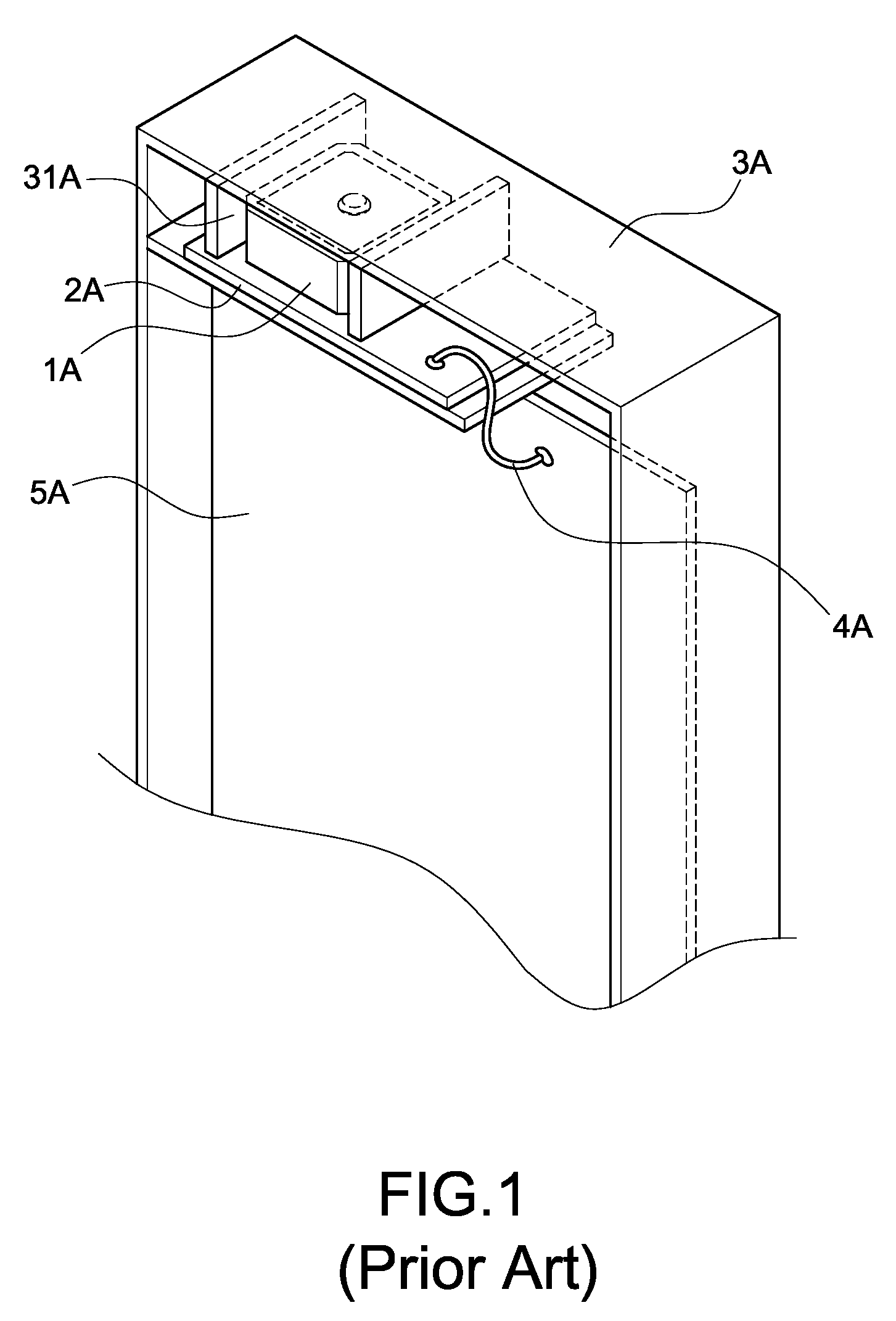

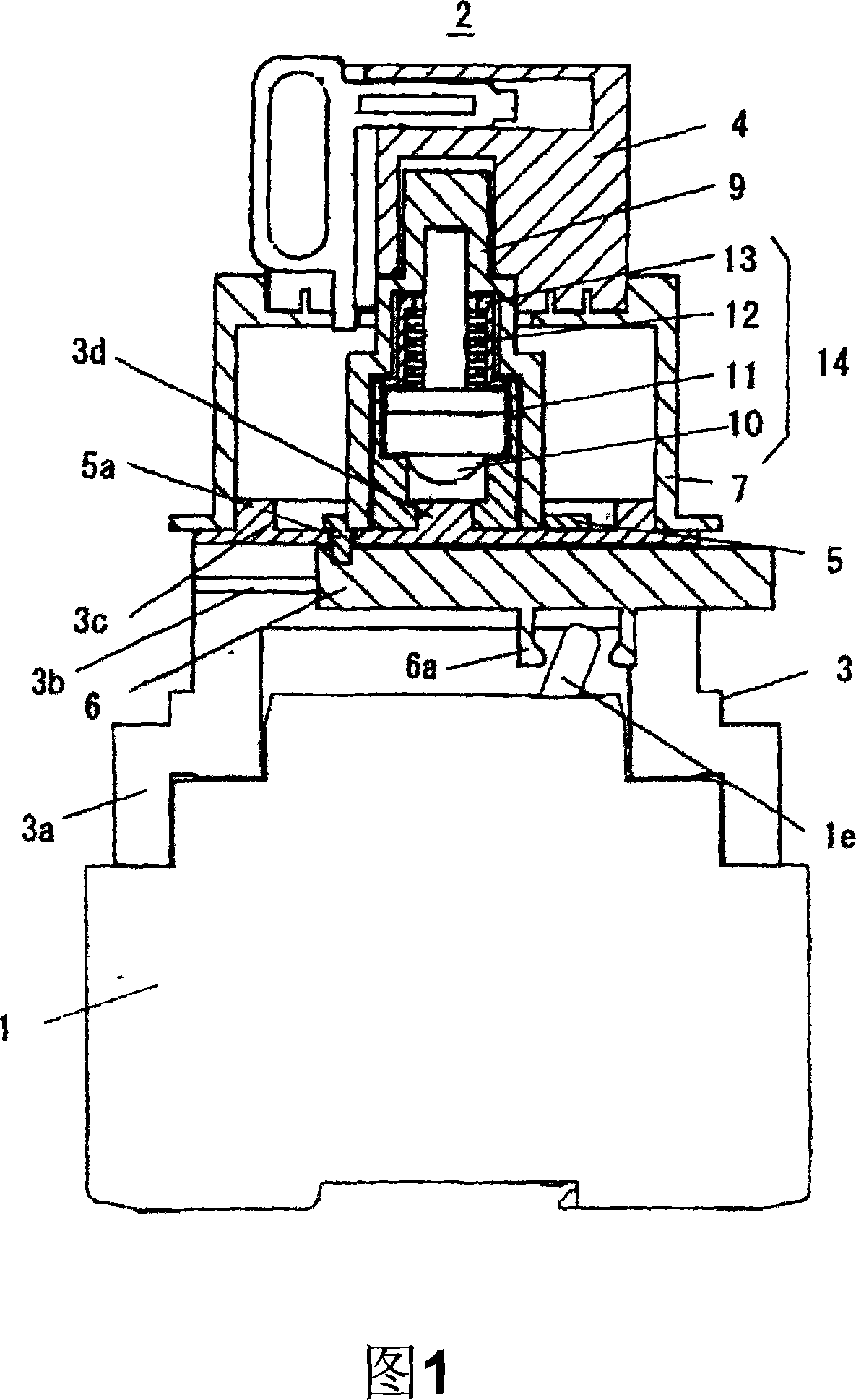

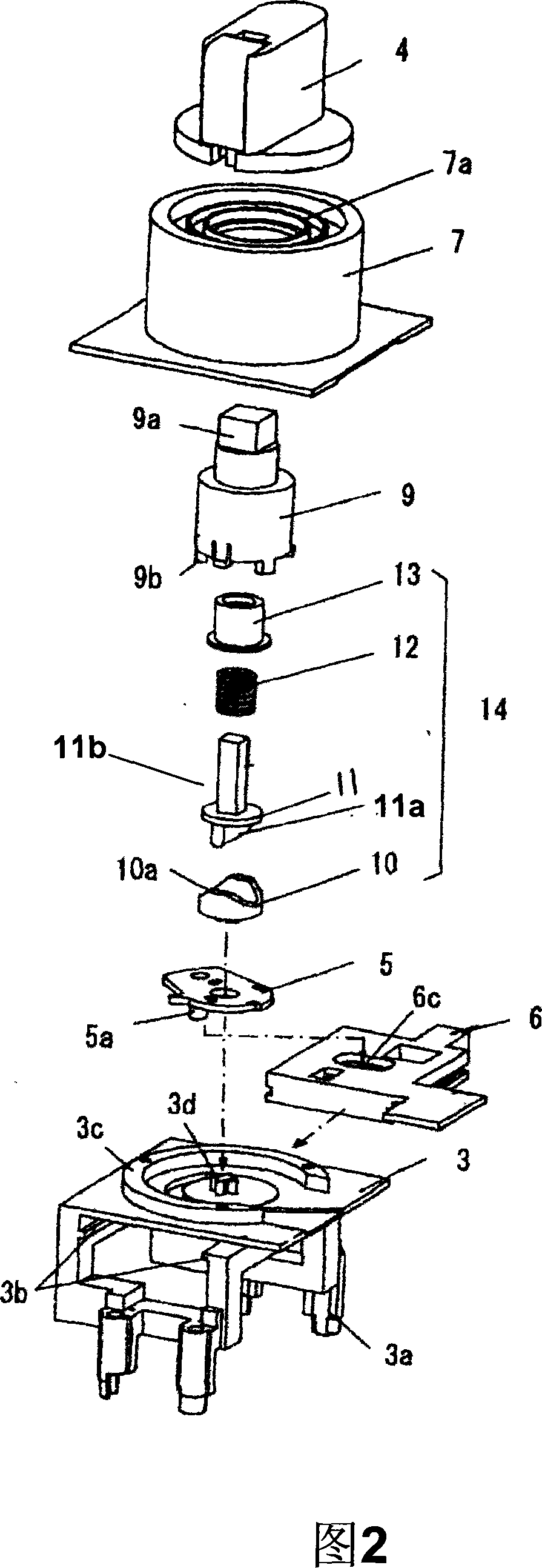

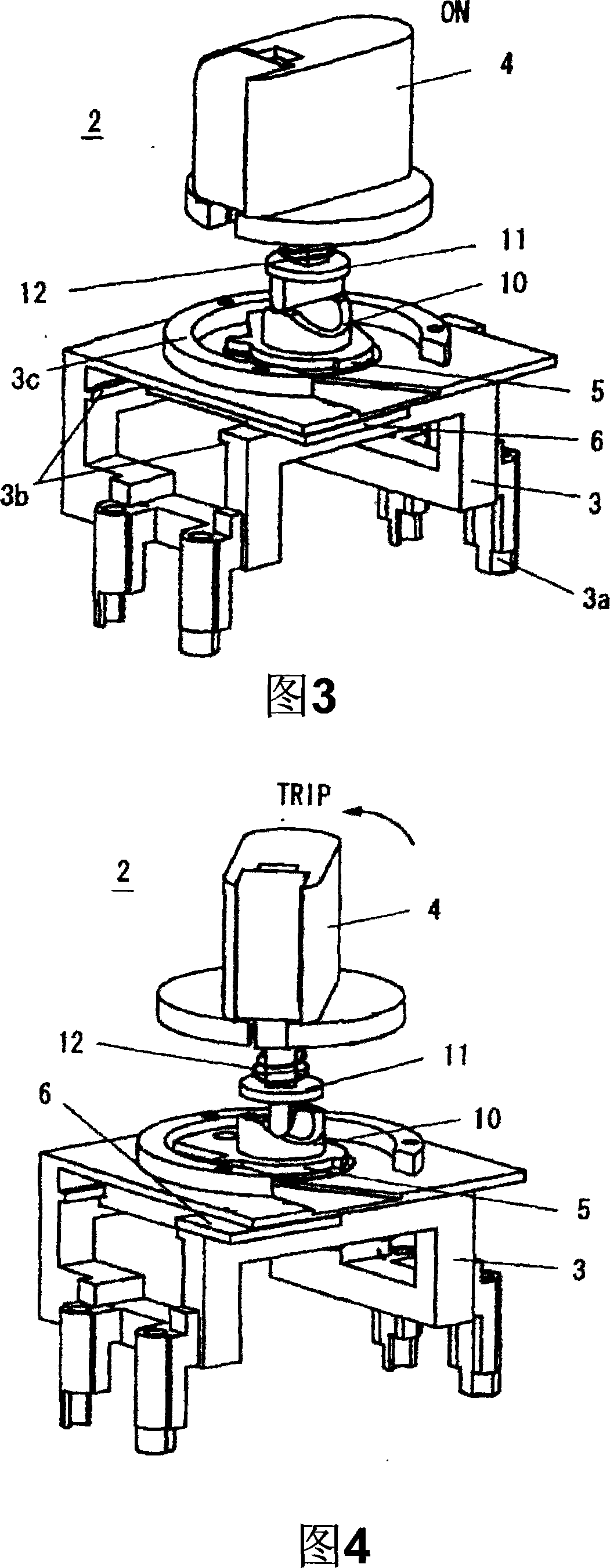

External operation handle device for a circuit breaker

InactiveCN101083183AReduced parts countReduced assembly effortContact driving mechanismsContact operating partsCouplingSpring force

To incorporate an assisting system of a simple structure into an external operation handle device, and make the handle knob move to the TRIP display position surely during a tripping movement of a circuit breaker. In an external operation handle device which becomes an assembling structure with a rotary type handle knob 4 on a mounting base 3, a turn base 5 coupled with the handle knob via a coupling shaft, and a slide base 6 linked to the turn base by being engaged with a locker handle 1e of the circuit breaker 1, in the inward of a hollow coupling shaft 9 that couples between the mounting base and the handle knob, an assisting mechanism 14 consisting of a cam body 10 fixed to the mounting base, cam follower 11 coupled with the handle knob and confronted with a cam face 10a of the cam body, and a biasing spring 12 that presses the cam follower to the cam face are installed, while during the tripping movement of the circuit breaker, the handle knob is made to acceleratedly move from ON position to the tripping display position by a rotating force acted on the cam follower in which the spring force of the biasing spring is received.

Owner:FUJI ELECTRIC ASSETS MANAGEMENT

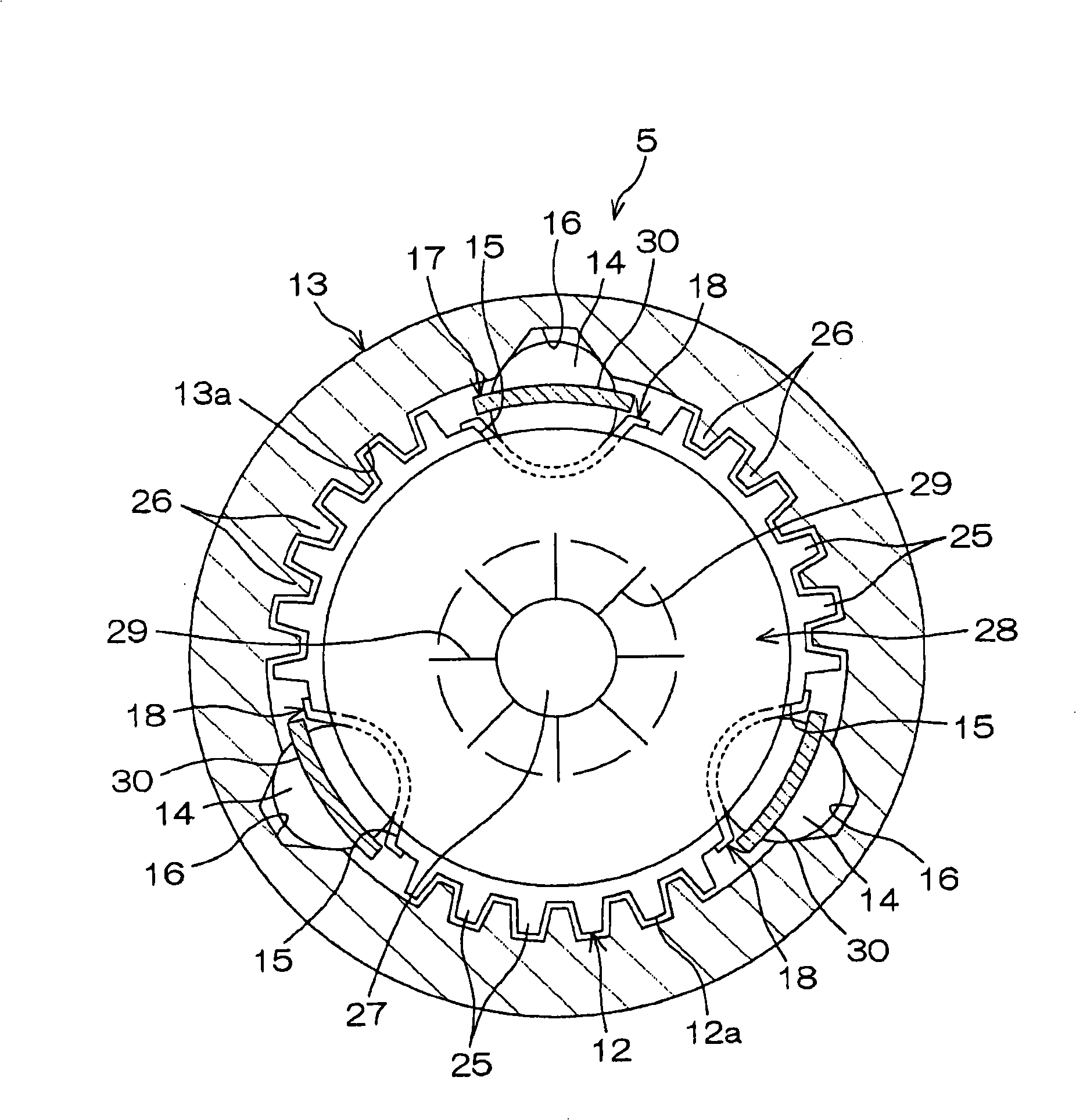

Driving device for wool spinning machine

ActiveCN102704059BReduce labor intensityReasonable structureContinuous wound-up machinesGear driveGear wheel

The invention relates to a driving device for a wool spinning machine. After a front roller motor decelerates, one path of front roller motor subjected to deceleration is connected with a front-right roller through the driving of a first belt; the other path of front roller motor subjected to deceleration is connected with a front-left roller through driving of a first intermediate gear pair and a second belt; after a rear-middle roller motor decelerates, one path of rear-middle roller motor subjected to deceleration is connected with an intermediate roller gearbox through driving of a third belt and a fourth belt; the other path of rear-middle roller motor subjected to deceleration is connected with the intermediate roller gearbox through driving of a second intermediate gear pair and a fifth belt; left and right intermediate rollers are connected with the intermediate roller gearbox; the third belt drives to be connected with a rear roller gearbox through the driving of a sixth belt; the second intermediate gear pair is connected with a rear roller gearbox through driving of a seventh belt; left and right rear rollers are connected with the rear roller gearbox; after a main motor decelerates, the main motor subjected to deceleration is connected with a spindle through a spindle belt via a main shaft and a rolling disk; and a lifting motor subjected to deceleration is connected with a ring rail through a worm gear and worm transmission pair, a stroke cam, a cam roller and a swing rod. The driving device disclosed by the invention has the advantages of simple structure, reduced amount of driving mechanisms and reduction of production cost.

Owner:常州市同和纺织机械制造有限公司

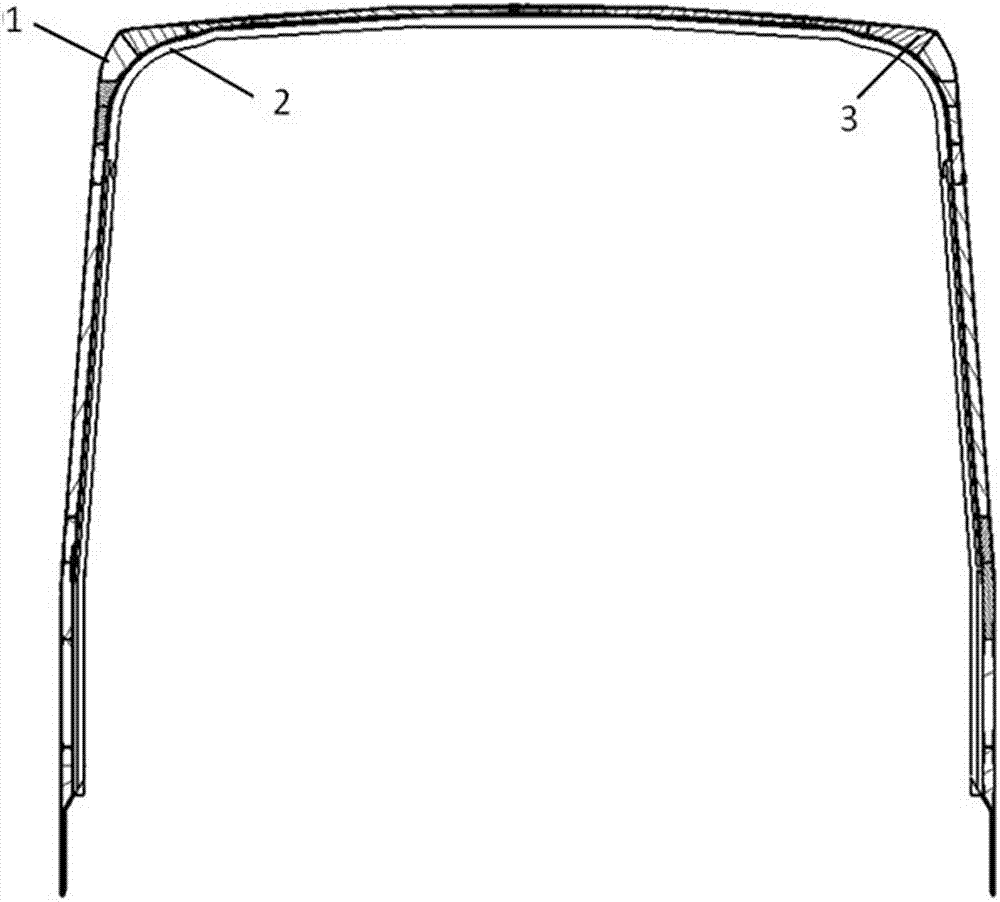

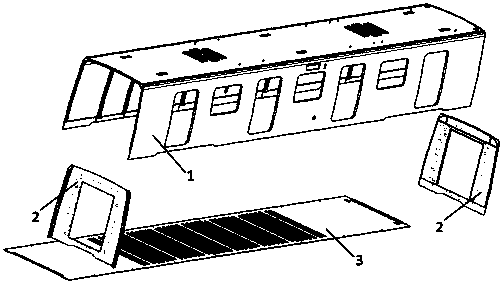

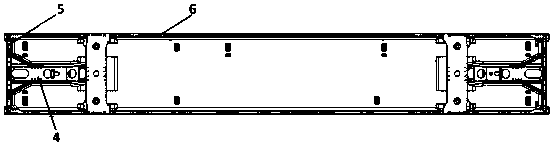

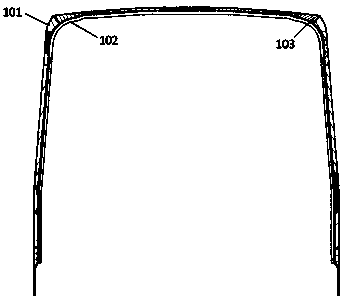

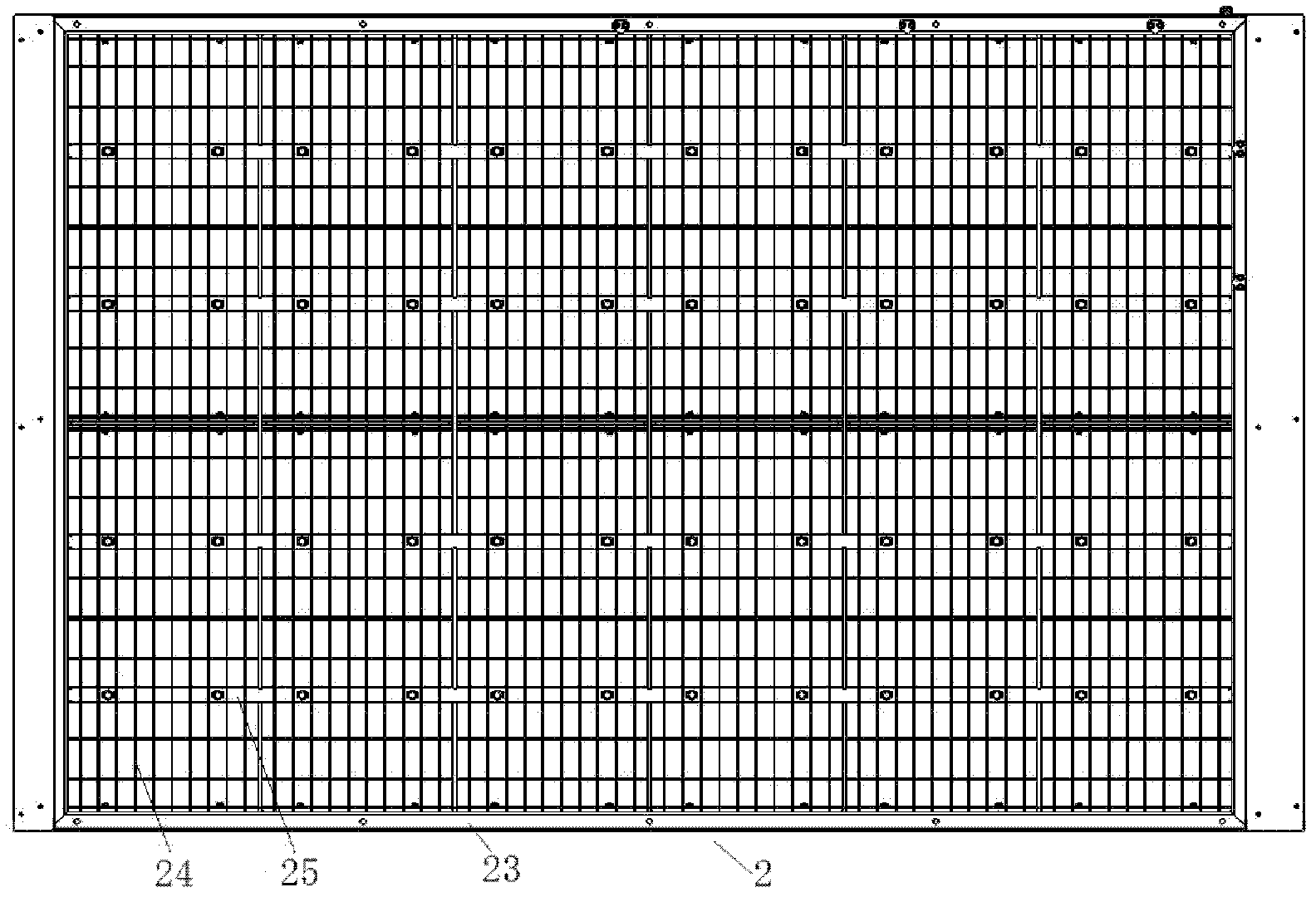

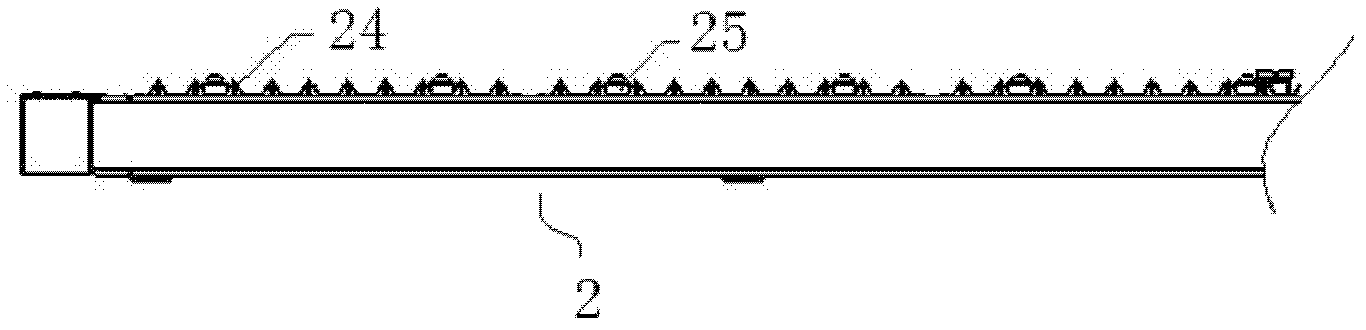

Carbon fiber composite subway vehicle body formed through low cost process

InactiveCN107600086ALow costGood heat insulationAxle-box lubricationRailway bodiesFibrous compositesSpare part

The invention provides a carbon fiber composite subway vehicle body formed through a low cost process. The carbon fiber composite subway vehicle comprises a U-shaped vehicle body, end walls and a bottom frame, the U-shaped vehicle body is arranged on the bottom frame, and the end walls are arranged at the two joint ends of the U-shaped vehicle body and the bottom frame; the U-shaped vehicle body adopts a sandwich structure, the U-shaped vehicle body comprises a first outer skin, a first sandwich layer and a first inner skin which are sequentially arranged from outside to inside; the end wallsadopt the sandwich structure, each end wall comprises a second outer skin, a second sandwich layer and a second inner skin which are sequentially arranged from top to bottom; the bottom frame adopts the sandwich structure and comprises a third outer skin, a third sandwich layer and a third inner skin from top to bottom; not only is the number of spare parts reduced, but also heat-insulating performance is excellent, the low cost composite forming process is adopted for overall forming, the total cost of the carbon fiber composite subway vehicle body is reduced on the whole; and meanwhile, performance characteristics of carbon fiber composite is fully exerted, the defects that an existing vehicle body is great in weight, poor in corrosion resistance and anti-fatigue performance and short inusing period are overcome.

Owner:HENGSHEN

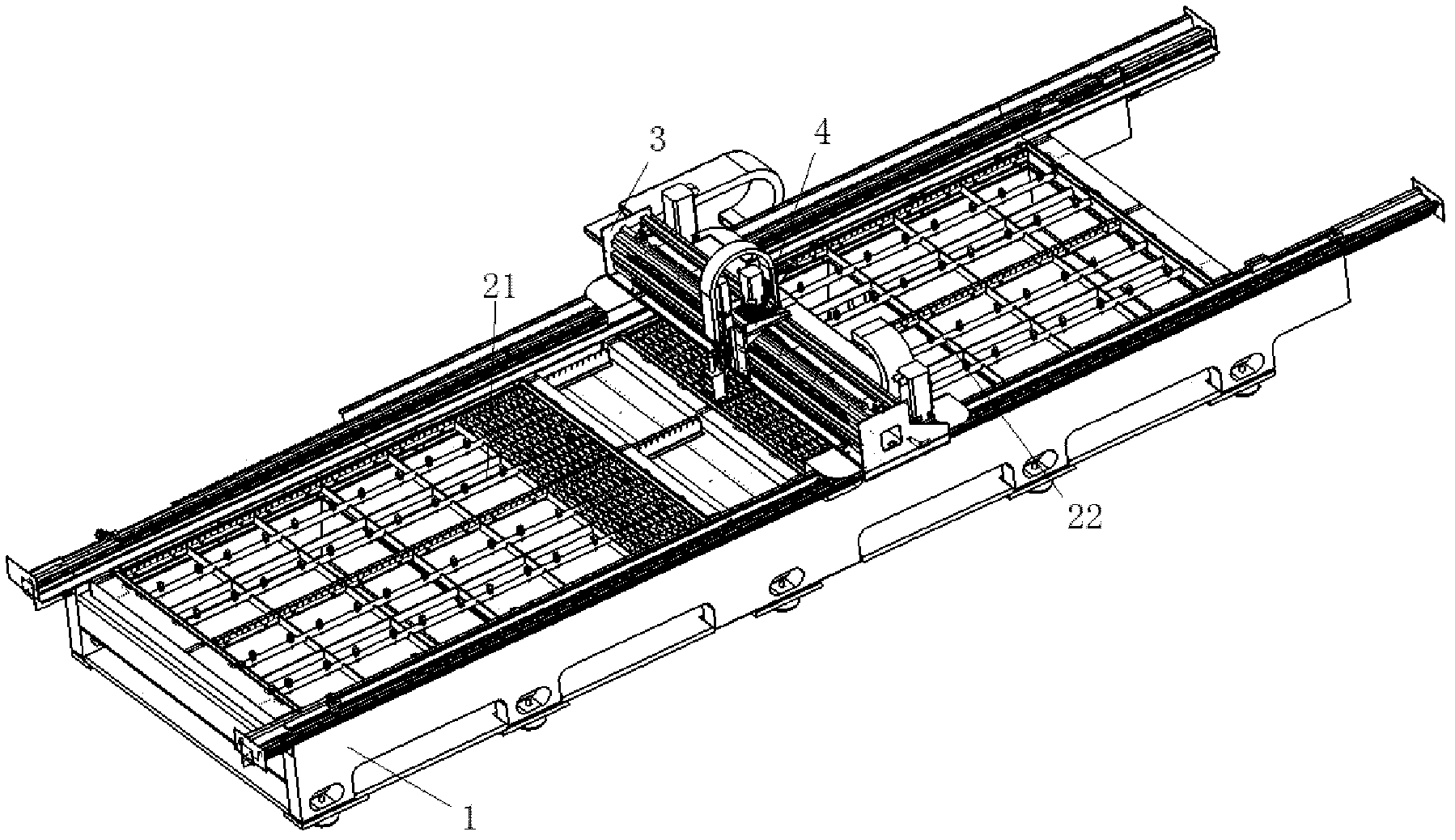

Laser cutting machine

InactiveCN102398115AReduce the number of partsReduced assembly effortLaser beam welding apparatusLaser cuttingMachine tool

The invention discloses a laser cutting machine. The laser cutting machine comprises a lathe bed, an operating platform, a cross beam and a Z shaft, wherein a guide rail is arranged on the lathe bed; the operating platform is arranged on the lathe bed; the cross beam is arranged on the guide rail in a sliding way; the Z shaft is arranged on the cross beam in the sliding way; the operating platform comprises a platform body, a supporting plate strip for supporting workpieces and a plurality of ball supporting oscillating bars for supporting the workpieces and conveying the workpieces; the supporting plate strip is welded on the platform body; the ball supporting oscillating bars are arranged in the slot of the supporting plate strip; the lathe bed is divided into an A operating region and a B operating region; and the A operating region and the B operating region are provided with an operating platform respectively. By the machine, the amount of parts of the conventional exchange operating platform laser cutting machine is reduced; the production period of a machine tool is shortened; the assembling and debugging difficulties of the machine tool are reduced; the fault points of the machine tool are reduced, and the reliability of the machine tool is improved; the amount of reserve parts and spare parts is reduced; and the manufacturing cost and the maintenance cost of the machine tool are substantially reduced.

Owner:SHANGHAI ACL CNC MACHINE TOOL

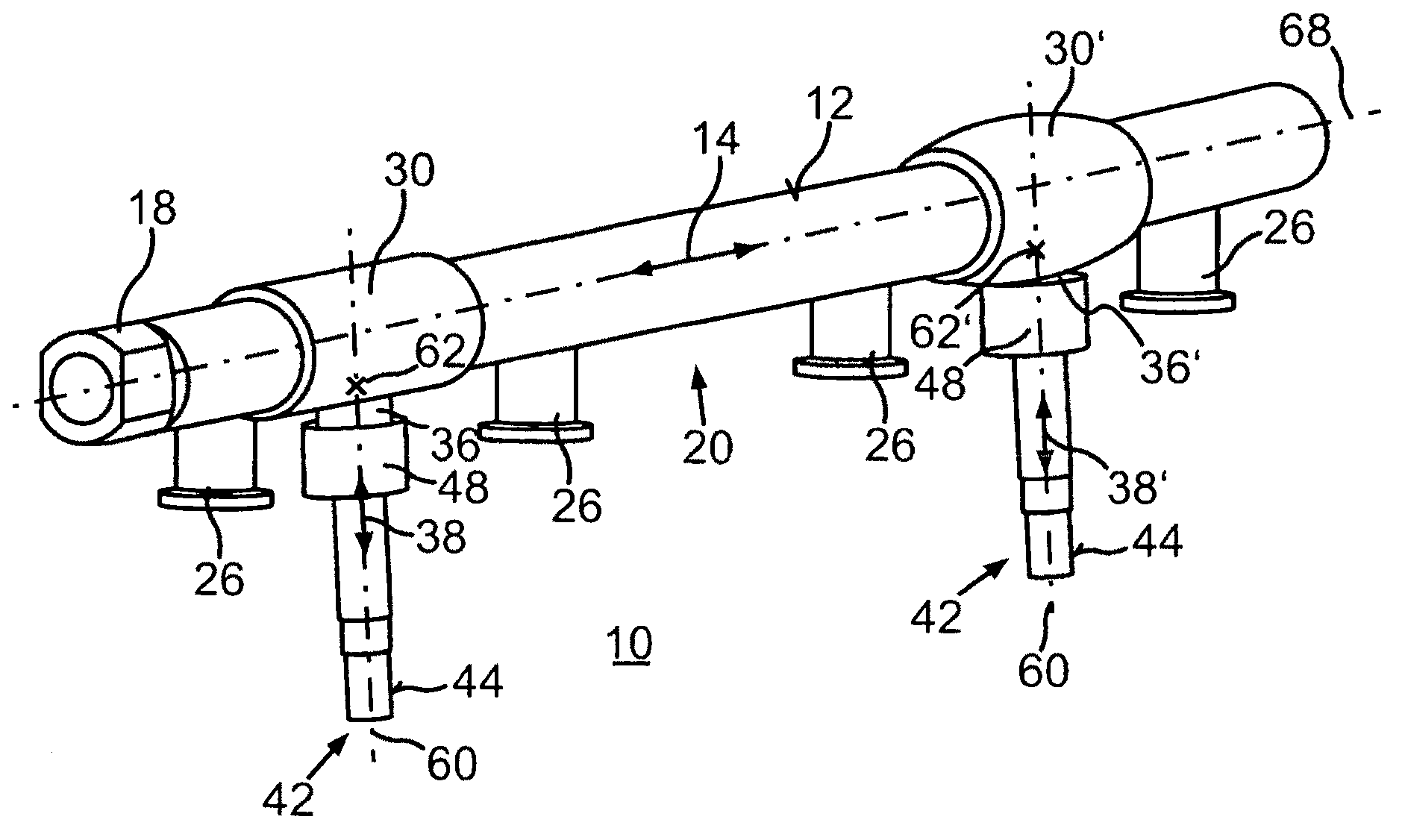

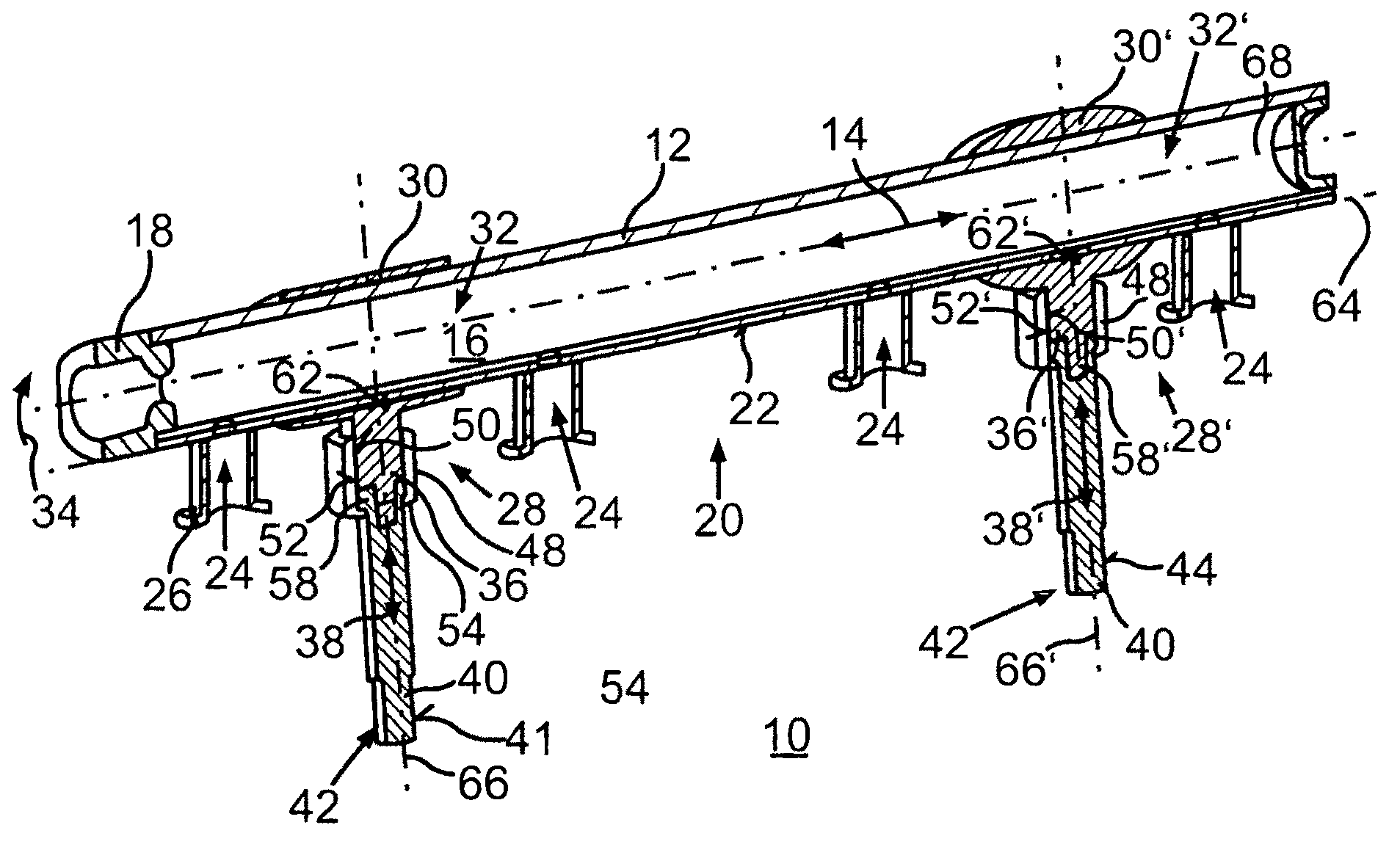

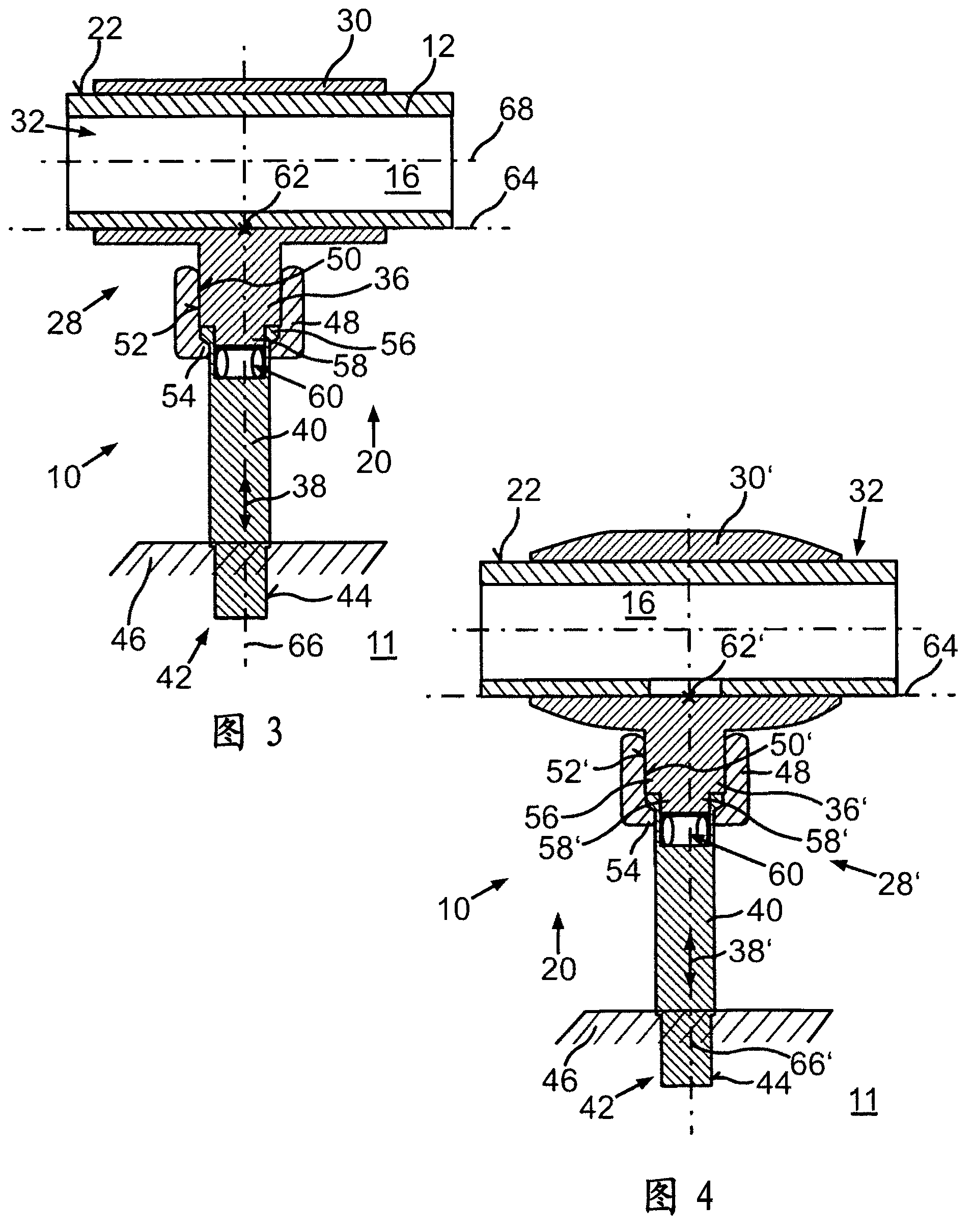

A fastening arrangement of a fuel supply device on an internal combustion engine, and a method for fastening a fuel supply device to the internal combustion engine

ActiveCN103210204AShorten the timeLow costLow-pressure fuel injectionMachines/enginesExternal combustion engineEngineering

The invention relates to a fastening arrangement (11) of a fuel supply device (10) on an internal combustion engine, and also relates to a method for fastening the fuel supply device (10) of said type to the internal combustion engine. In the fastening arrangement (11), at least one fuel distributing element (12) which runs along a longitudinal direction (14) and which has at least two connection openings (24) for connecting a respective fuel injection device is fastened to the internal combustion engine by means of at least one connecting part (36, 36'), wherein the connecting part (36, 36') is connected to the fuel distributing element (12) via a holding part (30, 30') which has a receptacle (32, 32') which completely surrounds at least one outer circumferential region of the fuel distributing element (12) and in which at least one portion of the fuel distributing element (12) is held, and wherein a point (62, 62'), which is situated in an elongation of the connecting element (36, 36') in a direction of extent (38, 38'), of the fuel distributing element (12) lies on a straight line (64) which connects the two connection openings (24).

Owner:AUDI AG

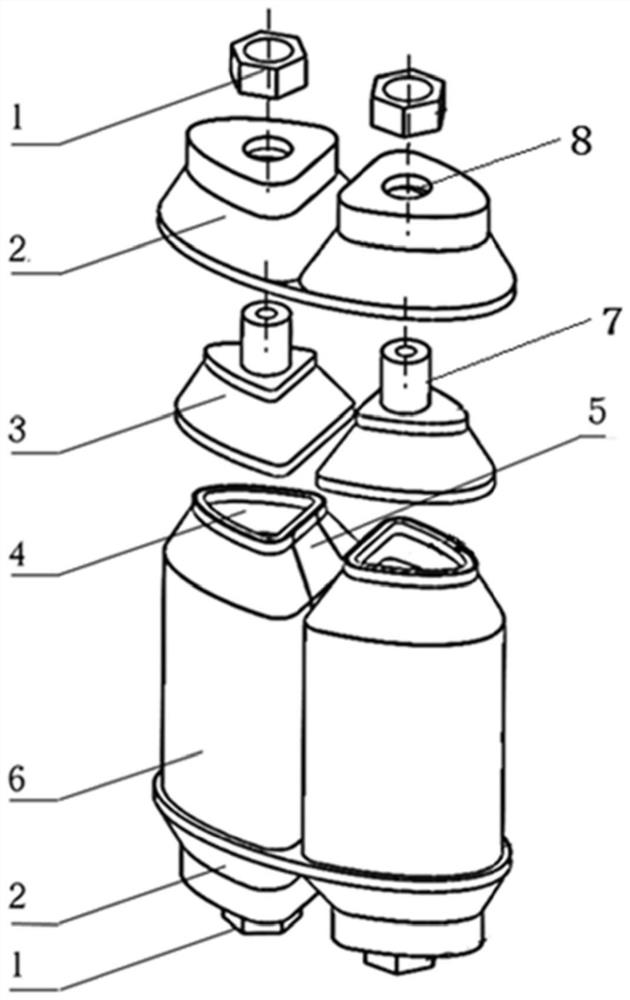

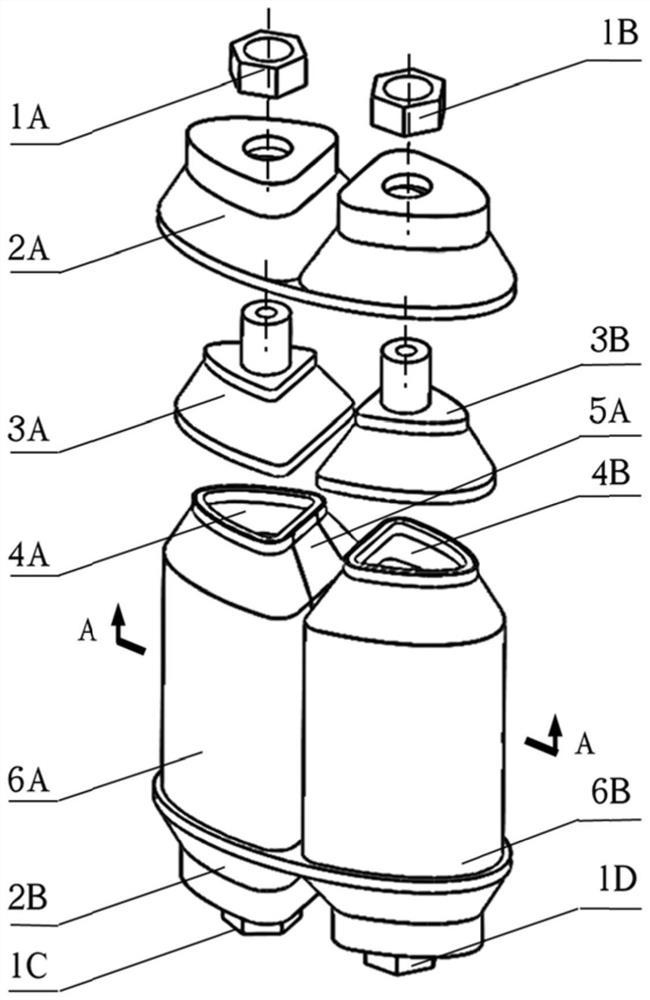

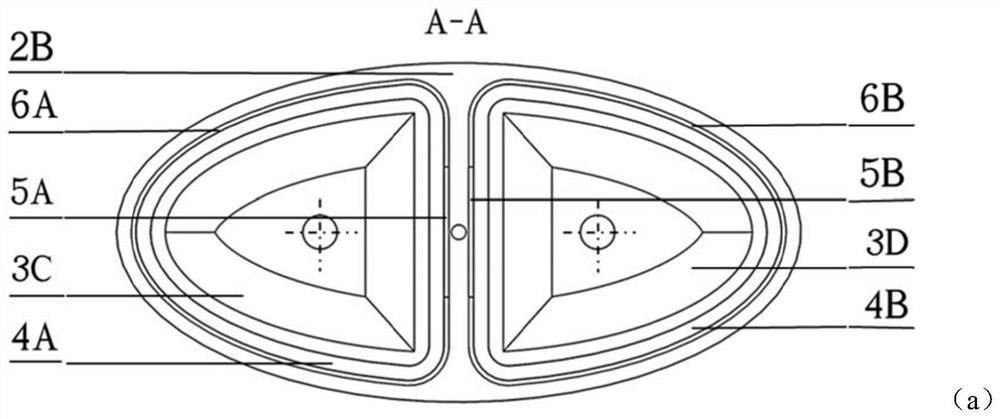

Soft driving structure of lower limb rehabilitation robot

ActiveCN112618280AIncrease contact areaImprove stress toleranceChiropractic devicesWalking aidsPhysical medicine and rehabilitationPhysical therapy

The invention provides a soft driving structure of a lower limb rehabilitation robot. The soft driving structure of the lower limb rehabilitation robot comprises a double-layer air bag and a fixed connecting piece, wherein the double-layer air bag comprises a soft air bag body made of silicon rubber, the end of the soft air bag body is connected with the fixed connecting piece, and a conical surface is arranged at the joint of the inner side of the soft air bag body and the fixed connecting piece; the fixed connecting piece comprises an end cover, an air hole cover and a fixing nut, the air hole cover is in sealed connection with the double-layer air bag, the end cover covers the air hole cover, a vent pipe is arranged on the air hole cover, a through hole is formed in the end cover, one end of the vent pipe penetrates through the through hole and is exposed out of the end cover, and the exposed part is assembled and fixed through the fixing nut; and the air hole cover is provided with a conical surface used for being attached to the conical surface of the soft air bag, and a conical surface attached to the air hole cover is arranged on the inner side of the end cover. With adoption of design of conical surface assembly, the pressure resistance and tolerance of the soft driving structure are improved, the joint rotating torque can be effectively improved, and the part loss is reduced.

Owner:SHANGHAI JIAO TONG UNIV

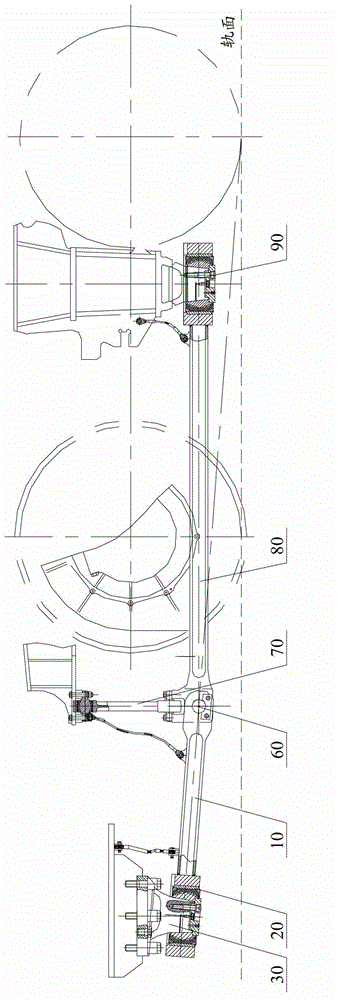

Single-draw-bar traction device and engine applying same

The invention discloses a single-draw-bar traction device used for an engine. The traction device comprises an engine body traction seat, a frame traction seat and a traction bar, wherein the engine body traction seat is fixedly arranged on an engine body, and the frame traction seat is fixedly arranged on a traction beam of a steering frame. Two ends of the traction bar are respectively in elastic connection with the engine body traction seat and the frame traction seat through two traction assemblies, and no gap is reserved lengthwise of the traction bar in terms of the elastic connection. On the basis of ensuring curve and hill passage performance, the traction device is simple and reliable in structure and easy to demount and mount, and manufacturing and maintenance costs can be controlled effectively. On the basis, the invention further provides an engine provided with the single-draw-bar traction device.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

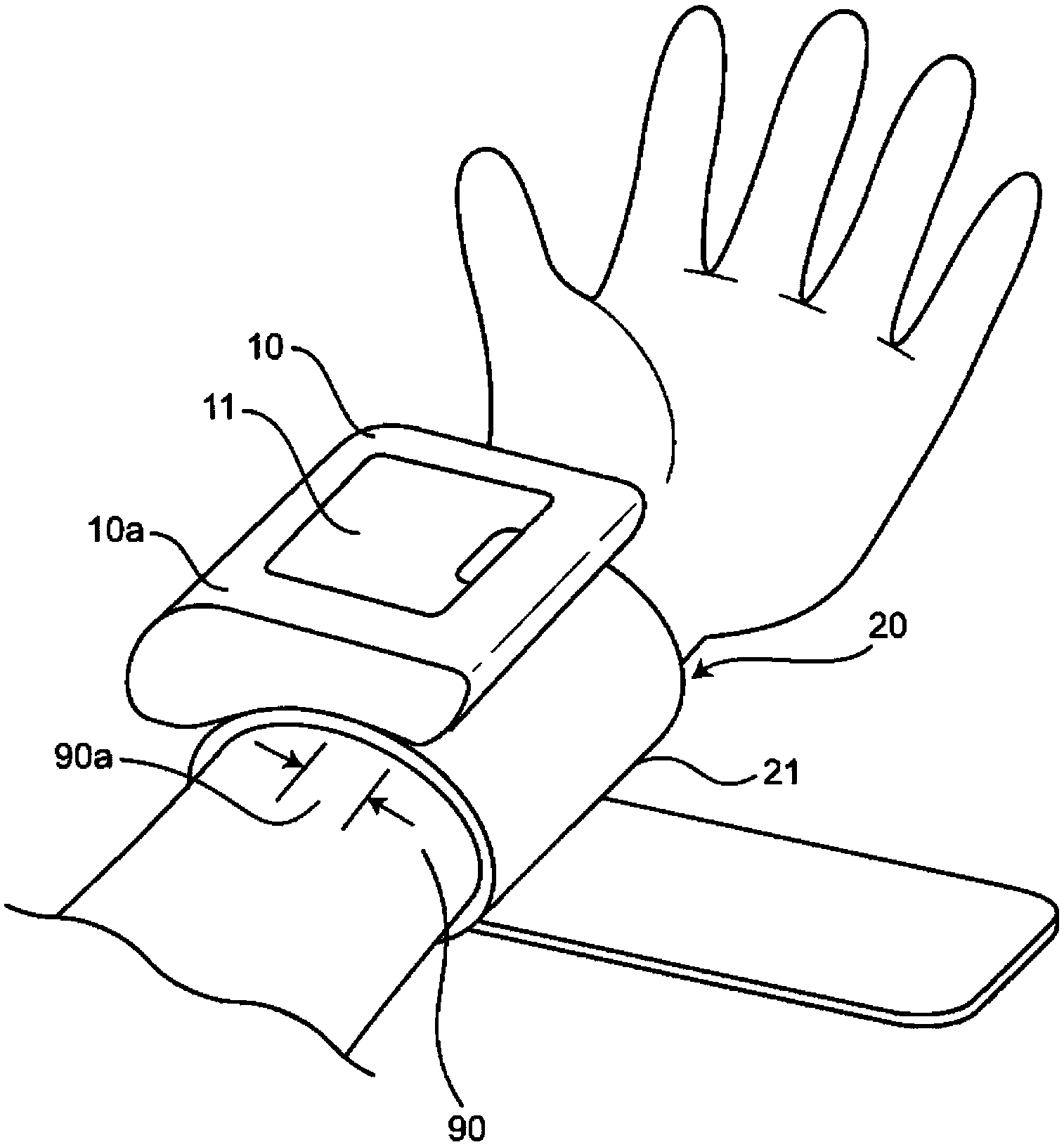

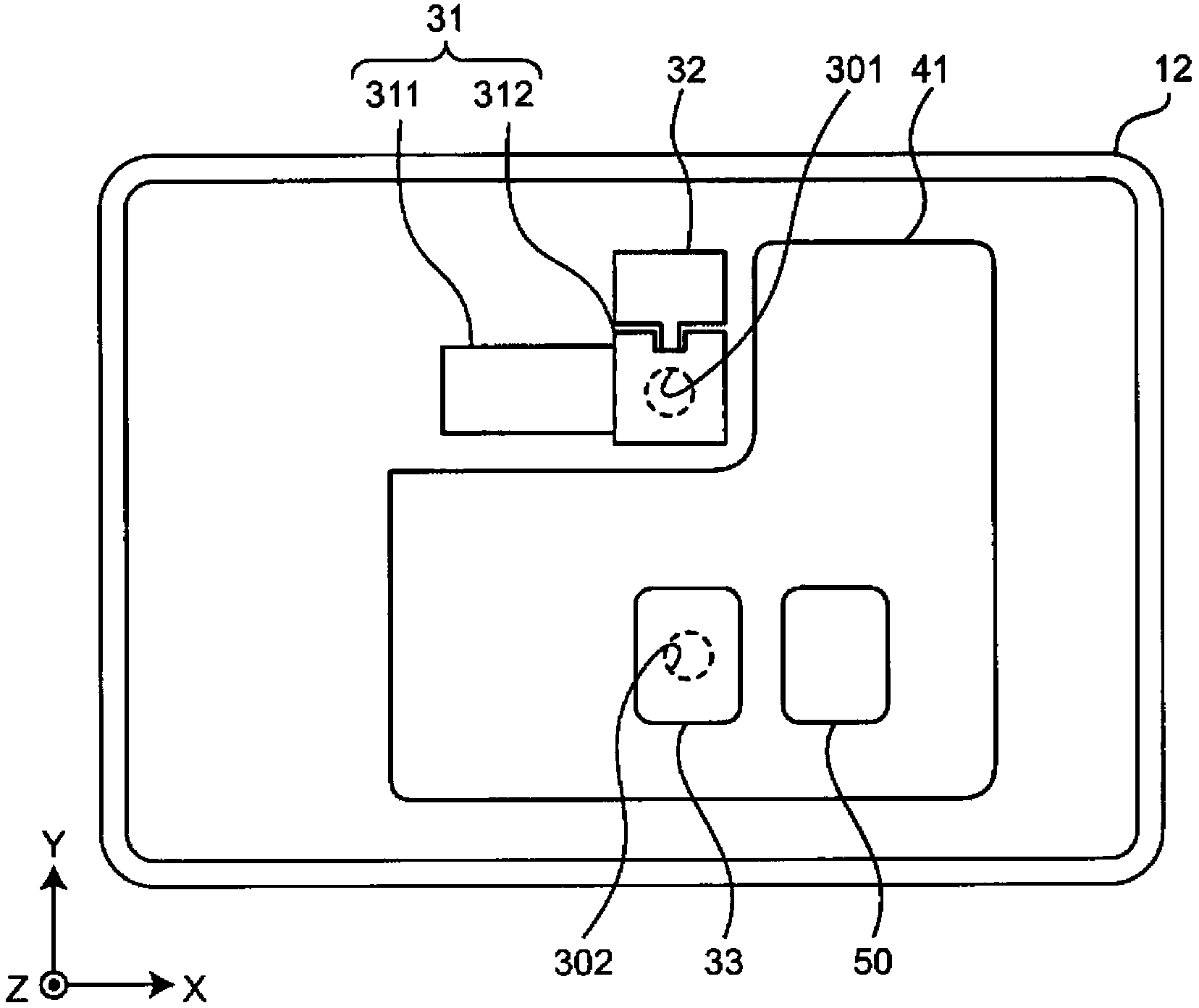

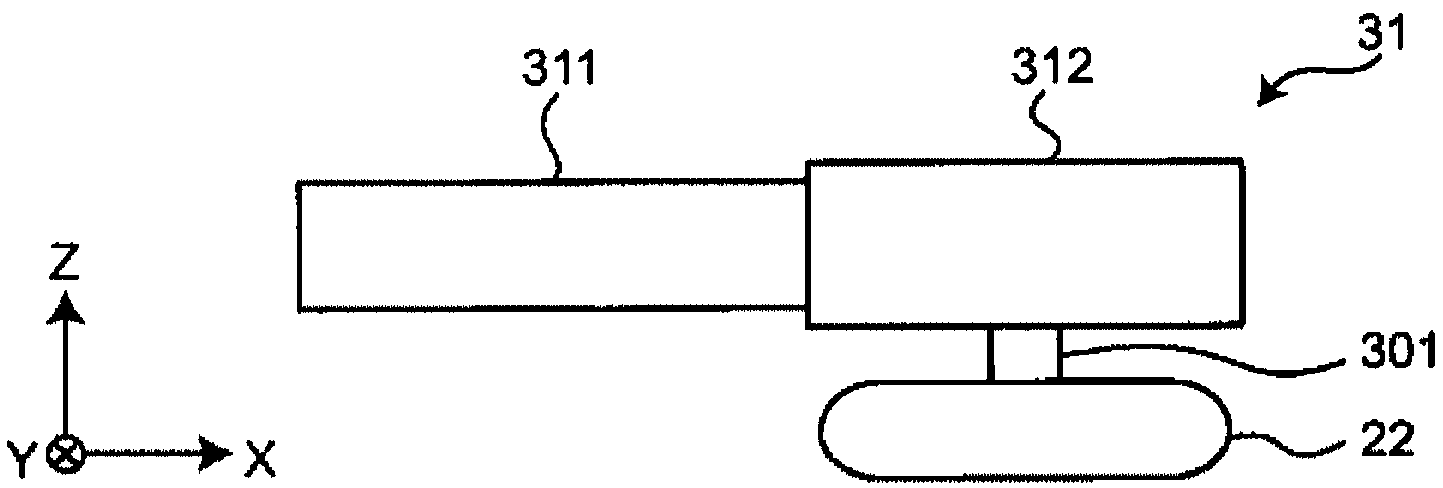

Blood pressure meter

ActiveCN104168822AReduce the numberReduced assembly effortEvaluation of blood vesselsSensorsBlood pressure kitBiomedical engineering

This blood pressure meter is configured in such a manner that a pump unit (31) is connected to a fluid bag (22) through a first fluid path (301). The first fluid path (301) extends straight in the Z-direction between the pump unit (31) and the fluid bag (22) and is adapted so as to deliver air, which is supplied from the pump unit (31), into the fluid bag (22) or so as to deliver air, which is within the fluid bag (22), to a valve.

Owner:OMRON HEALTHCARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com