Carbon fiber composite end wall structure for subway

A composite material and carbon fiber technology, which is applied in the direction of railway car body, railway car body parts, transportation and packaging, etc., can solve the problems of increasing assembly workload, difficulty in meeting the development needs of lightweight rail transit, and complex structural forms, etc., to achieve Reduce the assembly workload, highlight the effect of weight reduction, and optimize the effect of metal welding structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

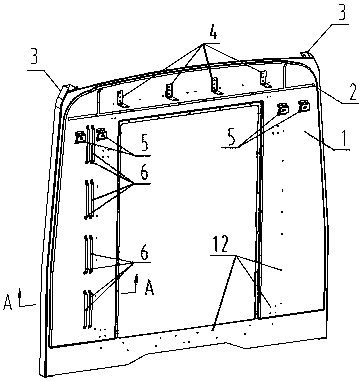

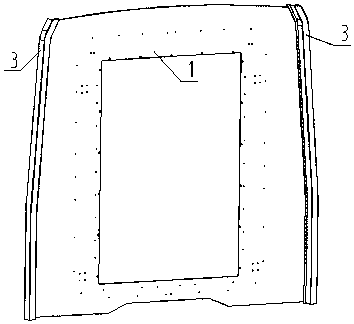

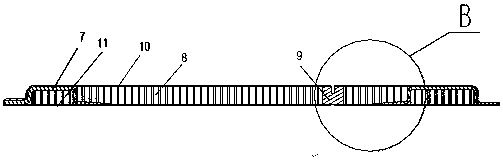

[0027] Such as figure 1 with figure 2 As shown, a carbon fiber composite material end wall structure for subway, including an end wall interlayer structure 1, a grounding copper bar 2, a drain pipe 3, a wire trough installation hanger 4, an electrical cabinet mounting seat 5 and a cable tie rod 6, the end wall interlayer Structure 1 includes an integral reinforcement frame 7, a honeycomb sandwich core 8, end wall inserts 9, an inner skin 10 and an outer skin 11, and the overall reinforcement frame 7, honeycomb sandwich 8, and end wall inserts 9 are all built into the inner skin 10 and the outer skin 11. There are 11 outer skins, and the overall reinforcement frame 7 adopts an integrally formed hat-shaped structure. The two sides of the overall reinforcement frame 7 are respectively provided with honeycomb sandwich cores 8, and the end wall inserts 9 are arranged in the honeycomb sandwich core 8, and the end wall inserts The block 9 is provided with threaded holes 12, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com