Small unmanned plane undercarriage buffer

A landing gear buffer and a technology for small unmanned aerial vehicles, applied in the field of aviation aircraft, can solve the problems of low buffering efficiency, easy rebound, unable to meet the high reliability requirements of unmanned aerial vehicles, etc., achieve high buffering efficiency, prevent landing rebound, The effect of short modification and upgrade cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

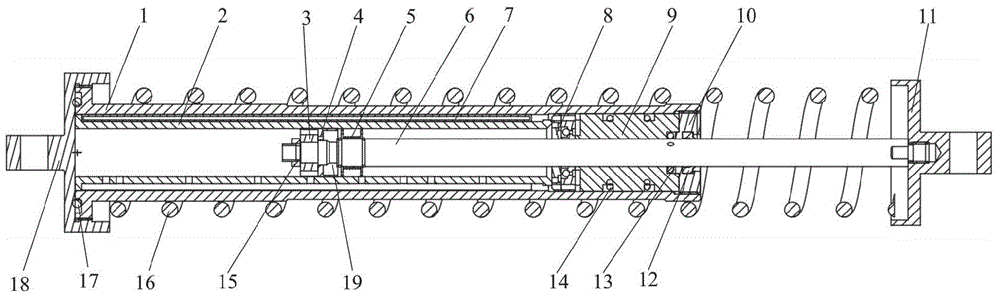

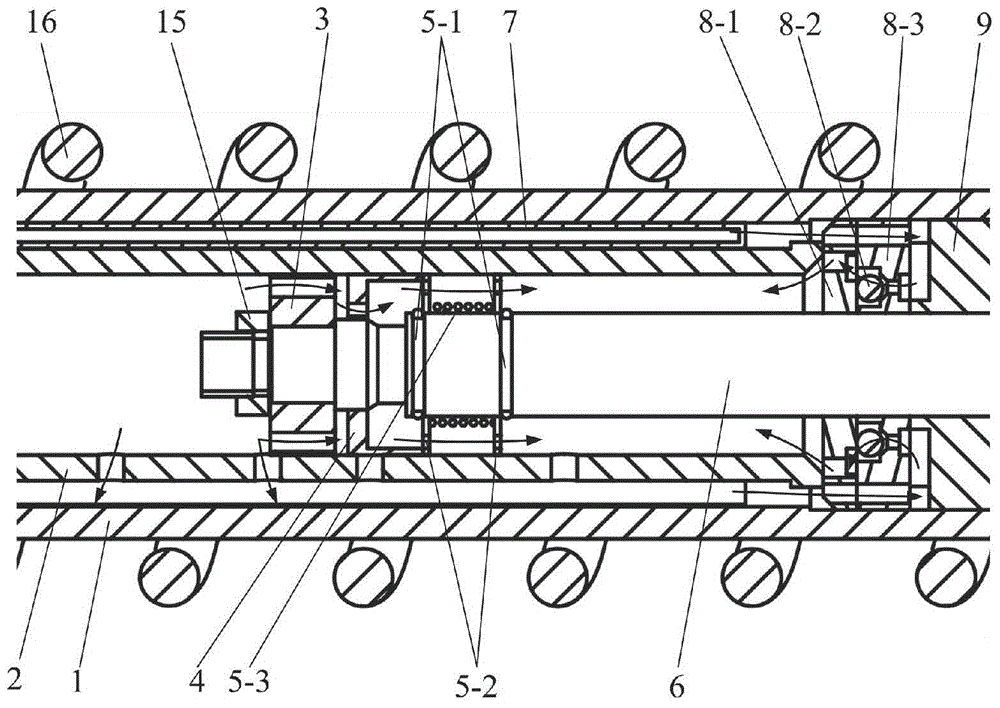

[0045] Such as figure 2 As shown, the small UAV landing gear buffer of the present invention is mainly composed of outer cylinder 1, inner cylinder 2, piston 3, damping plate 4, pressure limiting valve 5, piston rod 6, air bag 7, one-way valve 8, guide Sleeve 9, locking cover 10, upper joint 11, dustproof ring 12, first sealing ring 13, second sealing ring 14, nut 15, first spring 16, third sealing ring 17 and lower joint 18, through the first A spring 16 provides elastic force, and provides damping force through oil throttling.

[0046] One end of the outer cylinder 1 is provided with a flange, and the outer cylinder 1 is fixedly connected with the lower joint 18 through the flange, and a third sealing ring 17 is installed between the flange end surface of the outer cylinder 1 and the inner end surface of the lower joint 18, Used to seal the outer cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com