Waterborne sound insulation and thermal insulation coating and preparation method and construction method thereof

A technology of sound insulation, heat insulation and sound insulation material, applied in the direction of coating, can solve the problems of complicated construction, can not meet people's needs, high maintenance cost, etc., to achieve enhanced sound insulation effect, enhanced thermal insulation effect, good elasticity and flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

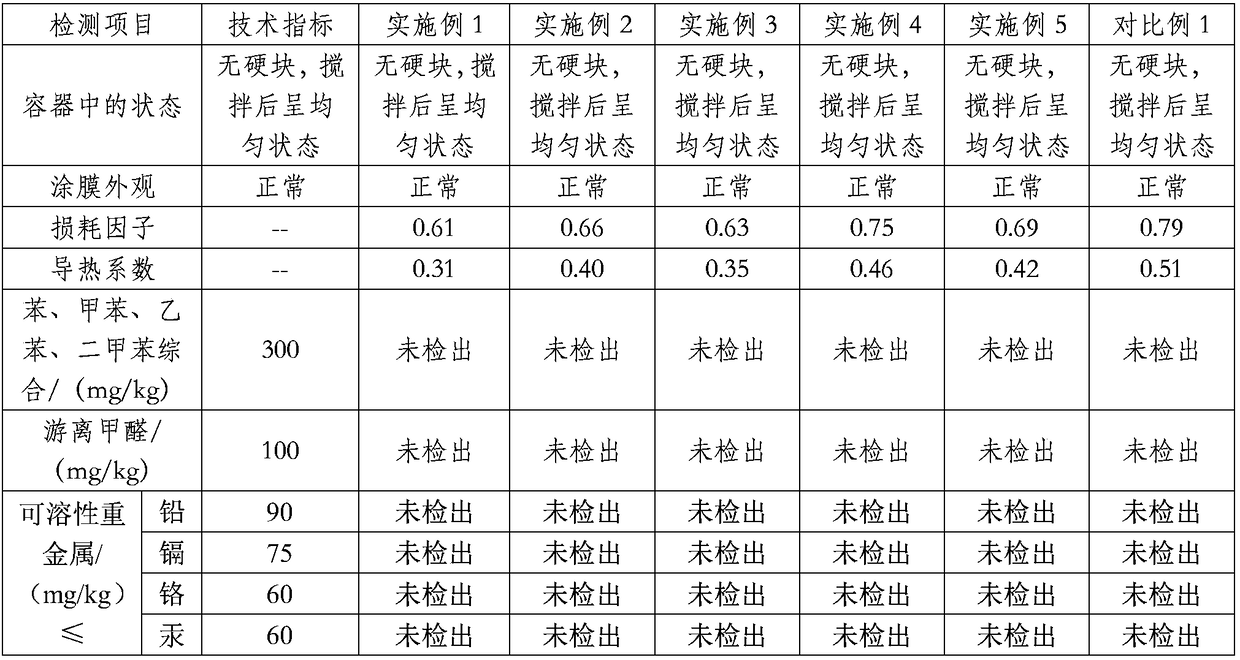

Examples

Embodiment 1

[0033] In this embodiment, a water-based sound-insulating and heat-insulating coating is prepared from the following raw materials in mass percentage: 43.0% of water-based synthetic resin emulsion, 35.0% of modified sound-insulating material, 6.0% of heat-insulating material, and 0.6% of wetting agent. 0.6% dispersant, 0.2% pH adjuster, 7.0% diatomaceous earth, 3.2% thickener, 0.6% defoamer, 1.0% antifreeze, 0.3% fungicide, 1.0 film-forming aid %, deionized water is 1.5%;

[0034] Wherein, the modified sound-insulating material is a powder sound-insulating material modified by a thermally decomposable foaming agent; based on the mass percentage of the modified sound-insulating material, the dosage ratio of the powder sound-insulating material to the foaming agent is (90:10).

[0035] The thermal decomposition type foaming agent described therein is azobisisobutyronitrile.

[0036] Wherein, the modification treatment method of the modified sound insulation and thermal insulat...

Embodiment 2

[0043]In this embodiment, a water-based sound-insulating and heat-insulating coating is prepared from the following raw materials in mass percentage: 22.0% of water-based synthetic resin emulsion, 45.0% of modified sound-insulating material, 17.0% of heat-insulating material, and 0.6% of wetting agent. 0.6% dispersant, 0.2% pH regulator, 3.0% kaolin, 5.0% thickener, 0.6% defoamer, 1.0% antifreeze, 0.3% fungicide, 1.0% film-forming aid , deionized water is 3.7%.

[0044] Wherein, the modified sound-insulating material is a powder sound-insulating material modified by a pyrolytic foaming agent. Based on the mass percentage of the modified sound-insulating material, the dosage ratio of the powdered sound-insulating material to the foaming agent is (95:5).

[0045] The thermal decomposition type foaming agent described therein is azobisisobutyronitrile.

[0046] Wherein, the modification treatment method of the modified sound insulation and thermal insulation coating includes th...

Embodiment 3

[0053] In this embodiment, a water-based sound-insulating and heat-insulating coating is prepared from the following raw materials in mass percentage: 35.0% of water-based synthetic resin emulsion, 24.0% of modified sound-insulating material, 13.0% of heat-insulating material, and 2.0% of wetting agent. 2.0% dispersant, 0.8% pH adjuster, 1.0% diatomaceous earth, 2.0% kaolin, 1.4% thickener, 2.0% defoamer, 2.0% antifreeze, 0.8% fungicide, 3.0% film-forming aid, 11.0% deionized water.

[0054] Wherein, the modified sound-insulating material is a powder sound-insulating material modified by a pyrolytic foaming agent. Based on the mass percentage of the modified sound-insulating material, the dosage ratio of the powdered sound-insulating material to the foaming agent is (90:10).

[0055] The thermal decomposition type foaming agent described therein is azobisisobutyronitrile.

[0056] Wherein, the modification treatment method of the modified sound-insulating and heat-insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com