Patents

Literature

39results about How to "Less prone to wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

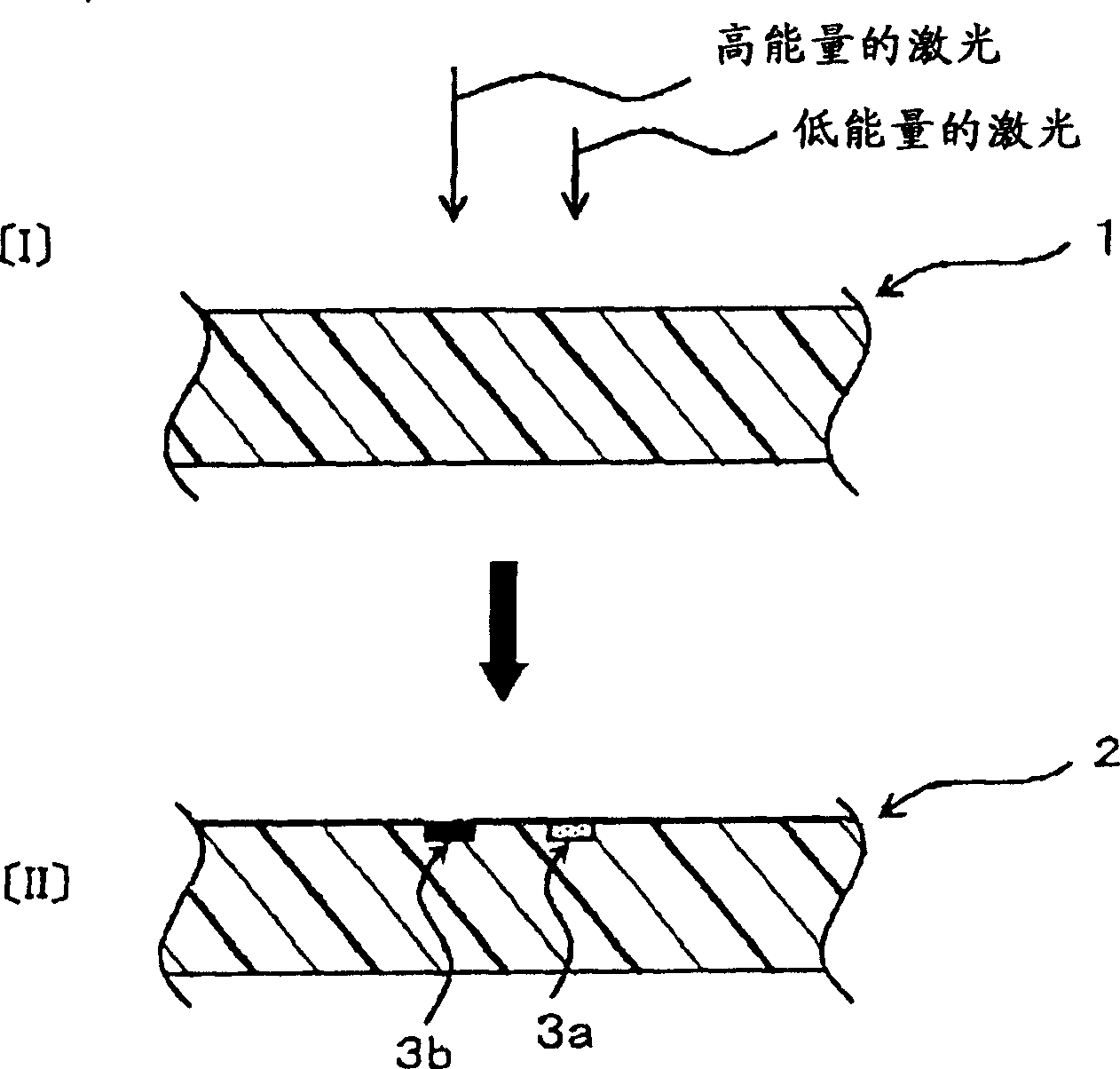

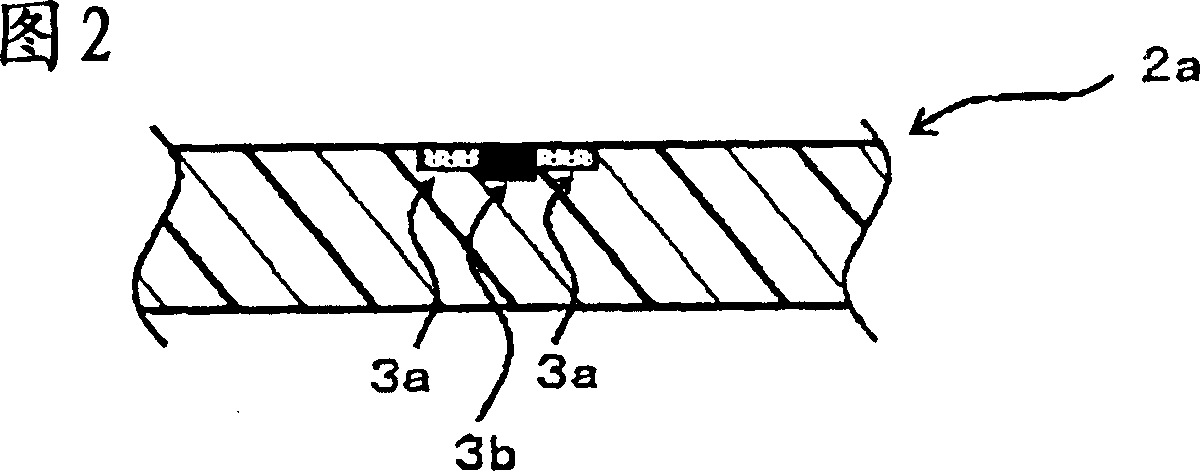

Multi-color coloring laser marking-use chromatic color colorant, multi-color coloring laser marking-use composition and molding containing it, multi-color marking-carrying molding and laser marking me

InactiveCN1910238AAvoid deformationLess prone to wearOrganic dyesThermographyColored whiteBlack substance

Owner:TECHNO POLYMER CO LTD

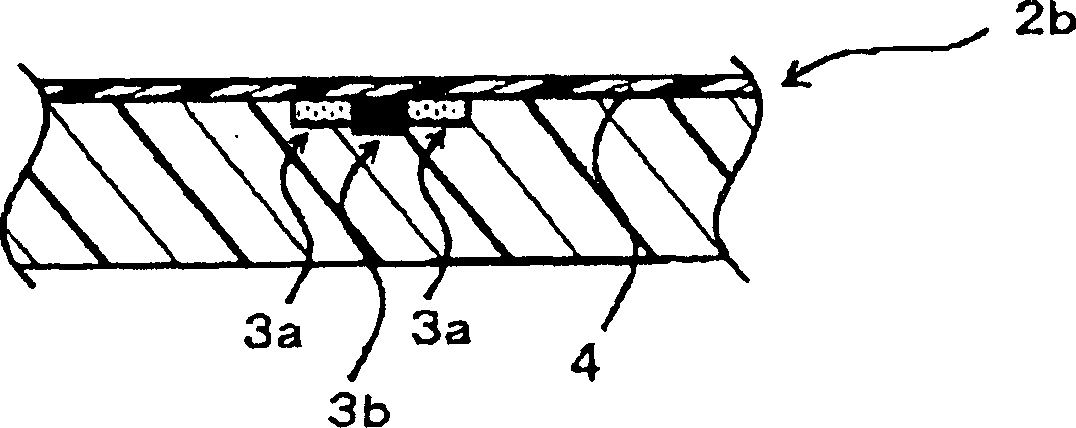

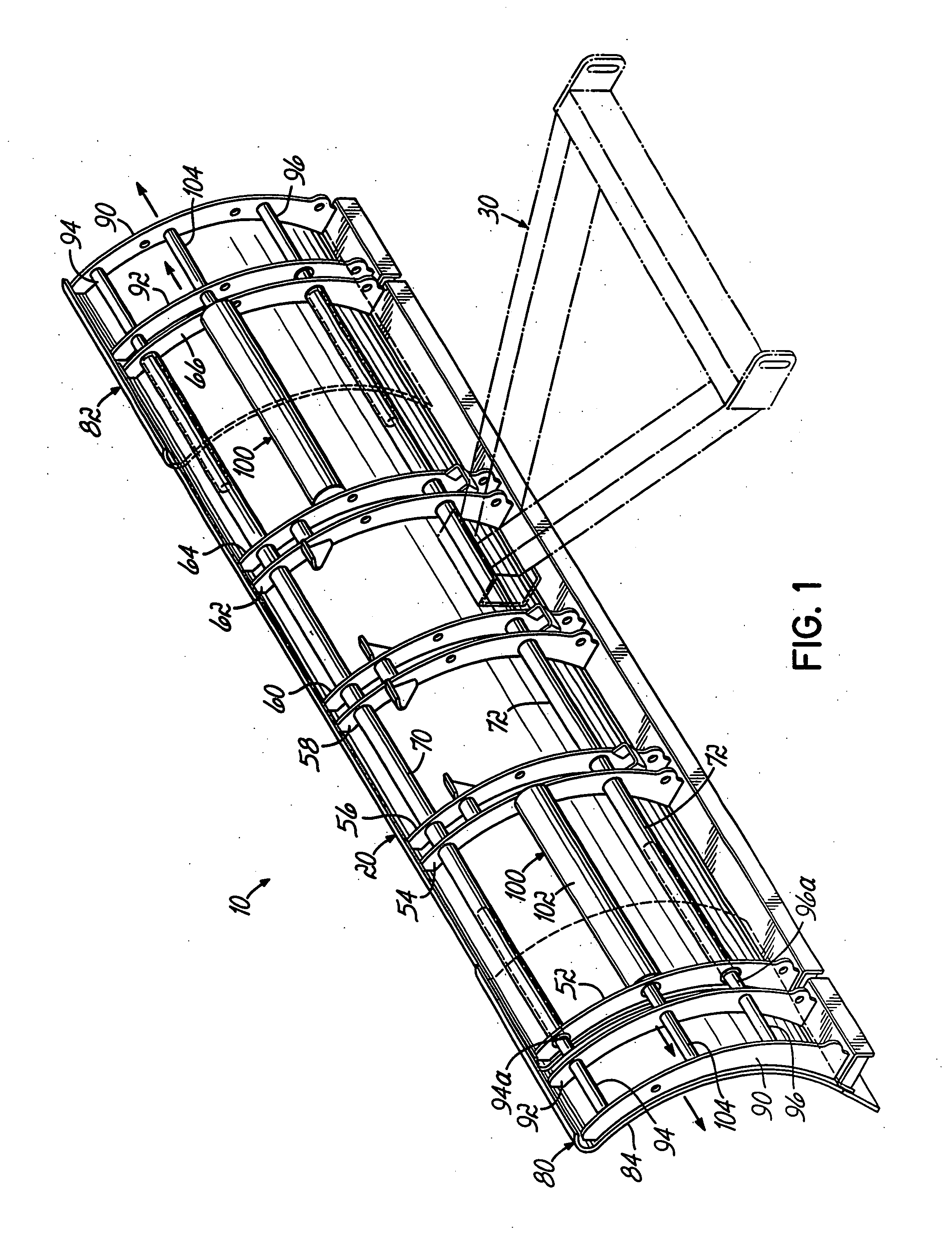

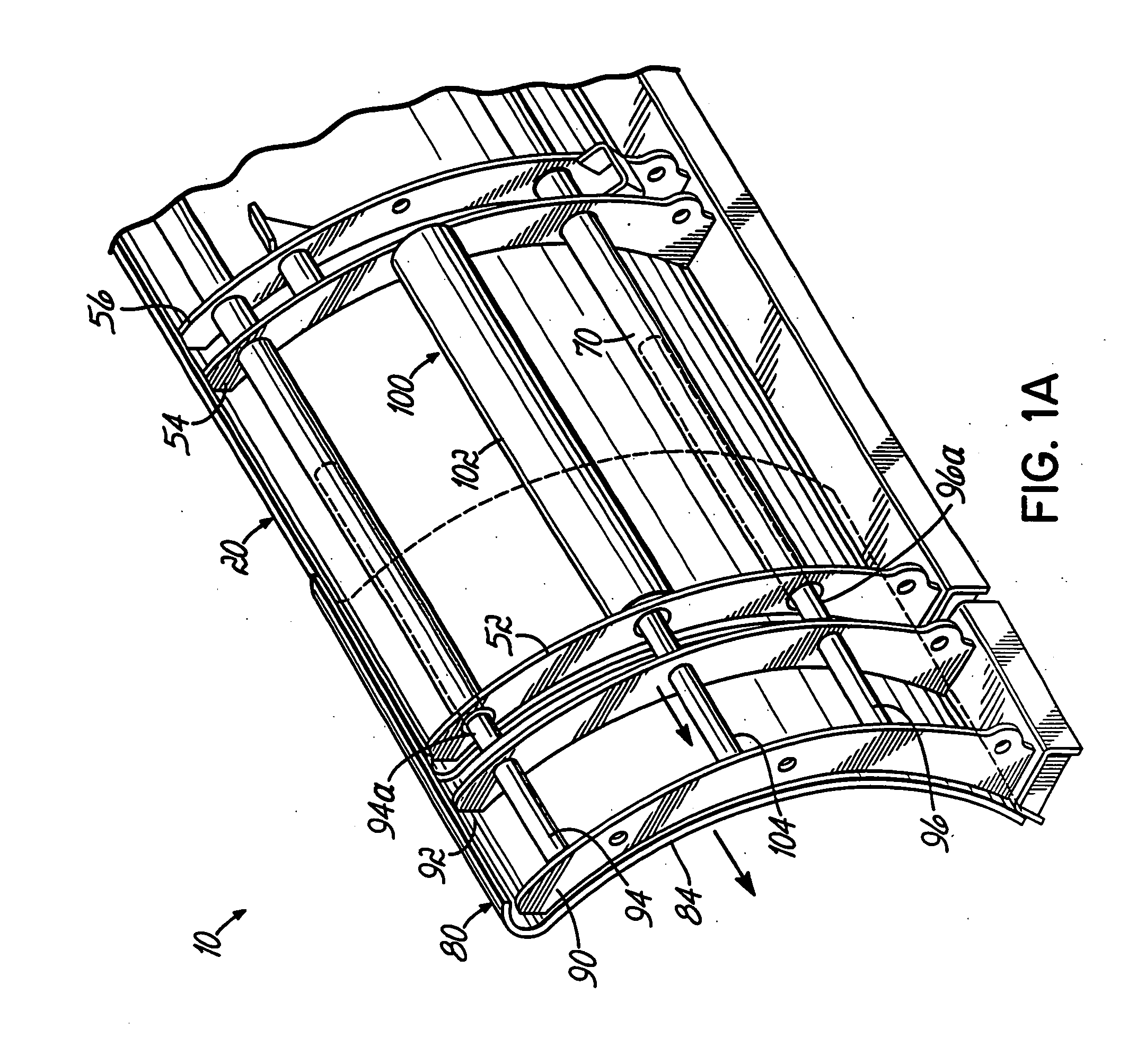

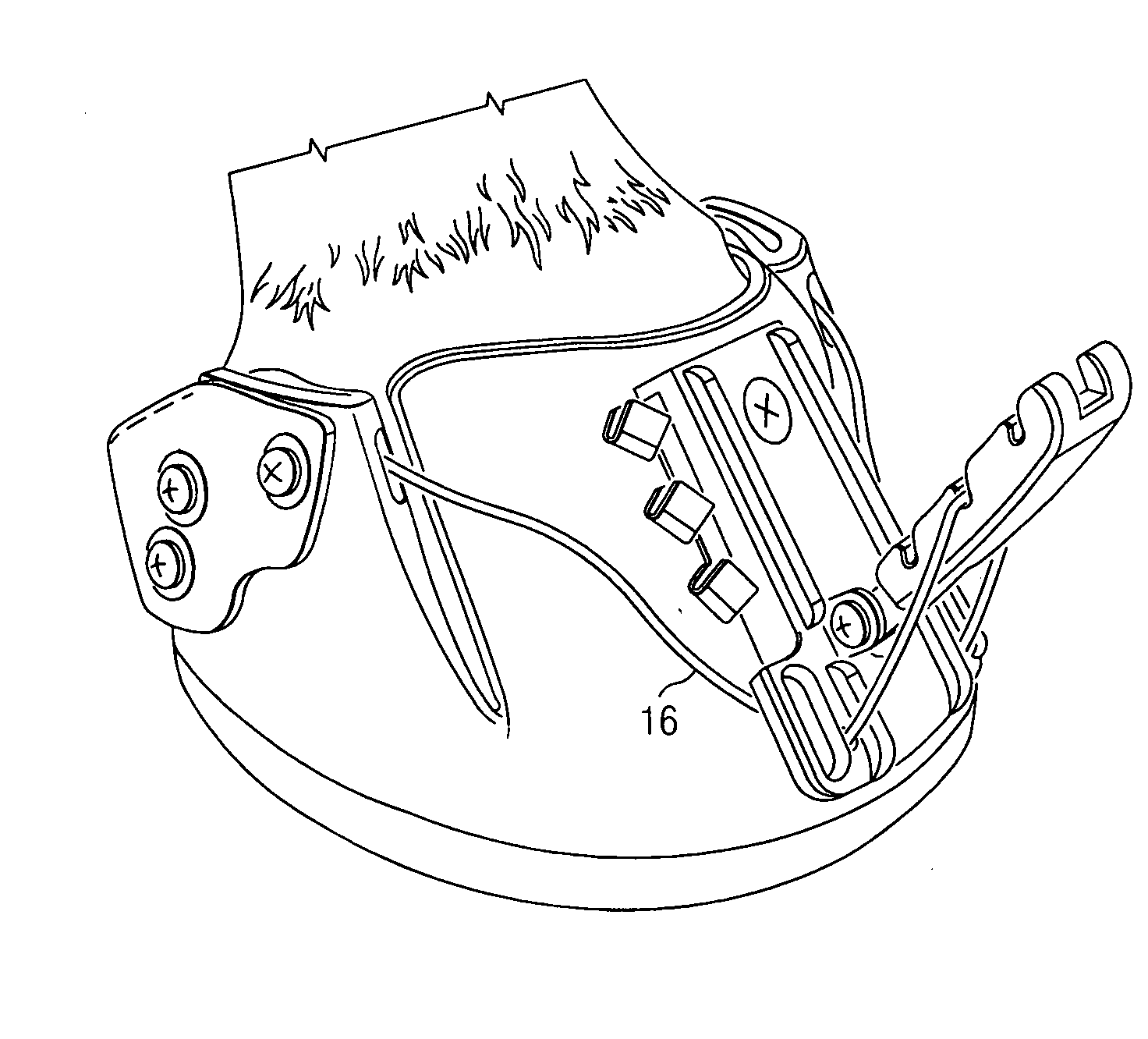

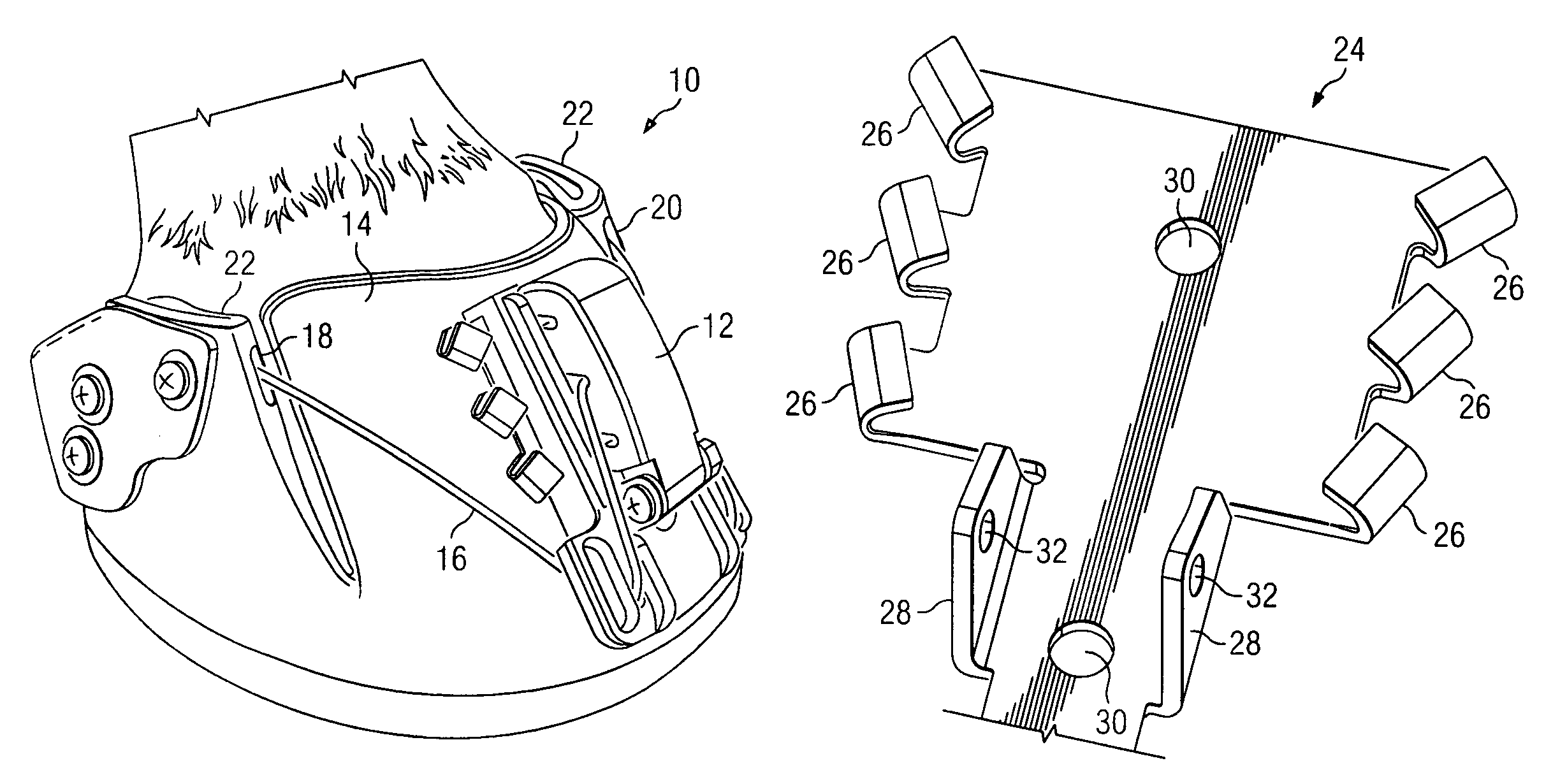

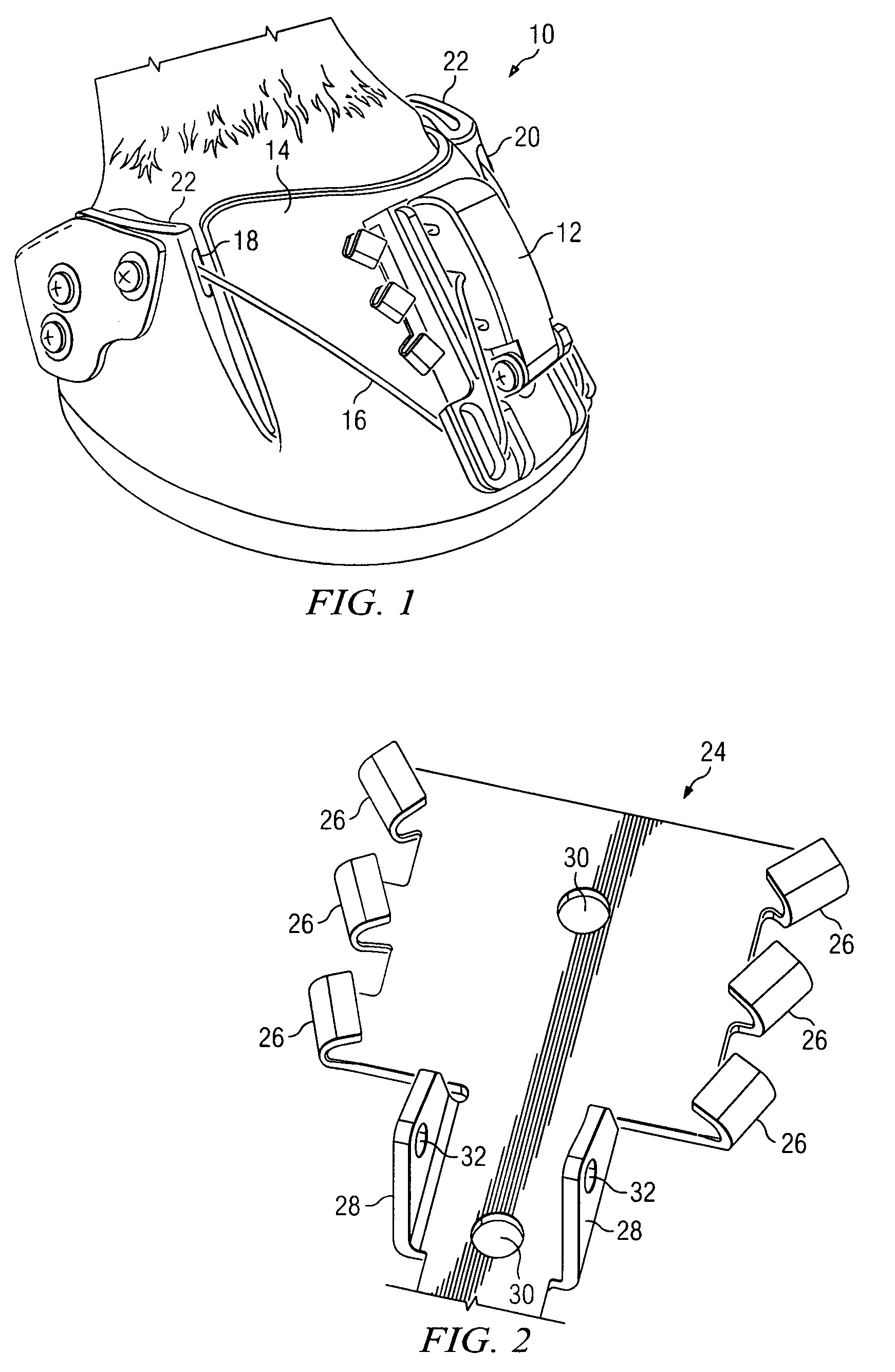

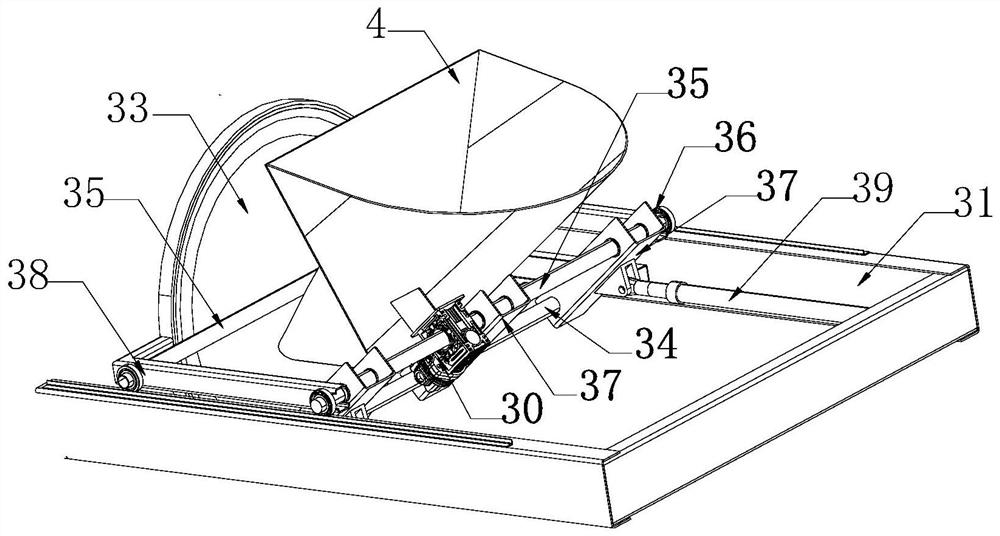

Plow with blade wing

A plow assembly comprises a blade, structure attached to the blade and adapted to be attached to a vehicle for mounting the blade to and supporting the blade from the vehicle, and a wing attached to an end of the blade. The wing has a first portion mounted to the blade for translational movement relative thereto, and a second portion mounted to the first portion for rotational movement relative thereto. An actuator has a cylinder and first and second oppositely movable piston rods. The first piston rod and the cylinder operable to move the first portion of the wing relative to the blade, and the second piston rod and the cylinder are operable to move the second portion of the wing relative to the fist portion of the wing.

Owner:DOUGLAS DYNAMICS

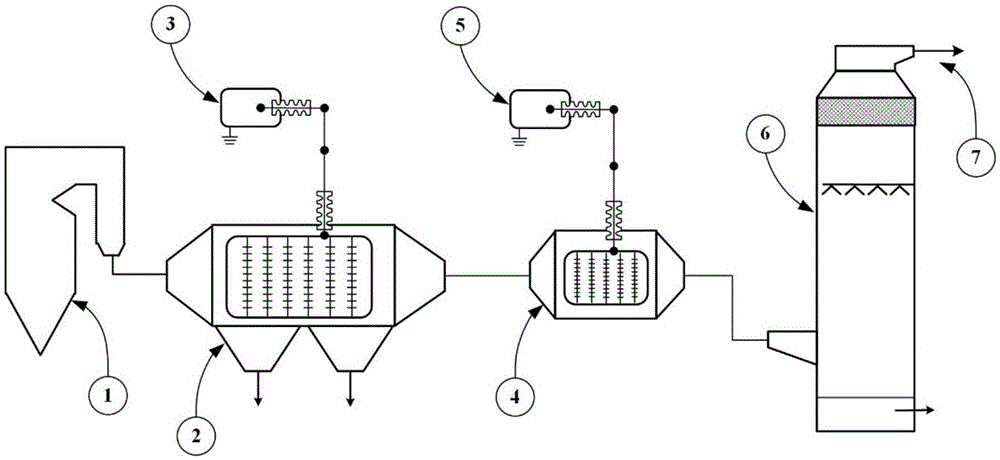

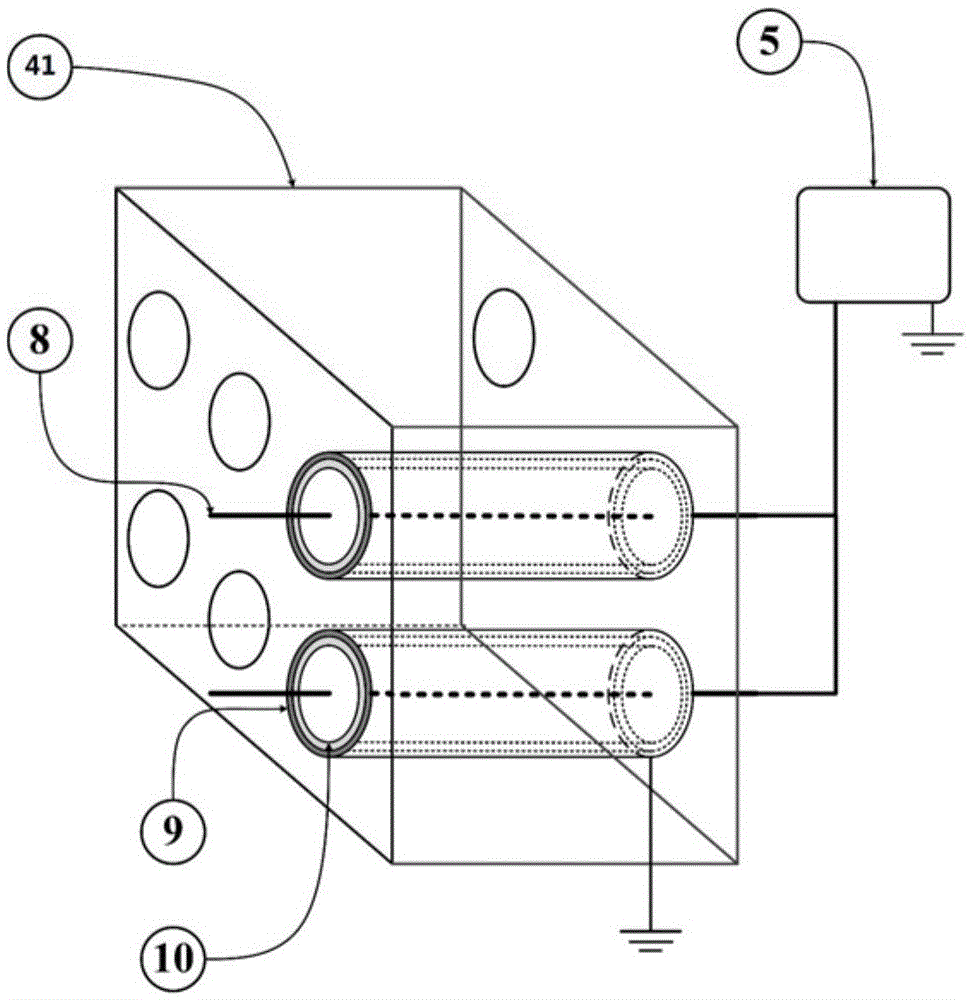

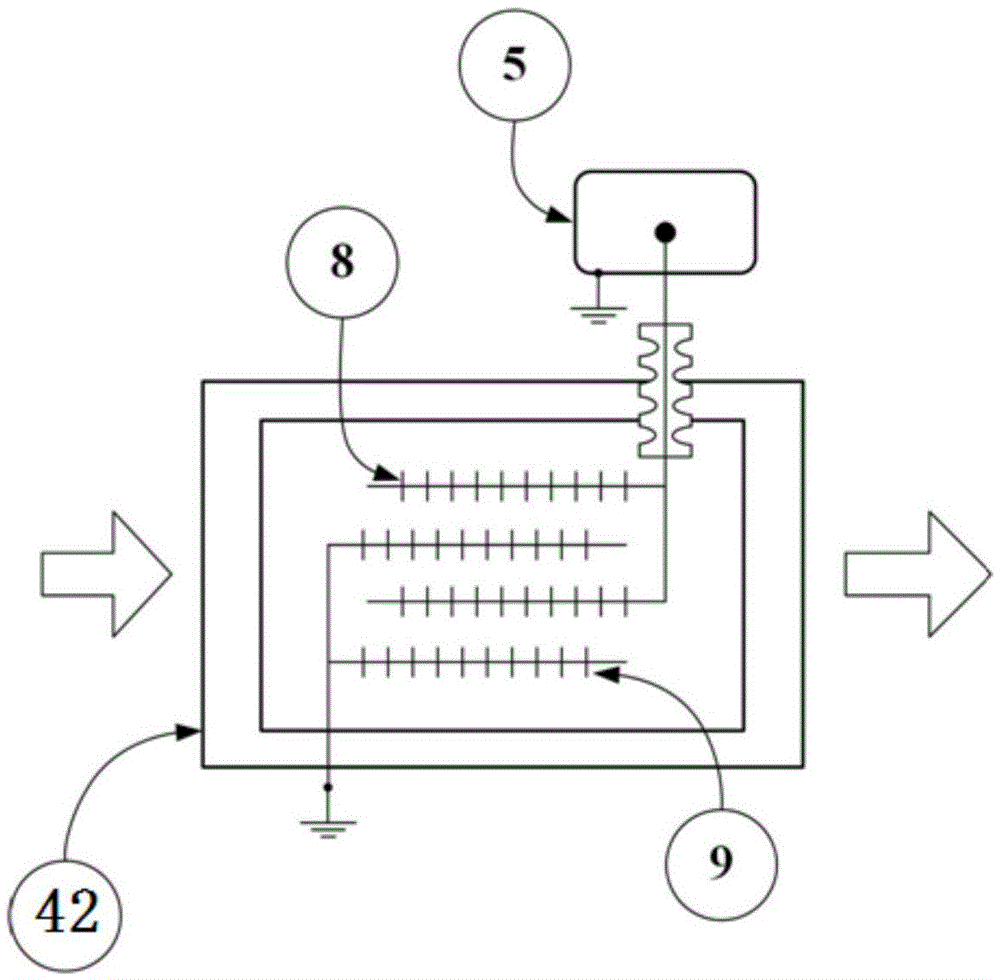

Device and method for purifying flue gases

InactiveCN105642080ANot easy to wearExtended maintenance cycleElectrostatic separationDispersed particle separationElectricityFlue gas

low-temperaturetes to the field of flue gas treatment and discloses a device and a method for purifying flue gases. The device for purifying the flue gases comprises an electrical precipitator (2), a low-temperature plasma reactor (4) and wet desulphurization equipment (6) which are connected in sequence, wherein an outlet of the electrical precipitator (2) is connected with an inlet of the low-temperature plasma reactor (4); an outlet of the low-temperature plasma reactor (4) is connected with an inlet of the wet desulphurization equipment (6). The method for purifying the flue gases comprises the following steps of introducing the flue gases containing dust and nitrogen oxide into the electrical precipitator (2) for performing dust removing treatment; enabling the flue gases subjected to the dust removing treatment to enter into the low-temperature plasma reactor for oxidation treatment; then introducing the flue gases formed by the oxidation treatment into the wet desulphurization equipment for absorption treatment. By adopting the device and the method disclosed by the invention, the oxidation and dust charging efficiency of nitric oxide is high; the device is not easy to wear and is good in purifying effect of the flue gases.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

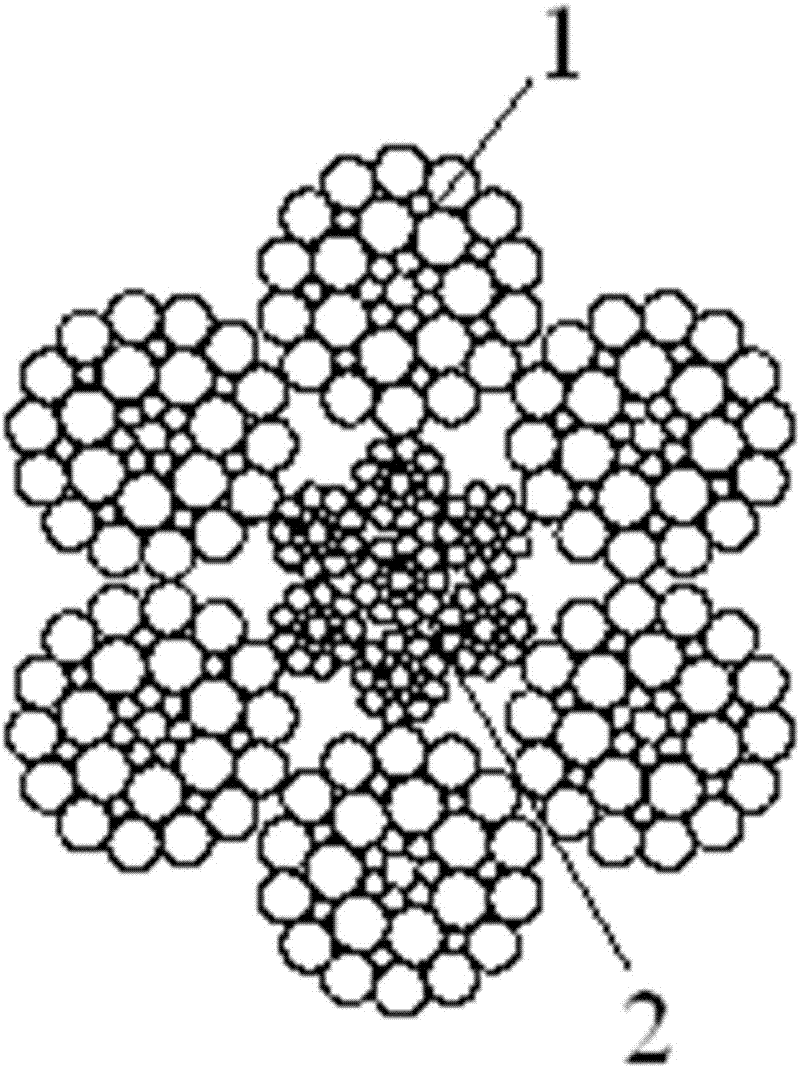

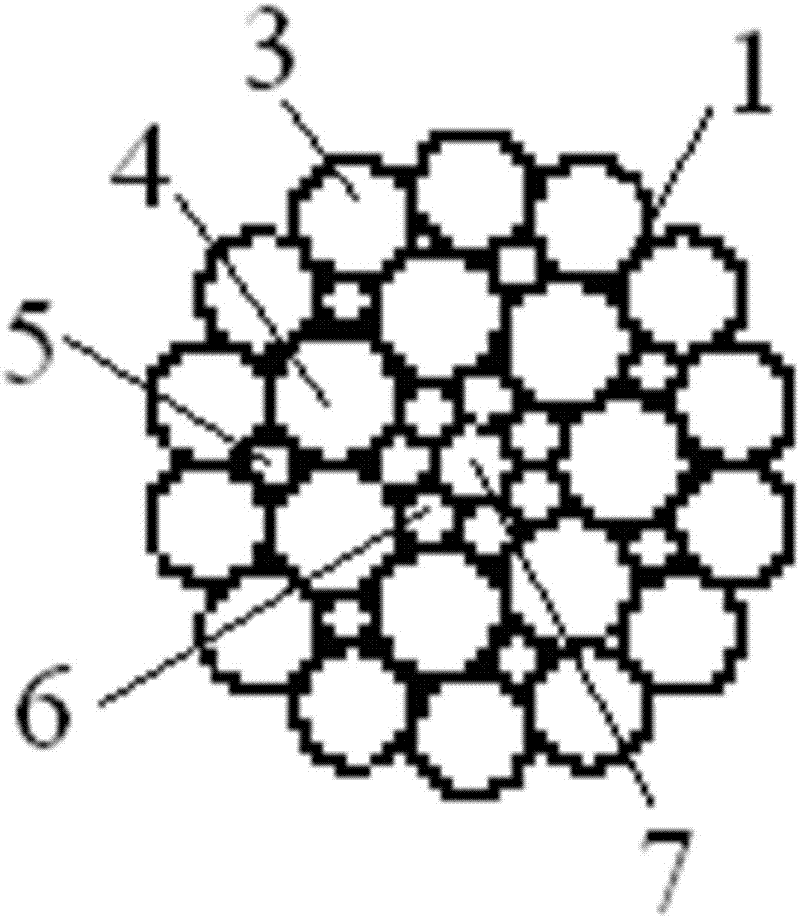

Parallel-laid steel wire rope for container equipment and manufacturing method thereof

The invention discloses a parallel twisted steel wire rope used for a container device and a manufacture method thereof. The steel wire rope comprises a rope core, wherein six strands of first outer-layer strands are arranged around the rope core, and the multiple of the lay length of the steel wire rope is 6.0-6.5 times. According to the structure and the diameter of the steel wire rope, steel wire breaking force summation and requirements on the value of gaps mutually between the twisted steel wires, the diameter of a finished product steel wire used in the steel wire rope is calculated according to the triangular geometry relationship formula; the spiral angle and the twisted circle of each layer of steel wires are calculated by the lay length; the proportional relation among different layers of steel wires can be deducted; the diameter of the raw material steel wire is calculated; a 65# wire rod of which the diameter is 6.5mm is processed and is drawn into the raw material steel wire; the raw material steel wire is drawn into the finished product steel wire after being subjected to heat treatment; and the finished product steel wire is twisted into the parallel twisted steel wire rope. The position of each steel wire in the steel wire rope is on the peak base of an adjacent steel wire on a lower layer, the position is very stable, the phenomena of abrading, breaking wires and breaking strands have small possibility of happening, and the service life is prolonged.

Owner:甘肃新实创科技有限公司

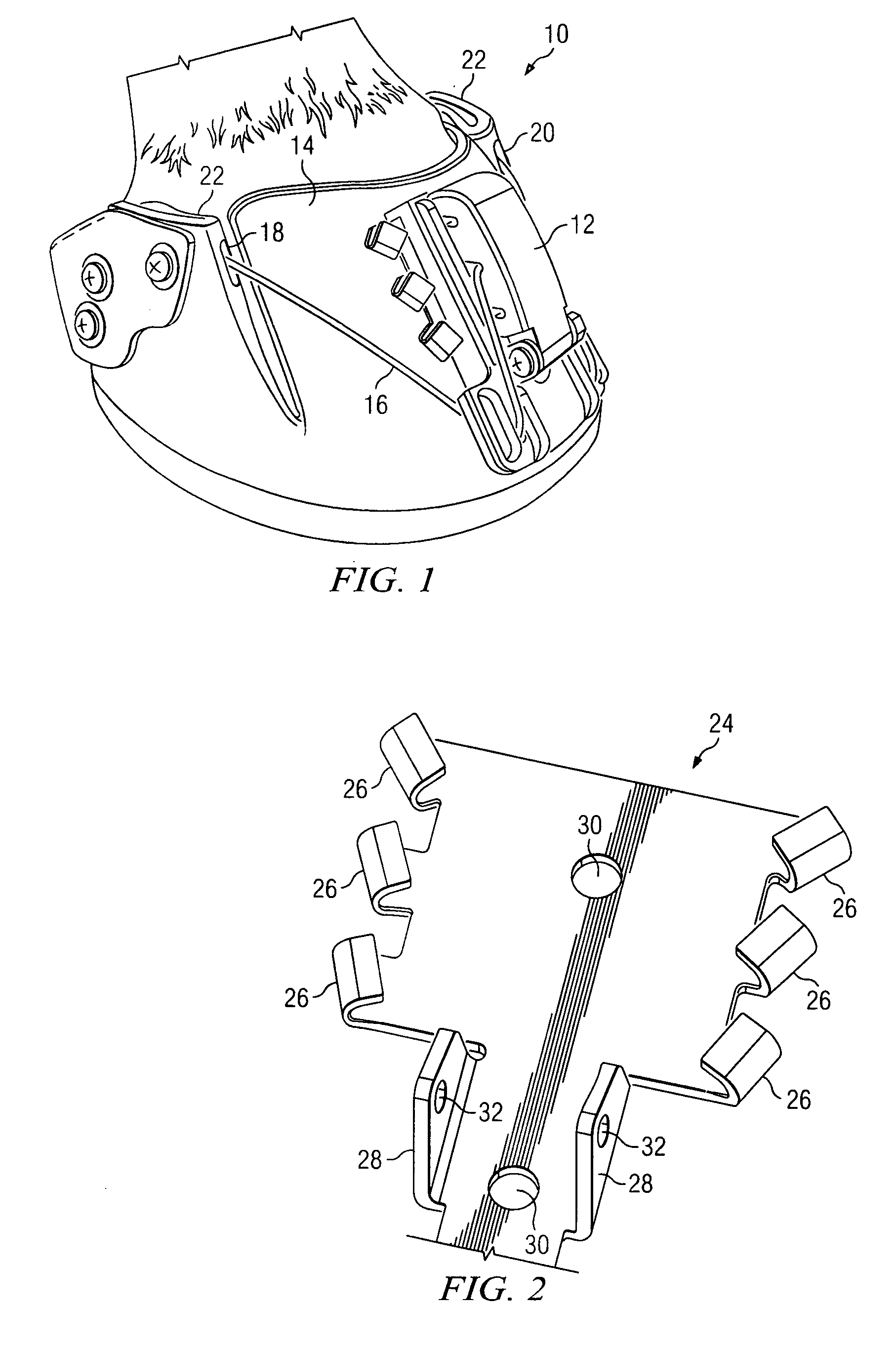

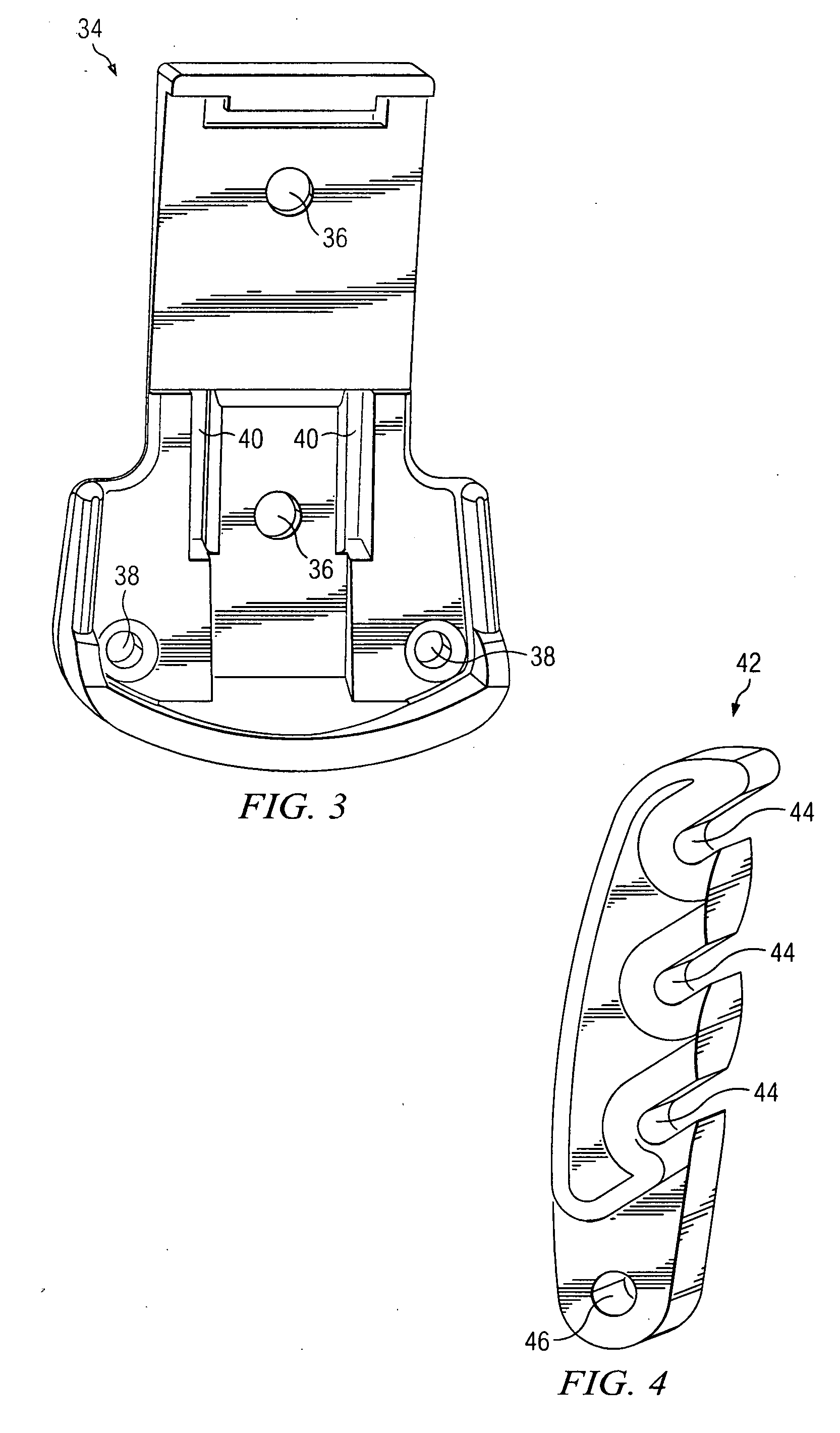

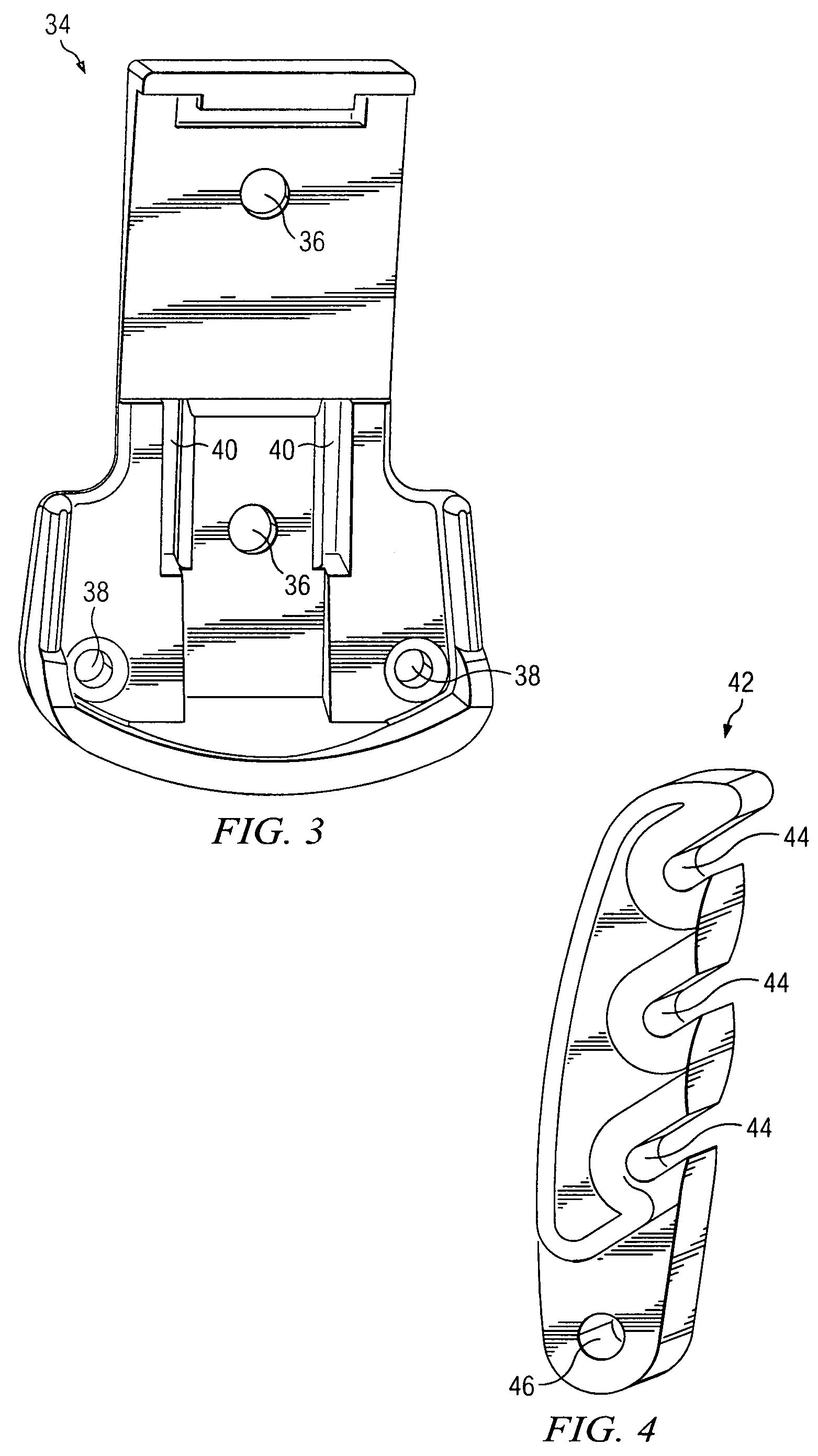

Adjustable horse-boot buckle

Owner:EASYCARE

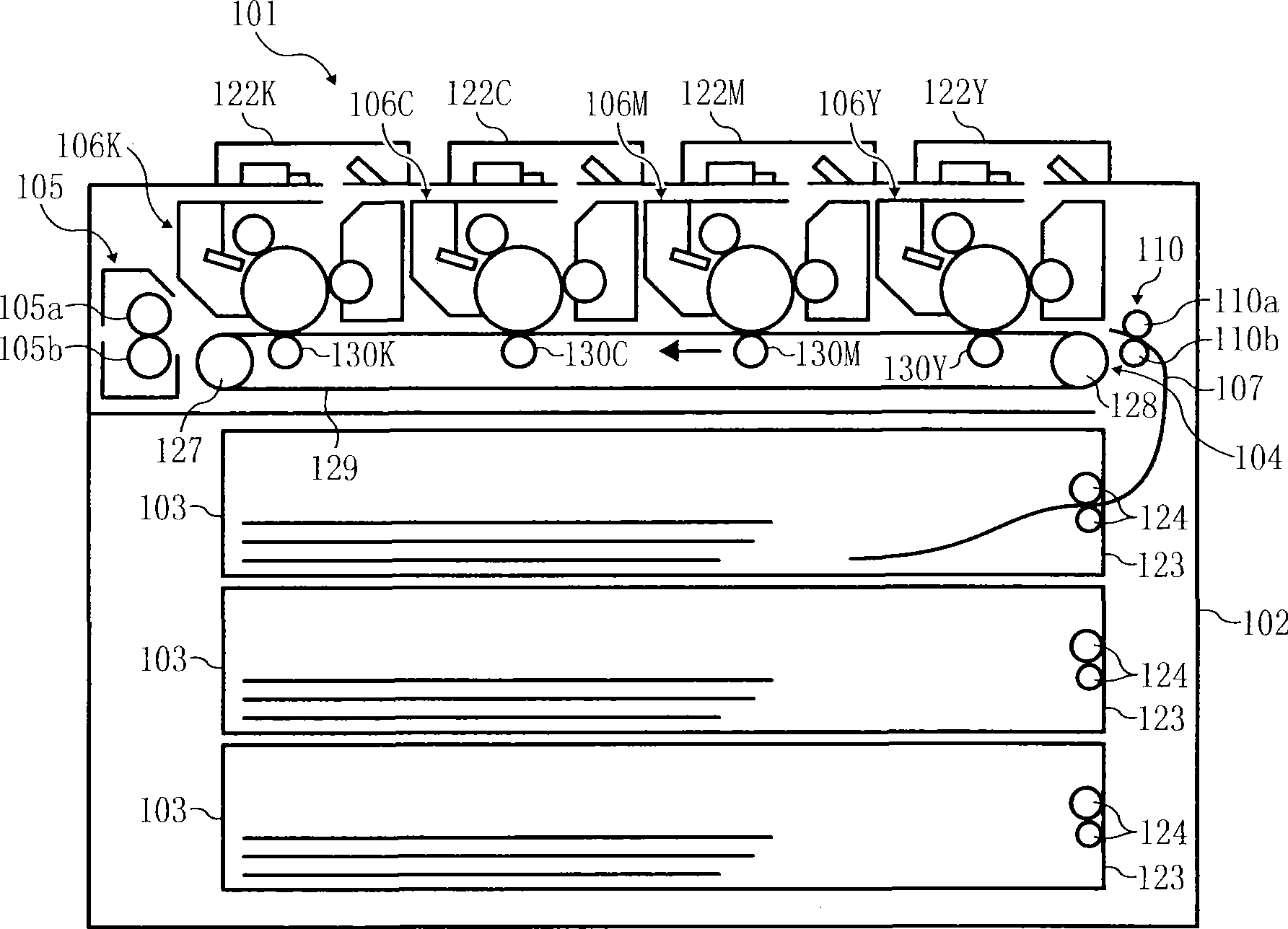

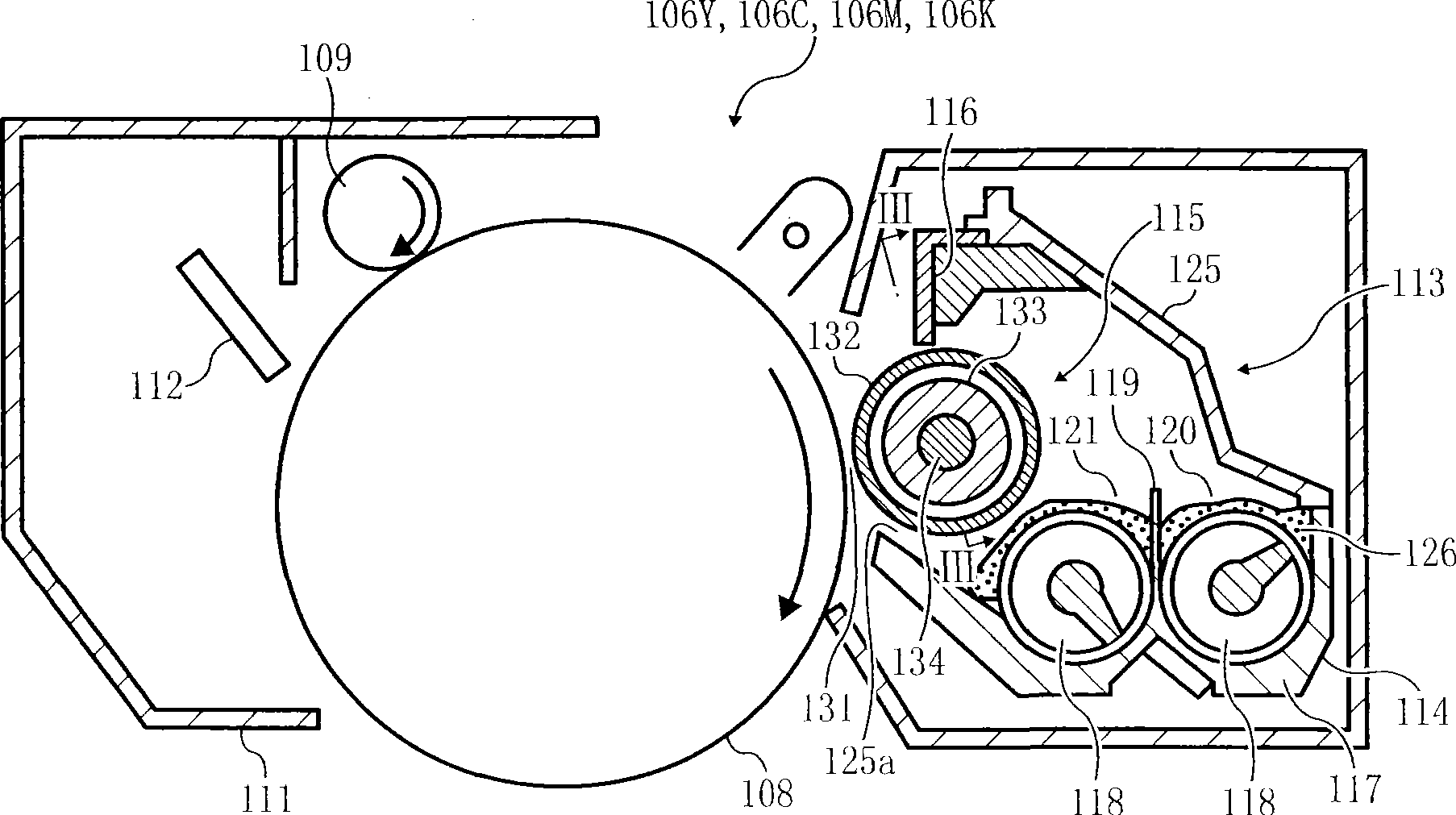

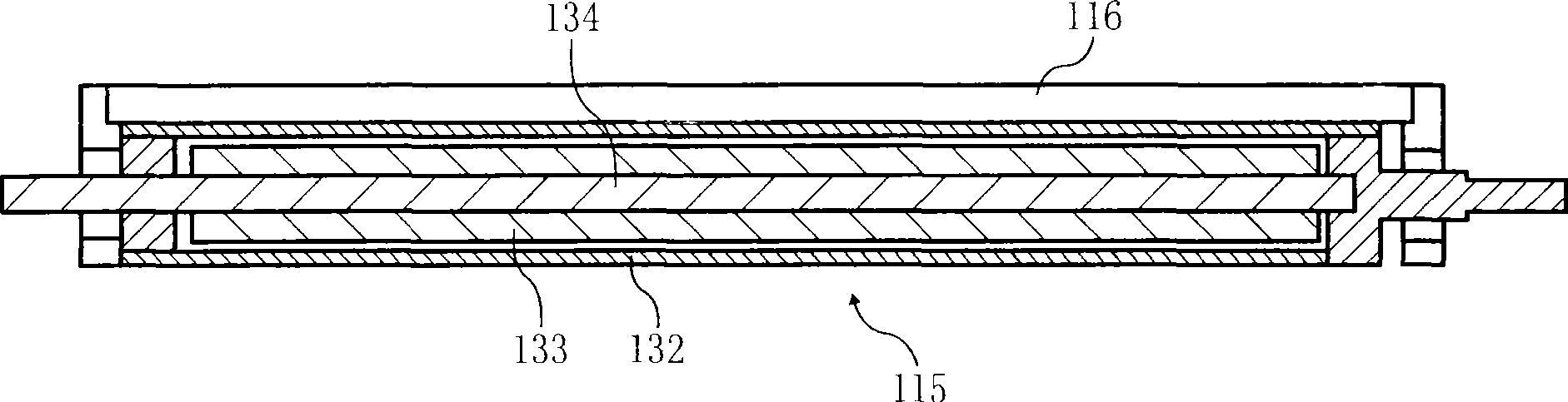

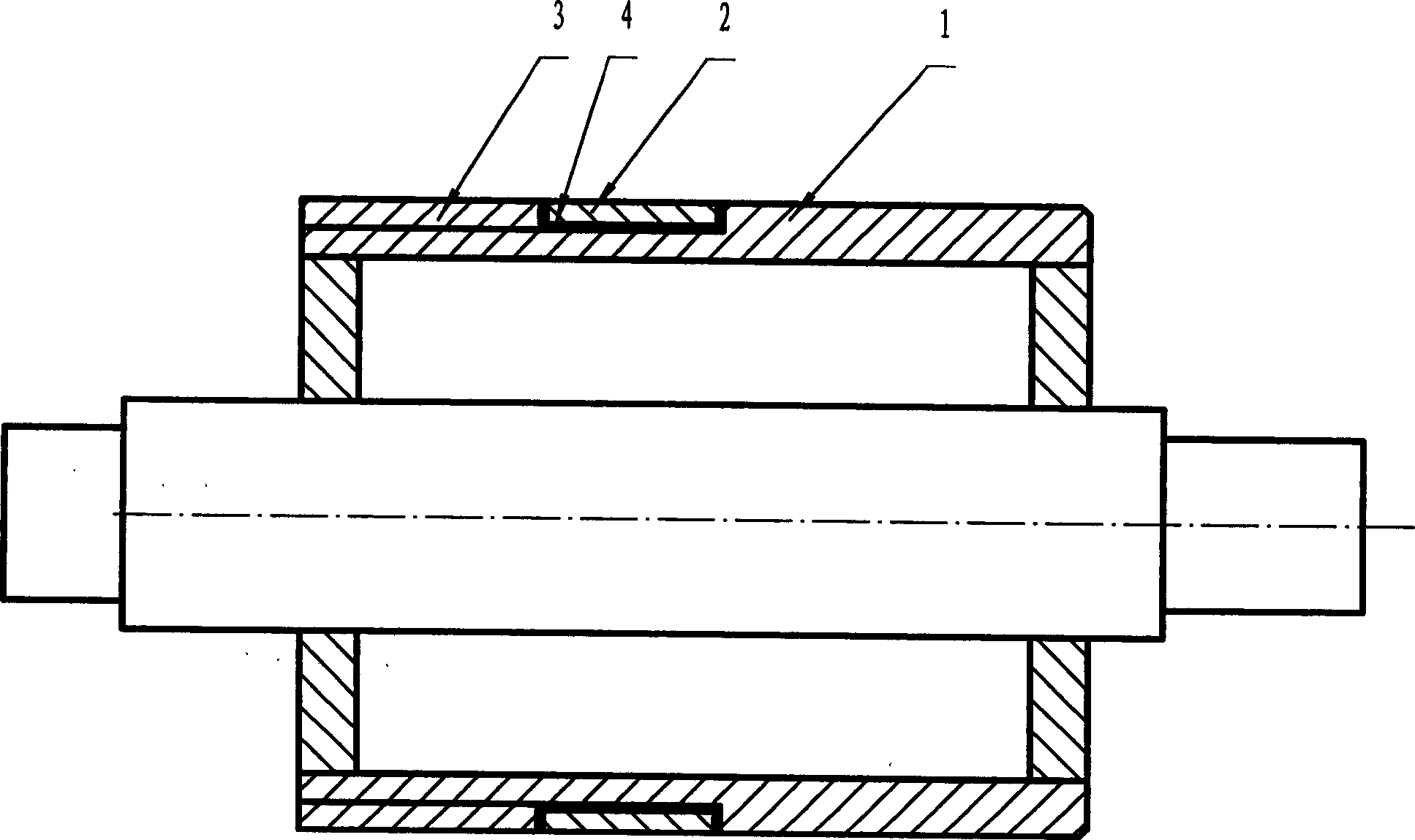

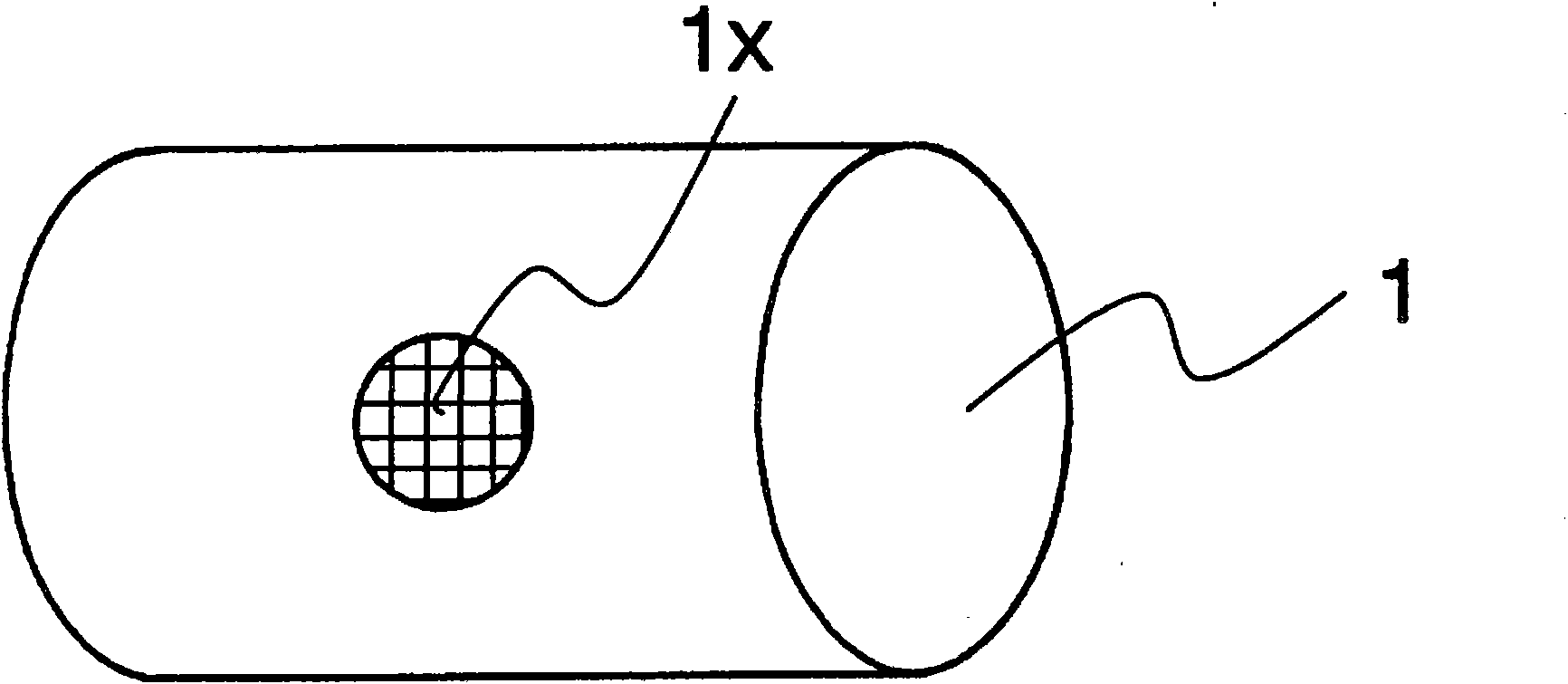

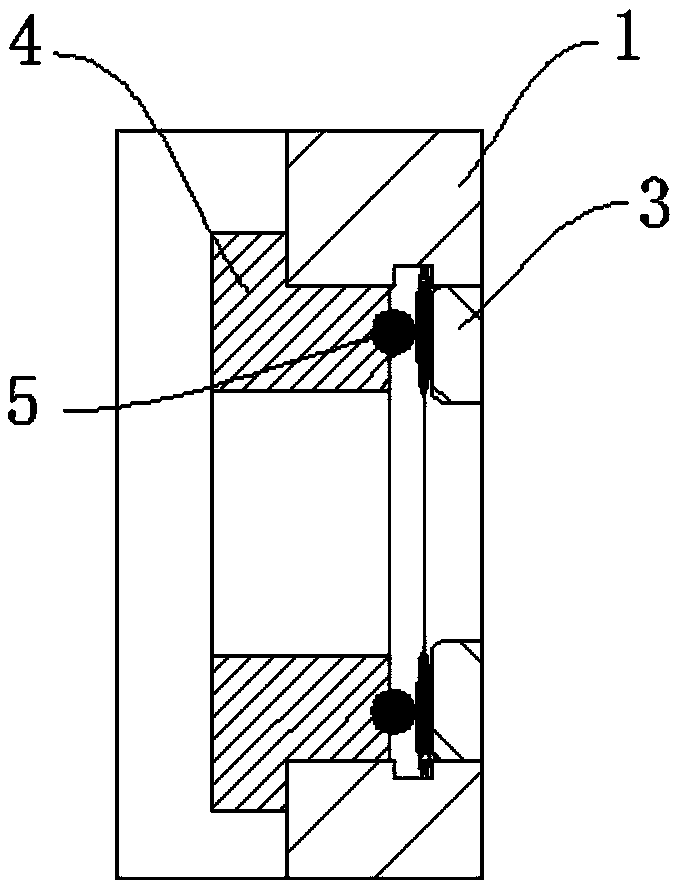

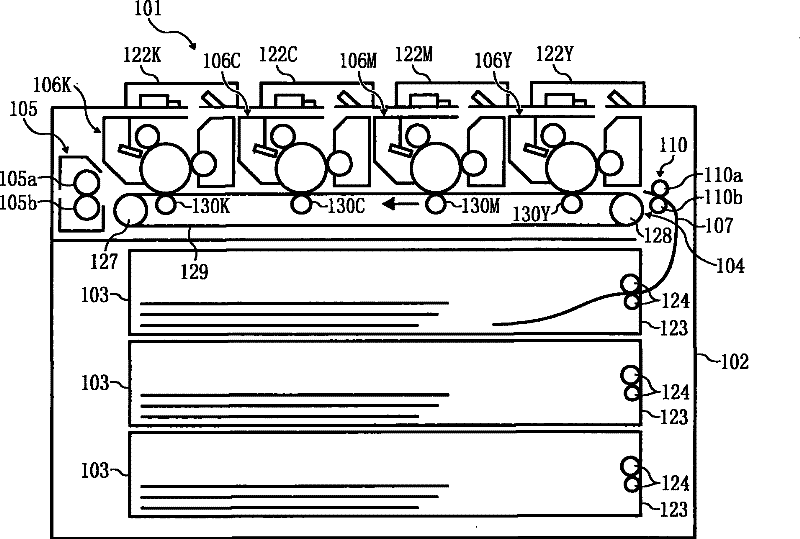

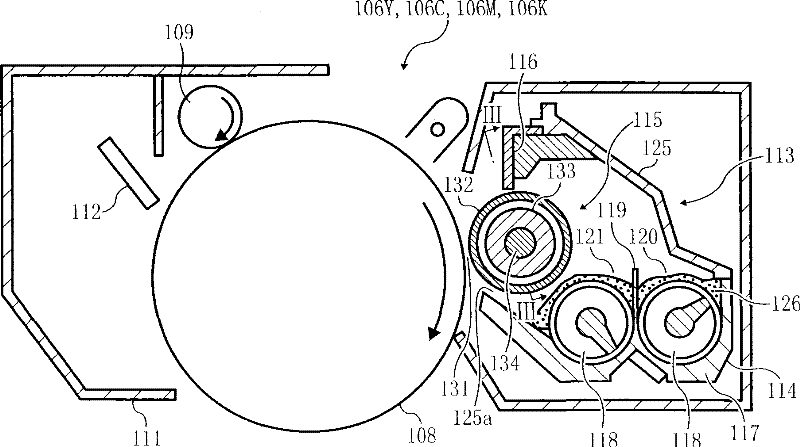

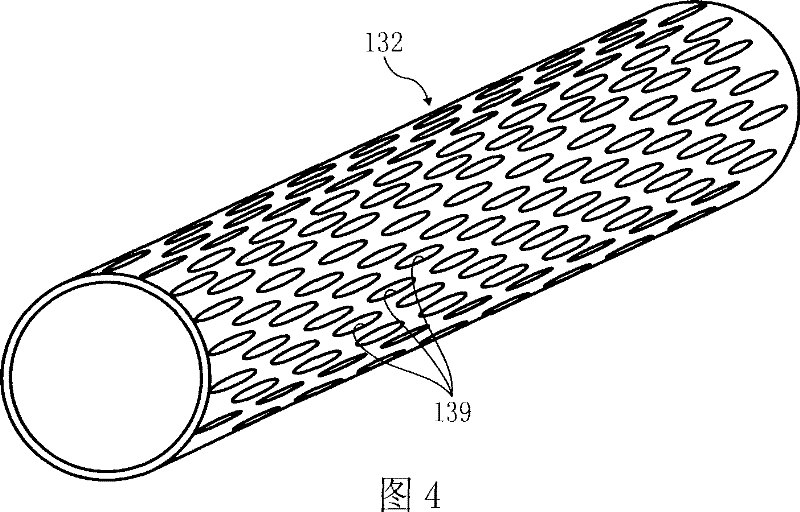

Developing roller, developing device, process cartridge, and image forming apparatus

InactiveCN101382761APreventing uneven image densityIncrease intakeElectrographic process apparatusMagnetEngineering

The present invention provides a developing roller, a developing device, a process cartridge and an image forming device, which may inhibit the reduction of transmitting amount due to the aging variation, thus avoiding unevenness of image intensity. Specifically, the process cartridge of the image forming device comprises a developing roller with a fixed magnet roller and a developing sleeve (132). The outer surface of the developing sleeve has a plurality of recesses (139) of elliptic shape in plan view regularly or irregularly arranged therein so as not to overlap, and the long axis of the recess is in parallel with the length direction of the developing sleeve (132).

Owner:RICOH KK

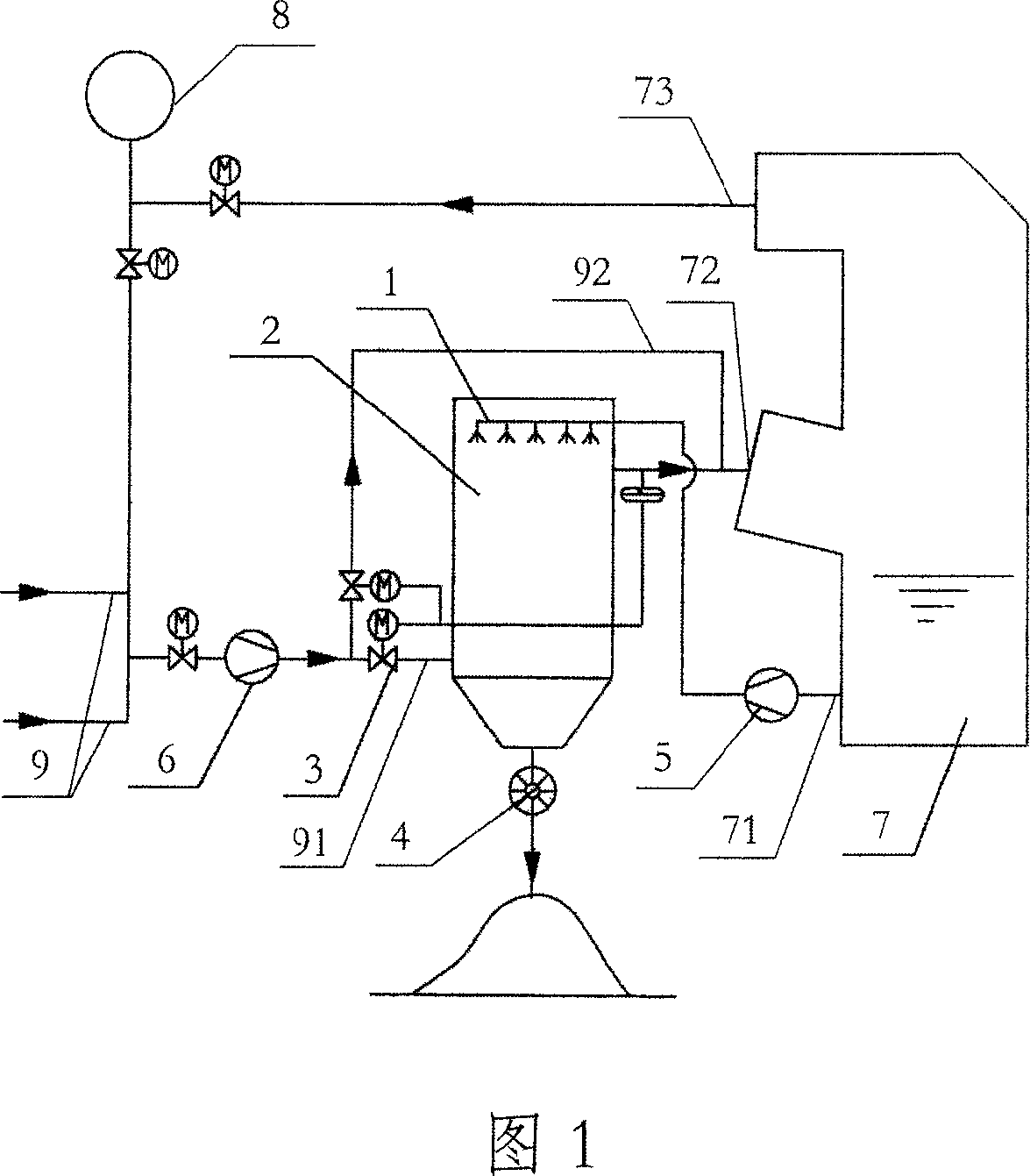

Dehydration method and apparatus of flue gas desulfurization gypsum slurry

The dewatering method and device for gypsum slurry in flue gas desulphurization comprise: connecting a drying tower near the desulphurization absorption tower with a slurry discharge pipe on bottom connected to the sprayer unit on drying tower top by a gypsum discharge pump; connecting the first branch pipe of flue gas channel to the smoke inlet on bottom of the drying tower by an in-series booster fan, a gypsum moisture controller or flue gas distributor; joining the flue gas outlet pipe with the second branch pipe and connecting to the flue gas inlet of the absorption tower; connecting the exhaust flue gas channel of the absorption tower with the chimney. This invention makes full use of original flue gas heat with small area and volume to complete dewater, and improves desulphurization effect fit to wide application.

Owner:国能朗新明环保科技有限公司

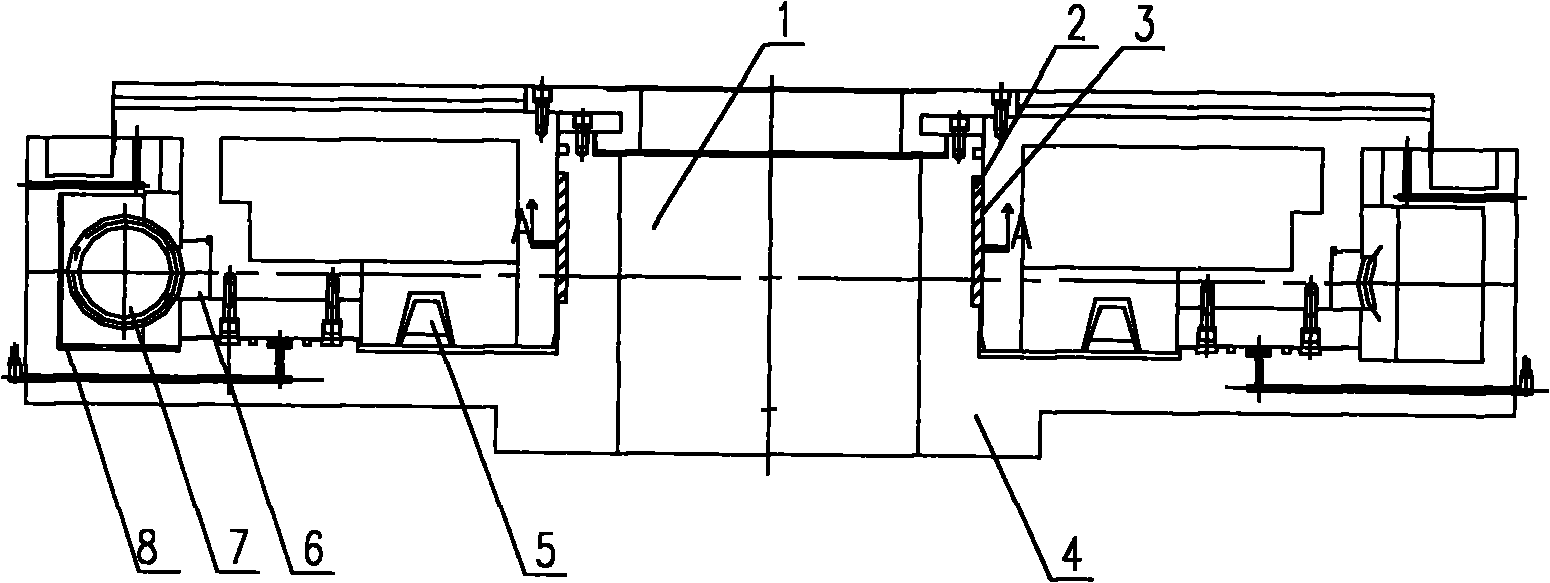

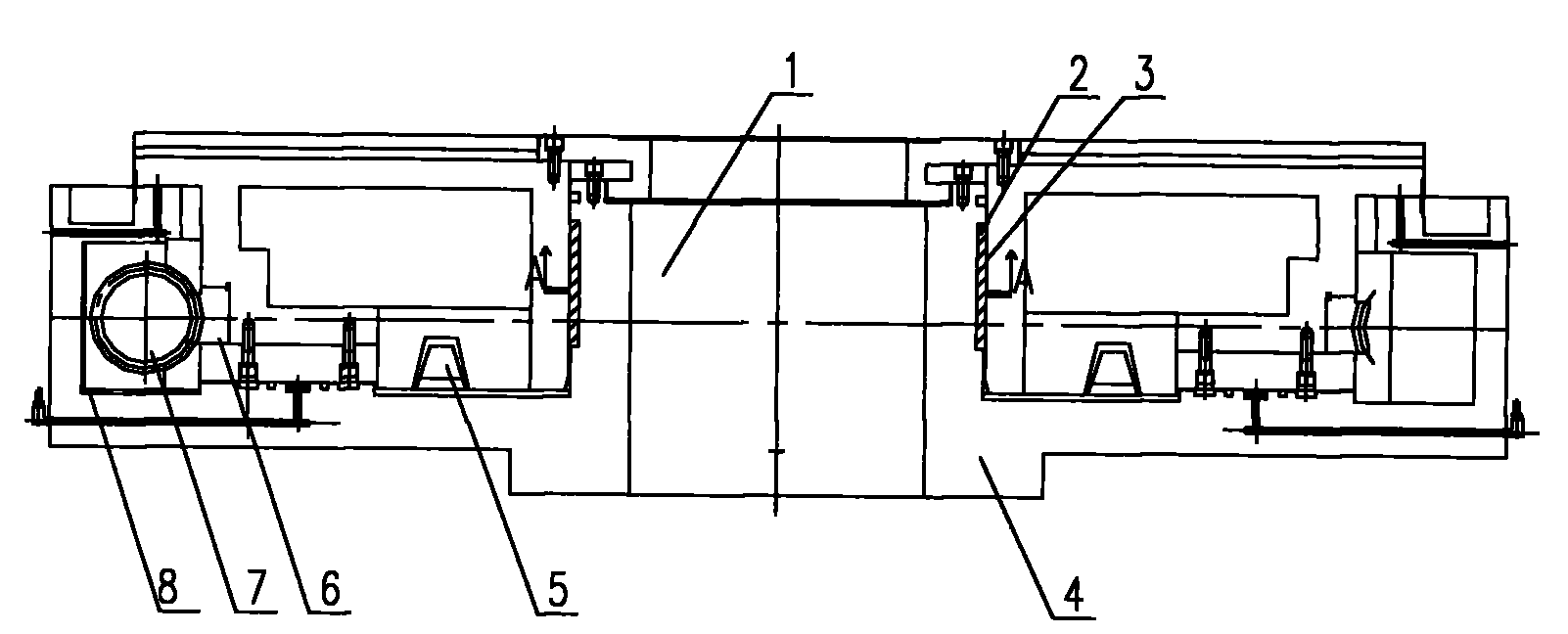

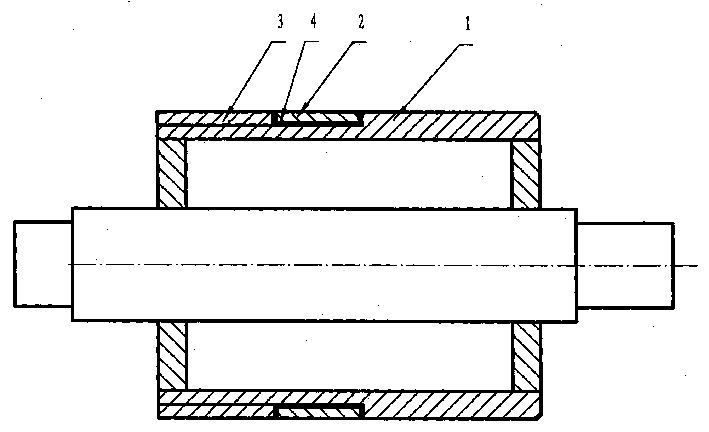

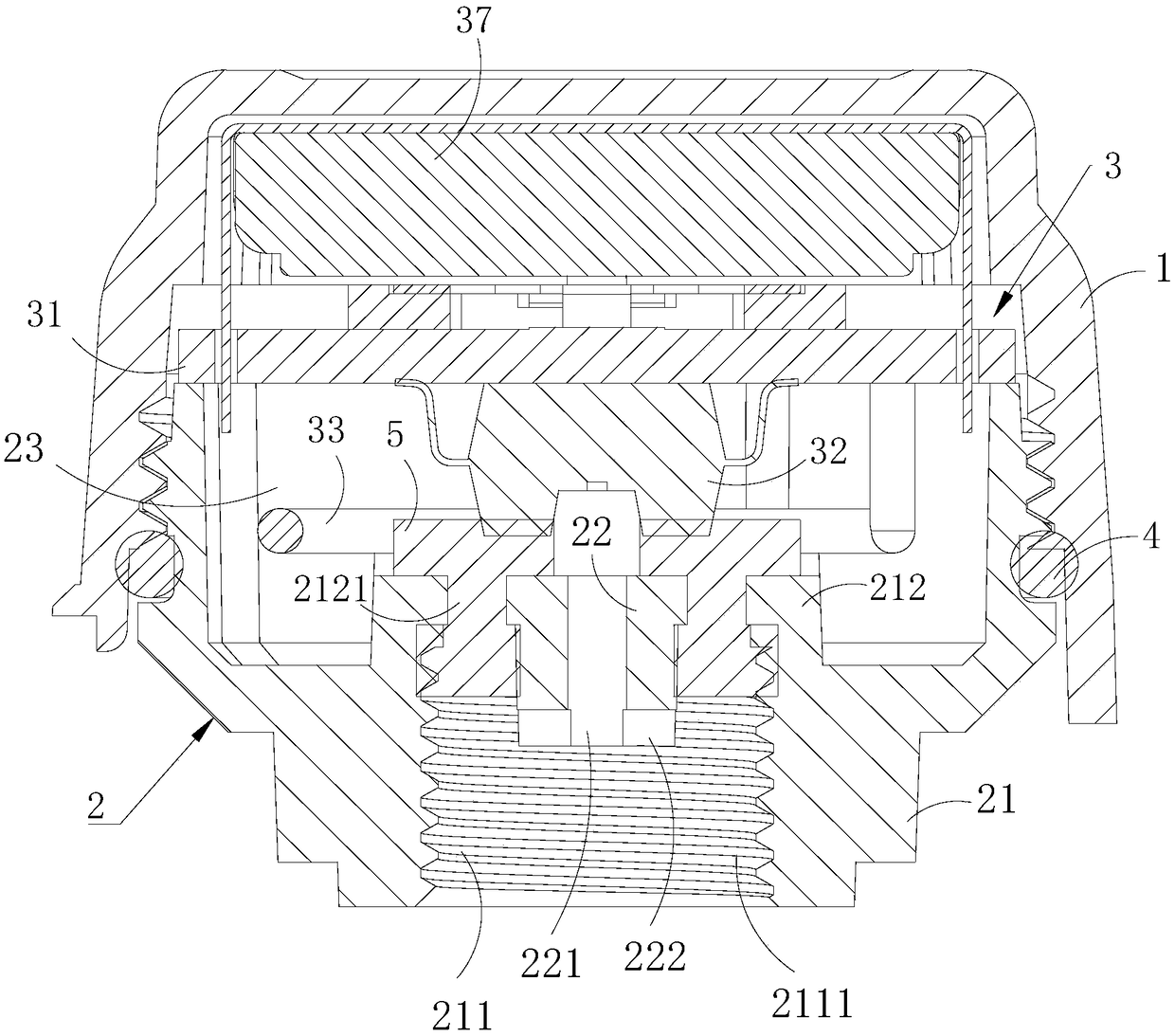

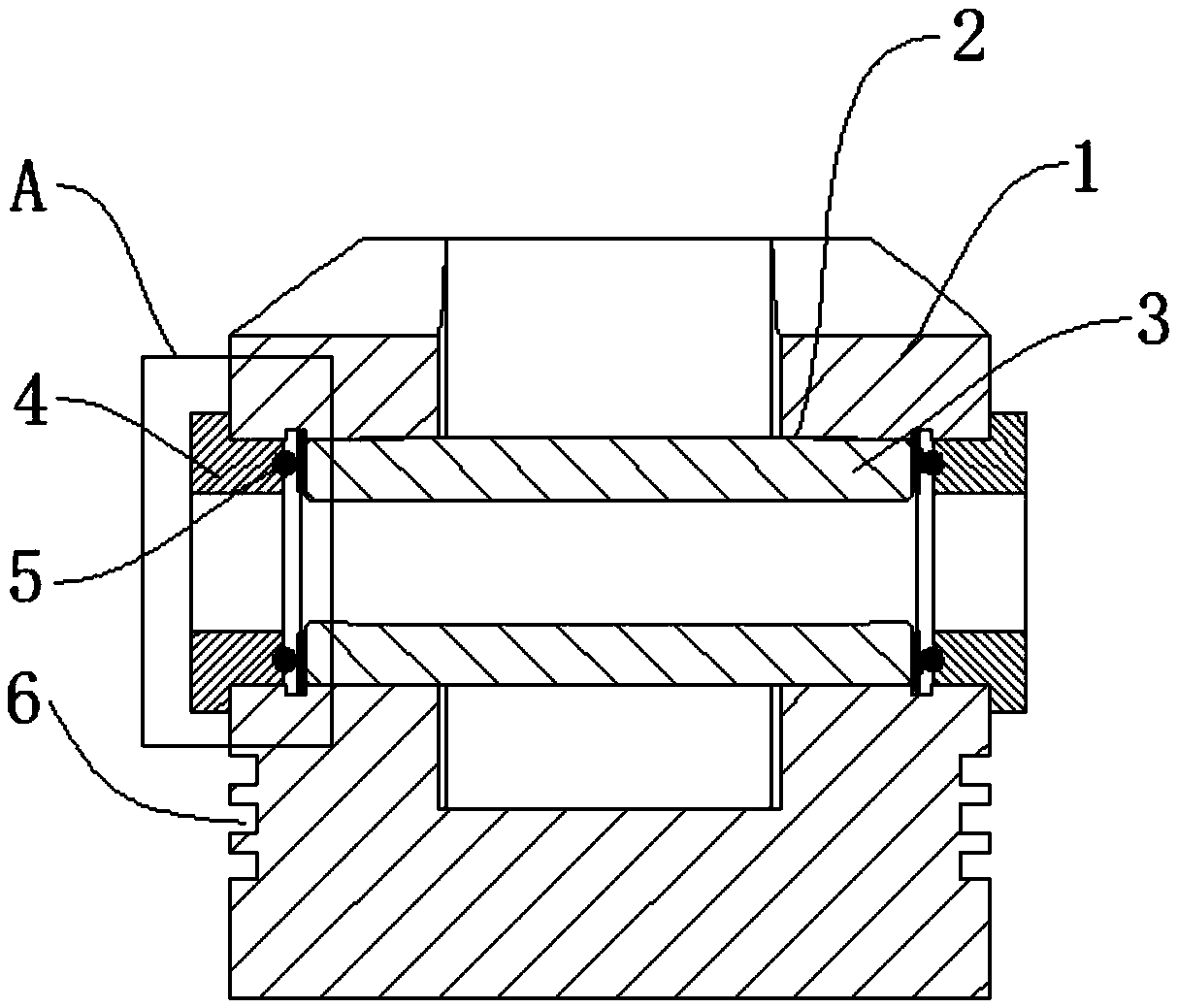

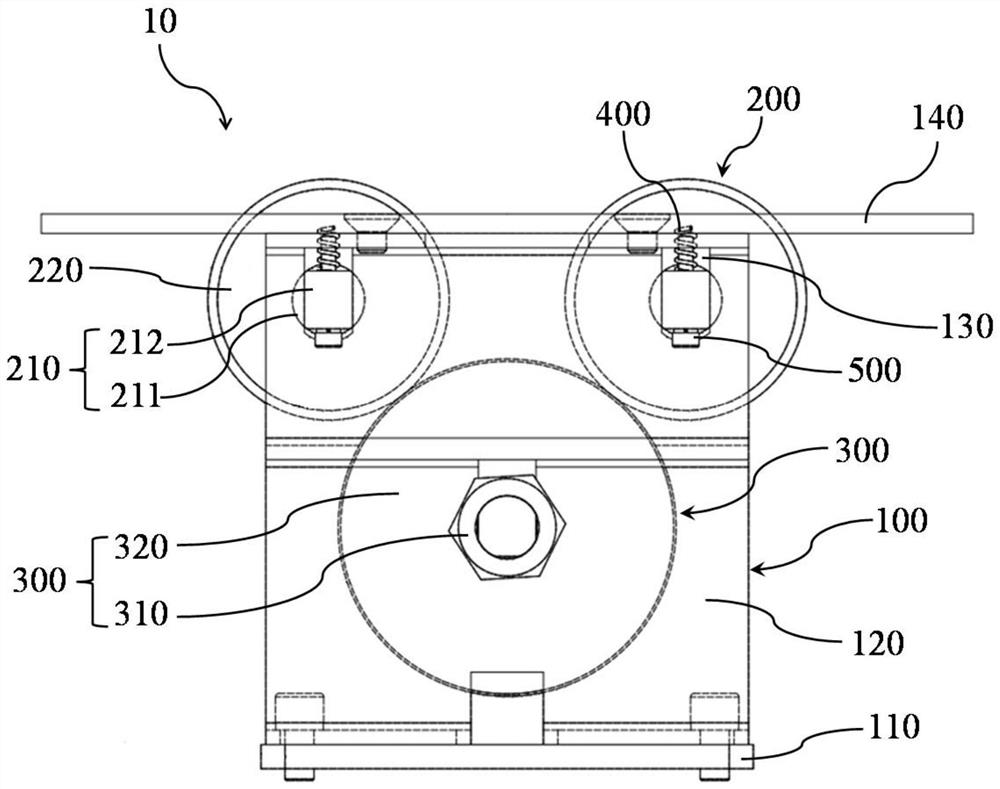

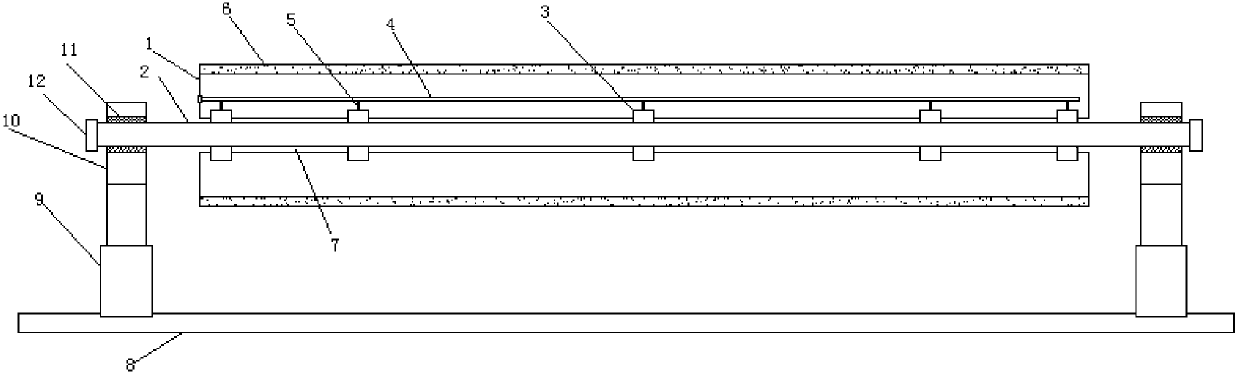

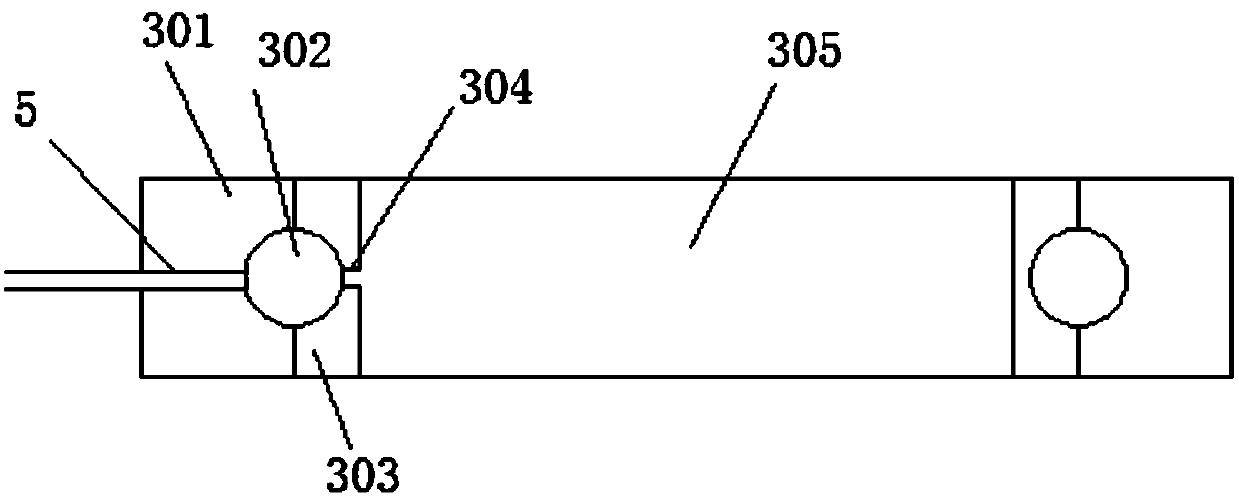

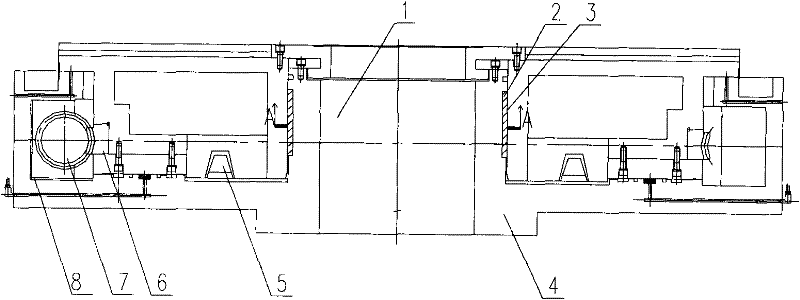

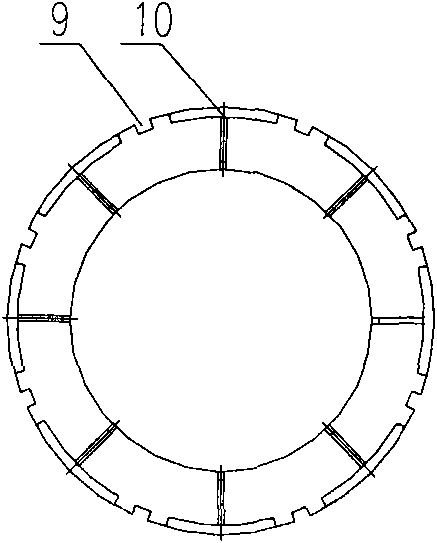

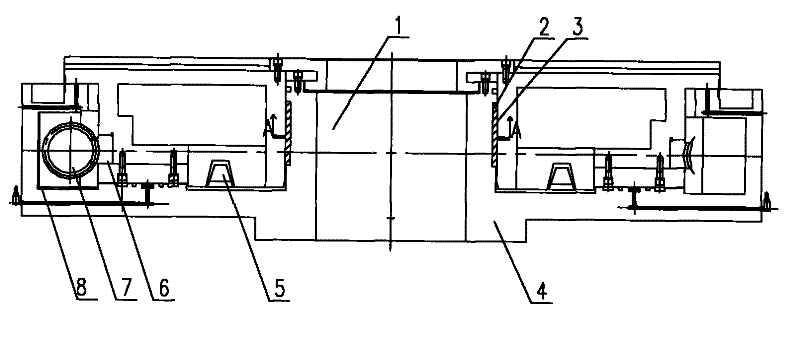

Constant flow static pressure working table for gear shaping machine or gear milling machine

InactiveCN102029527ALess prone to wearReduce material requirementsLarge fixed membersGear-cutting machinesMechanical engineeringCentral spindle

The invention discloses a constant flow static pressure working table for a gear shaping machine or a gear milling machine. By constant flow static pressure technology, a static pressure cavity is formed on a central spindle, and lubricating oil is fed into the static pressure cavity by a constant pressure oil pump, so that an oil film is formed between the spindle of the working table and a pedestal to keep contact surfaces between the spindle and the pedestal in a constant pressure full-liquid lubricating state; therefore, the center of the working table is positioned well, a wear phenomenon is almost avoided during movement, and the rigidity and the accuracy of the working table are greatly improved and the life of the working table is greatly prolonged; and the pedestal is provided with a dual lead worm, and adjusting pads are arranged in both axial direction and radial direction of the worm, so the working table can work under a smaller backlash condition, and the dividing accuracy of a rotary working table can be improved.

Owner:WUHAN GEWEI MACHINERY

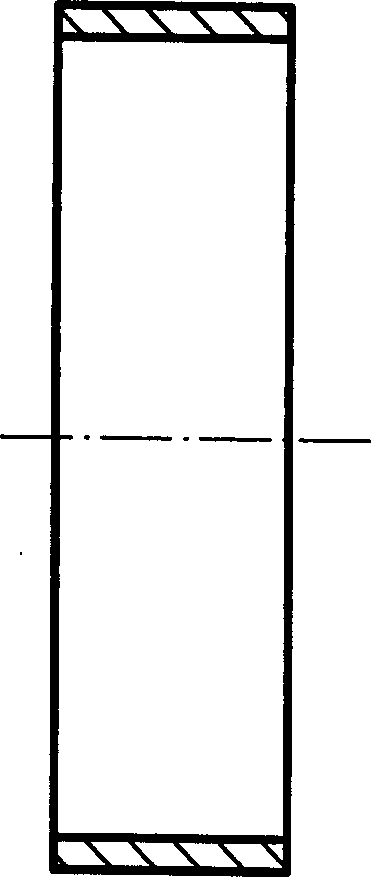

Steel billet feeding cylinder and the method of making and repairing it

InactiveCN1481945ADifferent hardnessImprove red hardnessMetal rolling arrangementsHardnessSteel casting

The present invention is the manufacture and repair of roller for conveying steel billet. The roller consists of basal body of cast steel or cast iron and roller ring, which is made of WC is braze welded onto the basal body and has hole. The manufacture and repair process includes machining the basal body, cleaning, and braze welding the WC roller ring to the basal body. Owing to the high hardness, especially the high red hardness of the roller ring, the roller has long service life, 10-15 times that of cast steel and cast iron ones. The roller is suitable for use in conveying steel billet in rolling mill and steel plant.

Owner:王树敏

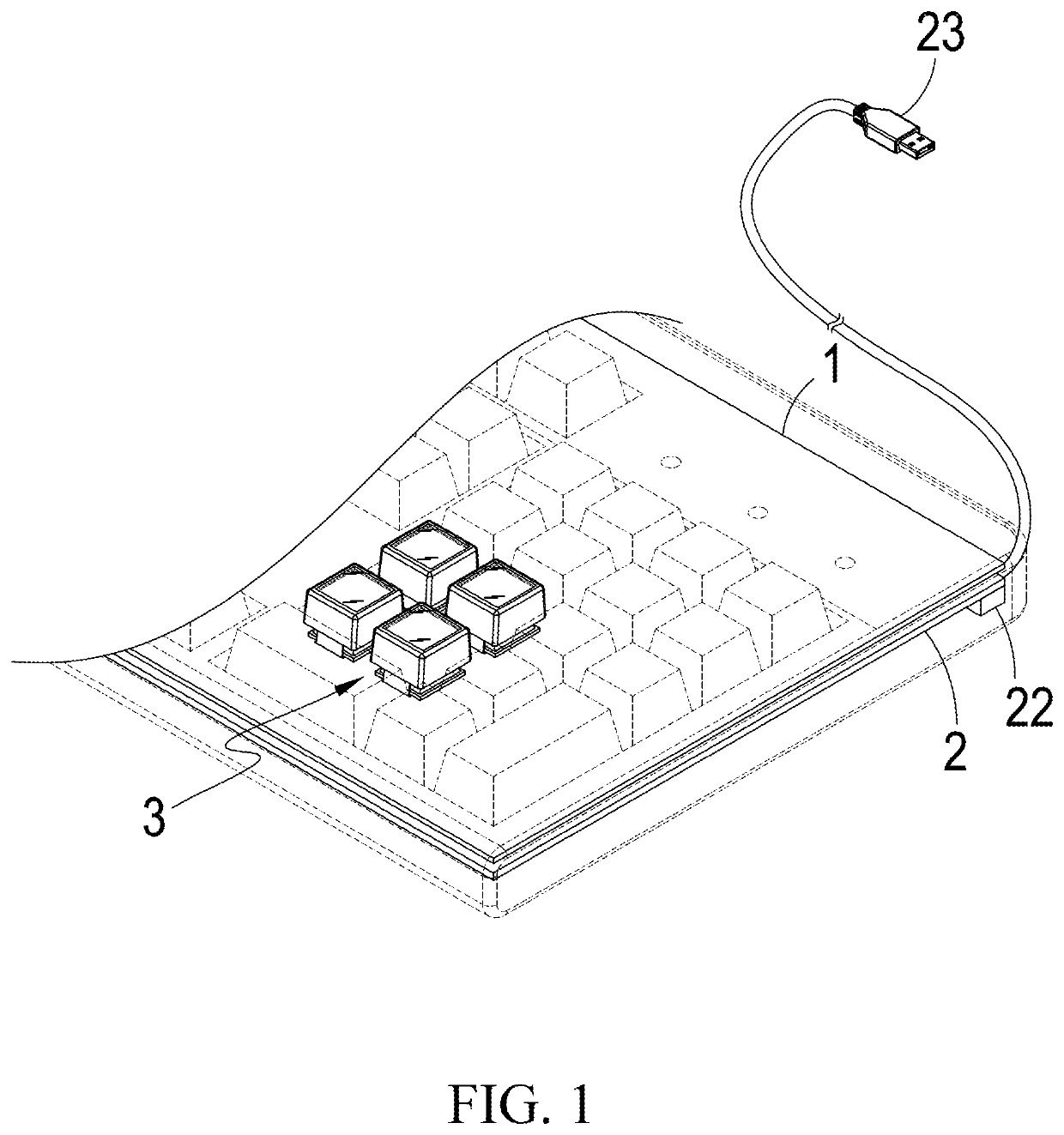

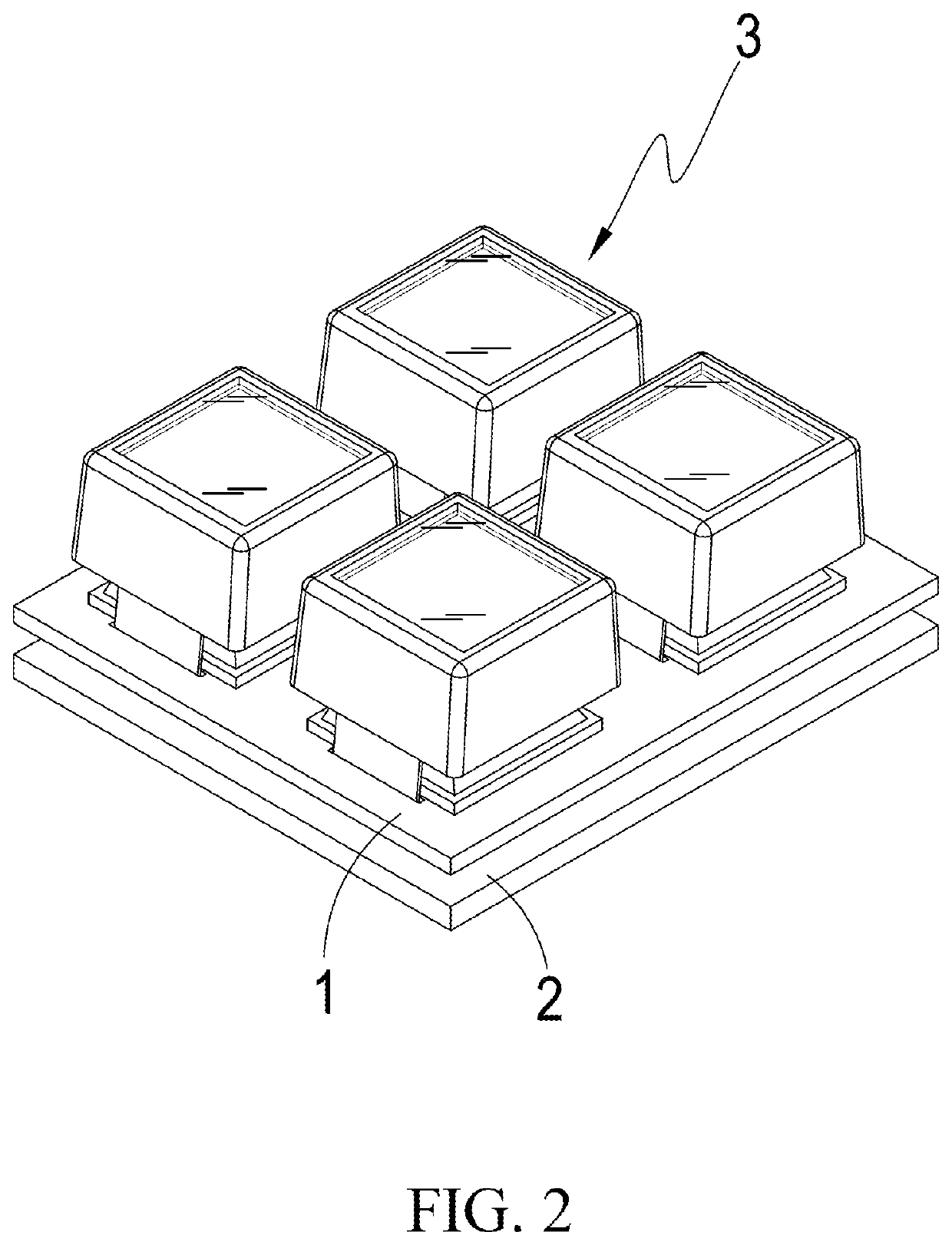

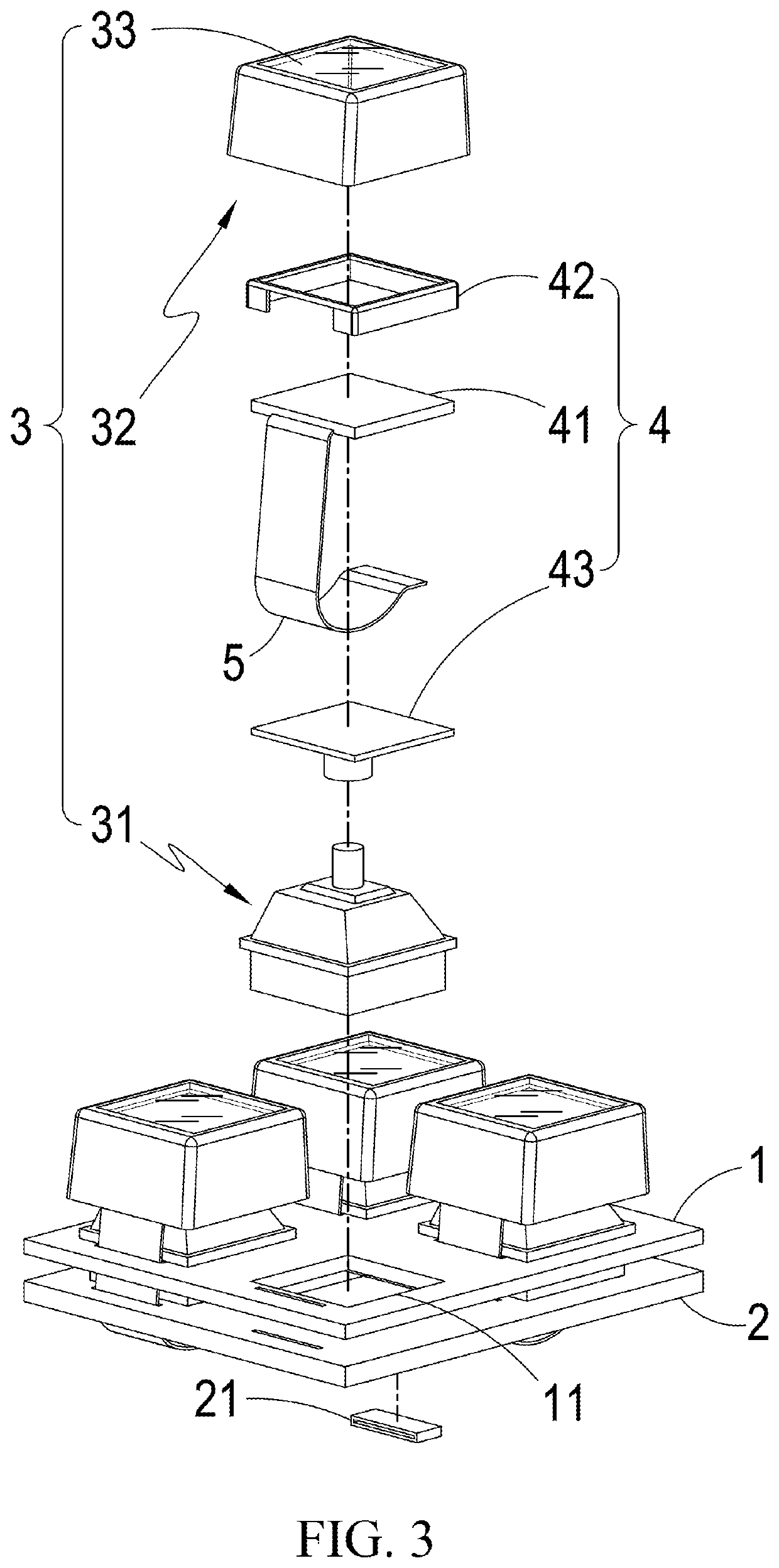

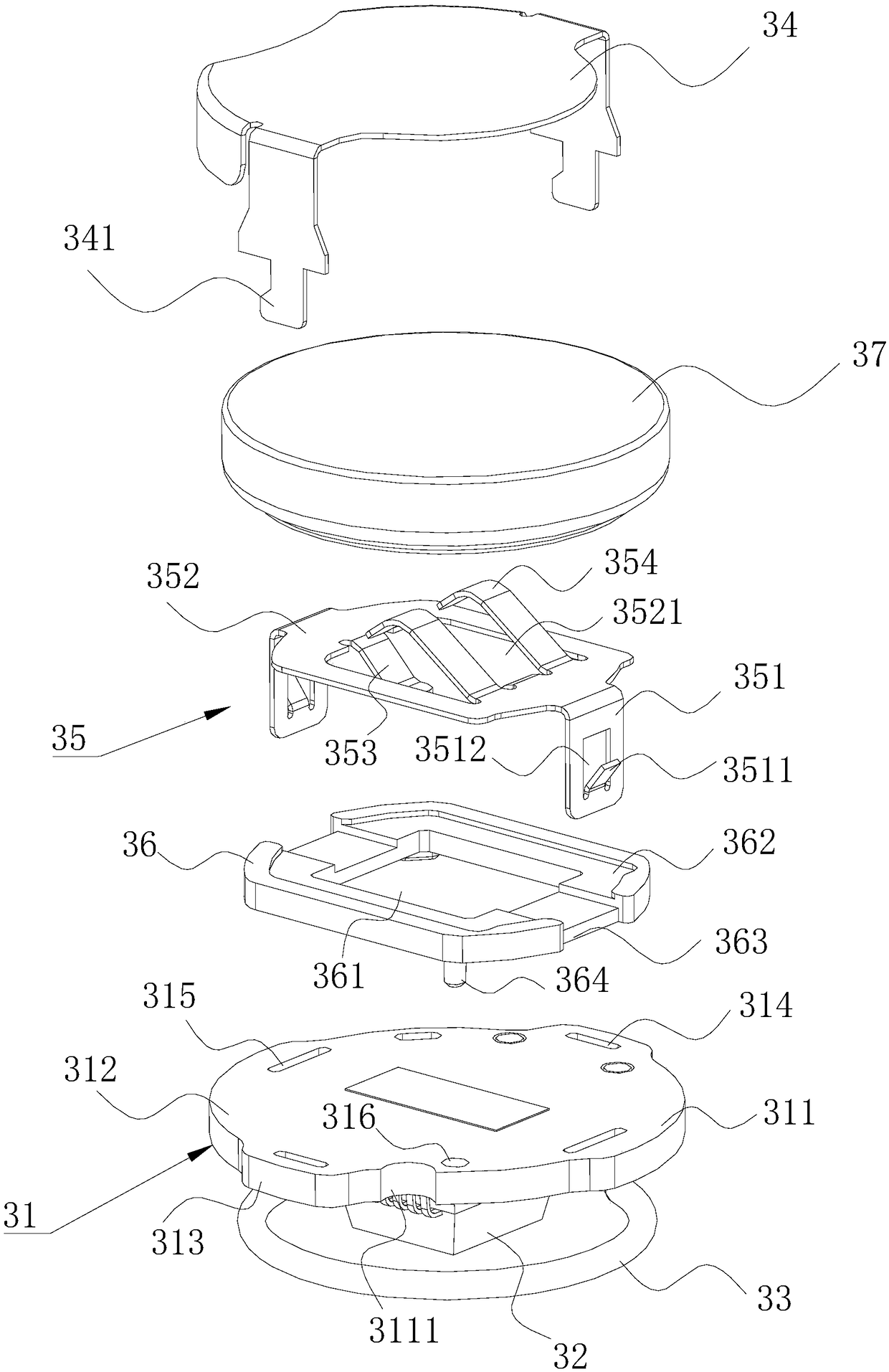

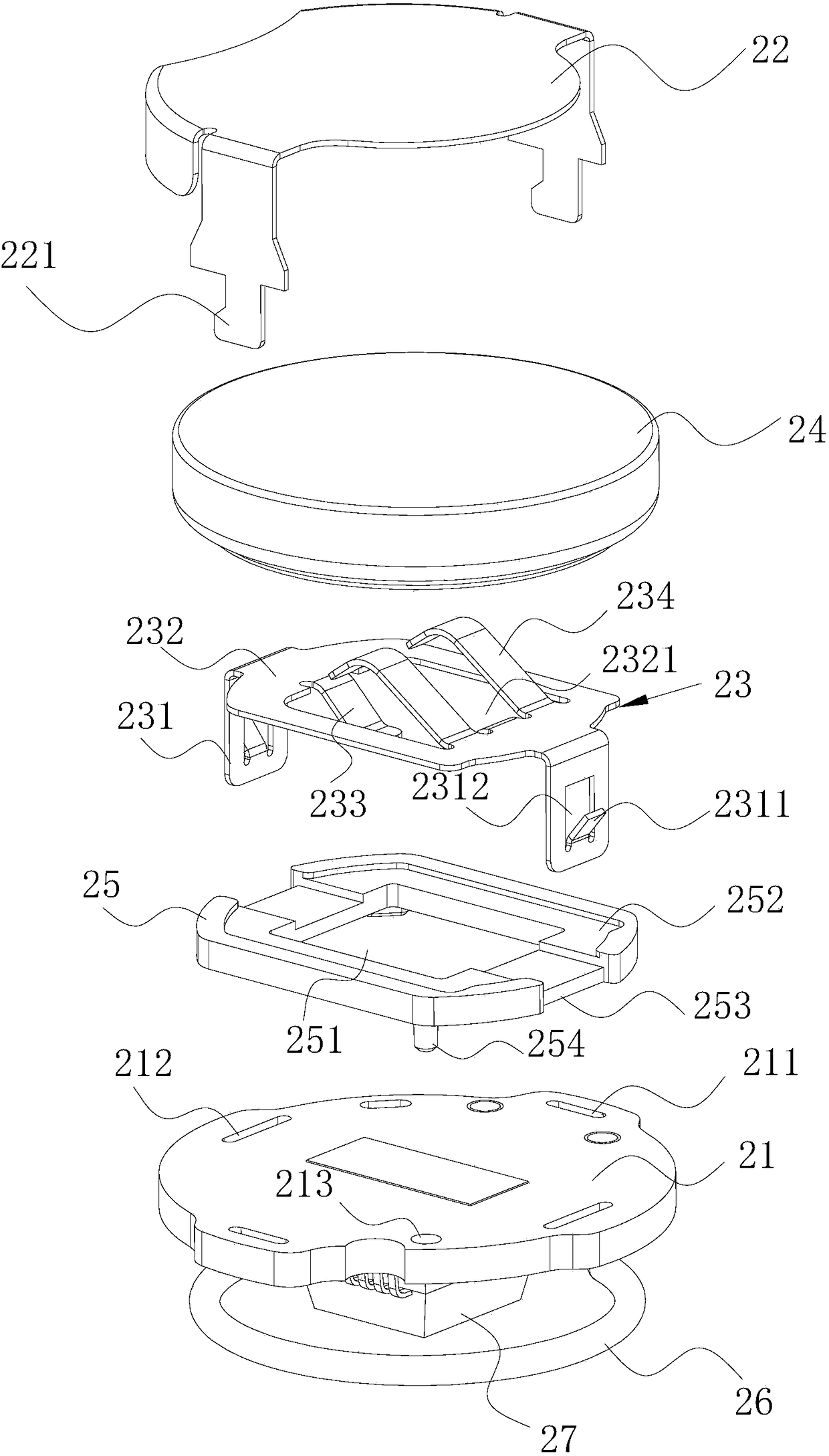

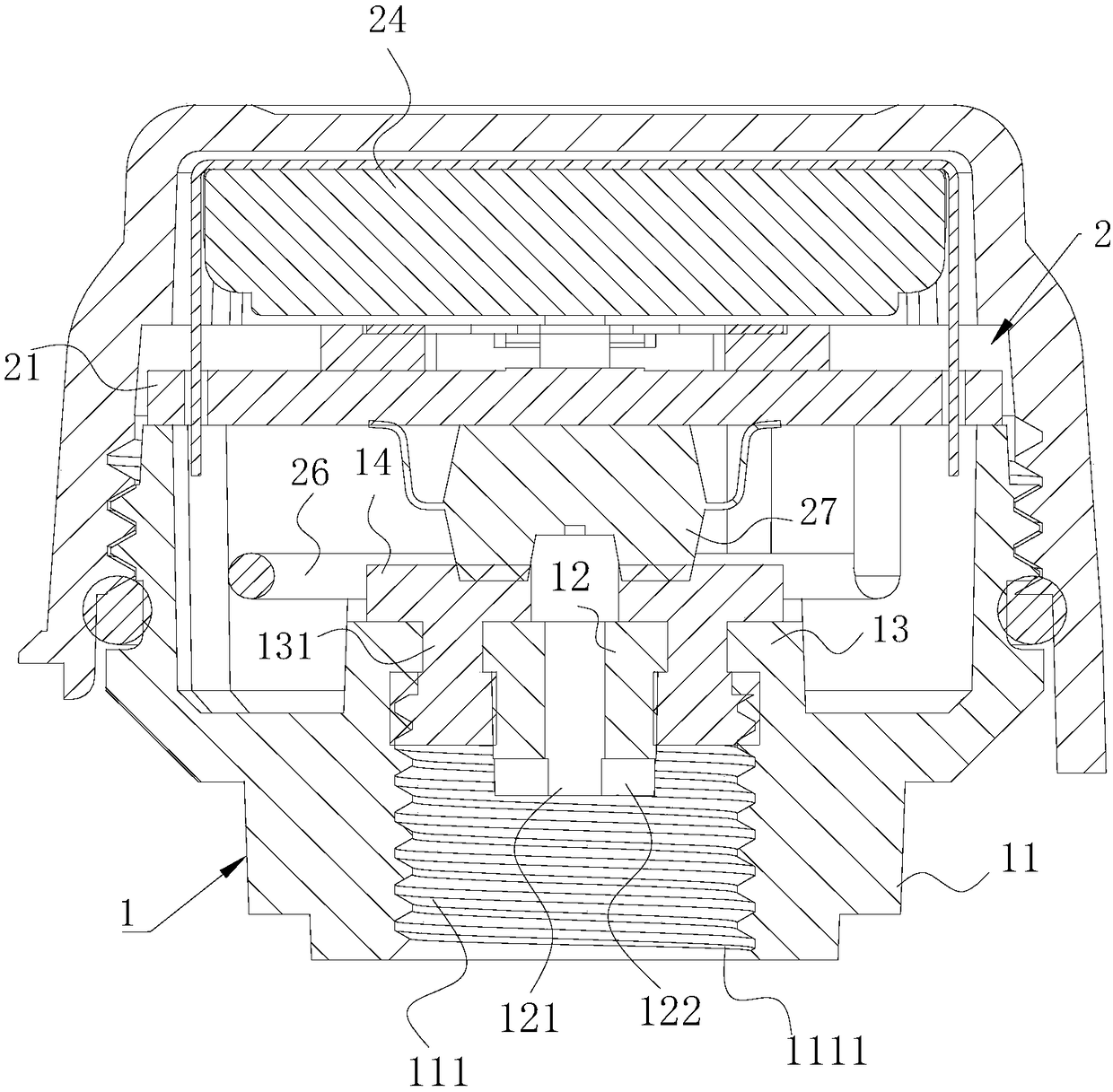

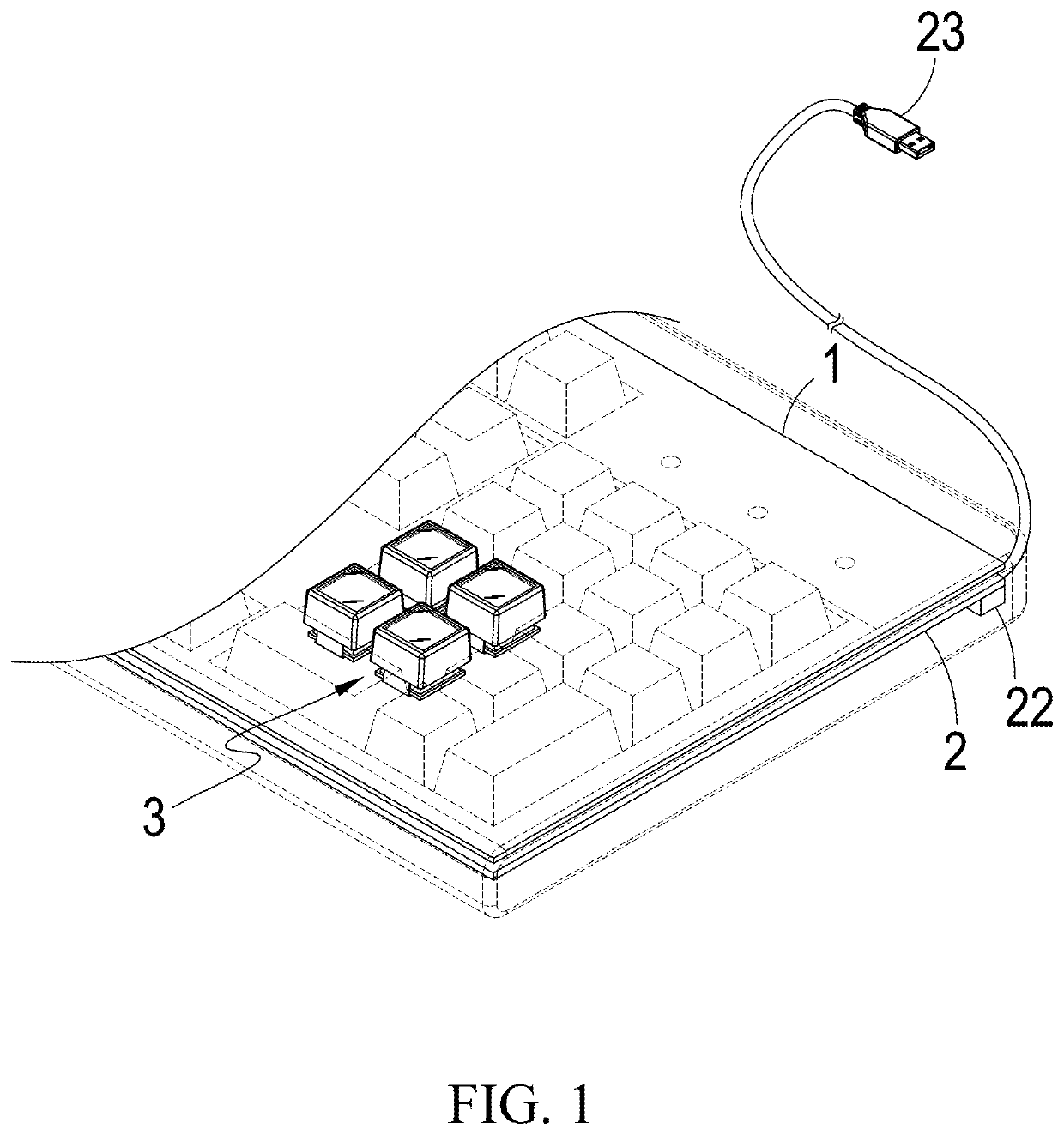

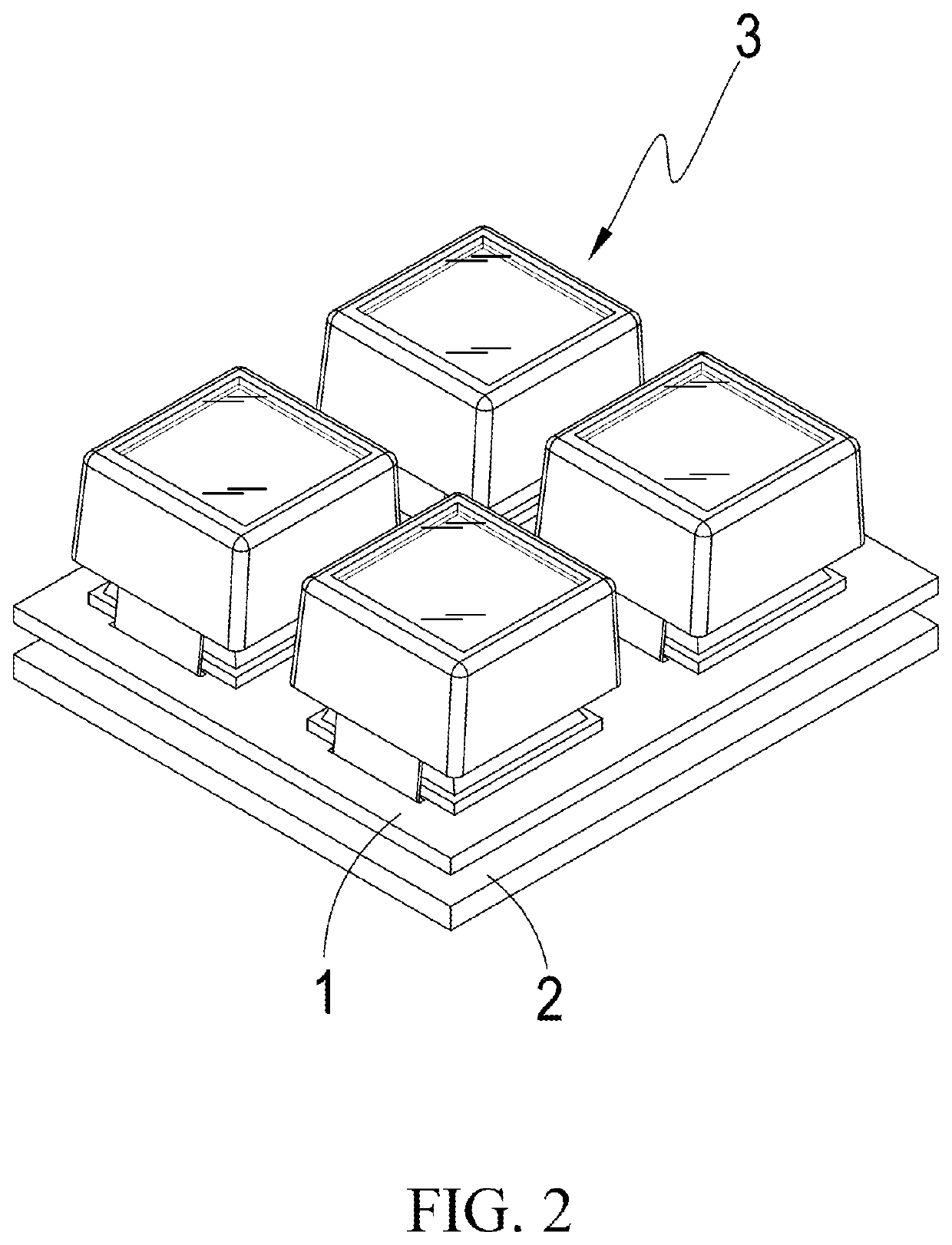

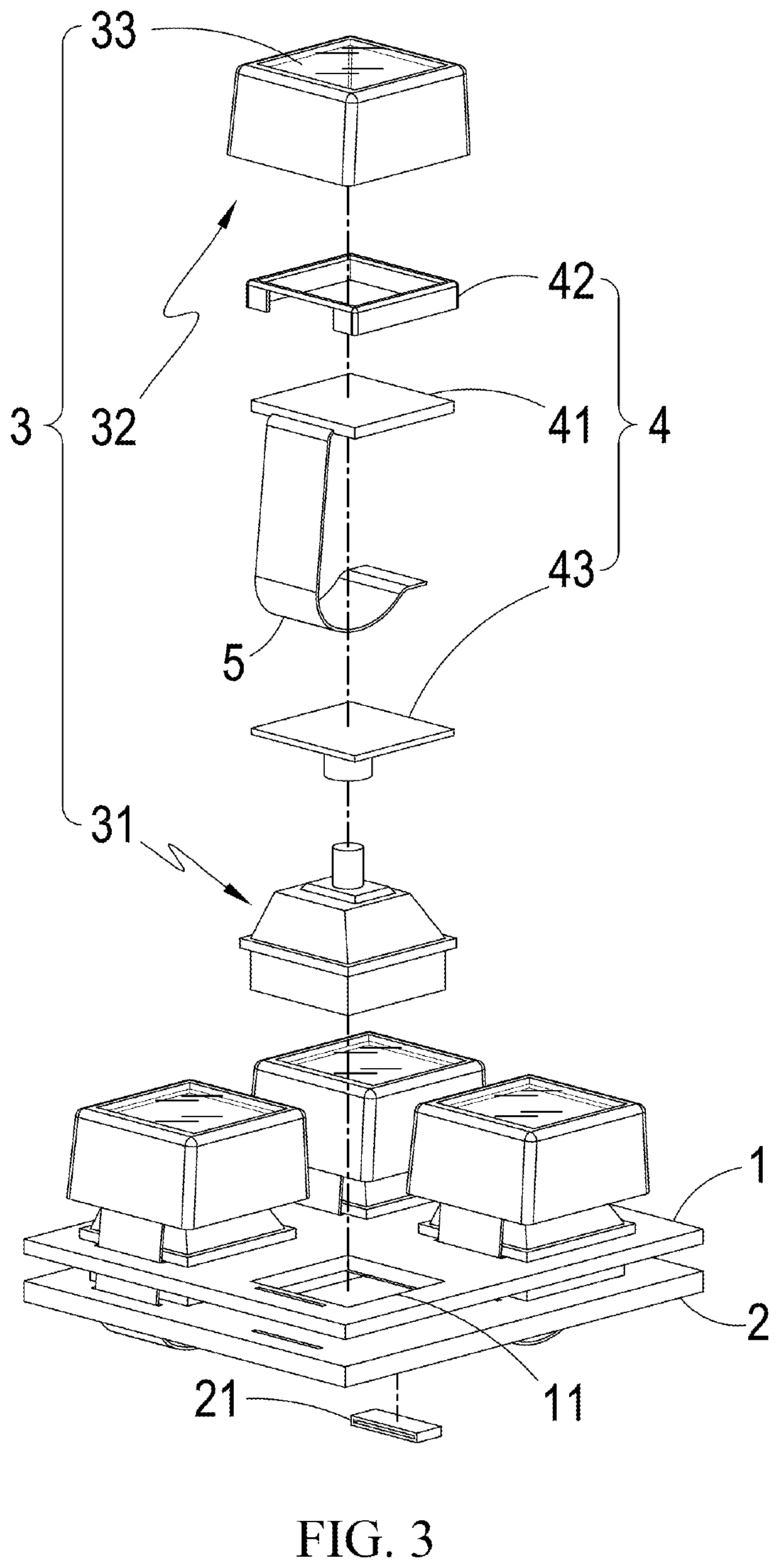

Display assemblies disposed inside mechanical keys in a mechanical keyboard

ActiveUS10592004B1Less-prone to damageLess-prone to wearInput/output for user-computer interactionEmergency actuatorsEngineeringComputer science

The mechanical keyboard includes a base plate having multiple through openings, a circuit board disposed to a side of the base plate, multiple mechanical keys disposed at the through openings and connected to the circuit board. Each mechanical key includes a keyswitch, a keycap, and at least a transparent piece. The keyswitch is connected to the circuit board. The keycap is mounted on the keyswitch, and the transparent piece is configured to a top side of the keycap. There are multiple display assemblies, each disposed inside a mechanical key between the keycap and the keyswitch. Each display assembly is data-linked to the circuit board through a signal transmission element. The display assemblies may be installed on conventional mechanical keys and may be viewed from different angles. The mechanical keyboard also has longer operation life.

Owner:ELGATO IDISPLAY LTD

External tyre pressure gauge

PendingCN109050176AHigh hardnessSave assembly troubleTyre measurementsTire-pressure gaugePlastic materials

An external tire pressure gauge As that problem of troublesome machining cost and high material cost of the assembly of the base and the top block are sol, A technical scheme comprise a housing, A pressure sensor and a circuit board are arranged in the housing, the housing includes a base and a top block, The base comprises a bottom plate located at the bottom of the mounting groove, a pressure sensor arranged on the side of the base remote from the opening of the mounting groove, a top block arranged at the central position of the bottom plate, and an air guide passage arranged in the top block, which is communicated with the pressure sensor and the mounting groove. As that top block and the shell are integrally for, the top block and the shell do not need to be assemble, the processing cost is reduced, and the top block and the shell are made of plastic material, thereby saving the material cost; At the same time, the top block made of plastic material is harder than the top block made of silica gel material, and the valve stem on the top pressure valve nozzle is not easy to be worn after long-term use, so that the service life is prolonged.

Owner:STEELMATE CO LTD

Guide plate for rolling mill and its manufacture and repair method

InactiveCN1453079ADifferent hardnessImprove wear resistanceGuiding/positioning/aligning arrangementsCrack resistanceAdhesive

The guide plate may have tungsten carbide blocks with hardness over HRA80 adhered with inorganic adhesive to its wearable parts. During its manufacture and repair, the wearable parts are machined, cleaned and adhered with tungsten carbide blocks. The guide plate has high wear resistance, crack resistance and long service life. The guide plate is suitable for use of rod rolling mill, wire rolling mill and shape steel rolling mill.

Owner:王树敏

Adjustable horse-boot buckle

InactiveUS7493963B2Less-prone to breakageLess-prone to wearProtection coversHorseshoeLeading edgeEngineering

Owner:EASYCARE

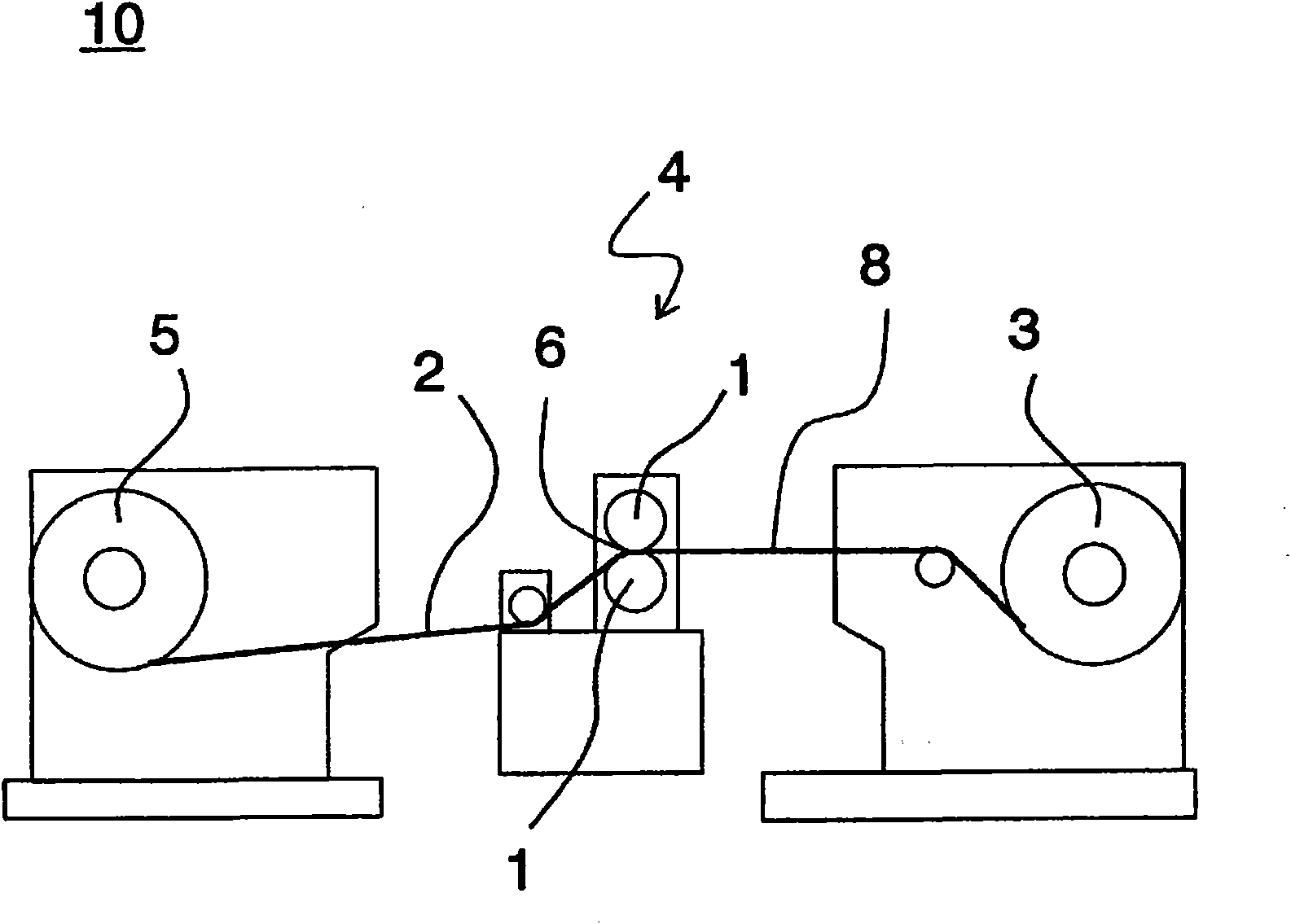

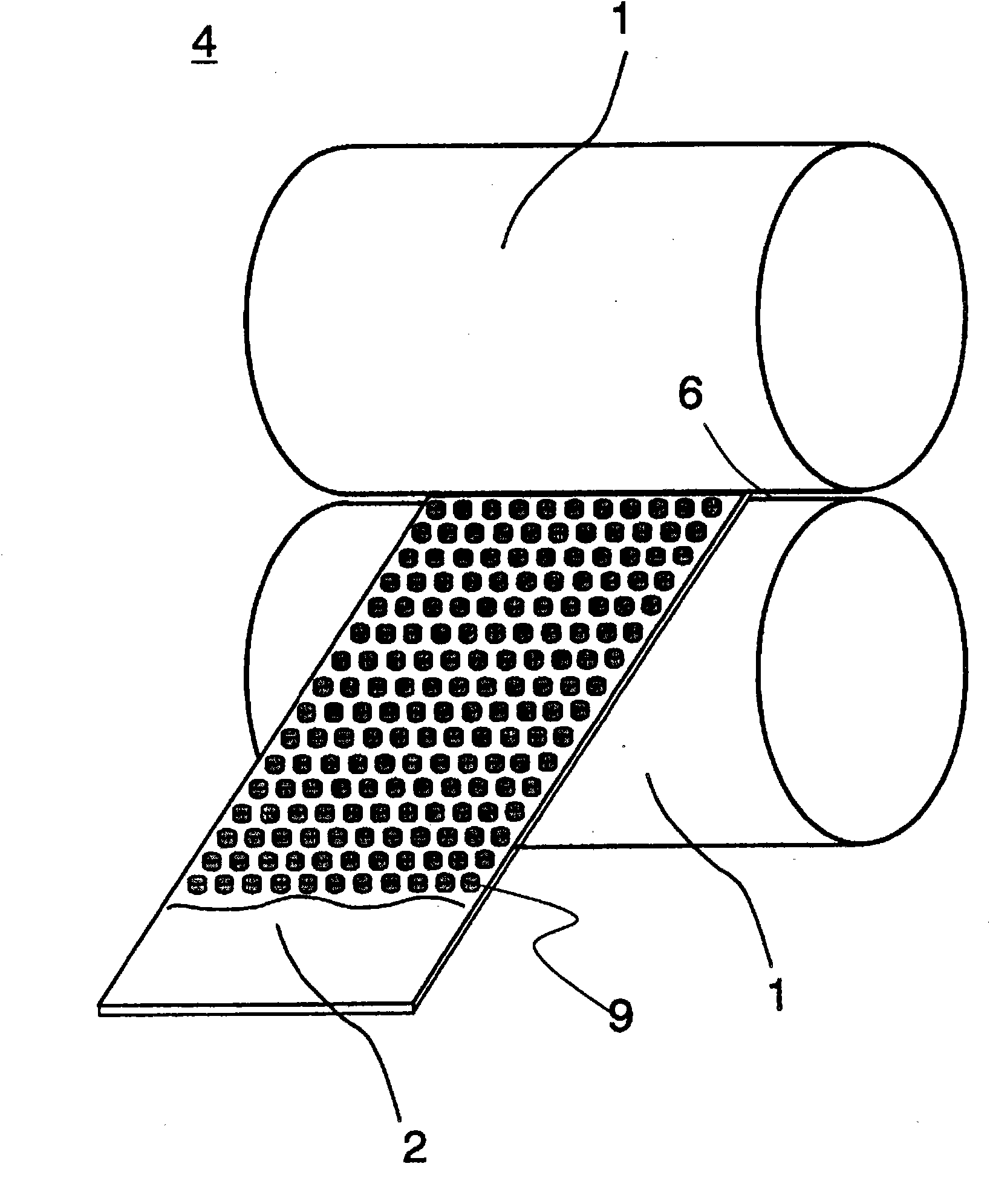

Roller for machining metal foil

InactiveCN101808758AIncreased durabilityStable and efficient formationRollsMetal rolling arrangementsMetal foilMetallic materials

A roller for machining a metal foil has a plurality of recesses formed in the circumferential surface of a roller containing a metal material having a Rockwell hardness HRA of 81.2-90.0 in A scale and a deflecting strength of 3GPa-6GPa. When a metal foil is pressed using this metal foil machining roller, protrusions in substantially uniform shape having dimensions from several microns to several tens of microns can be formed efficiently on the surface of the metal foil in an industrial scale.

Owner:PANASONIC CORP +1

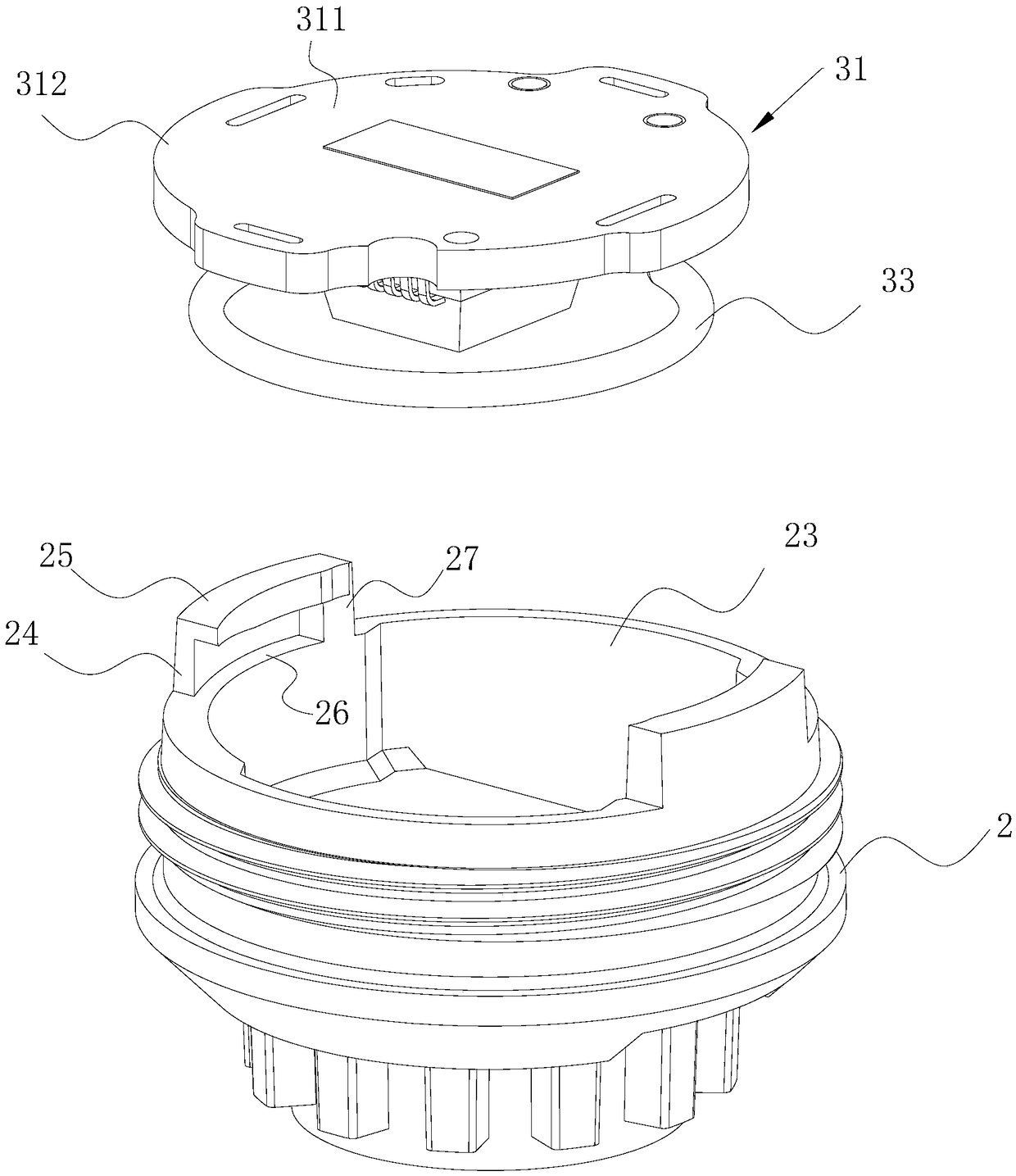

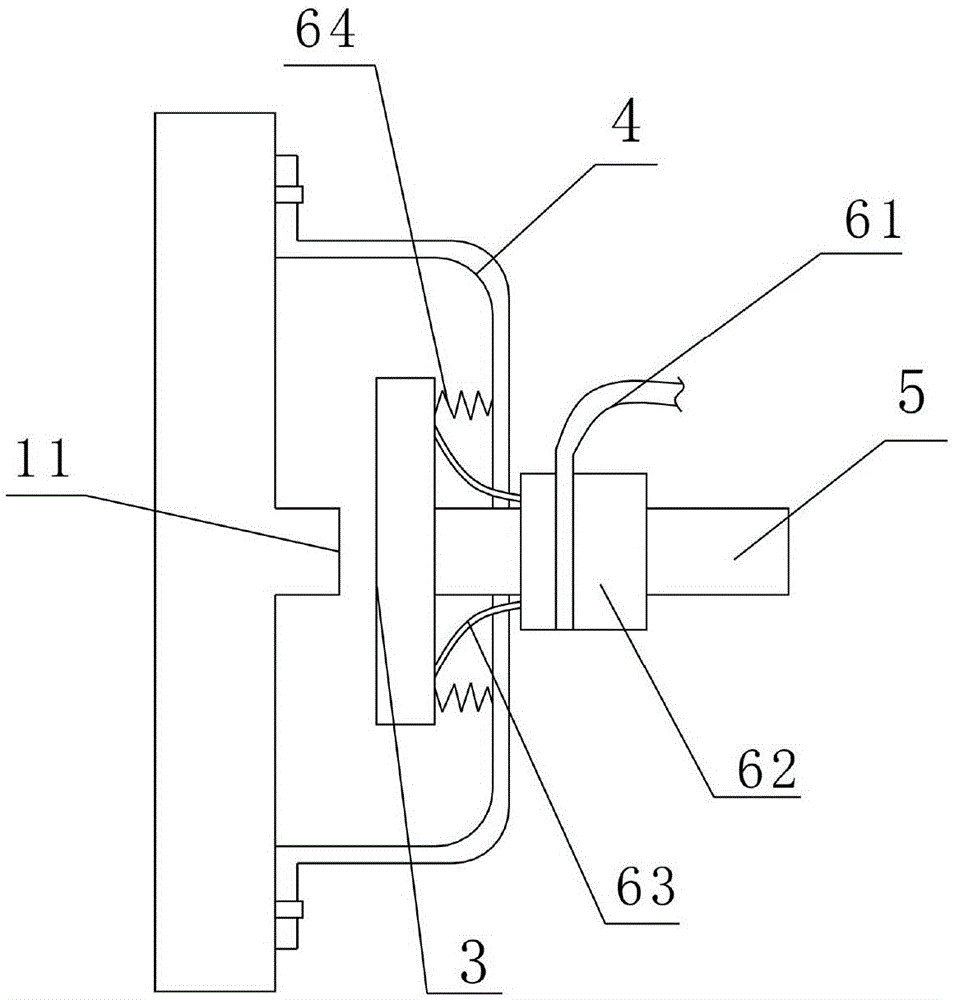

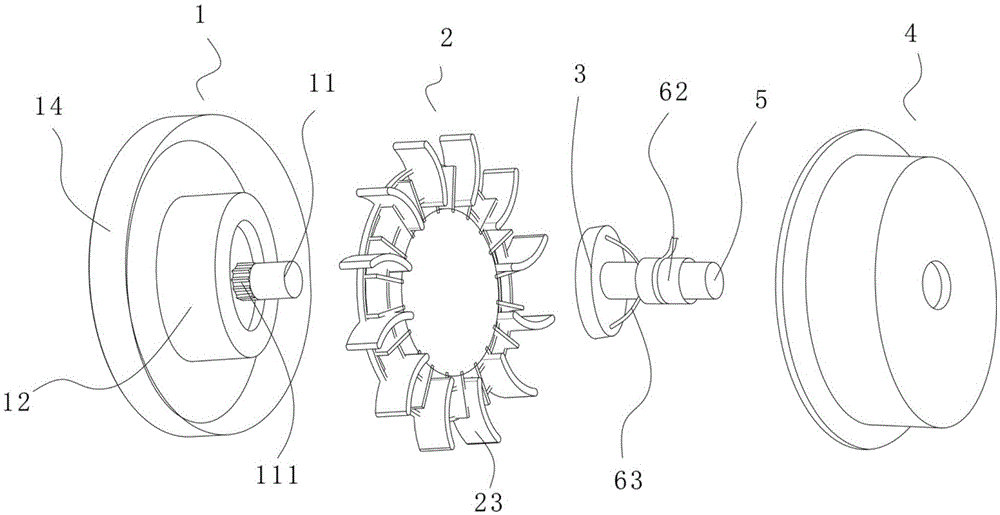

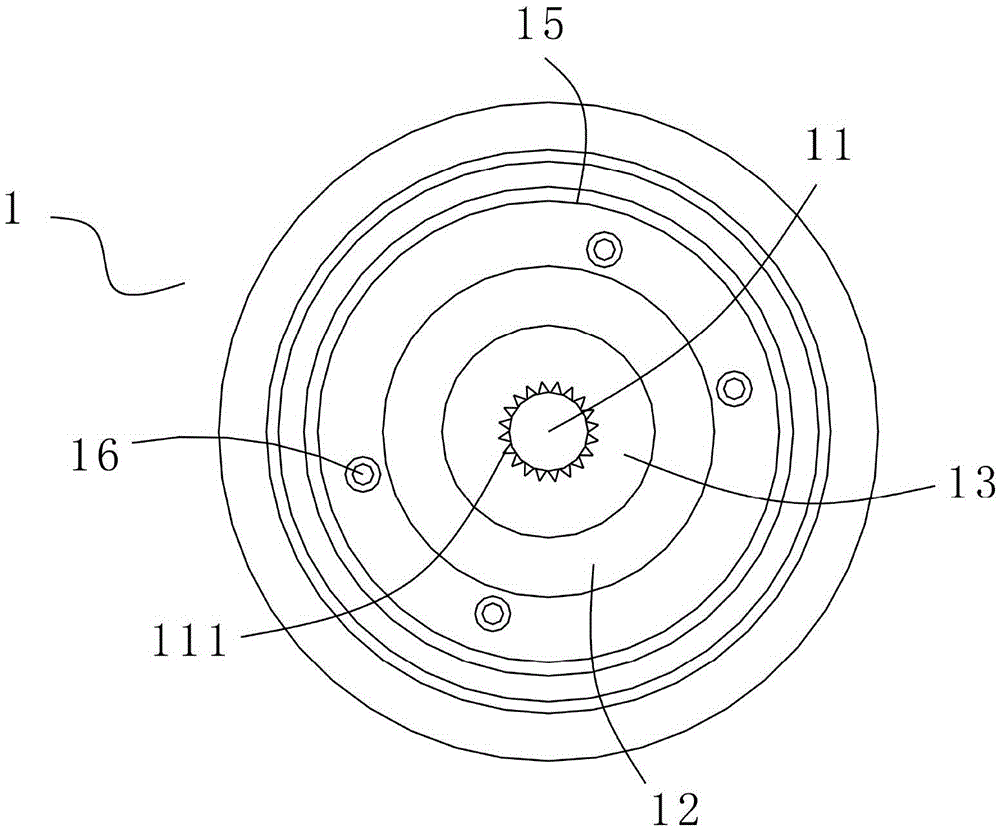

Flywheel clutch

The invention discloses a flywheel clutch. The flywheel clutch comprises a clutch cover, a flywheel fixedly connected to the clutch cover, a clutch block, a transmission input shaft fixedly connected to the clutch block, and a control mechanism; the control mechanism includes a pull rod, a slide sleeve fixedly connected to the end part of the pull rod, a separation fork for connecting the clutch block with the slide sleeve, and a pressing spring; the separation fork is splayed; one end part of the pressing spring is connected with the clutch block, and the other end is connected with the clutch cover; the flywheel includes a base molded by pressing an aluminum alloy, and an impeller made of plastic; the base is provided with a mounting column made of an aluminum alloy; the mounting column and the base are integrally molded by die casting; an outer ratchet is formed on the outer surface of the mounting column, and is in rotation stop matching with an inner ratchet of the clutch block; and the length of the outer ratchet is 1 / 3 of the length of the mounting column. A blade is made of plastic, and is not easy to damage; the base is integrally molded by die casting; the flywheel is light in self weight, so that the rotating speed is fast; and the flywheel clutch is low in cost and high in working efficiency.

Owner:茹咪娜

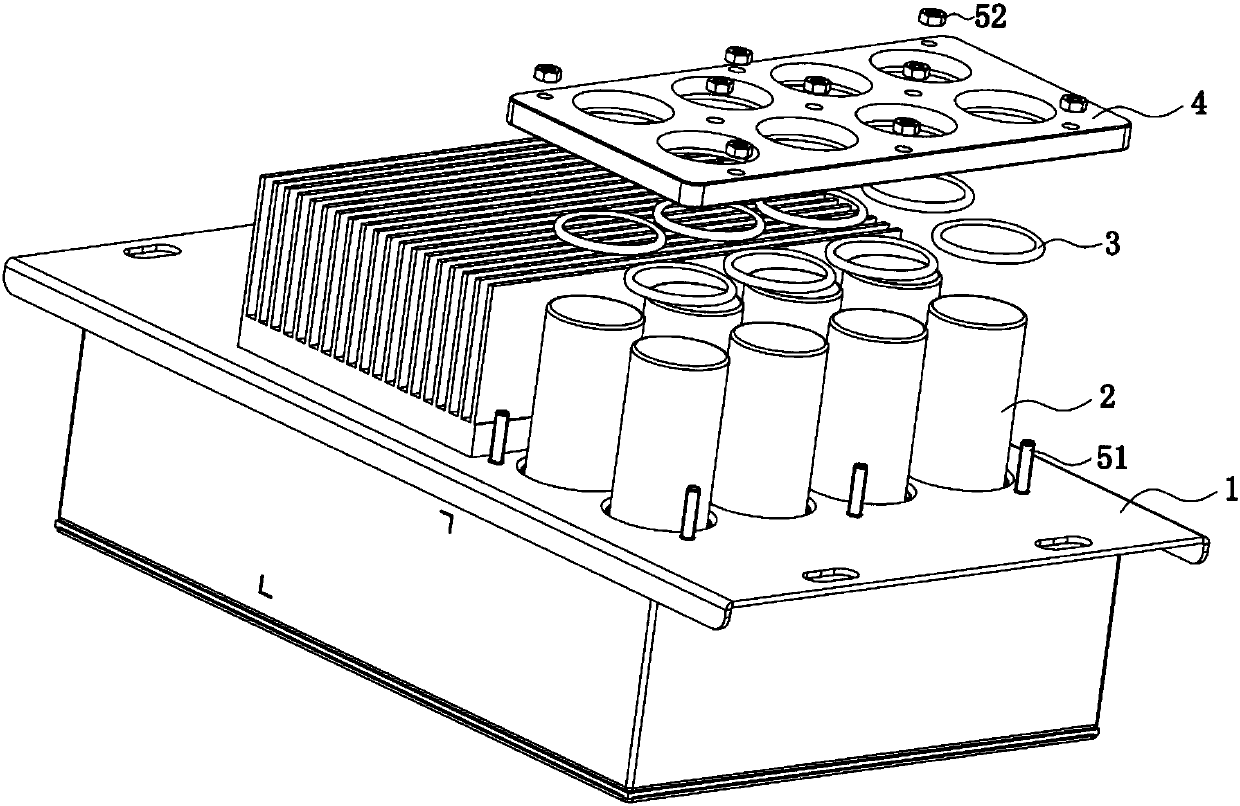

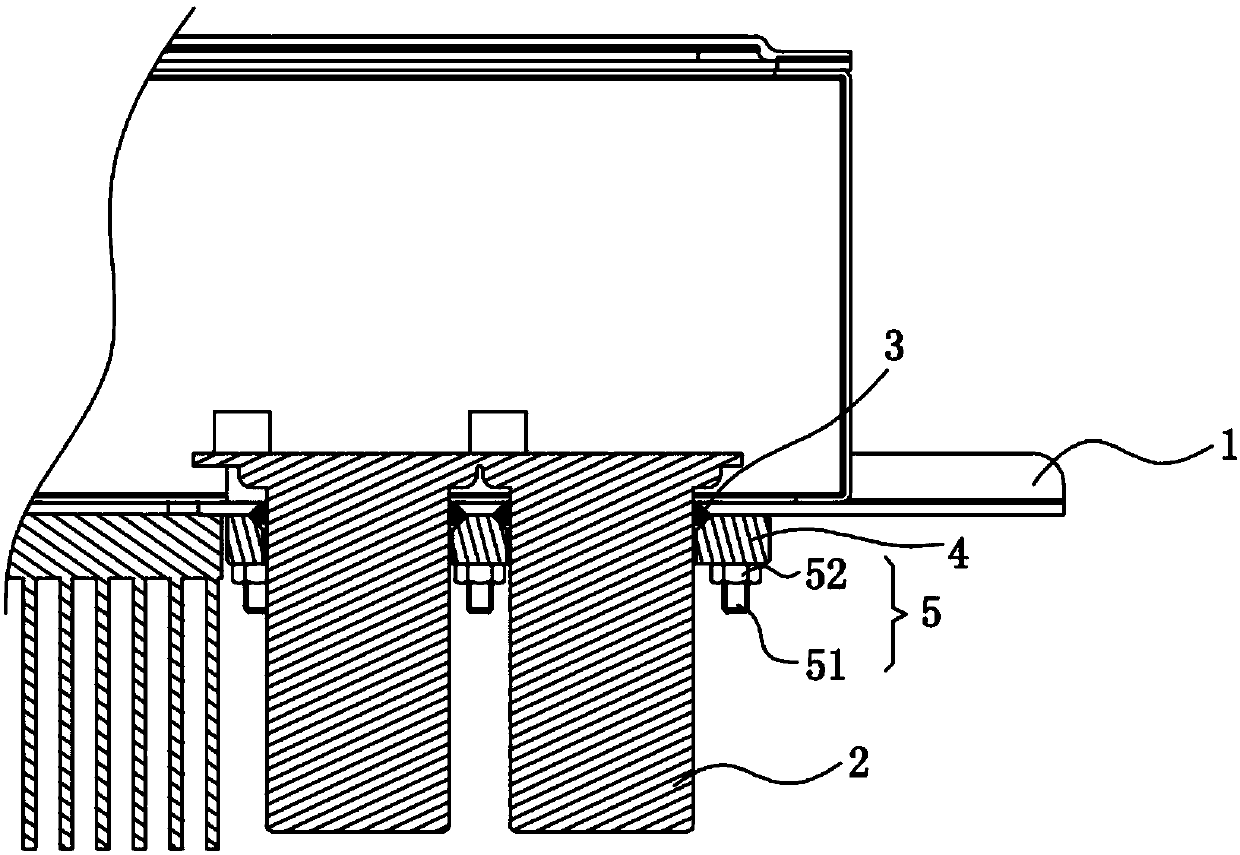

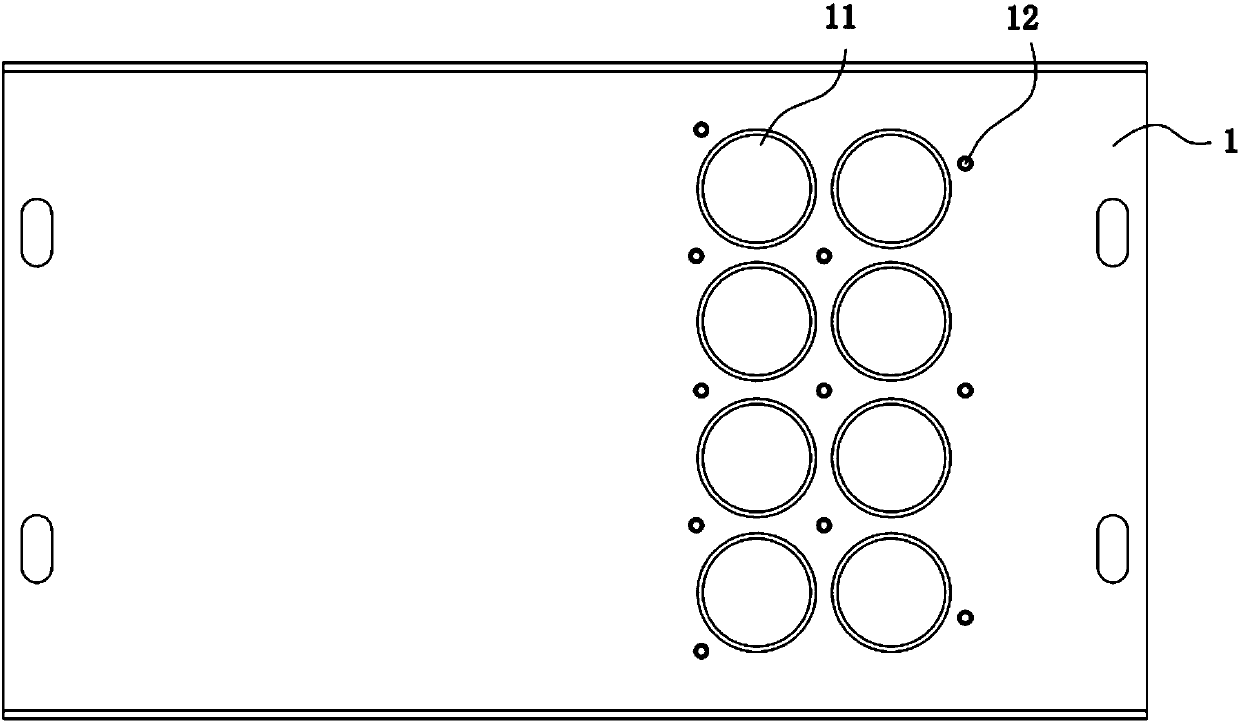

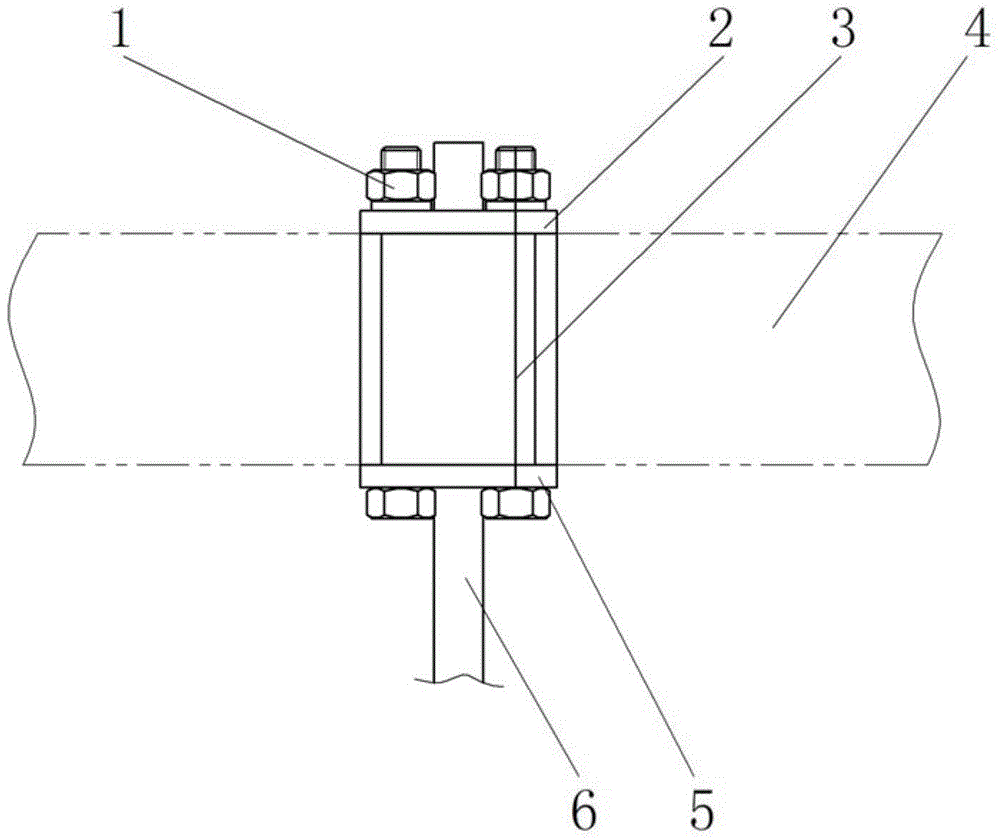

Insulated sealing device and method of variable-frequency drive

PendingCN107733209AAchieving tightnessGood insulation and sealingCasings/cabinets/drawers detailsHermetically-sealed casingsCapacitanceFrequency changer

The invention discloses an insulated sealing device of a variable-frequency drive. The device comprises a variable-frequency drive shell, electrolytic capacitors, sealing rings, a pressing plate and fastening parts, wherein first capacitor via holes are formed in the variable-frequency drive shell, the free ends of the electrolytic capacitors are located outside the variable-frequency drive shelland sleeved with the sealing rings, second capacitor via holes are formed in the pressing plate, the free ends extend out of the second capacitor via holes, and the pressing plate is connected with the sealing rings in an abutting mode and fixed onto the variable-frequency drive shell by the fastening parts. The invention further discloses an insulated sealing method. The method comprises the steps that the free ends are sleeved with the sealing rings, and the sealing rings abut against the tops of the first capacitor via holes; the free ends penetrate the second capacitor via holes in the pressing board, so that the pressing board is connected with the sealing rings in an abutting mode; by means of the fastening parts, the pressing plate is fixed onto the variable-frequency drive shell. According to the device and the method, the pressing board can closely press the sealing rings, and through elastic deformation of the sealing rings, gaps among the electrolytic capacitors, the variable-frequency drive shell and the pressing plate are filled, so that a sealing effect is achieved.

Owner:BEIJING DINGHAN TECH GRP CO LTD

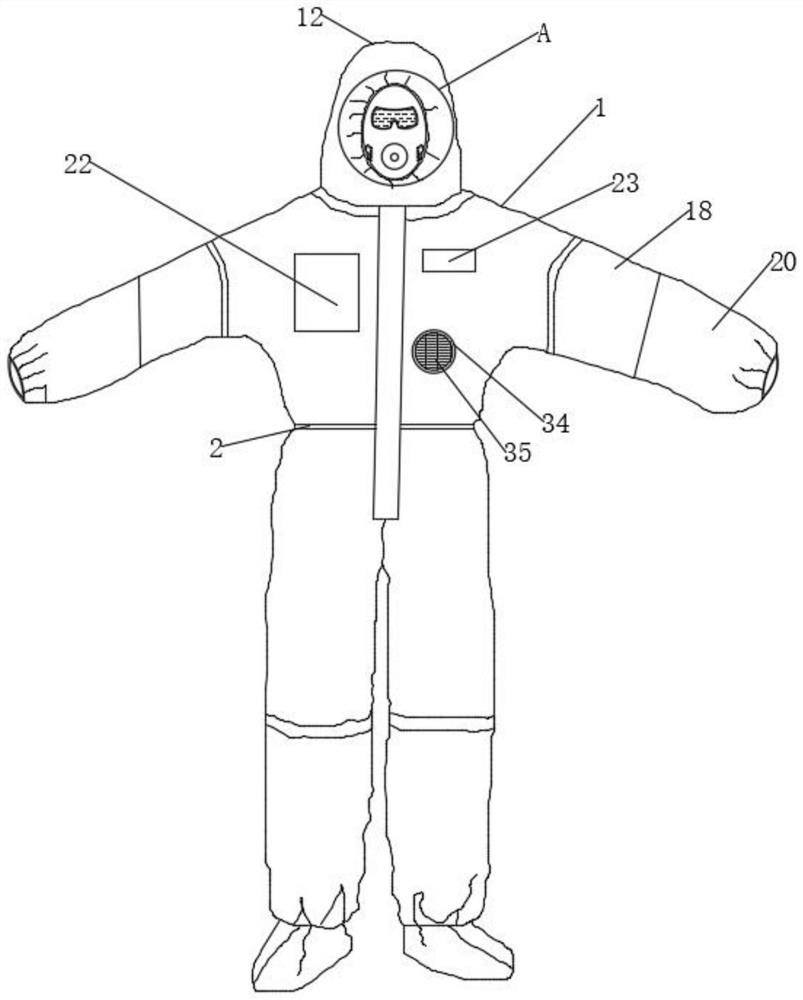

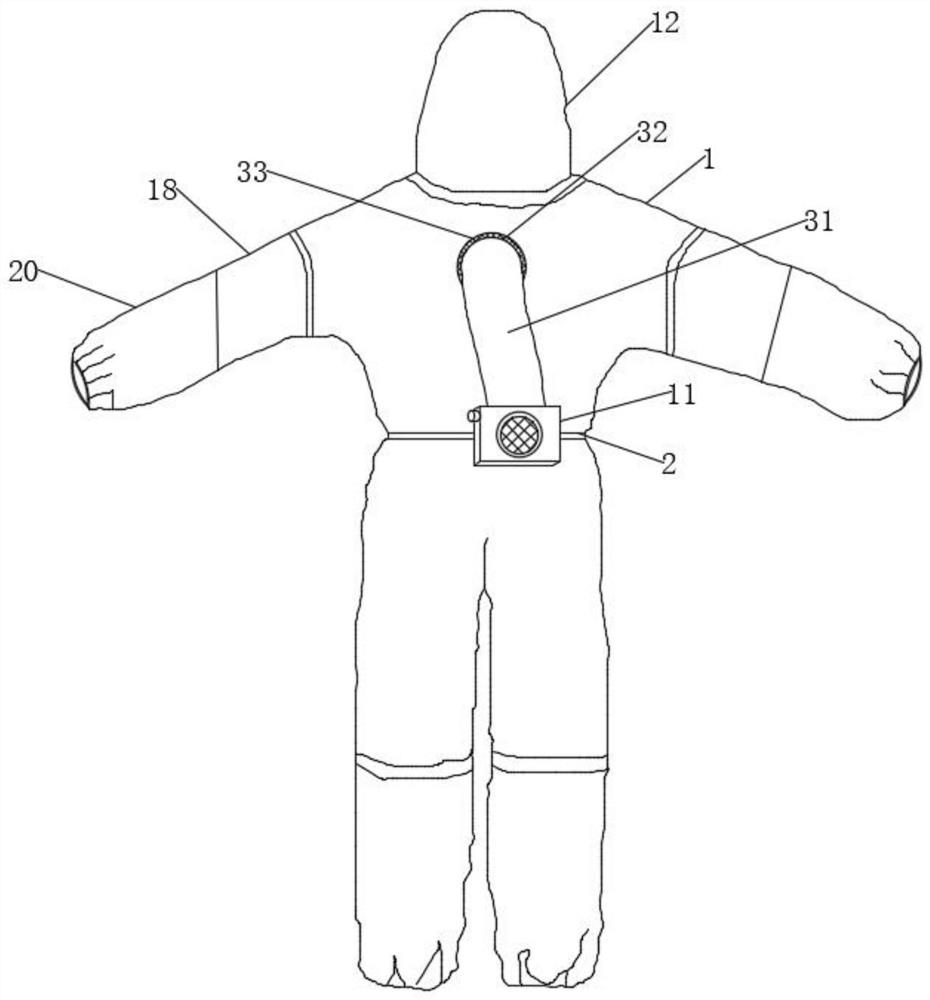

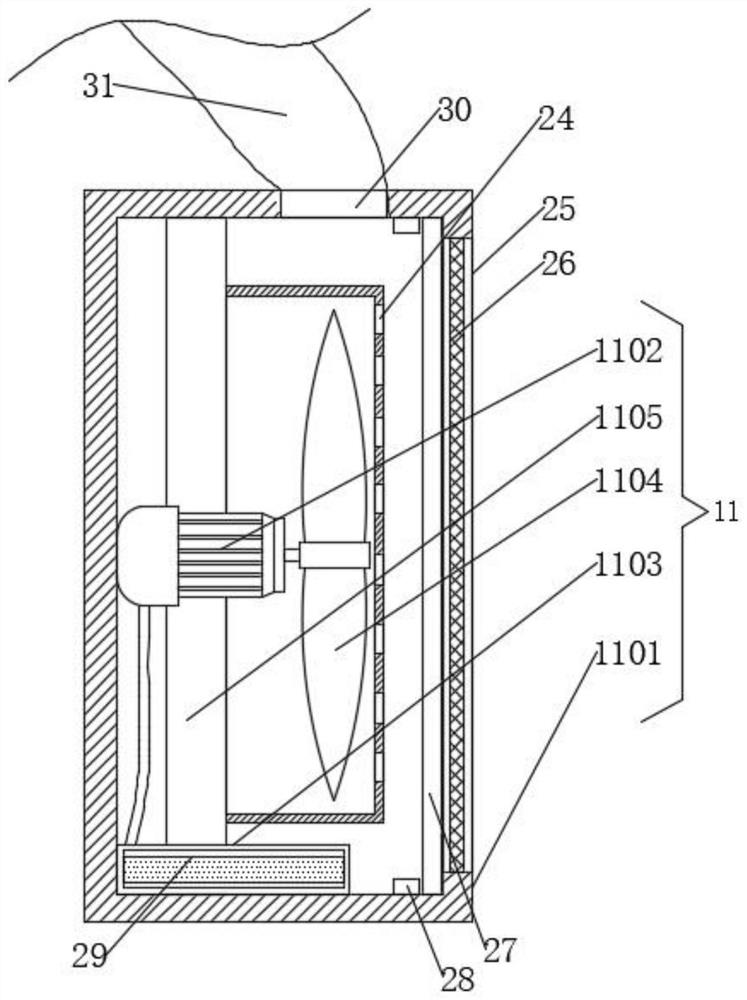

Adjustable anti-infection medical protective clothing with high adaptability

PendingCN112545086AAdaptableWith ventilationProtective garmentSpecial outerwear garmentsSoft layerHazardous substance

The invention discloses adjustable anti-infection medical protective clothing with high adaptability. The clothing comprises a protective clothing body and a waistband, wherein a surface of the protective clothing body is fixedly connected with the waistband, a base cloth layer is arranged on the inner wall of the protective clothing body, one side of the base cloth layer is fixedly connected witha soft layer, and the other side of the base cloth layer is fixedly connected with the waistband; a lower surface of the soft layer is fixedly connected with absorbent cotton, and a surface of the waistband is fixedly connected with a ventilation mechanism. The clothing is advantaged in that a worker firstly effectively filters outside air through a filter screen, outside harmful substances are prevented from entering the protective clothing body and affecting life and health of the worker, air is secondarily filtered and purified through a filter plate, air for ventilation is effectively disinfected through an ultraviolet disinfection lamp, and the protective clothing has advantages of being high in practicability and convenient to popularize and apply; the life health of workers is guaranteed, finally, filtered air is exchanged through the connecting pipeline, the purification effect on internal air is improved, and safety of the workers is guaranteed.

Owner:江苏广达医材集团有限公司

Graphene joint assembly for robot arm and assembly equipment of graphene joint assembly

PendingCN108724245AReasonable structural designQuick machining and installationJointsOther manufacturing equipments/toolsGraphene coatingScrew thread

The invention discloses a graphene joint assembly for a robot arm and assembly equipment of the graphene joint assembly. The graphene joint assembly comprises a main dimension joint, and a mounting hole and an outer threaded groove are formed in the joint; a connecting sleeve is arranged in the mounting hole, and a gasket and a limiting component are symmetrically arranged at the two ends of the connecting sleeve. The assembly equipment comprises a machine cabinet, and a joint clamp base, a feeding mechanism, a material receiving seat, a drilling base, a material ejecting seat, a guide rail and a driving air cylinder which are arranged on the machine cabinet. The joint assembly is reasonable in structural design; the connecting sleeve coated with a graphene coating is arranged in the maindimension joint of the main dimension joint, a limiting assembly is used for limiting, and a self-lubricating effect is achieved in this way, so that a pipeline is not likely to be abraded under the displacement conditions such as frequent rotation of the joint, and the working efficiency is guaranteed. The assembly equipment can quickly machine the mounting hole and an outer thread on the main dimension joint, and the connecting sleeve is arranged in the machined mounting hole, so that the assembly efficiency is high.

Owner:常州市知豆信息科技有限公司

External tyre pressure gauge

PendingCN109050177AAchieve fixationReduce installation difficultyTyre measurementsElectricityTire-pressure gauge

An external tire pressure gauge which solves the problem that the connection between the negative electrode and the circuit board is difficult, A technical scheme comprise a circuit module, The circuit module comprises a circuit board and a negative electrode piece, wherein the negative electrode piece is electrically connected with a button battery and the circuit board; the negative electrode piece is provided with a fixing pin; the circuit board is provided with a fixing hole through which the fixing pin passes; the fixing pin is provided with an elastic clip; and the elastic clip can be abutted on the side of the circuit board opposite to the negative electrode piece after the fixing pin passes through the fixing hole of the circuit board. When connecting the negative plate to the circuit board, the operator only needs to insert the fixing pin on the negative plate into the fixing hole, the elastic deformation of the elastic clip on the fixing foot occurs when the elastic clip passes through the fixing hole, When the elastic card passes through the fixing hole completely, the elastic card returns to the original shape and is engaged with the circuit board. In the installation process, the operator can fix the negative electrode piece with the circuit board only by pressing, which reduces the difficulty of operation, improves the production efficiency and reduces the labor cost.

Owner:STEELMATE CO LTD

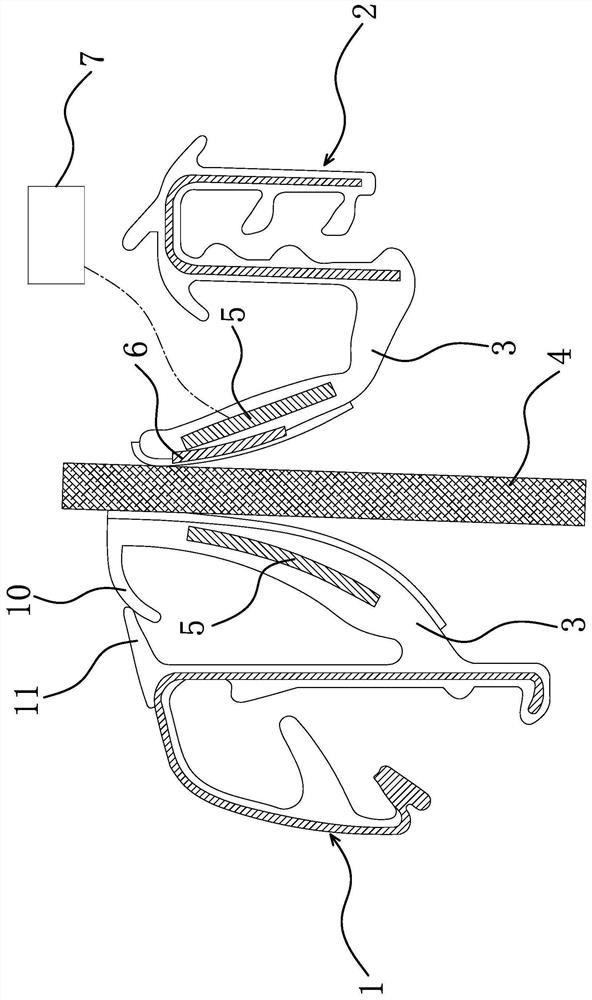

Water cutting structure of vehicle window glass

ActiveCN113306377AImprove sealingLess prone to wearEngine sealsVehicle sealing arrangementsMagnetic polesStructural engineering

The invention provides a water cutting structure of vehicle window glass, and belongs to the technical field of automobiles. The problem that lips of an existing internal and external water cutter are extremely prone to abrasion is solved. The water cutting structure of the vehicle window glass comprises an outer water cutting part and an inner water cutting part, each of the outer water cutting part and the inner water cutting part is provided with a supporting arm, the upper ends of the supporting arms abut against the side face of the vehicle window glass, electromagnets are arranged in the supporting arms, and the two electromagnets are oppositely arranged. The water cutting structure further comprises a pressure sensor and a controller, the pressure sensor is used for detecting the pressure, acting on the window glass, of the upper ends of the supporting arms, the controller can adjust the magnetic force intensity of the electromagnet and change the magnetic pole of the electromagnet, the pressure sensor is arranged in one supporting arm, and the electromagnets and the pressure sensor are electrically connected with the controller. According to the water cutting structure of the vehicle window glass, the upper end of the supporting arm is not prone to abrasion while it is guaranteed that water cutting has good sealing performance on the vehicle window glass, and the service life of the water cutting is prolonged.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

Display assemblies disposed inside mechanical keys in a mechanical keyboard

ActiveUS20200089330A1Less-prone to damageLess-prone to wearEmergency actuatorsLegendsEngineeringComputer science

The mechanical keyboard includes a base plate having multiple through openings, a circuit board disposed to a side of the base plate, multiple mechanical keys disposed at the through openings and connected to the circuit board. Each mechanical key includes a keyswitch, a keycap, and at least a transparent piece. The keyswitch is connected to the circuit board. The keycap is mounted on the keyswitch, and the transparent piece is configured to a top side of the keycap. There are multiple display assemblies, each disposed inside a mechanical key between the keycap and the keyswitch. Each display assembly is data-linked to the circuit board through a signal transmission element. The display assemblies may be installed on conventional mechanical keys and may be viewed from different angles. The mechanical keyboard also has longer operation life.

Owner:ELGATO IDISPLAY LTD

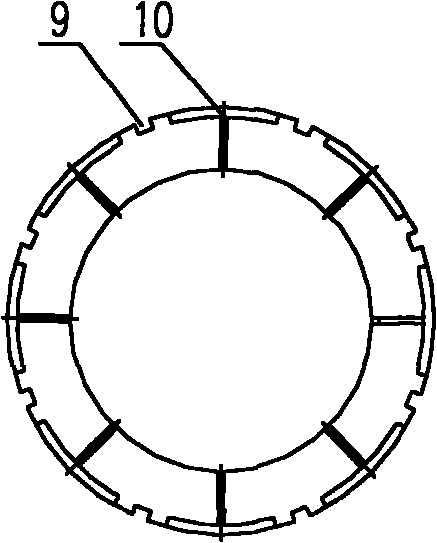

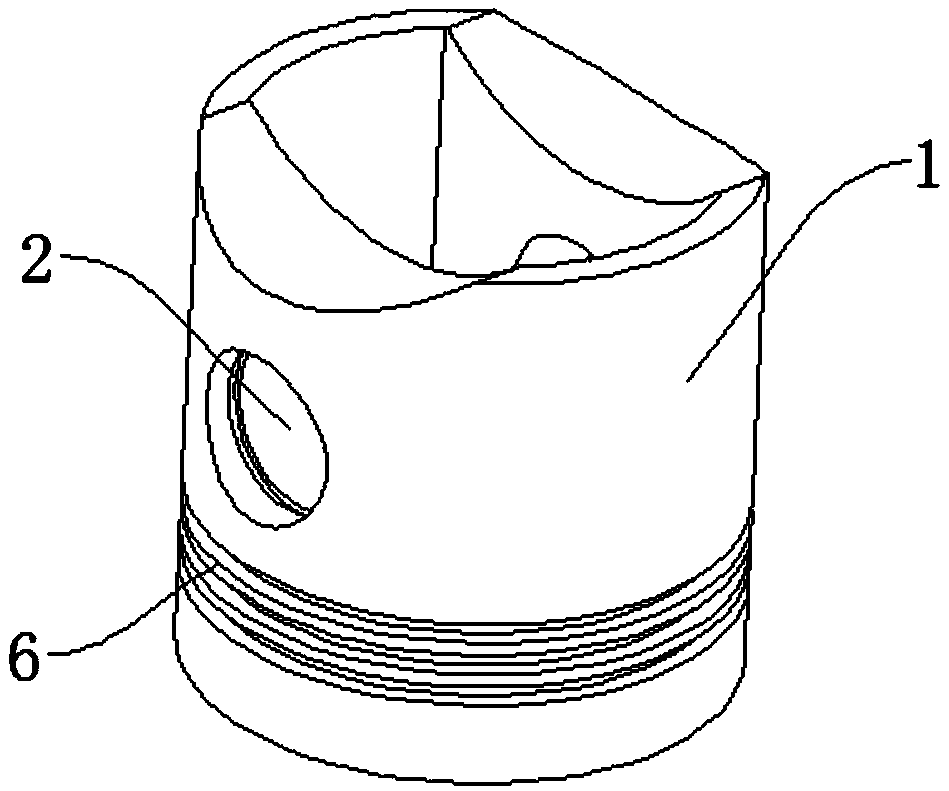

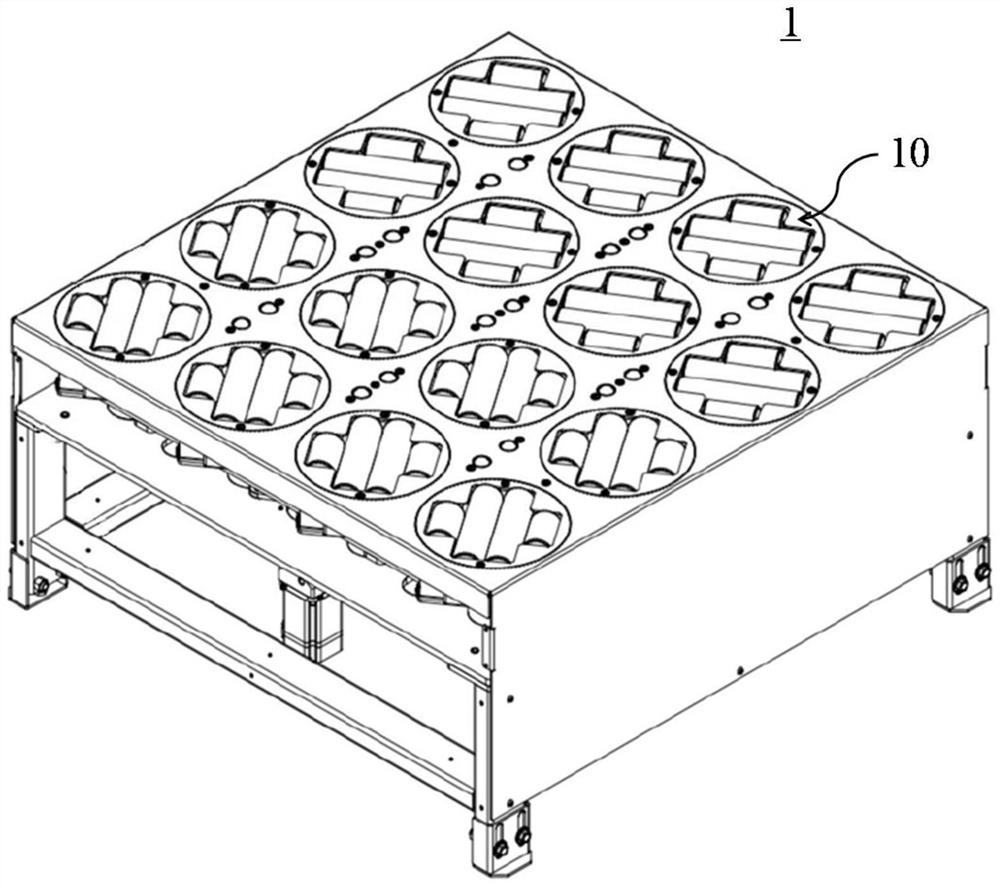

Sorting module for balance wheel sorting equipment and balance wheel sorting equipment

PendingCN112871681AReduce maintenance costsLess prone to wearSortingAgricultural engineeringStructural engineering

The embodiment of the invention provides a sorting module for balance wheel sorting equipment and the balance wheel sorting equipment. The sorting module comprises a fixed frame, a first roller assembly, a second roller assembly and an elastic piece. The first roller assembly is installed on the fixed frame in a sliding mode, and a part of the first roller assembly protrudes out of the top of the fixed frame. The second roller assembly is mounted in the fixed frame. The elastic piece is arranged between the fixed frame and the first roller assembly, the elastic piece is configured to provide elastic force for the first roller assembly, so that the first roller assembly abuts against the second roller assembly. According to the sorting module, due to the fact that the first roller assembly abuts against the second roller assembly under the action of the elastic force of the elastic piece, abrasion is not prone to occurring between the first roller assembly and the second roller assembly, the frequency of maintenance and replacement of parts is relatively low, and therefore the maintenance cost of the balance wheel sorting equipment can be reduced.

Owner:杭州祥龙物流设备科技股份有限公司 +1

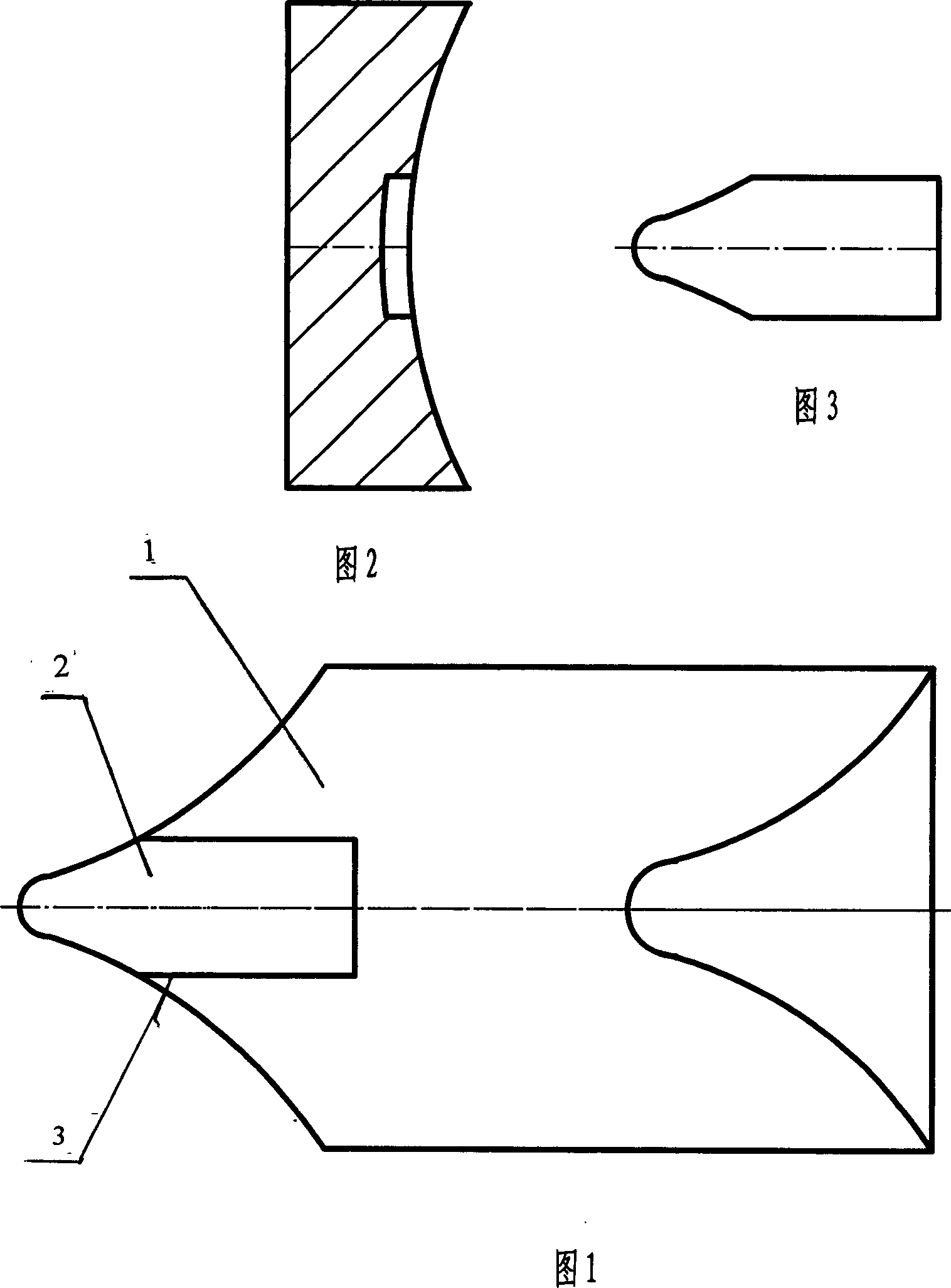

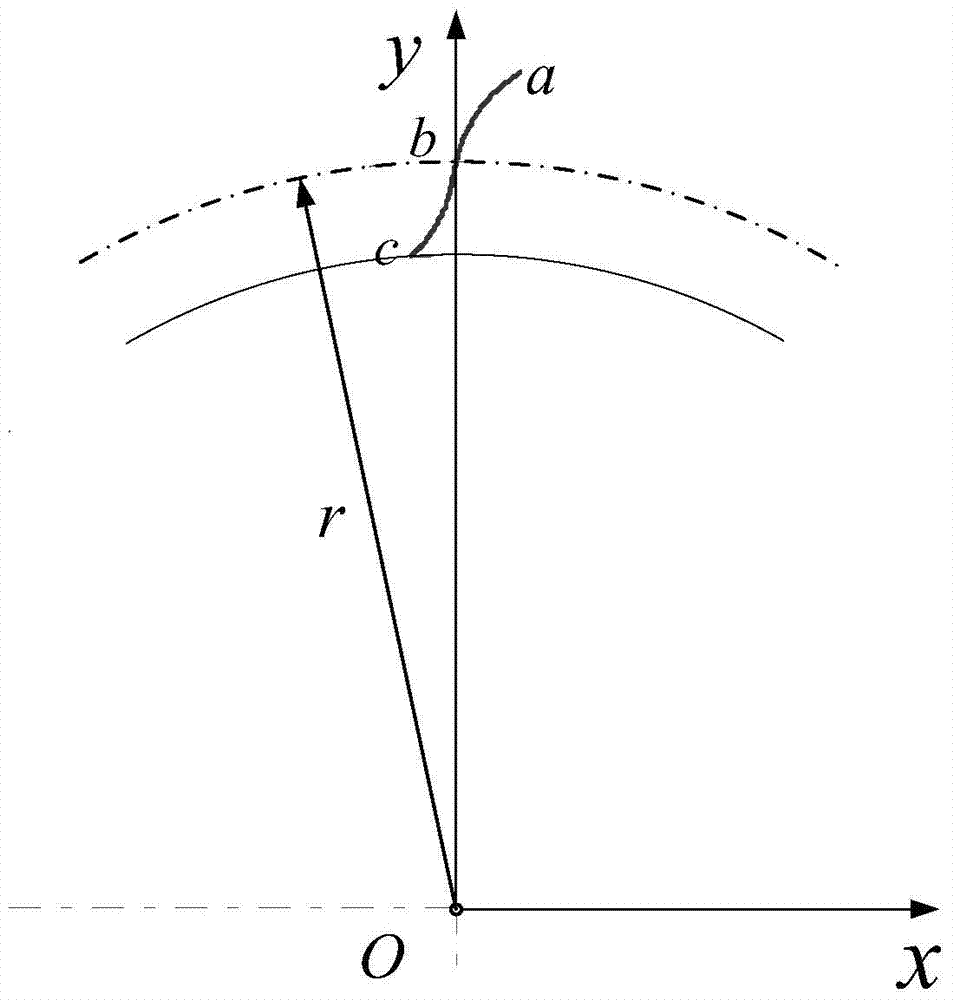

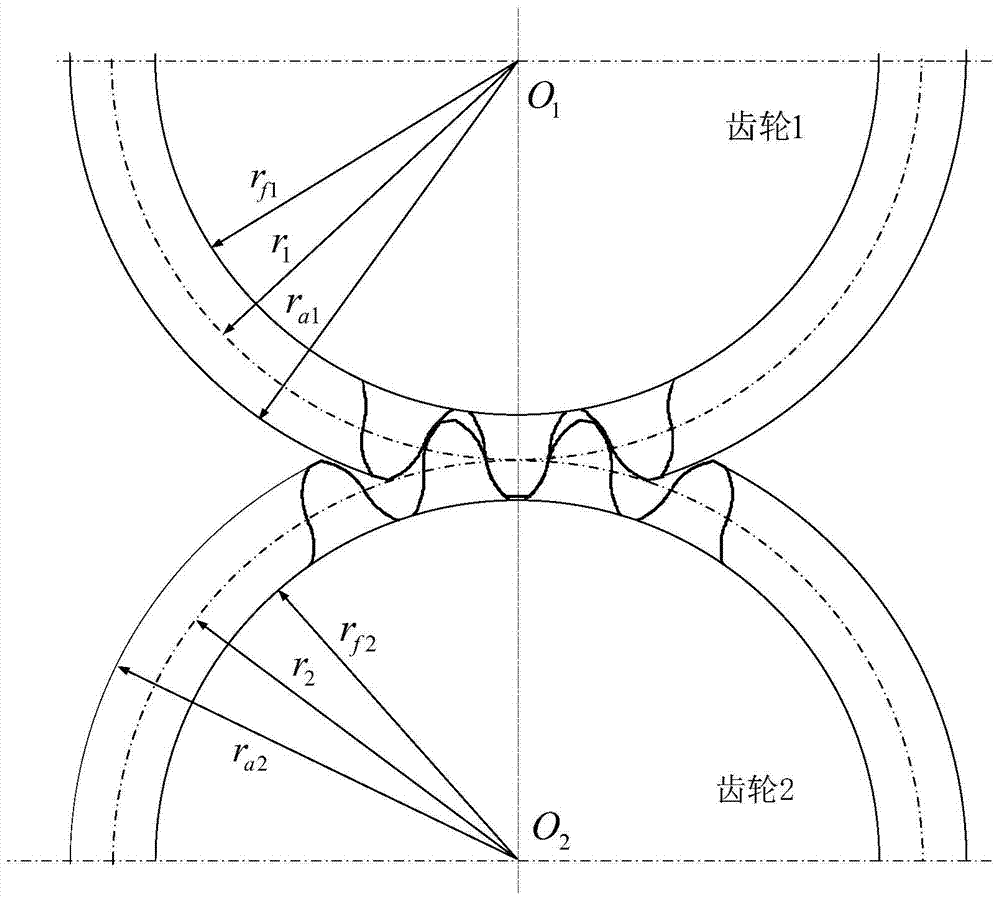

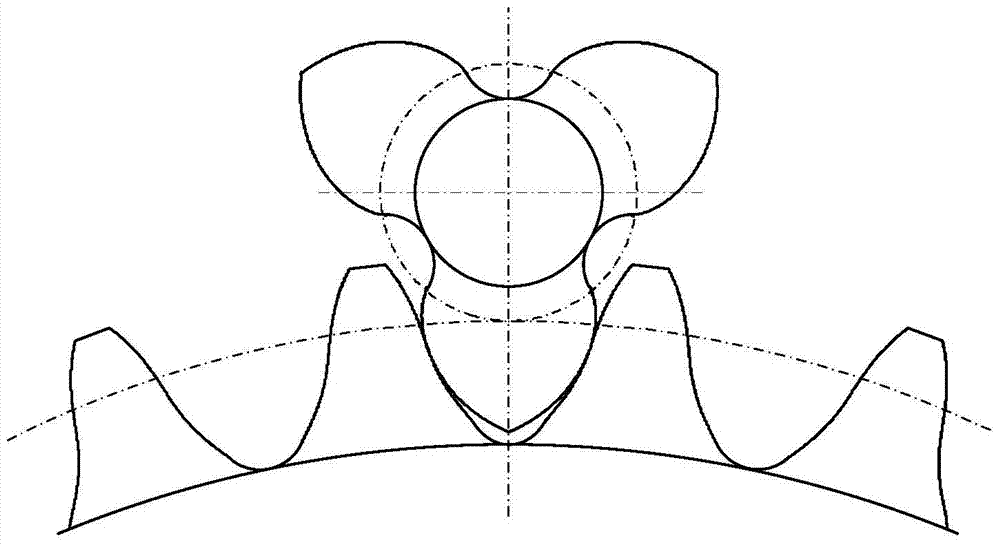

A gear with a special tooth profile curve

ActiveCN104455315BHigh contact fatigue strengthSmall slip ratePortable liftingGearing elementsHobbingGear wheel

The invention discloses a gear with a novel tooth profile curve. A tooth profile curve at the tooth top of the gear is in a convex shape. A tooth profile curve at the tooth root of the gear is in a concave shape. A meshed tooth pair of a gear pair is in convex-concave arc meshing. In a coordinate system O-xy with the gear center as an original point, through a gear parameter and tooth profile curve parameter equation, the tooth profile curve is obtained, the tooth profile curve is subjected to symmetry and rotation transformation, then the end face profile of the gear is obtained, and the gear pair formed by gears is in conjugation and in convex-concave arc meshing. The gear can be used in tooth profile design in large-load gear transmission, the bearing capacity of the gear is greatly increased compared with an involute, when a rack tool or hobbing is used for machining, machining tool design is simple, and only one tool needs to be machined. The gear is also used in design of a small-tooth-number gear pair with a small tooth number (z is smaller than or equal to 6), and accordingly the bearing capacity is improved.

Owner:TIANJIN UNIV

Conveying roll mechanism for automatic conveying line

InactiveCN107792615ASimple structureEasy to assemblePackagingRollersEngineeringMechanical engineering

Owner:安徽纽创自动化装备有限公司

Constant flow static pressure working table for gear shaping machine or gear milling machine

InactiveCN102029527BLess prone to wearReduce material requirementsLarge fixed membersGear-cutting machinesEngineeringMechanical engineering

The invention discloses a constant flow static pressure working table for a gear shaping machine or a gear milling machine. By constant flow static pressure technology, a static pressure cavity is formed on a central spindle, and lubricating oil is fed into the static pressure cavity by a constant pressure oil pump, so that an oil film is formed between the spindle of the working table and a pedestal to keep contact surfaces between the spindle and the pedestal in a constant pressure full-liquid lubricating state; therefore, the center of the working table is positioned well, a wear phenomenon is almost avoided during movement, and the rigidity and the accuracy of the working table are greatly improved and the life of the working table is greatly prolonged; and the pedestal is provided with a dual lead worm, and adjusting pads are arranged in both axial direction and radial direction of the worm, so the working table can work under a smaller backlash condition, and the dividing accuracy of a rotary working table can be improved.

Owner:WUHAN GEWEI MACHINERY

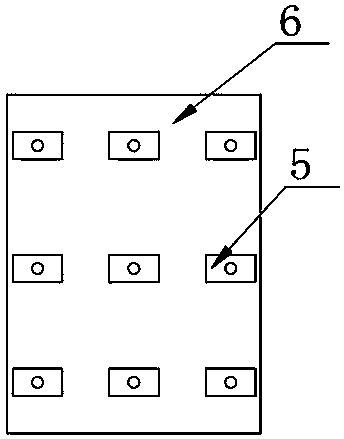

Developing roller, developing device, process cartridge, and image forming apparatus

InactiveCN101382761BReduce delivery volumeLess prone to wearElectrographic process apparatusLong axisMechanical engineering

The present invention provides a developing roller, a developing device, a process cartridge and an image forming device, which may inhibit the reduction of transmitting amount due to the aging variation, thus avoiding unevenness of image intensity. Specifically, the process cartridge of the image forming device comprises a developing roller with a fixed magnet roller and a developing sleeve (132). The outer surface of the developing sleeve has a plurality of recesses (139) of elliptic shape in plan view regularly or irregularly arranged therein so as not to overlap, and the long axis of the recess is in parallel with the length direction of the developing sleeve (132).

Owner:RICOH KK

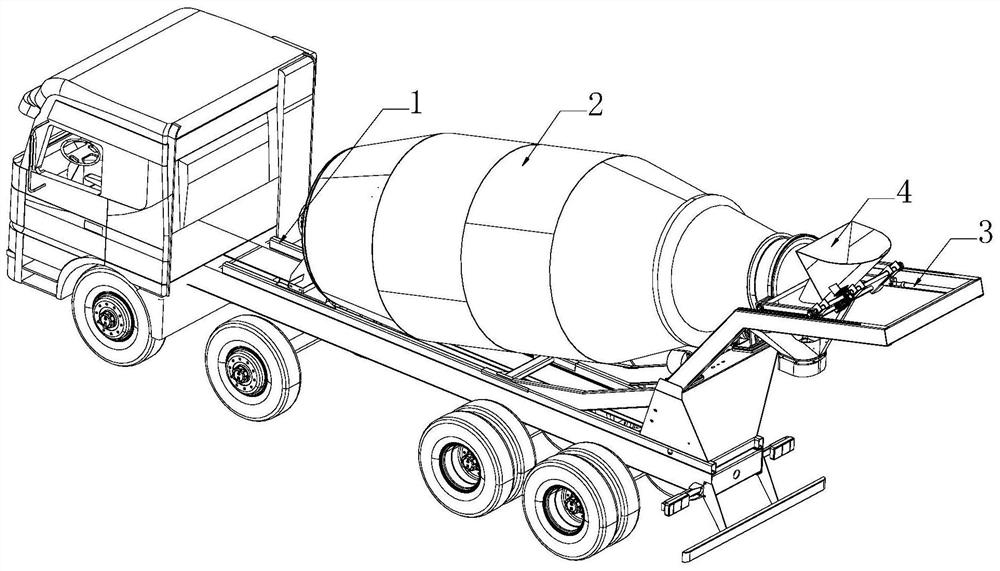

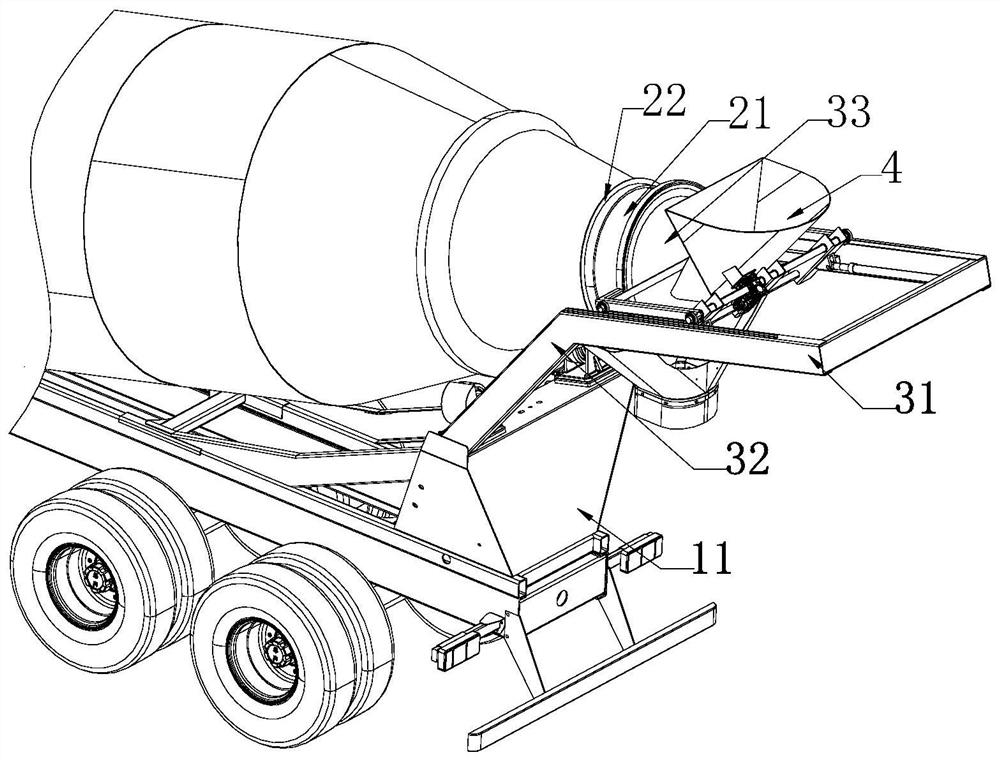

Mixer truck

InactiveCN112318723AEffective isolationPrevent penetrationCement mixing apparatusVehicle frameEngineering

The invention provides a mixer truck which is reliable in sealing and capable of reducing the water loss of concrete in the transportation process and guaranteeing the quality of the concrete. The mixer truck comprises a frame, a sealing assembly, a feeding hopper and a driving device, wherein a mixing drum is rotatably connected to the frame; the sealing assembly comprises a sealing cover; the sealing cover is used for opening or closing a feeding and discharging opening of the mixing drum; the feeding hopper is used for inputting materials into the mixing drum through the feeding and discharging opening; the driving device is in transmission connection with the sealing cover and the feeding hopper, and is used for driving the sealing cover and the feeding hopper to move forward and backward along the axial direction of the mixing drum and driving the sealing cover to do turnover motion relative to the mixing drum, so that the sealing cover is switched back and forth between a first position state and a second position state; when the sealing cover is at the first position state, the sealing cover is positioned between the mixing drum and the feeding hopper; and when the sealing cover is at the second position state, the sealing cover is located on the side, deviating from the mixing drum, of the feeding hopper.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

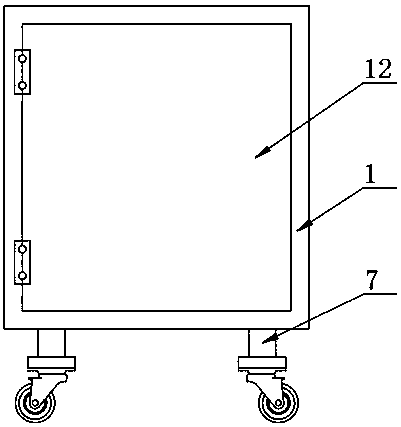

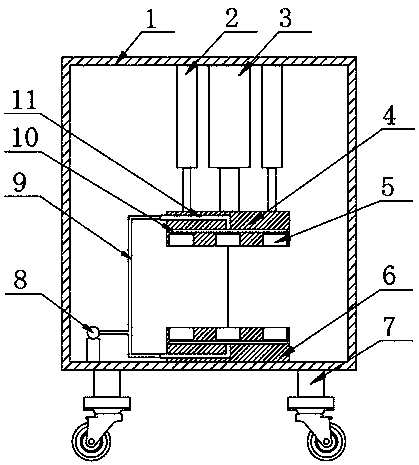

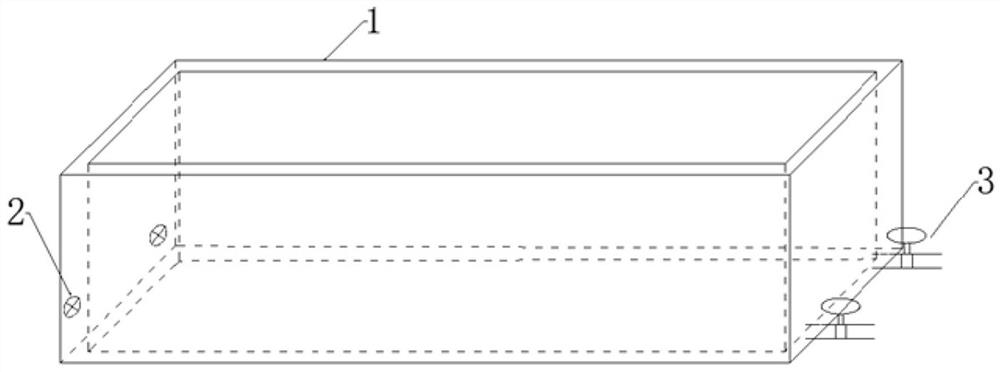

Assembly equipment for charger production

InactiveCN110666479AImprove assembly efficiencyLess prone to wearMetal working apparatusSuction forceVacuum pump

The invention discloses an assembly equipment for charger production and particularly relates to the technical field of charger production. The assembly equipment comprises a box body, wherein a second fixing block is fixedly arranged at the bottom end in the box body, a first fixing block is arranged at the top of the second fixing block, through grooves are formed in the first fixing block and the second fixing block, a plurality of adsorption grooves are formed in the top end of the second fixing block and the bottom end of the first fixing block, the adsorption grooves communicate with thethrough grooves, connecting pipes are fixedly arranged at the outer ends of the two through grooves, the two connecting pipes are respectively arranged in the first fixing block and the second fixingblock, and the two connecting pipes respectively extend out of one sides of the first fixing block and the second fixing block. The suction force is generated through a working through groove of a vacuum pump, an electric push rod works to drive the first fixing block to extrude the second fixing block, charger shells are buckled together under the action of pressure, manual assembly is not needed in the process, the charger shells can be assembled in a large amount, and the working efficiency is improved.

Owner:江苏创优佳新能源科技有限公司

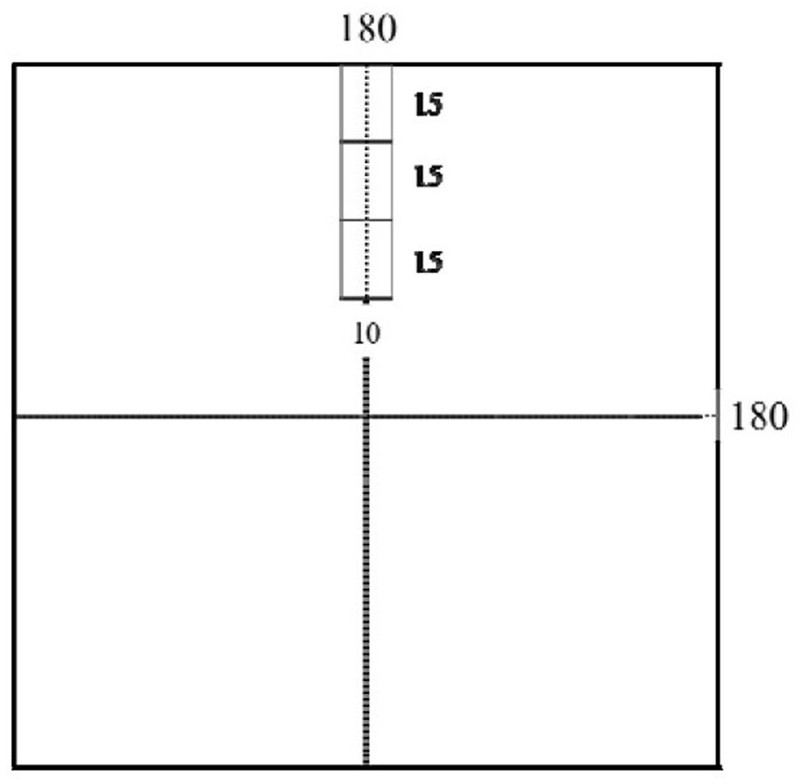

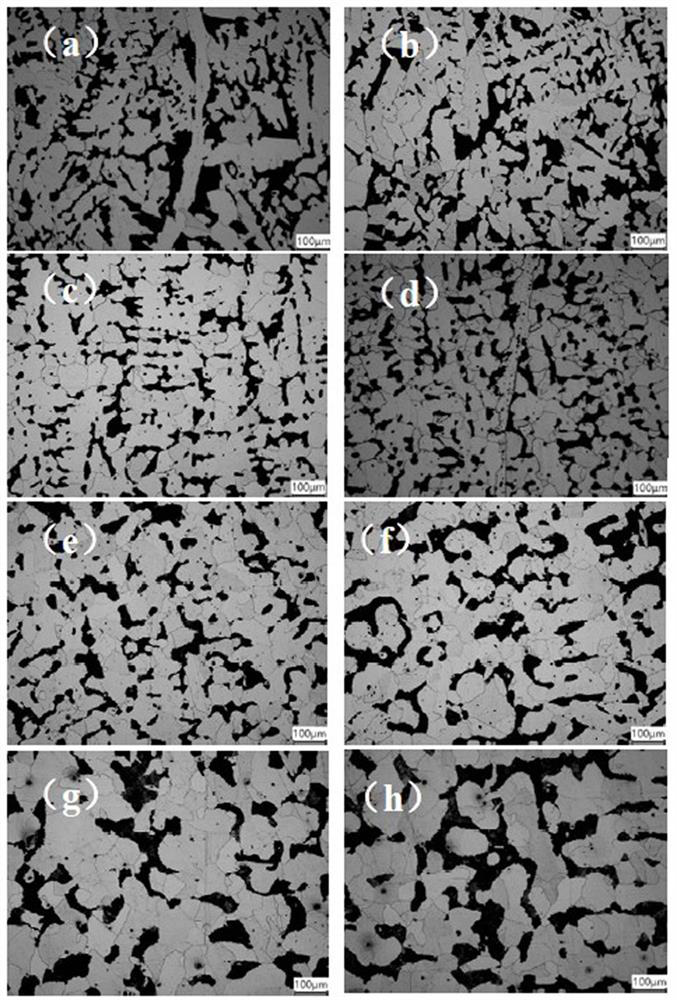

Method for surface quenching treatment of 10B21 casting blank and compact-surface 10B21 casting blank obtained by same

The invention relates to a method for surface quenching treatment of a 10B21 casting blank and the compact-surface 10B21 casting blank obtained by the same. The method comprises the following steps that a 10B21 casting blank is provided; the casting blank is subjected to surface quenching, and a quenched casting blank is obtained; tempering is conducted through the core part waste heat of the quenched casting blank, and the 10B21 casting blank with the compact surface is obtained; the quenching time is 40-100s, the initial temperature is 808-857 DEG C, the final temperature is 211-667 DEG C, the through quenching depth is 8-10mm, and the tempering highest point temperature is 535-695 DEG C; and in the depth direction from the surface of the casting blank to a core part, the organization structure of the 10B21 casting blank with the compact surface is gradually converted from tempered sorbite as the main part to bainite as the main part, and then is gradually converted into ferrite and pearlite as the main part. According to the method, effective control over the surface structure type of the 10B21 casting blank is achieved through the surface quenching technology, and therefore, generation of surface cracks in the casting blank hot delivery process is effectively restrained.

Owner:UNIV OF SCI & TECH BEIJING

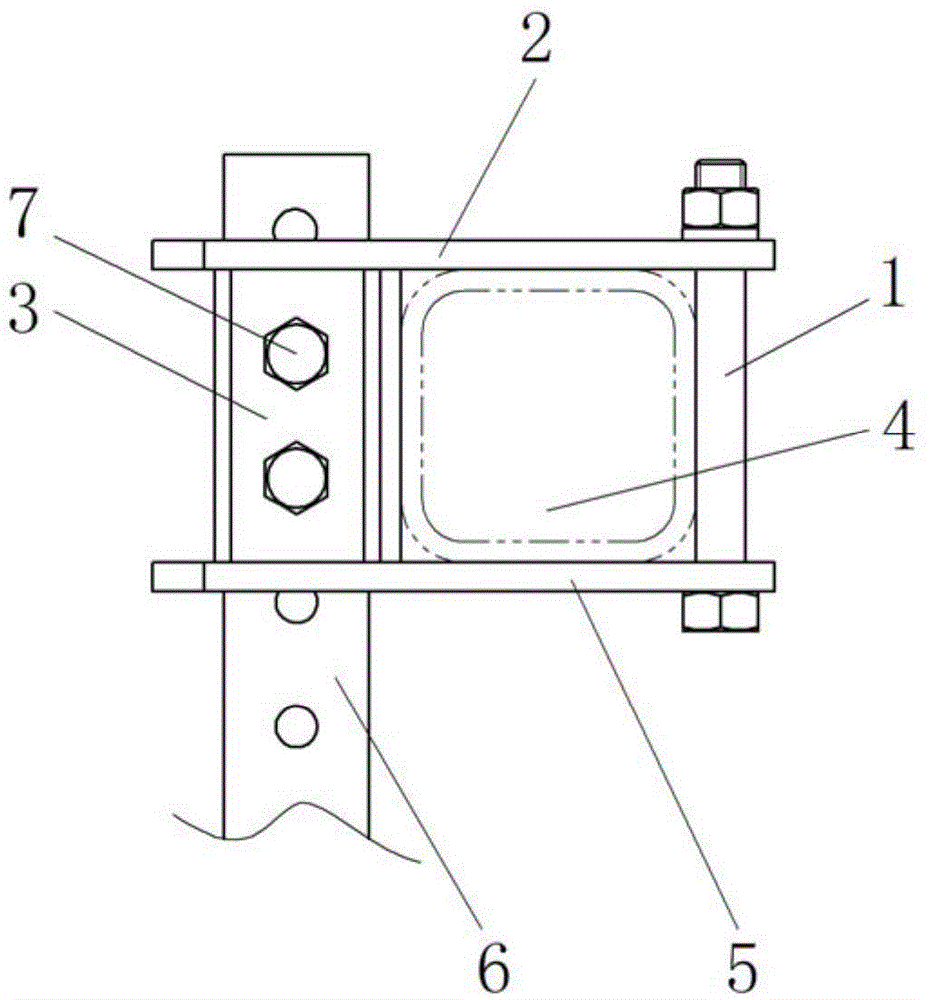

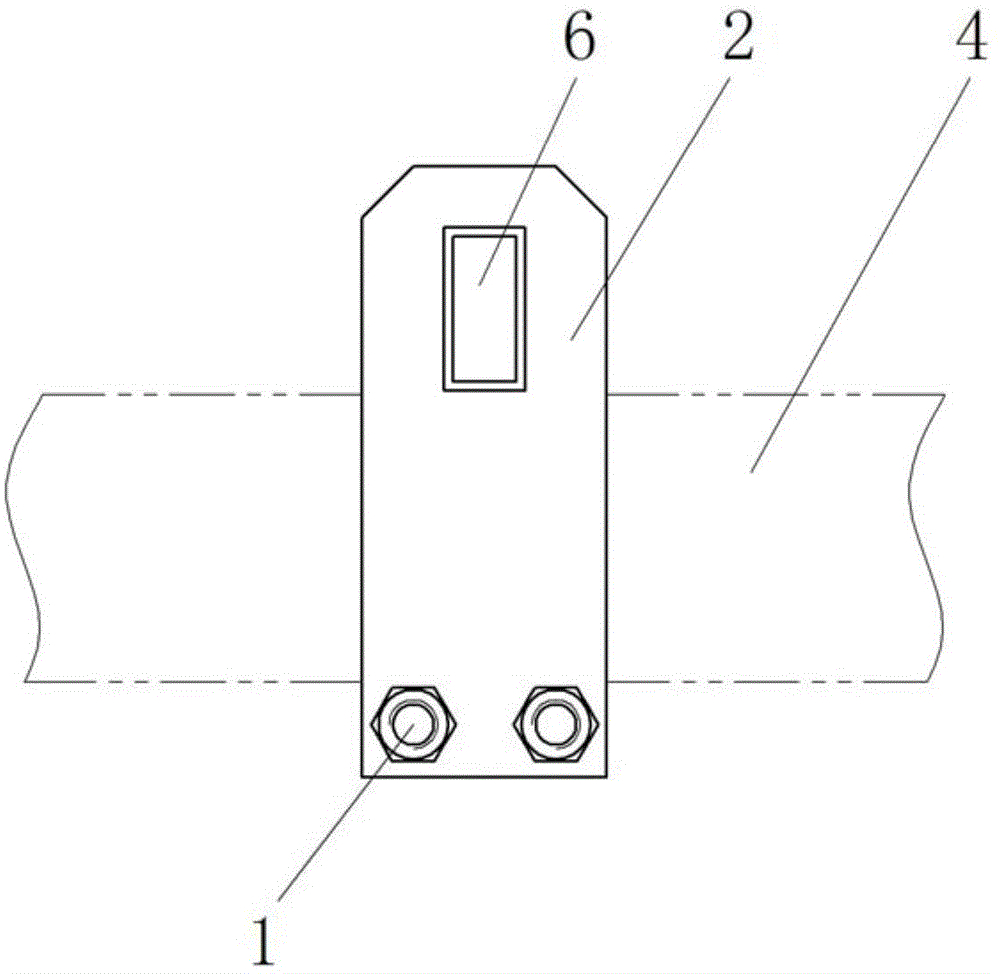

Ridging ploughshare connecting device of plate-type retest tillage implement

InactiveCN104521357AEnsure that the entry angle remains unchangedChange the connection structureAgricultural machinesJackscrewEngineering

A ridging ploughshare connecting device of a plate-type retest tillage implement comprises a rod ruler fixing sleeve, an upper clamping plate, a lower clamping plate, fastening bolts and a jackscrew and is characterized in that the rod ruler fixing sleeve is connected with the upper clamping plate and the lower clamping plate, the upper clamping plate and the lower clamping plate are connected with the fastening bolt, the rod ruler fixing sleeve is connected with the jackscrew, and the rod ruler fixing sleeve, the upper clamping plate and the lower clamping plate are matched with an implement square beam and are fixed through the fastening bolts. Due to the fact that the plate type structure design is adopted, the contact face between the ridging ploughshare connecting device and the implement square beam is large, a connecting structural mode in the prior art is changed, the ridging ploughshare connecting device is firm and reliable in connection and does not easily loosen or deform, is not easily abraded, it is ensured that a soil piercing angle of a ridging ploughshare is constant, the implement is not easily changed, and the expected technical effect of improving tillage quality is improved.

Owner:黑龙江辉桐农业机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com