Water cutting structure of vehicle window glass

A technology for window glass and external water cutting, which is used in vehicle parts, engine sealing, sealing devices, etc., can solve the problems of easy wear and tear of support arms, and achieve the effect of prolonging service life and avoiding product aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

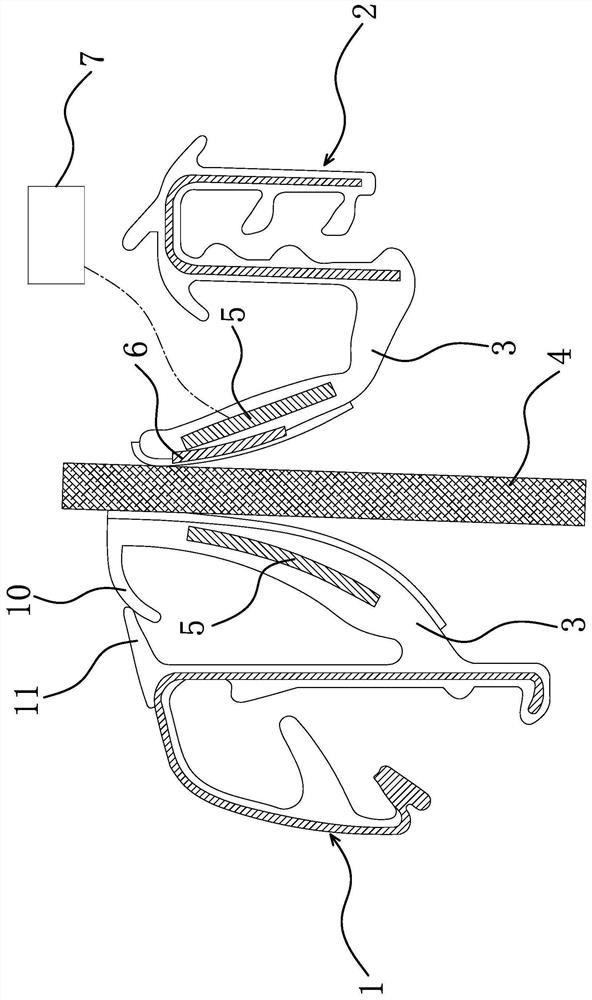

[0022] Such as figure 1As shown, the water cut structure of the vehicle window glass includes the outer water cut 1 and the inner water cut 2, the outer water cut 1 and the inner water cut 2 both have a support arm 3, and the upper ends of the support arm 3 are all against the side of the window glass 4, An electromagnet 5 is arranged in the support arm 3, and two electromagnets 5 are arranged oppositely. The water-cutting structure also includes a pressure sensor 6 for detecting the pressure exerted on the window glass 4 by the upper end of the support arm 3 and an adjustable electromagnet. 5 magnetic force intensity and change the controller 7 of the magnetic pole of electromagnet 5, pressure sensor 6 is arranged in wherein one support arm 3, electromagnet 5, pressure sensor 6 are all electrically connected with controller 7. The pressure sensor 6 is used to detect the pressure value that the upper end of the support arm 3 acts on the window glass in real time. The structure...

Embodiment 2

[0027] The content of this embodiment is basically the same as that of the above-mentioned embodiment 1, except that the cross section of the electromagnet 5 inside the support arm 3 of the outer water cutter 1 is arc-shaped. When the upper end of the support arm 3 abuts against the window glass 4, the support arm 3 has a certain curvature, and the cross section of the electromagnet 5 is arc-shaped to match the curvature of the support arm 3, so that the upper end of the support arm 3 The tightness of the fit between the upper portion and the window glass 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com