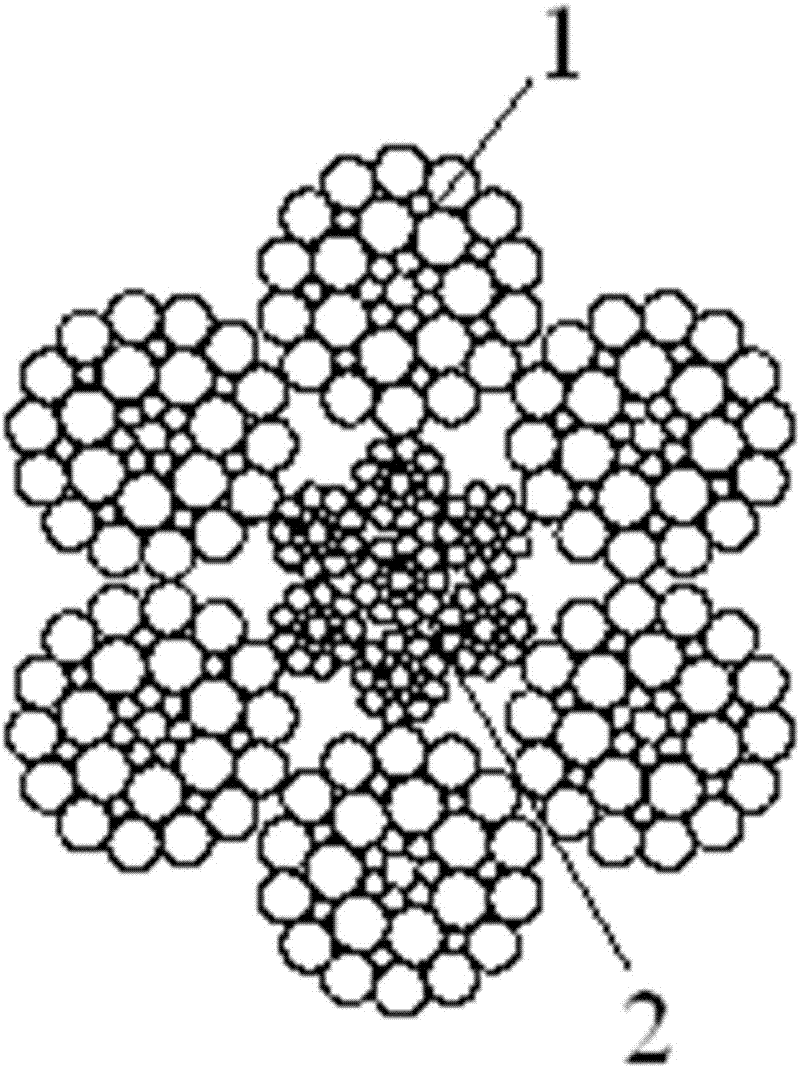

Parallel-laid steel wire rope for container equipment and manufacturing method thereof

A wire rope and parallel laying technology, which is applied in the field of hoisting and traction wire rope manufacturing, can solve the problems of poor fatigue and mechanical properties of steel wires, easy wear of steel wires, broken wires and broken strands, shortened service life of steel wire ropes, etc. Great, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

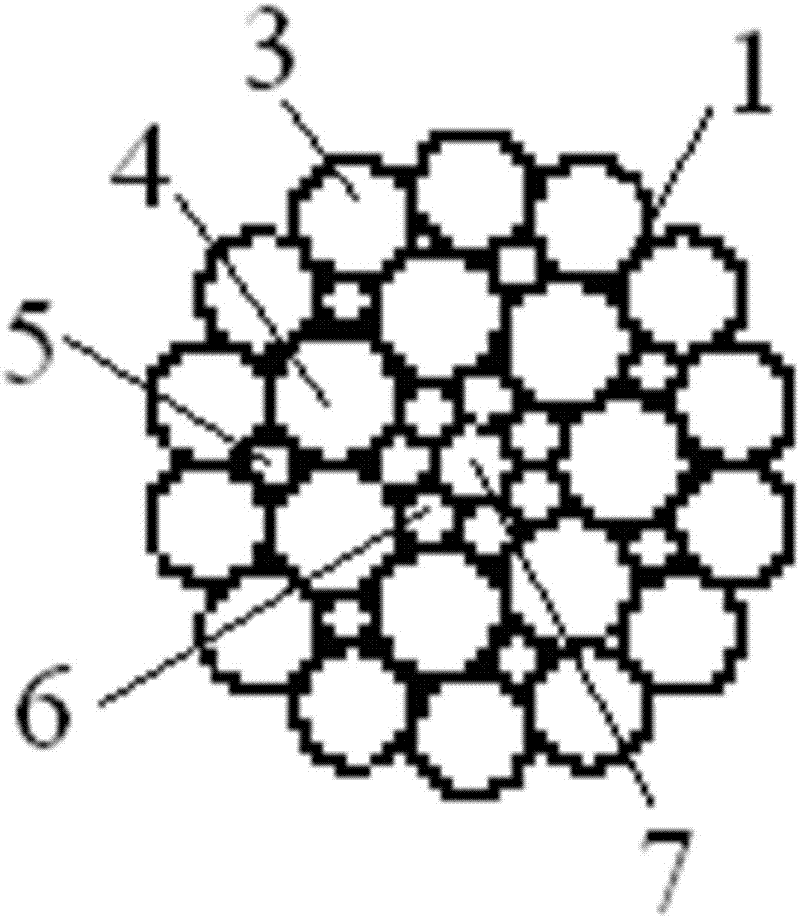

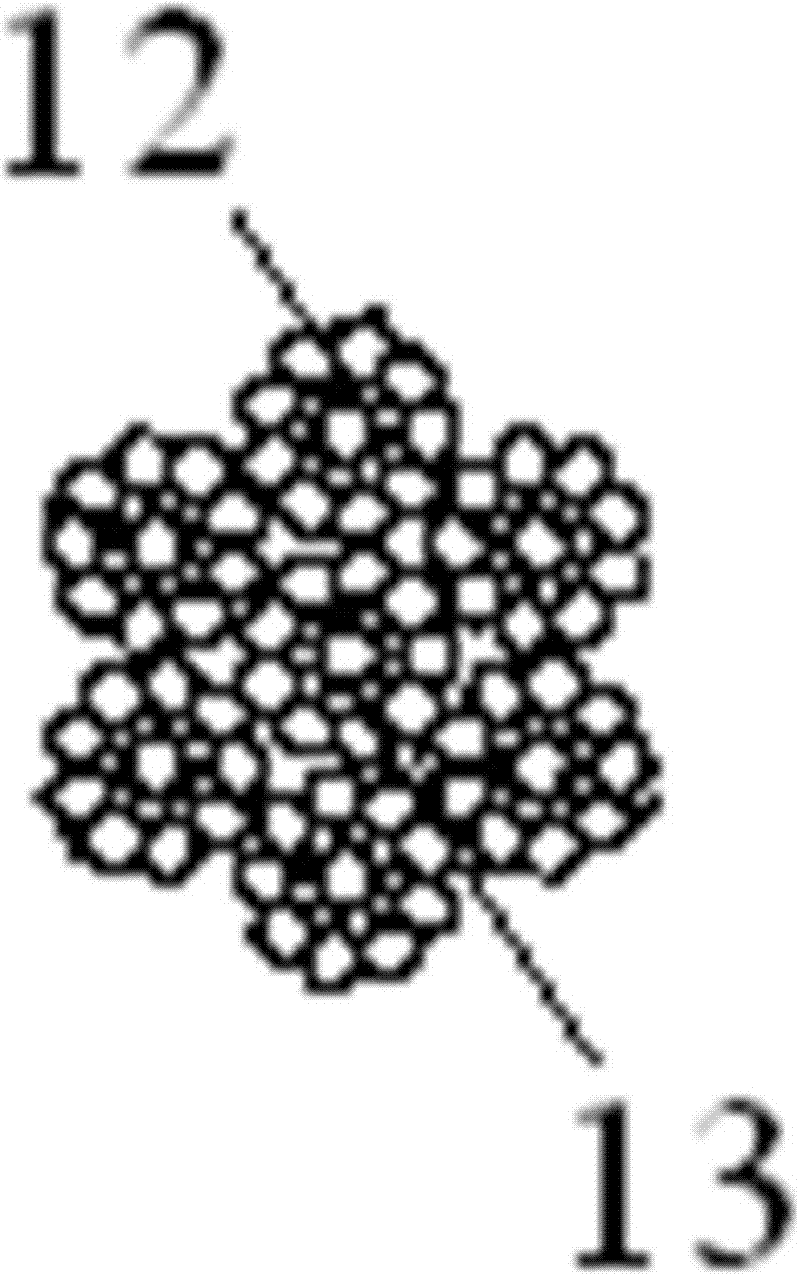

[0076] Determine that the diameter of the first outer layer steel wire 3 in the parallel twisted steel wire rope is 1.14mm, the diameter of the filling steel wire 5 is 0.82mm, the diameter of the first middle layer steel wire 4 is 1.80mm, the diameter of the first inner layer steel wire 6 is 0.72mm, and the diameter of the first center steel wire 7 The diameter is 1.57mm; the diameter of the second outer layer steel wire 9 is 0.95mm, the diameter of the second inner layer steel wire 10 is 0.46mm, the diameter of the second center steel wire 8 is 0.82mm; the diameter of the third outer layer steel wire 15 is 1.15mm, the third The inner steel wire 16 has a diameter of 0.56mm, and the third central steel wire 14 has a diameter of 1.00mm; according to the formula d n =d- 0 × (σ n / Kσ 0 ) 2 Calculate the diameter d of the raw steel wire corresponding to the above-mentioned finished steel wire with different diameters n : σ 0 Indicates the strength of 65# steel wire after quenc...

Embodiment 2

[0085]Determine that the diameter of the first outer layer steel wire 3 in the parallel twisted steel wire rope is 1.14mm, the diameter of the filling steel wire 5 is 0.82mm, the diameter of the first middle layer steel wire 4 is 1.80mm, the diameter of the first inner layer steel wire 6 is 0.72mm, and the diameter of the first center steel wire 7 The diameter is 1.57mm; the diameter of the second outer layer steel wire 9 is 0.95mm, the diameter of the second inner layer steel wire 10 is 0.46mm, the diameter of the second center steel wire 8 is 0.82mm; the diameter of the third outer layer steel wire 15 is 1.15mm, the third The inner steel wire 16 has a diameter of 0.56mm, and the third central steel wire 14 has a diameter of 1.00mm; according to the formula d n =d- 0 × (σ n / Kσ 0 ) 2 Calculate the diameter d of the raw steel wire corresponding to the above-mentioned finished steel wire with different diameters n : σ 0 Indicates the strength of 65# steel wire after quench...

Embodiment 3

[0090] Determine that the diameter of the first outer layer steel wire 3 in the parallel twisted steel wire rope is 1.14mm, the diameter of the filling steel wire 5 is 0.82mm, the diameter of the first middle layer steel wire 4 is 1.80mm, the diameter of the first inner layer steel wire 6 is 0.72mm, and the diameter of the first center steel wire 7 The diameter is 1.57mm; the diameter of the second outer layer steel wire 9 is 0.95mm, the diameter of the second inner layer steel wire 10 is 0.46mm, the diameter of the second center steel wire 8 is 0.82mm; the diameter of the third outer layer steel wire 15 is 1.15mm, the third The inner steel wire 16 has a diameter of 0.56mm, and the third central steel wire 14 has a diameter of 1.00mm; according to the formula d n =d- 0 × (σ n / Kσ 0 ) 2 Calculate the diameter d of the raw steel wire corresponding to the above-mentioned finished steel wire with different diameters n : σ 0 Indicates the strength of 65# steel wire after quenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com