Conveying roll mechanism for automatic conveying line

A technology of conveying rollers and transportation lines, which is applied in the direction of conveyor objects, transportation and packaging, and rollers, and can solve the problems of roller mechanism wear, roller rotation restriction, and abnormal noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0028] In the present invention, unless stated otherwise, the orientation words included in the term such as "radial direction" only represent the orientation of the term in the normal use state, or the common name understood by those skilled in the art, and should not be viewed as a limitation of this term.

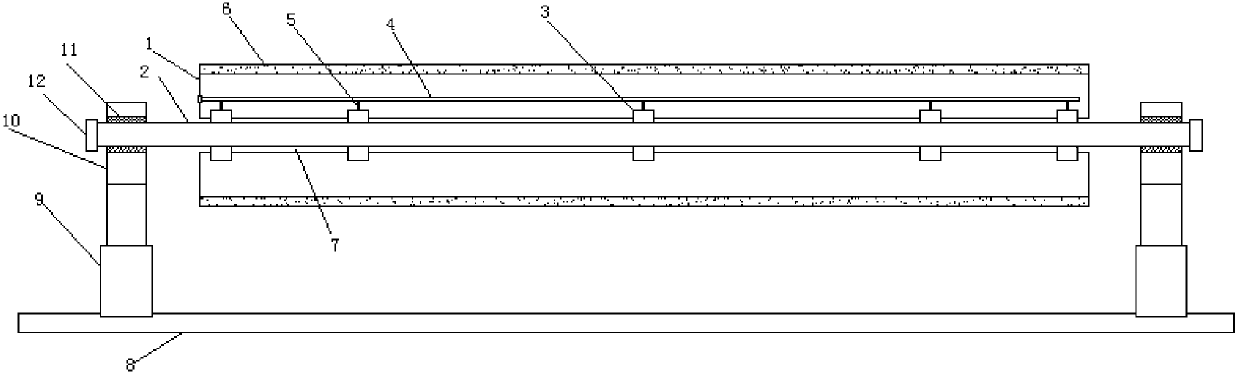

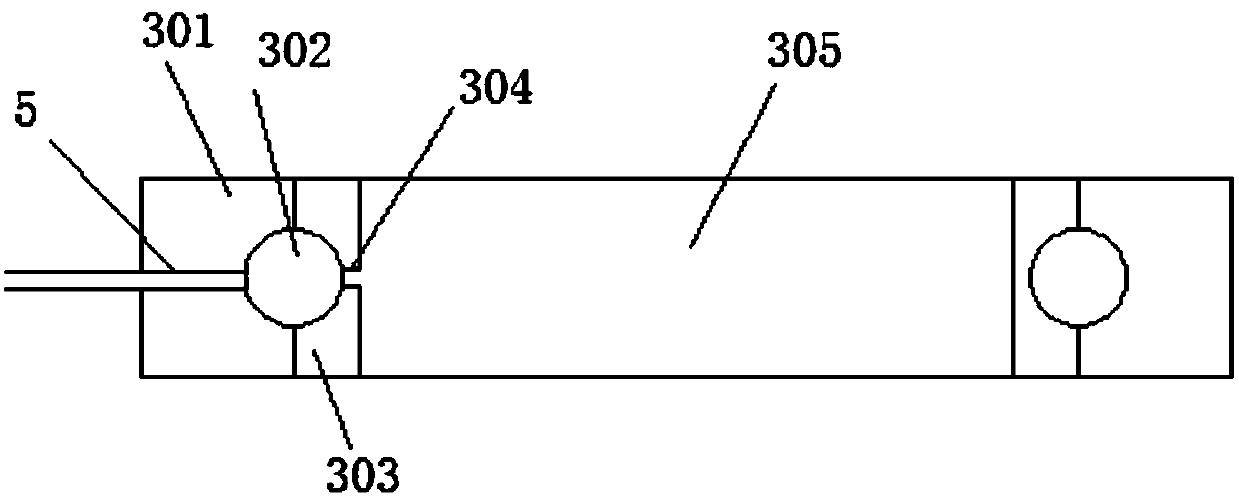

[0029] like figure 1 and figure 2 As shown: the present invention provides a conveying roller mechanism for an automatic transportation line, the conveying roller mechanism includes a roller 1 and a rotating shaft 2, and the roller 1 is provided with a penetrating hole along the length direction of the roller 1 The hole 7, the inner wall of the through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com