Multi-color coloring laser marking-use chromatic color colorant, multi-color coloring laser marking-use composition and molding containing it, multi-color marking-carrying molding and laser marking me

A laser marking and colored technology, applied in the direction of copying/marking method, temperature recording method, organic dyes, etc., can solve the problems of visibility and design pattern restrictions, and achieve long-term high maintenance, not easy to deform, easy to identify Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0308] Hereinafter, the present invention will be specifically explained with examples. In addition, the present invention is not limited by these examples. In addition, "%" and "parts" in the examples are quality standards unless otherwise specified.

[0309] [I] There are colored colorants

[0310] [I-I] Types of colored colorants and exothermic peak temperature

[0311] Regarding the colorants shown below, the exothermic peak temperature was measured by differential thermal analysis. The measuring device is "TG-DTA320 type (horizontal furnace)" manufactured by Seiko Electronics. An aluminum dish-shaped container with a diameter of 5 mm × a height of 2.5 mm was uniformly and densely filled with a sample of 3 mg. The temperature increase rate was set at 10° C. / min. The measurement was carried out at a flow rate of 200 ml / min in air. In addition, the temperature correction in the measuring device is performed using indium and tin. In addition, weight calibration is performed at ro...

Embodiment A-1

[0343] Using a mixer, 0.2 parts of the above-mentioned colored colorant (1), 0.1 parts of black substance (trade name "Mitsubishi Carbon #45", manufactured by Mitsubishi Chemical Corporation), and 100 parts of rubber reinforced copolymer obtained by the following method After mixing the resin for 5 minutes, use a 50mm extruder to perform melt kneading and extrusion at a drum set temperature of 180-220°C to obtain pellets. The obtained pellets were sufficiently dried, and a sample piece (80 mm in length, 55 mm in width, and 2.5 mm in thickness) for evaluation was obtained using an injection molding machine (model name "EC-60", manufactured by Toshiba Machine Co., Ltd.).

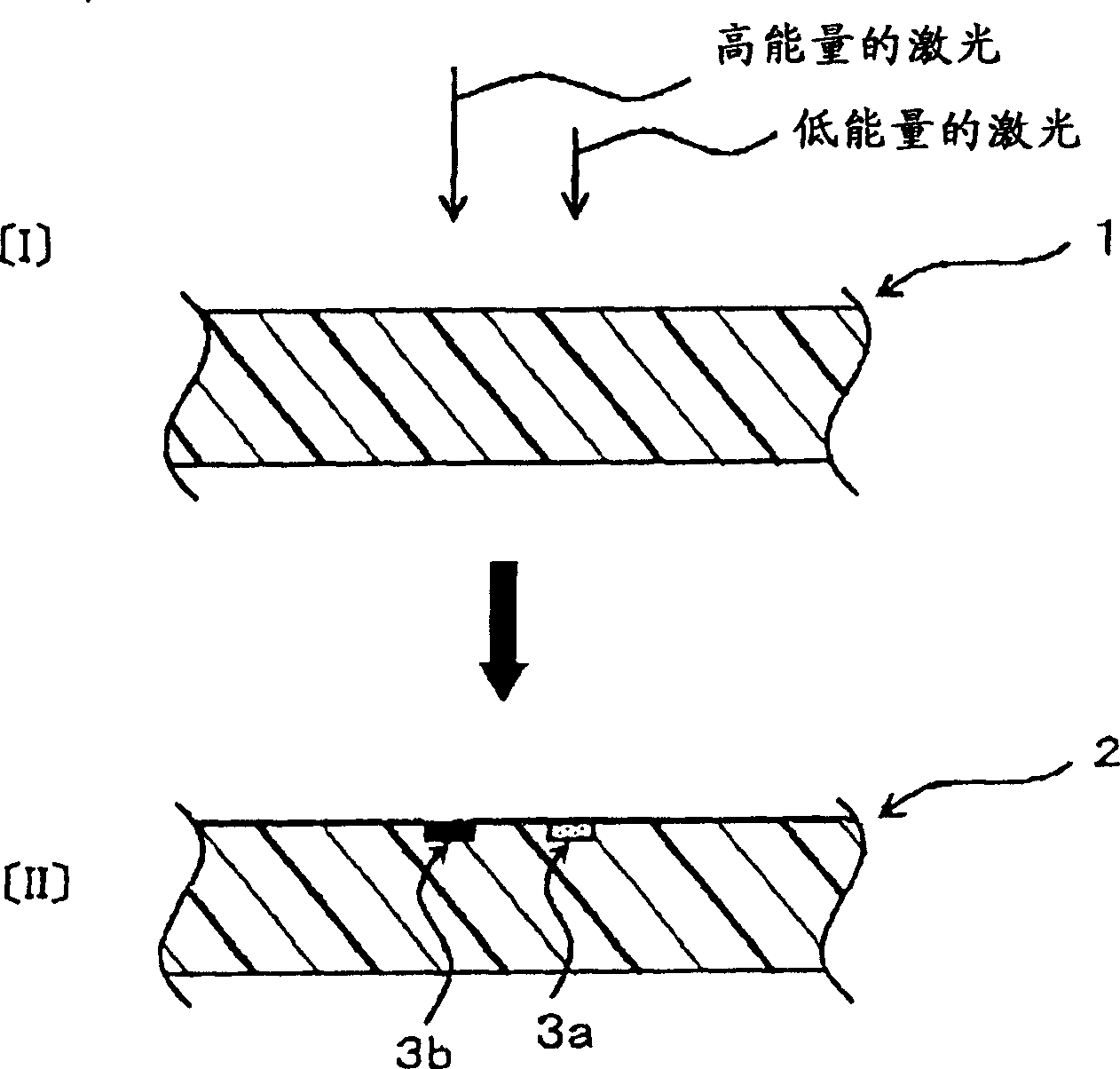

[0344]For laser marking, the Rofin Power Line "E / SHG" manufactured by Rofin Baasel and the laser marker "RSM30D" manufactured by the same company are used. The wavelength of the laser is set to 532nm and 1064nm, respectively. Each laser is irradiated at different positions on the surface of the specimen. . When t...

Embodiment A-2

[0350] Except that the chromatic colorant (2) was used instead of the chromatic colorant (1), and the blending amount was set to 0.1 parts, a sample piece was produced and evaluated in the same manner as in the above-mentioned Example A-1. The results are also shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com