Guide plate for rolling mill and its manufacture and repair method

A guide plate and rolling mill technology, applied in the guide plate and manufacturing of rolling mill, combined rolling mill guide plate, repair field, can solve the problem of low life of the guide plate, achieve the effect of not easy to wear, good red hardness, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

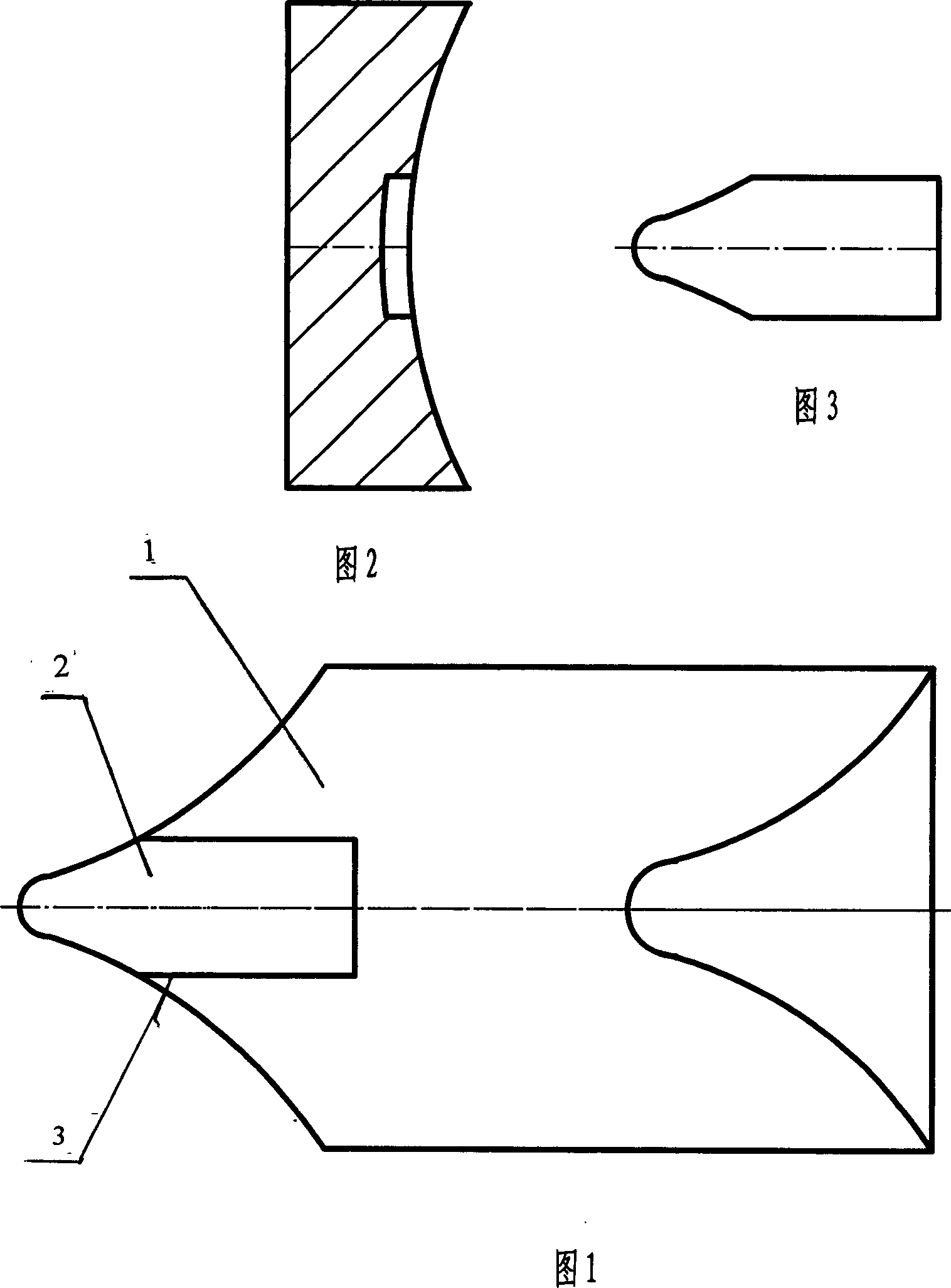

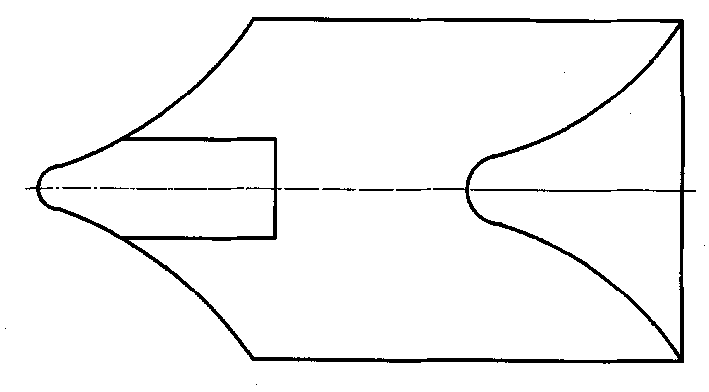

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] As shown in Figure 1, choose cast steel or cast iron guide plate substrate 1, and use inorganic glue 3 to bond tungsten carbide block 2 on the worn position. Its main components are WC70%, Co30%, and the thickness of tungsten carbide block 2 is 4mm. The fit gap of the tungsten carbide block is 0.2mm, the machined groove at the wear position of the guide plate base is 4mm, the roughness of the joint between the guide plate base and the tungsten carbide block is below 3, and the base 1 is a cast steel, cast iron guide plate or a worn guide plate. When the area of tungsten carbide block is large, bolts can be used to increase the strength. For the repair of the guide plate of the rolling mill bonded with the tungsten carbide block, if the glue needs to be removed, the guide plate can be soaked in ammonia water, and the glue layer can be destroyed by knocking and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com