Two wire spring making machine and method

A coil spring and coil technology, applied in the field of spring manufacturing, can solve the problems of complex and expensive machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

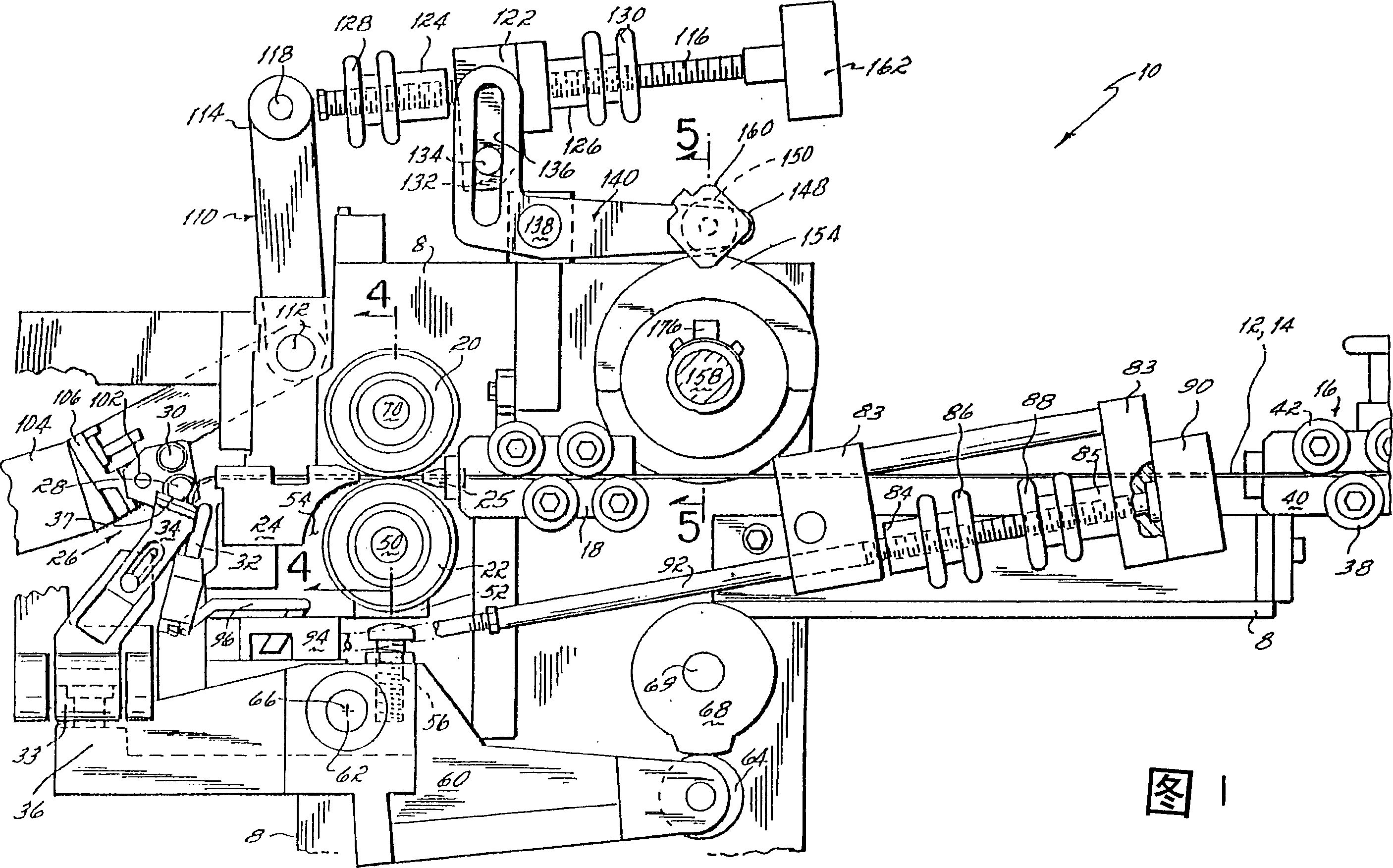

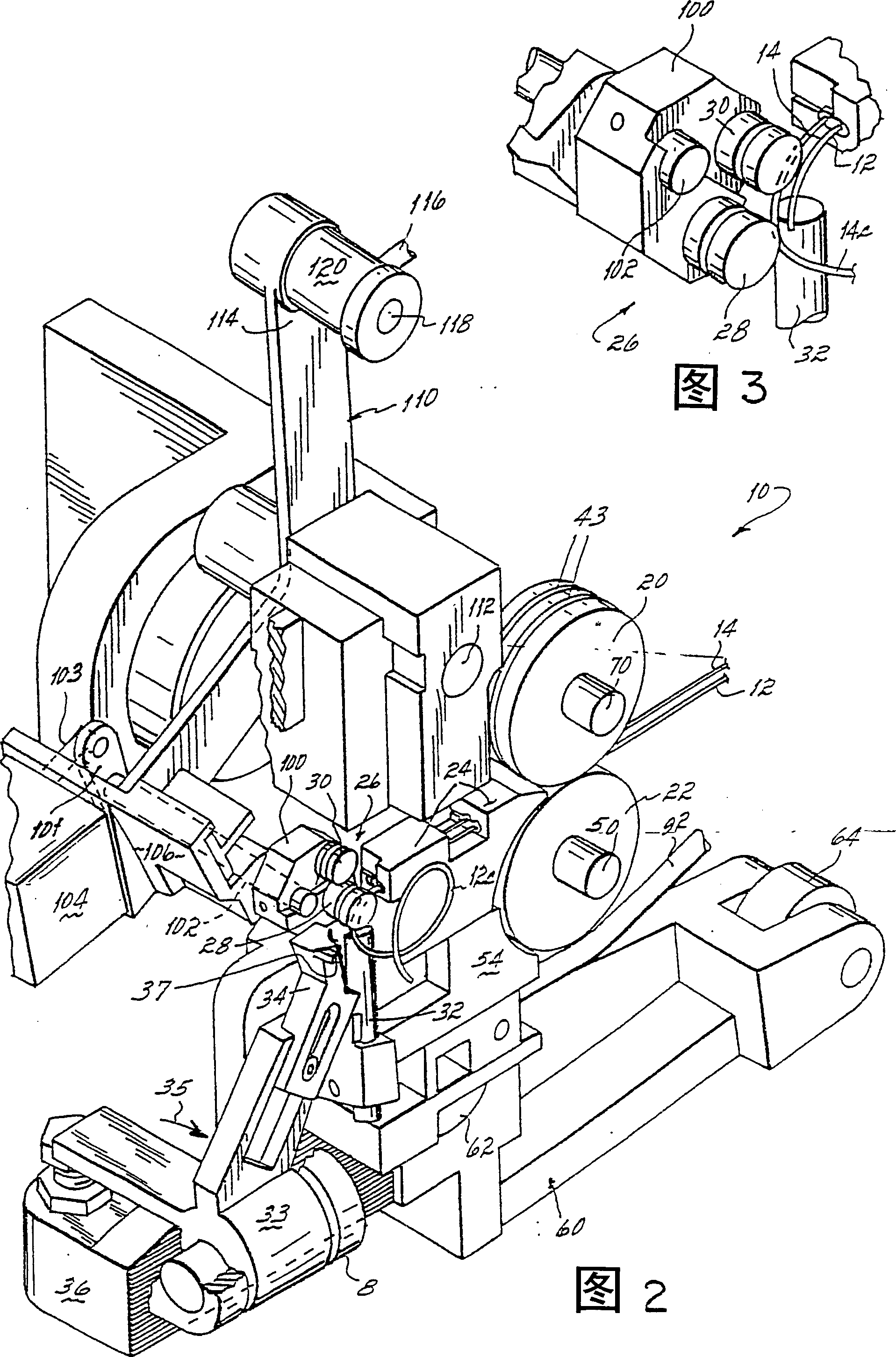

[0017] General composition of spring coiling machine

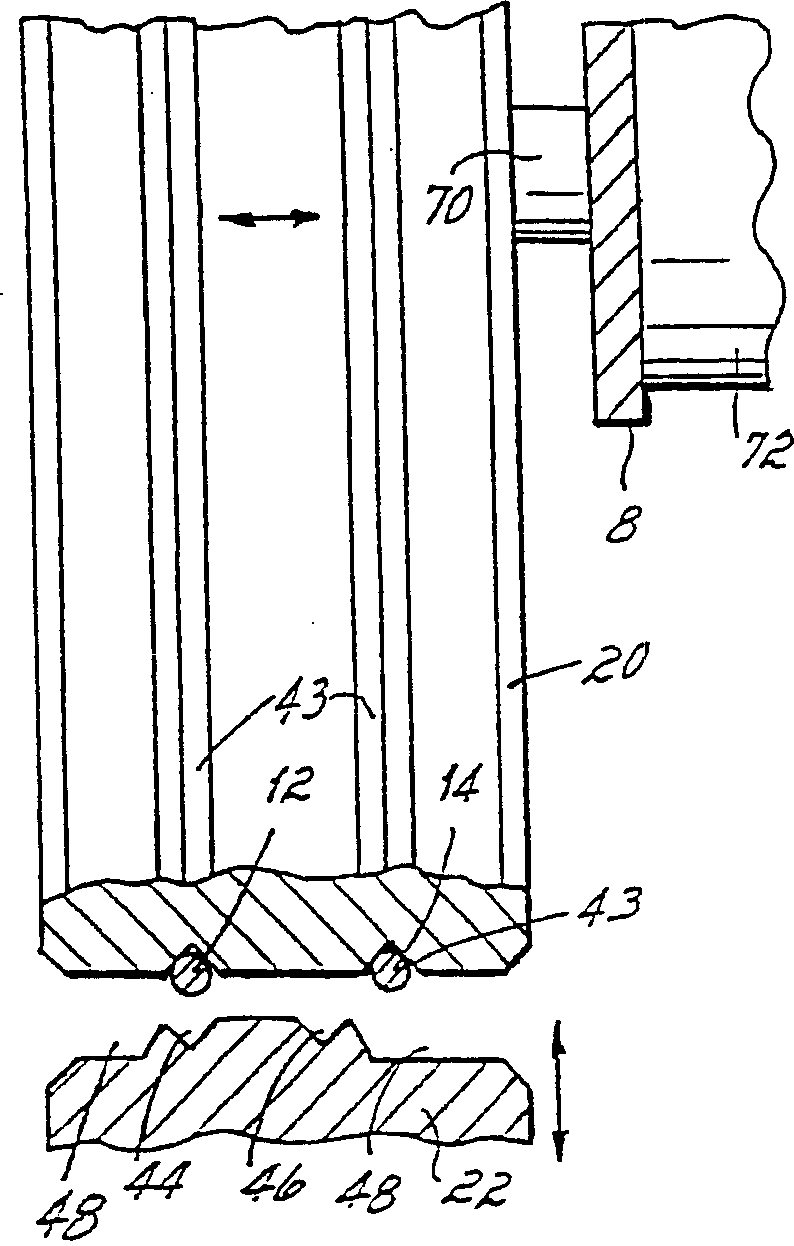

[0018] The spring coiling machine 10 of the present invention is used to form two steel wires 12 and 14 into spring coils 12c and 14c, respectively. These wires 12 and 14 are preferably of different diameters and are supplied to the spring coiler 10 by two separate wire supply reels (not shown).

[0019] The spring coiler 10 includes a conventional wire straightener 16 for straightening the wire as it is fed from the supply reel to the machine. After leaving the straightener 16, the wire is fed to a wire guide 18 on the input side of a pair of opposed conveyor rollers 20,22. On the output side of the opposed delivery rollers 20 , 22 there is a wire guide 24 for supplying and guiding wire to a wire forming station 26 . In this forming station, one or the other of the two wires is engaged with one or the other of a pair of coil forming rollers 28, 30 and a pitch determining tool 32, as selected. After the wire has been fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com