Epoxy resin curing agent, and preparation method and application of epoxy resin curing agent

An epoxy resin curing and epoxy resin technology, which is applied in the field of epoxy resin curing agent, can solve the problems that it cannot be used as an epoxy resin curing agent, the number of active group mercapto groups is small, and the reactivity is low, and the production cost is low, and the The effect of flexible molecular design and environmentally friendly preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

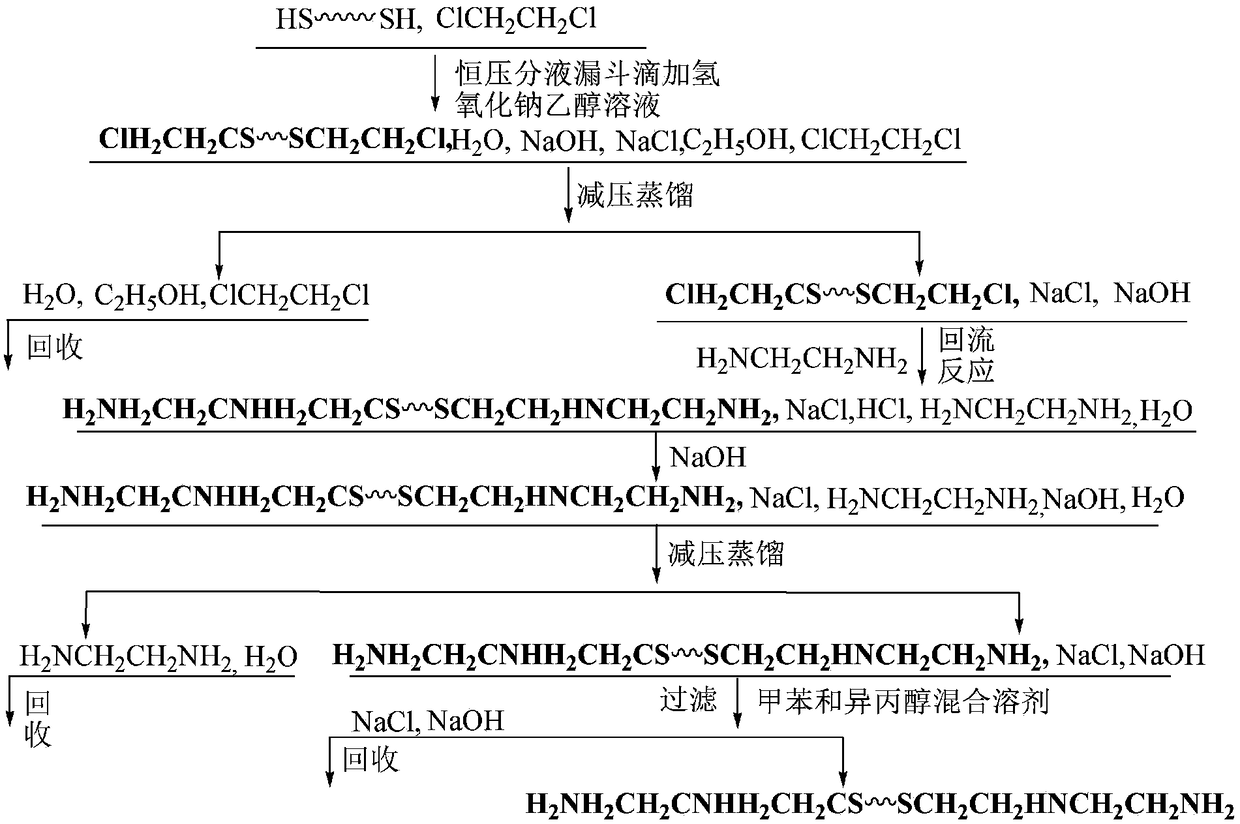

[0030] One aspect of the present invention provides the preparation method of epoxy resin curing agent, it comprises: step 1 sodium hydroxide solid is added in the beaker, add dehydrated alcohol, carry out ultrasonic dissolution in ultrasonic cleaner, the obtained sodium hydroxide ethanol The solution was introduced into No. 1 constant pressure separatory funnel with a glass rod.

[0031] Step 2 In the No. 1 three-neck flask equipped with a thermometer, a mechanical stirrer, and a No. 1 constant-pressure separating funnel, add polysulfide rubber and 1,2-dichloroethane to mix, and stir it evenly with a mechanical stirrer. Ethyl chloride can completely dissolve the polysulfide rubber, open the No. 1 constant pressure separating funnel, add sodium hydroxide ethanol solution dropwise to the No. 1 three-necked flask, and stir the reaction at a constant temperature of 50°C to 70°C for 2.5h to 3.5h. The speed is 200-400r / min, and the intermediate product is obtained.

[0032] In ste...

Embodiment 1

[0046] Add solid sodium hydroxide to a beaker, add absolute ethanol, perform ultrasonic dissolution in an ultrasonic cleaner, and use a glass rod to guide the obtained sodium hydroxide ethanol solution into No. 1 constant-pressure separating funnel.

[0047] In the No. 1 three-necked flask equipped with a thermometer, a mechanical stirrer, and a No. 1 constant-pressure separating funnel, add 1 molar amount of polysulfide rubber and 4 molar amounts of 1,2-dichloroethane to mix, and mechanically Stir it evenly with a stirrer, dichloroethane can completely dissolve the polysulfide rubber, open the No. 1 constant pressure separating funnel, add sodium hydroxide ethanol solution dropwise to the No. 1 three-necked flask, and stir and react at a constant temperature of 50°C for 3.5h , the stirring speed was 400r / min, and the intermediate product was obtained. After the temperature dropped to room temperature, the obtained intermediate product was distilled under reduced pressure, and...

Embodiment 2

[0052] Add solid sodium hydroxide to a beaker, add absolute ethanol, perform ultrasonic dissolution in an ultrasonic cleaner, and use a glass rod to guide the obtained sodium hydroxide ethanol solution into No. 1 constant-pressure separating funnel.

[0053] In the No. 1 three-necked flask equipped with a thermometer, a mechanical stirrer, and a No. 1 constant-pressure separating funnel, add 1 molar amount of polysulfide rubber and 4 molar amounts of 1,2-dichloroethane to mix, and mechanically Stir it evenly with a stirrer, dichloroethane can completely dissolve the polysulfide rubber, open the No. 1 constant pressure separating funnel, add sodium hydroxide ethanol solution dropwise to the No. 1 three-necked flask, and stir the reaction at a constant temperature of 60 ° C for 3 hours. The stirring speed was 300r / min, and an intermediate product was obtained. After the temperature dropped to room temperature, the obtained intermediate product was distilled under reduced pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com