Polyurethane urea dispersoid, adhesive composition and application thereof in preparation of zero-aldehyde-added ultrathin high-density fiberboard

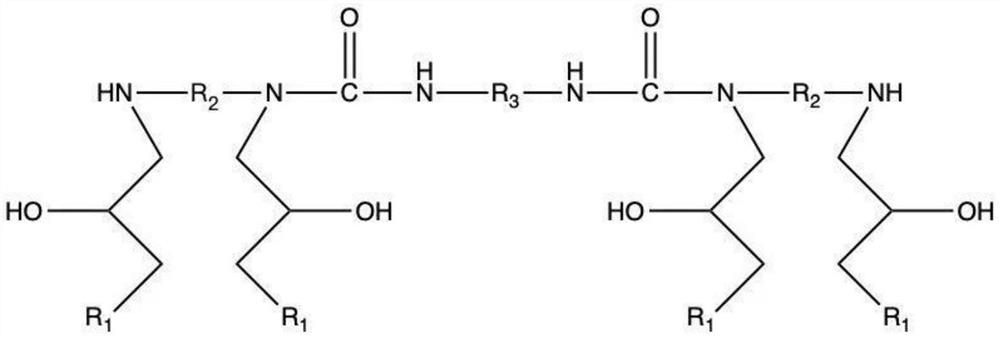

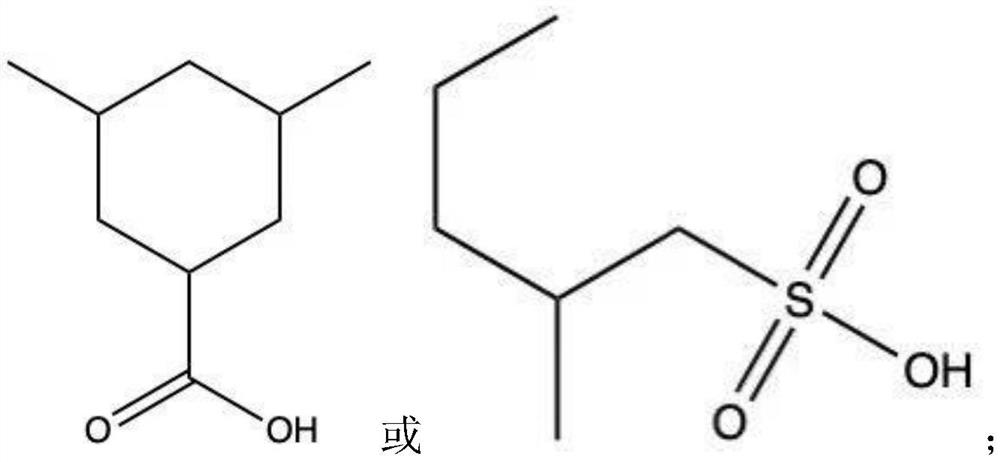

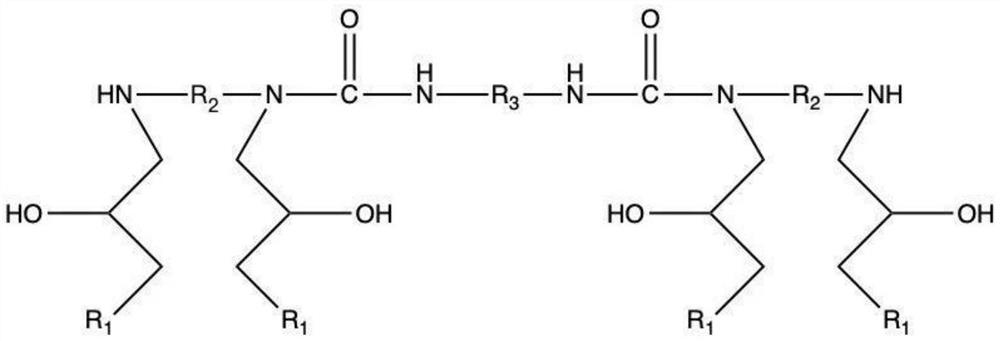

A polyurethane urea and dispersion technology, which is applied in the field of ultra-thin and high-density fiberboard with zero aldehyde addition, can solve the problems of easy corruption, obstacles to batch production, and low strength of biomass adhesives, so as to increase the active hydrogen content and improve the initial strength. Viscosity and solubility enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] In a 50L reactor equipped with a stirrer, a thermometer, and a condenser, put 50 parts by mass of polyurea polyol I, 19.3 parts by mass of isocyanate II, 20 parts by mass of polyester polyol I through dehydration, and 2.37 parts by mass. Parts by mass of diethanolamine and 0.1 part by mass of bismuth neodecanoate were stirred at 80-90° C. until the NCO reached 0.72%. The resulting prepolymer was dissolved in 100 parts by mass of acetone and cooled to 48°C. Add 8.33 parts by mass of N-(2-aminoethyl)-2-aminoethanesulfonate sodium and 100 parts by mass of water to the acetone solution in which the prepolymer is dissolved and stir for 20 minutes to fully disperse, and use triethylamine to dissolve the water dispersion The pH was adjusted to 8. After high-speed emulsification and separation of acetone by distillation under reduced pressure, an aqueous dispersion of polyurethane urea was obtained, which had a solid content of 50 wt%.

[0077] The combination materials used ...

Embodiment 2

[0081] In a 50L reactor equipped with a stirrer, a thermometer, and a condenser, put 43 parts by mass of polyurea polyol II through dehydration treatment, 27.3 parts by mass of isocyanate I, 22 parts by mass of polyester polyol II through dehydration treatment, 1.84 Parts by mass of N-methyl-n-propylamine and 0.15 parts by mass of bismuth neodecanoate were stirred at 80-90° C. until the NCO reached 0.53%. The resulting prepolymer was dissolved in 100 parts by mass of acetone and cooled to 48°C. Add 5.86 parts by mass of N-(3-aminopropyl)-3-aminopropanesulfonate sodium and 100 parts by mass of water to the acetone solution in which the prepolymer is dissolved, and stir vigorously for 20 minutes to fully disperse, and use triethylamine to dissolve the water The pH of the dispersion was adjusted to 7.8. After high-speed emulsification and separation of acetone by distillation under reduced pressure, an aqueous dispersion of polyurethane urea was obtained, which had a solid conte...

Embodiment 3

[0086]In a 50L reactor equipped with a stirrer, a thermometer, and a condenser, put 39 parts by mass of polyurea polyol III through dehydration treatment, 19.45 parts by mass of isocyanate I, 30 parts by mass of polyester polyol I through dehydration treatment, 8.6 In parts by mass of diethanolamine, 0.08 parts by mass of bismuth neodecanoate was stirred at 80-90° C. until the NCO reached 0.68%. The resulting prepolymer was dissolved in 100 parts by mass of acetone and cooled to 48°C. 2.95 parts by mass of sodium N-(2-aminoethyl)-2-aminoethanesulfonate and 100 parts by mass of water were added to the acetone solution in which the prepolymer was dissolved while vigorously stirring. Stir for 20 minutes to fully disperse, emulsify at high speed, and distill under reduced pressure to separate acetone to obtain an aqueous dispersion of polyurethane urea, which has a solid content of 50 wt%.

[0087] The combination materials used for ultra-thin high-density fiberboard with zero al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com