Insulated sealing device and method of variable-frequency drive

A technology of insulation sealing and frequency converter, which is applied in the direction of output power conversion devices, sealed casings, electrical components, etc., can solve the problems of poor sealing effect of external electrolytic capacitors, complicated parts processing technology, high maintenance cost, etc., and achieve good insulation and sealing , not easy to wear, fixed and firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

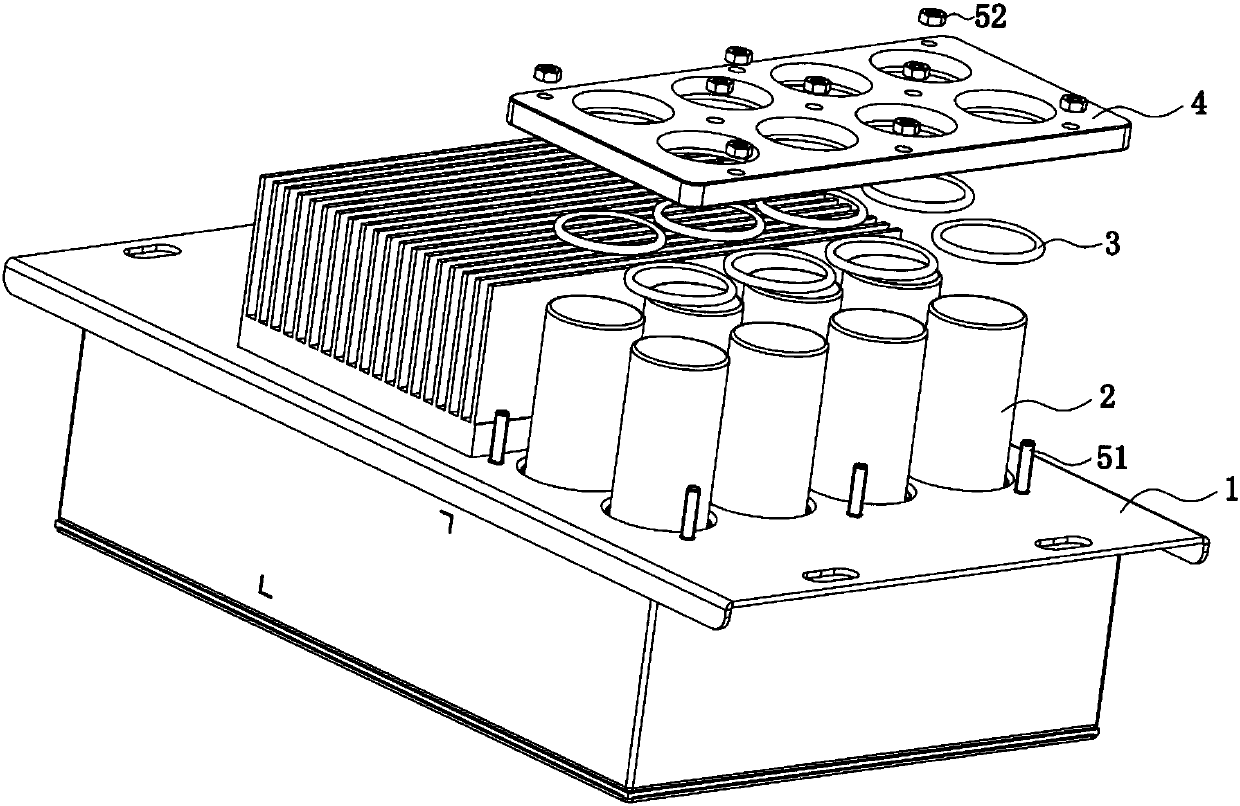

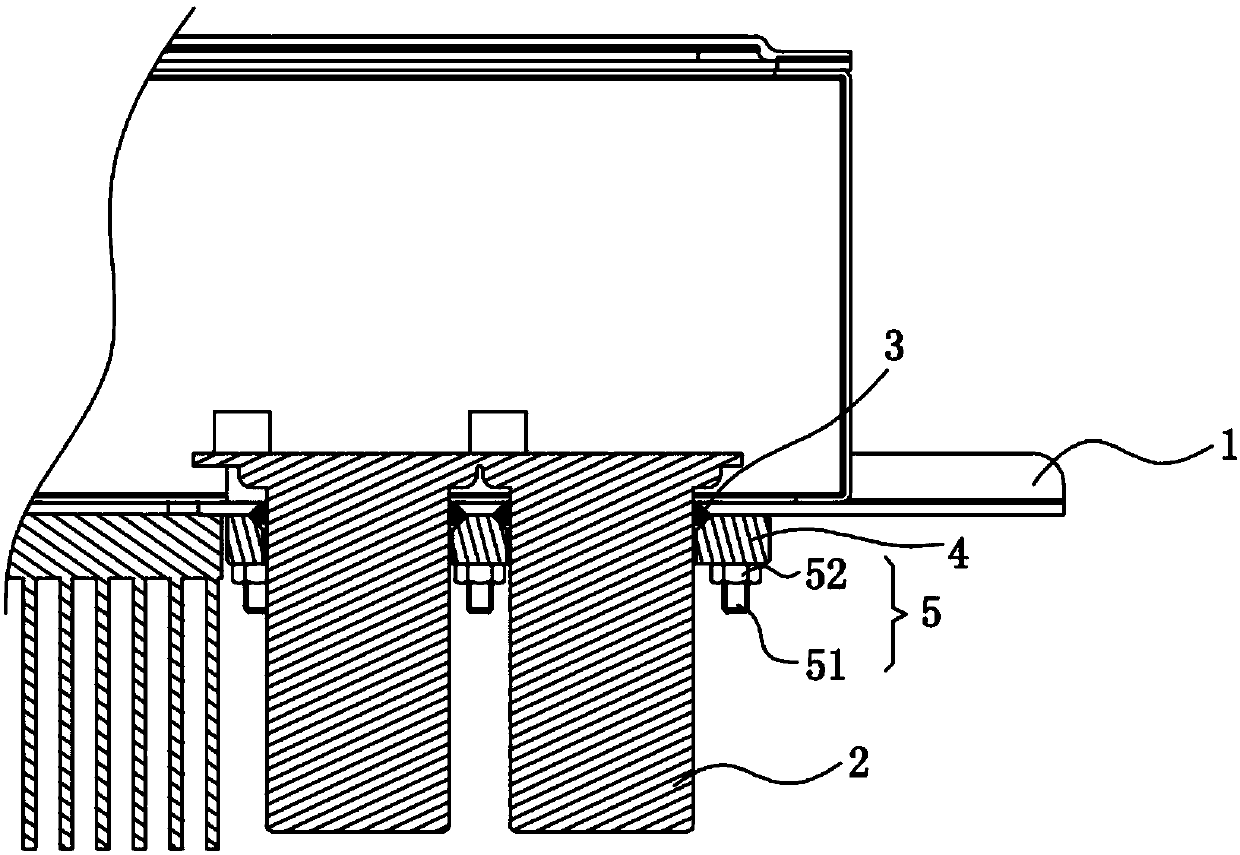

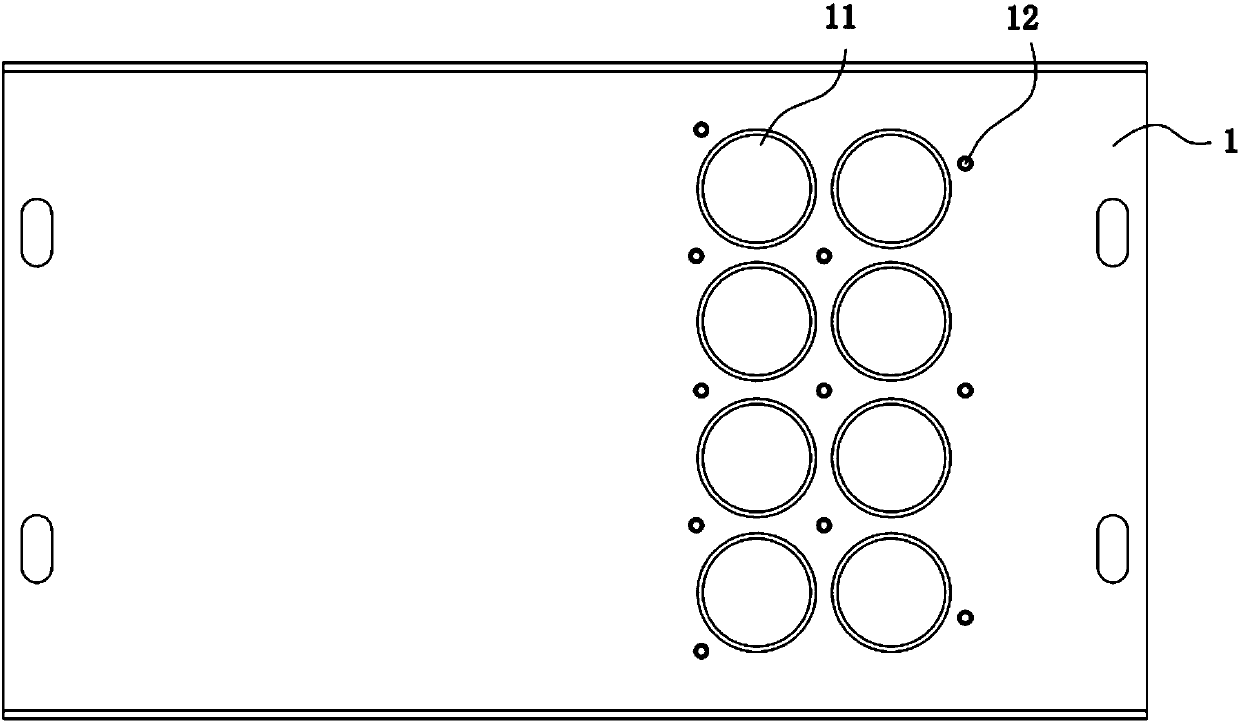

[0039] see figure 1 and figure 2 The free end of the electrolytic capacitor 2 and the radiator are placed outside the inverter housing 1 of this embodiment, and the radiator is arranged on one side of the electrolytic capacitor 2 to dissipate heat for high-power components in the inverter. During the working process of the radiator, hot air will be generated, and dust will also be deposited. The electrolytic capacitor 2 is installed near the heat sink, which is equivalent to being installed near the dusty environment. The dust in the local air can fall into the inside of the inverter housing 1 through the gap between the electrolytic capacitor 2 and the inverter housing 1, thereby affecting Normal operation of the inverter.

[0040] In view of this, this embodiment discloses an insulating and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com