Device and method for purifying flue gases

A flue gas purification and flue gas technology, applied in chemical instruments and methods, separation methods, electrostatic effect separation, etc., can solve the problems of low nitric oxide oxidation efficiency, difficulty in bipolar discharge, etc. Abrasion, effect of low dust concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment is used to illustrate the device and method for purifying flue gas provided by the present invention.

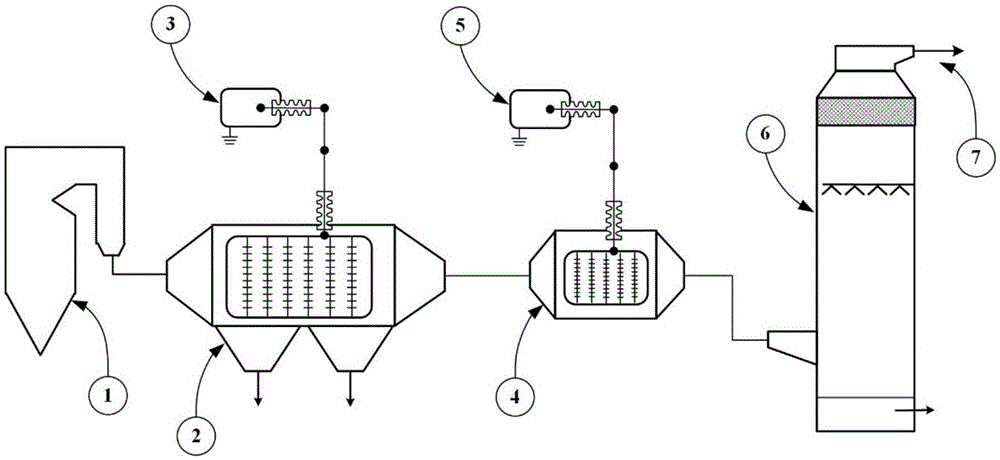

[0058] (1) Construction of the device

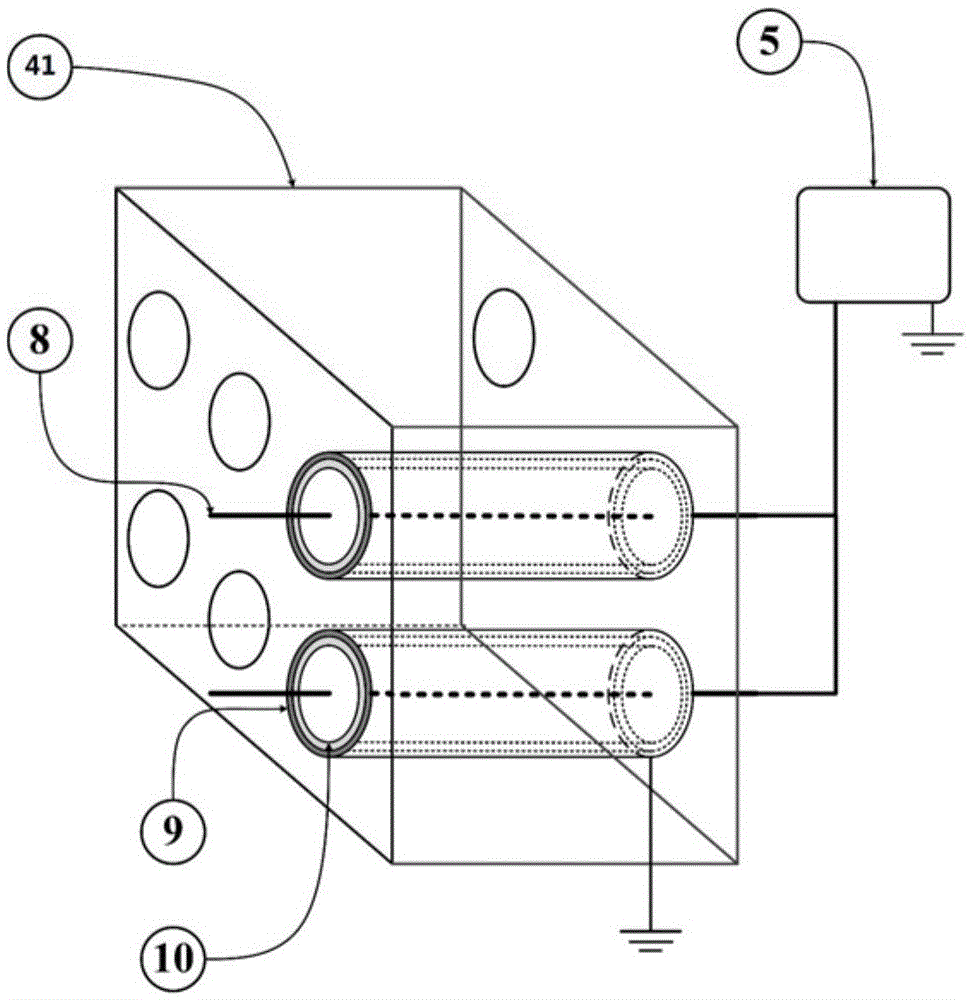

[0059] Connect boiler 1, electrostatic precipitator 2, dielectric barrier discharge reactor 41, and wet desulfurization equipment 6 sequentially, the outlet of dielectric barrier discharge reactor 41 is connected to the inlet of the absorption tower of wet desulfurization equipment 6, and electrostatic precipitator 2 is connected to The first high-voltage power supply 3 (single-phase DC high-voltage power supply), the dielectric barrier discharge reactor 41 is connected to the second high-voltage power supply 5 (ZH2006 pulse high-voltage power supply, peak voltage 60kV, discharge frequency 300Hz), and the flue gas is installed on the wet desulfurization equipment 6. Gas outlet 7. get figure 1 The flue gas cleaning device shown.

[0060] (2) Flue gas purification

[0061] according to figure 1 The flue gas de...

Embodiment 2

[0065] This embodiment is used to illustrate the device and method for purifying flue gas provided by the present invention.

[0066] (1) Construction of the device

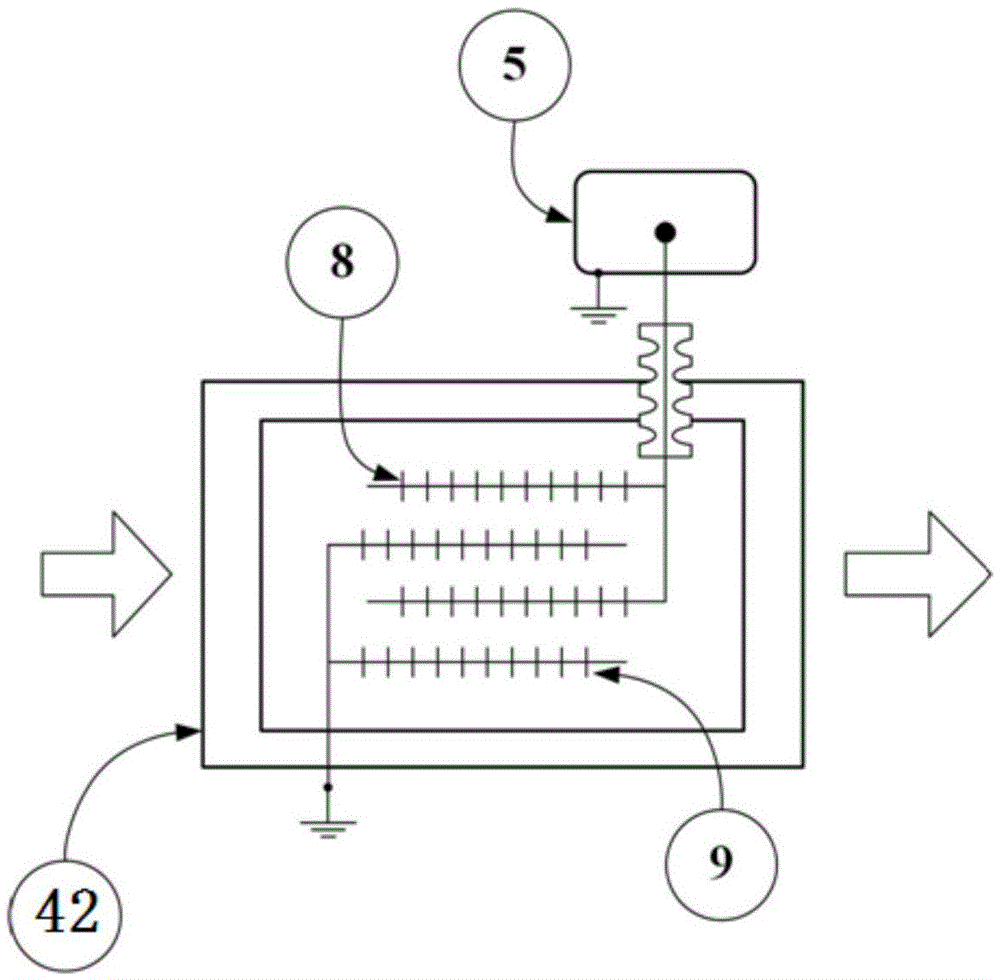

[0067] Connect boiler 1, electrostatic precipitator 2, streamer corona discharge reactor 42, and wet desulfurization equipment 6 sequentially, the outlet of streamer corona discharge reactor 42 is connected to the inlet of the absorption tower of wet desulfurization equipment 6, and the electrostatic precipitator 2 Connect the first high-voltage power supply 3 (three-phase DC high-voltage power supply), and the streamer corona discharge reactor 42 is connected to the second high-voltage power supply 5 (bipolar DC high-voltage power supply, the negative polarity discharge is 72kV, and the positive polarity discharge is 60kV). The flue gas outlet 7 is set on the wet desulfurization equipment 6 . get figure 1 The flue gas cleaning device shown.

[0068] (2) Flue gas purification

[0069] according to figure 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com