Printed organic silicone synthetic leather and preparation method thereof

A silicone synthetic leather and printing technology, applied in application, coating, ink, etc., can solve the problems of ink difficulty, environmental hazards, and harmful substances, and achieve the effect of simple preparation method, clear layering, and rich variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

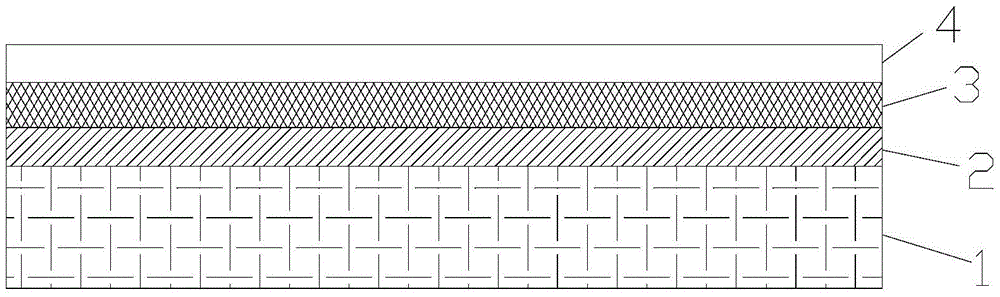

[0059] A kind of printing organosilicon synthetic leather of the present embodiment, such as figure 1 As shown, it includes a silicone layer 4 , an ink layer 3 , a colored silicone layer 2 and a substrate 1 which are sequentially connected together from top to bottom.

[0060] The thickness of the silica gel layer 4 is 0.01-0.10 mm.

[0061] The silica gel layer 4 is formed by vulcanizing transparent or translucent silica gel coated on release paper or film.

[0062] The ingredients and contents of the raw materials of the silica gel layer 4 are as follows:

[0063] Vinyl polydimethylsiloxane uses 69.6g of side chain vinyl silicone oil of 10000mpa.s, wherein Vi=1.0%.

[0064] Filler adopts the white carbon black 25g of model A200.

[0065] The platinum series catalyst adopts 0.3 g of chloroplatinic acid isopropanol solution, and the content of Pt atoms in the chloroplatinic acid isopropanol solution is 3000 ppm.

[0066] As the inhibitor, 0.1 g of methyl butynol was used.

...

Embodiment 2

[0094] The difference between this embodiment and Embodiment 1 is that the thickness of the silica gel layer 4 is controlled at 0.03mm.

Embodiment 3

[0096] The difference between this embodiment and Embodiment 1 is that the thickness of the silica gel layer 4 is controlled at 0.05 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com