Patents

Literature

122results about How to "Avoid uneven color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light-emitting apparatus and illuminating apparatus

InactiveUS20050211991A1Reduce light intensitySignificant rateOther plywood/veneer working apparatusMechanical surface treatmentColor temperatureEngineering

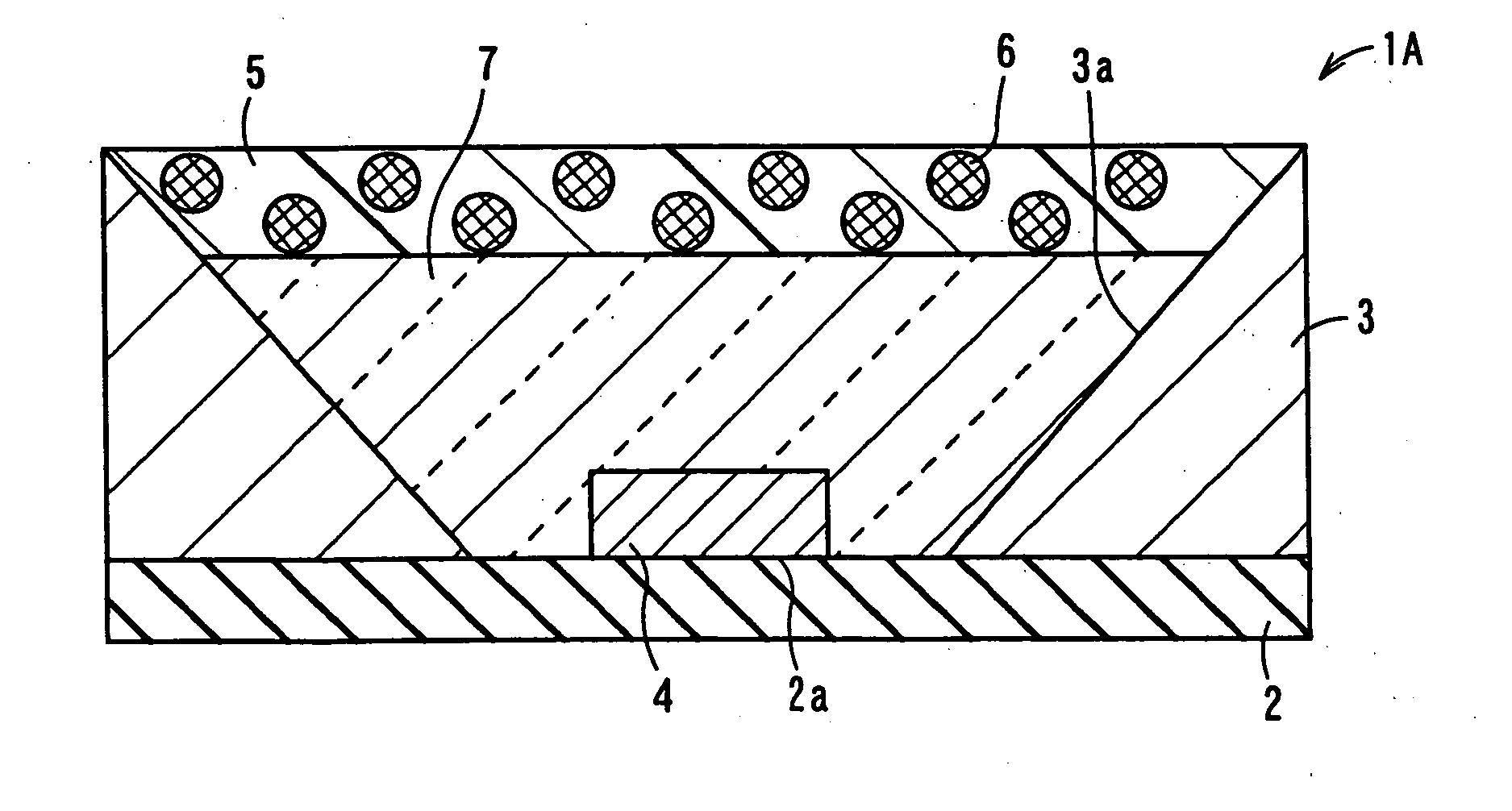

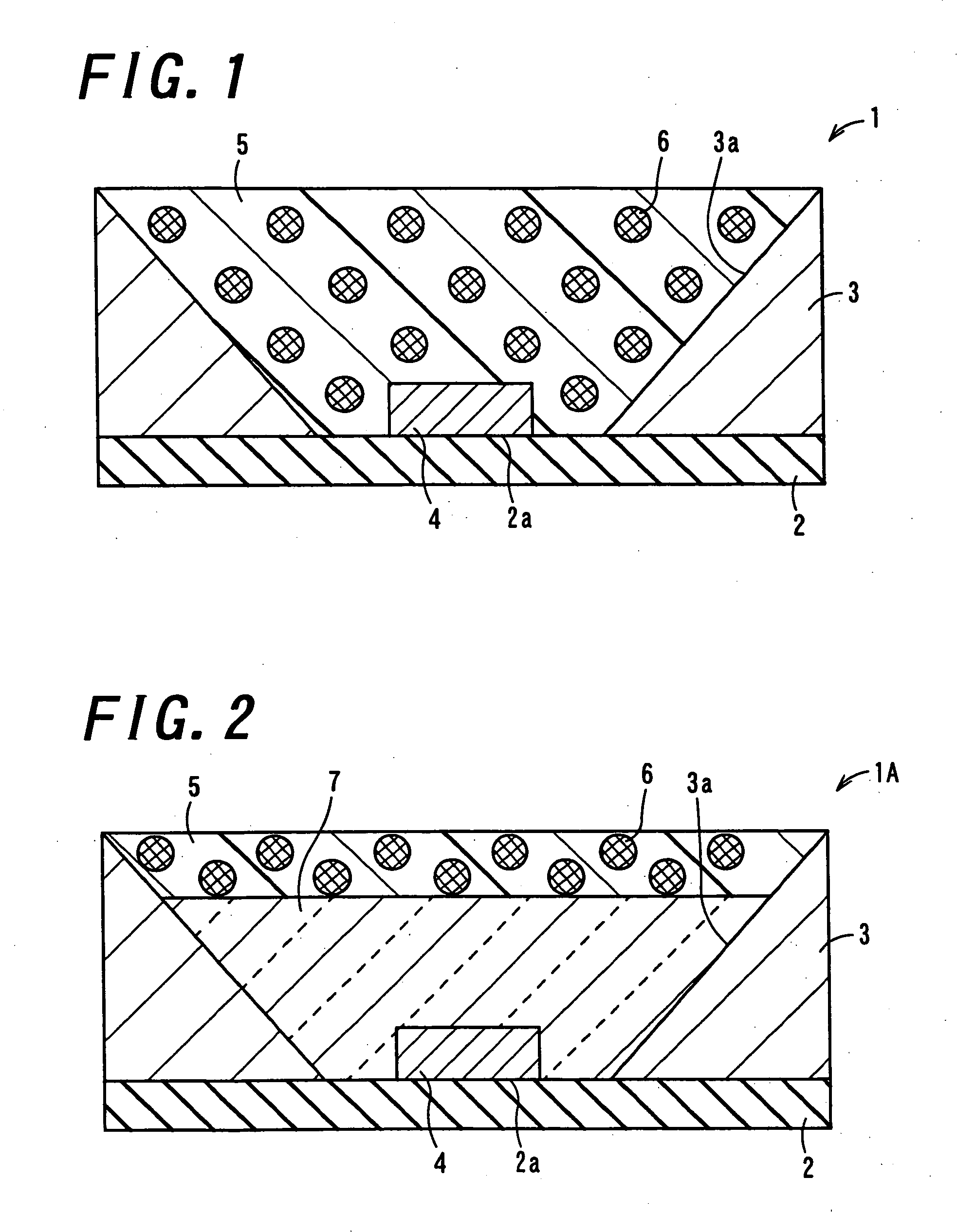

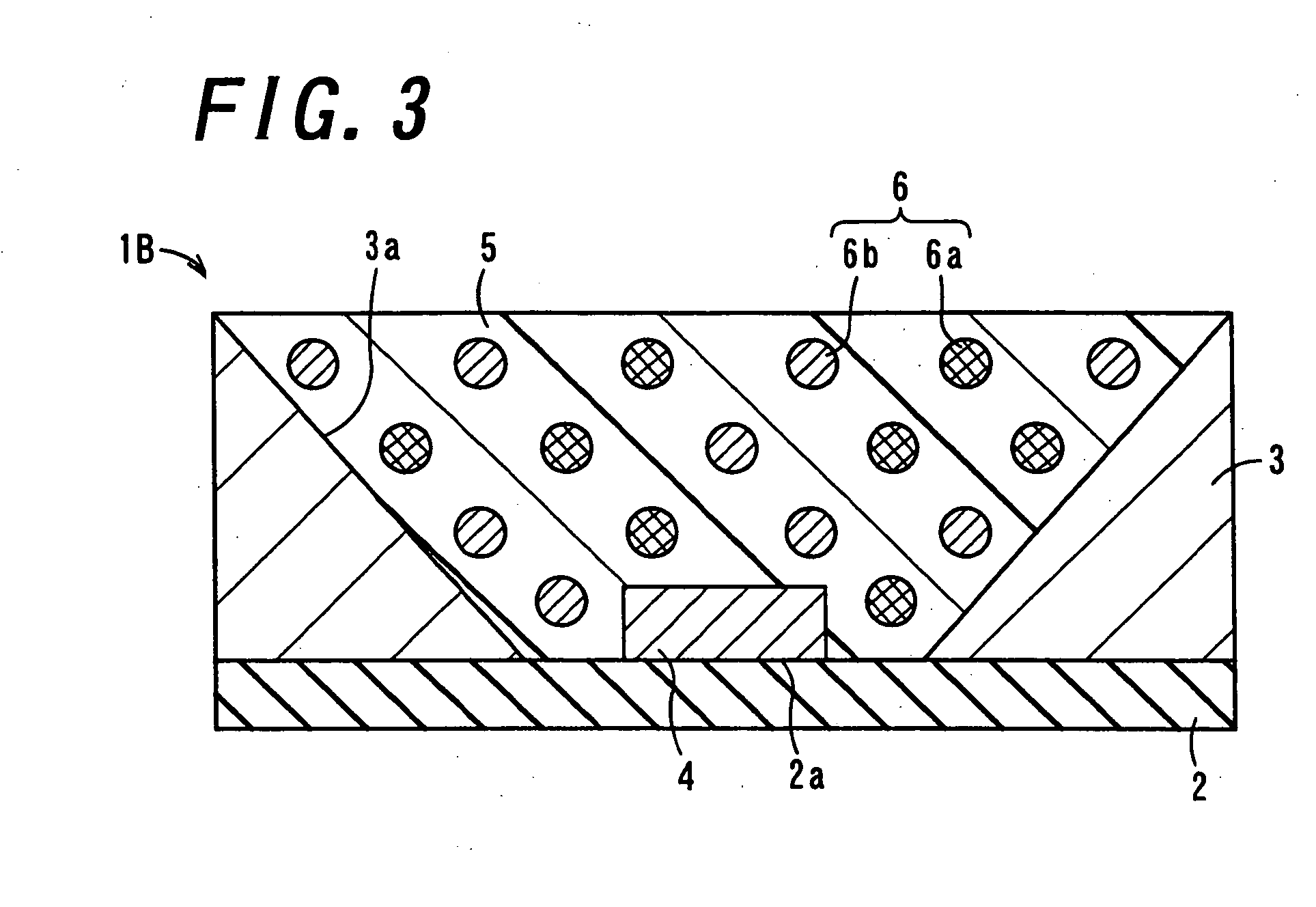

There is provided a light-emitting apparatus with favorable radiation light intensity, which is excellent in light extraction efficiency, color temperature and color rendering property. The light-emitting apparatus includes a light-emitting element, a base body having, on its top surface, a placement portion for emplacing thereon the light-emitting element, a frame body attached to the top surface of the base body so as to surround the placement portion, a light transmitting member disposed inside the frame body so as to cover the light-emitting element, and phosphors contained in the light transmitting member, which performs wavelength conversion on the light emitted from the light-emitting element. The light transmitting member has a pre-cured viscosity ranging from 0.4 to 50 Pa.s.

Owner:KYOCERA CORP

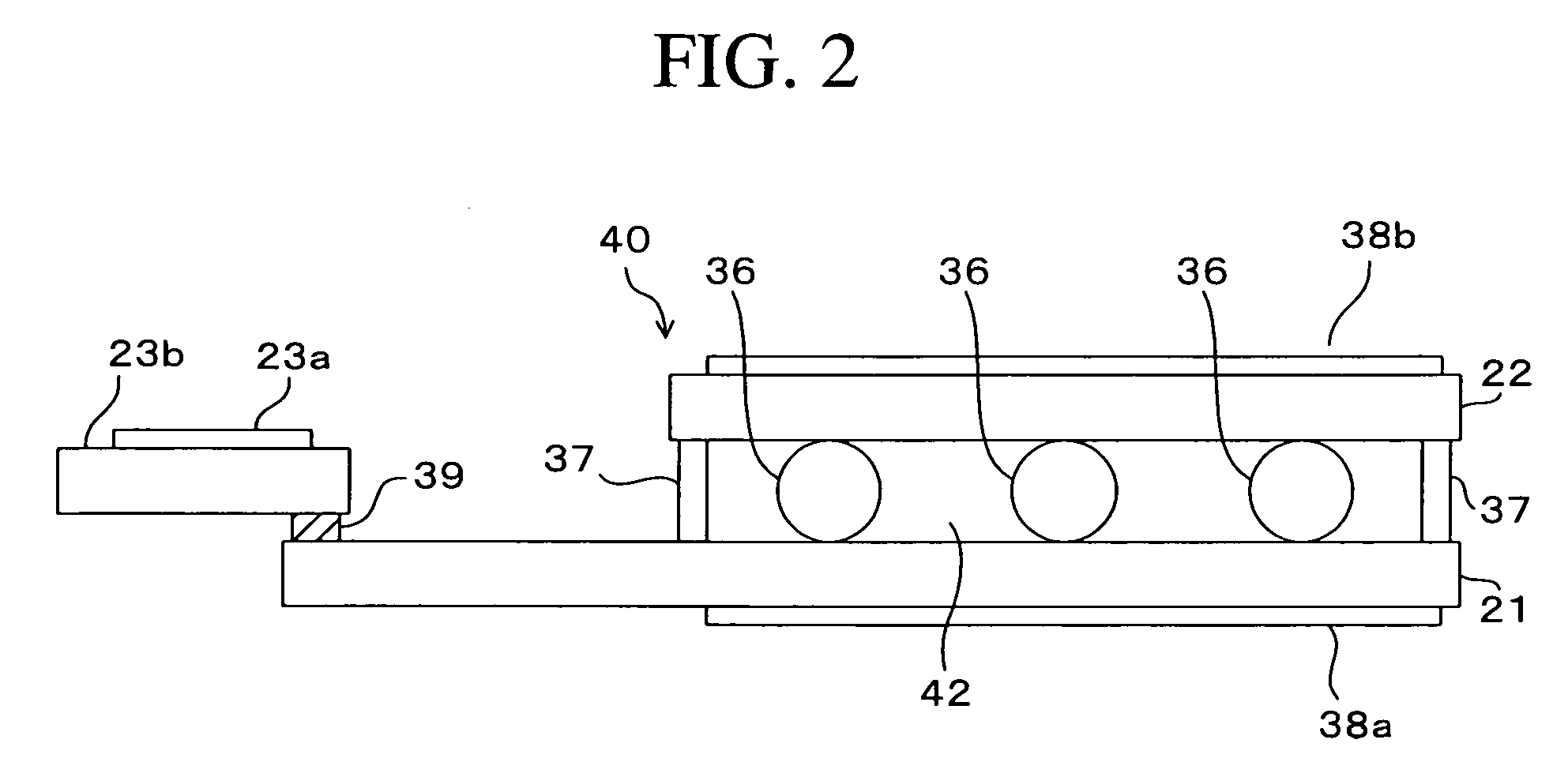

Emission device, surface light source device and display

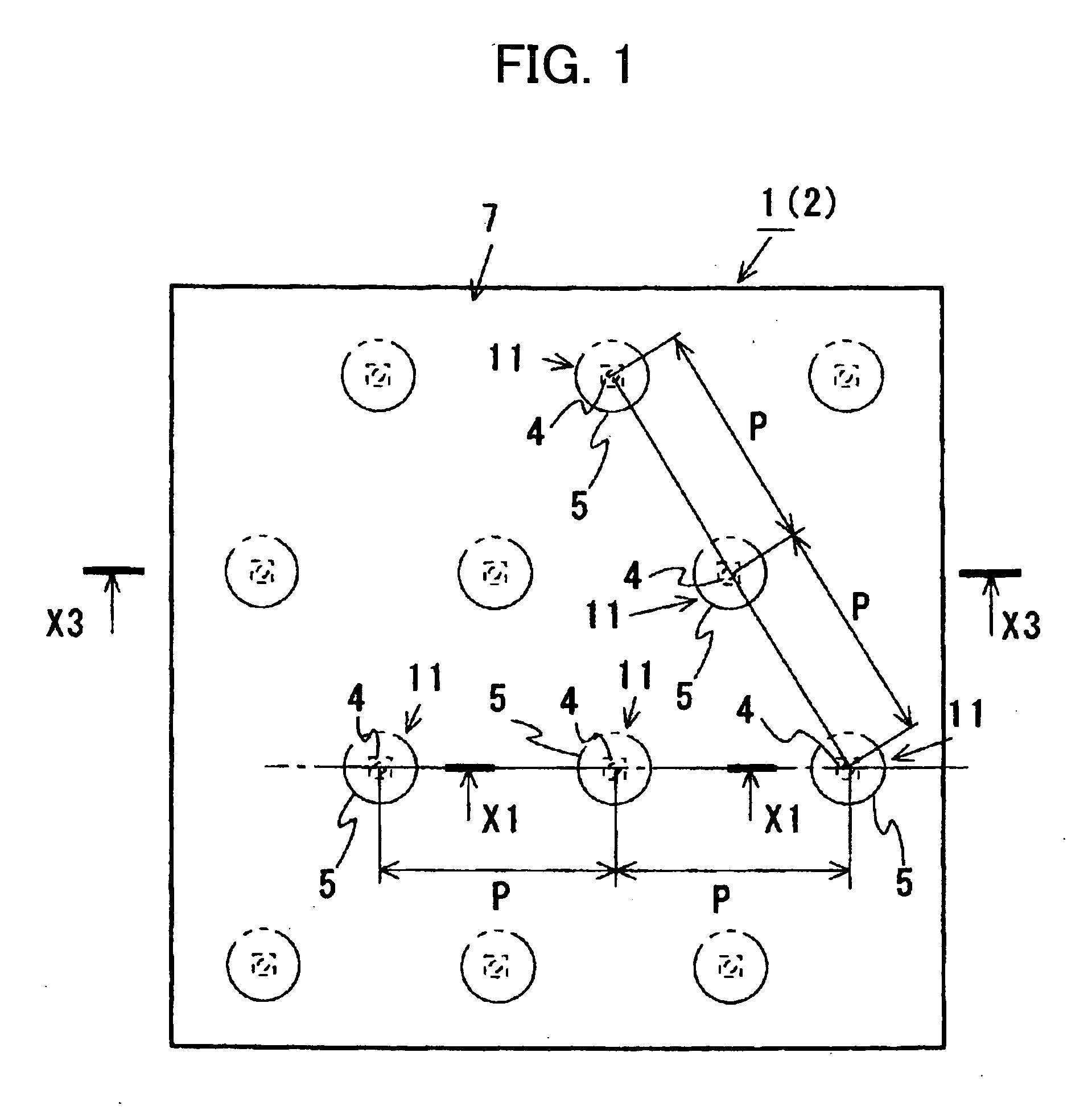

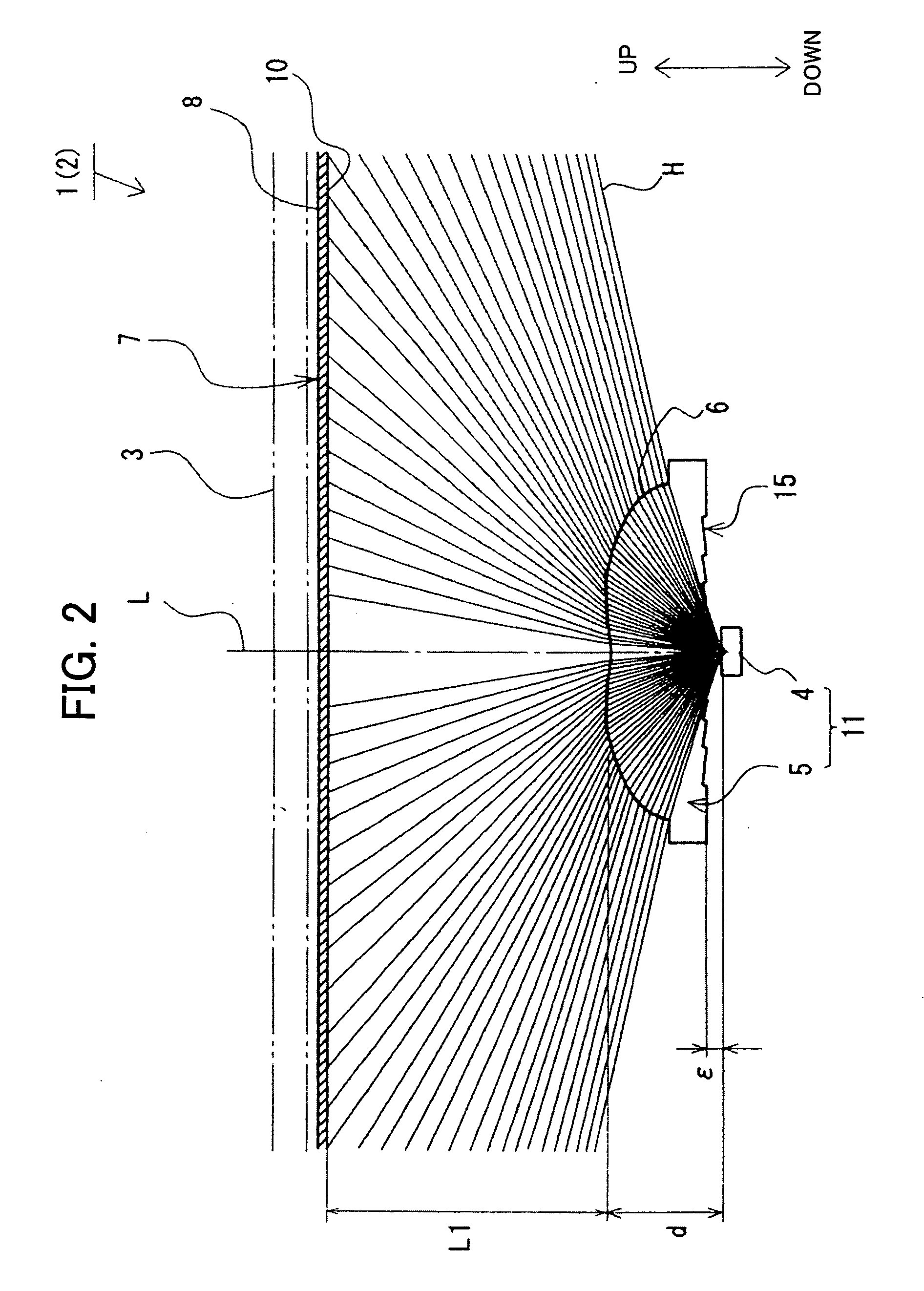

ActiveUS20090116245A1Reduces illumination qualityHigh qualityPoint-like light sourceElectric lightingLight fluxOptical axis

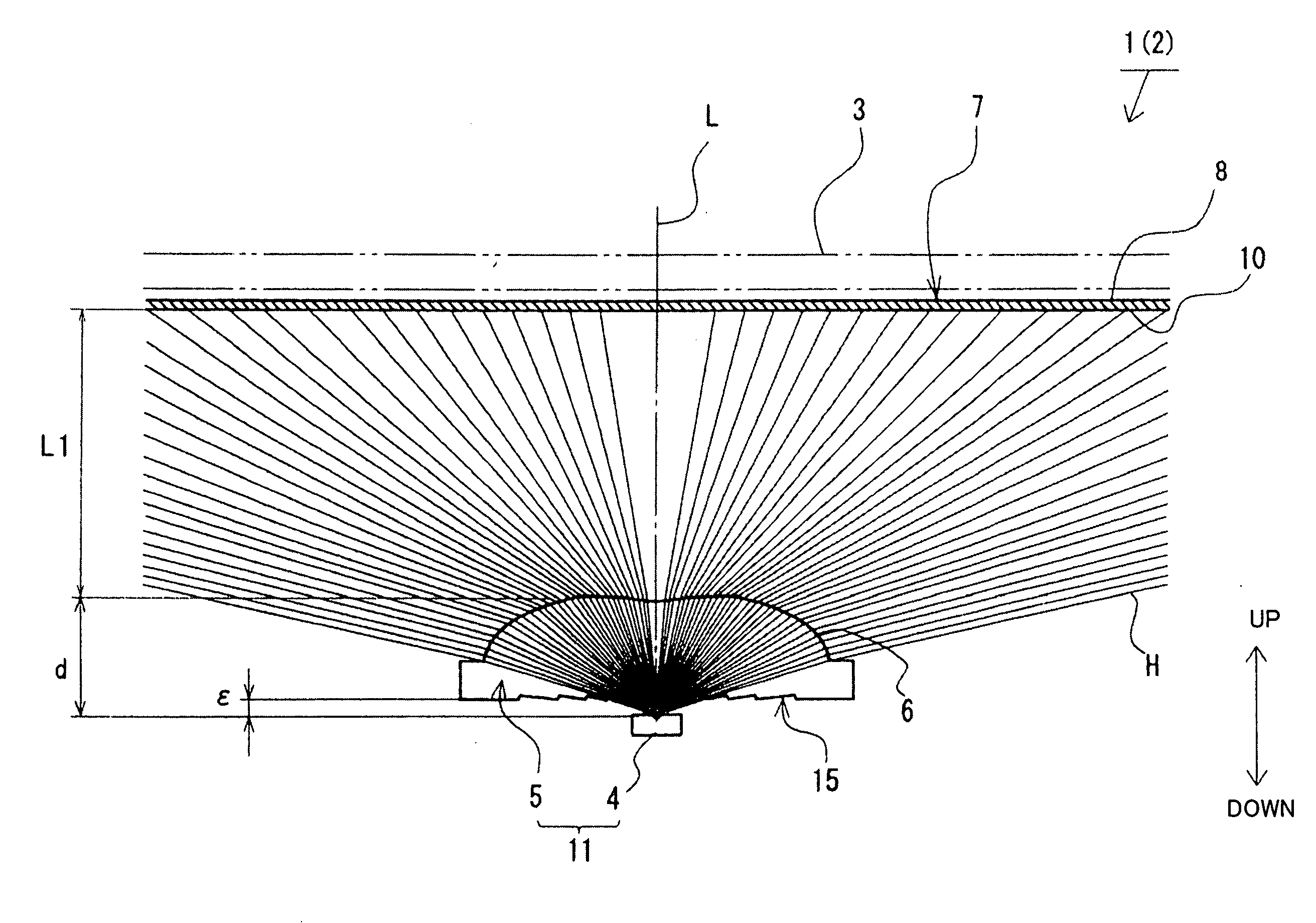

A light flux control member has a back face provided with a recess and a ring-like-recess-portion surrounding the recess. Output light of a point-like-light-source (light emission element) is incident to the recess and the ring-like-recess-portion. Incident light to the recess is emitted from a light control emission face after inner-propagation. Incident light to the ring-like-recess-portion is refracted as to hardly generate inner-propagation light deflected to directions near to a direction of reference optical axis L, resulting in outgoing from any part of the light control emission face, or, if some outgoing occurs from the light control emission face, such outgoing occurs only at an outer periphery portion of the light control emission face. As a result, illumination light quality is avoided from being reduced by appearance of conspicuous ring-like bright part. In addition, uniform illumination light can be supplied to a broad angle range. Even if a plurality of point-like-light-sources are arranged at intervals, respective light fluxes originated from respective point-like-light-sources are well mixed.

Owner:ENPLAS

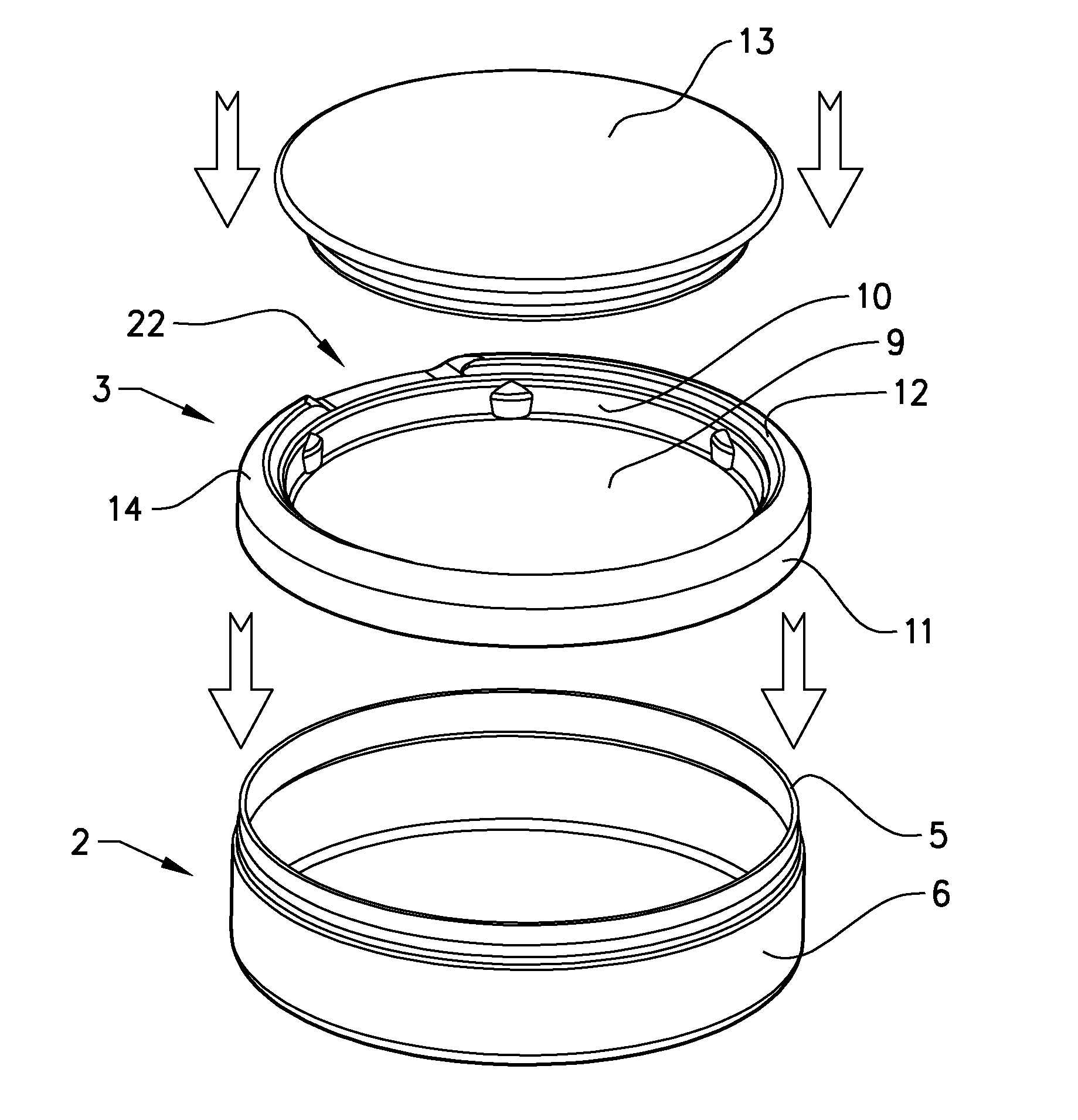

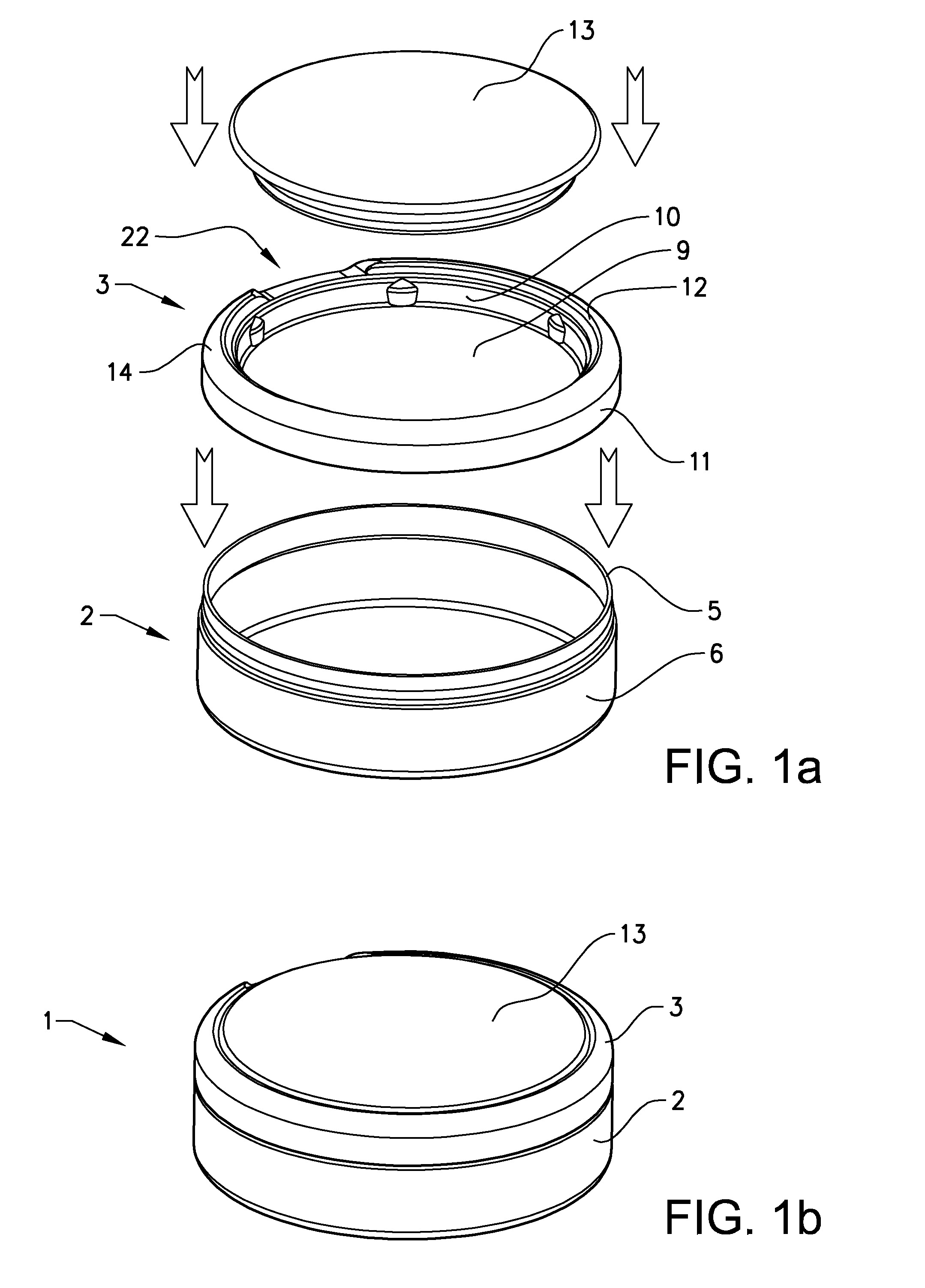

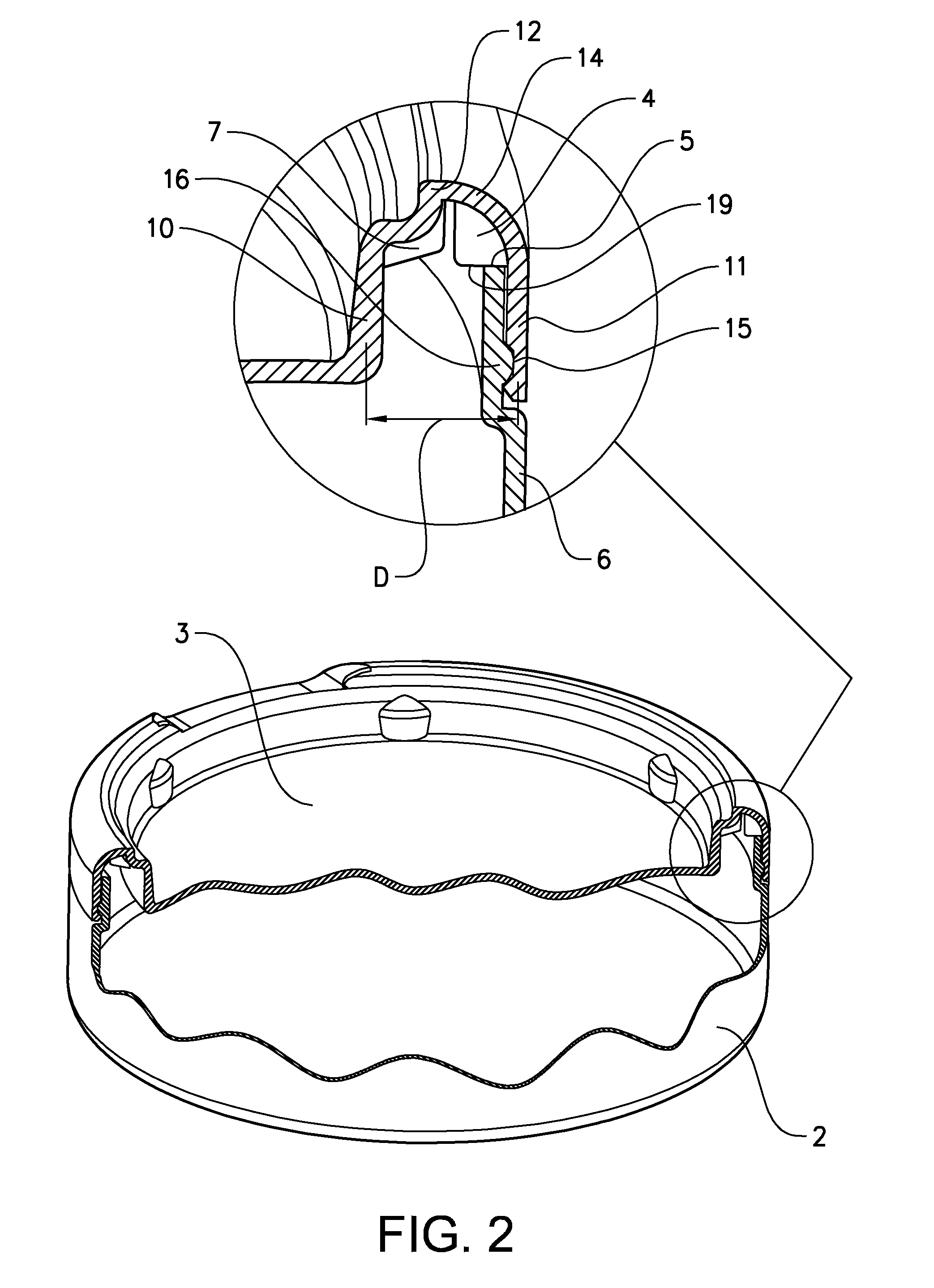

Container having a base and a lid

InactiveUS20160368670A1Easy to closeAvoid uneven colorClosure with auxillary devicesUsed articlesEngineering

The disclosure concerns a container (1) having a base (2) and a lid (3), wherein the lid (3) comprises a first plurality of abutment projections (4) positioned circumferentially spaced apart on an inside of the lid (3) and configured to contact an upwardly facing abutment surface (5) of a side wall (6) of the base (2) when the base (2) and lid (3) are arranged parallel to each other and pressed together to form a closed container. The lid (3) further comprises a second plurality of abutment projections (7) positioned circumferentially spaced apart on an inside of the lid (3) and configured to contact an upwardly facing abutment surface (5) of a side wall (6) of the base (2) when the base (2) and the lid (3) are arranged inclined to each other and pressed together. The disclosure concerns a container (1) having a base (2) and a lid (3), wherein the lid (3) comprises an upper wall (12) and at least two depressions (22) positioned spaced apart along the circumference of the upper wall (12).

Owner:SWEDISH MATCH NORTH EURO

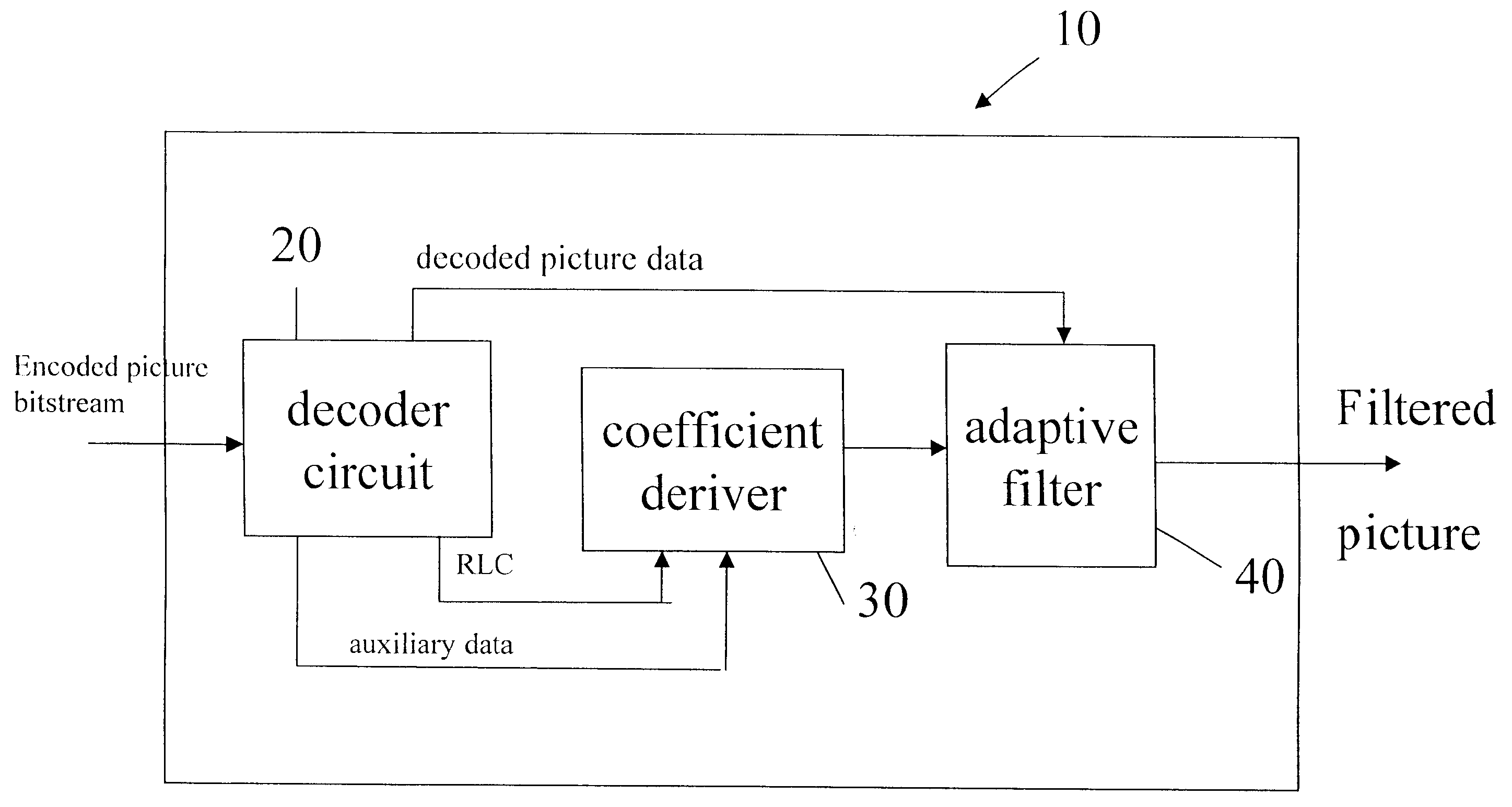

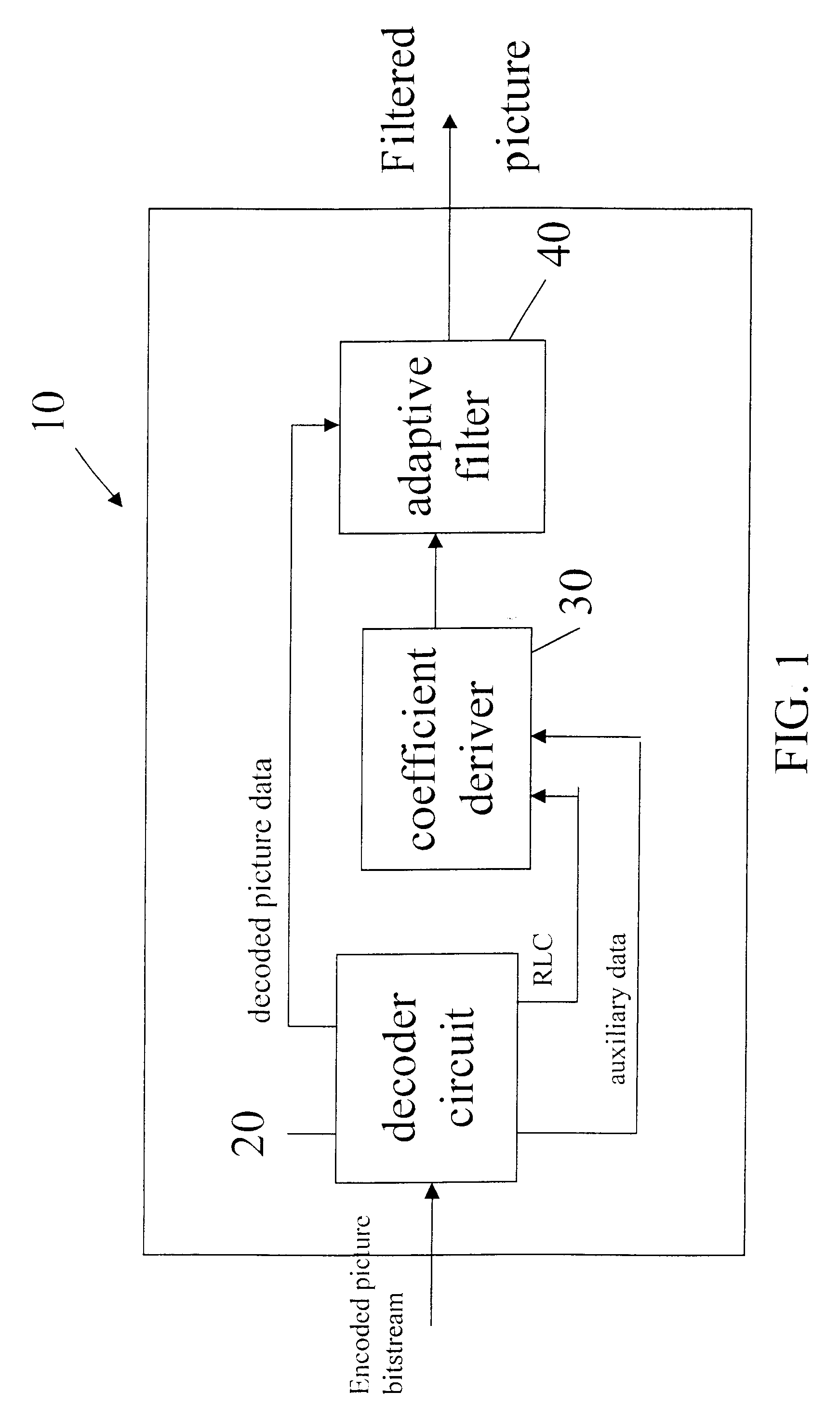

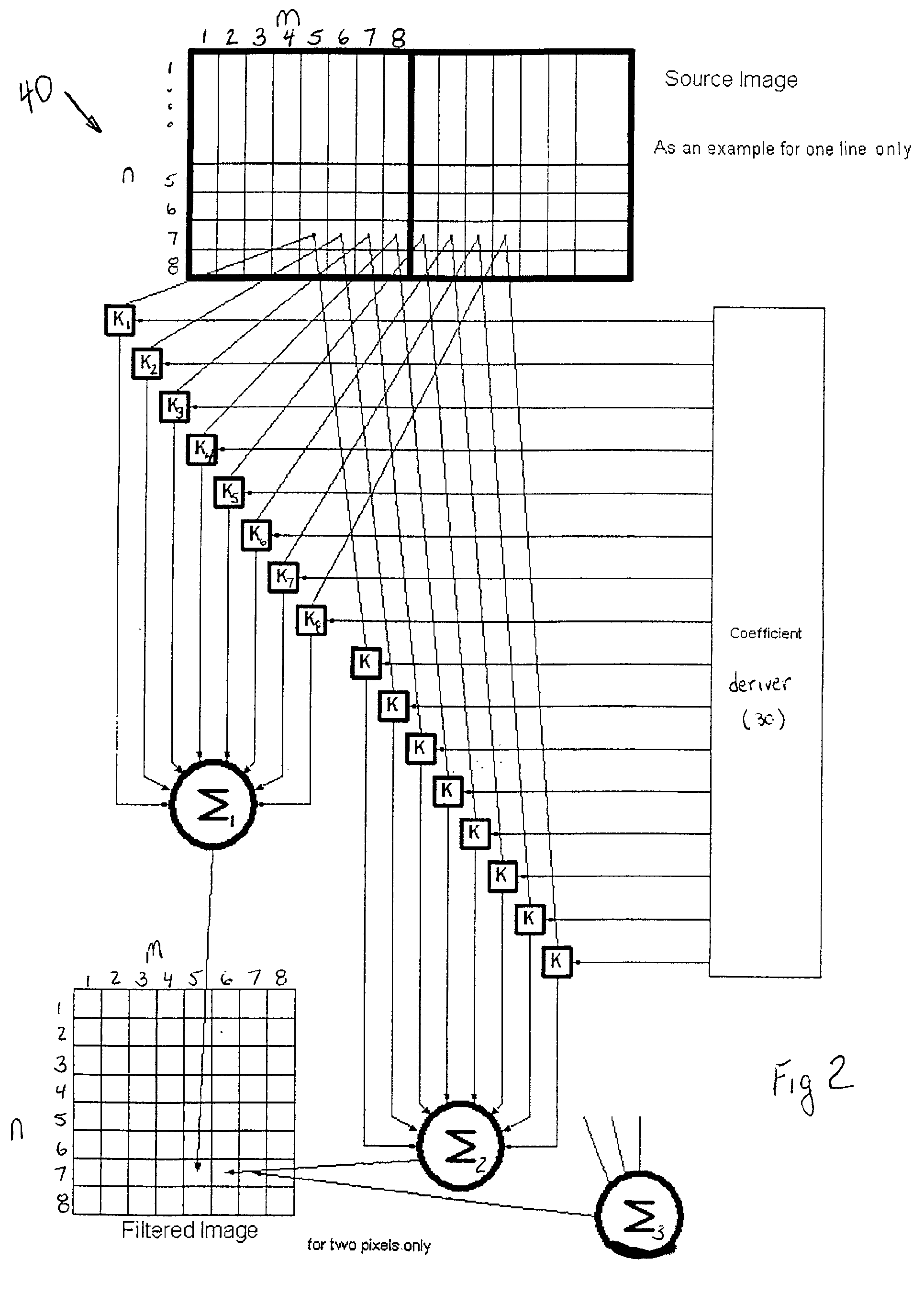

Method and apparatus for reducing the "blocky picture" effect in MPEG decoded images

InactiveUS6865229B1Reduce effectAvoid uneven colorImage enhancementPicture reproducers using cathode ray tubesAdaptive filterSelf adaptive

A method and apparatus for applying blockiness reduction techniques to encoded video or other picture images by utilizing the run-length codes of neighboring pixel blocks to adaptively filter the decoded pixel data of interest, thereby smoothing out the gradations of intensity and color between neighboring blocks of pixels. The present invention can adaptively filter pixel data within a single picture block as well as between blocks. The method comprises the step of obtaining the run-length codes of a first encoded picture block and a neighboring picture block, deriving filter coefficients based on the run-length codes of the first encoded picture block and the neighboring encoded picture block and providing the filter coefficients, decoded first picture data and neighboring picture data to an adaptive filter, and filtering the decoded picture data of the first and neighboring picture blocks, thereby producing an outputted filtered picture signal. The apparatus comprises the necessary structure to carry out this method.

Owner:PHILIPS ELECTRONICS NORTH AMERICA

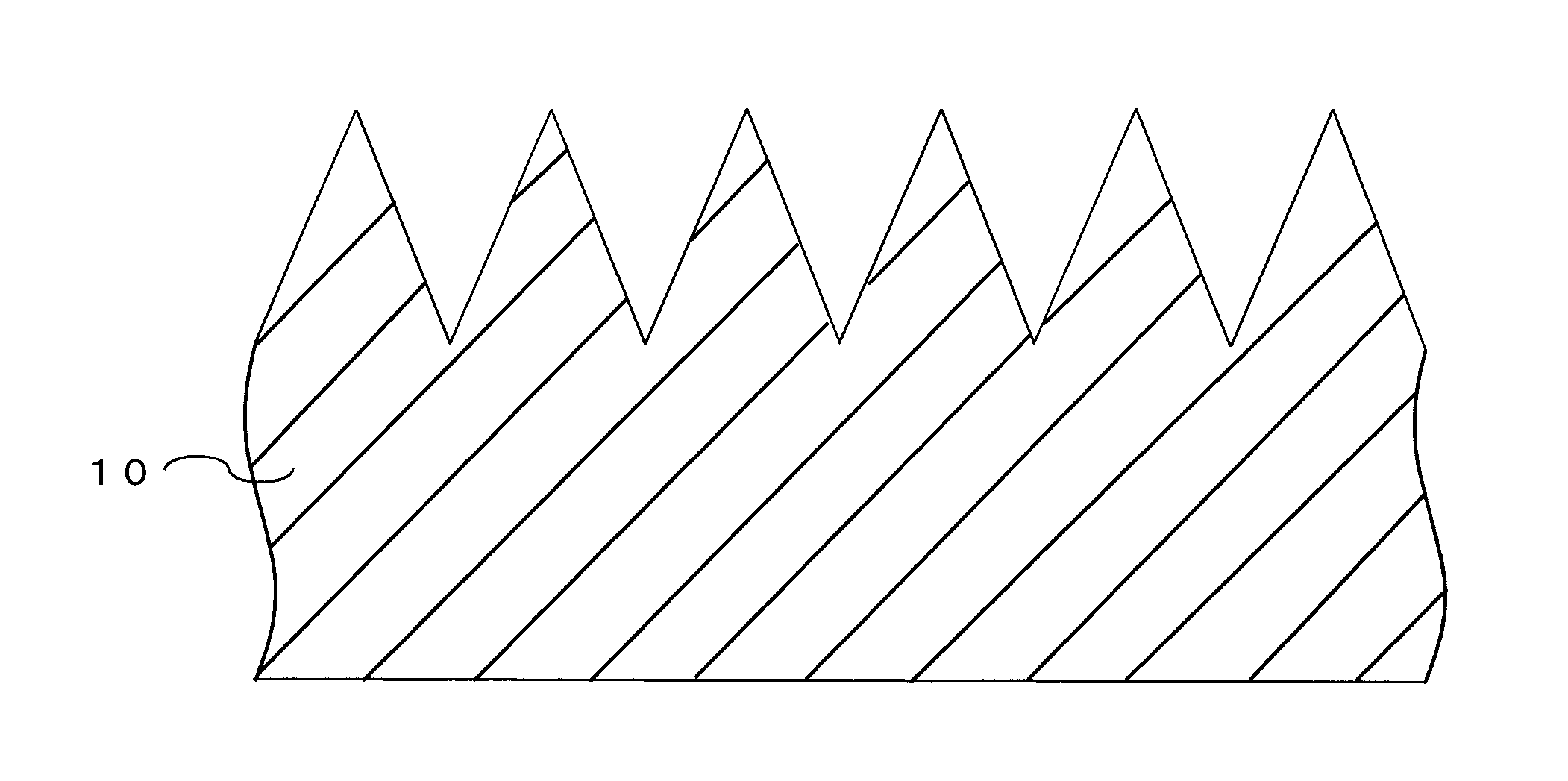

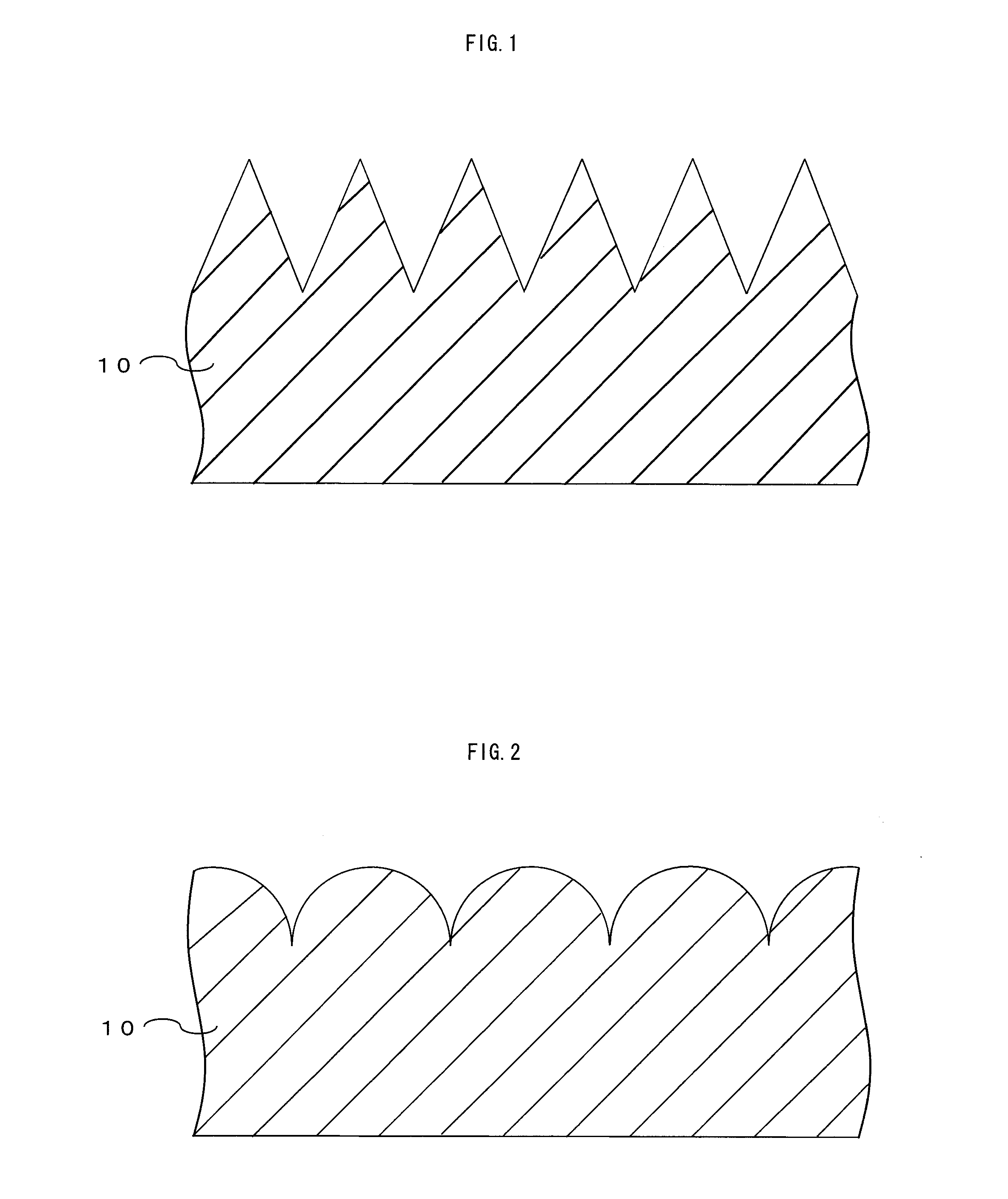

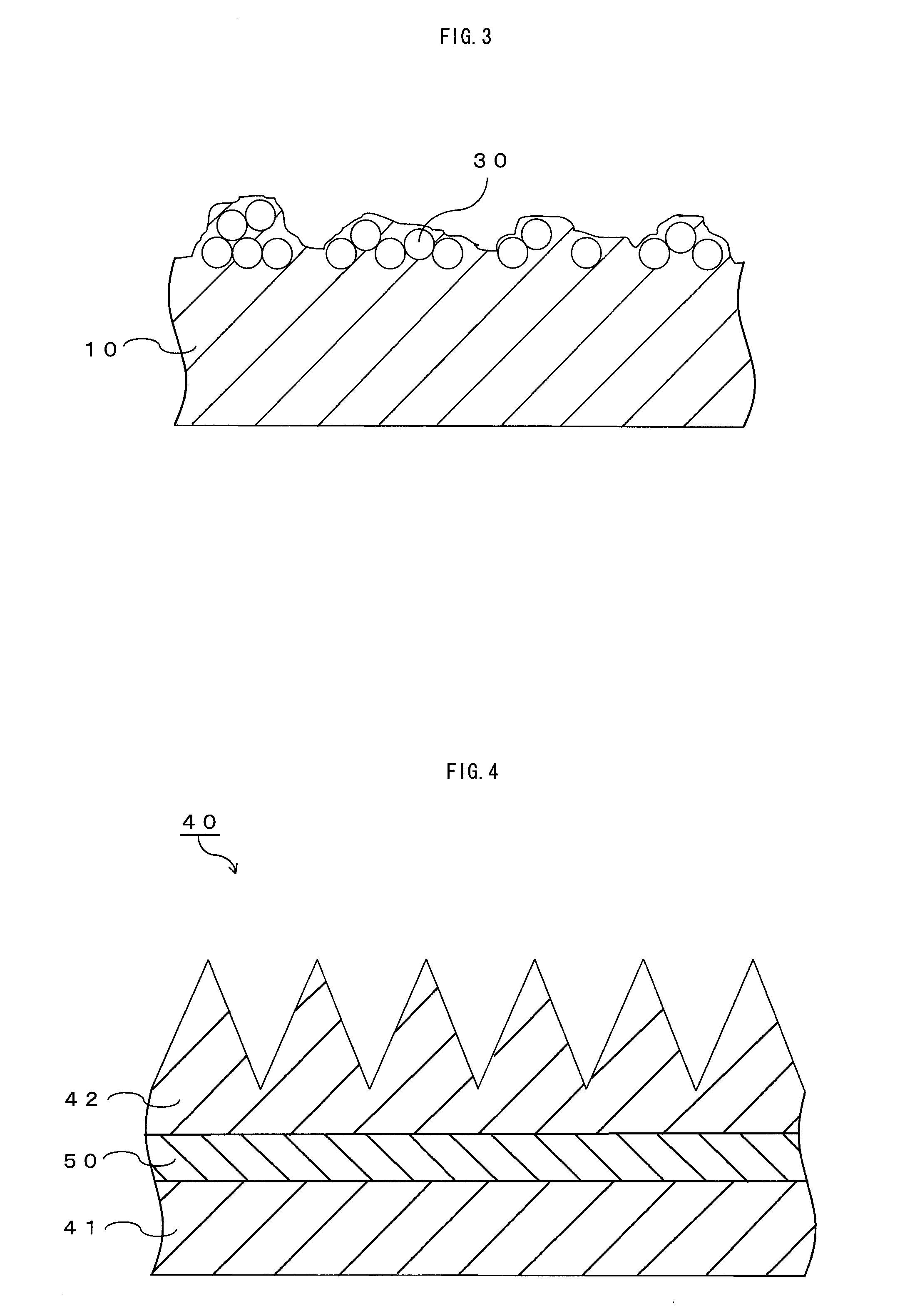

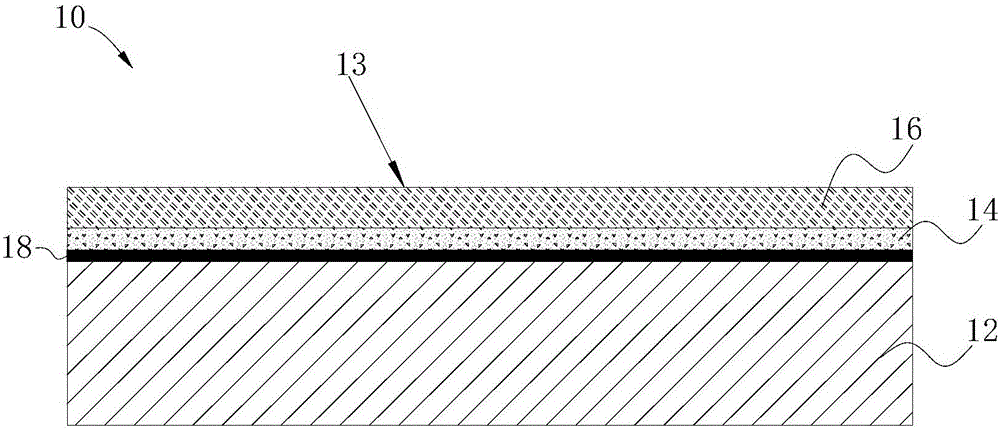

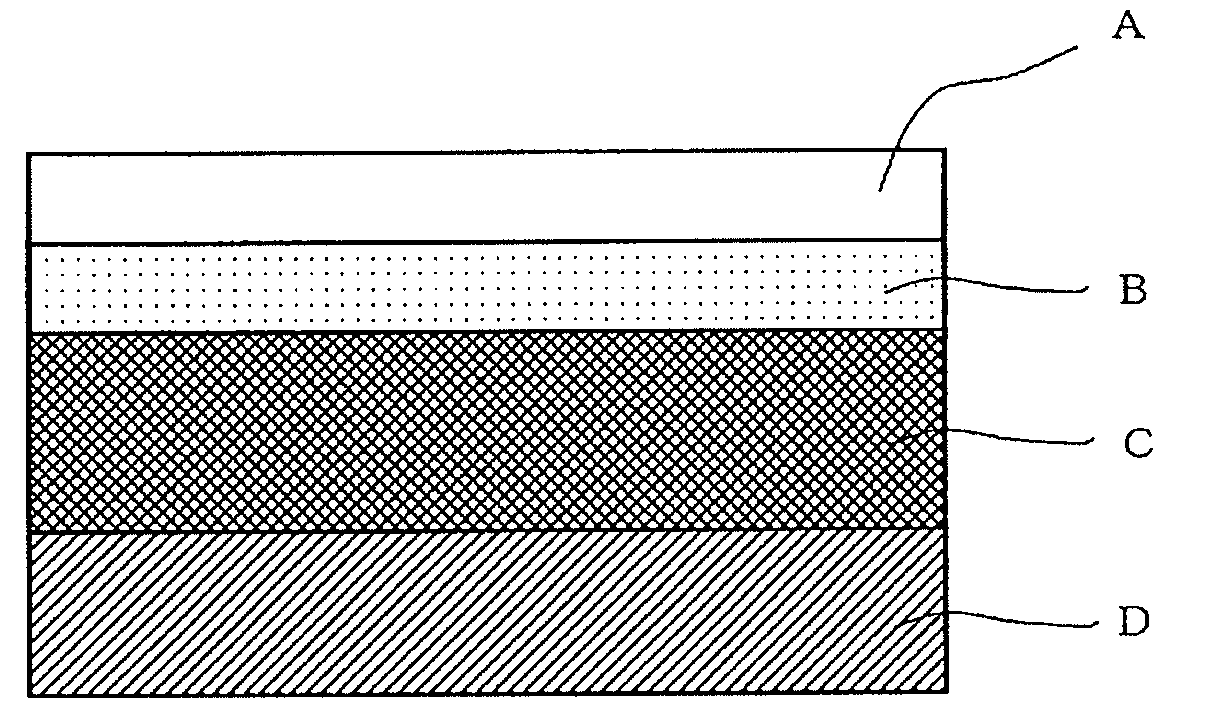

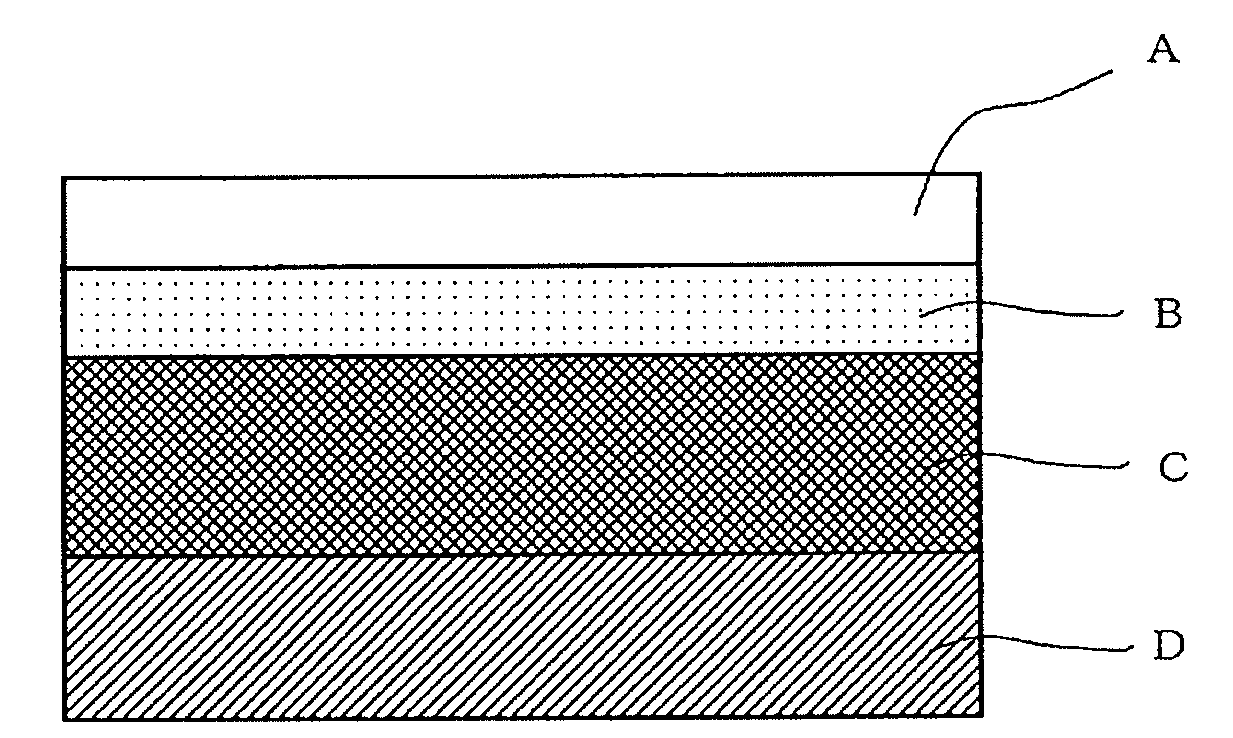

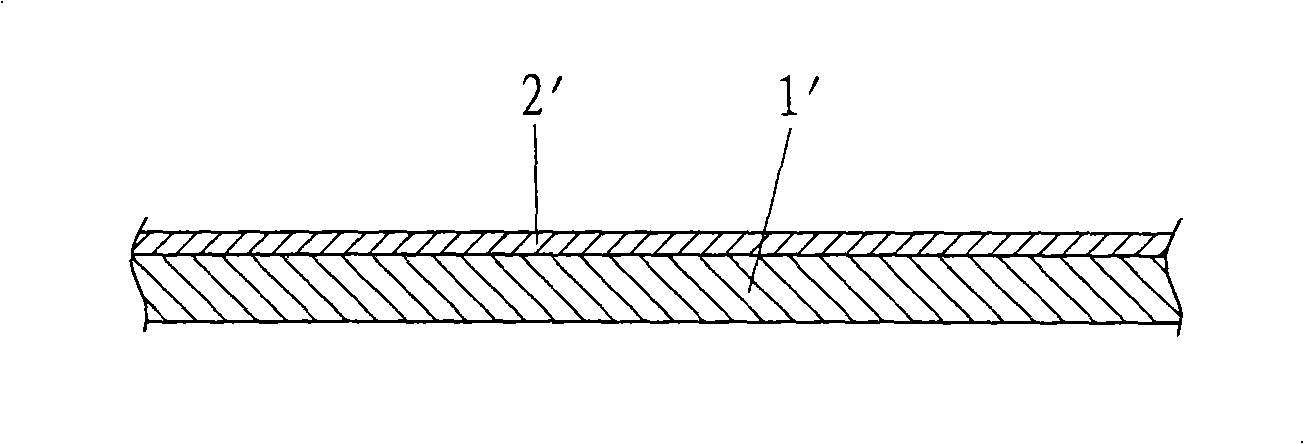

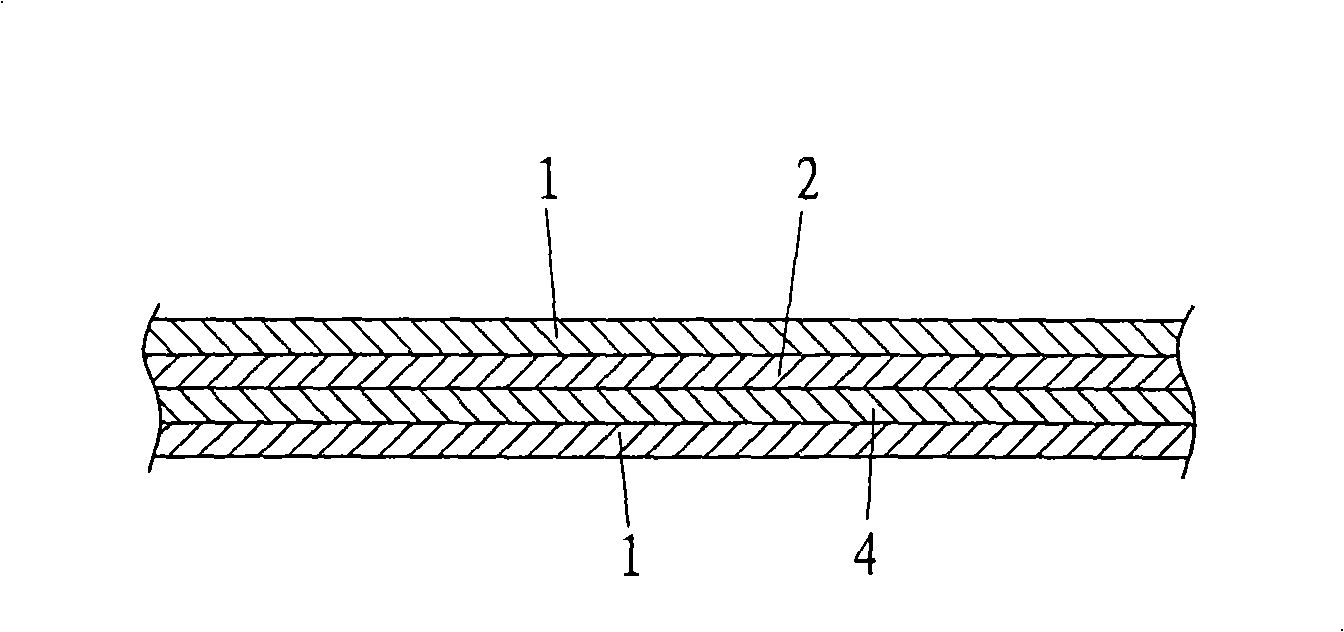

Color purity improving sheet, optical apparatus, image display, and liquid crystal display

InactiveUS20080213508A1High color purityConvenient lightingLiquid crystal compositionsLayered productsLiquid-crystal displayWavelength range

The present invention provides a highly practicable color purity improving sheet that while preventing unevenness in color and brightness from occurring, allows light with an improved color purity to be used for an image display efficiently and can improve color reproducibility of the image display. The color purity improving sheet includes a light-emitting layer which improves the purity of a color in a target wavelength range by absorbing light in a specific wavelength range other than the target wavelength range and converts the absorbed light to emitted light in the target wavelength range. The surface of the light-emitting layer on at least the light outgoing side is roughened so as to have an arithmetic average surface roughness Ra defined in JIS B 0601 (1994 version) in the range of 0.1 to 100 μm.

Owner:NITTO DENKO CORP

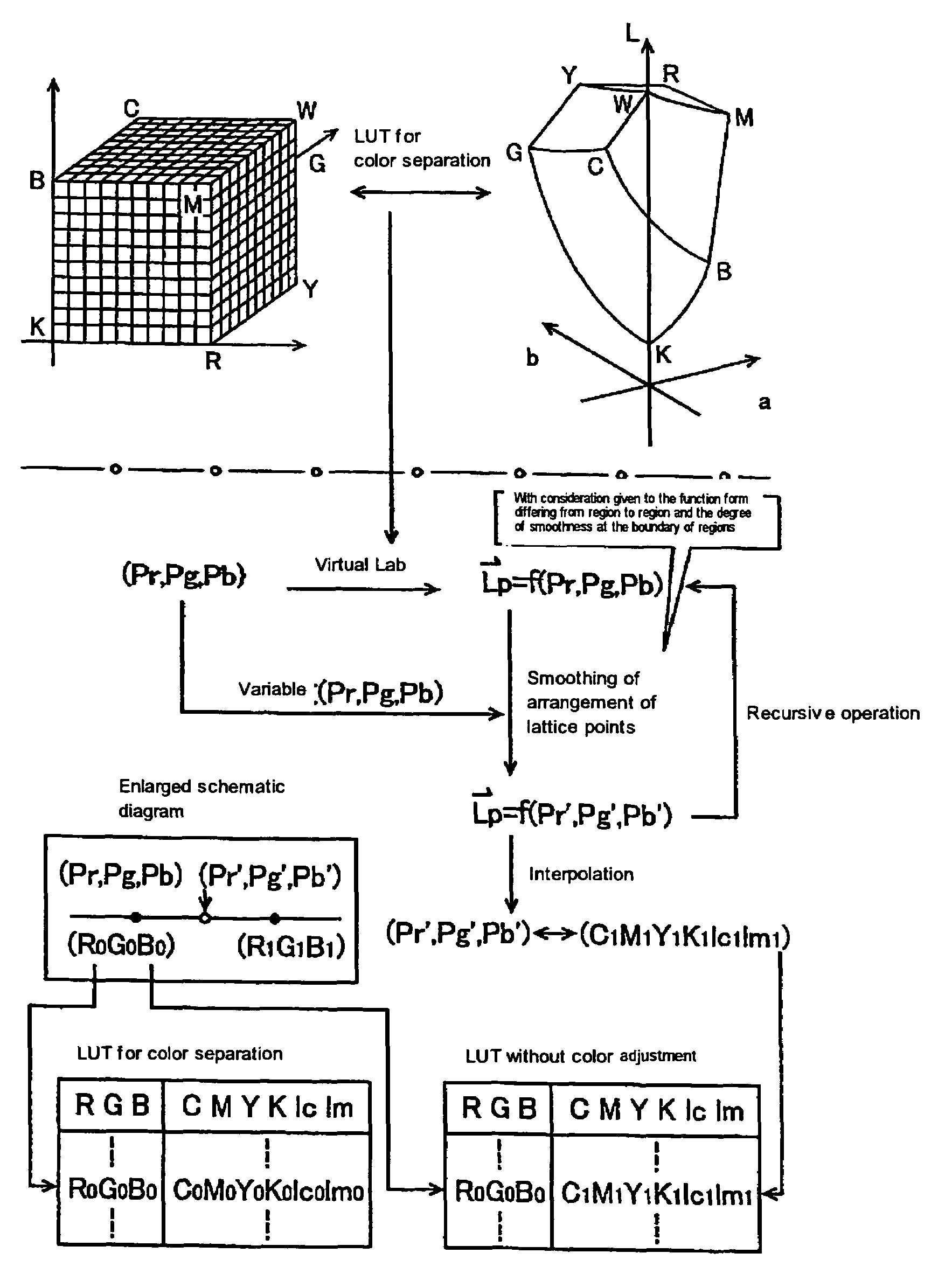

Accuracy of color conversion profile

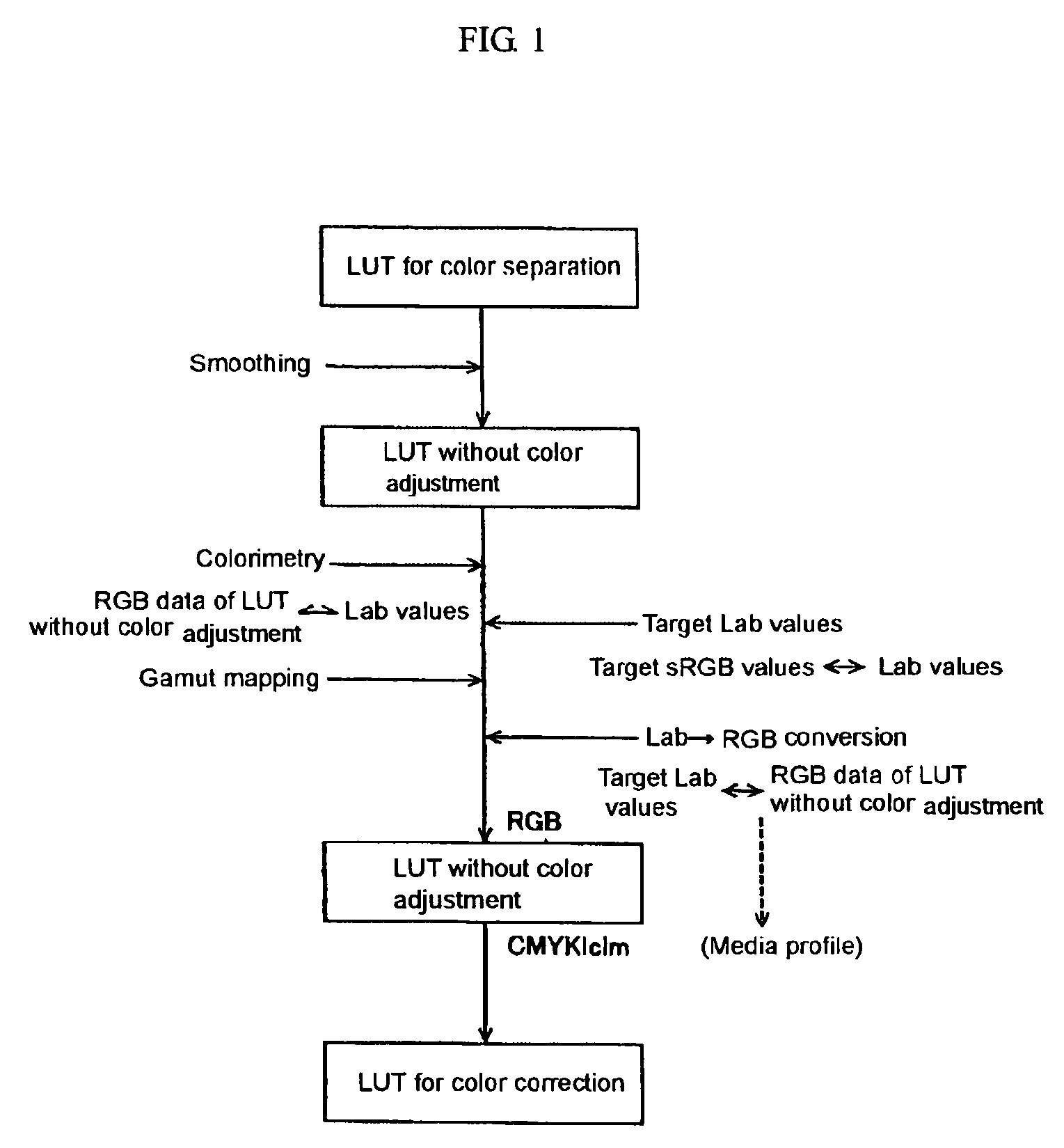

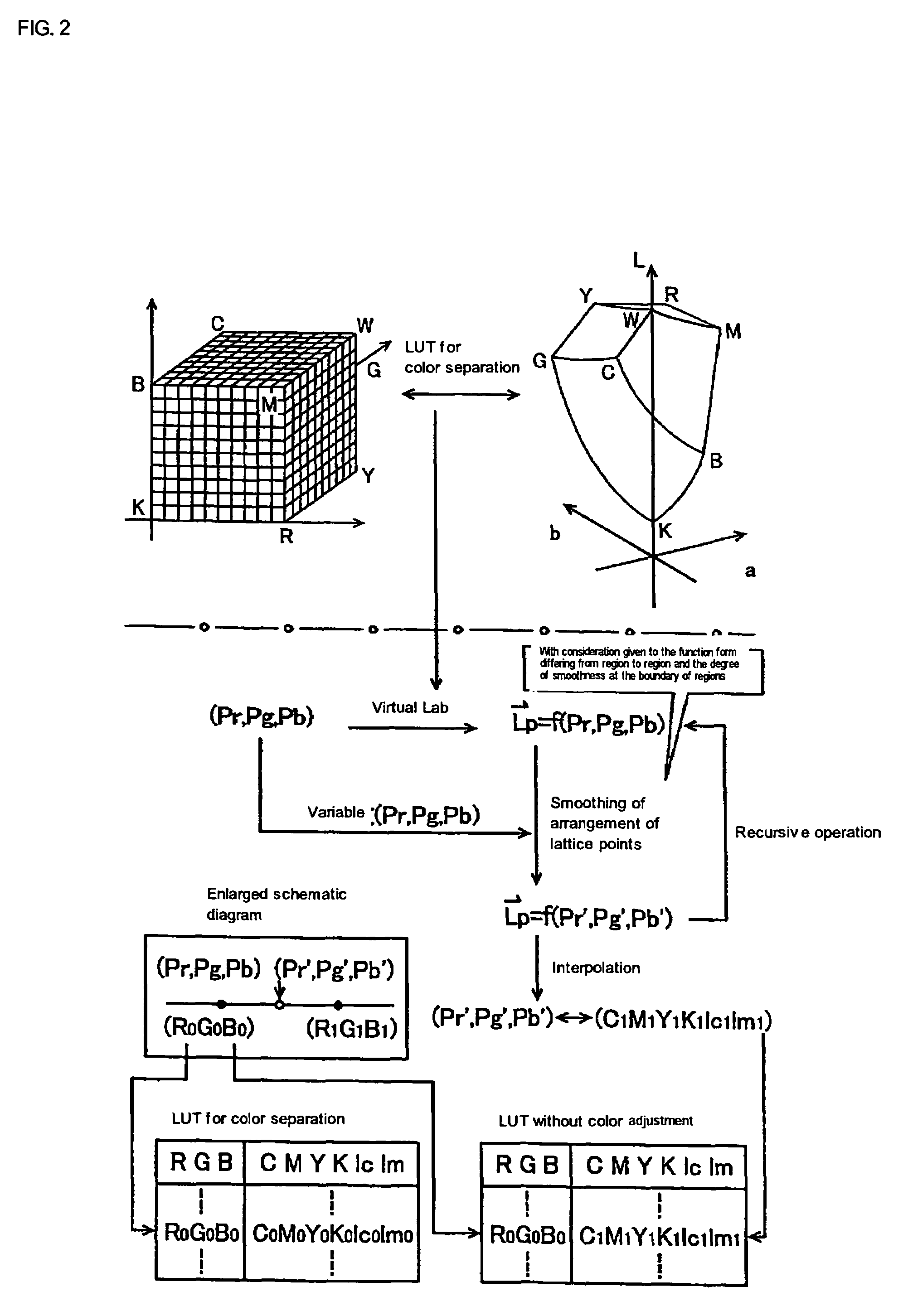

InactiveUS7345787B2Avoid uneven colorIncrease valueDigitally marking record carriersDigital computer detailsColor transformationGamut

A method for determining lattice points to be referenced to prepare the correspondence defining data, said method including steps of prescribing a smoothness evaluation function which has a function form differing depending on each region in the color gamut to which the lattice point to be evaluated belongs and also contains a constraint condition that the closer the lattice point is to the boundary of the region of the color gamut, the more the evaluated value decreases as the result of its movement, optimizing the arrangement of lattice points in the device-independent color space by improving the rating of the smoothness evaluation function, with the lattice point position information in the low-dimensional color space varied, and determining lattice points to be referenced to prepare the correspondence defining data in the optimized state.

Owner:SEIKO EPSON CORP

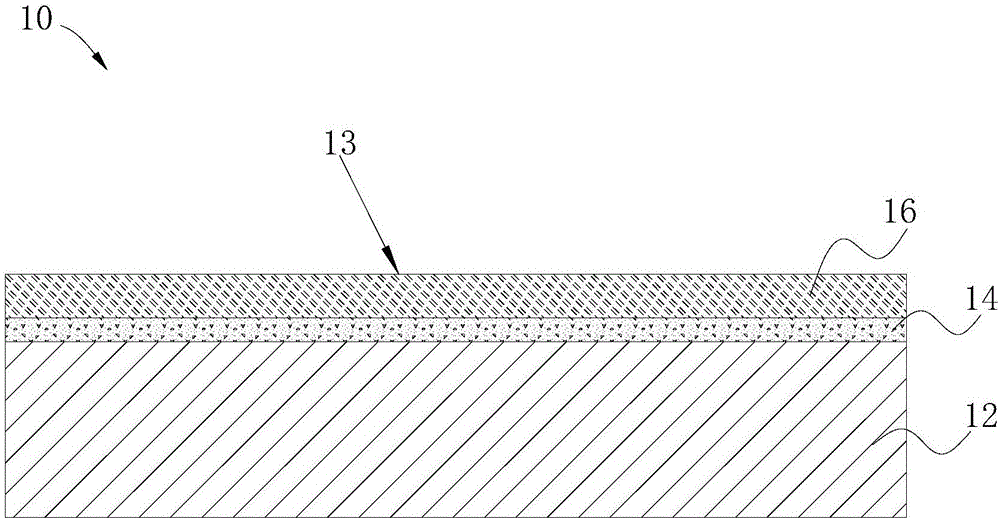

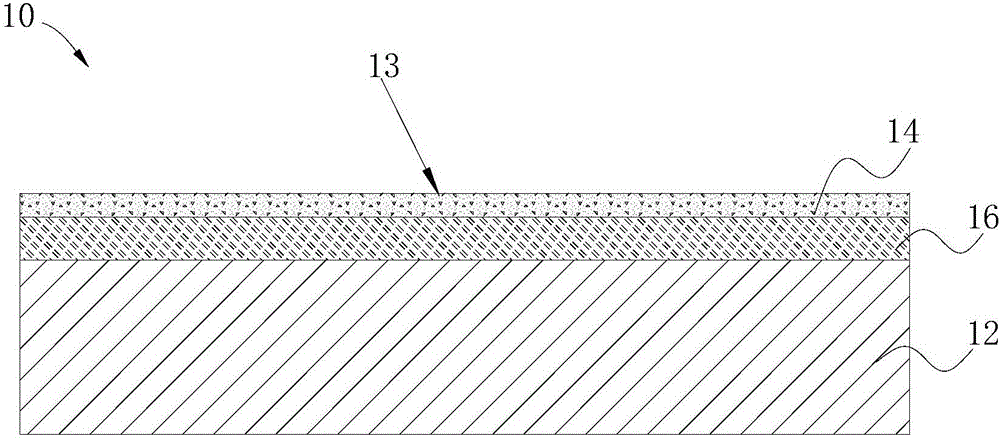

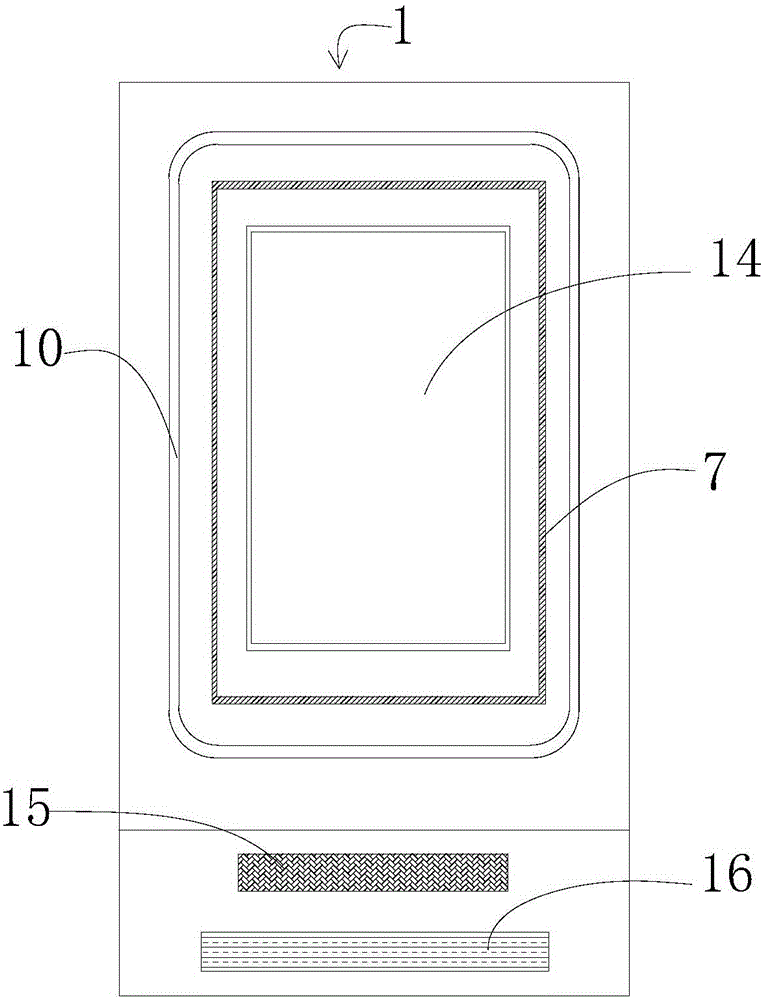

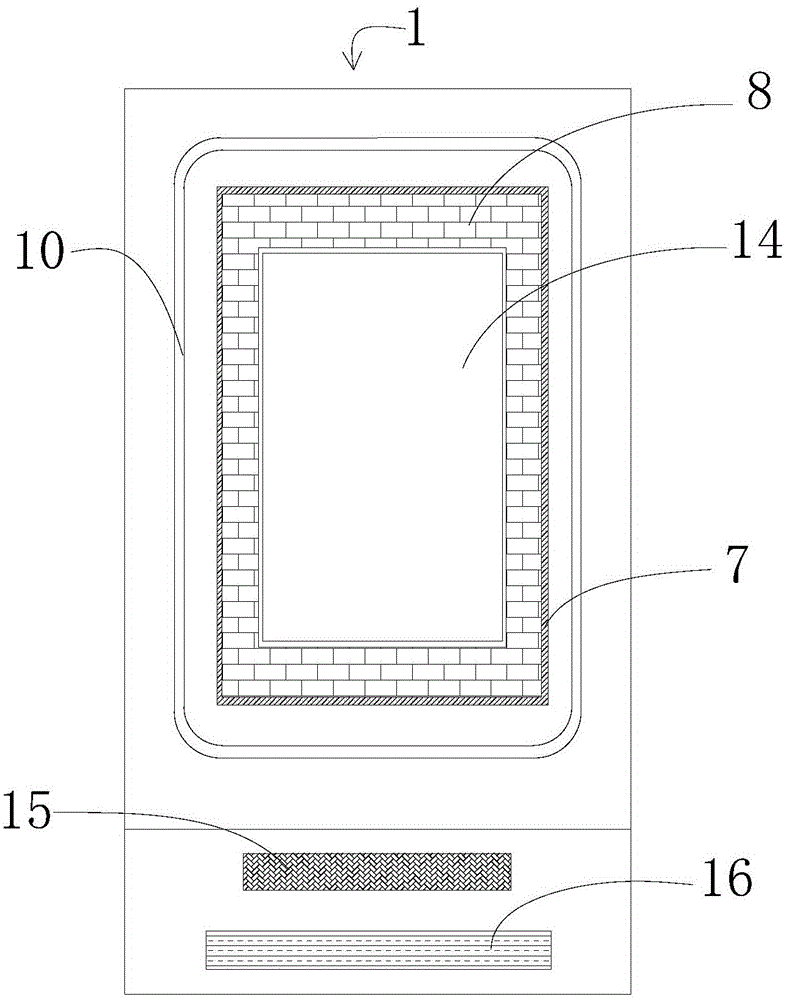

Shell, manufacturing method and mobile terminal

InactiveCN106534418ANot easy to fall offAvoid uneven colorVacuum evaporation coatingSputtering coatingFlagellar basal bodyMaterials science

The invention discloses a shell, a manufacturing method and a mobile terminal. The shell comprises a basal body and an optical film formed on the basal body; and the optical film is sintered on the basal body, so that the appearance expression colour of the basal body is adjusted. According to the shell in the embodiment of the invention, after being formed on the basal body, the optical film is attached onto the basal body in an enhanced manner through a sintering process; therefore, the optical film is difficult to fall off from the basal body; and the problem that the perceptive colour is non-uniform due to falling off of the optical film can be avoided.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

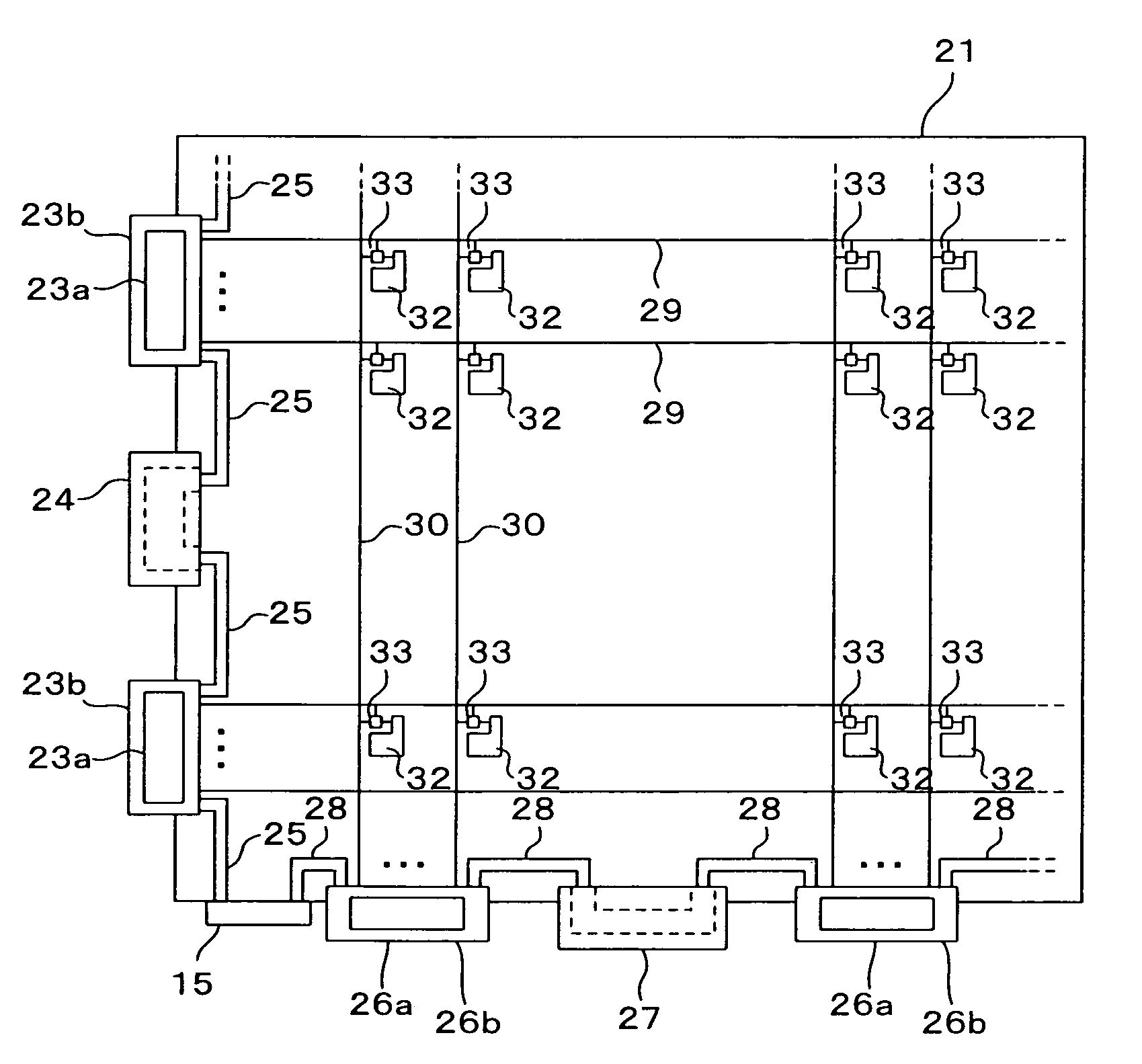

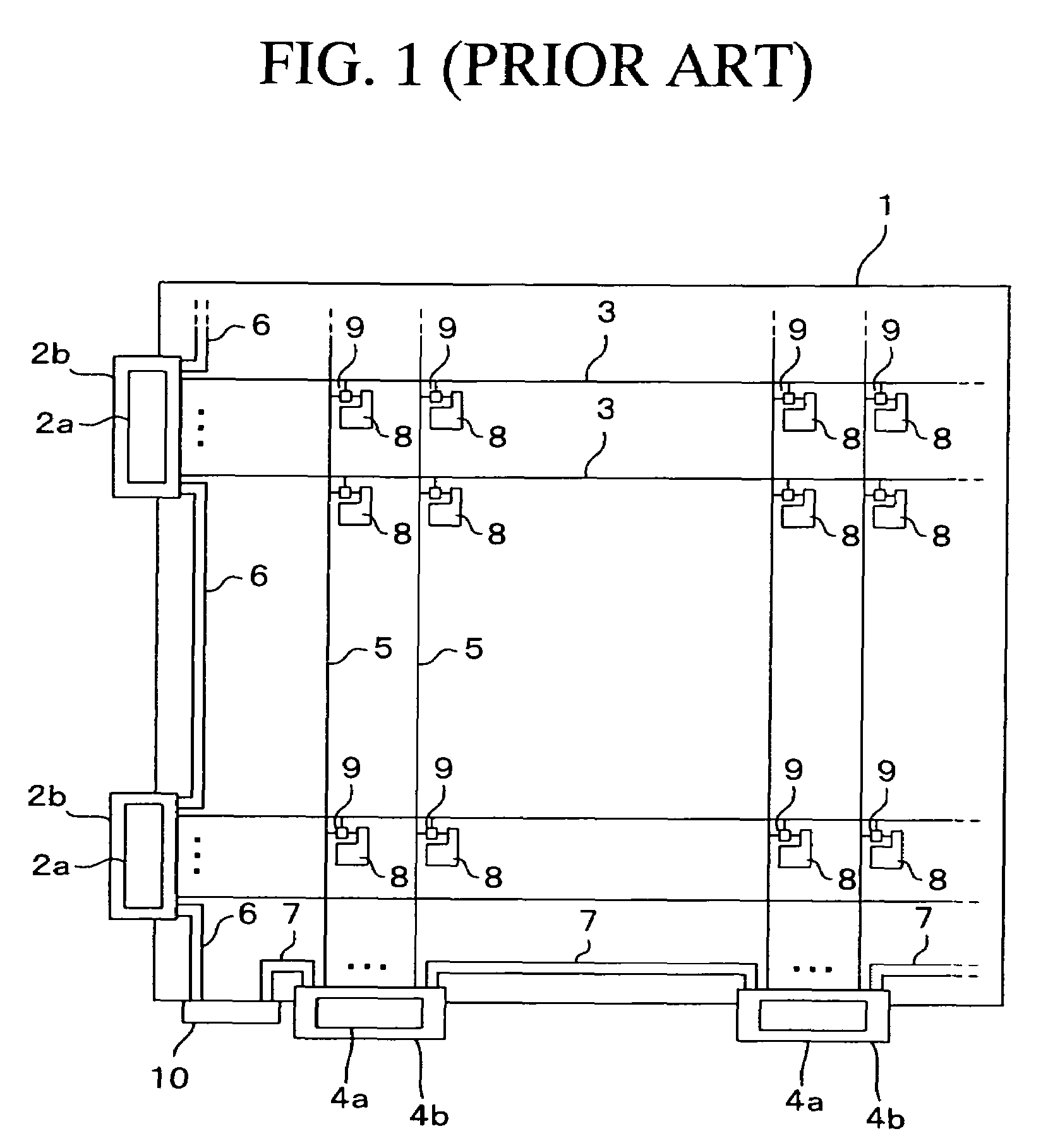

Liquid crystal display device

InactiveUS7414694B2Unevenness in brightnessUnevenness in colorNon-linear opticsLiquid-crystal displayEngineering

A plurality of gate driver boards are bonded to a first side of a TFT substrate, and a wiring board made of a flexible printed wiring board is bonded between the gate driver boards. Then, a wiring disposed on the wiring board provides connection between adjacent gate driver boards. In the same manner, a plurality of data driver boards are bonded to a second side of the TFT substrate, and a wiring board made of a flexible printed wiring board is bonded between the data driver boards. Then, a wiring disposed on the wiring board provides connection between adjacent data driver boards.

Owner:SHARP KK

Instant salted pig gristle food and processing technology thereof

InactiveCN102613588APreserve the flavorCompact structureFood preparationBiotechnologyReady to eat food

The invention relates to an instant salted pig gristle food and a processing technology thereof, and belongs to the fields of instant foods and processing technologies thereof. 100 to 105 parts of pig ear serving as a main material is matched with auxiliary material to be prepared into the instant salted pig gristle food. By the formula, the problem that slated meat foods cannot maintain the flavor of marinade for a long time and have thin salty flavor according to the formula in the prior art is solved, a formula and a proportion of the instant salted pig gristle food are provided, and a salted meat food with excellent taste can be provided and can maintain the flavor of the marinade for a long time. By the processing technology for the n instant salted pig gristle food, the product has a compact structure, good mouthfeel and attractive appearance without cutin, and the bag breakage or inflation rate is obviously reduced.

Owner:SICHUAN GAOJIN FOOD CO LTD

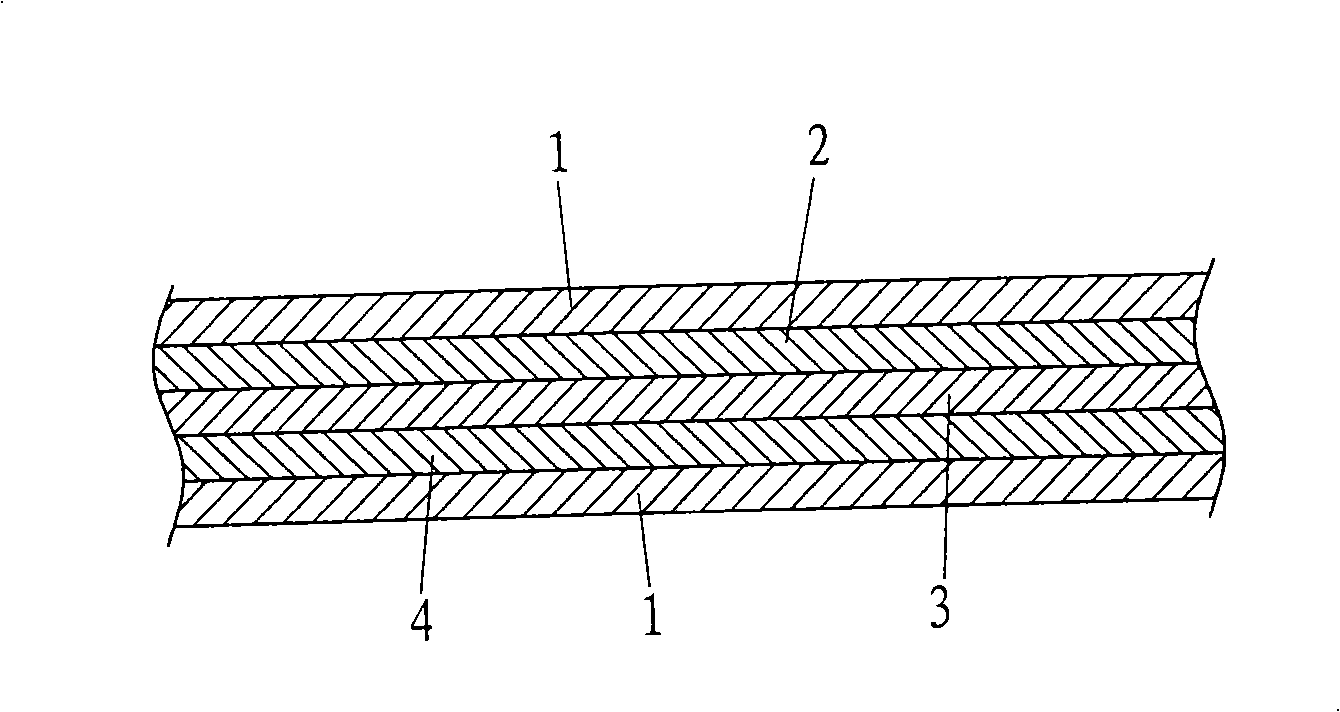

High-gloss multilayer plastic container

ActiveUS8097317B2Uniform toneEfficiently obtainedBottlesSynthetic resin layered productsPolyesterPolymer science

Provided is a high-gloss, multilayer plastic container, comprising: (1) a transparent polyester-based resin outer layer; (2) a transparent adhesive resin layer; and (3) a colored polyolefin-based resin layer in the stated order from an outer surface side of the container, wherein: the transparent polyester-based resin outer layer has a surface roughness Ra of 0.2 μm or less; and an interface between (2) the transparent adhesive resin layer and (3) the colored polyolefin-based resin layer has a concavoconvex level of 15 μm or less. An interface between (1) the transparent polyester-based resin outer layer and (2) the transparent adhesive resin layer preferably has a concavoconvex level of 15 μm or less. According to the present invention, a multilayer plastic container having an even, smooth surface, a high-gloss, deep color tone, and an extremely excellent external appearance can be obtained.

Owner:TOYO SEIKAN KAISHA LTD

Printing and dyeing technique for nylon-cotton blended fabric

InactiveCN109338748AAvoid uneven colorAvoid the influence of printing and dyeingDry-cleaning apparatus for textilesDyeing processDyeingEngineering

The invention discloses a printing and dyeing technique for nylon-cotton blended fabric. The printing and dyeing technique comprises the following preparation steps: 1, preparing the nylon-cotton blended fabric, comprising the substeps of inspecting raw fabric, reworking the fabric (in batches and in boxes, and printing) and sewing seams, wherein raw fabric inspection achieves the purposes of checking the quality of gray fabric and solving problems in time after the problems are found. Through singeing treatment to the nylon-cotton blended fabric, fluffs on the outer surface of the nylon-cotton blended fabric are removed so as to avoid a phenomenon that printing and dyeing are not uniform enough due to non-uniform lengths of the fluffs; then, through desizing and scouring treatment, the nylon-cotton blended fabric is scoured for a long time so as to remove impurities therein; then, through the following bleaching treatment, fiber has a natural pigment and the appearance thereof is notwhite enough, which causes a certain influence on printing and dyeing, so that occurrence of the problem that a dyeing agent cannot achieve uniform colorization due to the influence of the pigment isavoided.

Owner:ZHEJIANG YINGFENG TECH CO LTD

Liquid crystal display panel

ActiveCN105044991AGuaranteed tightnessAvoid uneven colorNon-linear opticsLiquid-crystal displayColor difference

The invention provides a liquid crystal display panel. The liquid crystal display panel comprises a first glass substrate and a second glass substrate. Multiple spacing structures are arranged on the inner side of the first glass substrate, and frame glue is arranged on the periphery of the first glass substrate. A flat layer is formed on the inner side of the second glass substrate. A display region is arranged in the middle of the liquid crystal display panel. The frame glue is used for connecting the first glass substrate with the second glass substrate. The display region is arranged in the range defined by the frame glue. The area of the display region is smaller than that defined by the frame glue, and grid-shaped grooves are formed in the region between the outer edge of the display region and the inner edge of the frame glue. According to the liquid crystal display panel, the sealing performance between the first glass substrate and the second glass substrate can be guaranteed, the gap between the first glass substrate and the second glass substrate is not affected, and the phenomenon of non-uniform color or color differences of the periphery of the liquid crystal display panel is avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD +1

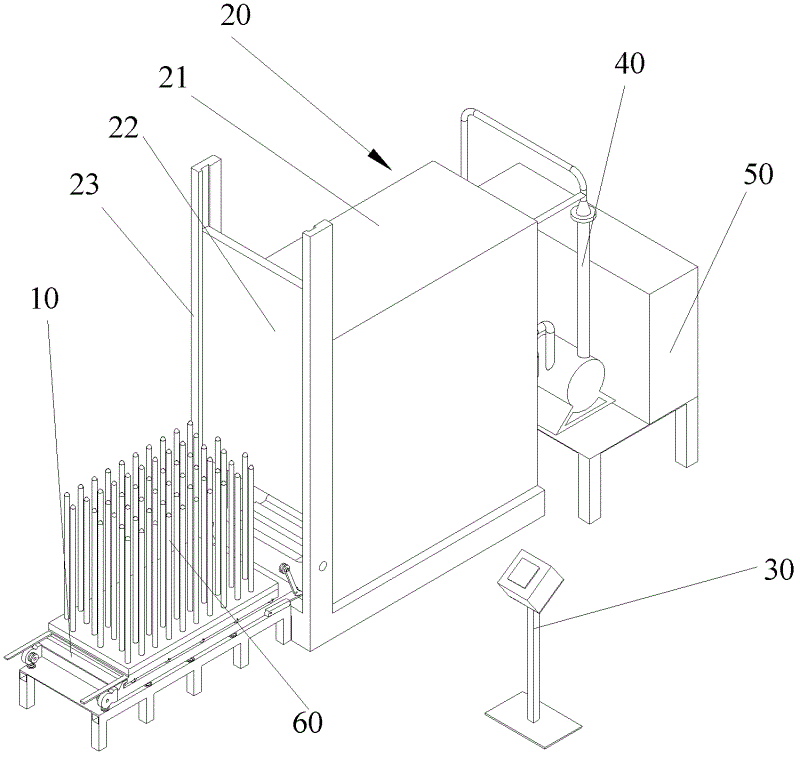

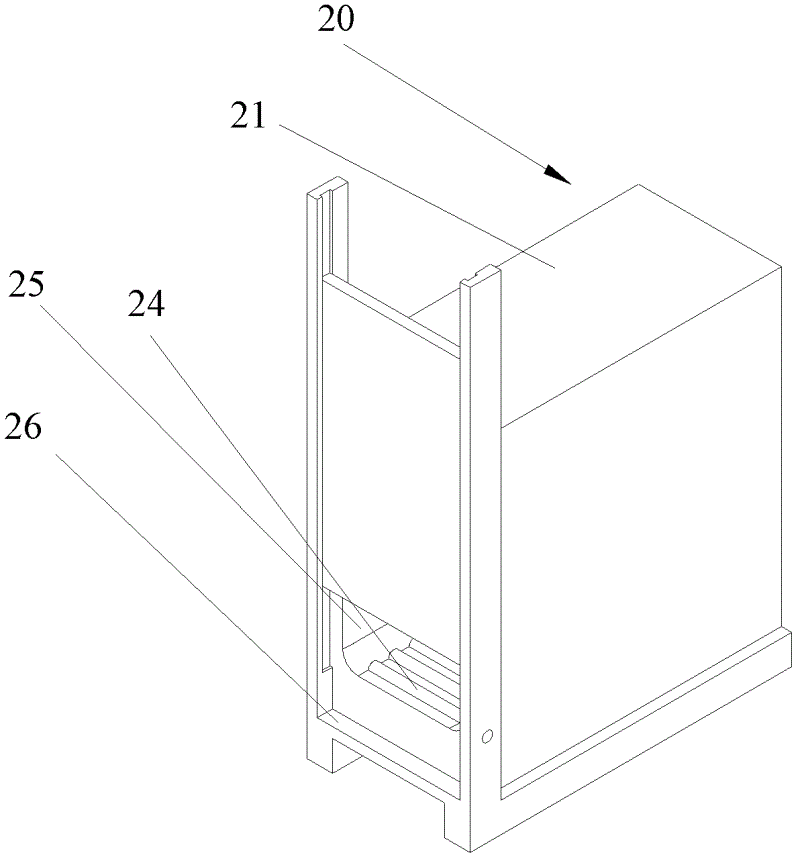

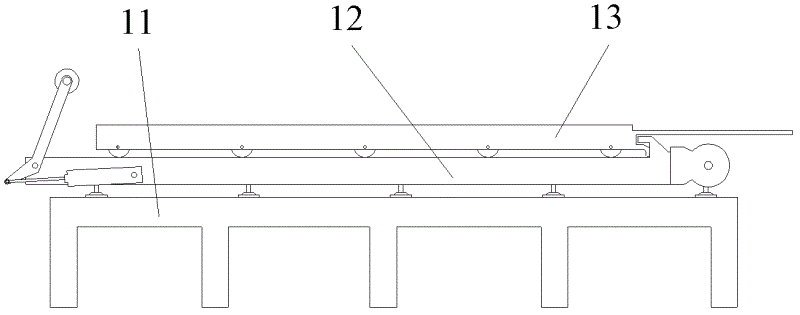

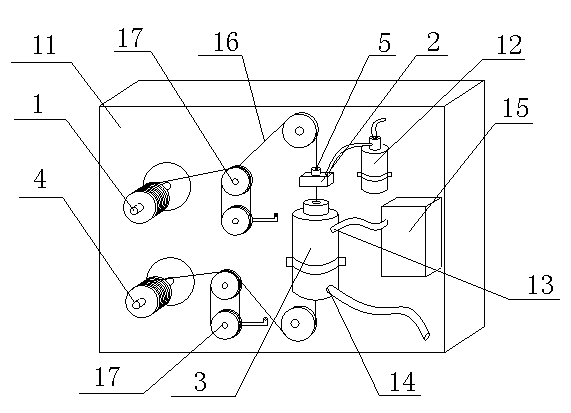

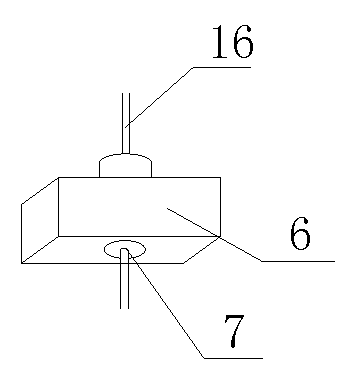

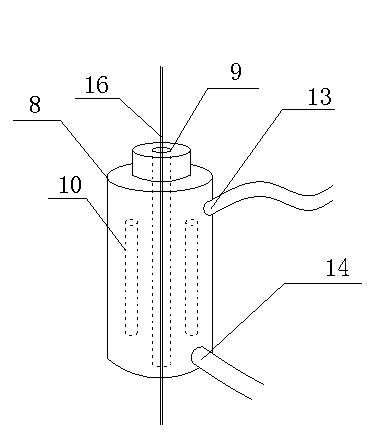

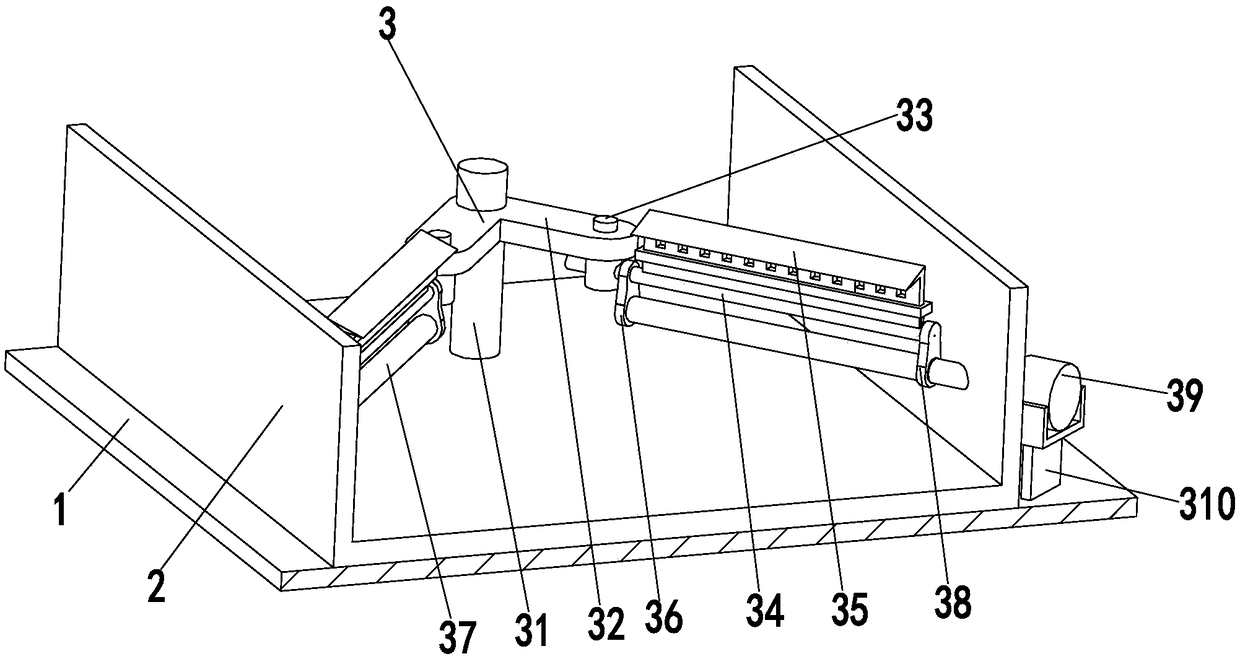

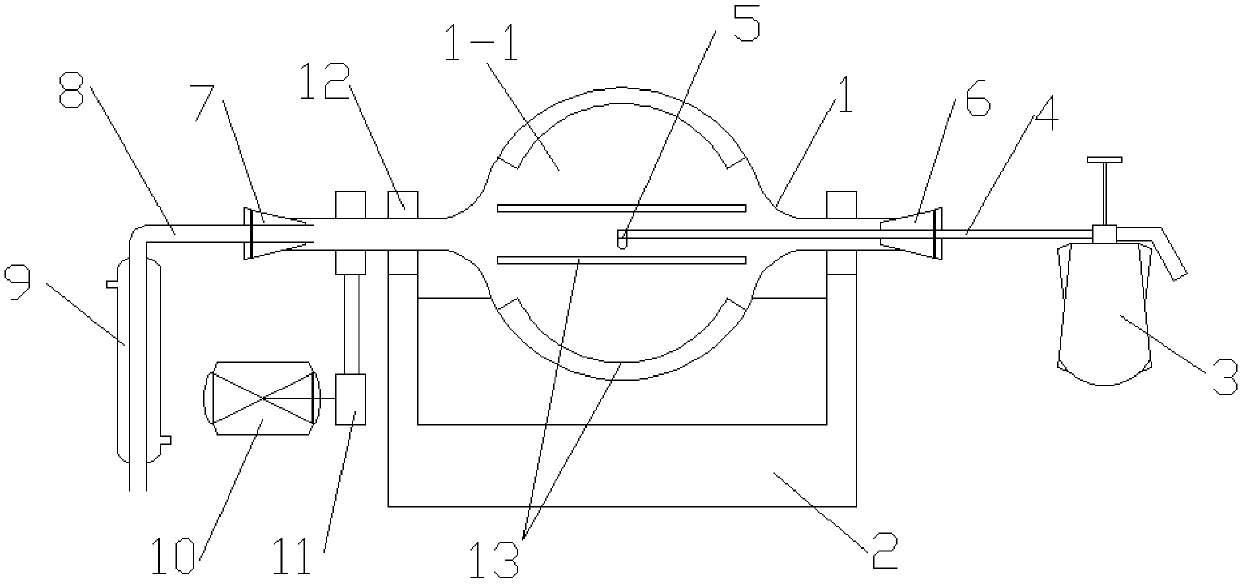

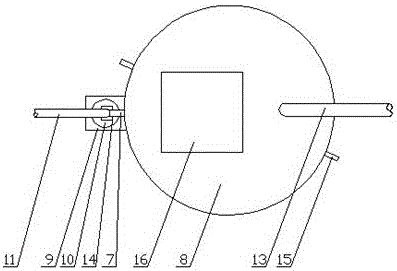

Yarn humidifying machine and humidifying method thereof

ActiveCN102619040AEasy to paint evenlyAvoid uneven colorTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentYarnEngineering

The invention provides a yarn humidifying machine and a humidifying method thereof. The yarn humidifying machine comprises a conveying system, a humidifying system and a steam system, yarns to be humidified are arranged on the conveying system, and are conveyed into the humidifying system by the conveying system, and the steam system is communicated with the humidifying system. The yarns are humidified by the aid of the yarn humidifying machine by the yarn humidifying method, and the yarn humidifying method includes steps: conveying the yarns to be humidified into the humidifying system; regulating the temperature and the pressure in the humidifying system; and feeding steam into the humidifying system and humidifying the yarns via the humidifying system. The yarns are humidified via the humidifying system, accordingly, the yarns are consistently humidified before being dyed, the weight of original yarns can be calculated conveniently according to the moisture content of the yarns, dye is matched, and matching of the dye is optimal.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

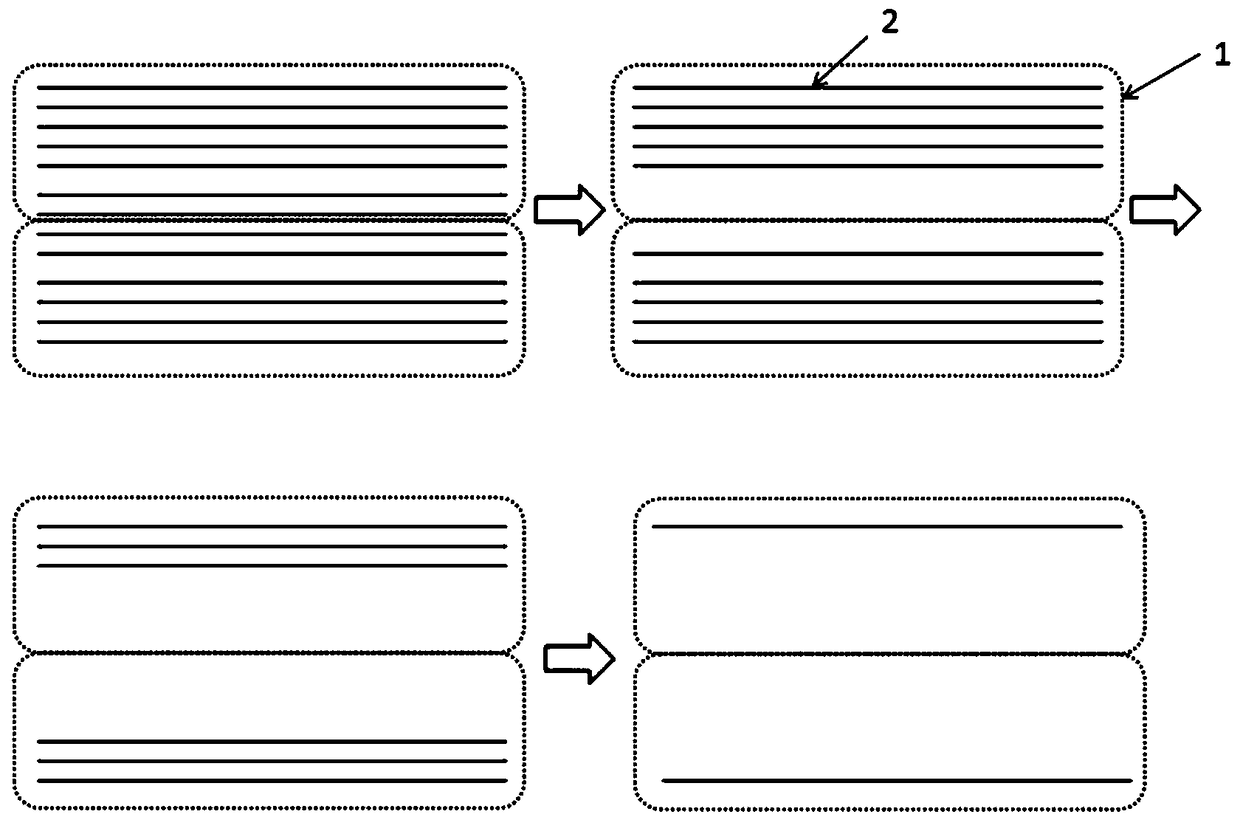

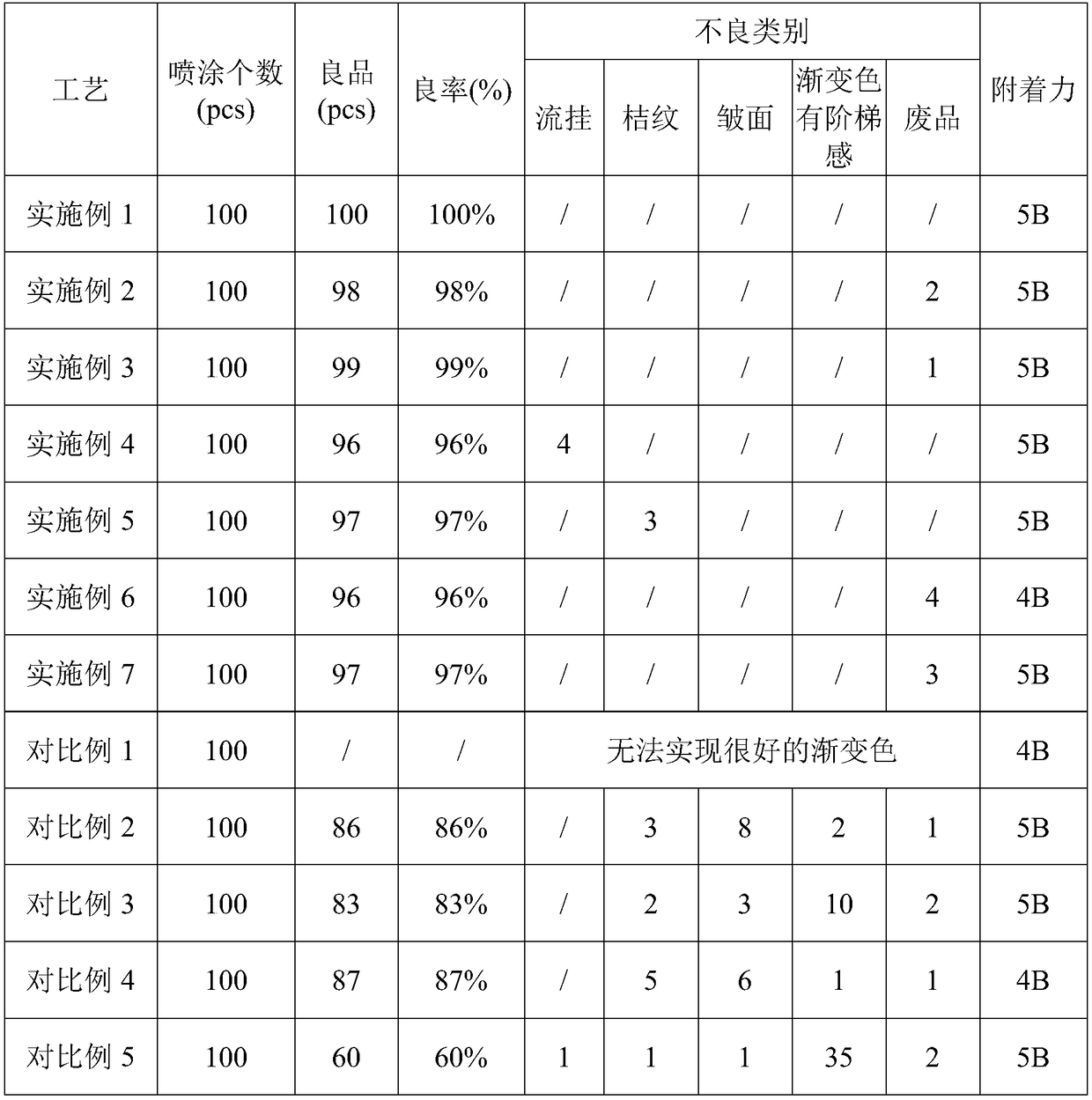

Glass gradient spraying technology, gradient ramp glass cover plate and electronic product

The invention discloses a glass gradient spraying technology, a gradient ramp glass cover plate and an electronic product, and relates to the technical field of ink spraying. The glass gradient spraying technology comprises the following steps: firstly, using semitransparent ink to carry out whole-surface spraying according to a plurality of parallel spraying paths; then, gradually reducing a spraying area to form an ink layer with a changed thickness gradient, wherein the viscosity of the semitransparent ink is 8-18Pa.s, an interval between adjacent spraying paths is 14-18mm, a spraying swathrange during spraying is 2-3cm, spraying height is 7-10cm, and 1-3 spraying paths are reduced for each piece of glass each time when the spraying area is gradually reduced. According to the glass gradient spraying technology, a spraying process condition is optimized, the surface of the ink after spraying is smooth and flat and is free from orange stripes or wrinkled surfaces, a color gradient effect is good, transitivity and continuity are good, and no ladder feeling is in the presence.

Owner:LENS TECH CHANGSHA

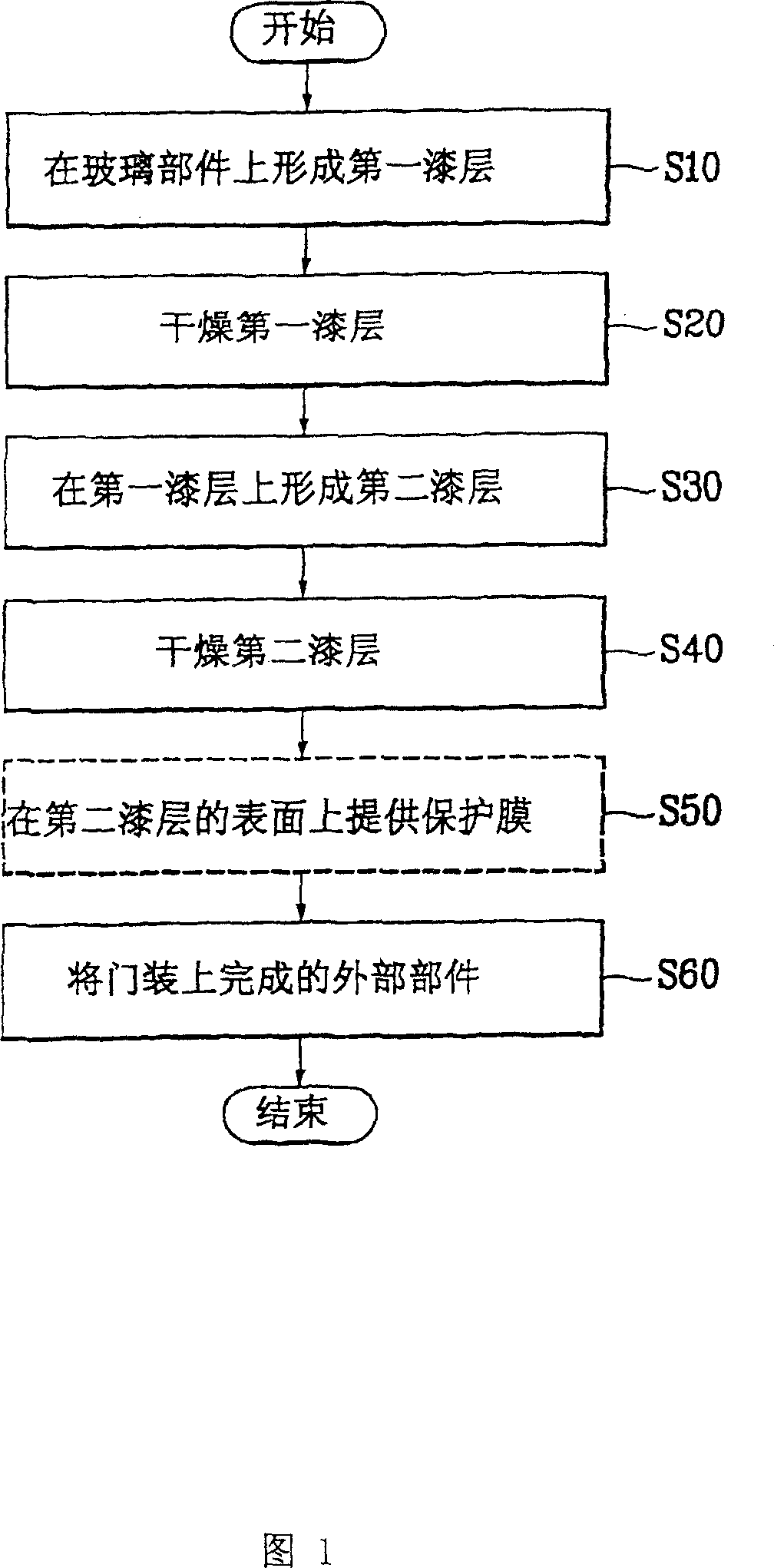

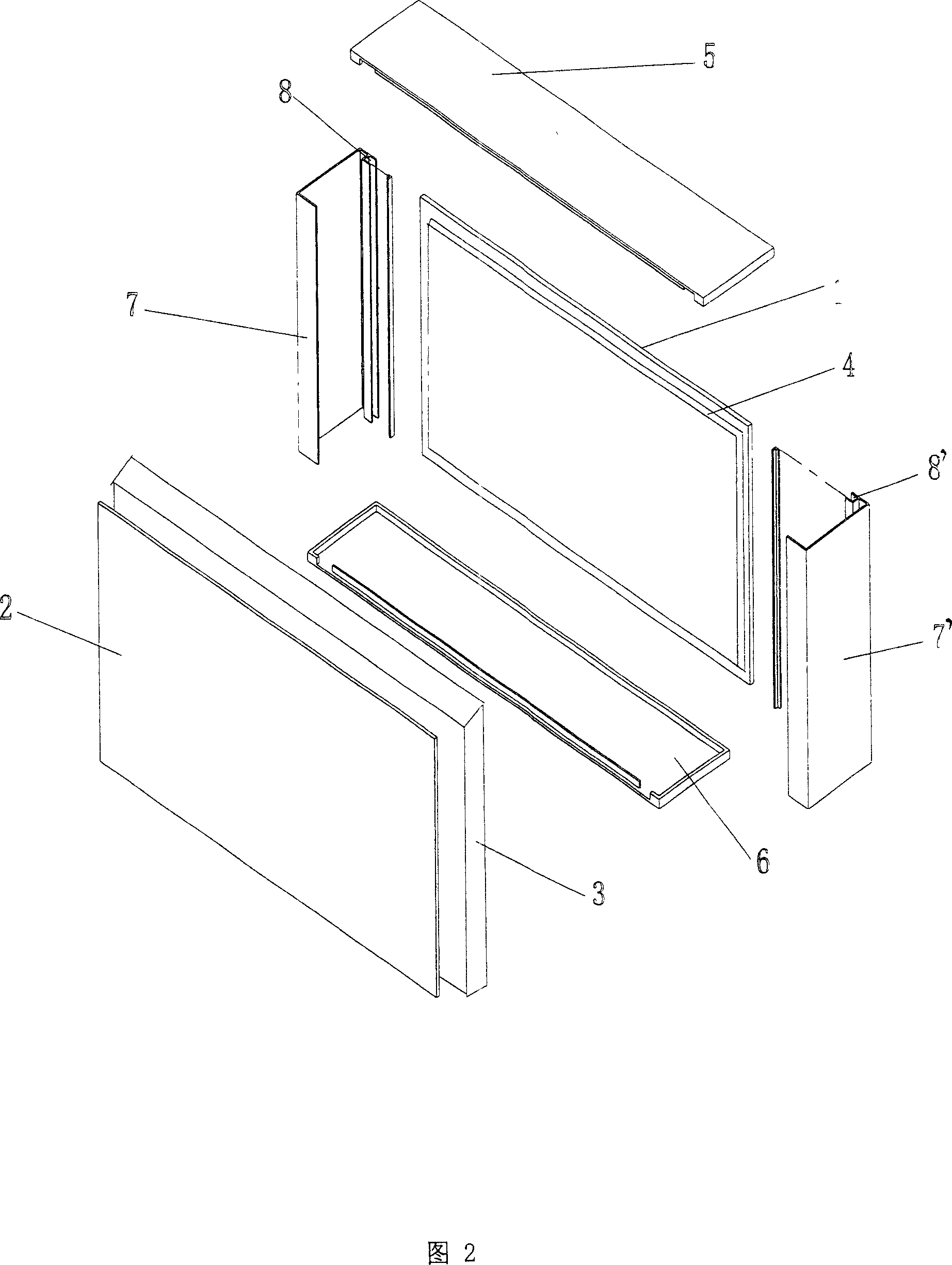

Refrigerator door

ActiveCN1920453AReduce riskAvoid harmDomestic cooling apparatusLighting and heating apparatusThermal insulationLacquer

The invention relates to a door of refrigerator, wherein its outer plate is made from glass, whose inner surface is adhered with one pad pasting; said glass can be transparent float glass or armoured glass; the pad pasting can be colorful. The inventive door can avoid plating; when needing the glass in outer color, only need to replace pad, to simplify process and improve efficiency. And the pad pasting via adhesive is adhered on the glass, to improve the safety; and it can use infrared-reflective pad pasting, to improve the thermal insulation and the energy-saving property.

Owner:HAIER GRP CORP +1

Construction method of exterior wall coating decorative finish

The invention discloses a construction method of exterior wall coating decorative finish. The method mainly includes the following five steps of performing base layer processing; subjecting a target wall base layer to texturing processing; blow-drying a well polished wall basement by using a high-power fan; subjecting a putty layer to batch scraping for twice along a vertical direction; and painting coatings. By means of the construction method, the problem that exterior wall coatings are not even in colors due to the fact that the target wall base layer is overhigh in moisture content is solved, the problem that putty scraping is not even and incomplete during the process of twice batch scraping of the putty is avoided, and alkali-resistant closed base coatings are painted on the target wall so that alkalization and color crossing of the exterior wall coatings are effectively prevented.

Owner:CHANGSHU ANCIENT STYLE GARDEN CONSTR CORP

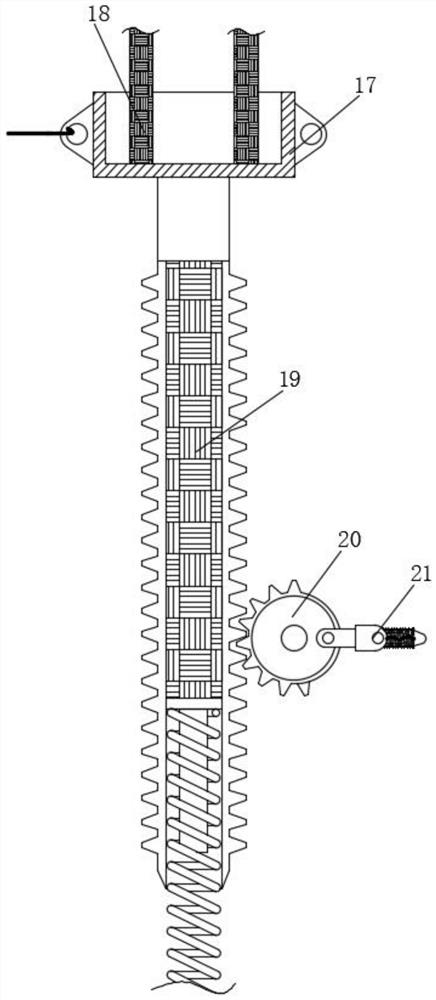

Uniform coloring machine of fibers

The invention discloses a uniform coloring machine of fibers. The machine comprises a base (11), and a pay-off reel (1), a coloring device (2), a curing furnace (3), a take-up reel (4) and a pigment pot (12) which are installed on the base (11), the pay-off reel (1), the coloring device (2), the curing furnace (3) and the take-up reel (4) are annularly assigned, a tension regulator (17) is arranged between the pay-off reel (1) and the coloring device (2), a tension regulator (17) is also arranged between the curing furnace (3) and the take-up reel (4), and the pay-off reel (1) and the take-up reel (4) are respectively installed on the base (11) through a motor. The machine which allows the tension regulator to be arranged in each of a pay-off position and a take-up position has the advantages of guarantee of the tension in fiber transmission, no fiber relax phenomenon, avoiding of the non-uniform dyeing phenomenon, and improvement of the fiber dying quality.

Owner:成都亨通光通信有限公司

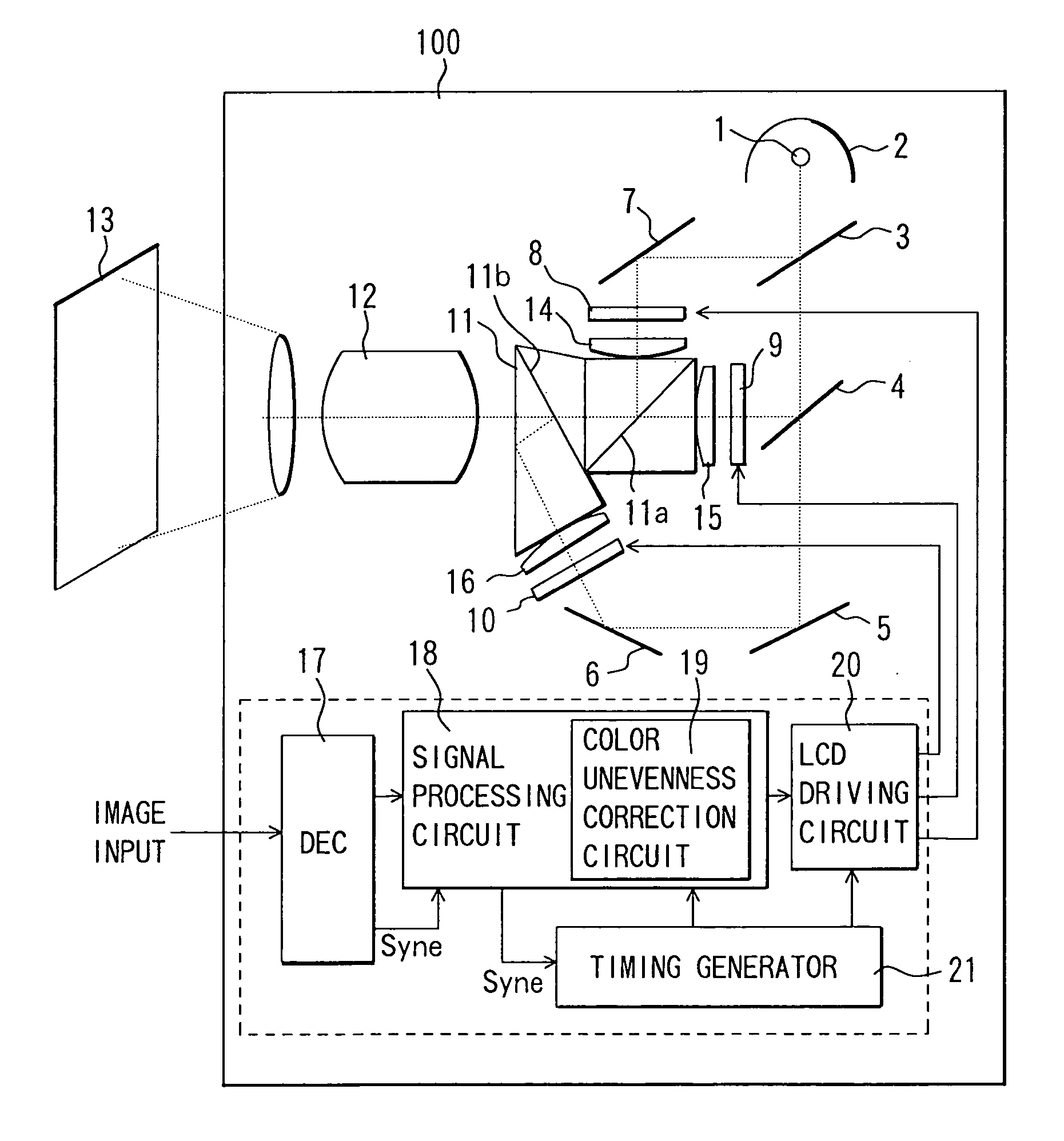

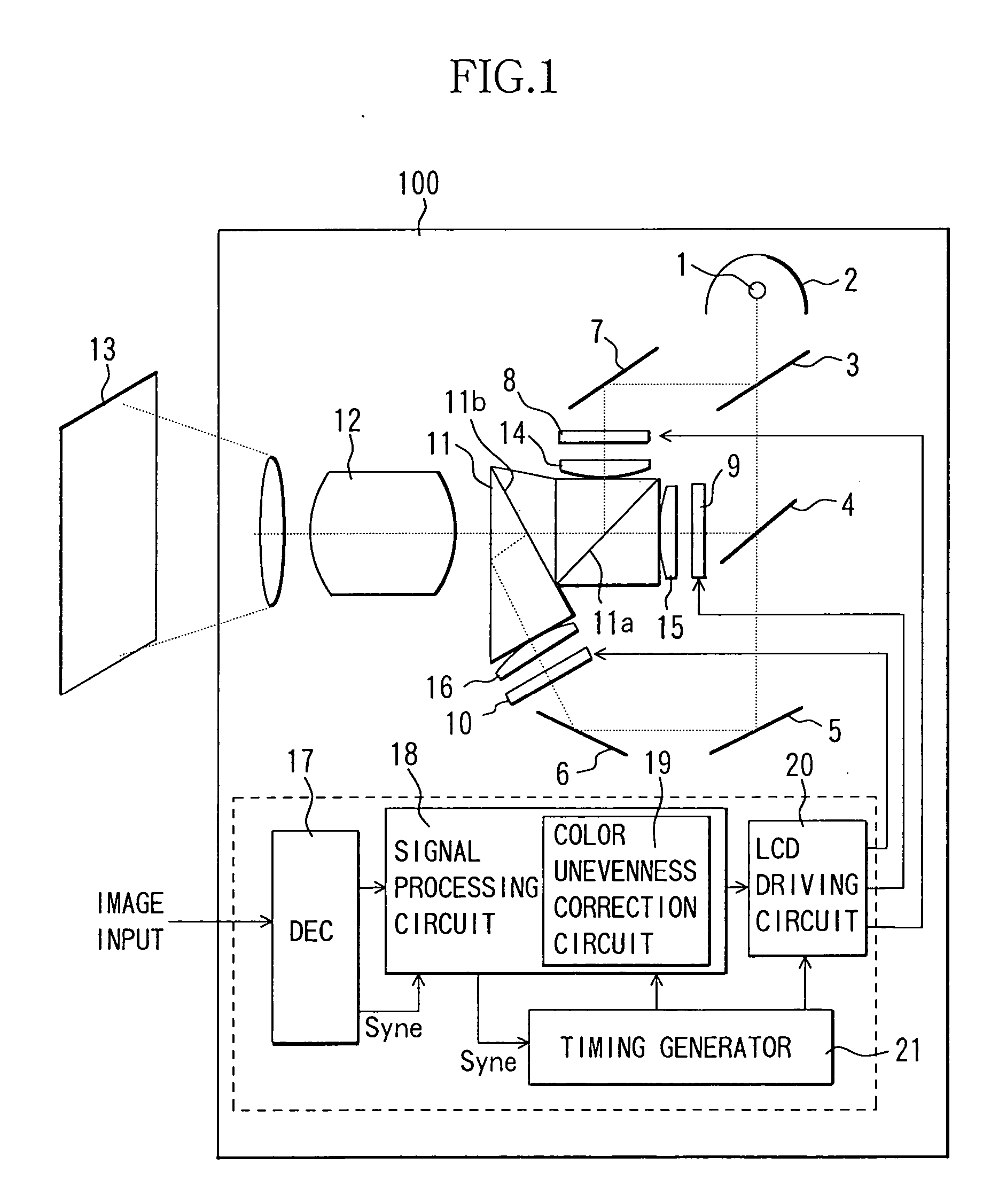

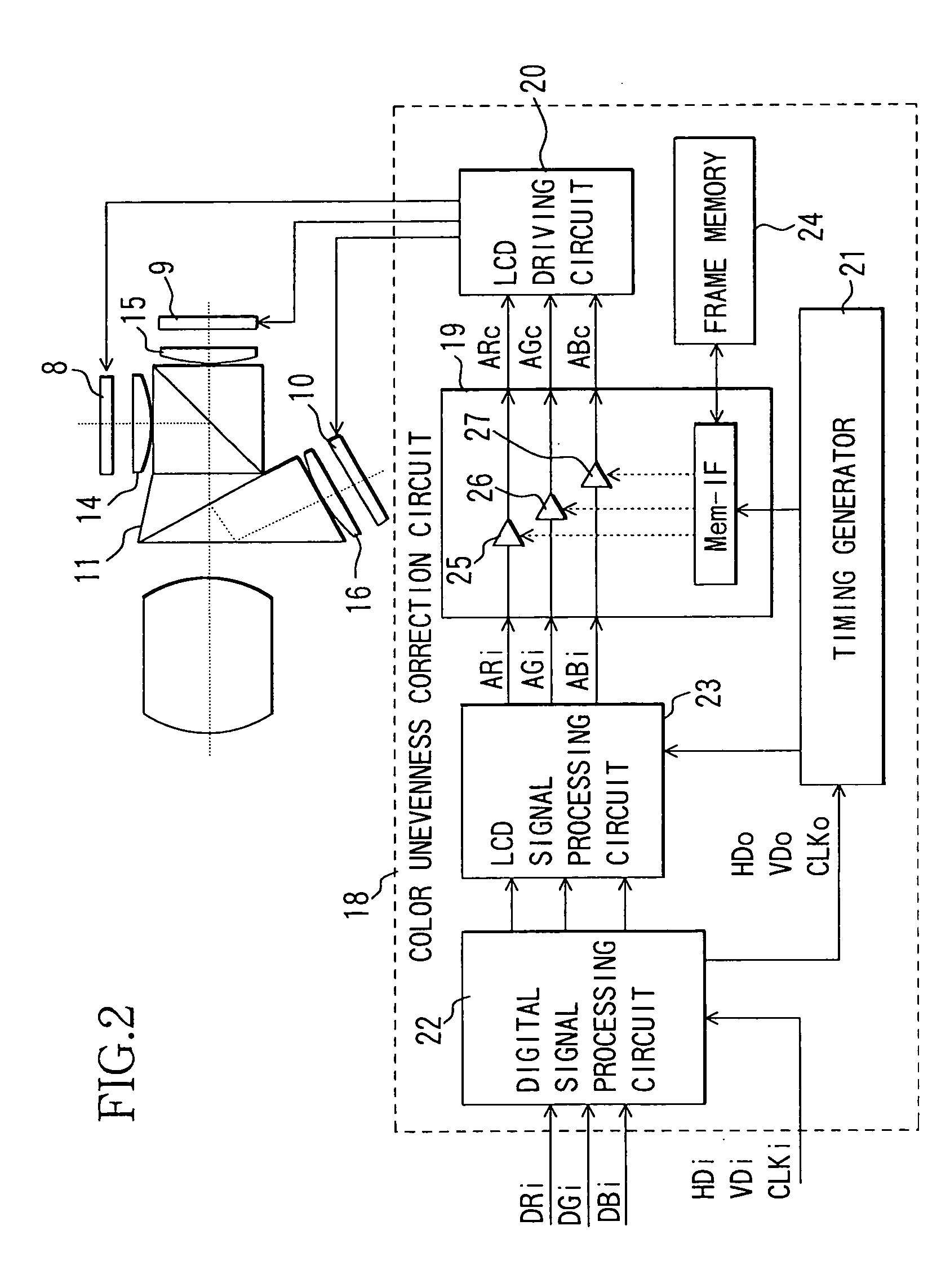

Projection type image display device

InactiveUS20050206851A1Correct color unevennessCorrecting color unevennessTelevision system detailsColor signal processing circuitsPhysicsProjection image

A projection type image display device includes a plurality of image display elements that perform modulation of light rays in accordance with an image signal, a color synthesizing optical element for synthesizing light rays having mutually different wavelength ranges that have been modulated by these image display elements by use of a dichroic membrane, lens groups having a positive refractive power as a whole that are disposed between the image display element and the color synthesizing optical element, and a projection optical system for projecting an image synthesized by the color synthesizing optical element. The projection type image display device further includes a storage circuit for storing data used to correct the brightness irregularity of a projected image, and a brightness irregularity correcting circuit for correcting brightness irregularity of a projected image on the basis of the data stored in the storage circuit.

Owner:CANON KK

Lens optical film products

InactiveCN101266303AInhibit sheddingAvoid uneven colorSpectales/gogglesOptical partsStaining techniqueUltraviolet

The invention discloses a lens optical film product, at least comprising plastic layers and a color changing layer wherein the color changing layer is attached between the two plastic layers. One of the polarization layer, UV absorbing material layer or dye layer or the three arbitrary combination can be attached between the between the two plastic layers. The color changing layer is sandwiched between the two plastic layers using the attaching technique, rather than the color changing layer is coated on the plastic layers using staining technique, so as to avoid unevenly dyeing and prevent the color changing layer from falling off. Moreover the color changing layer is attached with the plastic layer after independently moulding, thus the color changing time can be well controlled to prevent the color changing time from being slow.

Owner:ACTIF POLARIZERS (CHINA) CO LTD

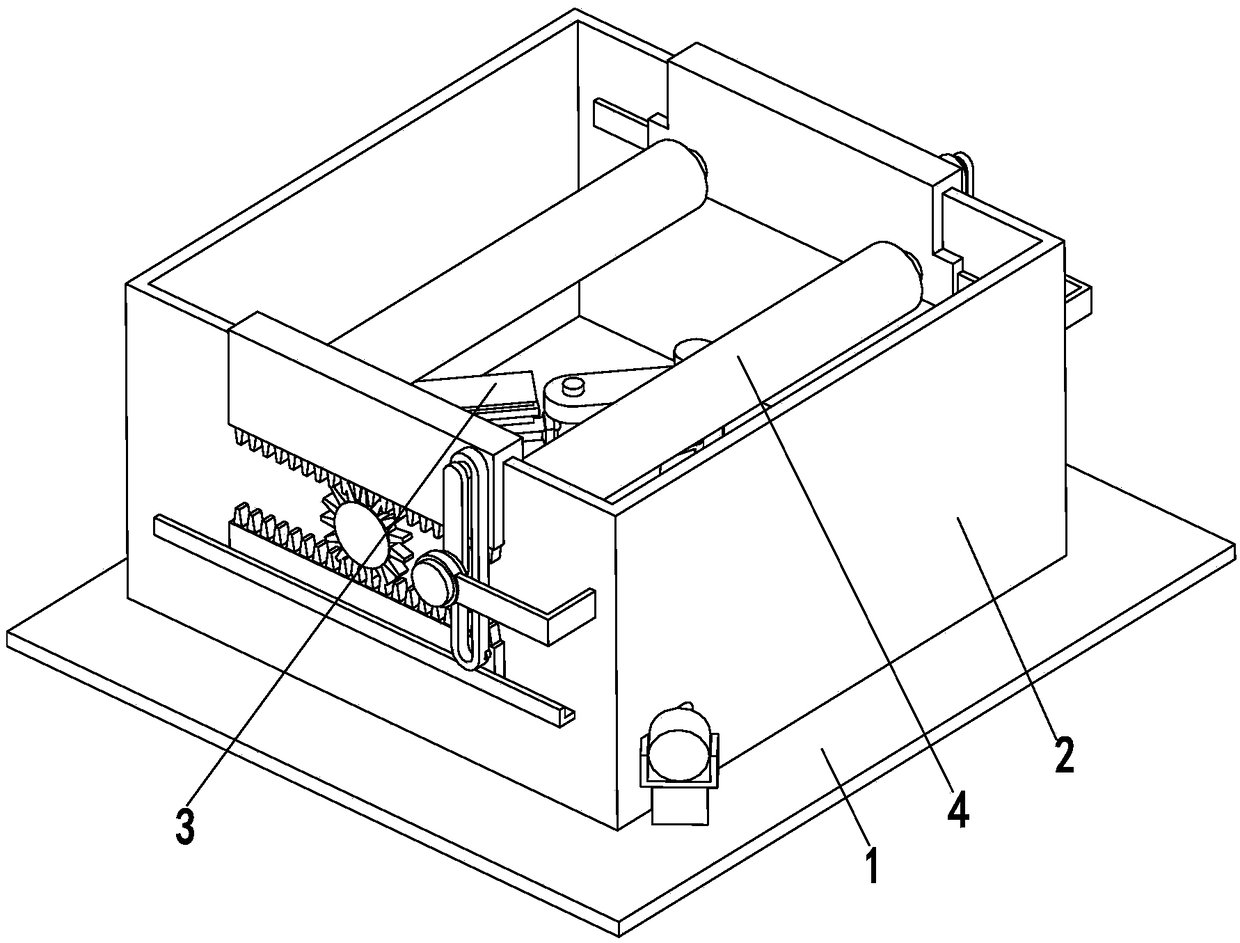

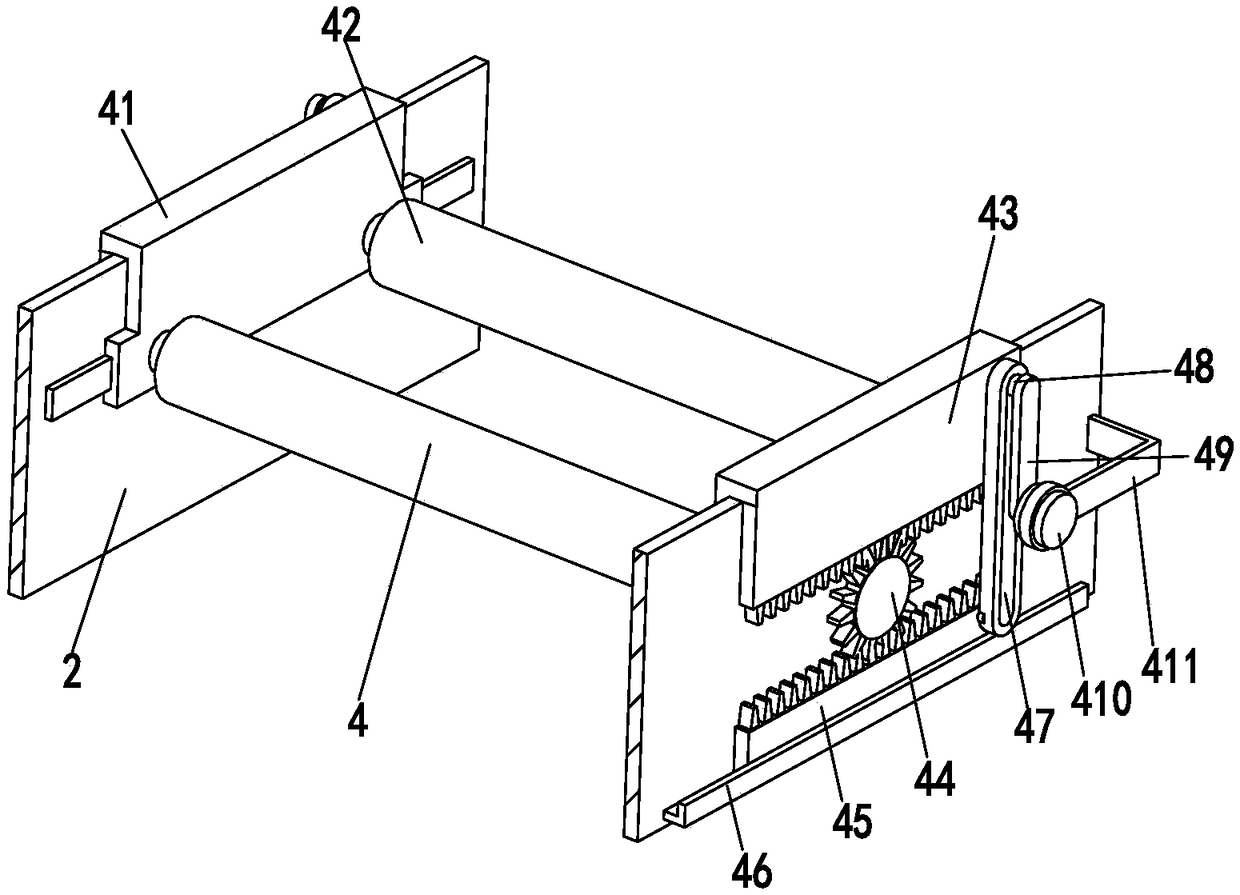

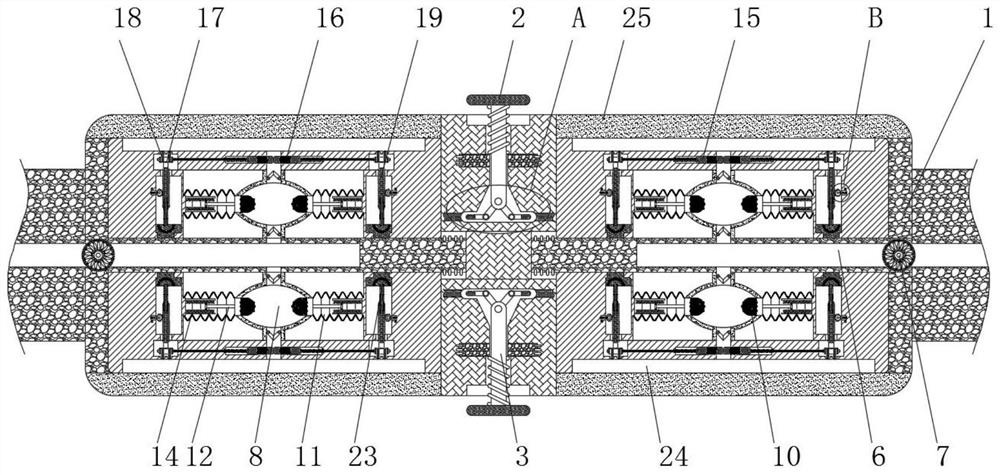

Dye vat for jig dyeing of textiles and automatic dye stirring technology

ActiveCN108754949AGuaranteed to proceed normallyExpand the scope of workLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsEngineeringFixed Slide

The invention relates to a dye vat for jig dyeing of textiles and an automatic dye stirring technology. The dye vat comprises a bottom plate, a tank, a stirring mechanism and an oscillating mechanism,the tank is mounted on the bottom plate, the stirring mechanism is mounted at the bottom of the tank, and the oscillating mechanism is mounted on sidewalls of the tank. The stirring mechanism comprises a fixed column, a sliding rack, connection columns, stirring racks, first connection plates, rotating shafts, second connection plates, a stirring motor and a fixed support. The oscillating mechanism comprises oscillating racks, auxiliary rollers, oscillating racks, gears, auxiliary racks, fixed slide grooves, working racks, protruding columns, rotating racks, rotating motors and mounting racks. The dye vat solves the problems of uneven dye distribution, uneven dyeing and the like of an existing jig dyeing process, can automatically stir dye in the dye vat and has the advantages of even dyedistribution, dyeing evenness and the like.

Owner:浙江旺盛控股集团股份有限公司

Plastic injection moulding technology

The invention discloses a plastic injection moulding technology, and relates to the field of the manufacturing technique of plastic products. The technology comprises the following steps of burdening, wherein raw materials are mixed according to a certain matching ratio and are evenly stirred; molten plasticizing, wherein the matched raw materials are put into an injection moulding machine and are heated to a certain temperature by adopting ultrasonic vibration, and heat preservation is carried out for 10 minutes to 25 minutes; pressure application injection, wherein under a certain pressure and speed, the molten raw materials are injected into a mould cavity through an injection device; mould filling cooling, wherein after the mould cavity is filled with the molten raw materials, a certain pressure is kept, and the molten raw materials are waited to be cooled and cured; mould ejection part taking; after the raw materials are completely cooled, mould sinking is carried out, and a mould ejection mechanism is used for ejecting out a product. According to the technology, ultrasonic vibration heating is carried out, colourment can be mixed with materials better, and the uneven color phenomenon can be obviously improved; in addition, due to ultrasonic vibration heating, energy resources can be saved, plasticizing time of the raw materials can be shortened, and the technological process is shortened.

Owner:NINGGUO GUANYU MOLD

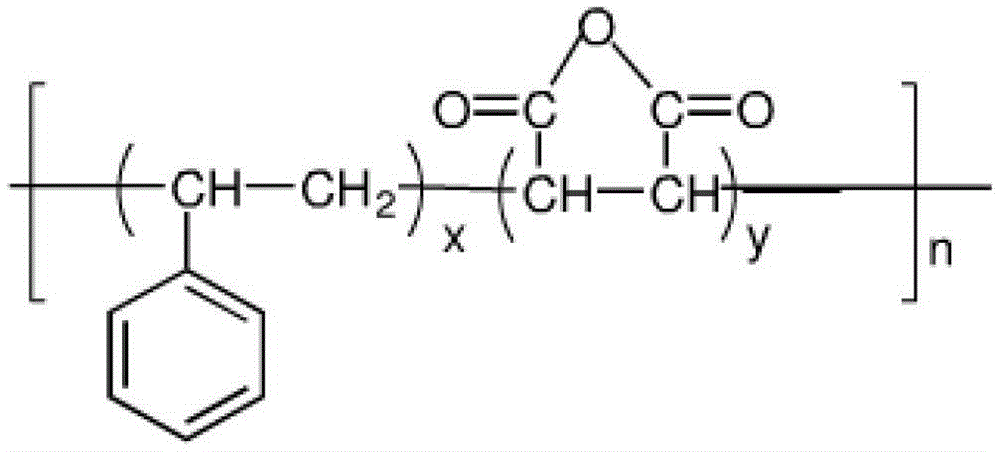

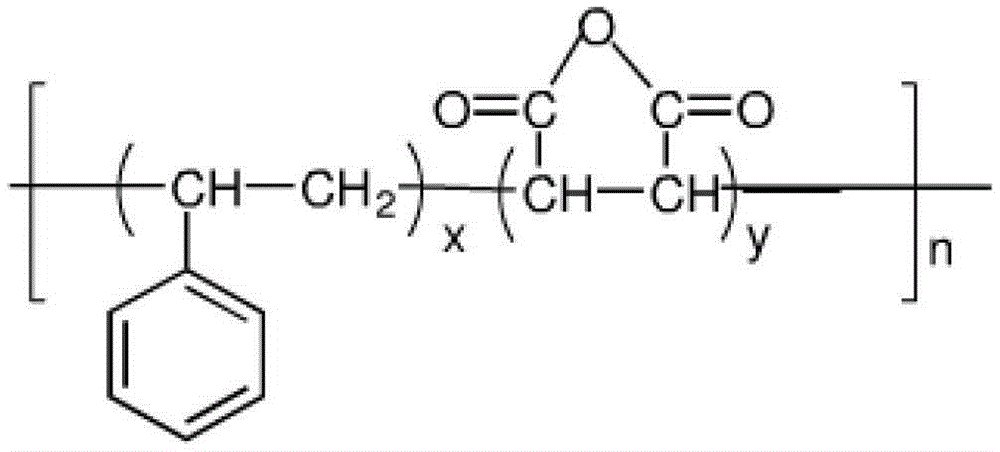

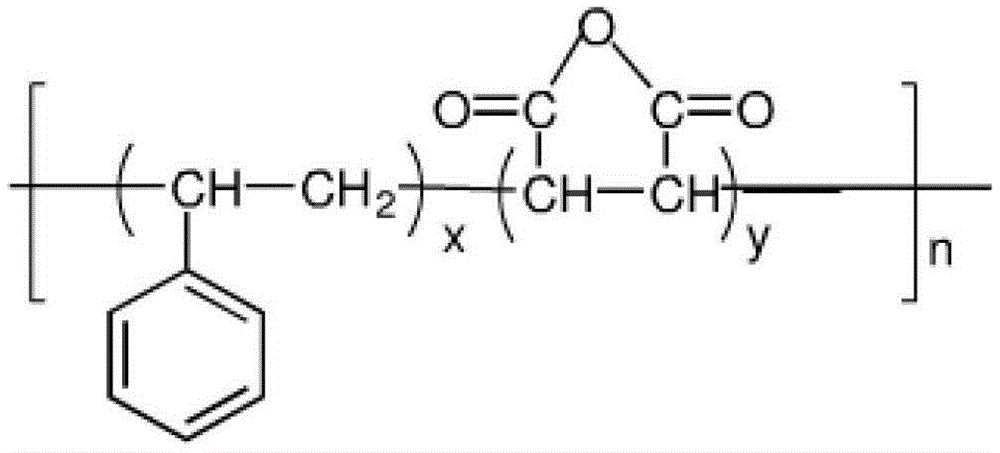

Application of styrene-maleic anhydride copolymer and derivatives thereof in preparation of ultraviolet cured printing ink

The invention discloses an application of styrene-maleic anhydride copolymer and derivatives thereof in preparation of ultraviolet cured printing ink, and belongs to the field of ultraviolet cured printing ink. The particular method comprises the following steps: firstly preparing color paste which comprises the following raw materials by weight: 0.1-5% of styrene-maleic anhydride copolymer and / or derivatives thereof, 80-94.9% of acrylate monomers, and 5-15% of toner, and then preparing the ultraviolet cured printing ink from the color paste; or directly preparing the ultraviolet cured printing ink which comprises the following raw materials by weight: 1-5% of styrene-maleic anhydride copolymer and / or derivatives thereof, 60-70% of acrylate oligomers, 1-10% of acrylate monomers, 7-20% of toner, and 8-18% of other additives, wherein the other additives comprise a levelling agent and / or an photoinitiator and / or a defoamer. According to the invention, through the addition of the styrene-maleic anhydride copolymer and derivatives thereof during the preparation of the ultraviolet cured printing ink, the storage stability of the ultraviolet cured printing ink product is improved, and the purpose of long-term stable storage is reached.

Owner:SHANGHAI PHICHEM MATERIAL CO LTD +1

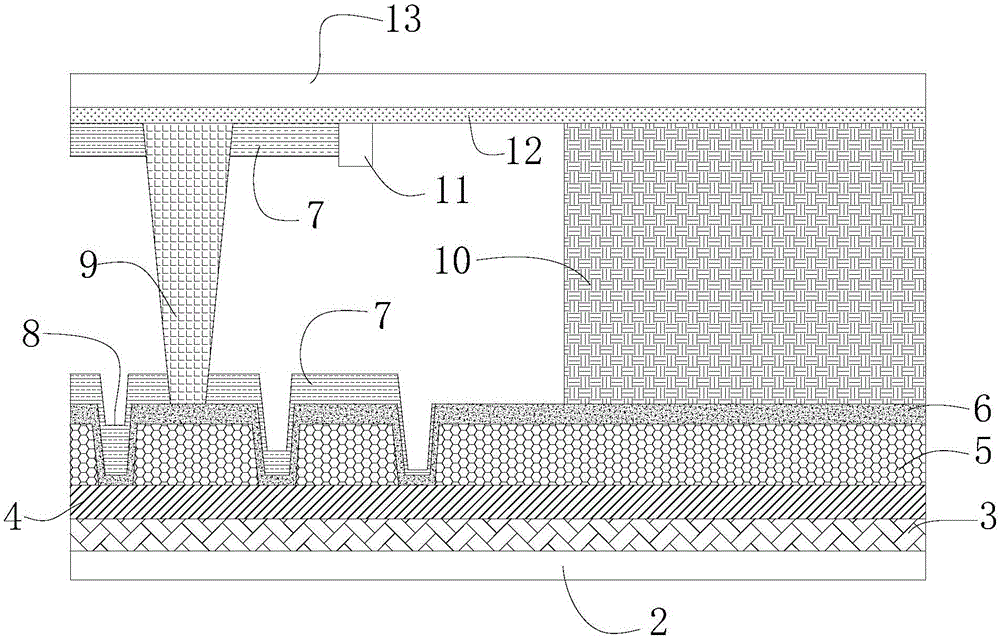

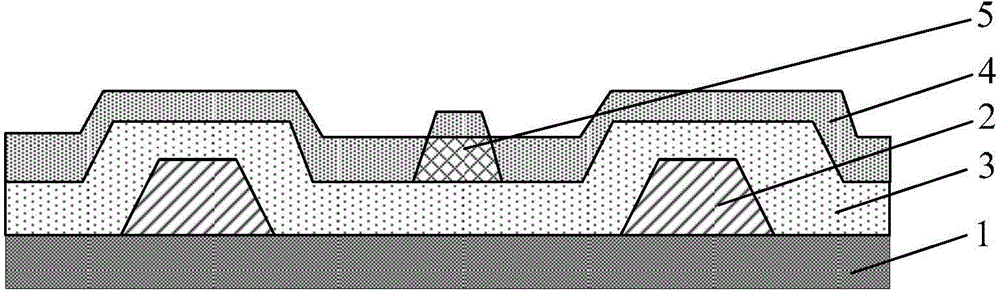

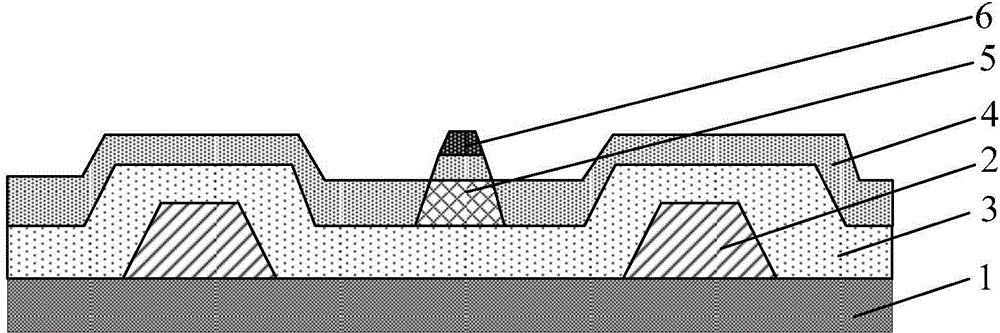

Array substrate, manufacturing method of array substrate and display panel of array substrate

ActiveCN104091806AAvoid uneven colorImprove pass rateSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSurface plate

The embodiment of the invention provides an array substrate, a manufacturing method of the array substrate and a display panel of the array substrate and relates to the technical field of display. The problem that an existing display panel is uneven in thickness of a partition pad corresponding to a grid line and / on a data line of the array substrate to cause different gaps after the display panel is boxed is solved. Furthermore, uneven color of a displayer is avoided, and the production cost is reduced. The array substrate comprises a substrate body, the grid line, a grid insulation layer and the data line. Through holes are formed in the grid line and / or the data line of the array substrate and at the positions corresponding to the partition pad. The array substrate is applied to manufacturing of displayers.

Owner:BOE TECH GRP CO LTD +1

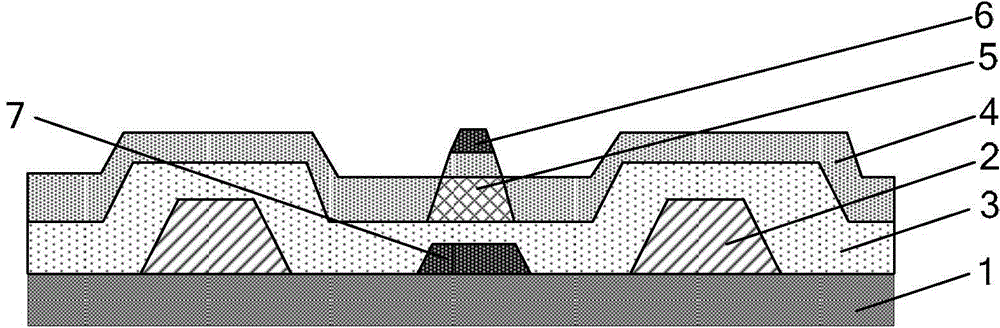

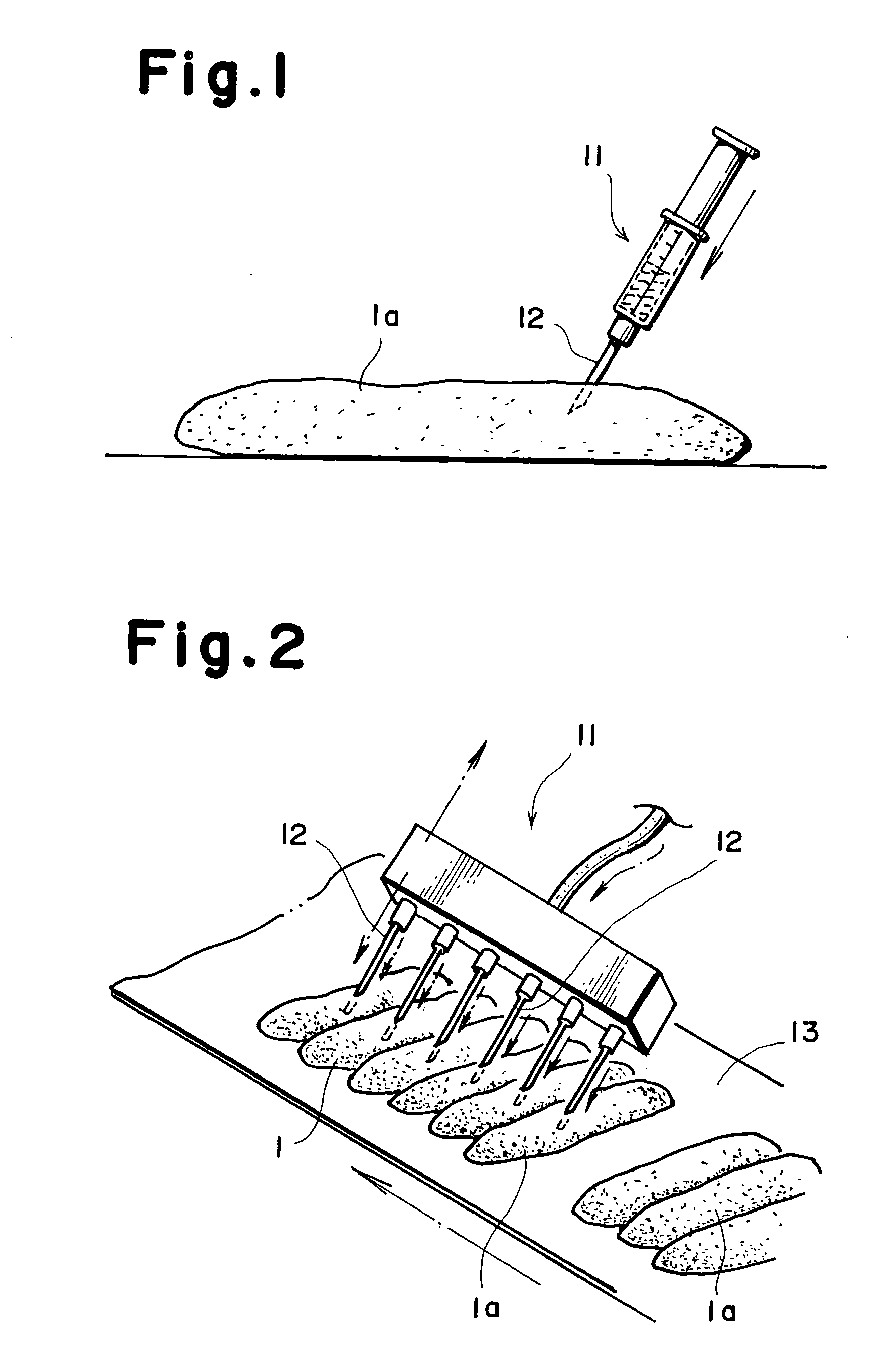

Method of producing salted cod roe

InactiveUS20040258810A1Quality improvementAvoid uneven colorInjection-based meat tenderisingPiercing-based meat tenderisingSaline solutionsState specific

Provided is a method of producing salted cod roe including pickling the roe with a seasoning solution by injecting the seasoning solution into the roe. In the method, frozen roe or fresh roe is washed with saline solution and then the seasoning solution is injected into the roe followed by standing for a predetermined time so that the seasoning solution can migrate into the roe to perform of pickling the roe with the seasoning solution. The method can produce salted roe of a high quality without causing uneven pickling and uneven coloring, achieve uniform migration of the seasoning solution therein in a short time, and maintain the most tasty state specific to salted cod roe. As a result, just-produced, fresh salted cod roe that can be eaten in the most tasty state is produced.

Owner:TOWA FOODS

Method for treating birch bark

InactiveCN104942939AAvoid crackingGuaranteed toughnessWood treatment detailsThermal wood treatmentPotassium nitrateBetula platyphylla

The invention relates to a method for treating birch bark. The method comprises the following steps: (1) peeling fresh birch bark, cleaning the surface, suffocating for 1.5-2 hours by a steamer, and then cooling naturally; (2) preparing a treatment solution, mixing 3.2-4 parts of polyethylene glycol, 6-8 parts of glycerinum, 4.5-6.8 parts of potassium nitrate, 1-1.8 parts of pine-seed oil, 1.5-2.4 parts of chlorinated paraffin and 25 parts of water evenly so as to prepare the treatment solution; (3) putting birch bark treated in the step (1) into the treatment solution prepared in the step (2), soaking for 2-3 days, flushing clean with clear water after treating is completed, then suffocating for 0.5 hour by the steamer, taking out, cooling to normal temperature at the cooling speed of 2 DEG C / min. The method for treating birch bark for bark pictures is simple, and is convenient to use; the treated birch bark is good in stability and is easy to color.

Owner:阜南佳利工艺品股份有限公司

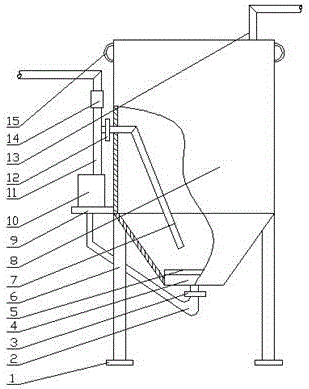

Device and method for preparing supported catalyst by spraying

PendingCN107837825AAvoid uneven colorEvenly dispersedCatalyst activation/preparationEngineeringActive component

The invention discloses a device for preparing a supported catalyst by spraying. The device comprises a pot-bellied glass tube and an oil bath pan, wherein the two ends of the pot-bellied glass tube are provided with openings, and a reaction chamber is arranged in the middle of the pot-bellied glass tube; the pot-bellied glass tube is arranged on the oil bath pan through a support, and the pot-bellied glass tube is connected with a motor through a transmission device; one end of the pot-bellied glass tube is connected with a watering pot, and a spray pipe of the watering pot extends into the reaction chamber of the pot-bellied glass tube; a nozzle is arranged on the spray pipe, and a first sealing plug is arranged between the spray pipe and the pot-bellied glass tube; the other end of thepot-bellied glass tube is connected with an L-shaped elbow pipe through a second sealing plug, and the pipe body of one end, away from the pot-bellied glass tube, of the L-shaped elbow pipe is sleevedwith a condensing device. The invention also discloses a method for preparing the supported catalyst by spraying by utilizing the device. The device provided by the invention has reasonable design and simple structure, can prepare the catalyst in which uniformly dispersed active components are dispersed on the surface of a carrier, and provides a novel solution for preparing the granular supported catalyst in a laboratory.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Superfine gelsemium elegans benth powder and preparation method

InactiveCN101972304AMaintain bioactive substancesImprove bioavailabilityPowder deliveryDigestive systemGelsemium elegansThree stage

The invention discloses superfine gelsemium elegans benth powder and a preparation method and relates to a Chinese veterinary medicament, a veterinary natural plant feed additive and a preparation method. The main process comprises the following steps of: cutting selected gelsemium elegans benth into segments of between 3 and 5 centimeters; performing far infrared drying on the segments until the water content of the segments is less than 3 percent; smashing the dried segments at three stages comprising air stream superfine smashing for lowering the average grain size to be less than 10 microns; and removing oxygen and performing vacuum packing so as to obtain a superfine gelsemium elegans benth powder product. Compared with the conventional powder, the superfine gelsemium elegans benth powder of the invention has higher processing quality. The surface area of the superfine gelsemium elegans benth powder product is enlarged, the adsorption capacity is enhanced and the dissolving speed is increased; simultaneously, the broken sporoderm rate of plant cells is increased by superfine smashing, so that the superfine gelsemium elegans benth powder can be easily digested and absorbed by a livestock organism.

Owner:张奎昌

Spinning liquid dye storage device

ActiveCN105905463AGuaranteed purityAvoid blockingLarge containersUnderwater structuresBiochemical engineering

The invention relates to the field of spinning, in particular to a spinning liquid dye storage device. The spinning liquid dye storage device can prevent liquid dyes are stored in barrels and used, so that production cost is reduced, manual use amount can be reduced, and production efficiency is improved. The device structurally comprises a tank body, and the lower portion of the tank body is of a conical structure. A base is arranged in the bottom of the tank body and is of a circular tube structure. A filter screen is arranged on the upper surface of the base and is of a grid structure. A water pump is supported on the side surface of the tank body through a bottom plate. The water pump is communicated with the base in the tank body through a first discharging pipe, and the outer surface of the first discharging pipe is sleeved with a first pipeline valve. The upper portion of the water pump is sleeved with a second discharging pipe, and the outer surface of the second discharging pipe is sleeved with a second pipeline valve. The spinning iquid dye storage device is large in storage space, high in use efficiency, low in use cost and suitable for storage and use of the spinning liquid dyes.

Owner:苏州青瓷纺织整理有限公司

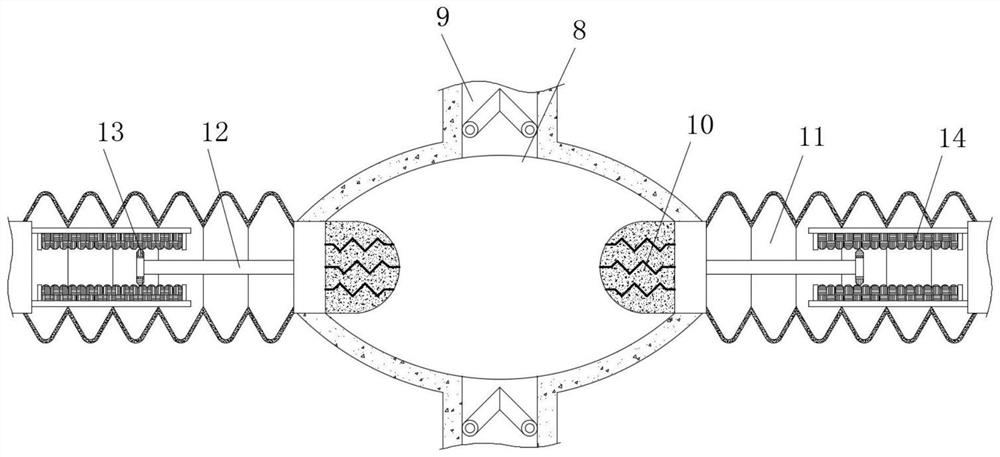

Printing and dyeing roller capable of avoiding color non-uniformity and liquid leakage

PendingCN112813622AAvoid uneven colorPrevent leakageTextile treatment machine arrangementsTextile treatment rollersTextile manufacturingTextile printer

The invention relates to the technical field of textile manufacturing, and discloses a printing and dyeing roller capable of avoiding color non-uniformity and liquid leakage. The printing and dyeing roller comprises a rack; a pressing plate is movably connected to the center of the side surface of the rack; a pressing rod is fixedly connected to the bottom of the pressing plate; a metal feeler lever is rotatably connected to the end, far away from the pressing plate, of the pressing rod; a metal strip is fixedly connected to the side face, close to the metal feeler lever, of the rack; a liquid inlet groove is formed in the circle center of the rack; a water pump is fixedly connected to the interior of the liquid inlet groove; and an elastic cavity is movably connected to the interior of the rack. The pressing plate is pressed, so that a dye solution in the elastic cavity in the side can enter a liquid cavity and is pad-dyed on the surface of cloth through a pressing roller; and a liquid conveying opening can be automatically closed on the non-pressed side of the pressing plate, so that the internal solution is prevented from flowing out, and the effects that a liquid outlet can be automatically closed, the surface of the cloth is prevented from being polluted due to overflow of the internal solution and printing is clearer are achieved.

Owner:海宁市骄阳旗材有限公司

Preparation method of gas-containing yoghurt drink

InactiveCN106035649APromote absorptionTaste cool and refreshingMilk preparationAdditive ingredientProduct gas

The present invention discloses a preparation method of a gas-containing yoghurt drink. The carbon dioxide content of the gas-containing yoghurt drink prepared by the method is 0.2%-1.2%. The product is poured into a cup and the carbon dioxide gas emerges, after the drink is poured out completely, the height of bubbles is 0.5 cm or more, and the duration time is 1 min or more. A production technology of twice fermenting is used, the tastes of the products are cooler and fresher in mouthfeel, the main nutrients of proteins, fats, carbohydrates, etc. are more conducive to digestion and absorption, and after the drink is drunk, the drink has a strong sense of fullness and significant weight losing effects. A production technology of thrice sterilizing is used to ensure that the gas-containing amount of the products is controlled and avoid the problems that the products may burst due to the fact that the gas-containing amount of the live bacterium yoghurt drink cannot be controlled. By further browning, the color of the yogurt is more uniform and the phenomenon of uneven color of the yogurt is avoided.

Owner:GAEA GEM RICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com