Device and method for preparing supported catalyst by spraying

A supported catalyst and catalyst carrier technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as uniform distribution of metals, and achieve the effect of avoiding uneven color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

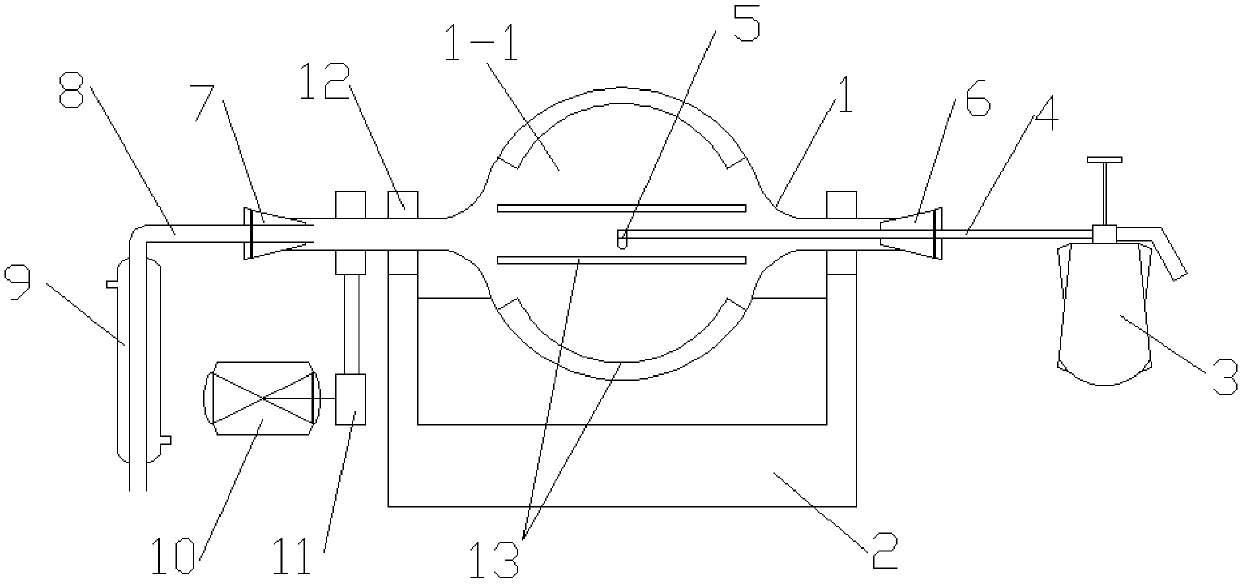

[0037] Such as figure 1 As shown, the present invention includes a big belly glass tube 1 and an oil bath 2, the two ends of the big belly glass tube 1 are open, and the middle part has a reaction chamber 1-1 for placing catalyst carrier particles, the big belly glass tube 1 The belly glass tube 1 is arranged on the oil bath 2 through a bracket 12, and the belly glass tube 1 is connected with a motor 10 for driving the belly glass tube 1 to rotate through a driver 11, and one end of the belly glass tube 1 Connect with the watering can 3 that is used to place the immersion liquid, the nozzle 4 of the watering can 3 stretches into the reaction chamber 1-1 of the big belly glass tube 1, the nozzle 5 is installed on the nozzle 4, and the nozzle 5 Located at the center of the reaction chamber 1-1, a first sealing plug 6 is arranged between the nozzle pipe 4 and the big-bellied glass tube 1, and the other end of the big-bellied glass tube 1 passes through the L-shaped elbow 8 The s...

Embodiment 2

[0047] Adopt the device of present embodiment 1 to be used for spraying and prepare the method for supported catalyst comprising the following steps:

[0048] Step 1, place the catalyst carrier particles in the reaction chamber 1-1 of the big-bellied glass tube 1, and place the prepared impregnating solution in the watering can 3 at the same time, then place the watering can 3 and the L-shaped elbow with the impregnating solution 8 are respectively assembled on the potted glass tube 1 through the first sealing plug 6 and the second sealing plug 7, and the watering pot 3 and the L-shaped elbow 8 are installed on the potted glass tube through the first sealing plug 6 and the second sealing plug 7 respectively. On both ends of the tube 1, the big belly glass tube 1 is installed on the oil bath 2 through the bracket 12, and the big belly glass tube 1 is connected with the motor 10 through the driver 11;

[0049] Step 2, turn on the oil bath 2, heat the carrier particles in the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com