Spinning liquid dye storage device

A storage device and dye technology, applied in the textile field, can solve the problems affecting the production efficiency of textile enterprises, low efficiency, more labor, etc., and achieve the effect of avoiding uneven coloring, preventing precipitation, and ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following describes the embodiments of the present invention with reference to the accompanying drawings, and the embodiments do not constitute a limitation to the present invention;

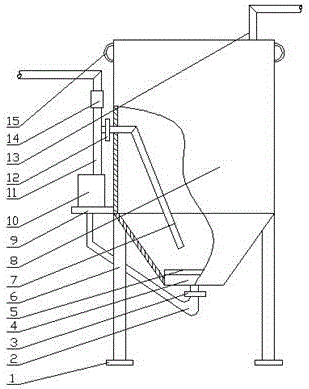

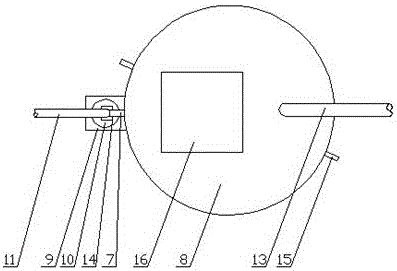

[0022] Such as figure 1 , figure 2 As shown, the liquid dye storage device for textiles has a structure including a tank body 8. The lower part of the tank body 8 is a cone structure. The tank body 8 is used to store liquid dyes when in use; the inner bottom of the tank body 8 is provided with a base 4 , The base 4 is a round tube structure. When in use, the base 4 is used to support the filter 5, and the filter 5 is lifted to a certain height to facilitate the staff to clean the filter 5; the upper surface of the base 4 is provided with a filter 5 to filter The net 5 has a grid structure. When in use, the filter net 5 can block impurities in the liquid dye, prevent the impurities from entering the first discharge pipe 2 and block the pipeline, and at the same time can ensure the purity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com