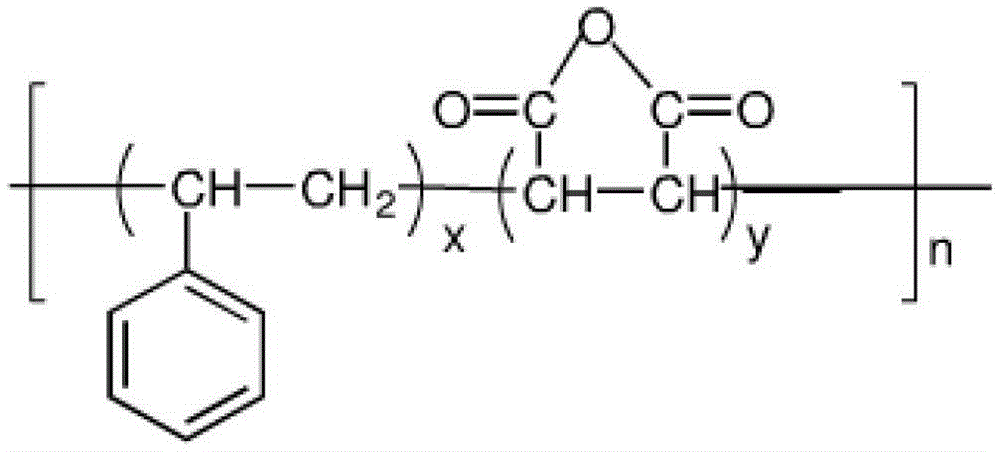

Application of styrene-maleic anhydride copolymer and derivatives thereof in preparation of ultraviolet cured printing ink

A technology of maleic anhydride and styrene, applied in the field of UV-curable ink, can solve the problems of particle reaggregation, uneven coloring, etc., and achieve the effect of stable properties, avoiding uneven coloring, and long-term stable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step (1), preparing color paste, the specific method is as follows:

[0032] Weigh raw materials: SMA50005g, trimethylolpropane acrylate (TMPTA) 80g, titanium dioxide 15g.

[0033] Grind the above raw materials with a sand mill until the particle size is less than 1um, and filter to obtain a white color paste.

[0034] Step (2), using the color paste prepared in the previous step to prepare UV-curable ink, the specific method is as follows:

[0035] The above-mentioned white color paste 16g, bisphenol A epoxy acrylic resin 50g, pentaerythritol triacrylate 20g, hexanediol acrylate diester 6.5g, TPO photoinitiator 5g, 184 photoinitiator 2g, BYK333 leveling agent 0.5g, Put it into the reaction kettle, stir at 60°C for 2 hours, filter and discharge to obtain the UV-curable optical fiber white ink product.

Embodiment 2

[0037] Step (1), preparing color paste, the specific method is as follows:

[0038] Weigh raw materials: SM10000.1g, 50g hexanediol acrylate (HDDA), 44.9g trimethylolpropane acrylate (TMPTA), 5g permanent violet.

[0039] Grind the above raw materials with a sand mill until the particle size is less than 1um, and filter to obtain a purple color paste.

[0040] Step (2), using the color paste prepared in the previous step to prepare UV-curable ink, the specific method is as follows:

[0041] With above-mentioned purple color paste 10g, the white color paste 4g that makes in embodiment 1, bisphenol A epoxy acrylic resin 50g, pentaerythritol triacrylate 20g, hexanediol acrylate diester 8.5g, TPO photoinitiator 5g, 184 Put 2g of photoinitiator and 0.5g of BYK333 leveling agent into the reaction kettle, stir at 60°C for 2 hours, filter and discharge to obtain UV-curable optical fiber purple ink product.

Embodiment 3

[0043] Step (1), preparing color paste, the specific method is as follows:

[0044] Weigh raw materials: 2 g of SMA octyl ester, styrene-maleic anhydride copolymer (the molar ratio of styrene and maleic anhydride is 2:11 g, 82 g of hexanediol acrylate (HDDA), 15 g of permanent red.

[0045] Grind the above raw materials with a sand mill until the particle size is less than 1um, and filter to obtain a red color paste.

[0046] Step (2), using the color paste prepared in the previous step to prepare UV-curable ink, the specific method is as follows:

[0047] With above-mentioned red color paste 8g, the white color paste 4g that makes in the embodiment 1, bisphenol A epoxy acrylic resin 50g, pentaerythritol triacrylate 22g, hexanediol acrylate diester 8.5g, TPO photoinitiator 5g, 184 Add 2g of photoinitiator and 0.5g of BYK333 leveling agent into the reaction kettle, stir at 60°C for 2 hours, filter and discharge to obtain the UV-curable optical fiber red ink product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com