Patents

Literature

63results about How to "Good steric hindrance effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

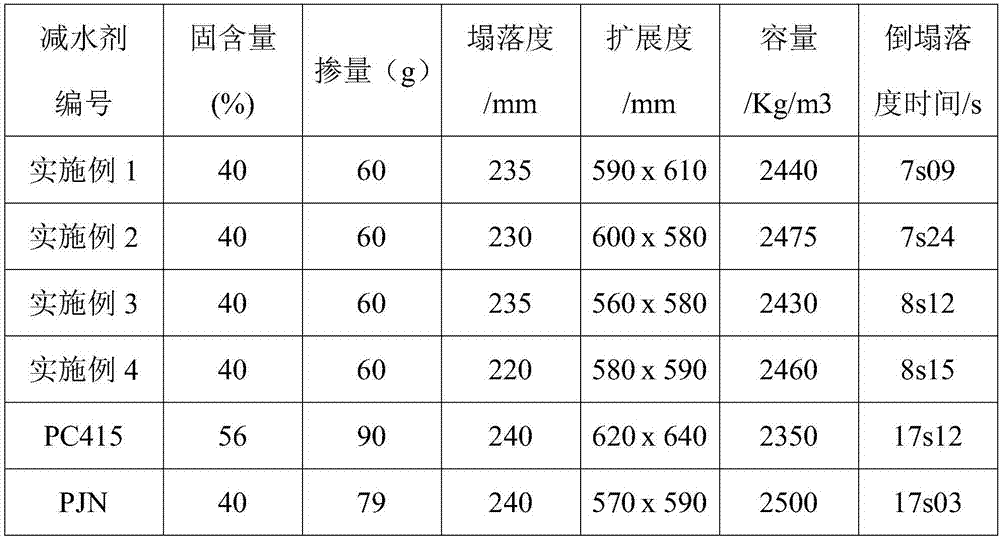

Method for preparing viscosity-reducing polycarboxylate superplasticizer

The invention provides a method for preparing viscosity-reducing polycarboxylate superplasticizer. The viscosity-reducing polycarboxylate superplasticizer is prepared through a bulk polymerization reaction, and the method comprises the following steps of: (1) mixing polyoxyethylene polyoxypropylene ether and polyoxyethylene ether, controlling the temperature at 40-60 DEG C, stirring the mixture evenly, and then adding an initiator and a mixture of unsaturated carboxylic acids, hydroxyalkyl unsaturated carboxylate and a chain transfer agent; and (2) performing aging for 1-1.5 hours after the step (1) is completed, and reducing the temperature to obtain the viscosity-reducing polycarboxylate superplasticizer. Since the bulk polymerization reaction is carried out at a low temperature, the method has strong operability, mild conditions and low energy consumption; the viscosity-reducing polycarboxylate superplasticizer prepared by using the method is at a liquid state at room temperature, has effective concentration of 100% and stable storage performance, and is suitable for long-distance transportation and use; meanwhile, the viscosity of a concrete mixture can be reduced effectively through the superplasticizer so that stirring, transportation and pumping of concrete can be facilitated, and the superplasticizer is suitable for the promotion and application of high-rise engineeringand high-performance concrete.

Owner:JIAHUA CHEM MAOMING

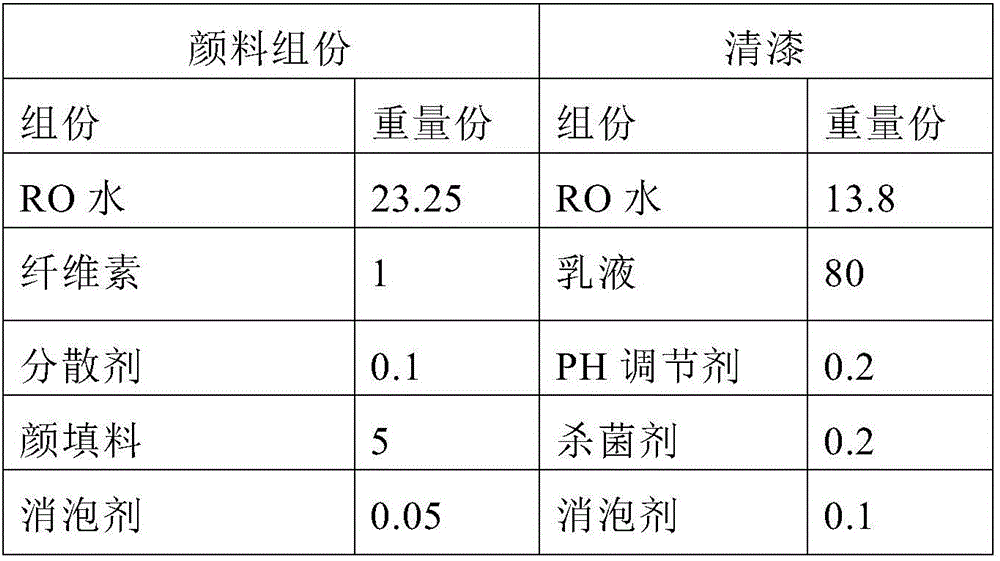

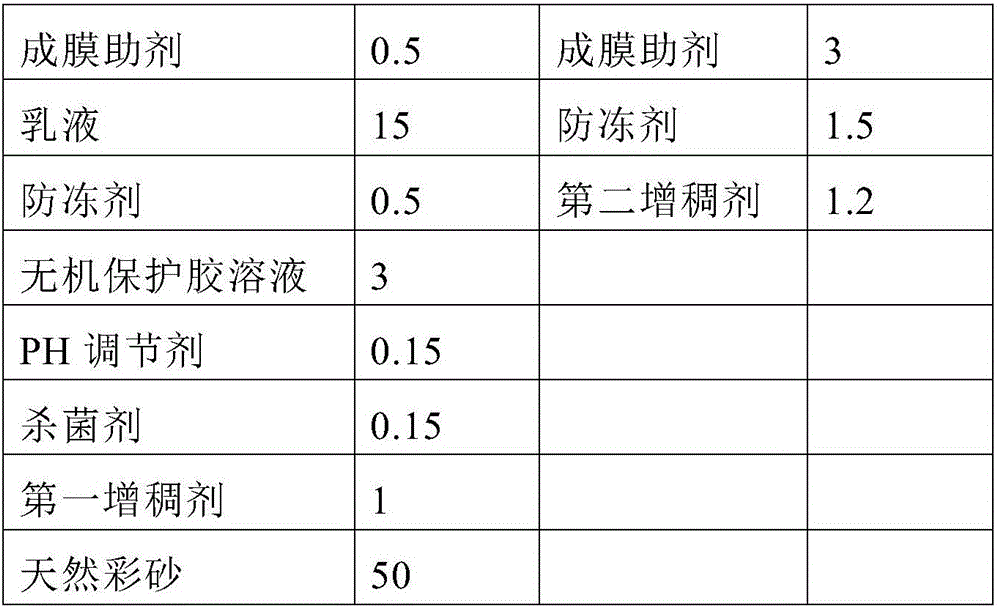

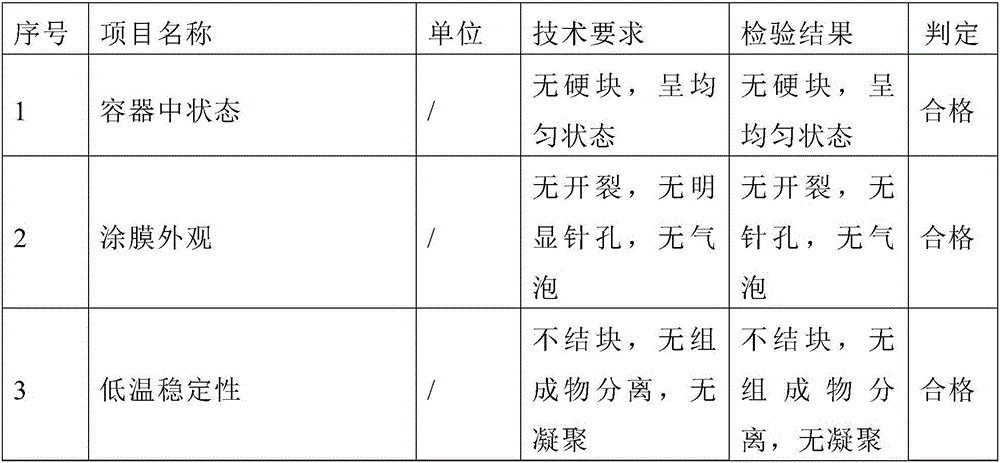

Sand-containing colorful environment-friendly coating and preparation method of same

ActiveCN106366814AGood storage stabilityGood construction stabilityMulticolor effect coatingsAdhesion forceClear Layer

The invention relates to a sand-containing colorful environment-friendly coating and a preparation method of the same. The coating is composed of a pigment component, a dispersion medium and varnish; the pigment component includes RO water, cellulose, a dispersant, pigments and fillers, a defoamer, a film forming additive, an emulsion, an anti-freeze agent, an inorganic protective glue solution, a pH regulator, a sterilizing agent, a first thickener, and natural colorful sands; the dispersion medium includes RO water, the film forming additive, a rheological agent, the emulsion, an organic protective glue solution, the defoamer and a coupling agent; and the varnish includes RO water, the emulsion, the pH regulator, the sterilizing agent, the defoamer, the film forming additive, the anti-freeze agent, and a second thickener. Compared with the prior art, the sand-containing colorful environment-friendly coating has good storage and construction stability, wherein a dried film of the coating is excellent in adhesion force and water resistant performance. The coating, when being used, has a good rough sense and has clear layer sense, thereby representing a texture effect of natural stone materials better.

Owner:上海磐彩环保科技股份有限公司

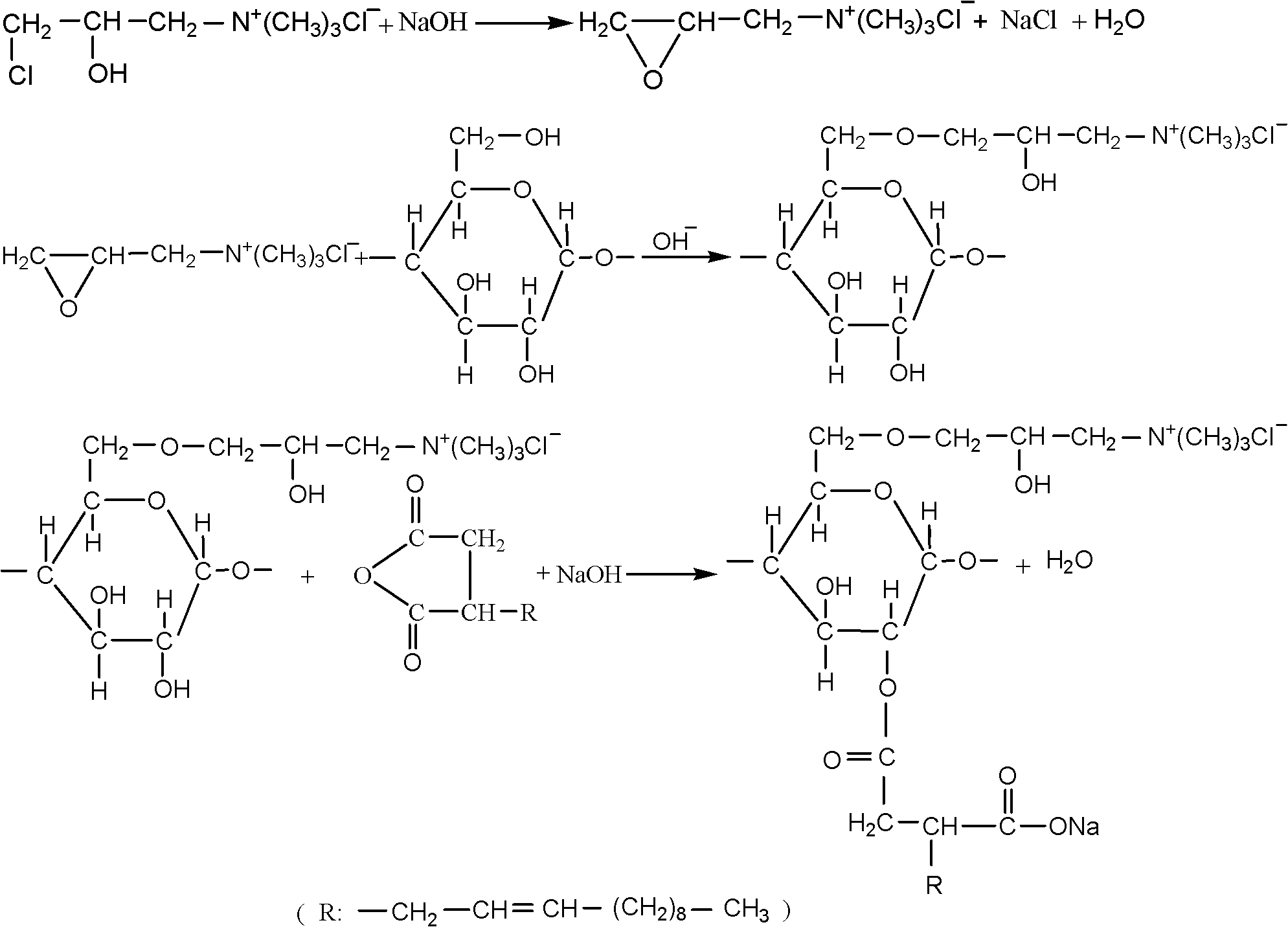

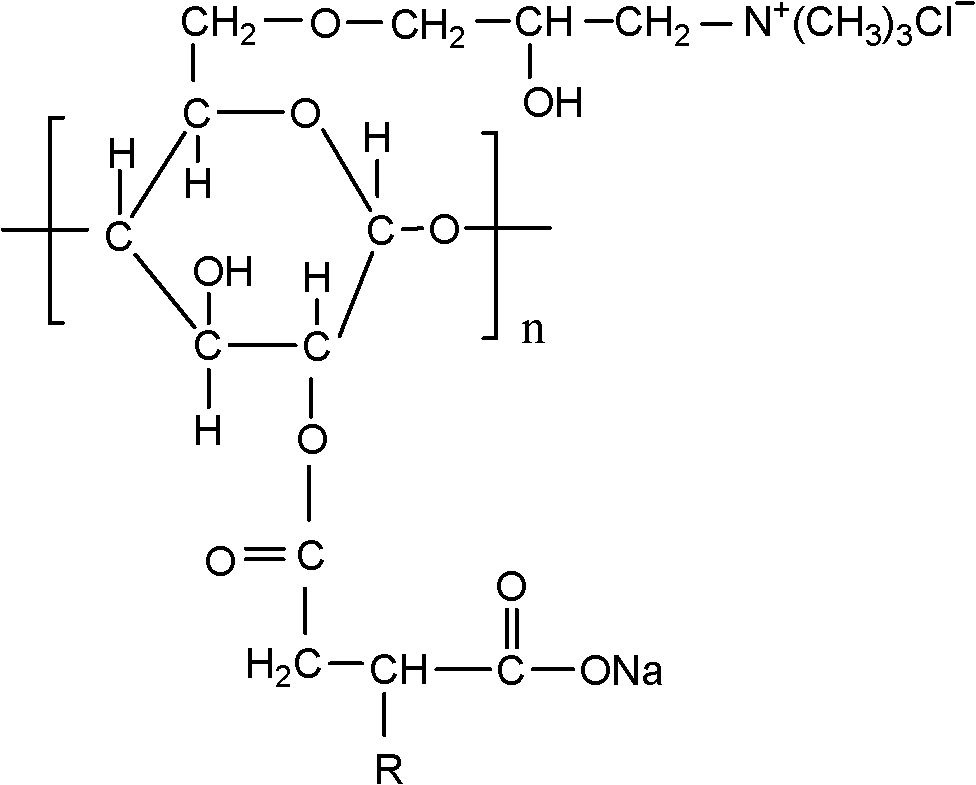

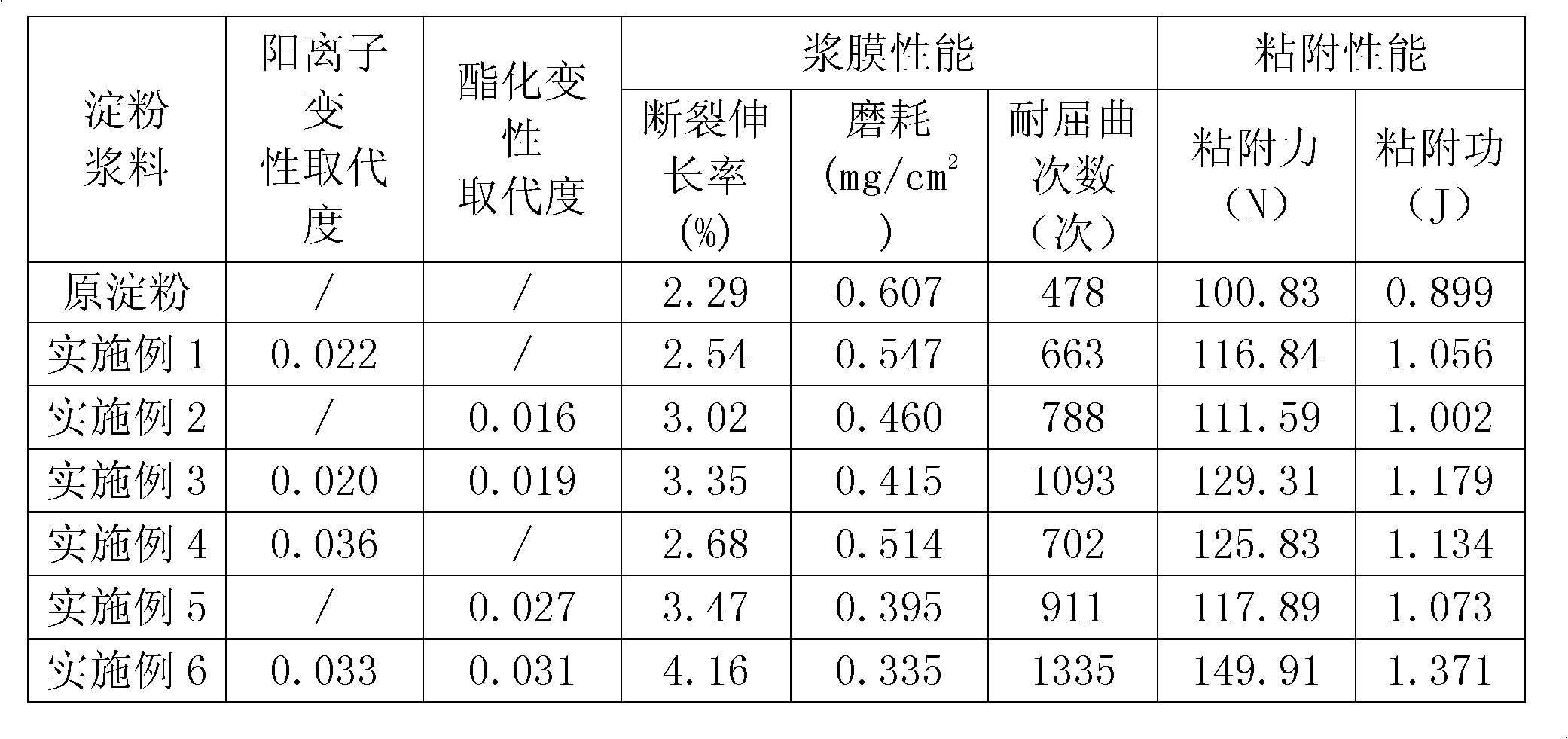

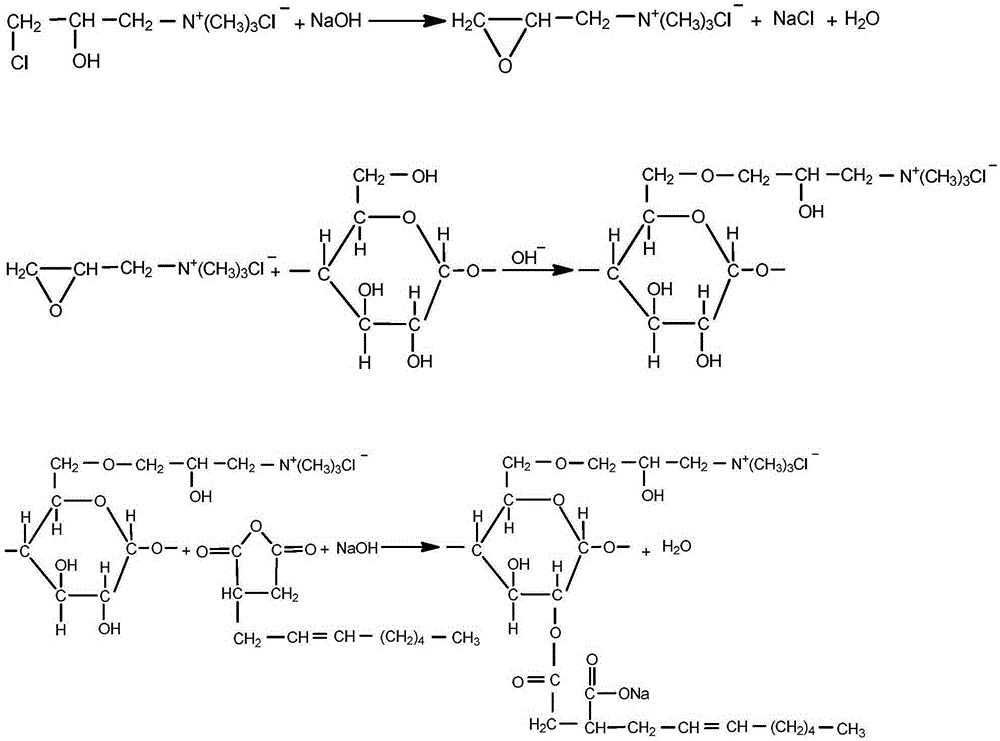

Method for synthesizing composite modified starch slurry

The invention discloses a method for synthesizing composite modified starch slurry, belonging to the technical field of methods for synthesizing the modified starch slurry applied to starching of spinning warps. The method comprises the following steps of: firstly carrying out positive ion modification on starch by utilizing quaternary ammonium type positive ion etherifying agent 3-chlorine-2-hydroxypropyltrimethylammonium chloride to synthesize positive ion starch, and carrying out an esterification reaction between the synthesized positive ion starch and dodecenylsuccinic anhydride so as to synthesize positive ion-dodecenylsuccinate composite modified starch slurry. According to the method for synthesizing the composite modified starch slurry, disclosed by the invention, positive ion groups and ester group which is large in volume and provided with vinyl group are introduced in a starch macromolecular chain so that film performances of the starch slurry is remarkably modified, and adhesion performance of the slurry to synthetic fibers such as terylene can be improved, thus starching requirements of warps, especially the terylene and the like, are better met. The method for synthesizing the composite modified starch slurry, disclosed by the invention, can be used for starching warps of fibers such as cotton, linen, mucilage glue and terylene / cotton, terylene / linen, terylene / mucilage glue through a common sizing machine or a high-speed sizing machine.

Owner:芜湖迅腾新材料有限公司 +1

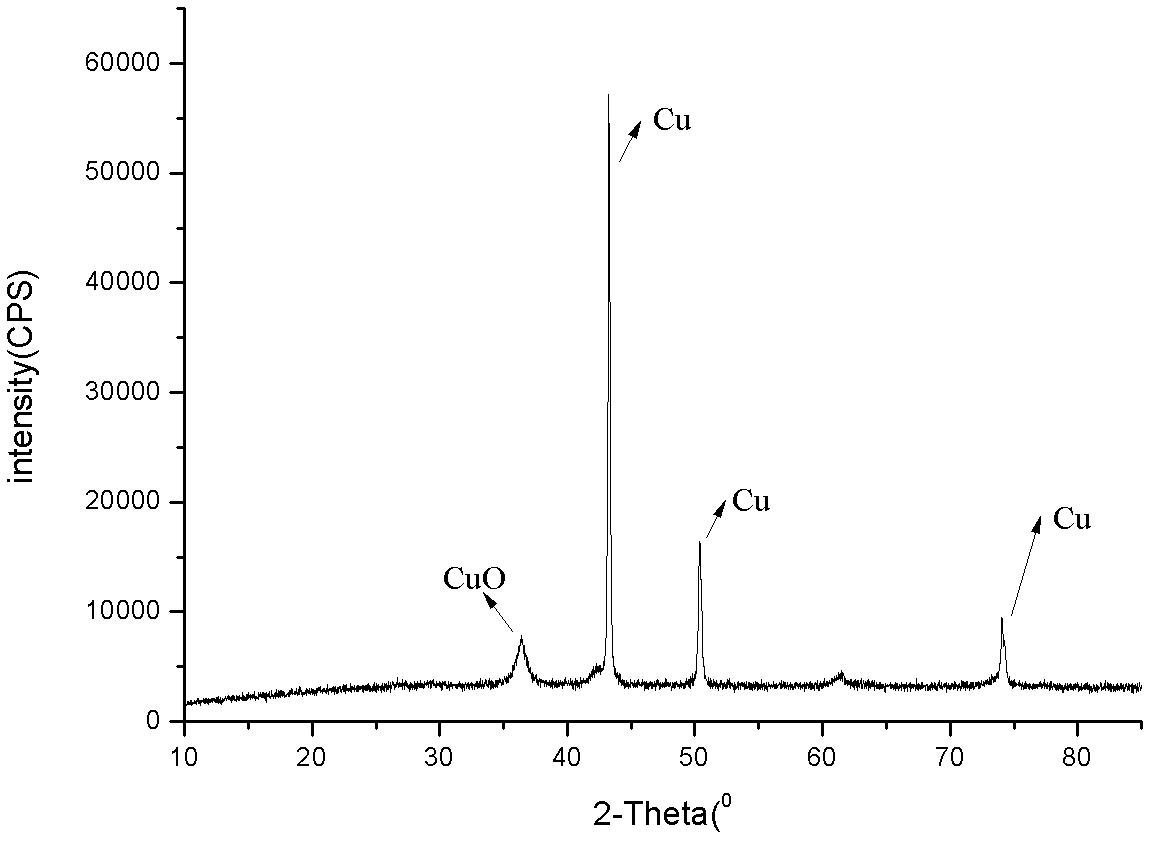

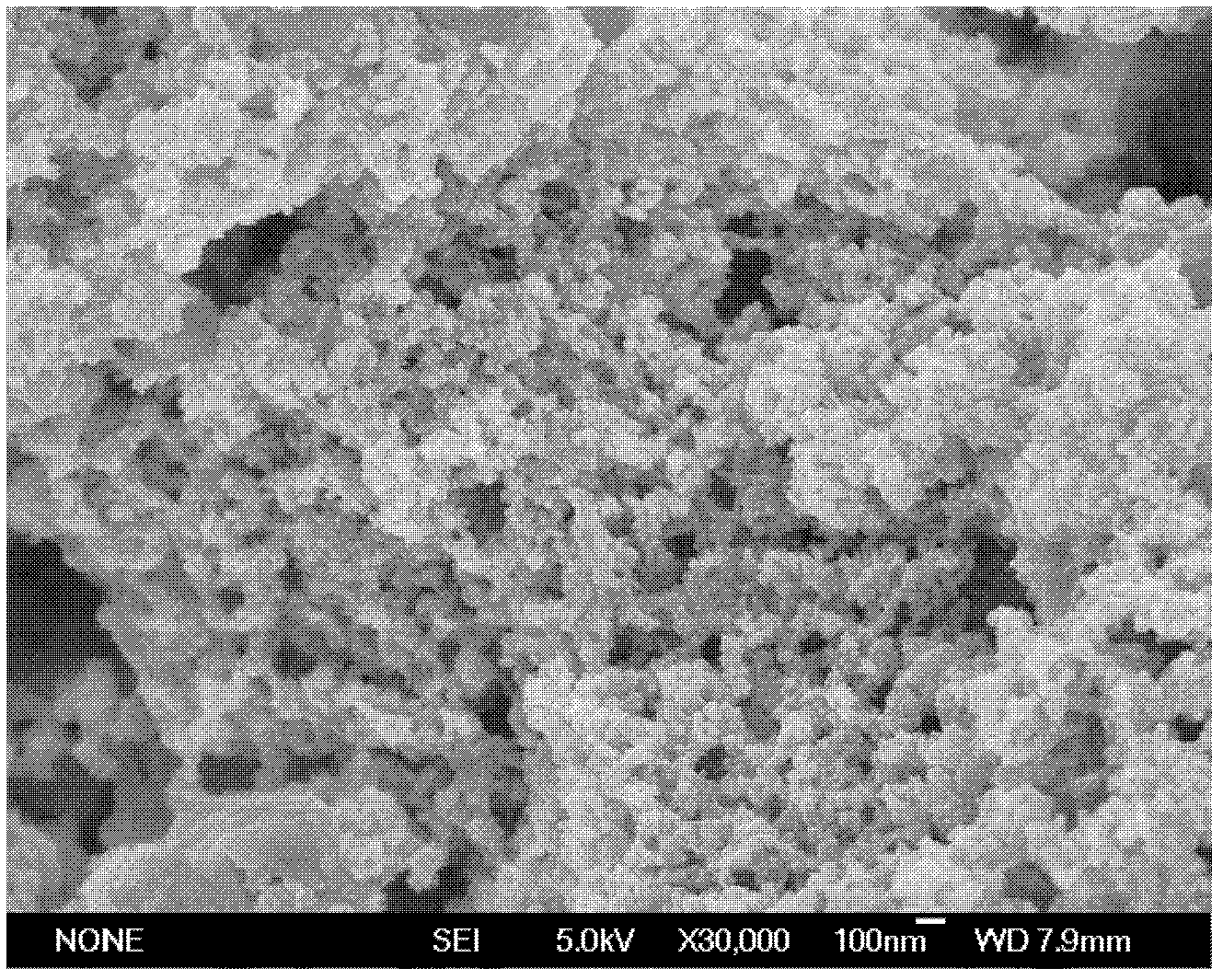

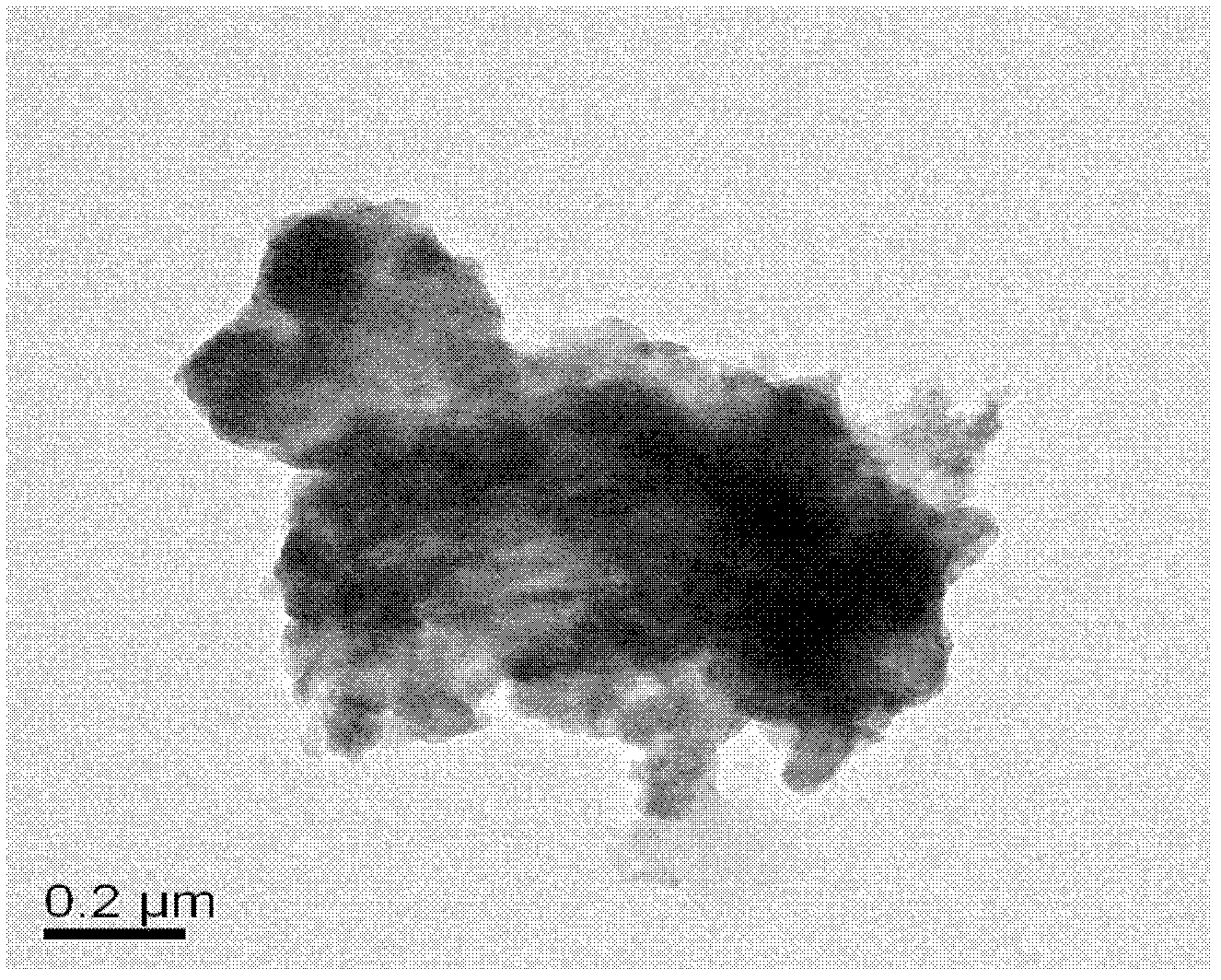

Method for preparing nano copper particle

The invention relates to a method for preparing a nano copper particle, in particular to a novel method for preparing a nano copper particle serving as a lubricating oil additive. The synthesis method comprises the following steps of: dissolving water-soluble divalent copper salt into water; adding a proper amount of acid organic extracting agent and coating agent into the solution; extracting divalent copper ions to an organic phase; and then simply and efficiently preparing spherical nano copper particles which have good dispersion, uniform particle size and good oxidation resistance by adopting a two-step liquid phase reduction method. The method provided by the invention has the advantages such as simple process, convenience for operation, low cost, easiness for industrialization and the like; and the prepared nano copper particle has the advantages of good dispersion, uniform particle size, good oxidation resistance, good friction property and the like.

Owner:CENT SOUTH UNIV

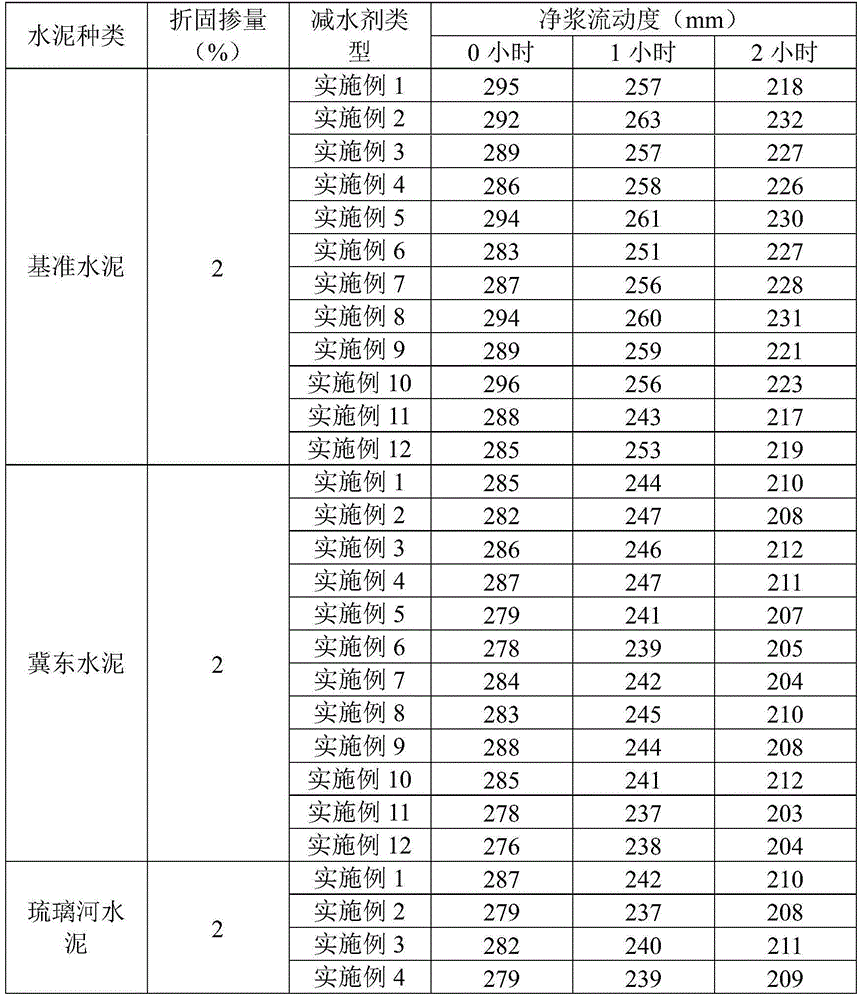

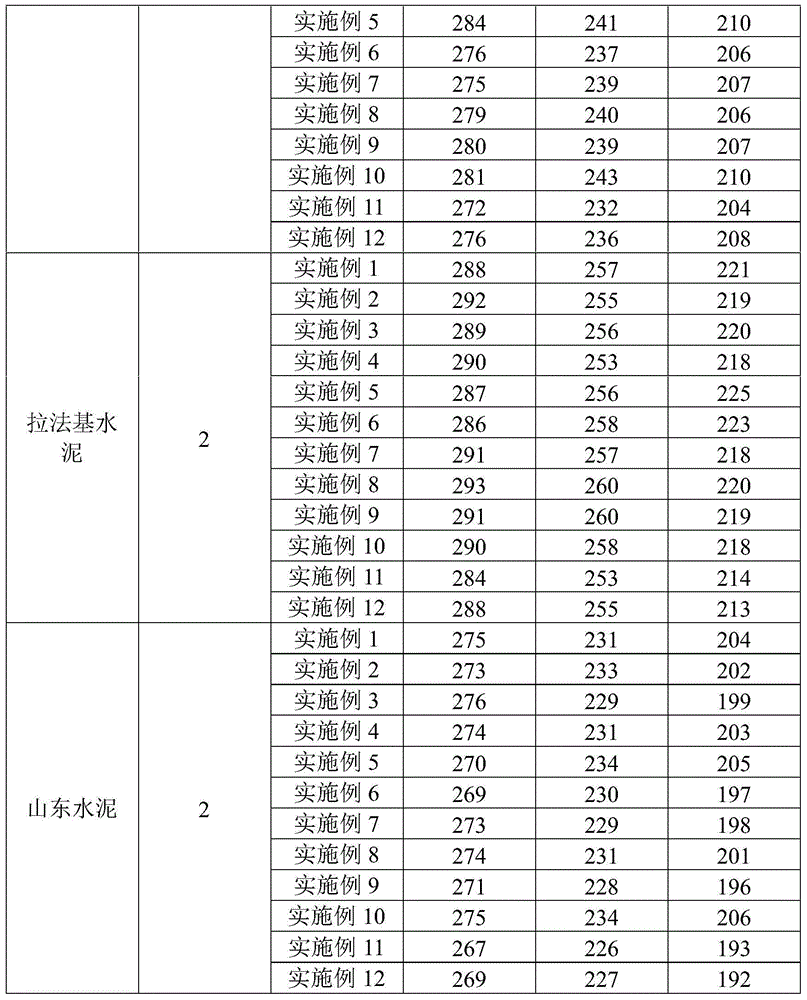

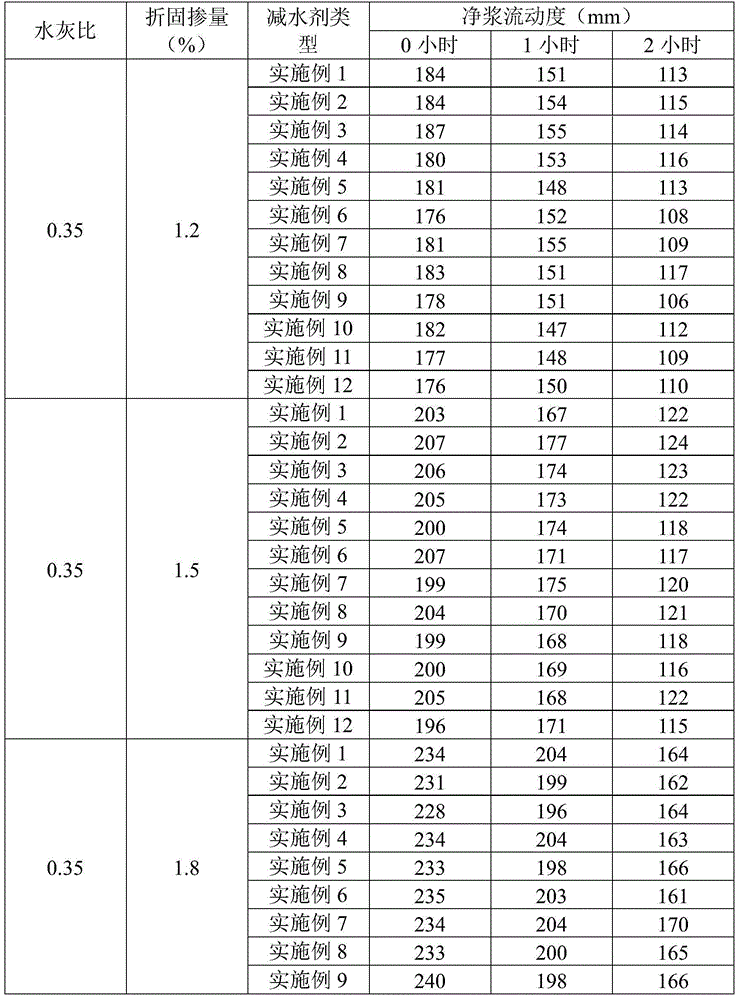

Method for preparing polycarboxylate superplasticizer by carrying out graft copolymerization on acrylic ester polymer and fatty acid vinyl ester

The invention relates to a method for preparing a polycarboxylate superplasticizer by carrying out graft copolymerization on acrylic ester polymer and fatty acid vinyl ester. According to the method for preparing the polycarboxylate superplasticizer by carrying out graft copolymerization on the acrylic ester polymer and fatty acid vinyl ester, acrylic ester polymer and fatty acid vinyl ester are taken as main reaction raw materials, polymerization is carried out firstly, then grafting is carried out and then alcoholysis and hydrolysis are carried out to prepare the polycarboxylate superplasticizer grafted and polymerized with the acrylic polymer and fatty acid vinyl ester, namely acrylic ester is taken as a reaction monomer, polymerization is carried out under the actions of an initiating agent and a molecular weight regulating agent, then graft polymerization is carried out with the fatty acid vinyl ester to obtain a graft copolymer with the acrylic ester polymer as a main chain and polyvinyl ester fatty acid as a side chain, and finally alcoholysis and hydrolysis are carried out on the graft copolymer. The method for preparing the polycarboxylate superplasticizer by carrying out graft copolymerization on the acrylic ester polymer and fatty acid vinyl ester has the advantages that a process is simple and easy to control, cost is low, environmental protection is realized, no pollution is produced, the fatty acid vinyl ester is used for replacing the existing polycarboxylate superplasticizer, and diversification of raw materials is enriched; and the prepared superplasticizer has good cement paste fluidity and holding capability and shows good cement adaptability and concrete application property.

Owner:GUIZHOU DR SHI TECH

Method for synthesizing cement dispersing agent by using terminated functional polyethylene fatty acid ester macromonomer

The invention relates to a method for synthesizing a cement dispersing agent by using a terminated functional polyethylene fatty acid ester macromonomer. The cement dispersing agent is prepared by taking fatty acid vinyl ester as a main reaction raw material through a method comprising the steps of autopolymerization, substitution, alcoholysis and copolymerization, namely, polymerizing by taking fatty acid vinyl ester as a reaction monomer under the action of an initiator and a chain transfer agent to generate a polymer; then, carrying out substitution reaction on the polymer and an unsaturated chlorinated substance to obtain a polyethylene fatty acid ester macromonomer of which the macromolecular chain terminal is a double bond; next, carrying out alcoholysis on the macromonomer to prepare a macromonomer with the double bond at the terminal and with a polyvinyl alcohol structure; and finally, carrying out copolymerization reaction on the macromonomer and a carboxylic acid micromonomer to prepare the cement dispersing agent. The method is simple and easily-controlled in process, low in cost, environment-friendly and pollution-free; and the cement dispersing agent prepared by taking fatty acid vinyl ester as the raw material has favorable net cement paste flowability and holding capacity and shows favorable cement adaptability and concrete application property.

Owner:BEIJING UNIV OF TECH

Polyurethane caulk compound for high-speed railway and preparation method for polyurethane caulk compound

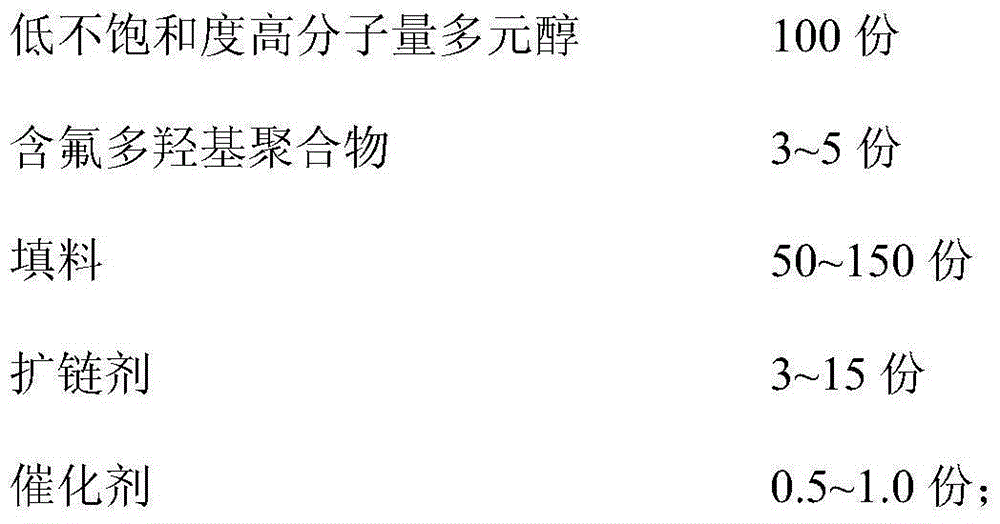

ActiveCN105131894AExtend the lifespanEasy to preparePolyureas/polyurethane adhesivesWeather resistancePolyol

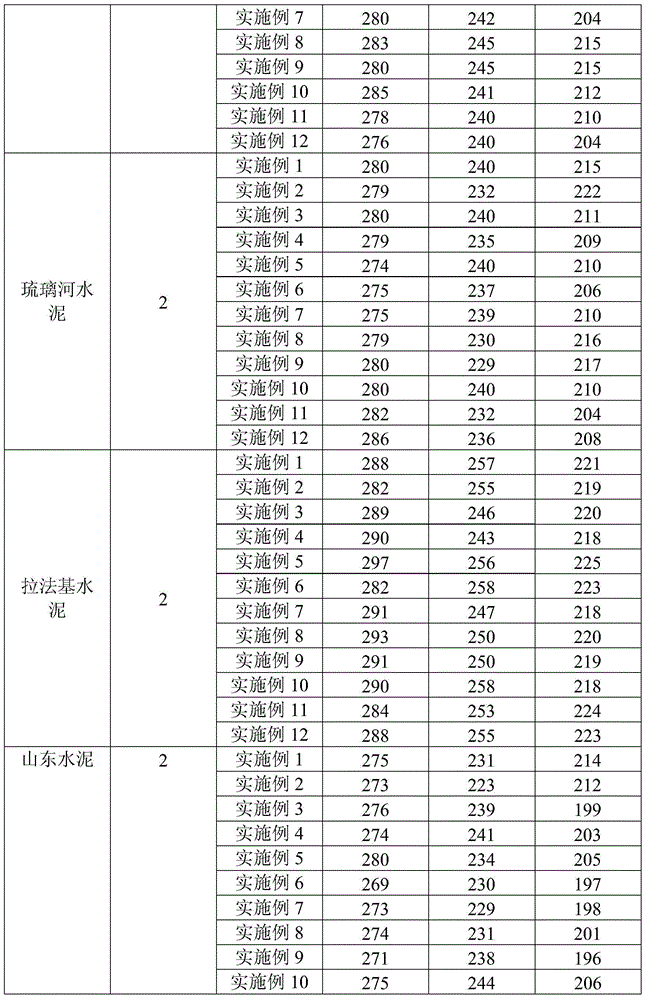

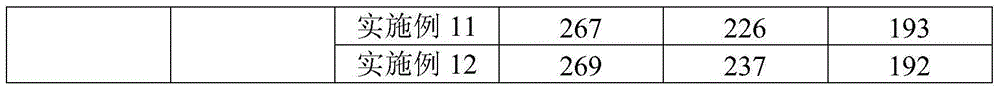

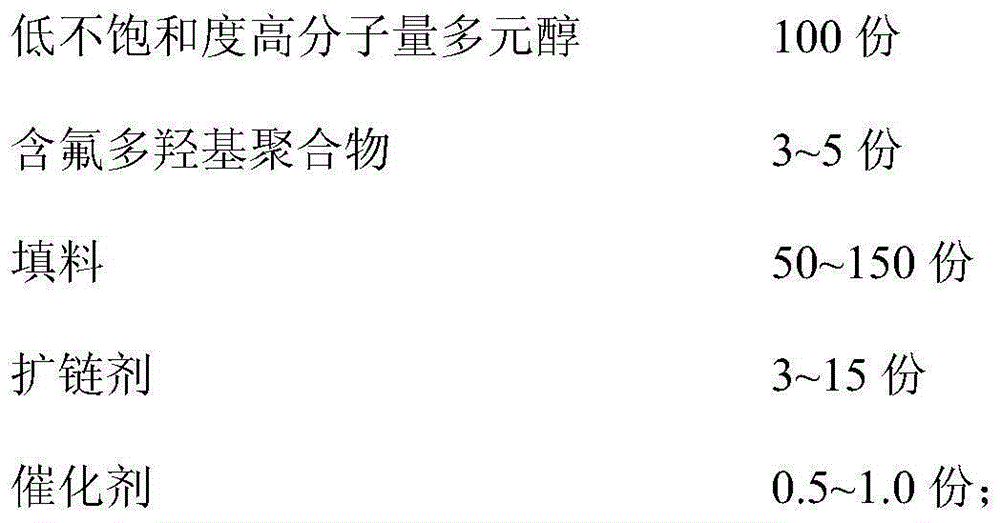

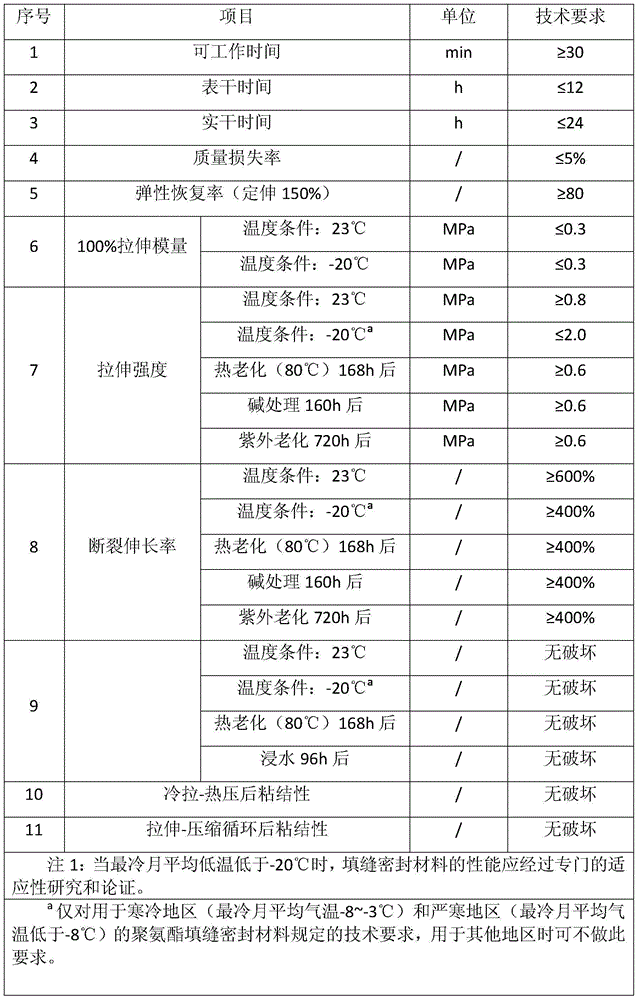

The invention discloses a polyurethane caulk compound for a high-speed railway and a preparation method for the polyurethane caulk compound. The weather resistance and the low-temperature resistance of a product are higher than those of a conventional polyurethane caulk compound, and the normal service life of the product can reach more than 15 years, and the product can be widely applied to a concrete roadbed slab of a roadbed of the high-speed railway and other concrete roads and structures. The polyurethane caulk compound for the high-speed railway comprises a component A and a component B, wherein the component A comprises the following components in parts by mass: 60 to 70 parts of low-unsaturation high-molecular weight polyol and 30 to 40 parts of aromatic isocyanate; the component B comprises the following components in parts by mass: 100 parts of low-unsaturation high-molecular weight polyol, 3 to 5 parts of a polyhydroxy fluorinated polymer, 50 to 150 parts of a filler, 3 to 5 parts of a chain extender and 0.5 to 1.0 part of a catalyst; and when the polyurethane caulk compound is used, the mass ratio of the component A to the component B is (1 to 1.0 ) to (1 to 4.0).

Owner:JIANGSU CHEM RES INST

Thermal paper manufacturing method capable of preventing mechanical pulp/ chemical mechanical pulp thermal paper from fading

InactiveCN102433798AFade effect preventionExtend the lifespanPaper coatingPaper/cardboardRecording layerMaterials science

Owner:HENAN JIANGHE PAPER

Method for preparing polyurethane macromolecule dispersing agent for pigment printing paste of fabric

The invention relates to a method for preparing a polyurethane macromolecule dispersing agent for pigment printing paste of a fabric, which comprises the following steps of: dissolving diisocyanate and hydrophilic carboxyl diatomic alcohol into an organic solvent and heating to 75 DEG C for reacting for 60 minutes; then dropwise adding a micromolecule diatomic alcohol solution in batch and carrying out multi-chain extension reaction for 60 minutes; after the chain extension reaction is finished, carrying out end sealing reaction for 120 minutes; cooling to 50 DEG C, dropwise adding a Na2CO3 solution and emulsifying during neutralization; and after the dropwise addition is finished and adding water for heating to 60 DEG C, continuously stirring and dissolving for 30 minutes to prepare the polyurethane macromolecule dispersing agent. The macromolecule dispersing agent has stronger affinity on the surface of pigment particles, difficult desorption, good flocculation resistance, simple preparation method, low cost and environmental protection; and the pigment paste prepared by the dispersing agent has high stability and can obtain high printing dry and wet friction fastness by being used for the printing processing of the fabric.

Owner:DONGHUA UNIV

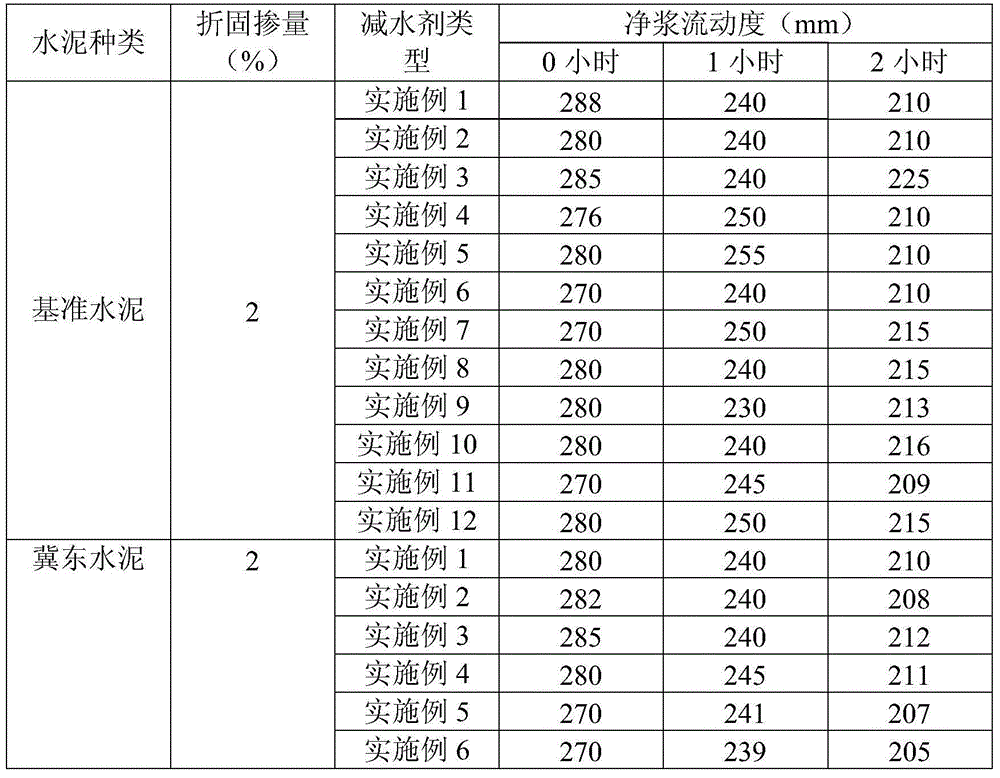

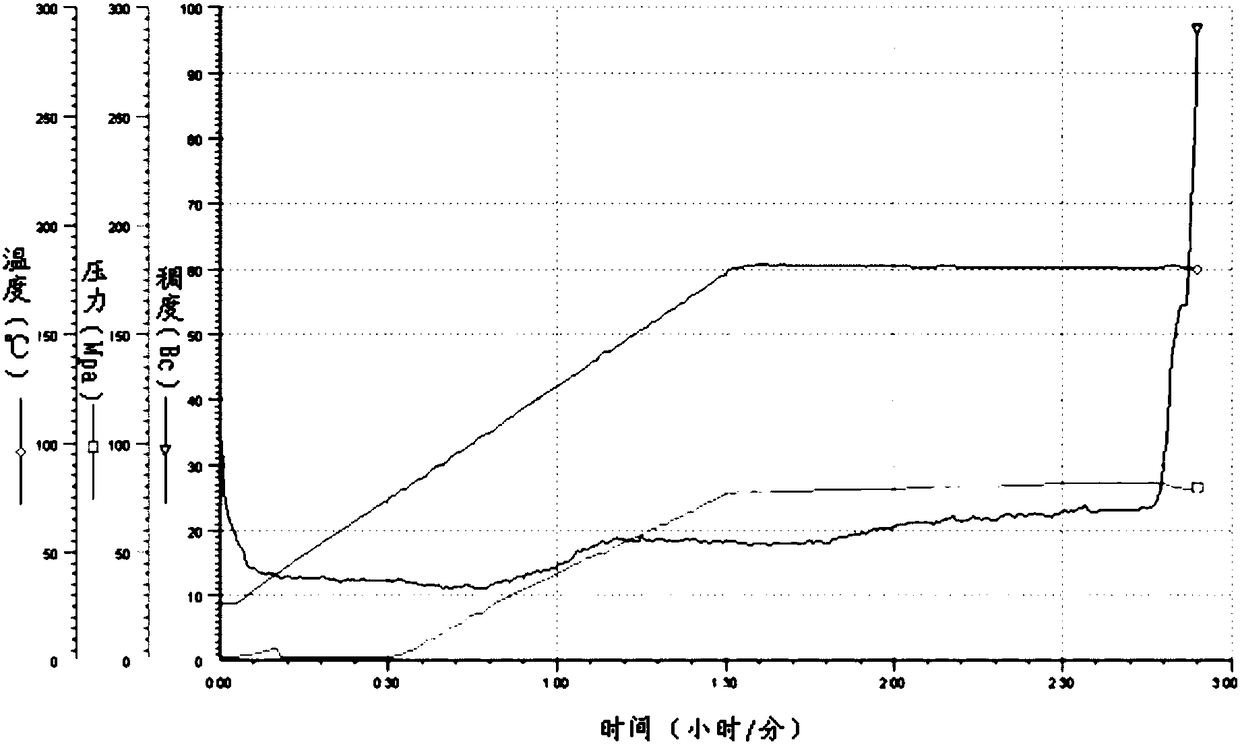

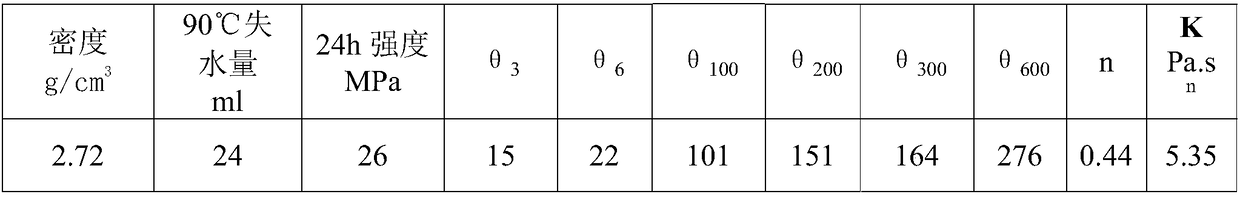

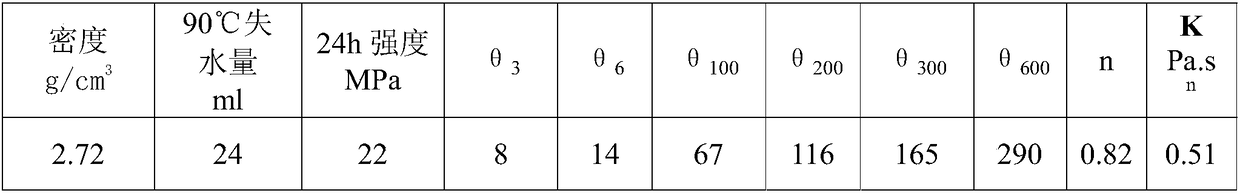

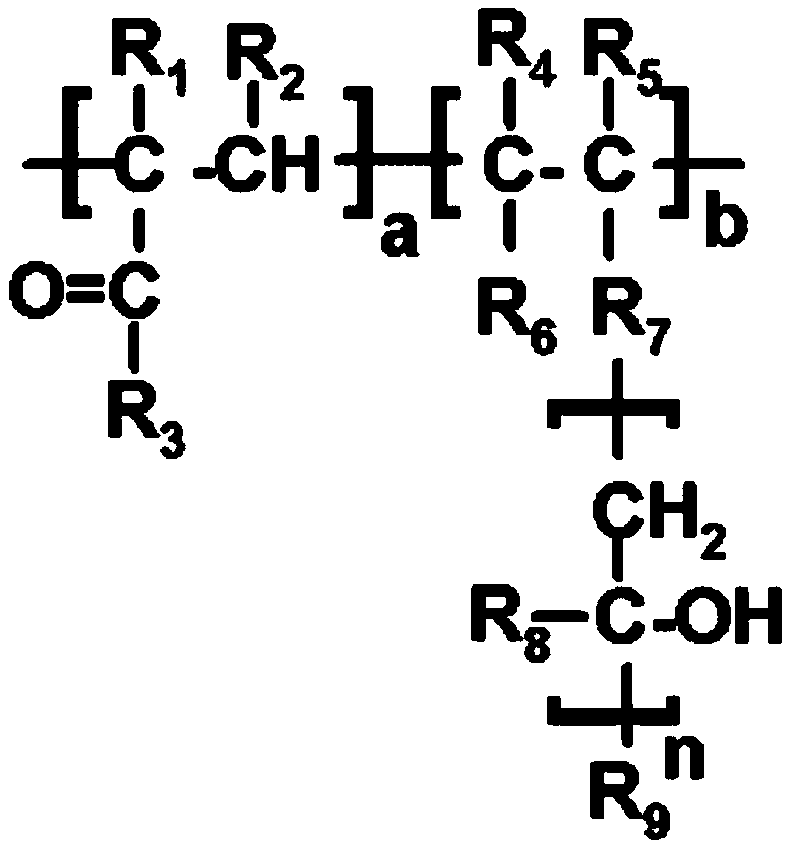

Drag reducer, preparation method thereof and application of drag reducer

The invention discloses a drag reducer, a preparation method thereof and an application of the drag reducer, and belongs to the technical field of well cementing. An unsaturated sulfonic acid monomer,an unsaturated ester monomer, a polyethylene glycol monomer containing a saturated group and a polyethylene glycol monomer containing an unsaturated group are polymerized to obtain the drag reducer,and the weight-average molecular weight of the drag reducer is 20000-120000. The drag reducer polymerized by the monomers is of a comb-type molecular structure, a main chain of the drag reducer has active groups such as a carboxylic acid group (-COOH) and a sulfonic acid group (-SO3H), the active groups can be effectively anchored on the surfaces of cement particles, a side chain of the drag reducer forms a solvation layer on the cement surface by the aid of polyethylene glycol macromolecular monomers, a network structure can be formed, the side chain is flexibly adsorbed on the surfaces of the cement particles in a comb shape manner, stereo-hindrance effect is obvious, the weight-average molecular weight of the drag reducer is controlled between 20000 and 120000, a high-density cement paste system containing salt can be effectively dispersed, and rheological properties can be improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

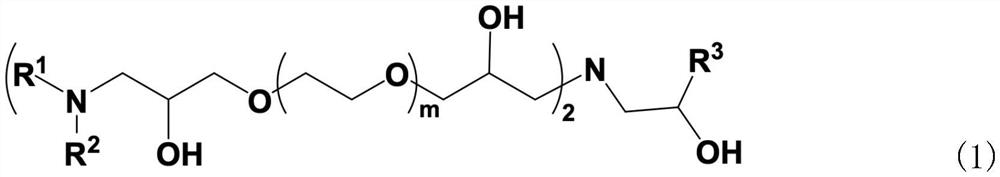

Preparation method of concrete anti-mud agent

The invention discloses a preparation method of a concrete anti-mud agent, which comprises steps of preparation of an organic amine initiator and preparation of the anti-mud agent, and the preparation of the organic amine initiator comprises the following steps: reacting glycidyl ether monomer and secondary amine monomer under certain temperature and pressure conditions, then continuously adding an alcohol amine monomer, reacting under certain temperature and pressure conditions, and obtaining the organic amine initiator; the preparation method of the anti-mud agent comprises the following steps: reacting the organic amine initiator, an alkylene oxide monomer and a catalyst under certain temperature and pressure conditions to obtain an amino polyether polyol, continuously adding a halogenated hydrocarbon into the system after the reaction is finished, and reacting under certain temperature and pressure conditions to obtain a finished product of the anti-mud agent.

Owner:江苏金木土新材料有限公司

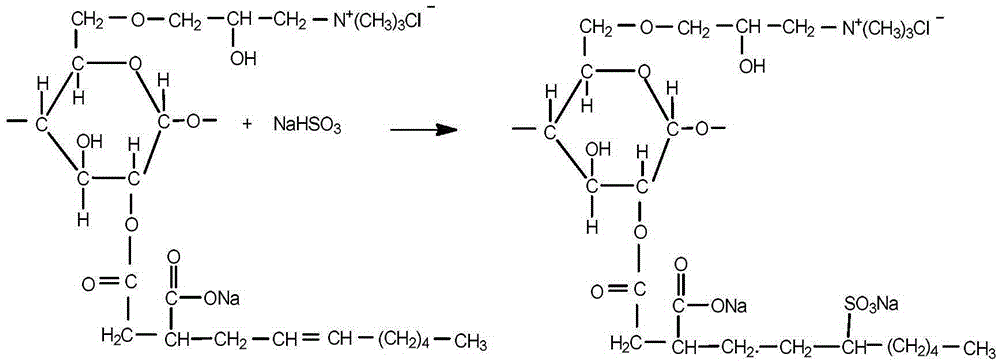

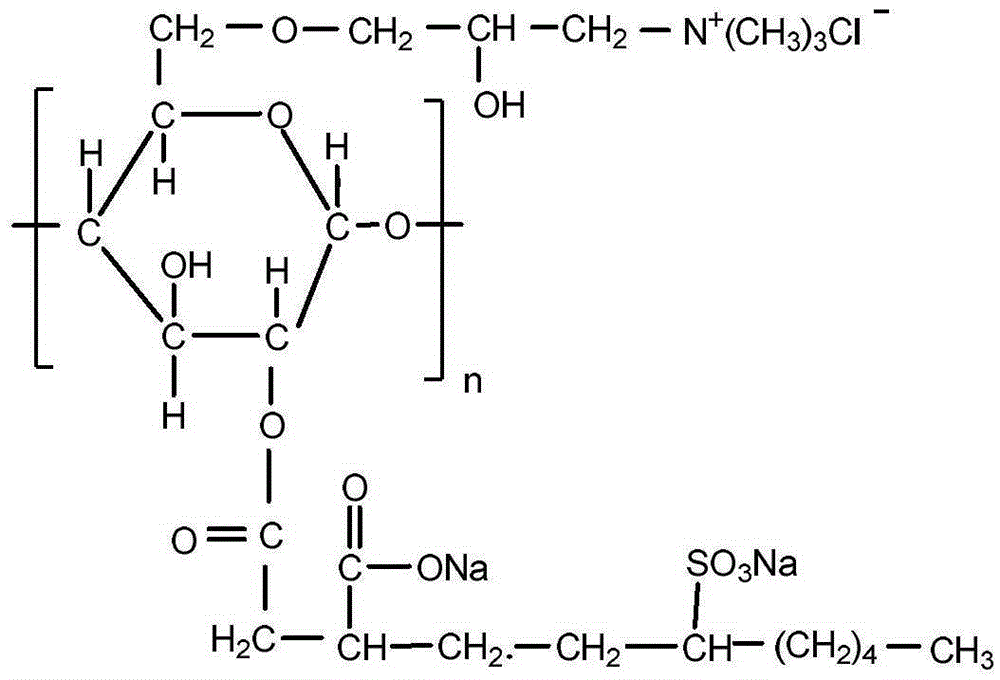

Preparation method for sulfonation modification type composite modified starch size

The invention discloses a preparation method for sulfonation modification type composite modified starch size. The preparation method comprises the following steps: carrying out cationic denaturation on starch by using a cationic etherifying agent, i.e., 3-chloro-2-hydroxypropyltrimethyl ammonium chloride, so as to prepare cation starch; then subjecting the prepared cationic starch and octenyl succinate anhydride to an esterification reaction so as to prepare cation-octenyl succinate composite modified starch; and reacting the prepared cation-octenyl succinate composite modified starch with sodium bisulfite so as to prepare the sulfonation modification type composite modified starch size. Compared with the prior art, the prepared sulfonation modification type composite modified starch size has substantially improved size film performance and enhanced adhesion on synthetic fibers like terylene, better meets requirements of sizing of warp yarns, especially sizing of synthetic fibers like terylene, and can be applied to sizing of the warp yarns of cotton, hemp, viscose, polyester / cotton, polyester / hemp, polyester / viscose and other fibers on a common warp sizing machine or high-speed warp sizing machine.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

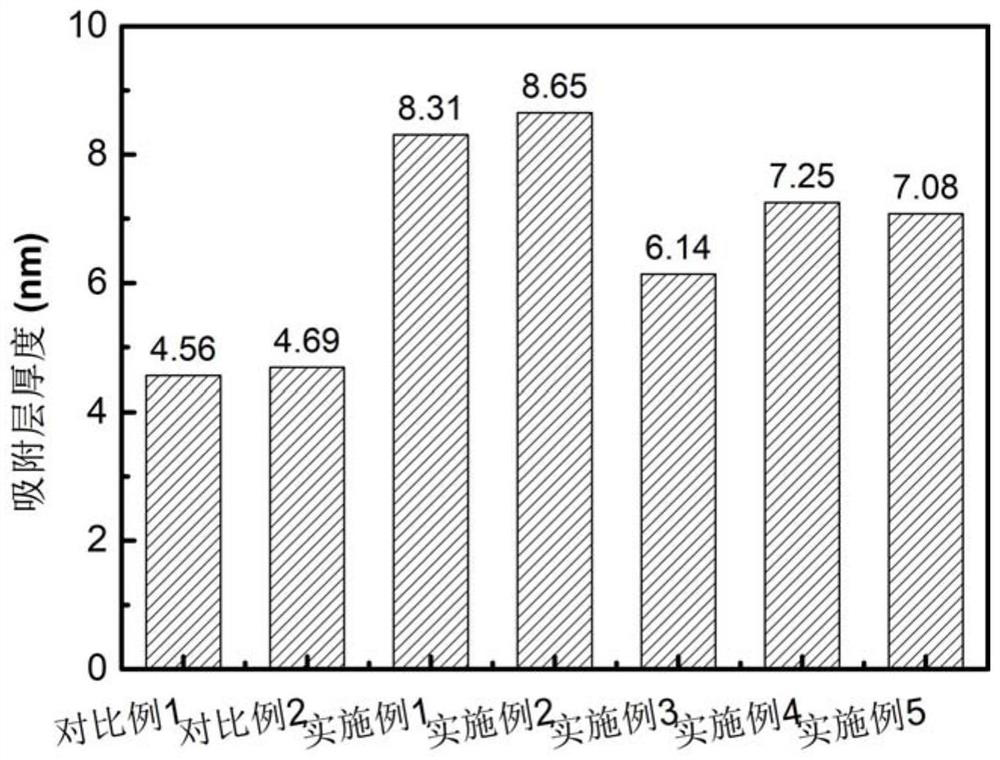

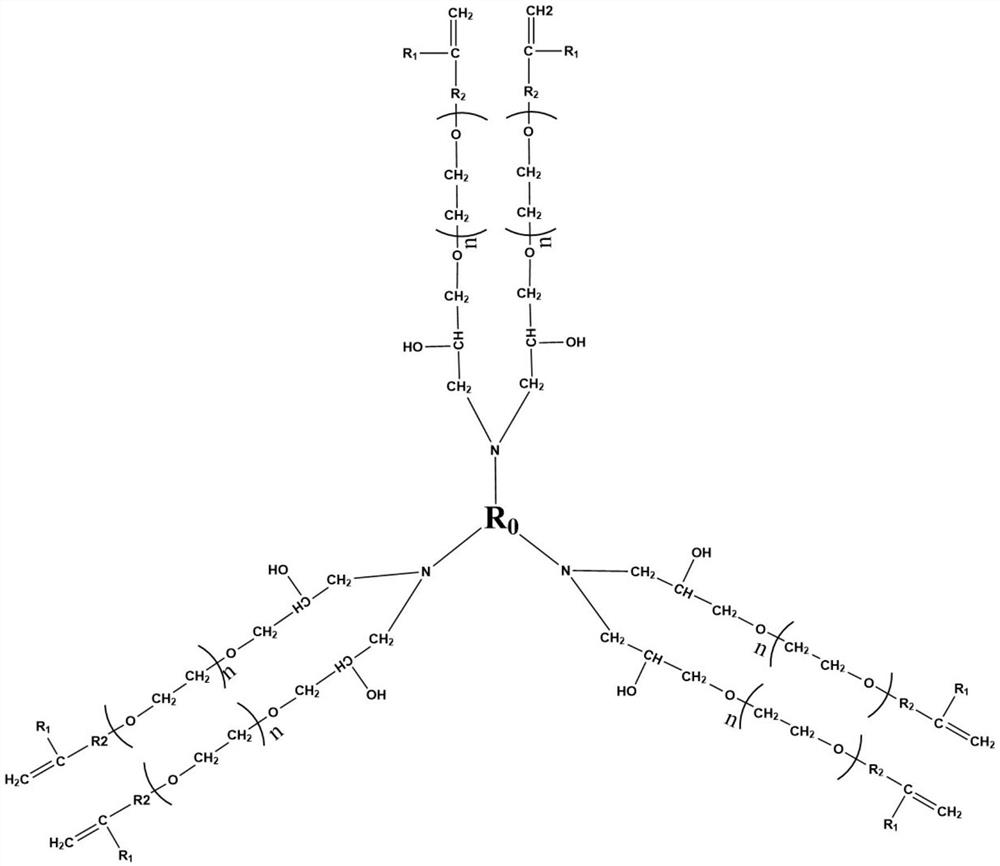

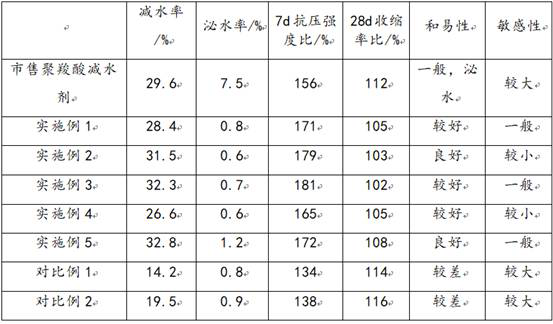

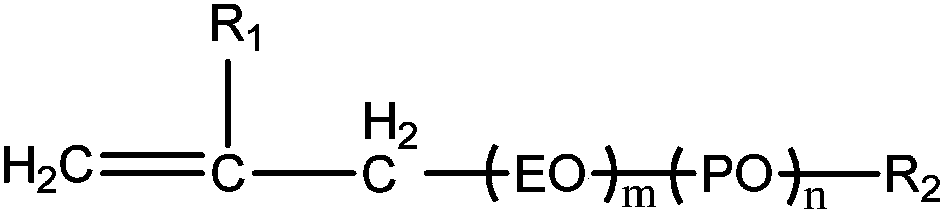

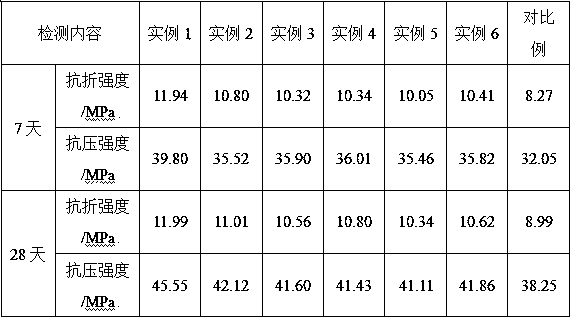

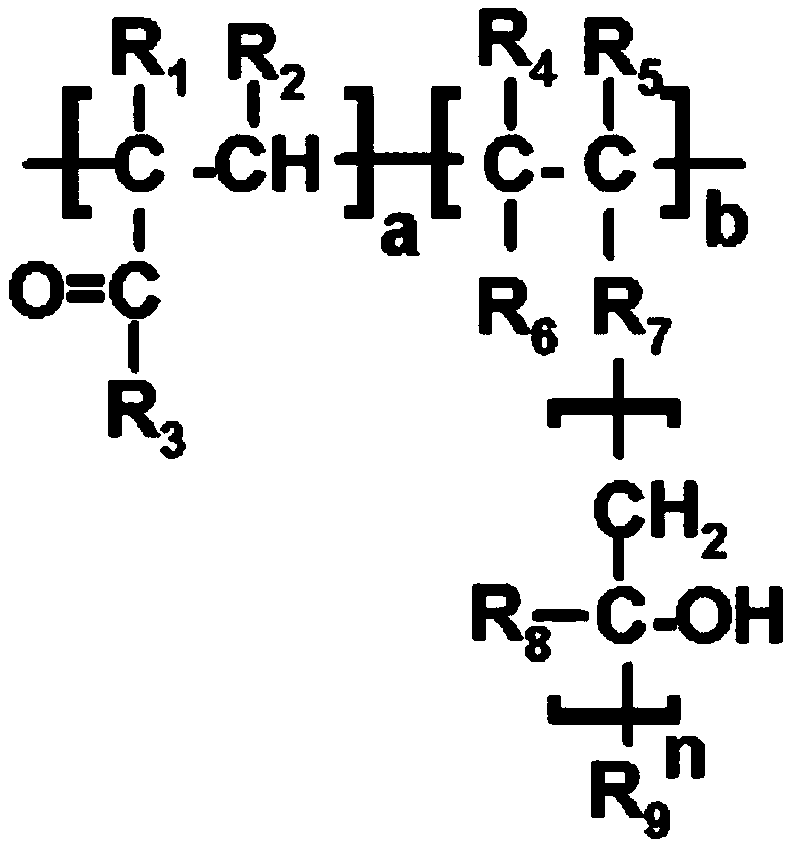

Vinyl-terminated hyperbranched polymer, viscosity-reducing type polycarboxylic acid water reducing agent with hyperbranched structure and preparation methods of vinyl-terminated hyperbranched polymer and viscosity-reducing type polycarboxylic acid water reducing agent

ActiveCN113372549AGood dispersionReduce dosageSolid waste managementPolymer scienceFunctional monomer

The invention discloses a vinyl-terminated hyperbranched polymer, a viscosity-reducing type polycarboxylate water reducing agent with a hyperbranched structure and preparation methods of the vinyl-terminated hyperbranched polymer and the viscosity-reducing type polycarboxylate water reducing agent, and belongs to the technical field of concrete admixtures. The viscosity-reducing type polycarboxylate water reducing agent with the hyperbranched structure is composed of the following raw materials in percentage by mass: 3 to 18 percent of unsaturated carboxylic acid, 1 to 10 percent of unsaturated anhydride, 0 to 1 percent of unsaturated phosphate, 75 to 93 percent of unsaturated polyether, 1 to 6 percent of a hyperbranched functional monomer, 0.1 to 1 percent of an initiator and 0.2 to 3.0 percent of a chain transfer agent. The prepared water reducing agent has the characteristics of special branched topological molecular structure, low intrinsic viscosity and the like, effectively weakens the intermolecular chain winding effect of the polycarboxylic acid water reducing agent, improves the dispersing performance of the water reducing agent, and reduces the dosage of the water reducing agent; and the thickness of an adsorption layer on the surface of a cementing material particle is increased, the thickness of a solvation layer on the surface of the particle is reduced, free water is released, and the viscosity of the high-strength concrete is reduced.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD

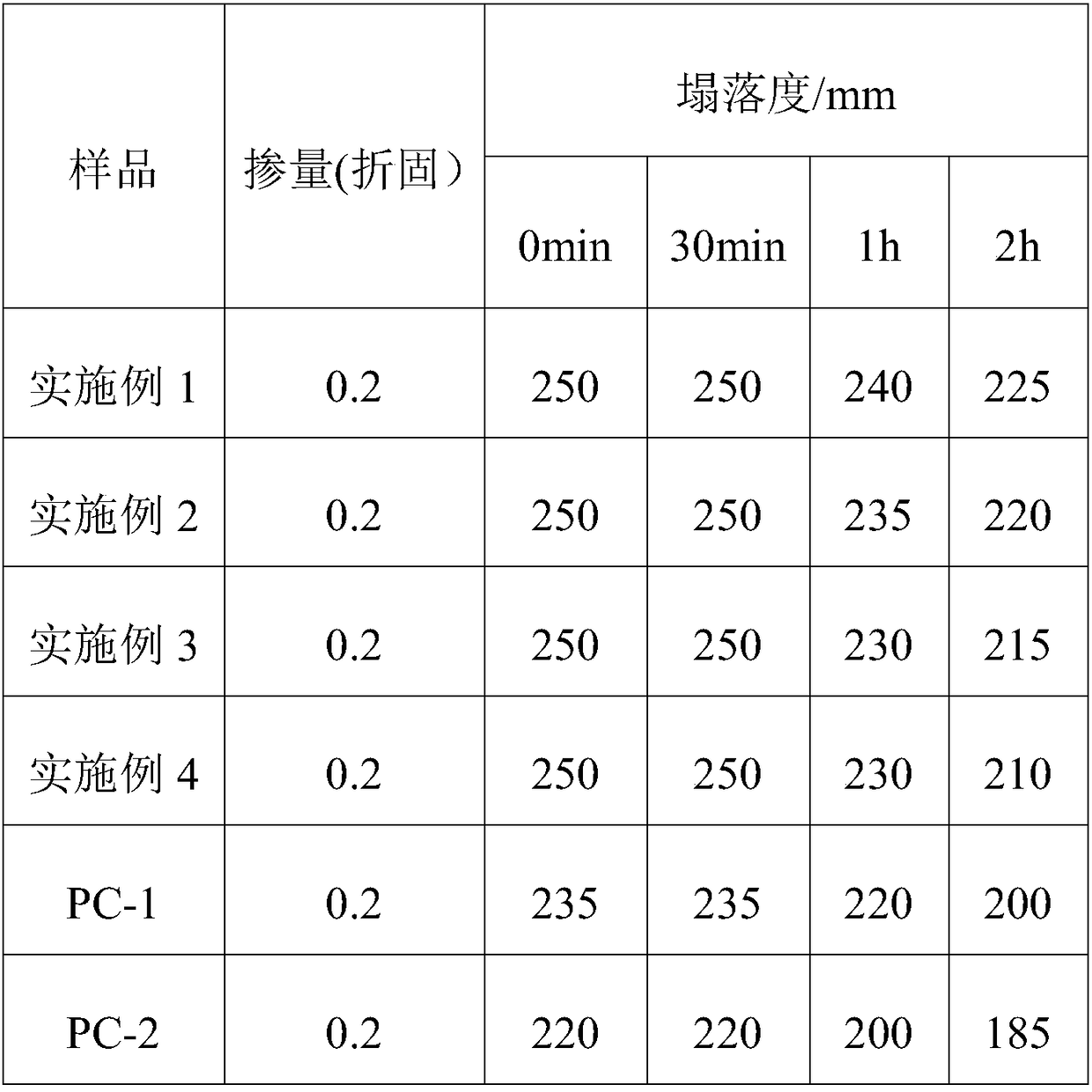

Efficient concrete water-reducing agent and preparation method thereof

The invention discloses an efficient concrete water-reducing agent and a preparation method thereof, and belongs to the technical field of concrete additives. Acrylic acid is used as a raw material, and polyethylene glycol monomethyl ether is added. Through an esterification reaction, a macromonomer is obtained; and citric acid is added for modification to reduce formation of calcium silicate hydrated gel so as to obtain higher water-reducing rate. L-aspartic acid is used as a raw material, and carboxyl anions are formed. Then, the water-reducing agent still can be greatly dispersed under thecondition of hard water to play a water-reducing effect. By introducing triethanolamine, solubility of concrete particle surface is raised, and water-reducing efficiency is enhanced. Problems of existing water-reducing agents, such as poor hard water resistance and low water-reducing efficiency are solved.

Owner:YANGQUAN GAOXING BUILDING MATERIAL ADDITIVE CO LTD

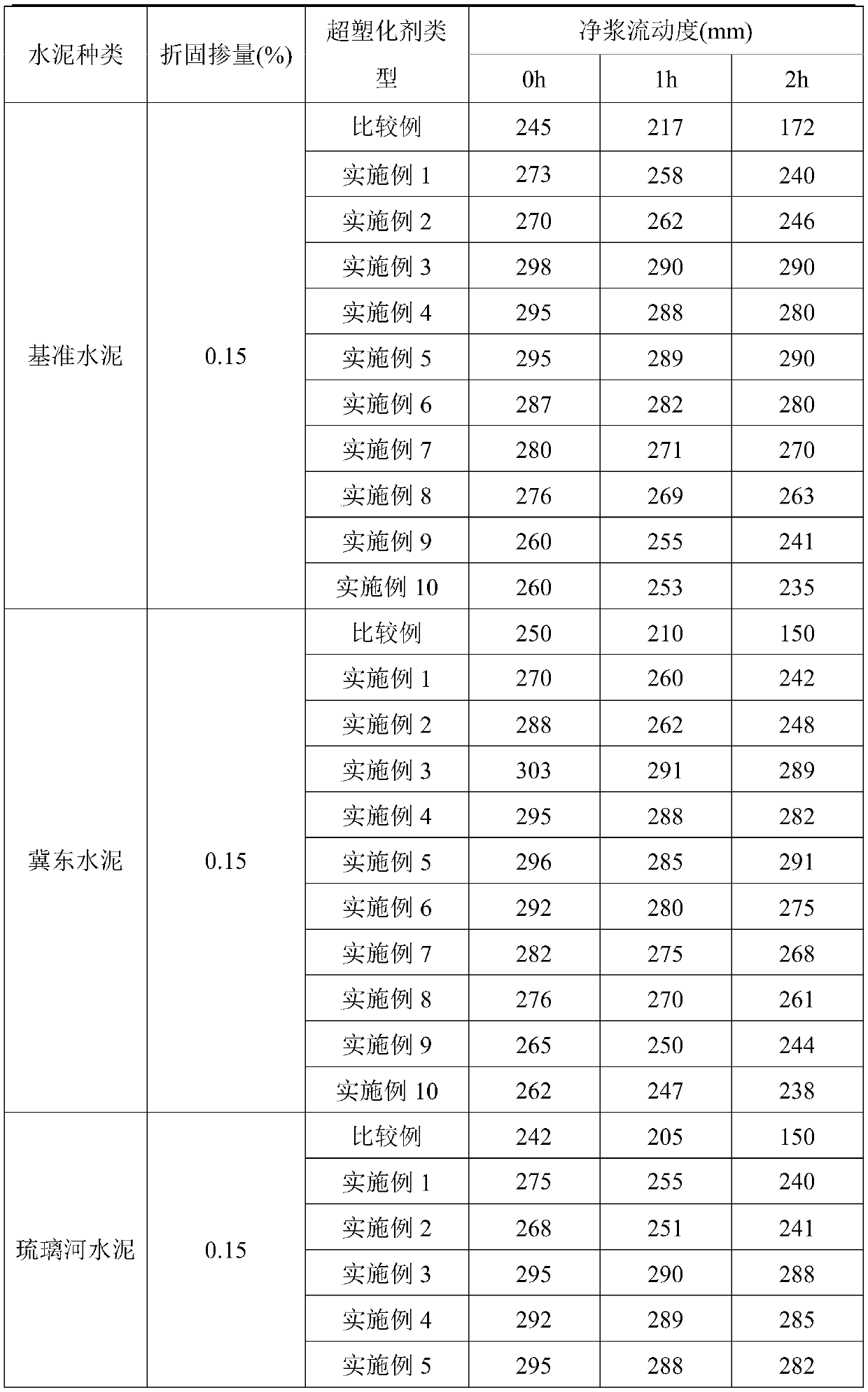

Method for preparing starch-based high-performance water reducing agent and product thereof

The invention discloses a method for preparing a starch-based high-performance water reducing agent and a product thereof, and the method comprises the steps of: taking a starch-based functional macromonomer as a main chain skeleton, and grafting the starch-based functional macromonomer to the starch-based main chain skeleton through unsaturated polyether and unsaturated carboxylic acid to form a molecular form of a rotary comb-shaped structure. The invention also discloses a preparation method of the starch-based high-performance water reducing agent. The preparation method mainly comprises the following steps: preparing a controllable acid-degraded starch raw material, preparing a starch-based functional macromonomer, and carrying out free radical copolymerization reaction. The process is simple, waste liquid, waste gas and waste residues are not generated in the preparation process, and the process is a green low-carbon synthesis process. The starch-based high-performance water reducing agent provided by the invention can effectively solve the problems of sensitivity and adaptability of a polycarboxylate water reducing agent in the mixing amount, can improve the workability, cohesiveness and other working states of concrete, and can reduce shrinkage cracking of the concrete. The method has excellent adaptability to different cement, admixtures, machine-made sand, tailing sand, environment temperature and concrete mix proportion fluctuation.

Owner:建研建材有限公司

Preparation method of slump-proof polycarboxylate superplasticizer

ActiveCN108084358ALower melting temperatureLow reaction temperatureBulk polymerizationTransport time

The invention provides a preparation method of a slump-proof polycarboxylate superplasticizer. The slump-proof polycarboxylate superplasticizer is prepared by bulk polymerization. The preparation method comprises the steps of (1) mixing polyoxyethylene polyoxypropylene ether and polyoxyethylene ether, stirring well at controlled temperature of 40-60 DEG C, and adding an initiator and a mixture ofunsaturated carboxylic acid, unsaturated carboxylates and a chain transfer agent; (2) curing for 0.5-1 hour after completion of step (1), and cooling to obtain the slump-proof polycarboxylate superplasticizer. The bulk polymerization is performed at relatively low temperature, the conditions are mild, operability is high, and the synthesized polycarboxylate superplasticizer has high water-reducingproperty. The polycarboxylate superplasticizer prepared herein is in liquid state at normal temperature, having an effective concentration of 100% and good stability of storage performance; the polycarboxylate superplasticizer is applicable to long-range transport and use; the polycarboxylate superplasticizer has excellent slump-proof performance; the problem can be solved that concrete slumps due to high temperature and long transport time; the polycarboxylate superplasticizer has a promising industrial application prospect.

Owner:JIAHUA CHEM MAOMING

Organic-inorganic composite sludge dewatering conditioner

ActiveCN110040938AHigh specific surface areaFacilitate the drainage of moistureSludge treatment by de-watering/drying/thickeningBiological sludge treatmentGraphite oxideOrganic inorganic

The invention discloses an organic-inorganic composite sludge dewatering conditioner and belongs to the technical field of environmental protection materials. The studied composite sludge dewatering conditioner is prepared from acid modified sepiolite, amination modified graphene oxide, urease, urea, self-made segmented copolymers, N'-hexadecyl-N,N-dimethylethyl amidine, a carbonate foaming agentand a dispersant. In the preparation process, all components are weighed according to raw material composition; the acid modified sepiolite, amination modified graphene oxide, urea, the self-made segmented copolymers, N'-hexadecyl-N,N-dimethylethyl amidine and the dispersant are stirred and mixed to obtain a mixture; the mixture and water are stirred and mixed, inert gas is continuously introducedin the stirring process, vacuum freezing drying is performed, and a dried material is obtained; the dried material, urease and the carbonate foaming agent are stirred and mixed, and the organic-inorganic composite sludge dewatering conditioner is obtained. The organic-inorganic composite sludge dewatering conditioner prepared with the technical scheme has the characteristic of excellent dewatering performance.

Owner:海环绿源环保科技(上海)有限公司

Polyester-resin-based cement material

The invention discloses a polyester-resin-based cement material, belonging to the technical field of building materials. The polyester-resin-based cement material developed by the invention is composed of an unsaturated polyester resin, styrene, an emulsifier, water, cement, aggregate, a water reducer, caprolactam, polyacrylamide and a curing agent. The preparation process comprises the followingsteps: stirring and mixing the unsaturated polyester resin and styrene, adding the emulsifier and water, and performing shearing and dispersion to obtain a polyester emulsion; and stirring and mixingthe polyester emulsion, cement, aggregate, water reducer and caprolactam, adding the curing agent, continuing stirring and mixing, performing injection molding, curing and demolding, performing high-pressure steam curing for 8-12 hours, and performing natural curing in air for 28 days to obtain the polyester-resin-based cement material. The polyester-resin-based cement material obtained in the invention has excellent mechanical properties.

Owner:朱东洋

Method for preparing delayed coagulation type super plasticizer through atom transfer radical polymerization

ActiveCN109942754AProlong clotting timeIncrease late strengthSide chainAtom-transfer radical-polymerization

The invention relates to a method for preparing a delayed coagulation type super plasticizer through atom transfer radical polymerization. The method comprises the steps of with a delayed coagulationtype monomer and a carboxylic acid small monomer as main reaction raw materials, sequentially carrying out atom transfer radical polymerization (ATRP), alcoholysis and copolymerization so as to prepare the delayed coagulation type super plasticizer, namely that carrying out atom transfer radical polymerization (ATRP) on the delayed coagulation type monomer as a reactant under the system formed byan unsaturated initiator, transition metal halide and a ligand so as to obtain an unsaturated macromonomer, carrying out alcoholysis so as to obtain a delayed coagulation type macromonomer, and copolymerizing with the carboxylic acid small monomer, so as to obtain the delayed coagulation type super plasticizer. According to the method, a functional side chain consisting of delayed coagulation typestructural monomers is innovatively designed and synthesized by virtue of a controllable polymerization technical measure, a traditional polymer side chain structure is replaced, the super plasticizer presents excellent capacities of dispersing element purified slurry, and the coagulation time of the element purified slurry can be remarkably delayed, so that the later-period strength of concreteis improved, and multiple effects of high water reduction, slump resistance and delayed coagulation are achieved.

Owner:BEIJING UNIV OF TECH

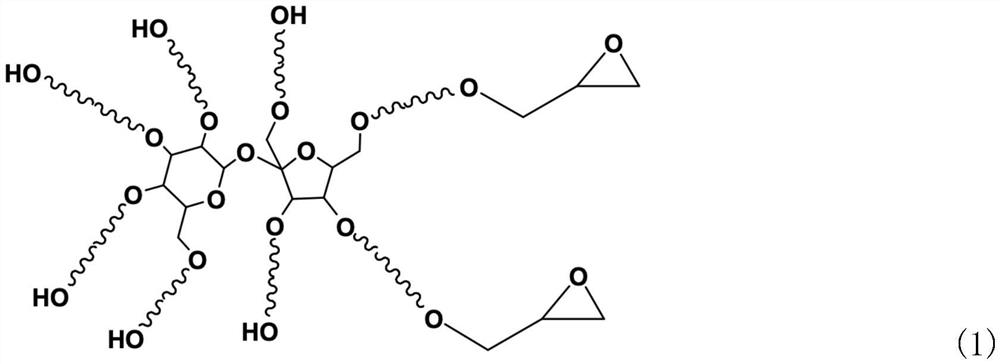

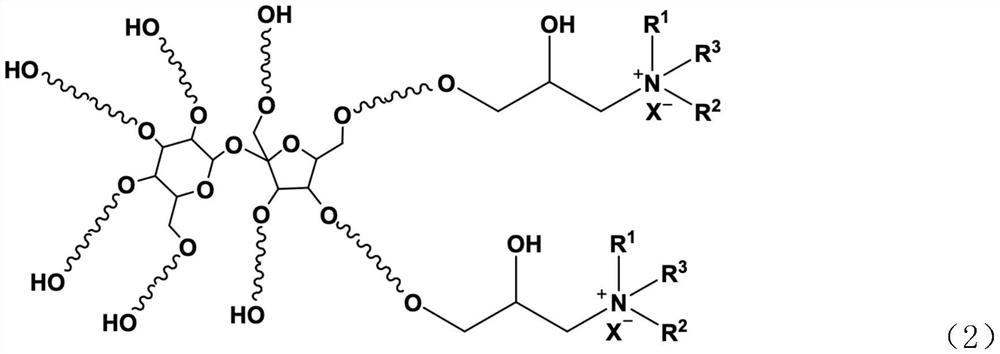

Preparation method of anti-clay concrete admixture

The invention discloses a preparation method of an anti-clay concrete admixture. The method comprises the preparation of polyether glycidyl ether and the preparation of the anti-clay admixture. The preparation of polyether glycidyl ether comprises the following steps: firstly, reacting a polyhydroxy initiator, alkylene oxide and a catalyst at a certain temperature and pressure to prepare polyether polyol; and then continuously adding epichlorohydrin, and performing reaction at a certain temperature and pressure to obtain the polyether glycidyl ether. The preparation method of the anti-clay admixture comprises the following steps: carrying out reaction on polyether glycidyl ether and a secondary amine monomer at a certain temperature and pressure to obtain tertiary amine polyether; and adding halogenated hydrocarbon into the tertiary amine polyether, and performing reaction at a certain temperature and pressure to obtain an anti-clay admixture finished product.

Owner:江苏金木土新材料有限公司

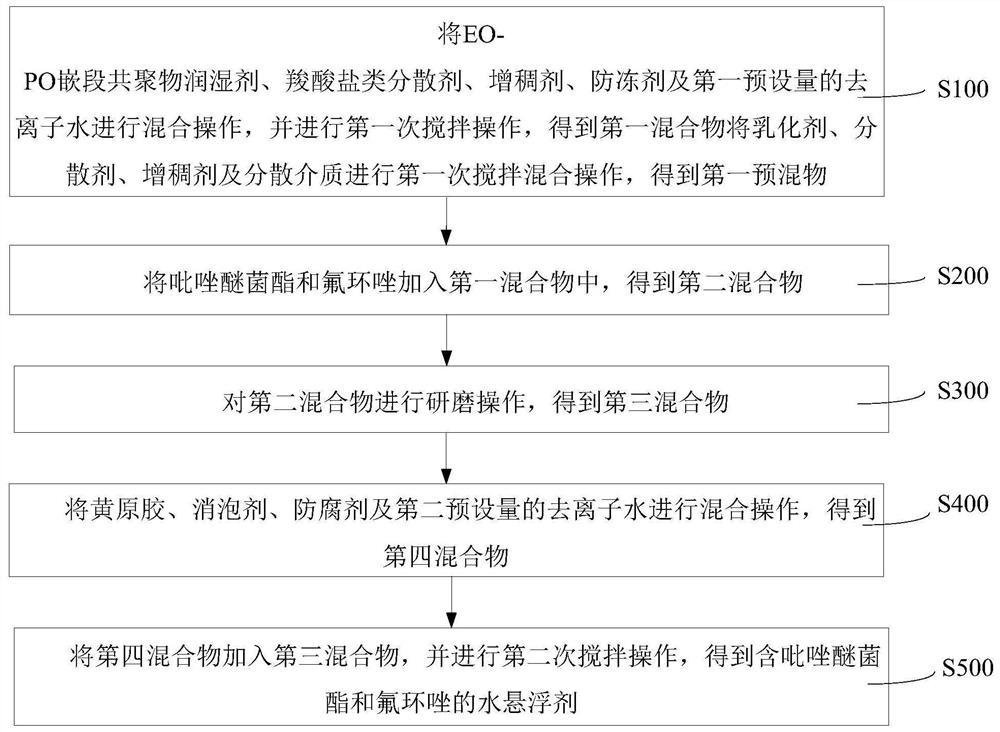

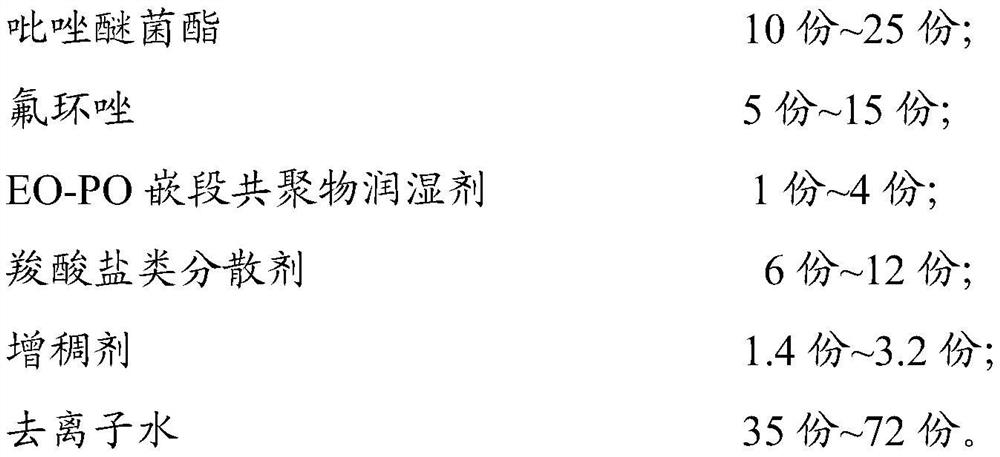

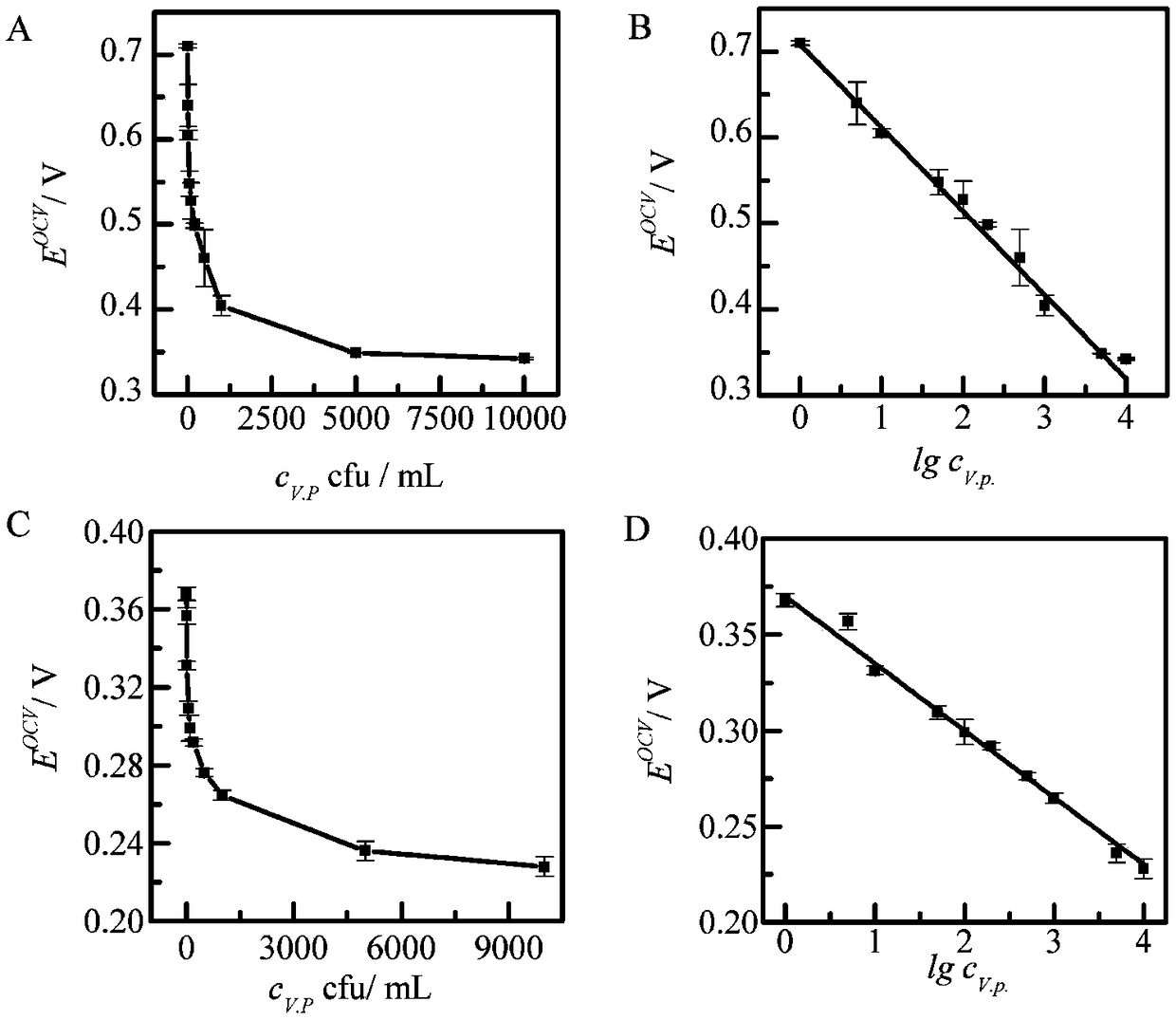

Water suspending agent containing pyraclostrobin and epoxiconazole and preparation method thereof

The invention provides a water suspending agent containing pyraclostrobin and epoxiconazole and a preparation method thereof. The water suspending agent containing the pyraclostrobin and the epoxiconazole is prepared from the following components in parts by mass: 10 to 25 parts of the pyraclostrobin, 5 to 15 parts of the epoxiconazole, 1 to 4 parts of an EO-PO block copolymer wetting agent, 6 to 12 parts of a carboxylate dispersing agent, 1.4 to 3.2 parts of a thickening agent and 35 to 72 parts of deionized water. The water suspending agent containing pyraclostrobin and epoxiconazole is relatively good in dispersity, relatively good in storage stability, high in pesticide effect and long in lasting period.

Owner:HUIZHOU YINNONG TECH

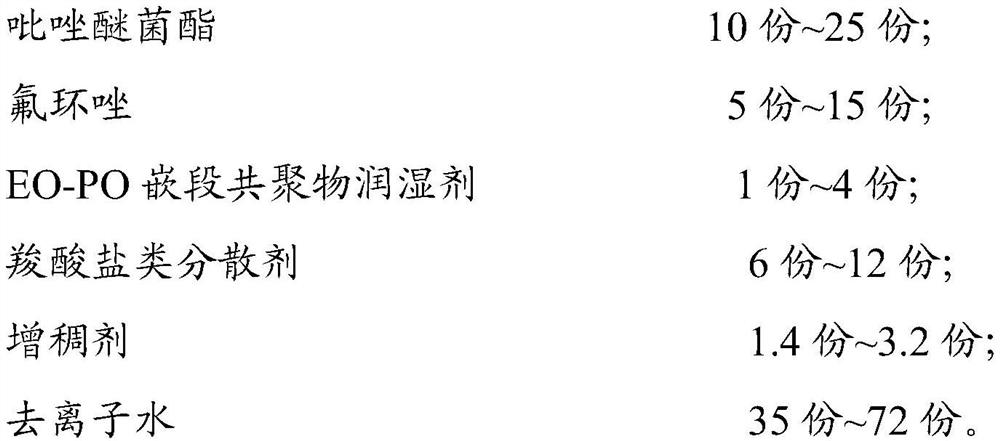

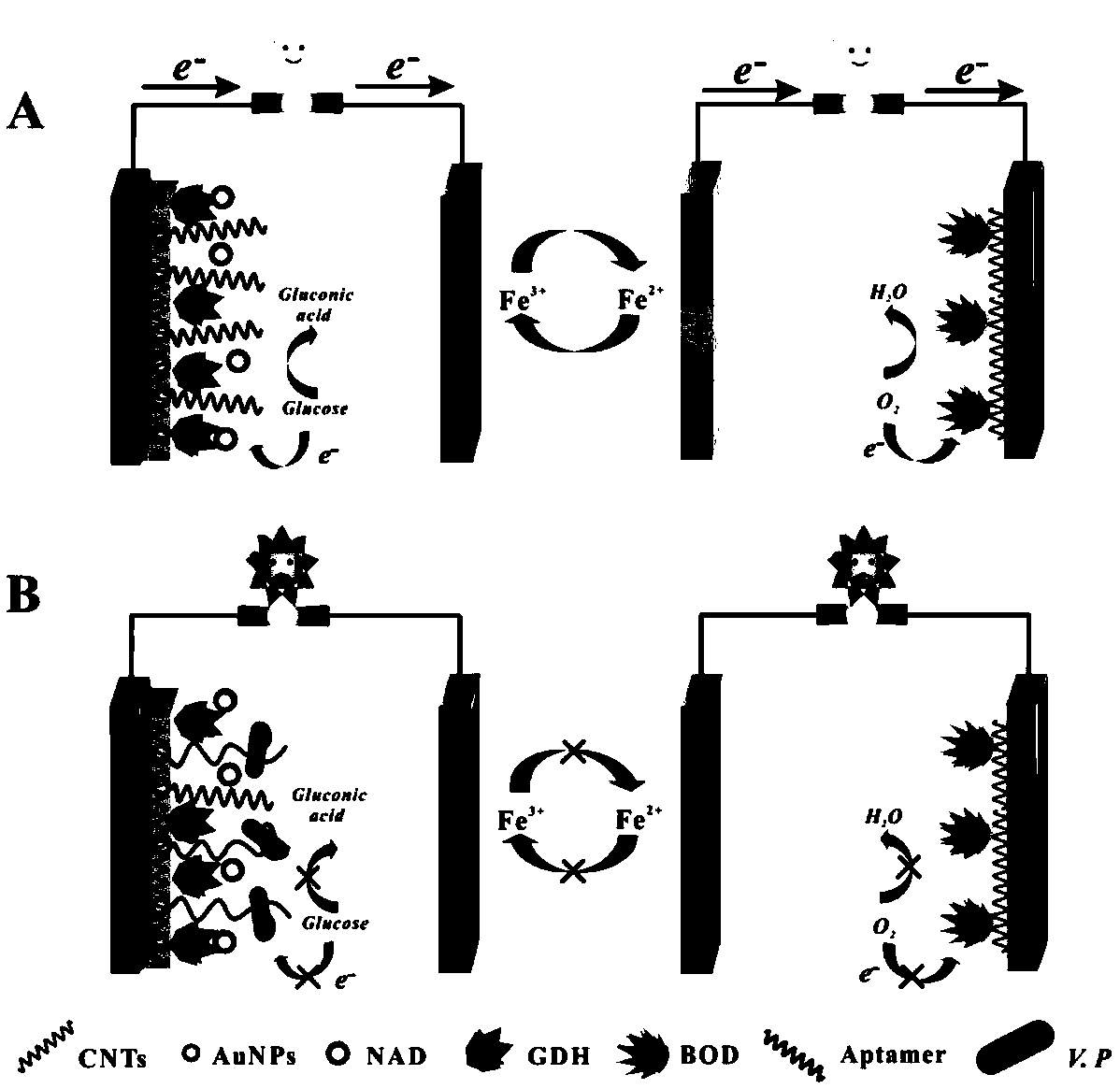

Enzyme biofuel cell (EBFC)-based self-powered bacteria biological sensor and application thereof

InactiveCN109254039ASensitive detectionEfficient detectionMaterial electrochemical variablesElectronOpen-circuit voltage

The invention builds an enzyme biofuel cell (EBFC)-based self-powered bacteria biological sensor and application thereof, and belongs to the technical field of biological sensors. Electrons from a biological positive electrode can be received by prussian blue (PB) and can be converted to prussian white (PW), blue of the PB also can be converted to transparent PW by obtaining the electrons, the changing speed from blue to nature is dependent on concentration of vibrio parahaemolyticus, and the color can be restored to an original PB state by connecting the color to the biological positive electrode. When target vibrio parahaemolyticus exists, an open-circuit voltage generated by the EBFCs is reduced accordingly, the amplitude of the open-circuit voltage is dependent on the concentration ofthe vibrio parahaemolyticus identified by a target adaptor. Due to a steric-hinerance effect of the vibrio parahaemolyticus, fuel glucose is prevented from being approaching an active site of glucosedehydrogenase on the positive electrode, and the color of the prussian blue is reduced. By the EBFC-based self-powered bacterial biological sensor, simple, convenient, rapid, sensitive and high-efficiency detection of food pathogens is achieved.

Owner:QINGDAO AGRI UNIV

Polymer supported catalyst and application thereof in aromatic selective chlorination reaction

ActiveCN104588113ALarge specific surface areaIncrease contact frequencyOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryAromatic hydrocarbonMacromolecule

The invention provides a polymer supported catalyst which comprises a polymer carrier and an inorganic metal salt / organic metal complex loaded to the polymer carrier. The invention also provides an application of the catalyst in an aromatic selective chlorination reaction. The polymer supported catalyst has large specific surface area, and the contact frequency is increased; the steric-hindrance effect is obvious, and the para-selectivity can be effectively improved; and moreover, when the catalyst is combined with sulfides, the para-selectivity of aromatic chlorination can be effectively improved, and the catalyst is stable in activity, mild in reaction conditions, simple in process and suitable for application and can be used for chlorination of all aromatic hydrocarbons and derivatives thereof.

Owner:SOUTHEAST UNIV

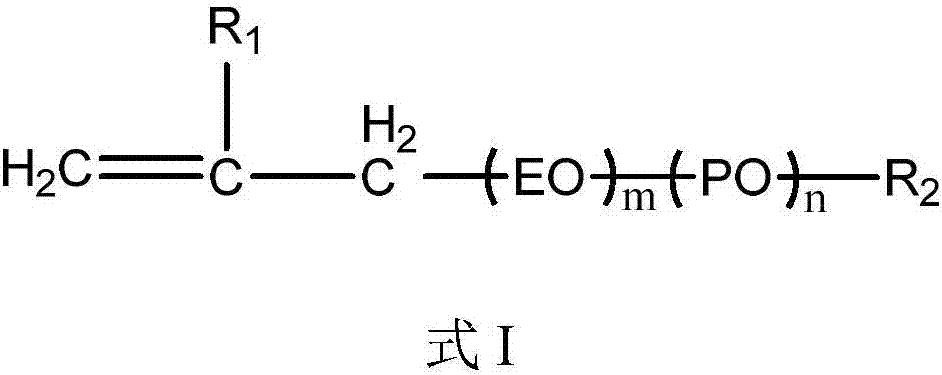

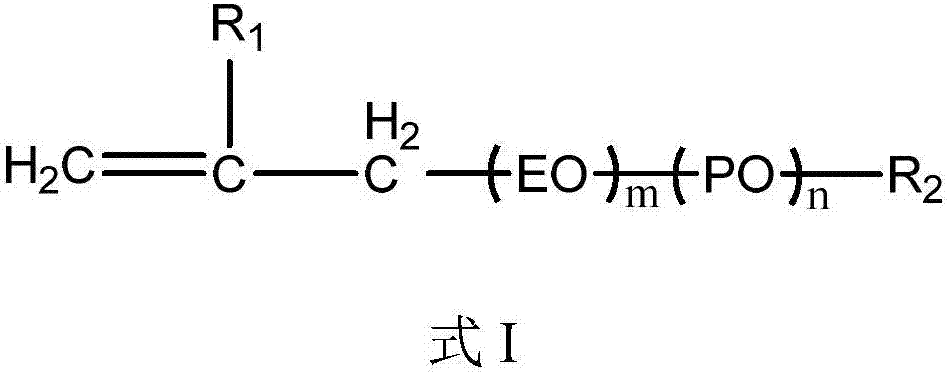

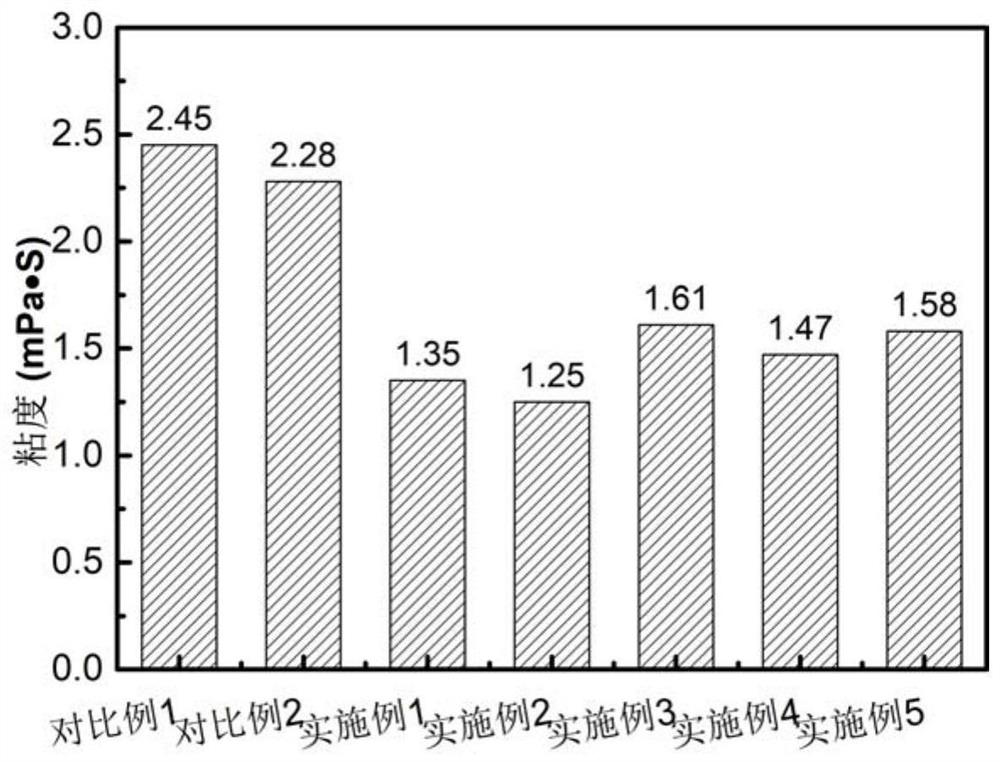

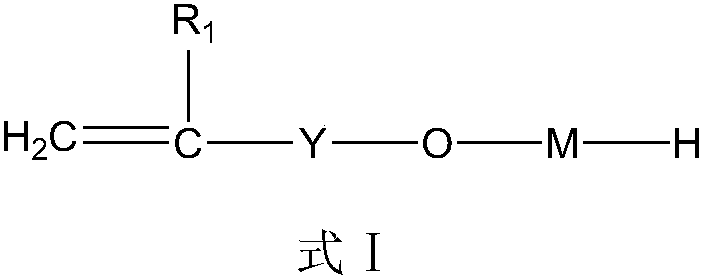

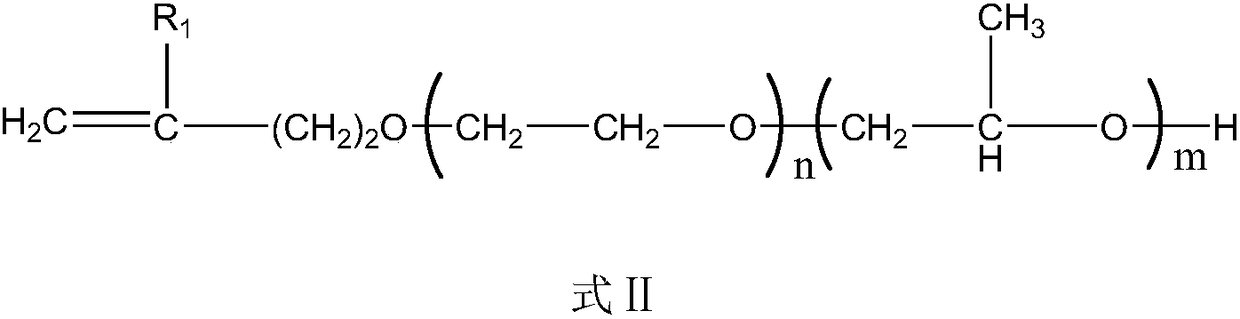

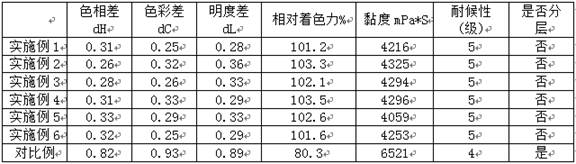

Viscosity reduction polycarboxylic acid water reducer and preparation method thereof

ActiveCN108264615ASignificant steric stabilization effectGood viscosity reductionPolymer scienceAcid water

The invention provides a viscosity reduction polycarboxylic acid water reducer and a preparation method thereof. The viscosity reduction polycarboxylic acid water reducer is a polymer taking unsaturated carboxylic acid, unsaturated polyalkoxylated ether and allyl or methyl allyl modified linear phenolic resin as co-monomers. The linear phenolic resin serving as the co-monomer is added into the viscosity reduction polycarboxylic acid water reducer, an aromatic nucleus structure can be introduced into the polycarboxylic acid water reducer, so that the adsorption efficiency and the adsorption thickness of cement particle surface polymer molecules can be effectively improved, the space stabilizing effect of the water reducer can be more remarkable, and the viscosity reduction polycarboxylic acid water reducer has obvious viscosity reduction effects and is simple in preparation method, strong in operability, low in energy consumption, low in cost and huge in market application potential.

Owner:LIAONING OXIRANCHEM INC

Two-component permeation type acid-resistant cement surface hardener and application method thereof

The invention discloses a two-component permeation type acid-resistant cement surface hardener and an application method thereof and belongs to the technical field of building materials. The developedhardener comprises a component A and a component B, wherein the component A is prepared from modified gelatin latex and calcium bicarbonate; and the component B is prepared from tetraethyl orthosilicate, phenyltrimethoxysilane, N,N-dimethyl cyclohexyl amine and drying oil. The application method comprises the following steps of in the application process, stirring and mixing absolute ethyl alcohol with water, regulating a pH value, dropwise adding the component B, performing constant-temperature stirring reaction, regulating a pH value to neutral to obtain a hydrolysate, uniformly stirring and mixing the component A and the hydrolysate to obtain the two-component permeation type acid-resistant cement surface hardener, brushing the surface of cement with the two-component permeation type acid-resistant cement surface hardener, performing still standing for solidification for 24-36 hours at room temperature, and finishing application of the two-component permeation type acid-resistant cement surface hardener. The obtained two-component permeation type acid-resistant cement surface hardener has excellent acid resistance and flexibility.

Owner:MUDANJIANG NORTH CEMENT CO LTD

High-stability fluorescent color paste and preparation method thereof

The high-stability fluorescent color paste is prepared from the following main raw materials in parts by weight: 40 to 50 parts of fluorescent pigment, 4 to 6 parts of macromolecular dispersing agent, 0.1 to 1 part of anti-settling agent, 4 to 10 parts of polyalcohol, 1 to 5 parts of micromolecular wetting agent, 0.1 to 0.3 part of preservative and 30 to 50 parts of water. Accroding to the invention, the product has the advantages of good stability, uniform dyeing, high production efficiency, no harm to the environment and human bodies and the like.

Owner:ZHEJIANG NAMEI MATERIAL TECH

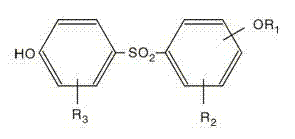

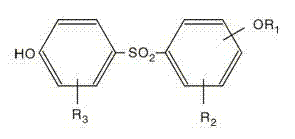

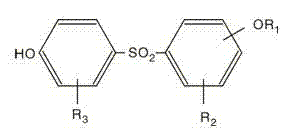

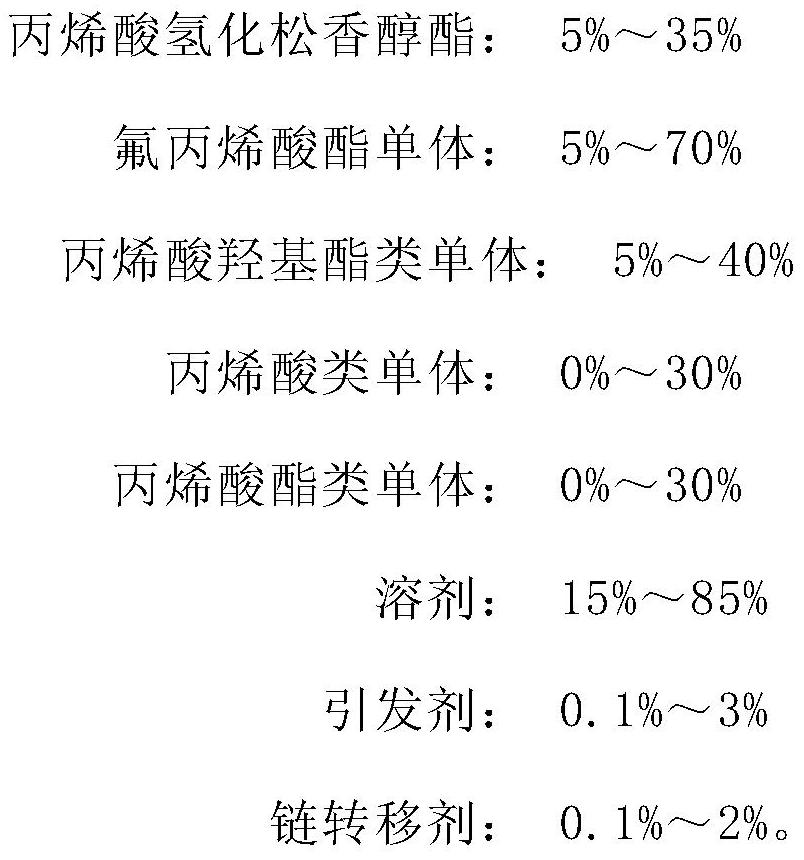

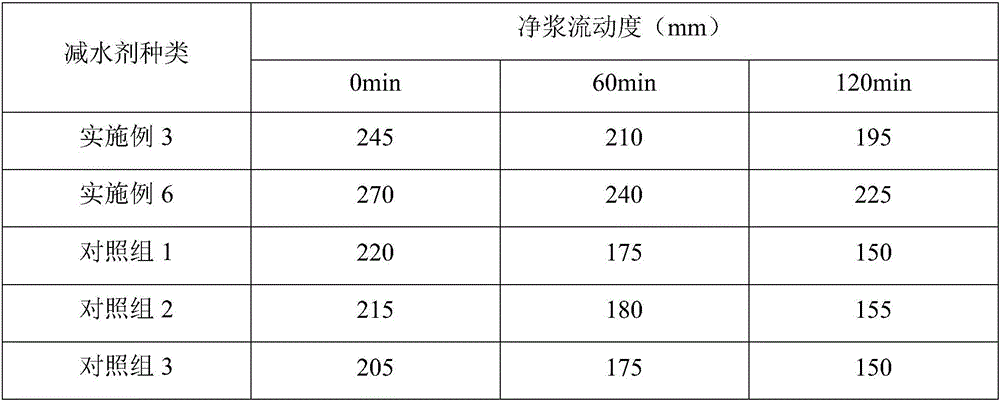

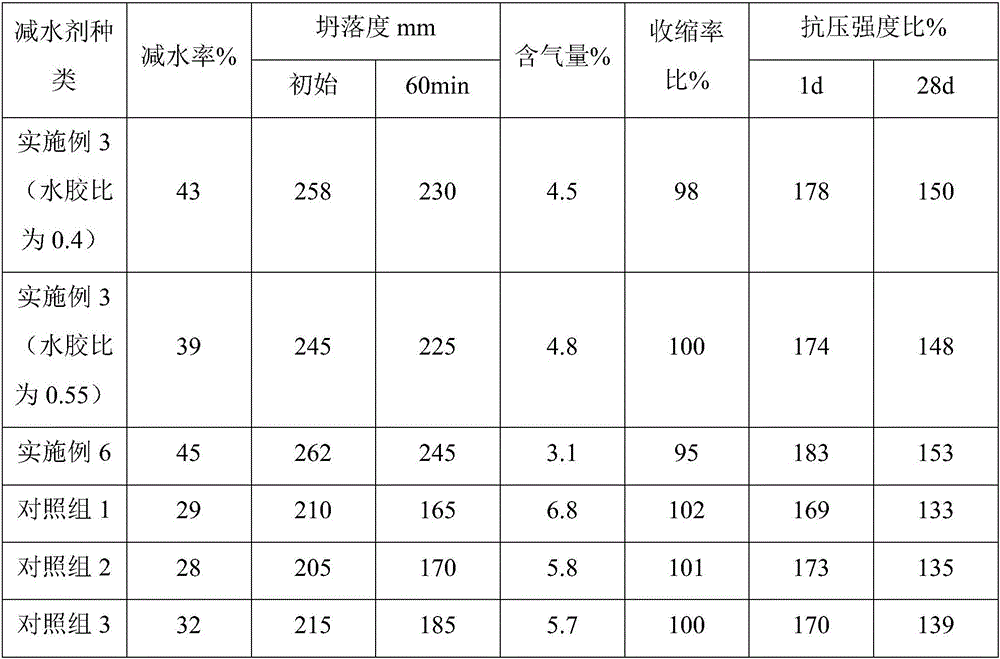

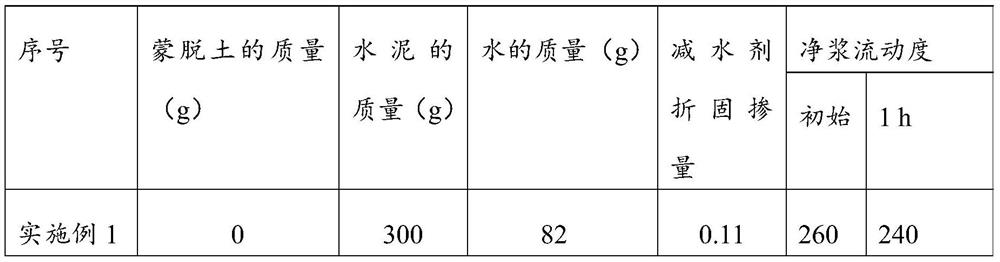

Acrylic acid hydrogenated abietinol ester modified fluorocarbon resin and preparation method thereof

PendingCN113861334AGood steric hindrance effectGood hydrophobicityAnti-corrosive paintsPolyurea/polyurethane coatingsFluorocarbon ResinsCorrosion prevention

The invention discloses an acrylic acid hydrogenated abietinol ester modified fluorocarbon resin, the molecular structure of which takes a carbon chain as a main chain structure, and a side group connected with a main chain carbon atom is composed of one or more of a hydrogenated abietinol ester group, a fluoroalkyl ester group, a hydroxyl group or an alkyl hydroxyl group, and / or a hydrogen atom, an alkyl group, an alkoxy group, a carboxyl group and an ester group; from the perspective of the molecular structure, the chemical structure of the fluorocarbon resin is designed and optimized, a large-volume rigid group is introduced into the molecular structure, the novel fluorocarbon resin is synthesized, the hydrophobicity and hardness of the fluorocarbon resin are further improved, the comprehensive performance of the fluorocarbon coating can be essentially improved, and the application of the fluorocarbon coating in the field of marine heavy corrosion prevention is further expanded.

Owner:GUANGXI UNIV FOR NATITIES

Polycarboxylate superplasticizer and preparation method thereof

The invention discloses polycarboxylate superplasticizer and a peparation method thereoof. The polycarboxylate superplasticizer comprises following raw materials, by weight, 40 to 60 parts of alkylphenol ethoxylates, 25 to 35 parts of TPEG, 10 to 15 parts of cinnamic acid, 10 to 15 parts of Octenyl succinic anhydride, 5 to 10 parts of 2-Propenoic acid, 3-phenyl-, ethyl ester, 5 to 10 parts of methacrylic acid, 3 to 8 parts of isopropanol, 3 to 8 parts of sodium persulfate and 0.5 to 2 parts of ascorbic acid. The polycarboxylate superplasticizer has lower amount of mixture than other common polycarboxylate superplasticizer and has a high water-reducing rate under the circumstance of water-binder ratio. The polycarboxylate superplasticizer has the advantages of wider range of application, good anti-collapse of concrete, environmental protection. The polycarboxylate superplasticizer, prepared by this method, is capable of having wider adaption to concrete, making the system more stable, reducing usage of air entraining agent and making shrinkage ratio of concrete lower than common water reducer.

Owner:GUANGXI JINHONG CONCRETE CO LTD

Polycarboxylate superplasticizer and preparation method thereof

The invention provides a polycarboxylate superplasticizer and a preparation method thereof, and aims to solve the problem that the existing superplasticizer is easily influenced by the mud content of concrete. The polycarboxylate superplasticizer is prepared from the following raw materials: mono6-glycidyl methacrylate-ethanolamine-beta-cyclodextrin, ethylene glycol monovinyl polyethylene glycol ether, acrylic acid, an oxidizing agent, a reducing agent, a chain transfer agent, a first pH regulator and water. The polycarboxylate superplasticizer disclosed by the invention is not easily influenced by the mud content of concrete in the use process, and takes a redox system as an initiating system, so that the reaction speed is controlled through the dropping speed in the preparation process, a polymerization reaction process without temperature control at normal temperature can be realized, and energy and cost can be saved.

Owner:HUNAN ZHONGYAN BUILDING MATERIAL TECH CO LTD

The method for synthesizing cement dispersant of acrylamide-fatty acid vinyl ester graft copolymer

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com