Preparation method for sulfonation modification type composite modified starch size

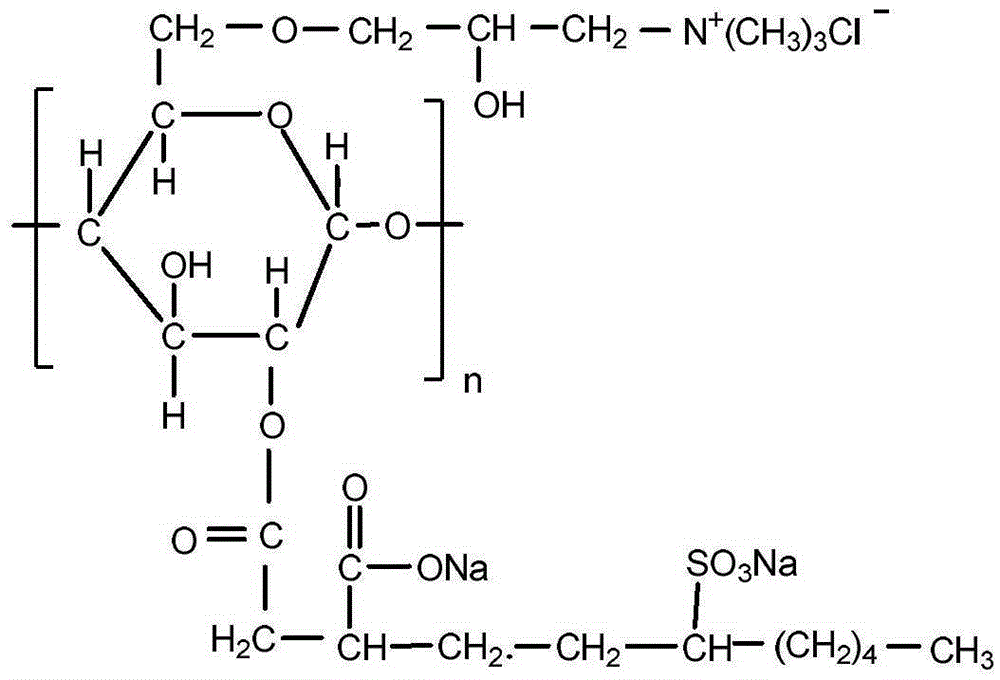

A technology of compound modified starch and sulfonation modification, applied in the field of slurry preparation, can solve the problems of insufficient serosal film performance, affecting the water dispersibility of slurry, limited steric hindrance, etc. The effect of enhanced serous properties, flexibility and segment mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

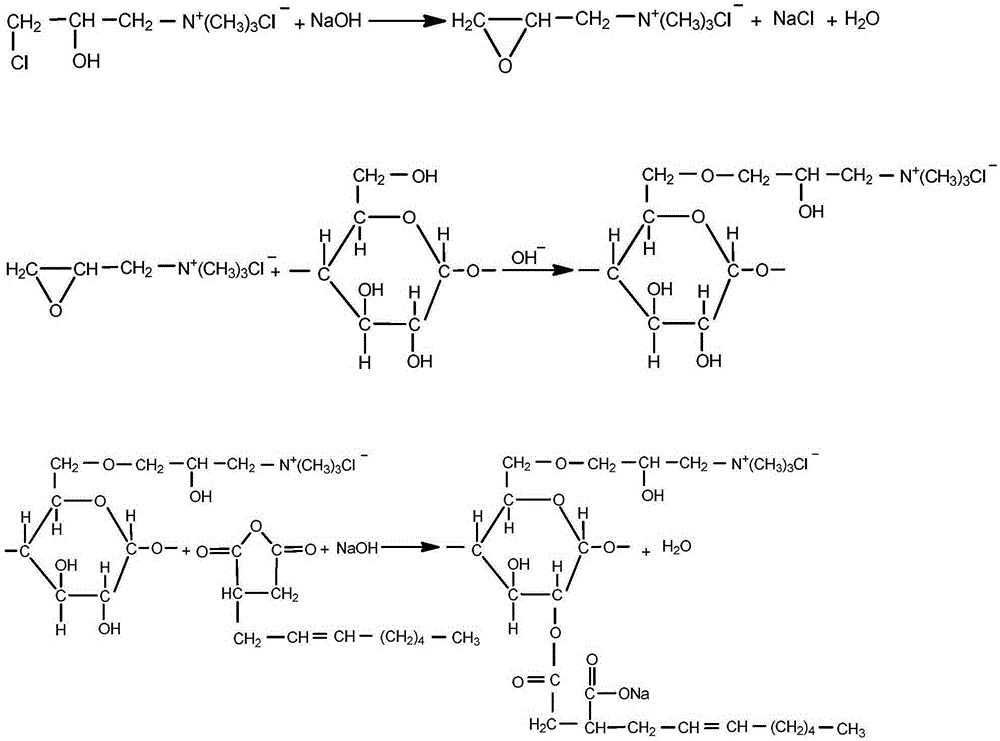

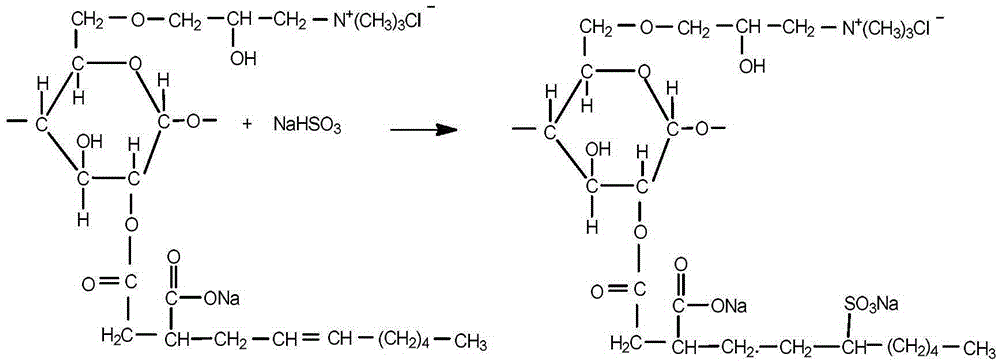

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of sulfonated modified composite modified starch size, comprising the following steps:

[0036] (1) Preparation of cationic starch:

[0037] Weigh 300 grams of cornstarch (dry weight), add water to make starch milk with a mass concentration of 40%, then transfer the starch milk into a 1000mL four-neck flask, install a stirring device, and then place the temperature in a water bath to 50°C , with a mass concentration of 3% sodium hydroxide solution to adjust the pH to 11 to 11.5, adding a mass concentration of 50% aqueous solution containing 12 grams of cationic etherifying agent 3-chloro-2-hydroxypropyltrimethylammonium chloride, Then use a 3% sodium hydroxide solution to adjust the pH to 11-11.5; after stirring for 8 hours, use a 3% hydrochloric acid solution to adjust the pH to 6.5-7; the product is filtered, washed 3 times with water, Dry at 45°C until constant weight, crush and sieve to obtain cationic starch.

[0038] (2) Preparation of catio...

Embodiment 2

[0045] A preparation method of sulfonated modified composite modified starch size, comprising the following steps:

[0046] (1) Preparation of cationic starch:

[0047] Weigh 300 grams of cornstarch (dry weight), add water to make starch milk with a mass concentration of 40%, then transfer the starch milk into a 1000mL four-neck flask, install a stirring device, and then place the temperature in a water bath to 50°C , with a mass concentration of 3% sodium hydroxide solution to adjust the pH to 11 to 11.5, adding a mass concentration of 50% aqueous solution containing 24 grams of cationic etherifying agent 3-chloro-2-hydroxypropyltrimethylammonium chloride, Then use a 3% sodium hydroxide solution to adjust the pH to 11-11.5; after stirring for 8 hours, use a 3% hydrochloric acid solution to adjust the pH to 6.5-7; the product is filtered, washed 3 times with water, Dry at 45°C until constant weight, crush and sieve to obtain cationic starch.

[0048] (2) Preparation of catio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com