High-stability fluorescent color paste and preparation method thereof

A fluorescent color paste, high stability technology, applied in the color field, can solve the problems of low grinding and dispersion efficiency, long grinding time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

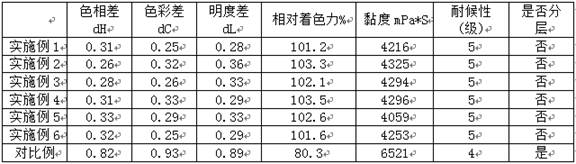

Examples

Embodiment 1

[0032] A highly stable fluorescent color paste, characterized in that the main raw materials and parts by weight of the fluorescent color paste are as follows: 50 parts of fluorescent pink, 5 parts of polyacrylate, 0.8 parts of organically modified bentonite, 6 parts of Polyethylene glycol, 4 parts of HY-1608A, 0.2 parts of 2-methyl-4-isothiazolin-3-one and 50 parts of water.

[0033] The preparation method of the fluorescent color paste with high stability according to the ratio of the above-described embodiment may further comprise the steps:

[0034] a. Mix water, polyethylene glycol, polyacrylate, HY-1608A, 2-methyl-4-isothiazolin-3-one, and stir evenly;

[0035] b. Add organically modified bentonite while stirring, add fluorescent pink after dispersing evenly, and then stir at a stirring speed of 1500 rpm for 60 minutes to obtain coarse fluorescent pink slurry;

[0036] c. Sand the coarse fluorescent pink slurry in step b with a sand mill, and the number of grinding time...

Embodiment 2

[0041] A highly stable fluorescent color paste, characterized in that the main raw materials and parts by weight of the fluorescent color paste are as follows: 50 parts of fluorescent pink, 5 parts of polyacrylate, 0.8 parts of organically modified bentonite, 6 parts of Polyethylene glycol, 4 parts of HY-1608A, 0.2 parts of 2-methyl-4-isothiazolin-3-one and 50 parts of water.

[0042] The fluorescent color paste also includes 2 parts of defoamer TEGO 810.

[0043] The preparation method of the fluorescent color paste with high stability according to the ratio of the above-described embodiment may further comprise the steps:

[0044] a. Mix water, polyethylene glycol, polyacrylate, HY-1608A, 2-methyl-4-isothiazolin-3-one, and stir evenly;

[0045] b. Add organically modified bentonite while stirring, add fluorescent pink and defoamer TEGO 810 after dispersing evenly, and then stir at a stirring speed of 1500 rpm for 60 minutes to obtain a thick fluorescent pink slurry;

[004...

Embodiment 3

[0051] A highly stable fluorescent color paste, characterized in that the main raw materials and parts by weight of the fluorescent color paste are as follows: 50 parts of fluorescent pink, 5 parts of polyacrylate, 0.8 parts of organically modified bentonite, 6 parts of Polyethylene glycol, 4 parts of HY-1608A, 0.2 parts of 2-methyl-4-isothiazolin-3-one and 50 parts of water.

[0052] The fluorescent color paste also includes 2 parts of defoamer TEGO 810.

[0053] The preparation method of the above-mentioned highly stable fluorescent color paste according to the ratio of the above-mentioned embodiment may further comprise the steps:

[0054] a. Mix water, polyethylene glycol, polyacrylate, HY-1608A, 2-methyl-4-isothiazolin-3-one, and stir evenly;

[0055] b. Add organically modified bentonite while stirring, add phosphor yellow and defoamer TEGO 810 after dispersing evenly, and then stir at a stirring speed of 1500 rpm for 60 minutes to obtain coarse phosphor yellow slurry; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com