Patents

Literature

118 results about "Fluorescent age pigment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

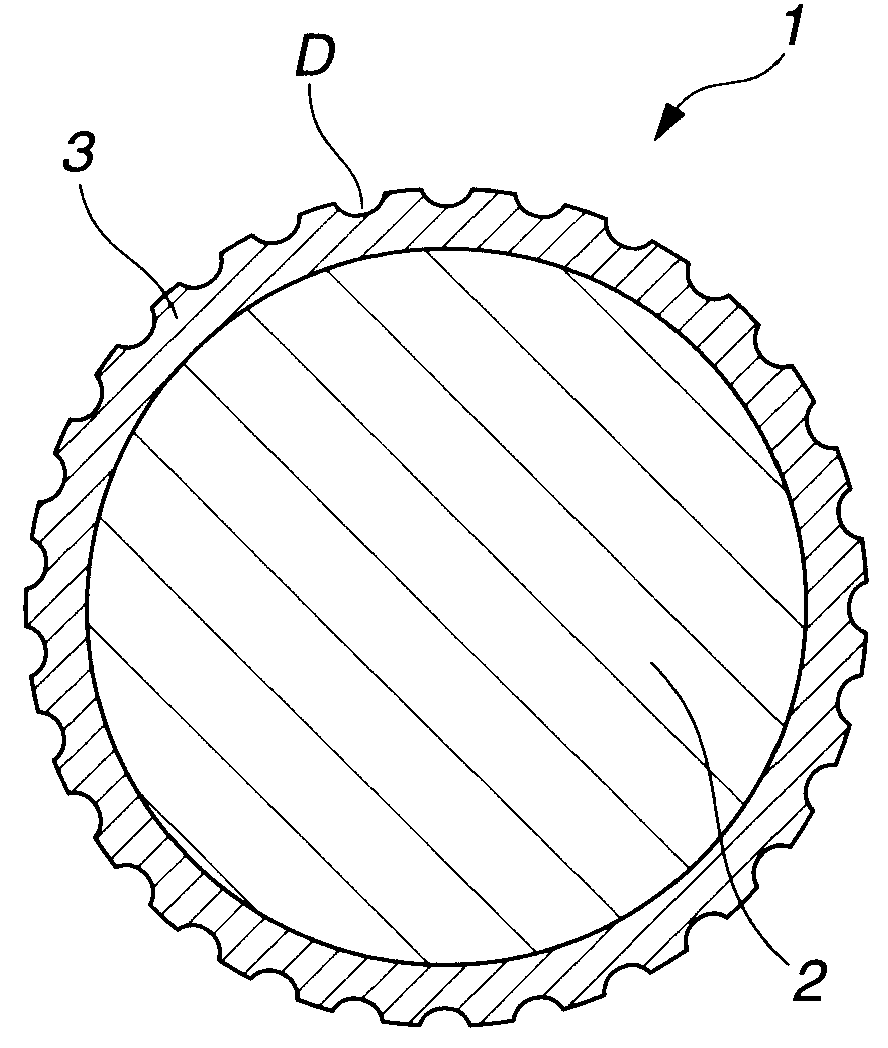

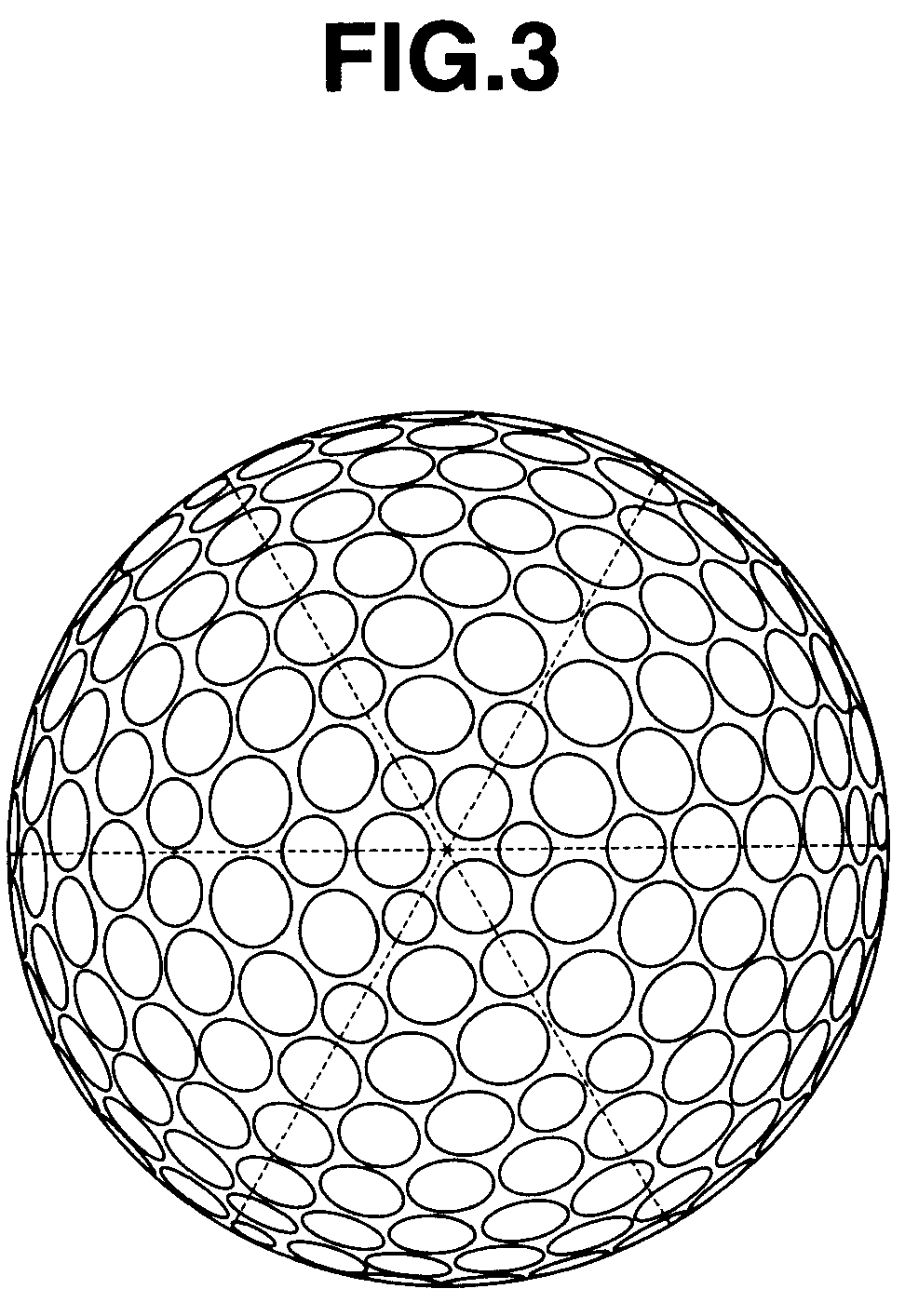

Golf ball

The invention provides a two-piece golf ball having a single-layer core, a single-layer cover and a surface on which a plurality of dimples are formed. The cover is made of a material which includes 100 parts by weight of a resin material, from 0 to 0.5 part by weight of titanium oxide, and from 0.1 to 2 parts by weight of a fluorescent pigment selected from the group consisting of yellow, orange, peach and red. The ball surface has a lightness L value, expressed in the Lab color system, of at least 50. The core surface has an L value of at least 82 and a chroma C, defined as (a2+b2)1 / 2, of 10 or less. The golf ball exhibits a brightly colored surface, is highly fashionable, and is readily visible during play.

Owner:BRIDGESTONE SPORTS

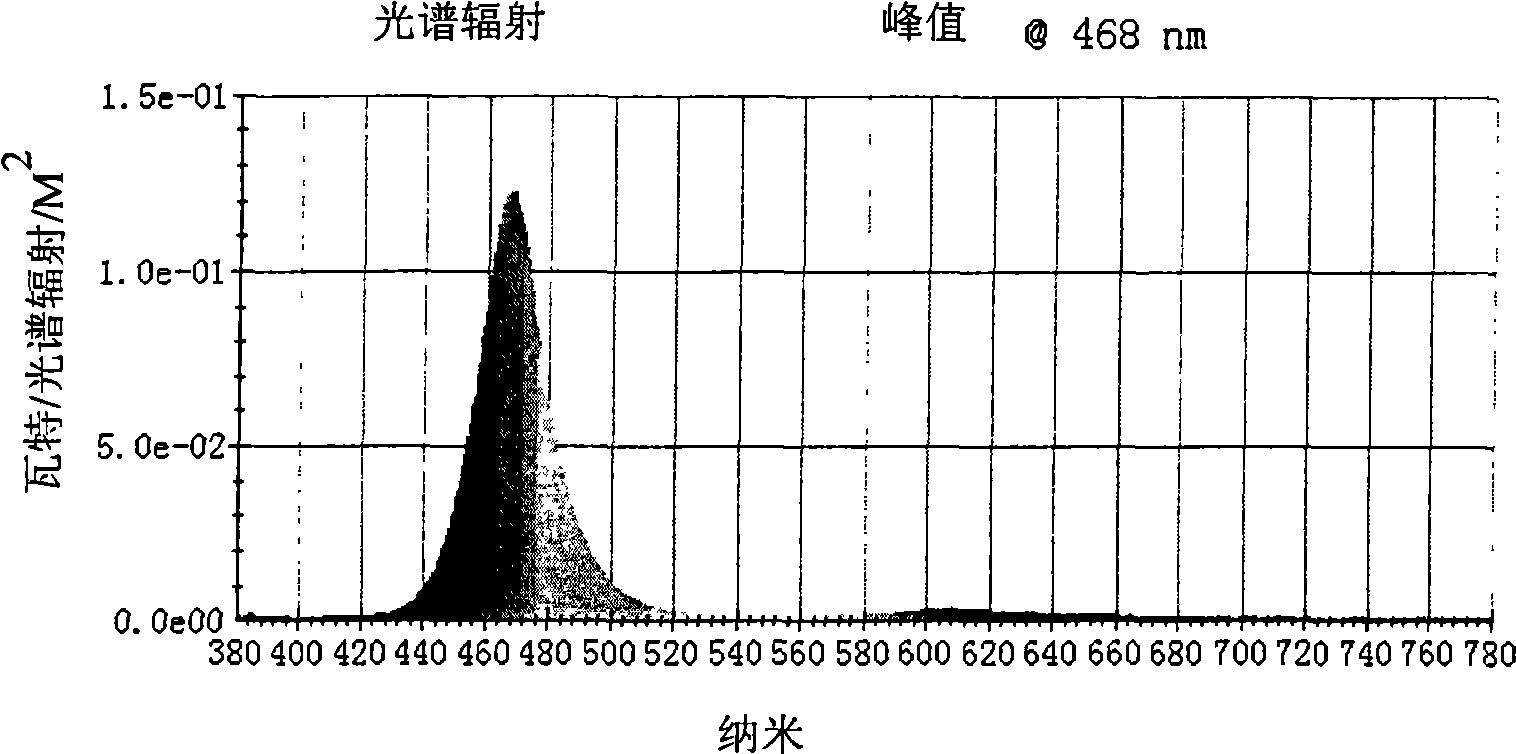

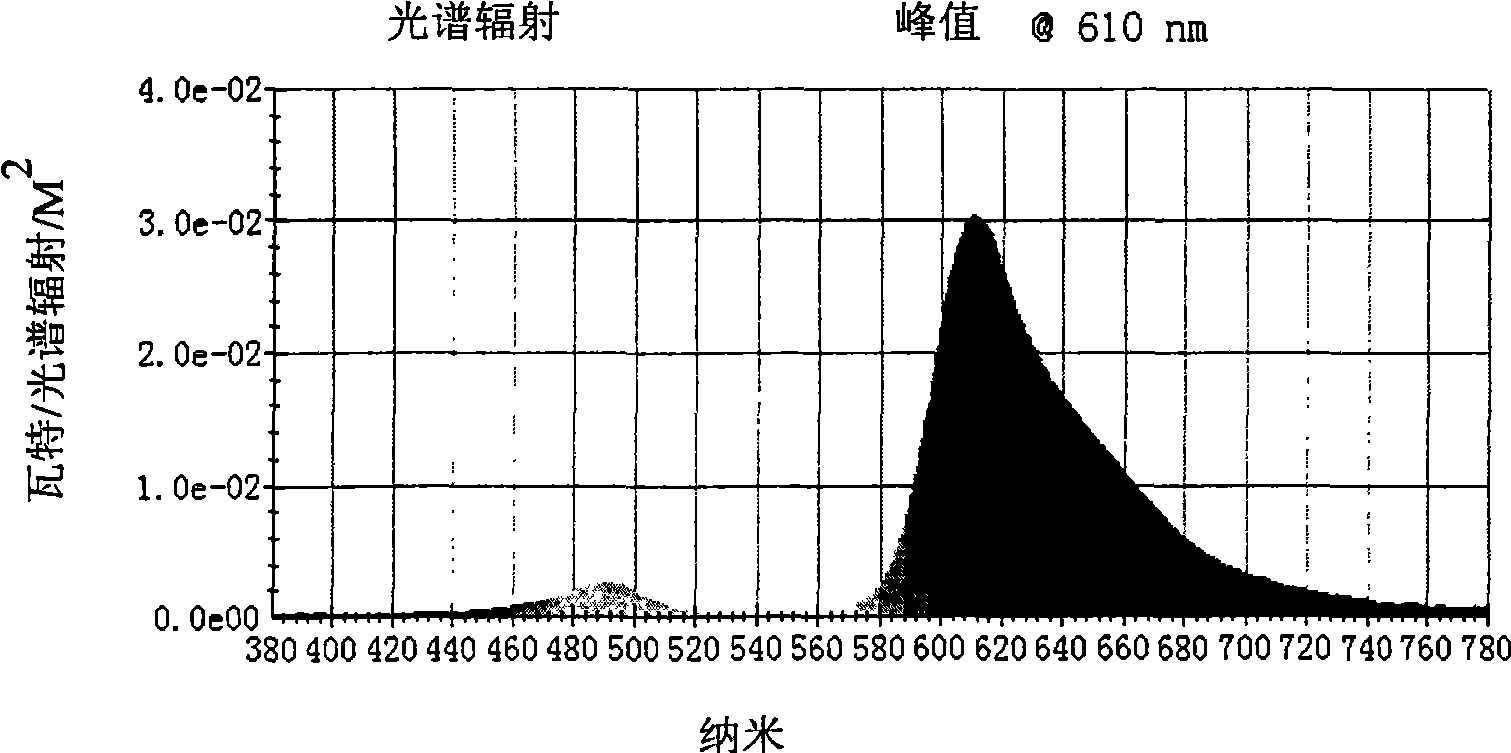

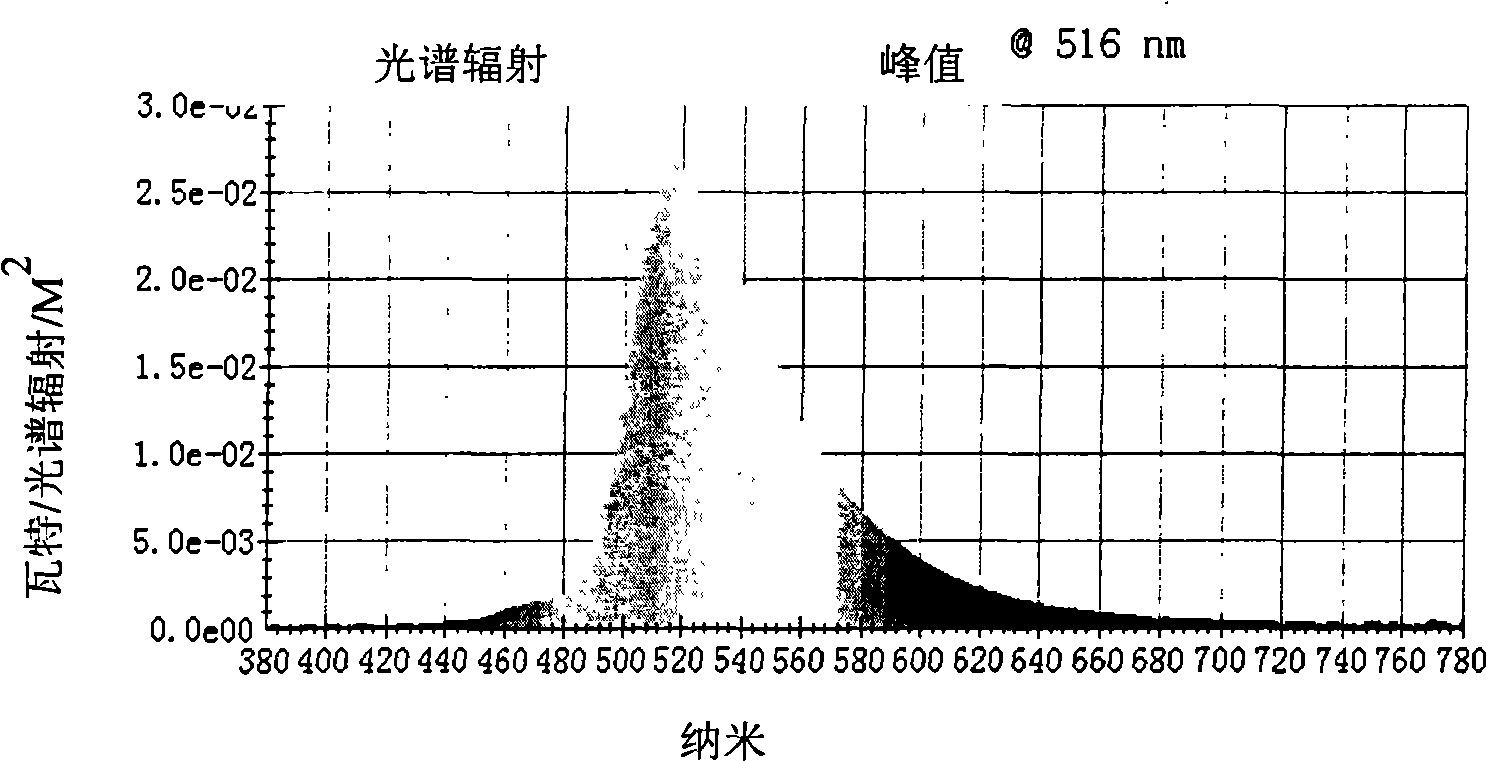

UV cured fluorescent color conversion film for electroluminescence display device and preparation

InactiveCN101481556AImprove performanceImprove adhesionLuminescent paintsSolid-state devicesColor transformationFluorescence

The invention relates to an ultraviolet-cured fluorescent color transformation film for a full-color electroluminescence display, and a preparing method thereof, belonging to the field of full-color electroluminescence displays. The ultraviolet-cured fluorescent color transformation film contains active oligopolymer, reactive diluent, light trigger, fluorescent pigment, macromolecular dispersant, flatting agent, foam killer and adhesive attraction promoting agent. The preparing method comprises the following steps: the above substances are proportionally mixed so as to obtain an ultraviolet-cured fluorescent paint which is printed through a screen on the luminescence exit face of the full-color electroluminescence display; and then, ultraviolet irradiation for curing is carried out so as to obtain the ultraviolet-cured fluorescent color transformation film for the full-color electroluminescence display. By means of taking a single high-brightness blue-fluophor as a background light source, fundamental colors of red and green, which are brighter than the background blue light, can be obtained after the background blue light passes through the film, so the fundamental colors of red and green, together with the background blue light, realize the full color displaying of the electroluminescence display. The invention has the advantages of simple production process and high color transformation efficiency.

Owner:INESA ELECTRON

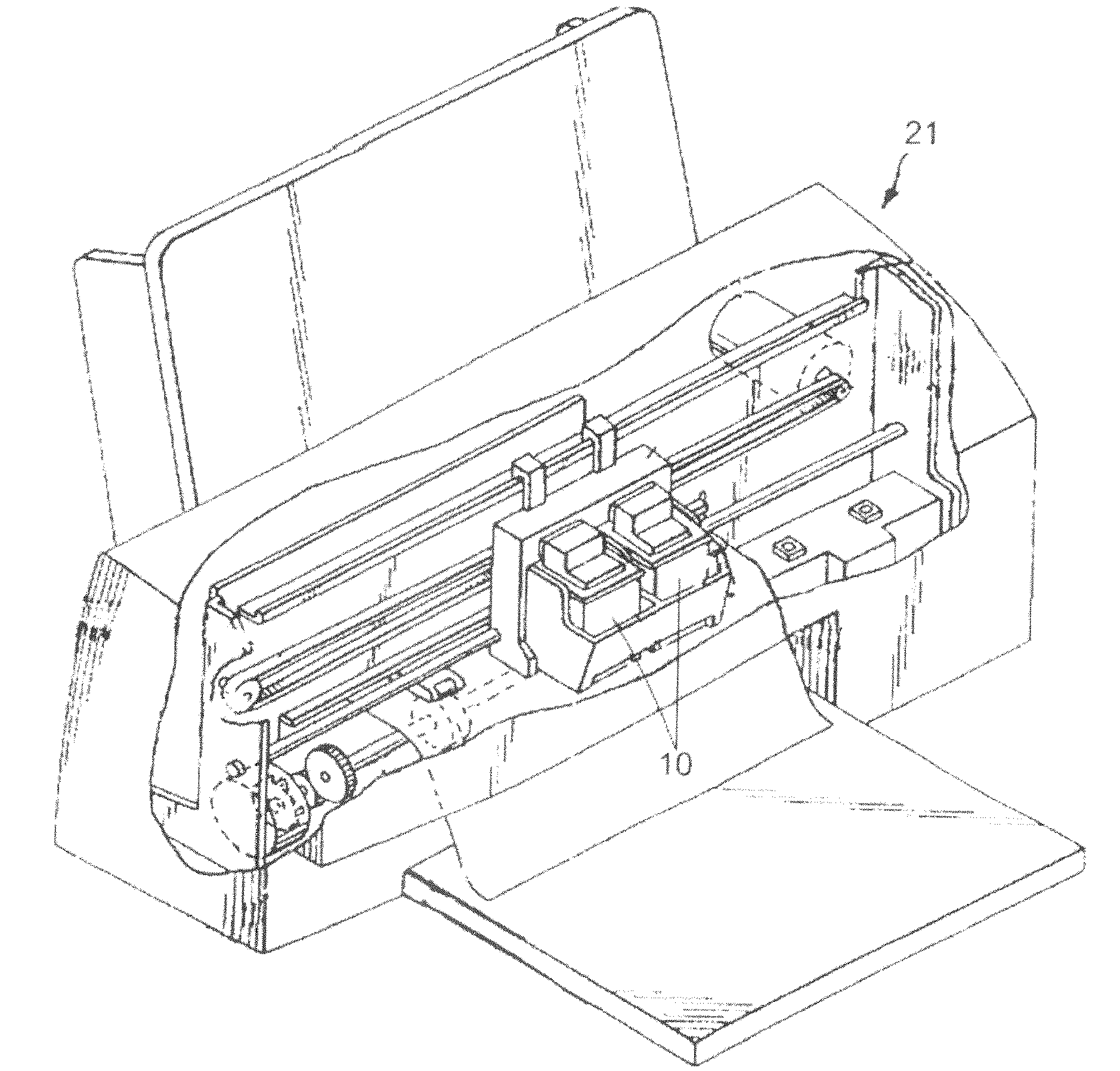

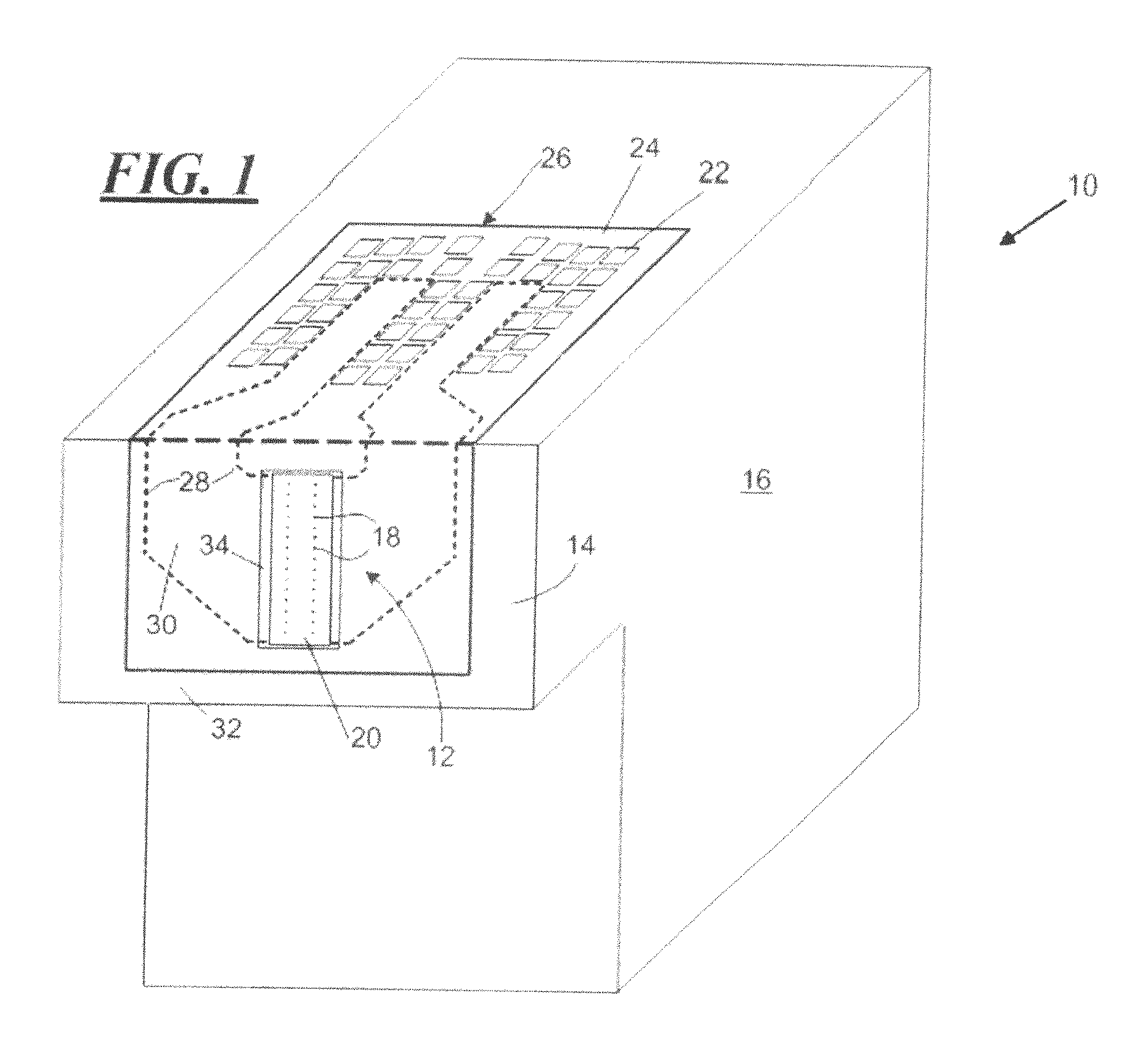

Adhesive compositions and methods for use in failure analysis

InactiveUS20110014354A1Improve adhesionImprove flow resistancePolyureas/polyurethane adhesivesGranular deliveryShear modulusFluorescence

Thermally curable adhesive compositions and method for failure analysis in micro-fluid ejections heads. The adhesive composition may be provided by a composition including from about 50.0 to about 95.0 percent by weight of at least one cross-linkable resin, from about 0.1 to about 30.0 percent by weight of at least one thermal curative agent, and from about 0.0 to about 5.0 percent by weight filler, from about 0.1 to about 10.0 percent by weight fluorescent pigment. Upon curing, the adhesive composition exhibits a relatively low shear modulus.

Owner:LEXMARK INT INC

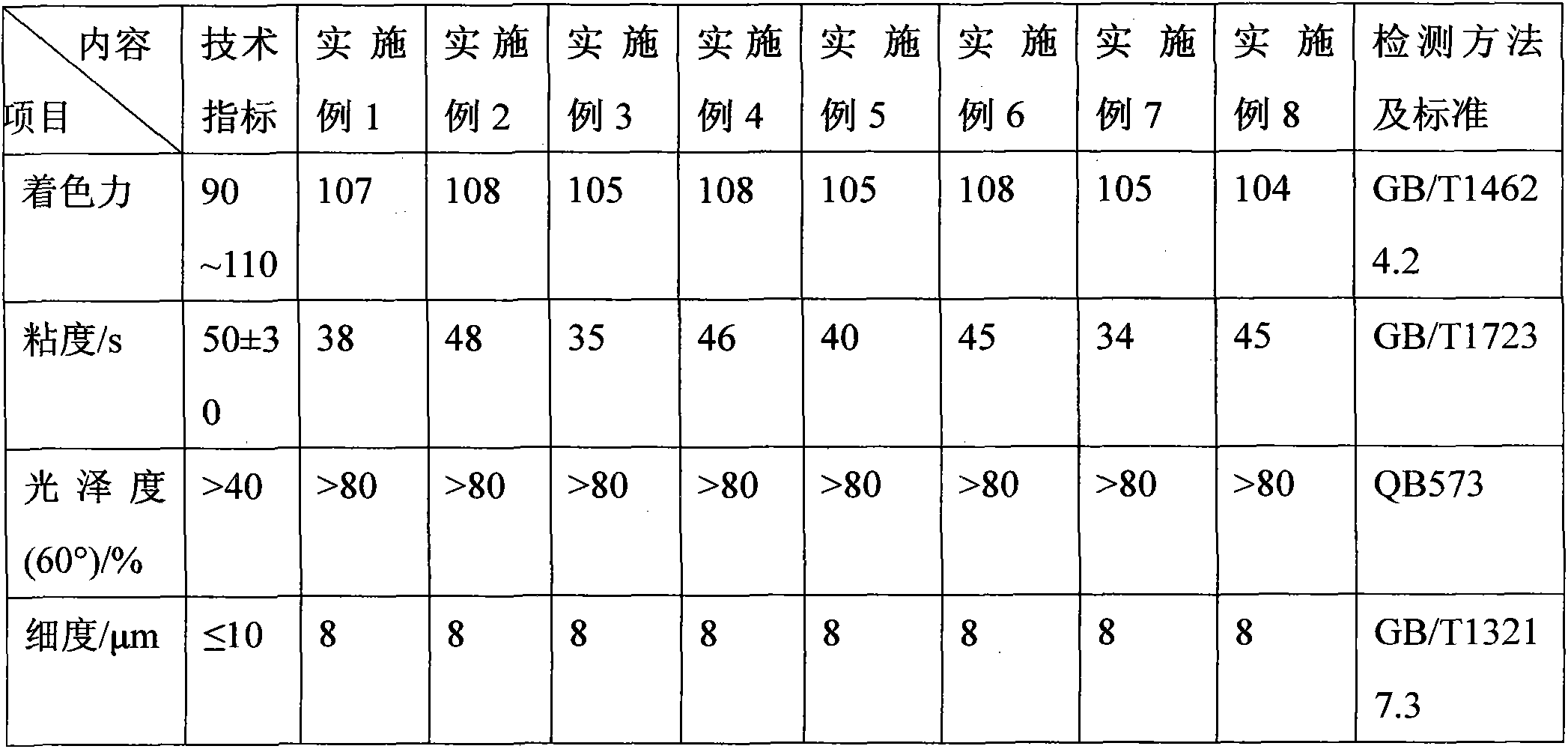

Waterproof, acid-resistant and alkaline-resistant fluorescent water-based ink universally used on paper and plastics and preparation method of ink

The invention relates to a waterproof, acid-resistant and alkaline-resistant fluorescent water-based ink universally used on paper and plastics. The ink is composed of the following raw materials in parts by weight: 10-30 parts of organic pigment, 1-10 parts of inorganic ultraviolet fluorescent pigment, 1-10 parts of dispersing agent, 0.1-1.5 parts of defoaming agent, 20-50 parts of deionized water, 50-100 parts of self-crosslinked acrylic emulsion, 0.1-1 part of thickening agent and 1-10 parts of cosolvent. The organic and inorganic ultraviolet fluorescent pigments are wetted and dispersed by using the self-crosslinked acrylic emulsion and the super water-based dispersing agent with a block structure so as to be uniformly and stably dispersed in a water-based ink system; the tinting strength and adhesive force of the water-based ink are enhanced through a self-crosslinking reaction; inorganic nano magnesium lithium silicate is adopted for regulating the viscosity of the water-based ink and improving the water resistance and acid-base resistance of the water-based ink, so that the water-based ink has favorable printability, water resistance, acid-base resistance and glossiness, and the defects of poor water resistance, acid-base resistance, pH stability and glossiness of the water-based ink are overcome.

Owner:万涛

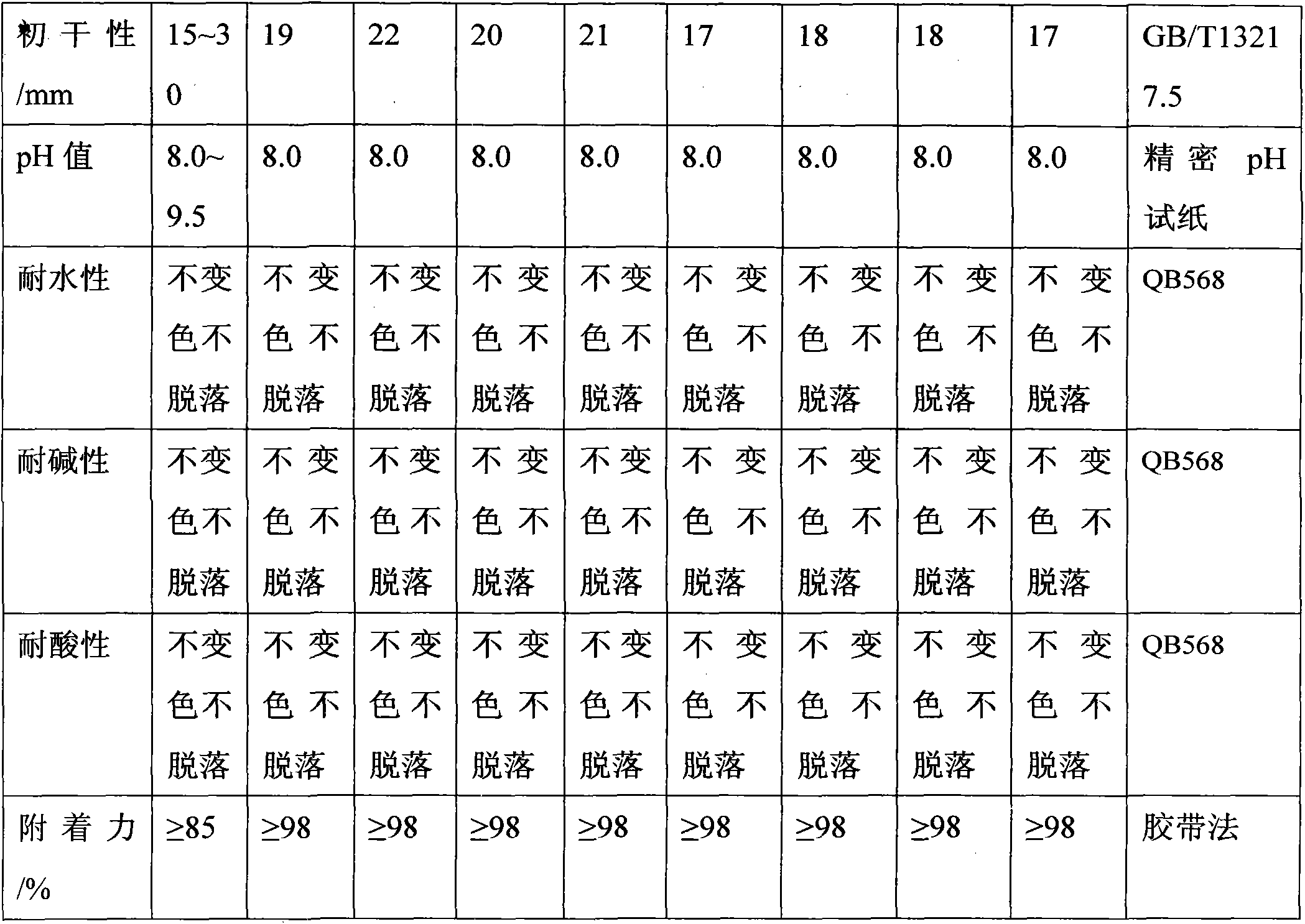

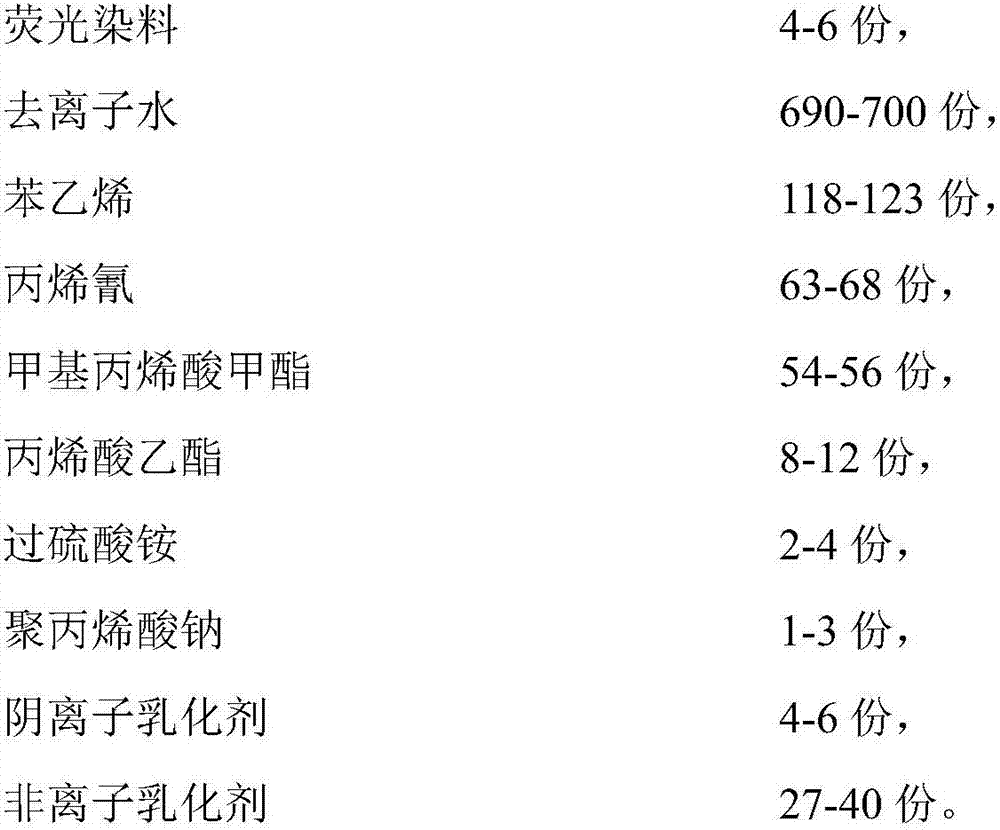

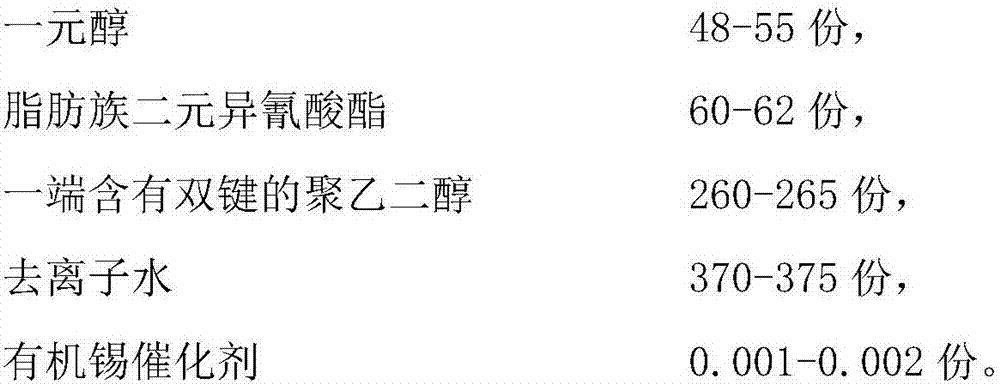

Preparation method of water-based fluorescent paint

InactiveCN103012174AHigh fluorescence intensityHigh yieldOrganic compound preparationLuminescent paintsAcrylic resinGlycol synthesis

The invention provides a preparation method of a water-based fluorescent paint. The method comprises the following steps of: by adopting a self-prepared ligand, diluting acrylic resin by using a defined amount of water and ethylene glycol or butyl cellosolve solvent until the viscosity is about 40mpa.s, adding a fluorescent pigment emulsion in the claim 3 under the condition of high-speed stirring, insulating heat for 30min at a temperature of 40-50 DEG C, adding a defoaming agent, a wetting dispersant, a multifunctional additive, a filler and the like, fully stirring, adding the wetting dispersant, a colloid modifying agent, an optical stabilizing agent and a thickening agent, sanding and grinding to obtain the water-based fluorescent paint, wherein the fineness of the water-based fluorescent paint is controlled to be 20-30mu m. The preparation method has the advantages that the process is simple, the yield is high, raw materials are easily available; and the ligand and a rare earth compound are used as the raw materials, and water is used as a dispersing agent, therefore the production cost is reduced, and the coating has the advantages of environment friendliness, high fluorescence intensity and excellent property.

Owner:HUAINAN NORMAL UNIV +1

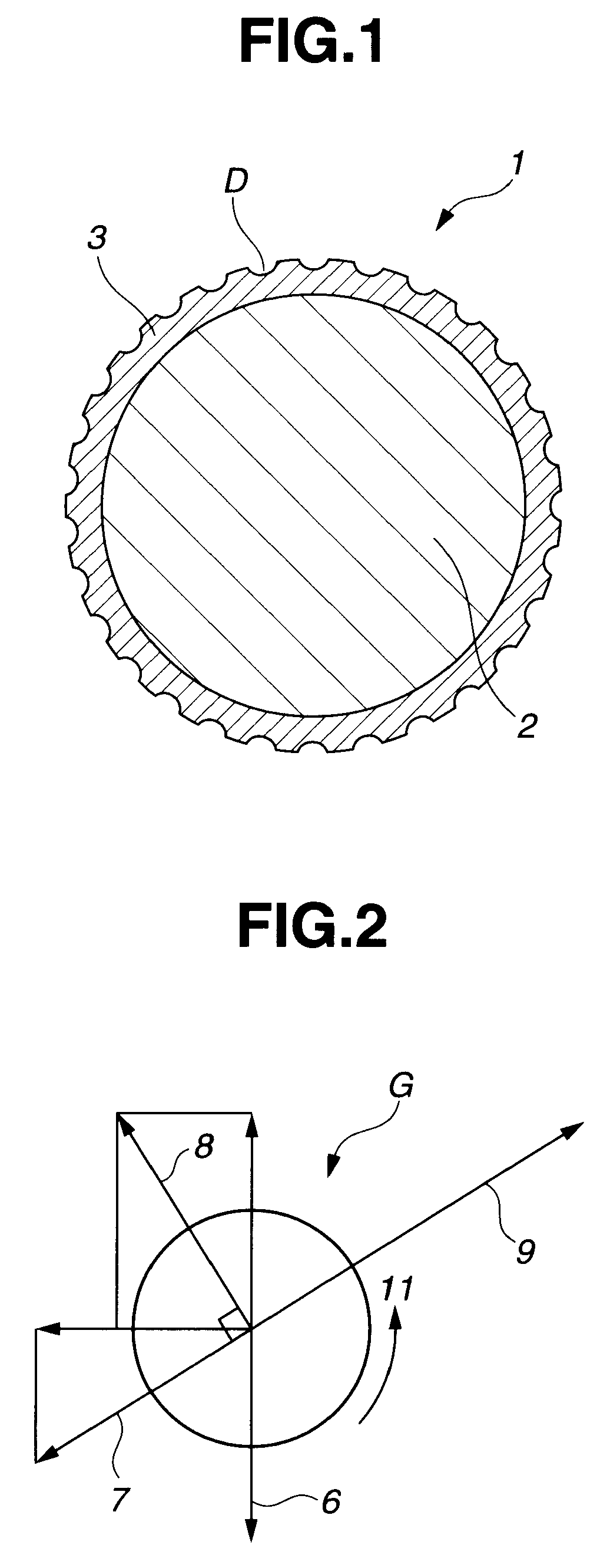

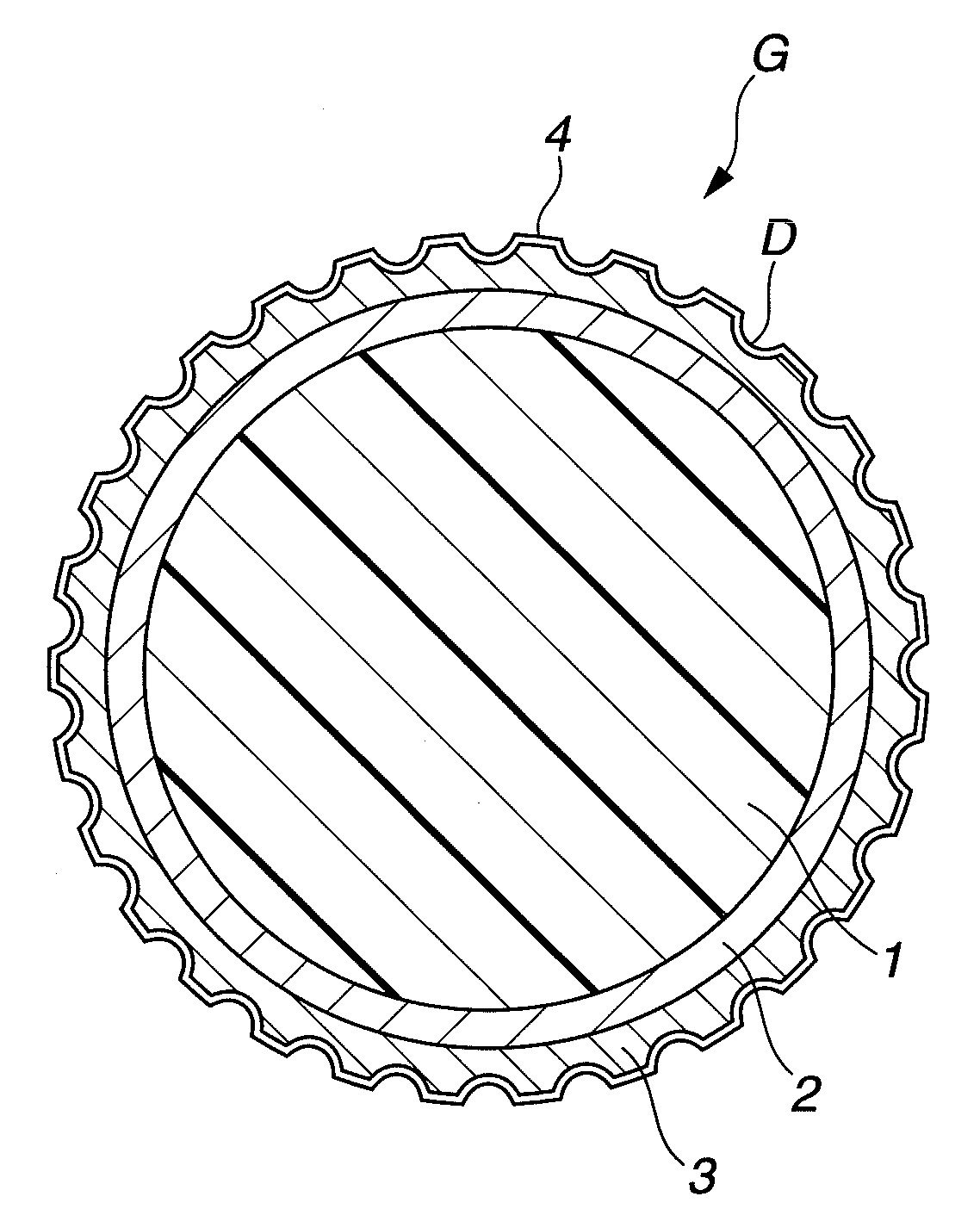

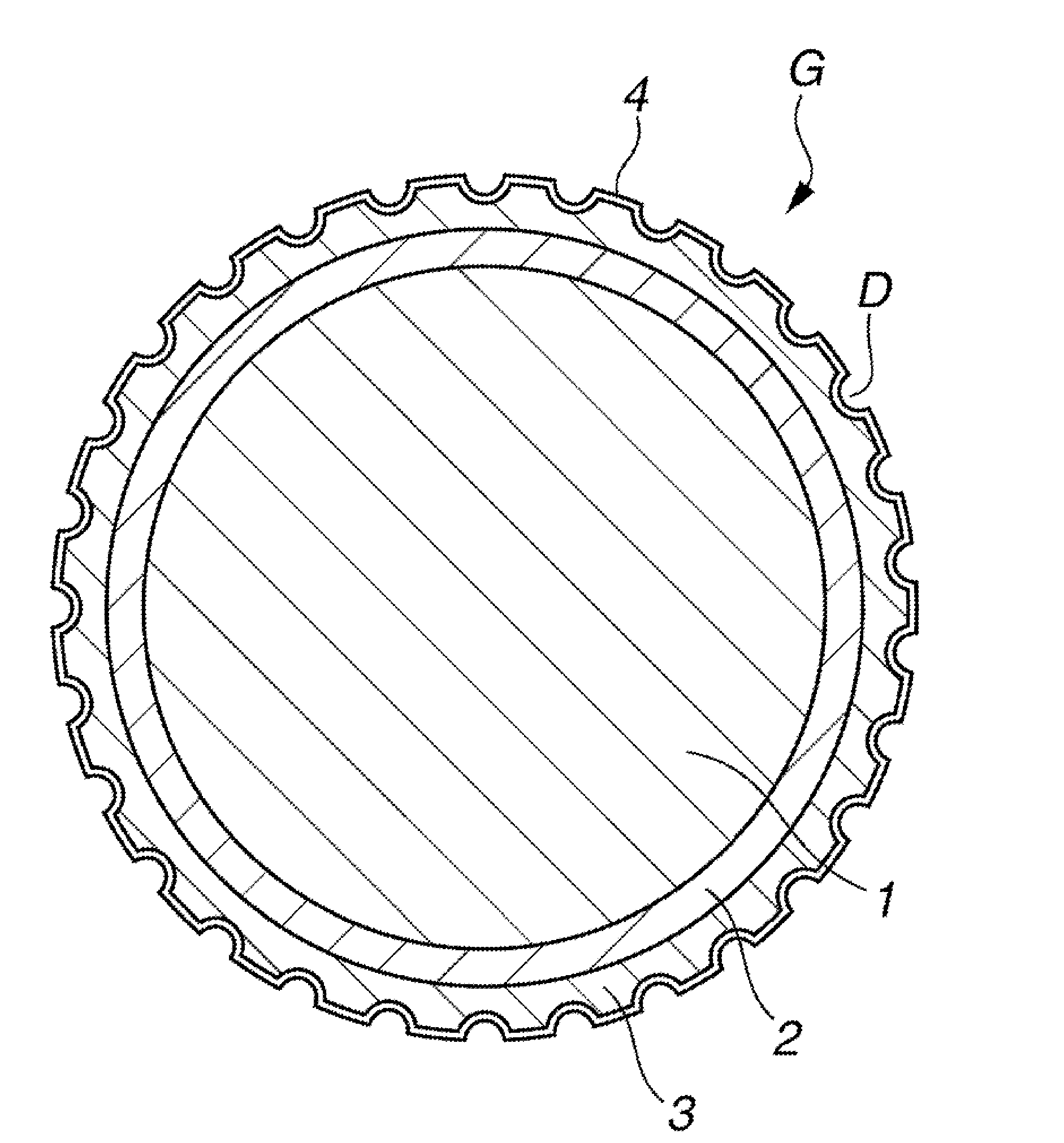

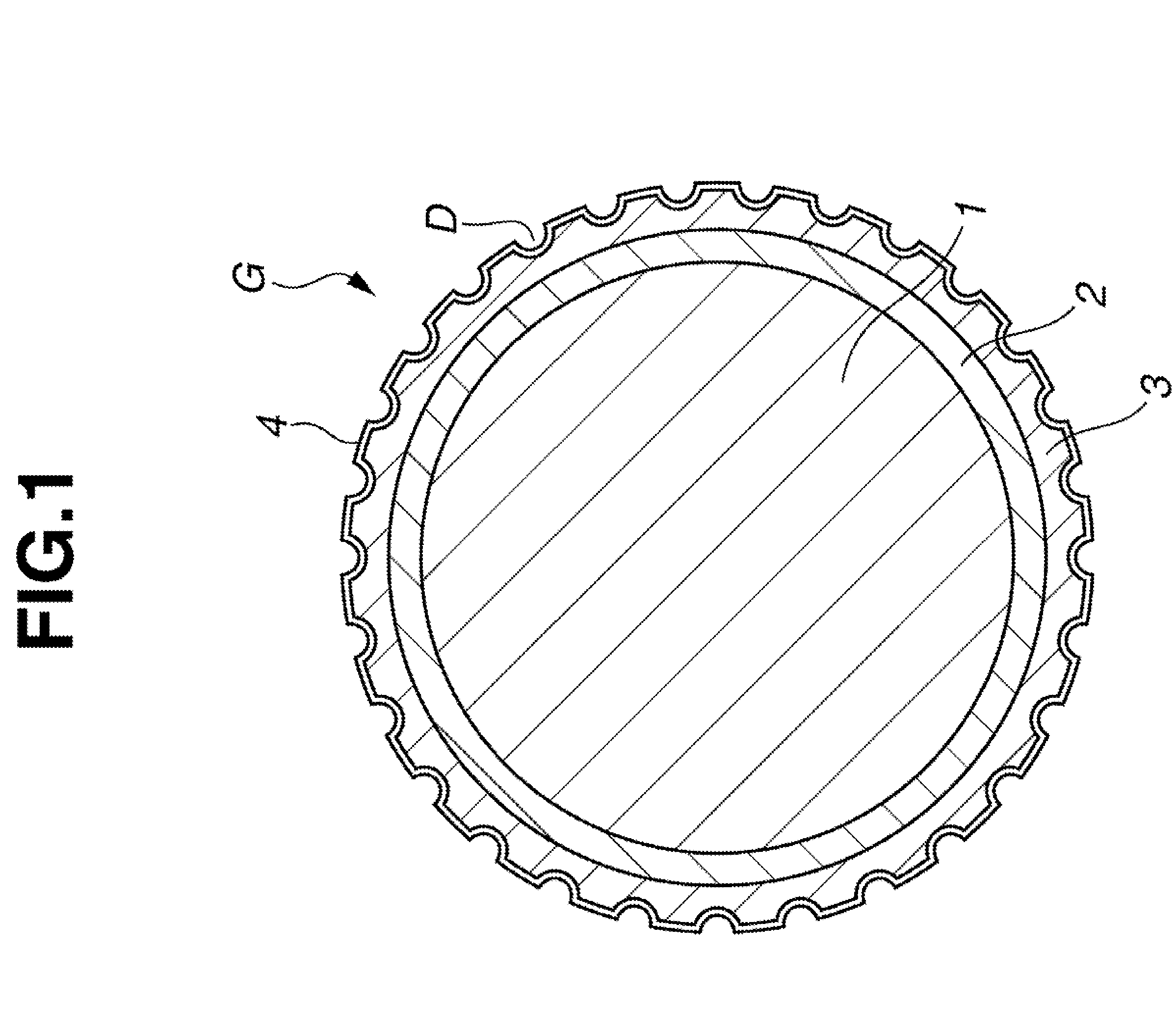

Colored golf ball

In a golf ball composed of a core, a cover of at least one layer encasing the core, and a coat of paint applied to a surface of an outermost layer of the cover, the outermost layer of the cover or the coat of paint is colored with a fluorescent pigment. The ball has a color tone, at a measurement area diameter of 5 mm in a method of measuring the color of a reflecting object according to JIS Z-8722, which satisfies specific conditions in the Lab color system. The ball is endowed with an excellent spin performance and durability, an appearance characterized by outstanding visibility, stylishness and luxury, and an excellent weather resistance.

Owner:BRIDGESTONE SPORTS

Colored golf ball

ActiveUS20120122614A1Increase brightnessSense of quality and eleganceGolf ballsSolid ballsEngineeringGolf Ball

In a colored golf ball having a core, a cover of two or more layers encasing the core, and a coat of paint applied to a surface of an outermost layer of the cover, the outermost cover layer is formed of a resin composition which includes (a) a thermoplastic resin, (b) a fluorescent color-containing color pigment and / or dye, and (c) titanium oxide. A layer adjoining an inner side of the outermost layer is formed of a resin composition containing a resin. The colored golf ball has an excellent rebound and weatherability, and also is endowed with a high brightness and a sense of quality and elegance.

Owner:BRIDGESTONE SPORTS

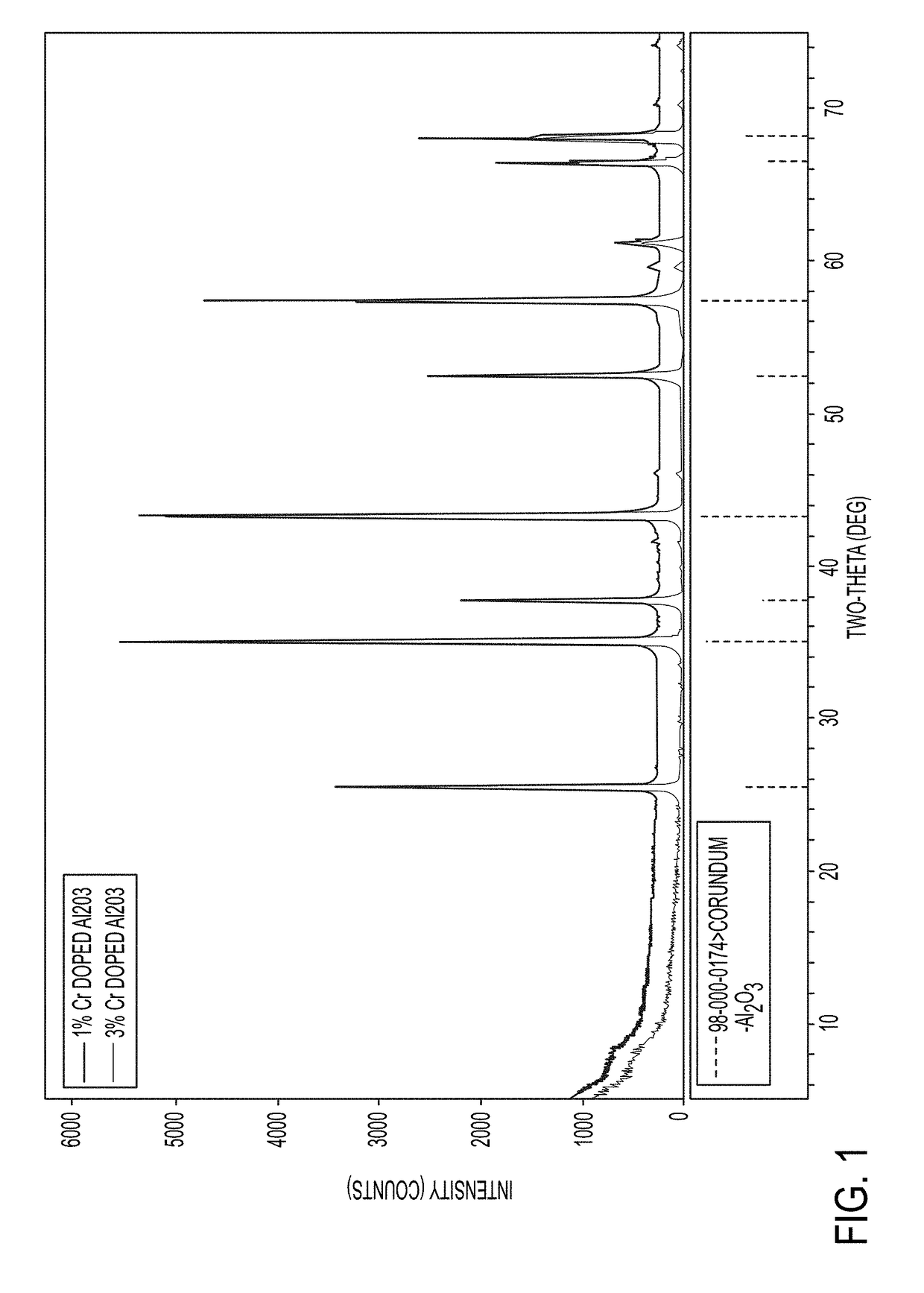

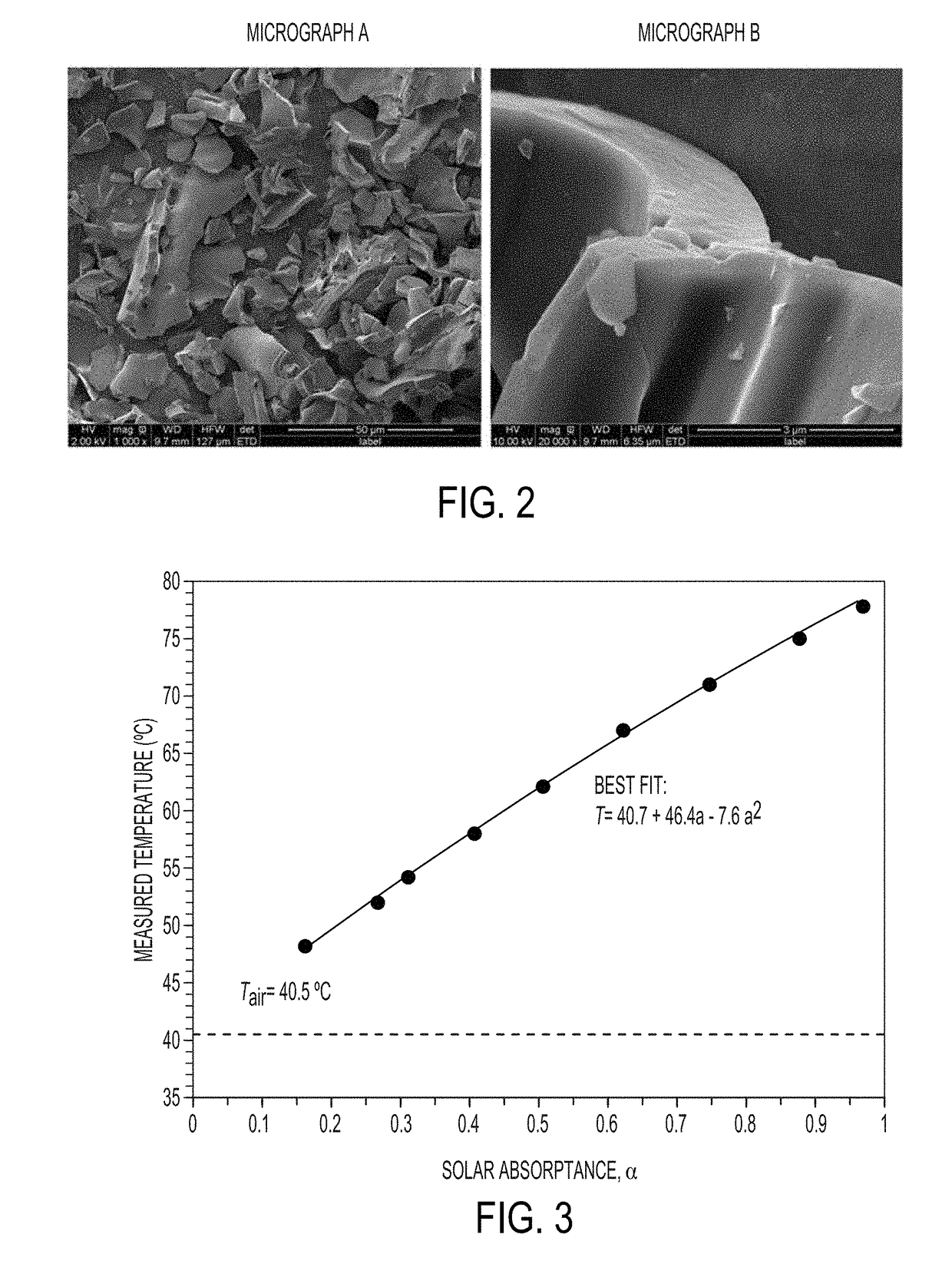

Infrared fluorescent coatings

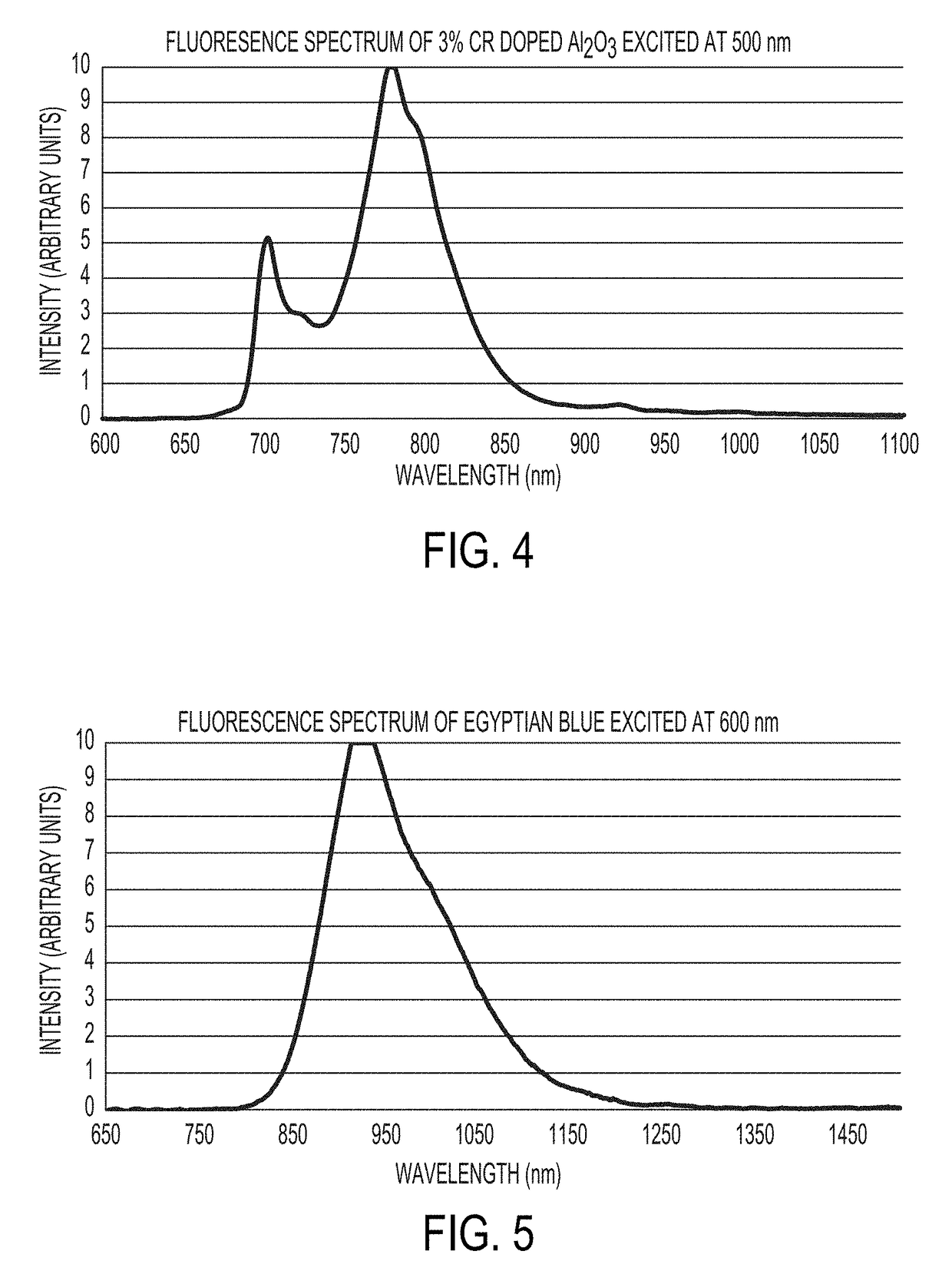

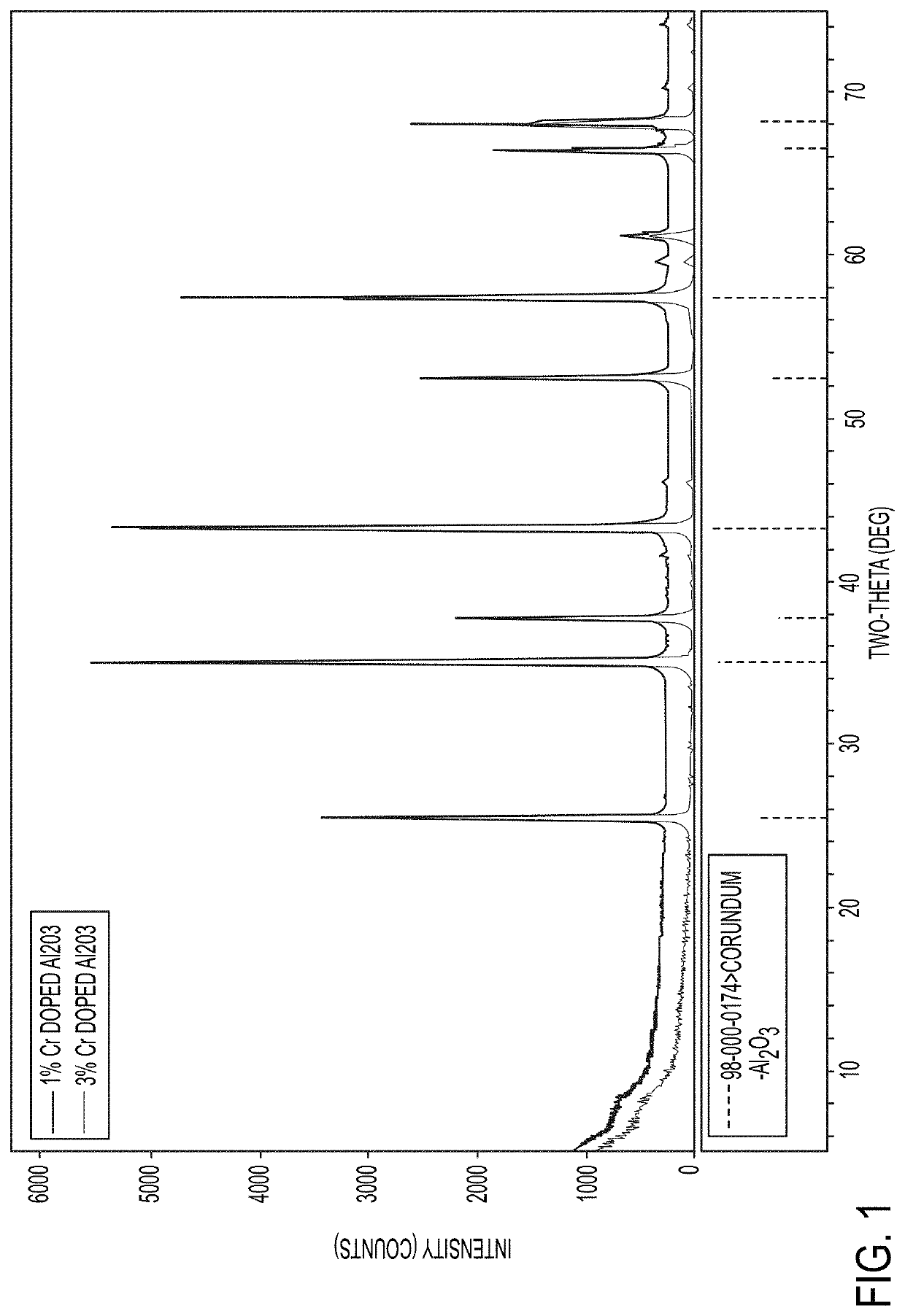

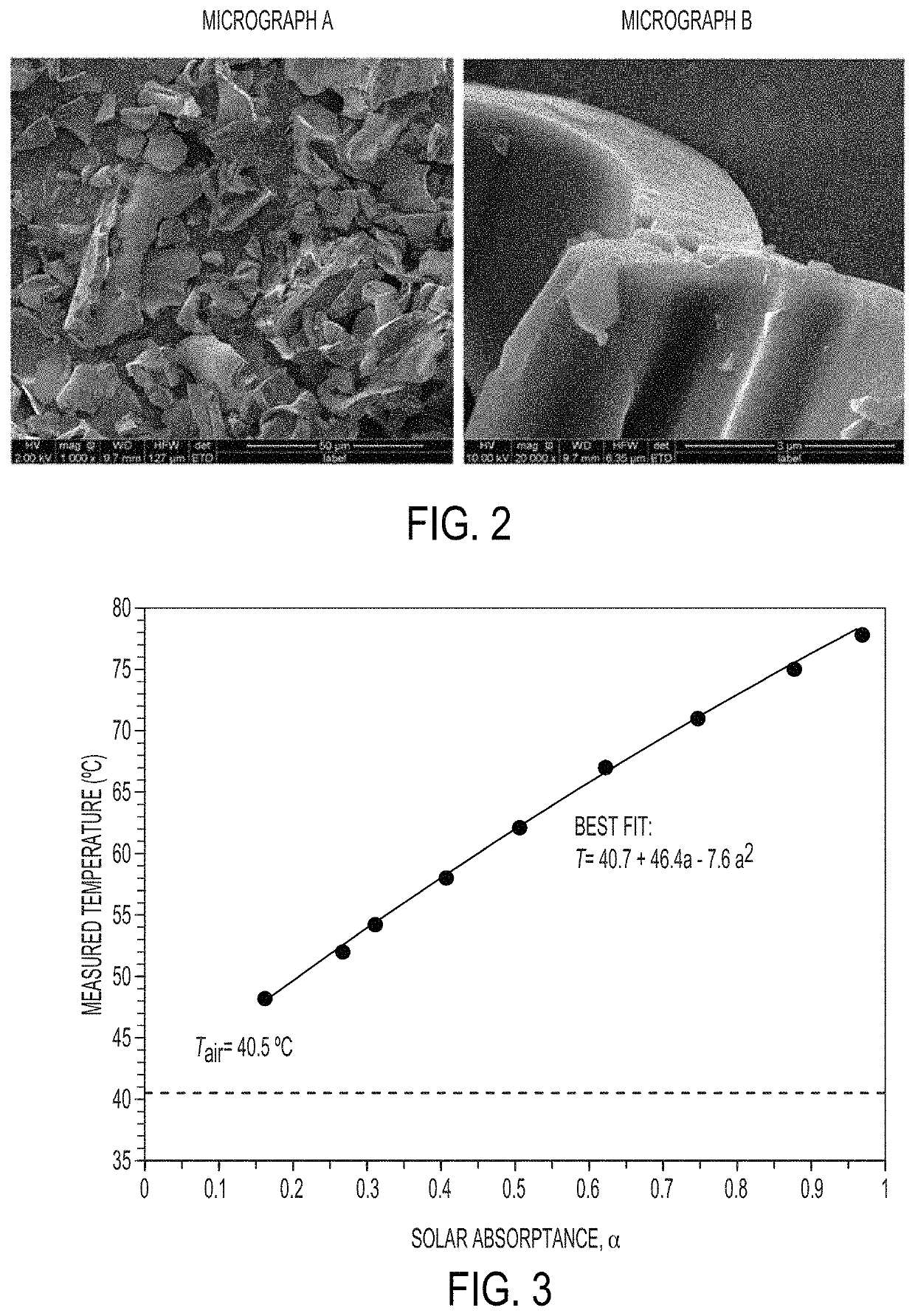

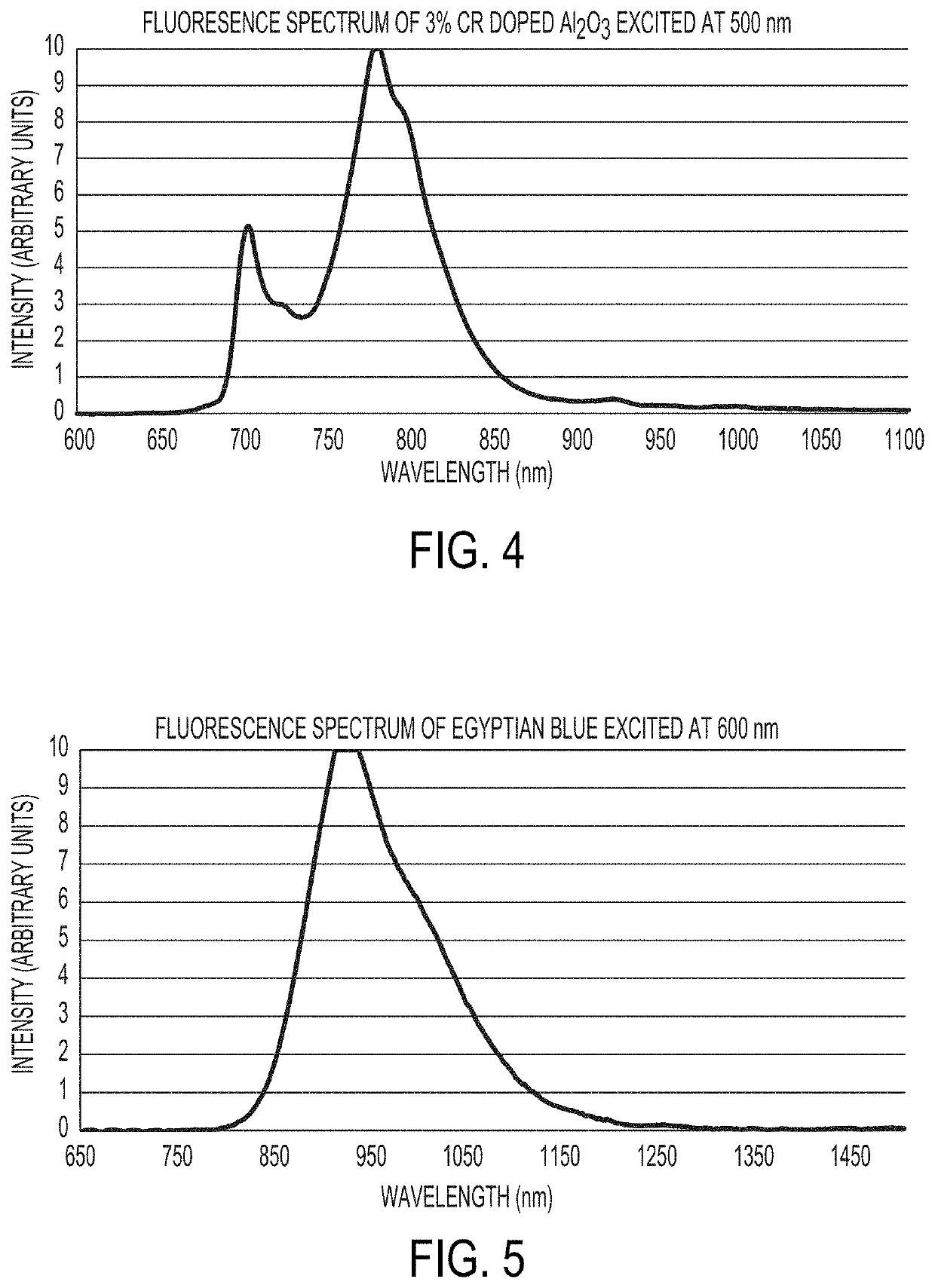

ActiveUS20170342278A1Reduce the temperatureLuminescent paintsPretreated surfacesRare earthSun exposure

The present invention provides for a composition comprising a pigment, wherein the composition is suitable for coating a surface that is, or is expected to be, exposed to the sun. The pigment comprises particles that fluoresce in sunlight, thereby remaining cooler in the sun than coatings pigmented with non-fluorescent particles. The particles comprise solids that fluoresce or glow in the visible or near infrared (NIR) spectra, or that fluoresce when doped. Suitable dopants include, but are not limited to, ions of rare earths and transition metals. A coating composition includes: (i) a film-forming resin; (ii) an infrared reflective pigment; and (iii) an infrared fluorescent pigment different from the infrared reflective pigment. When the coating composition is cured to form a coating and exposed to radiation comprising fluorescence-exciting radiation, the coating has a greater effective solar reflectance (ESR) compared to the same coating exposed to the radiation comprising fluorescence-exciting radiation except without the infrared fluorescent pigment. A multi-layer coating including the coating composition, and a substrate at least partially coated with the coating composition is also disclosed. A method of reducing temperature of an article includes applying the coating composition to at least a portion of the article.

Owner:RGT UNIV OF CALIFORNIA +1

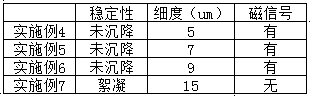

Preparation method of aqueous daylight fluorescent pigment color paste

The invention provides a preparation method of aqueous daylight fluorescent pigment color paste and relates to the technical field of preparing water-dispersibility daylight fluorescent pigment color paste. The aqueous daylight fluorescent pigment color paste comprises the following steps: preparing a disperse system, preparing of pre-emulsion, reacting, and adding an oxidative-reductive initiated system to react to obtain the aqueous daylight fluorescent pigment color paste. The aqueous daylight fluorescent pigment color paste prepared by the method disclosed by the invention is bright in color, has the excellent color paste hiding rate without color expanding and leaking effects, and further has long-term storage stability.

Owner:YANGZHOU UNIV

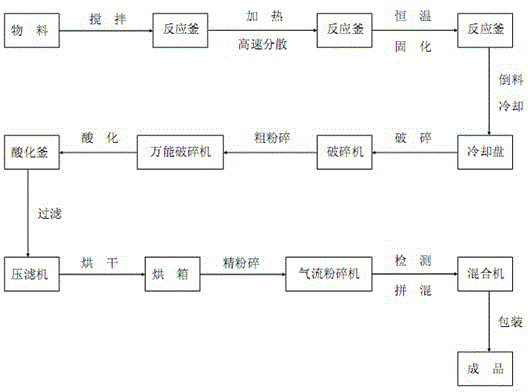

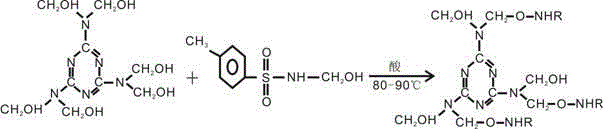

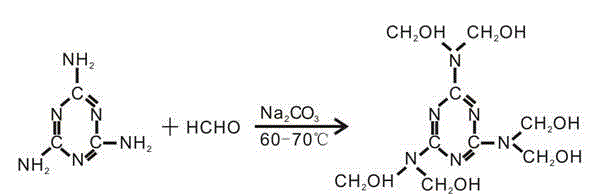

Production method of strong-solvent-resistant thermosetting organic fluorescent pigment

The invention relates to a production method of strong-solvent-resistant thermosetting organic fluorescent pigment. The production method comprises the following steps of: primary feeding, mixing, high-speed dispersion, polymerization, constant-temperature baking, curing, coarse grinding, fine grinding, secondary feeding, mixing, color matching, detection and package, wherein the polymerization is steam low-temperature polymerization; after the step of fine grinding and before the step of secondary feeding, adding the steps of acidizing, dehydrating and drying. The production method has the advantages that due to adoption of low-temperature steam for thermal reaction, the reaction time is prolonged by 2.5 hours compared with that in the existing process, the intermolecular hydroxylation and etherification reaction are effectively enhanced; due to the acidizing process, the free formaldehyde in a product is effectively removed, unreacted small molecules at the condensation stage are promoted to react continuously, and further the molecular crosslinking degree is improved; and the decomposition points of the product are improved, the damage of strong solvents such as ketone and ester can be effectively resisted, the solvent resistance is greatly improved, and the application of the thermosetting organic fluorescent pigment in the aspects of paint and oil ink is expanded.

Owner:HUANGSHAN JIAJIA FLUORESCENT MATERIAL

Manufacturing method of light-reflecting warning tape

ActiveCN105403939AImprove flame retardant performanceVacuum evaporation coatingSputtering coatingAdhesiveSilicone tape

The invention discloses a manufacturing method of a light-reflecting warning tape. The method comprises the following steps of a, discontinuously jointing an adhesive tape on a glass microbead surface of a light-reflecting planting bead film, wherein the adhesive tape comprises a PET layer and a pressure-sensitive adhesive layer; the pressure-sensitive adhesive layer is composed of a silicone pressure-sensitive adhesive and a curing agent and a proportion is 100:0.1-100:1.2; a proportion of a thickness of the pressure-sensitive adhesive layer and a grain size of the glass microbeads on the light-reflecting planting bead film is 2:1-3:1; b, carrying out vacuum aluminizing so as to form an aluminizing film; c, peeling the adhesive tape on the aluminizing film so as to form a clear boundary of aluminizing and non-aluminizing interfaces and acquiring a discontinuous aluminizing planting bead film; d, coating resin containing a fluorescent pigment on an aluminizing surface of the discontinuous aluminizing planting bead film, and after being dried through a 50DEG C-120 DEG C oven, compositing with a fabric base to form a light-reflecting warning tape. By using the manufacturing method of the light-reflecting warning tape, after long time use, the boundary of the aluminizing and non-aluminizing interfaces on the finally-obtained light-reflecting warning tape can be guaranteed to be clear.

Owner:浙江龙游道明光学有限公司

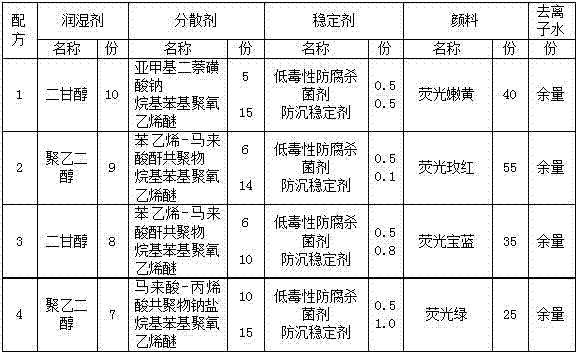

Water-based anti-settling non-laminated fluorescent pigment paste

InactiveCN103572617ASmall particlesUniform fineness distributionDyeing processPolyesterTextile printer

The invention relates to water-based anti-settling non-laminated fluorescent pigment paste and provides pigment printing paste applicable to pigment printing of pure cotton, polyester cotton and blended fabric. The water-based anti-settling non-laminated fluorescent pigment paste comprises the following components by weight: 2 to 20 percent of wetting agent, 1 to 20 percent of dispersing agent, 0.1 to 10 percent of stabilizing agent, 25 to 55 percent of pigment and the balance of deionized water, wherein the wetting agent is one of dibasic alcohol or condensed poly-dibasic alcohol; the dispersing agent comprises one or more of alkyl phenyl polyoxyethylene ether, disodium methylene dinaphthalene sulfonate, sodium salt or ammonium salt of an acrylic copolymer and a multi-anchor multi-chain macromolecular polymer; the stabilizing agent comprises an anti-settling stabilizing agent and a bactericide. The water-based anti-settling non-laminated fluorescent pigment paste is wide in application range, high in paste stability, not laminated, high in fluorescence, and convenient to use.

Owner:HUNAN XINLIHUA NANO TECH

Fluorescent water-based coating and preparation method thereof

InactiveCN105176234AStrong adhesionWith fluorescent effectAntifouling/underwater paintsLuminescent paintsFluorescenceOrganosolv

The invention discloses a fluorescent water-based coating. The fluorescent water-based coating is prepared from fluorescent pigment emulsion, light stabilizers, antibacterial preservatives, film-forming auxiliaries, water-based polyurethane resin, acrylic ester, China wood oil, titanium white powder, polyvinyl alcohol, light calcium carbonate, talcum powder, gypsum powder, titanium dioxide, silane compounds, guar gum, fluororesin, water-based modified epoxy resin, acrylic emulsion, Cr, Ni, Zn, Mo, Pd, Pt, Au, W, Ta, Nd, Ce, Eu, Lu and water. Due to the fact that the components such as Ni, Zn and Ti are contained in the fluorescent water-based coating, the fluorescent water-based coating has the high-temperature-resistant and anti-corrosion properties and meets the coating requirements of various occasions; in addition, the fluorescent water-based coating is free of toxic organic solvent and pollution and has the advantages that the coating surface is not prone to being cracked, aging resistance is achieved, and the adhesive force is high.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

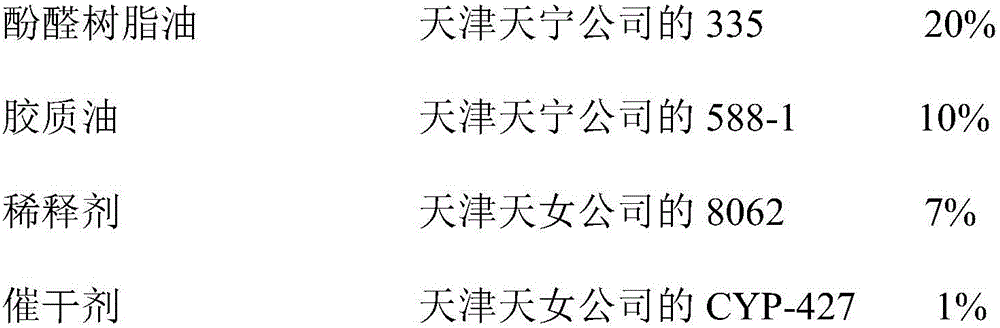

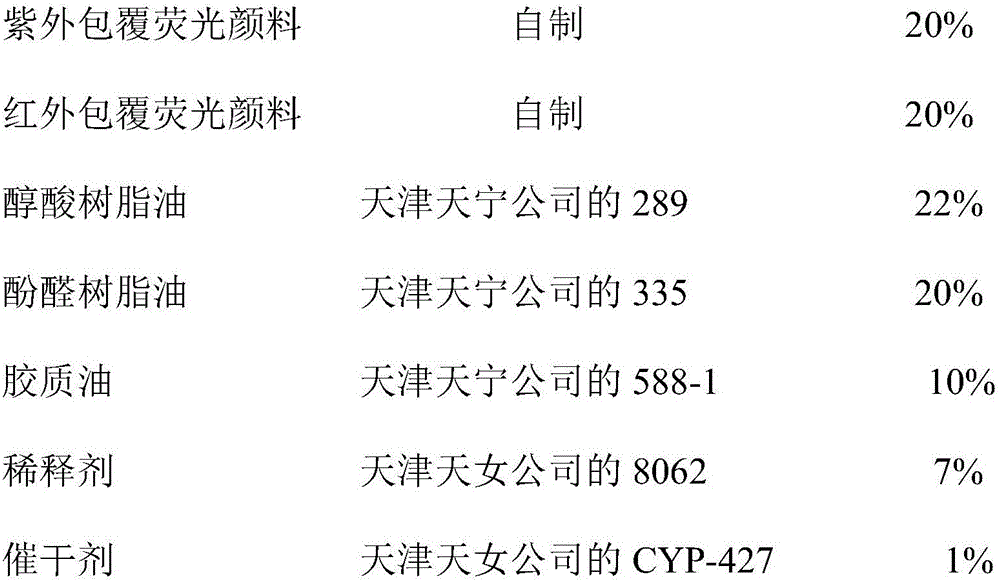

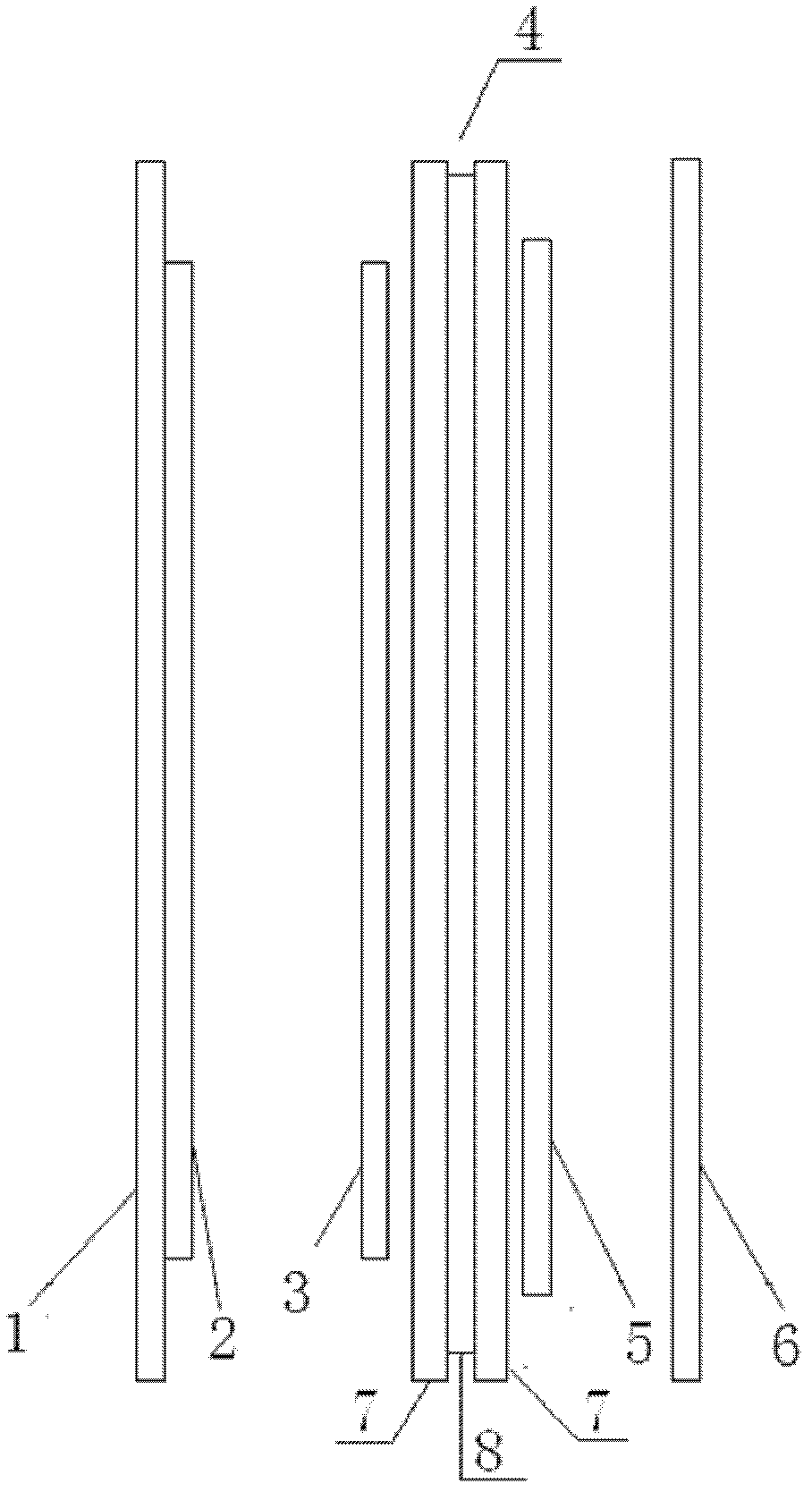

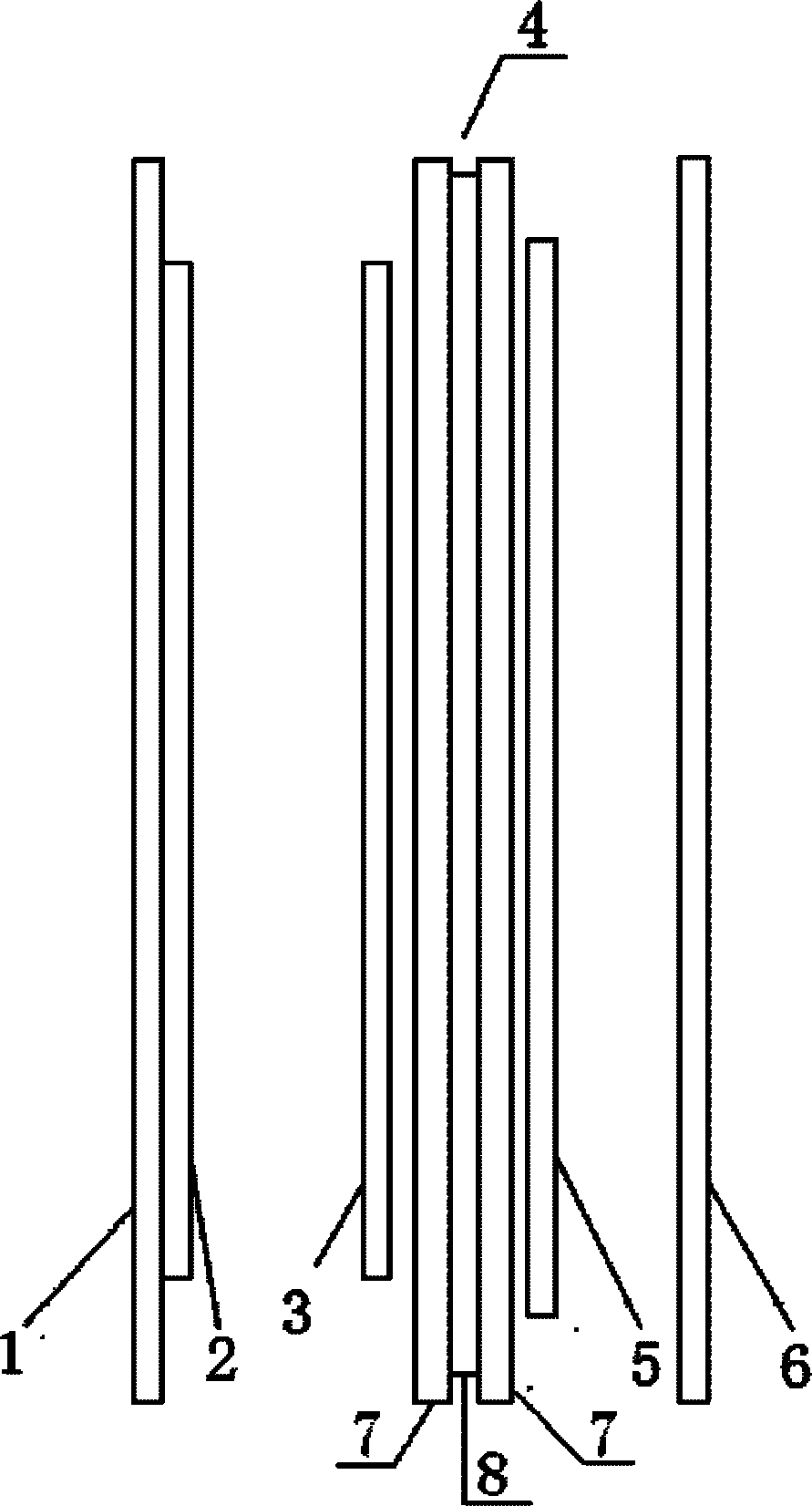

Cladded fluorescent pigment and compound color-changing pressure-sensitive fluorescent paint

ActiveCN106634959AAdd lessSmall particle size distributionInksLuminescent compositionsFluorescenceUltraviolet lights

The invention provides a color developing agent cladded fluorescent pigment and a compound color-changing pressure-sensitive fluorescent paint containing the fluorescent pigment. The fluorescent pigment is formed by cladding modified zinc salicylate resin as a color developing agent on the surface of the fluorescent pigment. Compared with the prior art, the cladded fluorescent pigment, a preparation method of the cladded fluorescent pigment and the compound color-changing pressure-sensitive fluorescent paint provided by the invention have the advantages that firstly, the adding amount of an anti-fake material can be reduced, and the technical problems of sedimentation and dispersion of the pigment in a printing ink system are improved; secondly, the particle size distribution of the fluorescent pigment is improved, and the fineness of the printing ink is reduced; and thirdly, during pressure-sensitive printing with the printing ink, a color former reacts with the color developing agent, prints are generated and do not disappear, different visual fluorescent effects can be displayed under the excitation of short wave ultraviolet light and near infrared light, and besides, multiple anti-fake functions are achieved, so that the reliability and safety of printed products are further improved, and economic benefits and social benefits are exetremely high.

Owner:天津环球磁卡科技有限公司

Special fluorescent pigment for leather

ActiveCN103306142AGood application effectHigh fluorescenceDyeing processPolymer scienceAcrylonitrile

The invention relates to a special fluorescent pigment for leather. The special fluorescent pigment is prepared from the following raw materials: para toluene sulfonamide, tripolycyanamide, formaldehyde and polyurethane resins at a ratio of 1.0:0.8:0.6:0.3. Compared with the prior art, the fluorescent pigment has the following advantages and effects: 1, by using a pigment polymer covered by copolymers such as monomer acrylonitrile and methyl methacrylate, the emulsion stability is improved, the various fastness such as soaping fastness and bleeding fastness can be improved, and the environment pollution is reduced; 2, by using the copolymers such as monomer acrylonitrile and methyl methacrylate, the glass transition temperature of the polymer can be improved, a function of protecting a primary color body is achieved after copolymers such as monomer acrylonitrile are covered, and the sun-proof fastness is improved.

Owner:WANLONG CHEM

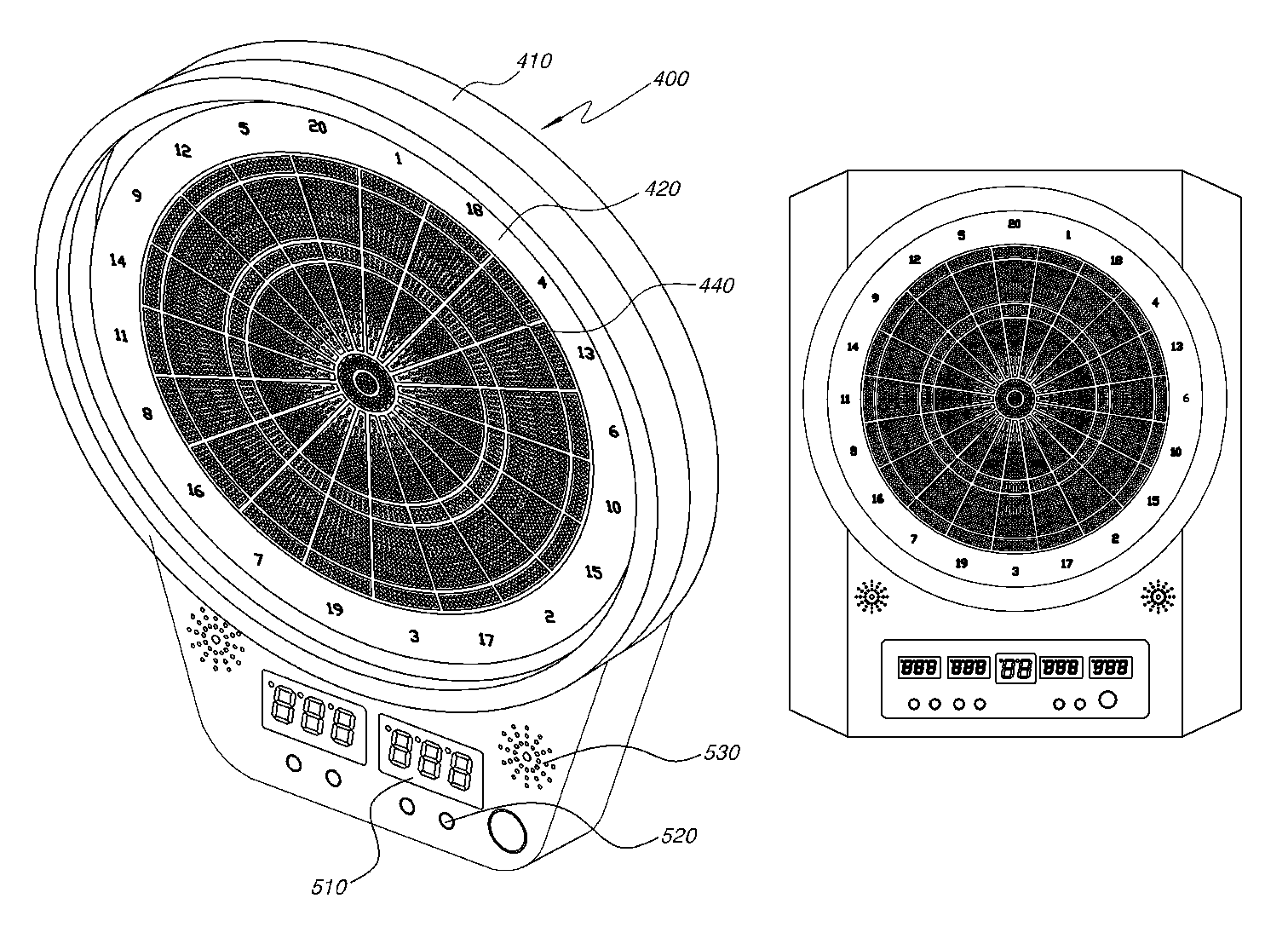

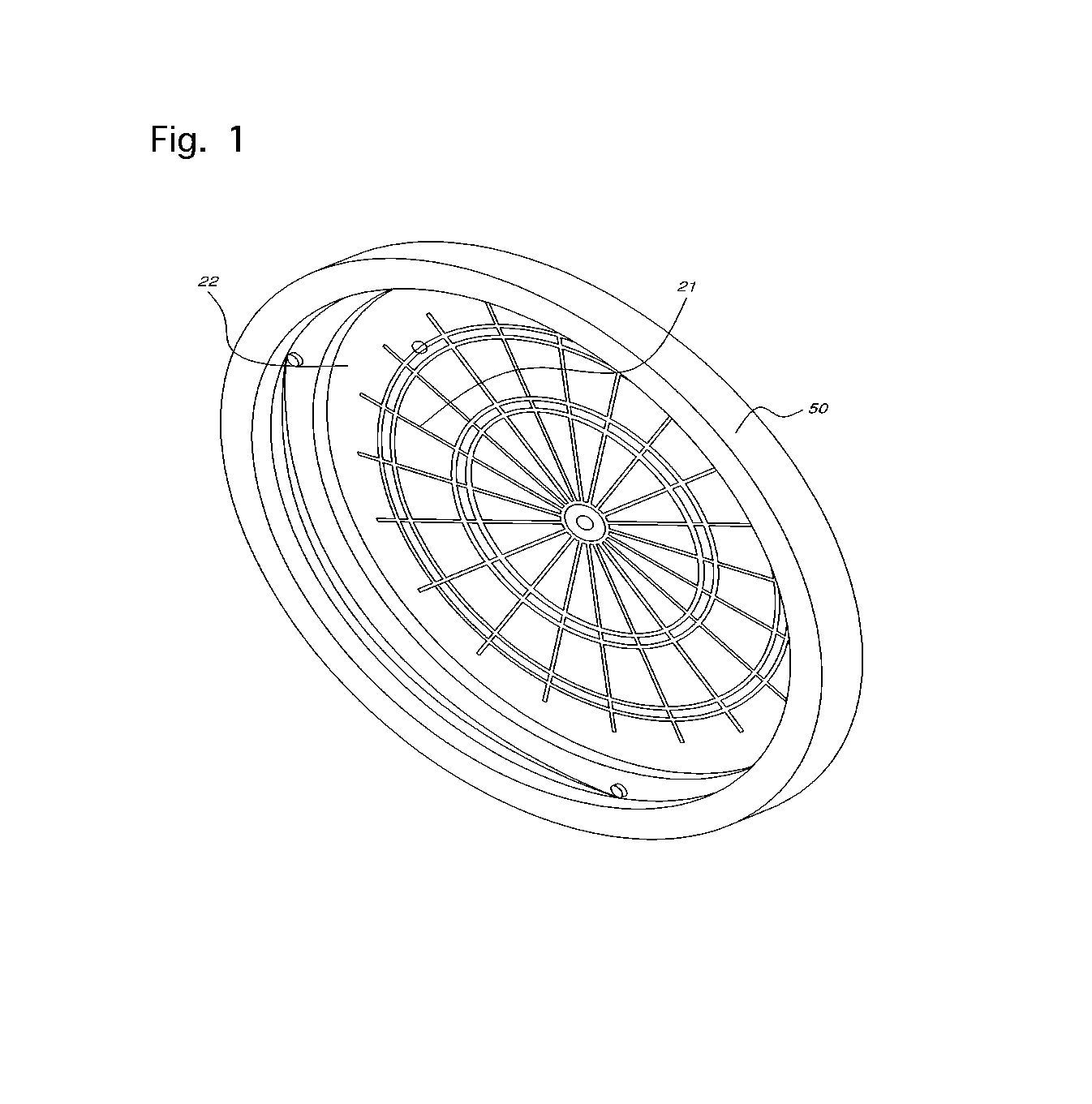

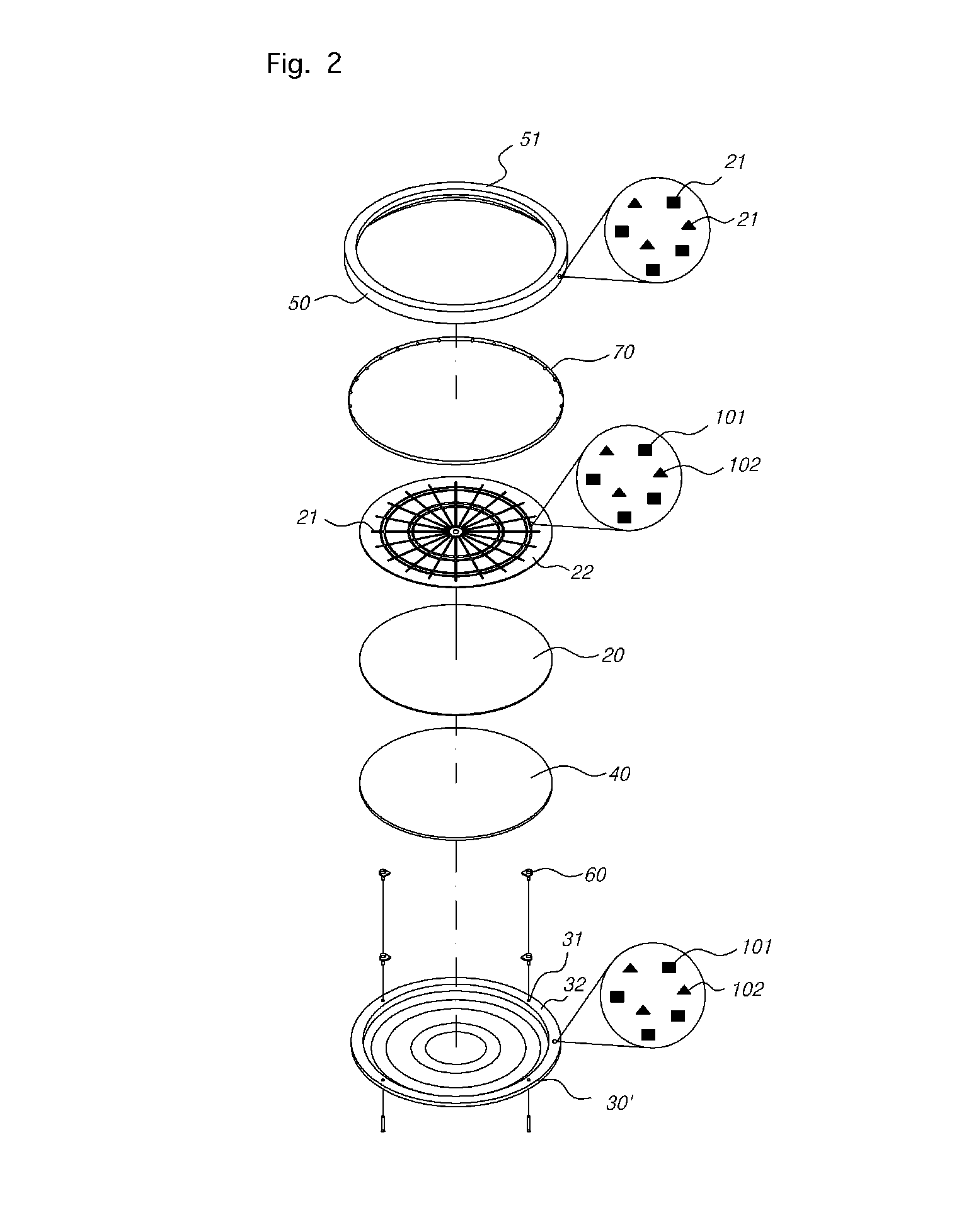

Luminous dart board set

InactiveUS8979092B2Good interior design effectEasy to seeTarget detectorsDartboardsEngineeringRubber sheet

Disclosed is a luminous dart board set. The luminous dart board set comprises: a dart pin (10) including a magnet (11) at the front portion thereof; a dart board (20) made of either an iron plate or an iron rubber sheet and including a printed matter (22) having a printing pattern (21) on the front surface thereof; a body (30) including a fixing part (32) coupled to a bottom surface of the dart board (20) and outwardly bent along the circumference thereof, and a reinforcement part (33) perpendicularly bent in a direction extending away from the fixing part (32); a rim cover (50) including a cover part (51) bent along the circumference of the body (30) so as to cover the front surface of the circumference of the body (30), and a floodlight space (52) spaced apart from the cover part (51); LED parts (70) disposed on the inner face of the rim cover (50) so as to emit light toward the floodlight space (52); and a fluorescent pigment, a phosphorescent pigment, and / or a mixture of the fluorescent pigment and the phosphorescent pigment which is added to the dart pin (10), the rim cover (50), and the printed matter (22).

Owner:KIM YONG CHUL

Invisible ultraviolet fluorescence color matching agent and manufacture method thereof

ActiveCN103092017AImprove general performanceHigh fluorescence intensityDevelopersBis(trimethylsilyl)aminePolyester resin

The invention discloses an invisible ultraviolet fluorescence color matching agent and a manufacture method thereof, wherein the invisible ultraviolet fluorescence color matching agent comprises the following raw materials in parts by weight: 60-70 parts of polyester resin with acid value of 5-20mgKOH / g, 1-10 parts of polypropylene wax, 20-30 parts of invisible ultraviolet fluorescence pigment, 0.2-2 parts of dimethylchlorosilane treated silicon powder and 0.5-3 parts of hexamethyldisilazane treated silicon powder, wherein the visible ultraviolet fluorescence pigment has the fineness of 0.5-2mu m in a color matching agent particle and exists in a spherical form. The invisible ultraviolet fluorescence color matching agent has stronger generality and excellent fluorescence intensity and printing property.

Owner:ICMI CHINA

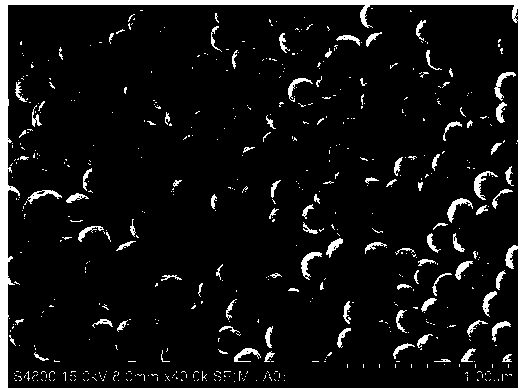

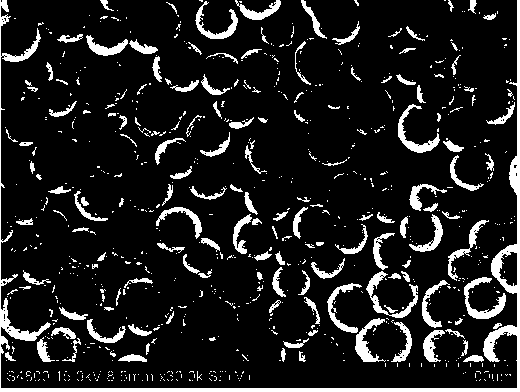

Preparation method and application of ultraviolet fluorescent powdered ink

The invention provides a preparation method of ultraviolet fluorescent powdered ink. The method comprises the following steps: (1) preparing a polyester dispersion; (2) preparing an ultraviolet fluorescent pigment dispersion; (3) preparing a polyester dispersion containing a charge control agent; and (4) mixing the polyester dispersion in the step (1), the ultraviolet fluorescent pigment dispersion in the step (2), a wax emulsion and the polyester dispersion containing a charge control agent in the step (3) to obtain the powdered ink grains which have a proper granular diameter and a core-shell structure. The invention further provides the powdered ink granules prepared by the method and an application thereof.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Superbright high-definition protective film with self luminescence under sunlight or ultraviolet light and manufacturing method thereof

InactiveCN102320174ASelf-luminousWith super bright HDSynthetic resin layered productsUltraviolet lightsLuminescence

The invention discloses a superbright high-definition protective film with self luminescence under sunlight or ultraviolet light which comprises: a scraping-resistant layer protective film PET substrate, a protective film glue layer, a scraping-resistant layer, a composite main film PET substrate, an installing glue layer, and an installing glue protective film PET substrate; wherein at least one layer of the scraping-resistant layer, the composite main film PET substrate, and the installing glue layer comprises fluorescent pigment or phosphor. According to the protective film of the invention, because at least one layer of the scraping-resistant layer, the composite main film PET substrate, and the installing glue layer comprises fluorescent pigment or phosphor, the whole protective film has the characteristics of self luminescence under sunlight or ultraviolet light, superbrightness, and high definition, is widely applicable to screen protective films of various liquid crystal display screens, and meets the trend of fashion pursuit for young people.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Anti-fake ink

The invention discloses an anti-fake ink which comprises the following components in parts by mass: 50-80 parts of a prepolymer, 10-20 parts of a composite photoinitiator, 20-30 parts of carboxylatedFe3O4 magnetic nanoparticles, 10-20 parts of hydrophobic gaseous silicon dioxide, 1-5 parts of an amphiphilic surfactant and 10-20 parts of a fluorescent pigment. The anti-fake ink is good in identification performance, magnetic nano-iron tetroxide particles are dispersed evenly, and the anti-fake ink is resistant to rubbing without degaussing.

Owner:湖北中北博睿科技有限公司

Ultraviolet fluorescent printing ink

InactiveCN103351715AAnti-counterfeiting features are obviousImprove printing qualityInksEpoxyFluorescence

The invention discloses ultraviolet fluorescent printing ink. The ultraviolet fluorescent printing ink consists of the following raw materials in parts by weight: 5 to 30 parts of fluorescent rare earth nanopaticles, 1 to 20 parts of epoxy resin, 5 to 10 parts of polyurethane, 10 to 35 parts of fluorescent pigment, 1 to 15 parts of flatting agent, 0.1 to 0.5 part of defoaming agent, 1 to 5 parts of opacifying agent, 0.1 to 5 parts of soya bean lecithin and 2 to 3 parts of ultraviolet light absorber, wherein the fluorescent pigment is organic ultraviolet fluorescent pigment with a macromolecule conjugated structure; and the opacifying agent is a mixture of zinc oxide, calcium carbonate and argil. The ultraviolet fluorescent printing ink has an obvious anti-counterfeit feature, is applicable to various printing modes and has high printing quality.

Owner:苏州凹凸彩印厂

Golf ball

InactiveUS20200406105A1Good lookingAvoid insufficient temperatureGolf ballsSolid ballsCarbamateEngineering

A matte colored golf ball which is free of luster and gloss has a good appearance in which injection marks that form during injection molding of a cover layer—be it an intermediate layer or an outermost layer—are difficult to see and scuffing on the cover surface is inconspicuous. The golf ball includes a core, an outermost layer, an intermediate layer therebetween, and a coat formed on the surface of the outermost layer. The intermediate layer is formed of a resin composition containing a thermoplastic resin and a colorant consisting of a fluorescent dye or a fluorescent pigment and has a specific visible light transmittance, the outermost layer is molded of a transparent or translucent resin composition that is free of fluorescent dye, and the coat is formed of a urethane-based coating composition containing delustering particles.

Owner:BRIDGESTONE SPORTS

Infrared fluorescent coatings

Owner:RGT UNIV OF CALIFORNIA +1

Colourless fluorescent red printing ink and preparation method thereof

The present invention relates to a colourless fluorescein red lithographic ink and its preparation process. Its composition includes (wt%) 36-50% of special grade rosin, 20-36% of oil and fat, 2-4% of polyethylene wax, 2-4% of xylene, 18-22% of 254 fluorescent pigment and 2-4% of grinding dispersing agent. Its preparation method includes the following steps: weighing all the components, placing the special grade rosin, polyethylene wax and xylene into reactor, heating and stirring to completely dissolve rosin, progressively adding the oil and fat into reactor, making them react at 260 deg.C, adding grinding dispersing agent and fluorescent pigment, uniformly mixing them, moving the mixture into three-roller machine and grinding until its grain size is less than 20 micron so as to obtain the invented product applicable for antifalse printing.

Owner:桑惠敏

Environmentally-friendly high-temperature-resistant polyester fluorescent pigment

InactiveCN103289436AGood dispersionMaintain vividnessOrganic dyesLuminescent compositionsPolyesterPolymer science

The invention relates to an environmentally-friendly high-temperature-resistant polyester fluorescent pigment. The environmentally-friendly high-temperature-resistant polyester fluorescent pigment is characterized by being prepared from the following raw materials: pentaerythritol, phthalic anhydride, m-phthalic acid, formic acid and disodium m-phthalate, wherein the proportioning ratio of pentaerythritol to phthalic anhydride to m-phthalic acid to formic acid to disodium m-phthalate is 1:(0.7-1.0):(0.02-0.2):(1.3-1.5):(0.02-0.25). The product is free from formaldehyde and forbidden heavy metals; the process equipment is simple and safe; the product is bright in colour, high in concentration, environmentally-friendly, and good in temperature resistance which achieves more than 240 DEG C.

Owner:WANLONG CHEM

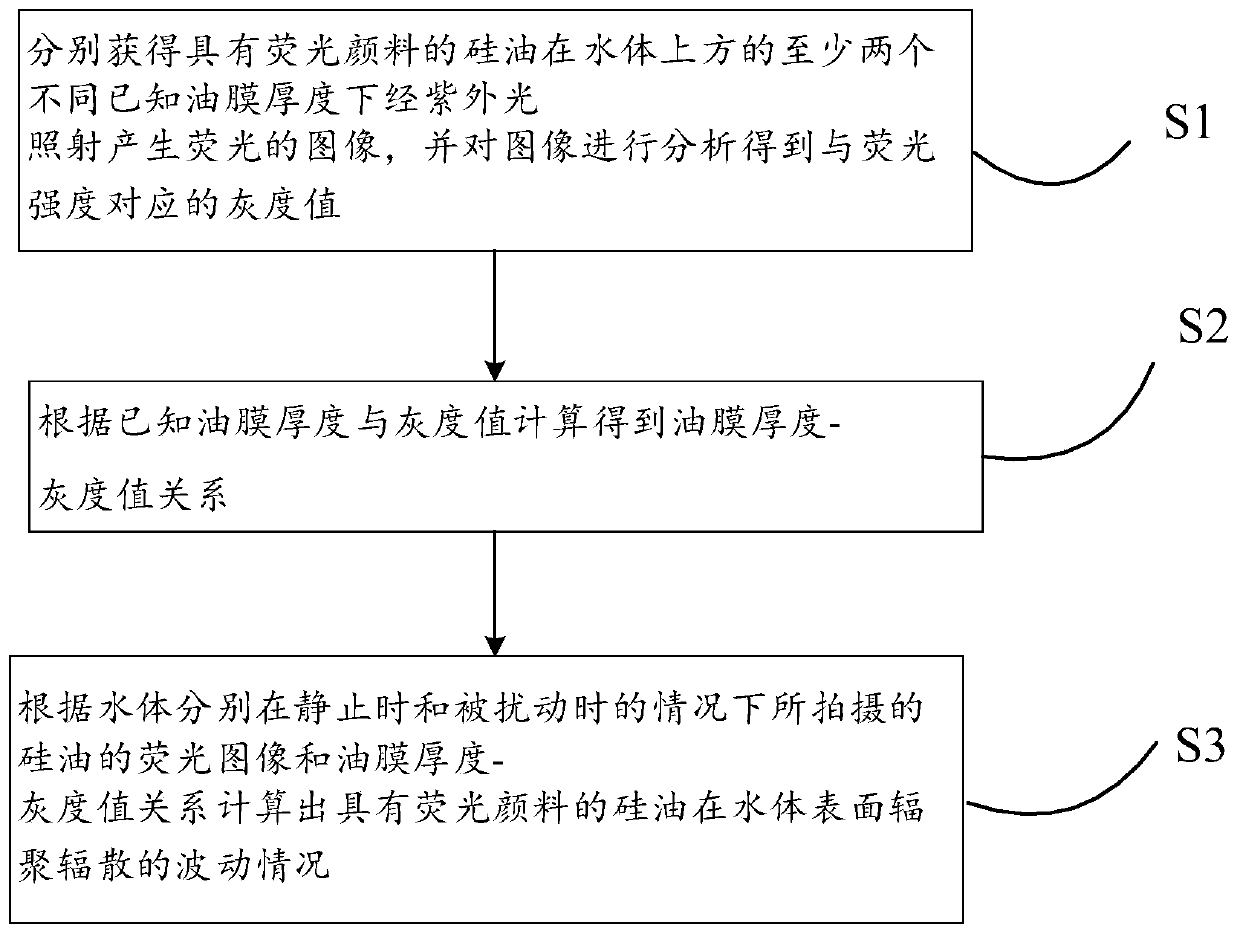

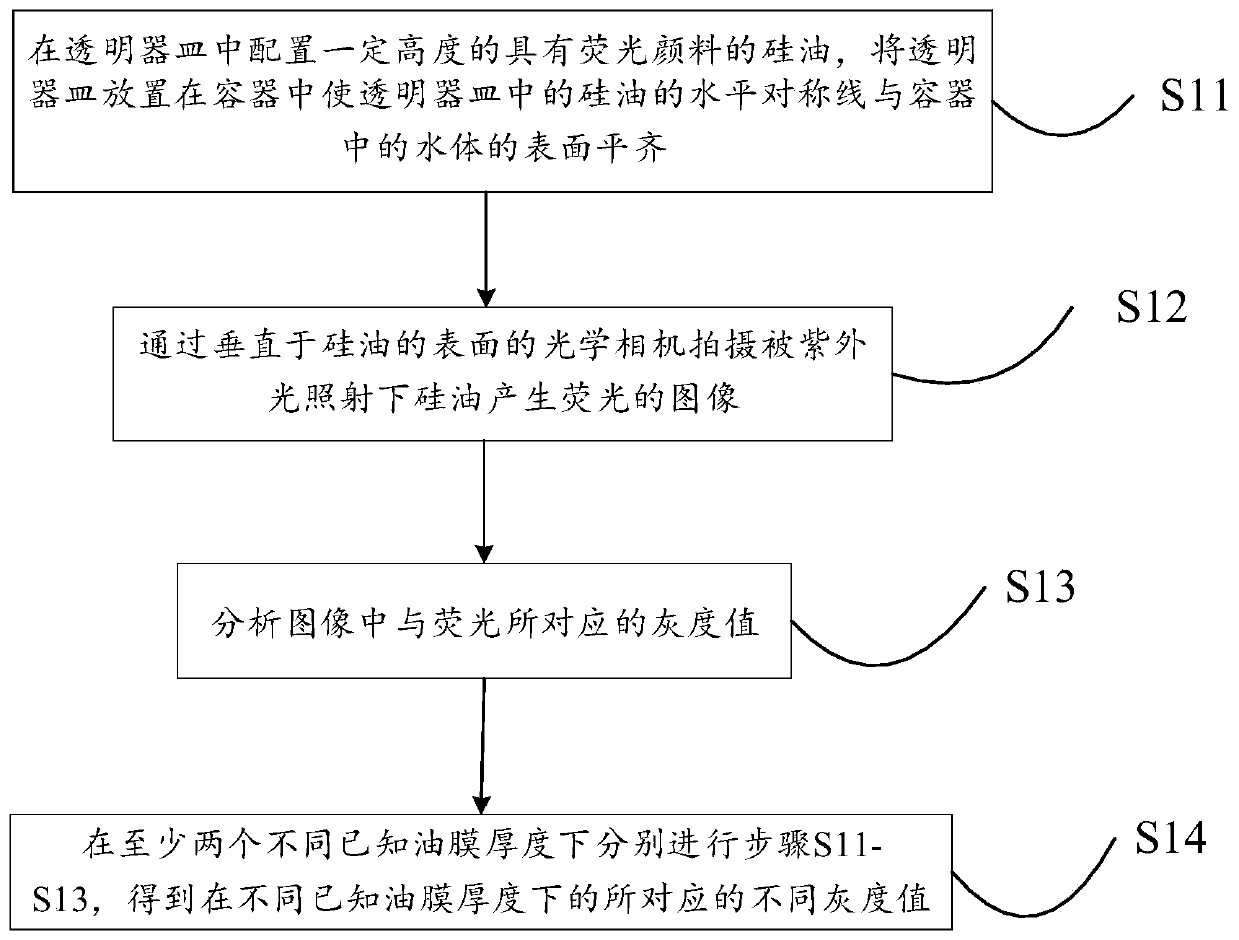

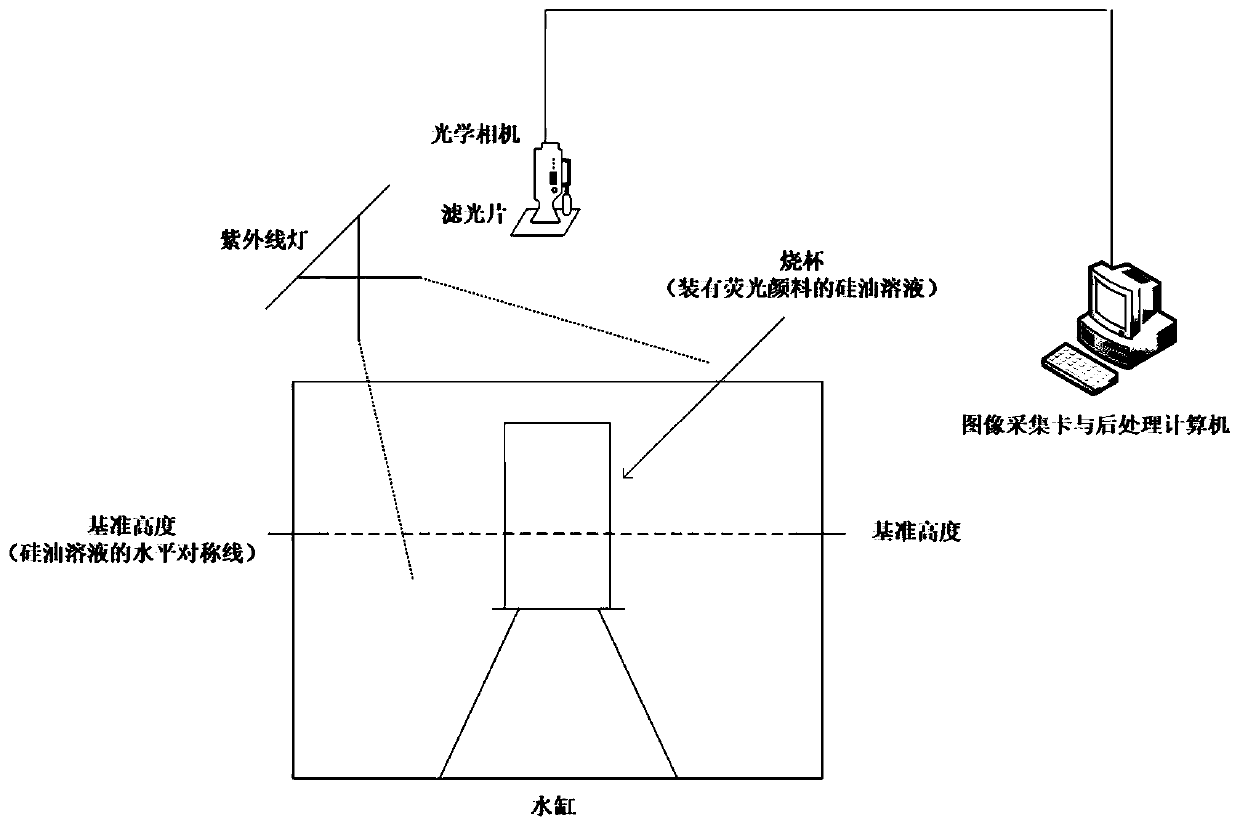

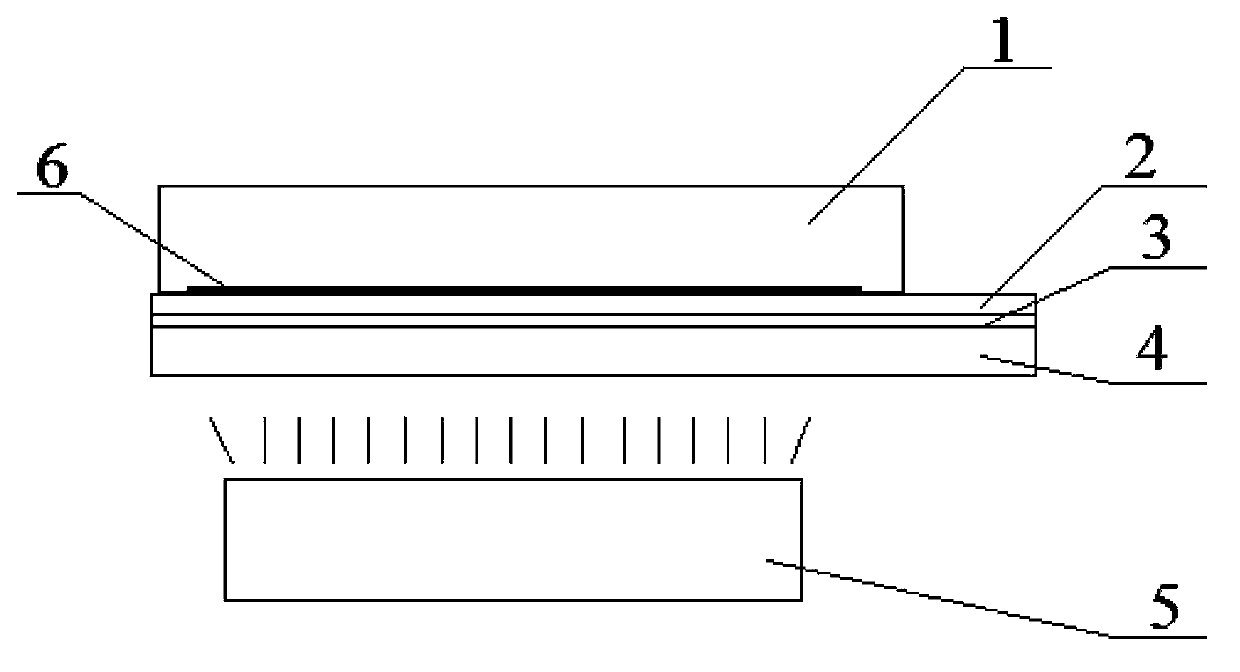

Flow field radiation gathering and radiation scattering measurement method based on oil film fluorescence brightness

ActiveCN111220588AOvercome limitationsReduce restrictionsFluorescence/phosphorescencePhoto irradiationRadiation scattering

The invention discloses a flow field radiation gathering and radiation scattering measurement method based on oil film fluorescence brightness, and the method comprises the following steps: respectively obtaining images of fluorescence generated by silicone oil with fluorescent pigment through ultraviolet irradiation under at least two different known oil film thicknesses above a water body, and analyzing the images to obtain a gray value corresponding to the fluorescence intensity; performing calculating according to the known oil film thickness and the gray value to obtain an oil film thickness-gray value relation; and calculating the fluctuation condition of radiation gathering and radiation scattering of the silicone oil with the fluorescent pigment on the surface of the water body according to the relation between the oil film thickness-gray value and the fluorescent images of the silicone oil shot when the water body is static and disturbed. According to the method, the detectionintuition is enhanced, the cost is low, the amount of data needing to be processed is small, the post-processing steps are simple, and the difficulty is greatly reduced. Quantitative analysis can beconveniently carried out on the fluctuation intensity of surface fluid radiation gathering and radiation scattering, and certain help is provided for summarizing the law of the fluid surface radiationgathering and radiation scattering phenomenon caused by underwater or water surface navigation bodies.

Owner:HARBIN INST OF TECH AT WEIHAI

Method for curing and shaping microstructural granules by ultraviolet

ActiveCN103971592AEase of mass productionWith UV anti-counterfeiting propertiesStampsIdentification meansPhoto irradiationMagnifying glass

The invention relates to a method for curing and shaping microstructural granules by ultraviolet. The method includes: coating a separate adhesive film on a basement film; coating a ultraviolet curing coating layer on the separate adhesive film; placing a formwork with microstructural patterns on the ultraviolet curing coating layer; irradiating the ultraviolet curing coating layer by the ultraviolet via the lower side of the basement film to enable the ultraviolet curing coating layer to cure and break to form the microstructural granules which are identical to the microstructural patterns on the formwork and adhered onto the basement film via the separate film; and separating the microstructural granules from the basement film. Compared with the prior art, the method for curing and shaping the microstructural granules by the ultraviolet has the advantages that the prepared microstructural granules can be added into base materials or printing ink; since the microstructural granules are extremely small in average grain size which is in the micrometer level, anti-counterfeiting information of the microstructural granules can be recognized by observing shapes of the microstructural granules via a high magnified glass only; an ultraviolet fluorescent pigment is contained in the microstructural granules, the anti-counterfeiting information can be detected via the ultraviolet, and multiple anti-counterfeiting effects are achieved.

Owner:上海紫格光学薄膜材料有限公司

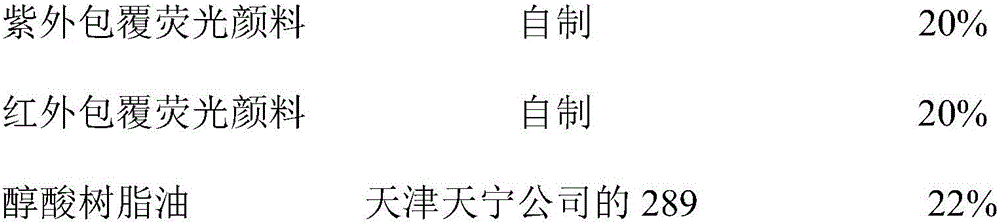

Novel camouflage painting coating material and preparation method thereof

InactiveCN113248996AFunctionalAdjustable intensityLuminescent paintsReflecting/signal paintsPolymer scienceNear infrared reflectance

The invention provides a novel camouflage painting coating material, which is prepared from the following components in parts by mass: a component A main paint and a component B curing agent, wherein the component A comprises 20-50 parts of resin, 20-40 parts of a special pigment, 4-20 parts of a near-infrared reflection type fluorescent pigment, 0.6-4 parts of an auxiliary agent, and 5-15 parts of a solvent; and the component B comprises the following components in parts by weight: 40-70 parts of isocyanate, 29-40 parts of a cosolvent and 1-5 parts of a dehydrating agent. The component A main paint is prepared by mixing and dispersing the special pigment, the near-infrared reflection type fluorescent pigment, the resin, the solvent and the auxiliary agent, and conducting grinding and compounding. The novel camouflage painting coating material provided by the invention effectively improves the camouflage stealth efficiency of weaponry in different background environments in a wartime state, and greatly improves the survivability of the weaponry. The product is highly targeted to use objects, and can be applied to the fields of false equipment, air force parachutes, targets and the like.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

Screen printing ink

InactiveCN104804541AHigh fastnessHas the function of anti-counterfeitingInksPrinting inkHexanediol diacrylate

The invention relates to the screen printing industry, in particular to a screen printing ink. The screen printing ink comprises the following raw materials in parts by weight: 40-65 parts of polyurethane diacrylate, 20-50 parts of hexanediol diacrylate, 5-10 parts of a photoinitiator, 10-30 parts of a coloring agent, 1-3 parts of an enhancer, 1-3 parts of a destaticizer, 0-3 parts of a foam killer, 0-3 parts of a fluorescent pigment, and 1-5 parts of polypropylene resin mixed with barium sulfate. The screen printing ink produced according to the formula has high color fastness. Meanwhile, as the fluorescent pigment is added into the screen printing ink, an anti-counterfeiting role can be played.

Owner:ANHUI JIAXIN PACKAGING & PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com