Anti-fake ink

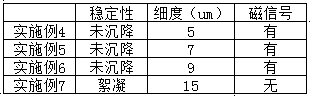

An anti-counterfeiting ink and fluorescent pigment technology, applied in the field of ink, can solve the problems of difficulty in dispersion, difficult to formulate and form ink, and agglomeration, and achieve the effect of solving easy agglomeration and improving dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of fluorescent pigments: Accurately weigh 1.5 g of hydroxypropyl carboxymethyl cellulose, dissolve it in 100 mL of deionized water, place it in an instant heating constant temperature magnetic stirrer, and pipette the EuCl 3 The solution makes the mass ratio of hydroxypropyl carboxymethyl cellulose to Eu be 15:1, and is added dropwise to the completely dissolved hydroxypropyl carboxymethyl cellulose solution, and reacted with 6mol / L HCl and 1mol / L NaOH The pH of the solution was adjusted to 6.0, and then the solution was placed in a microwave synthesizer to adjust the reaction temperature to 70°C, the reaction time was 10min, and the microwave power P=800W. After the reaction was completed, the reaction solution was poured into a dialysis bag and sealed for dialysis. bag, put it in deionized water to remove excess unreacted anions in the reaction solution, during dialysis, continuously use AgNO3 solution to detect Cl in deionized water -1 Pour the solution i...

Embodiment 2

[0020] Preparation of fluorescent pigments: Accurately weigh 1.5 g of carboxymethyl cellulose, dissolve it in 100 mL of deionized water, place it in an instant heating constant temperature magnetic stirrer, and pipette the EuCl 3 The solution was such that the mass ratio of carboxymethyl cellulose to Eu was 15:1, and was added dropwise to the completely dissolved carboxymethyl cellulose solution, and the pH of the reaction solution was adjusted to 6.0 with 6mol / L HCl and 1mol / L NaOH , and then place the solution in a microwave synthesizer to adjust the reaction temperature to 70°C, the reaction time to 10min, and the microwave power P=800W. After the reaction is completed, pour the reaction solution into a dialysis bag, seal the dialysis bag, and place it in Deionized water to remove excess unreacted anions in the reaction solution, during dialysis, continuously use AgNO3 solution to detect Cl in deionized water -1 Pour the solution in the dialysis bag into a clean petri dish ...

Embodiment 3

[0022] Preparation of carboxyl nano-ferric oxide: 3.48g Fe 3 o 4 Nanoparticles were ultrasonically dispersed in 100mL deionized water to prepare a suspension, and then the obtained suspension was transferred into a conical flask, stirred mechanically for 10 min, mixed evenly with 5mL oleic acid and 15mL absolute ethanol, and then slowly poured into the conical flask In a shaped bottle, the oil bath was heated to 75 °C, and the reaction was mechanically stirred at a constant temperature for 4 h to obtain a black suspension, which was washed with distilled water and absolute ethanol for several times, and the magnetic Fe coated with oleic acid was collected under an external magnetic field. 3 o 4 Nanoparticles, weigh 0.8 g KMnO 4 Dissolve it in 140 mL of deionized water, and add about 1 mL of concentrated sulfuric acid dropwise to it to prepare an acidic potassium permanganate solution. Washed oleic acid coated magnetic Fe 3 o 4 Place the nanoparticles in the conical flask,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com