Preparation method of water-based fluorescent paint

A technology of fluorescent coatings and fluorescent pigments, applied in the field of nanomaterials, can solve the problems of troublesome post-processing, complex wastewater components, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

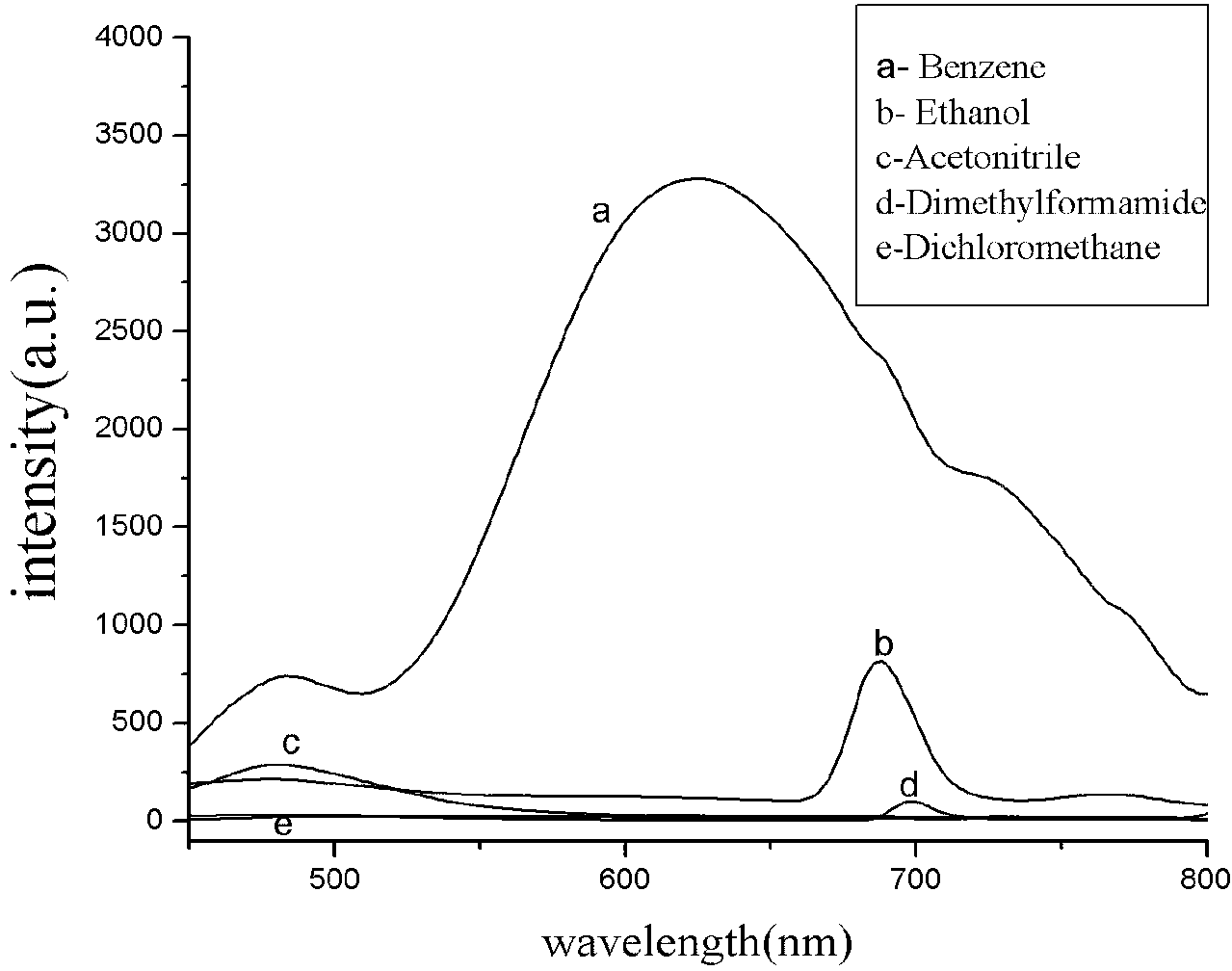

[0021] Further illustrate by embodiment below in conjunction with accompanying drawing:

[0022] 1 Ligand synthesis and characterization

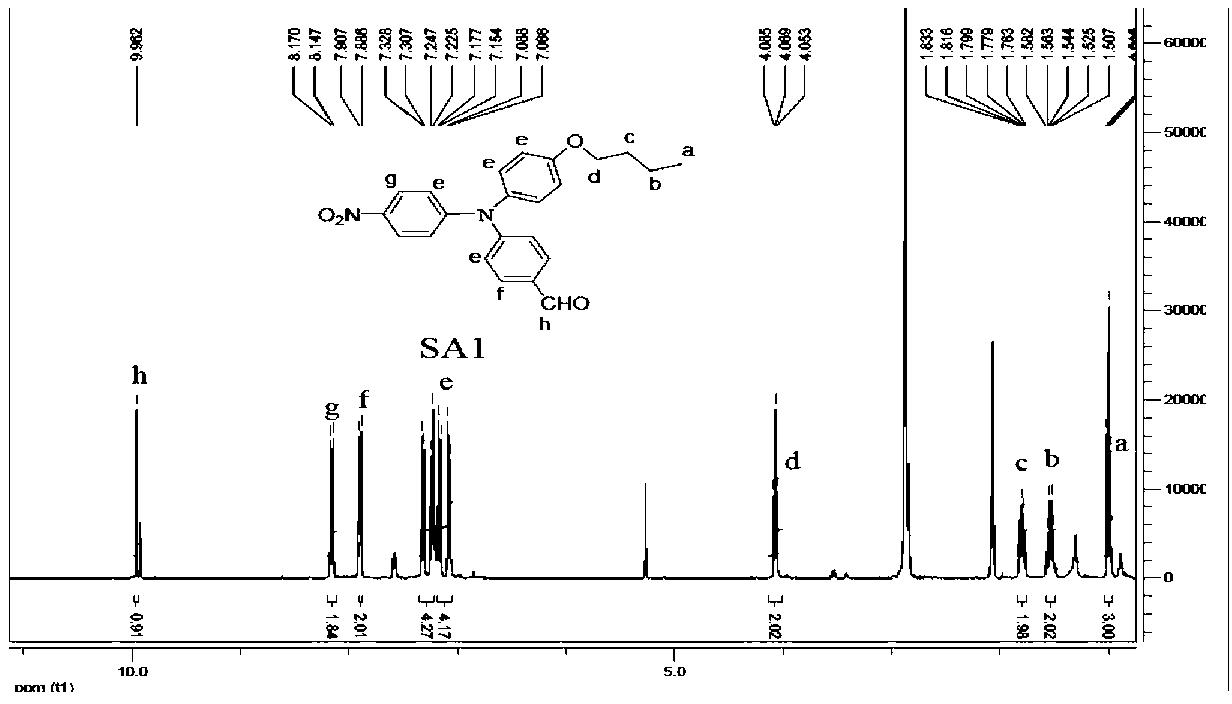

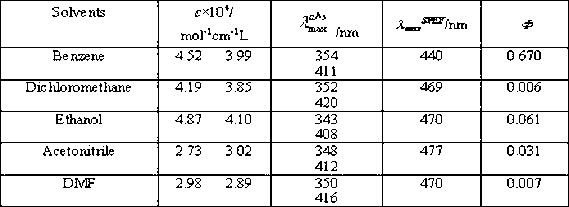

[0023] 1.1 Synthesis and characterization of 4-((4′-butoxyphenyl)(4″-nitrophenyl)amino)benzaldehyde

[0024]

[0025] Synthesis of Scheme 4-[(4′-butoxyphenyl)4″-nitrophenyl]aminobenzaldehyde

[0026] Weigh 2.88g (10mmol) of 4-butoxybenzene-(4'-nitro)aniline, 3.72g (30mmol) of p-fluorobenzaldehyde, and 2.0g (15mmol) of potassium carbonate, and place them in a 150ml volumetric flask. Add phase transfer catalyst Aliquat-336 (trioctylmethylammonium chloride) 0.5mmol, DMSO (dimethyl sulfoxide) 30ml as solvent, slowly heat to 90 ° C, react for 72h, TLC tracking reaction progress, when the raw material point disappear completely, stop the reaction, and cool to room temperature. Pour it into a beaker, add a large amount of ice water, extract 3-5 times with ethyl acetate, collect the organic phase, and dry it with anhydrous magnesium sulfate f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com