Fluorescent waterborne polyurethane based on chromophore in dihydric alcohol and preparation method thereof

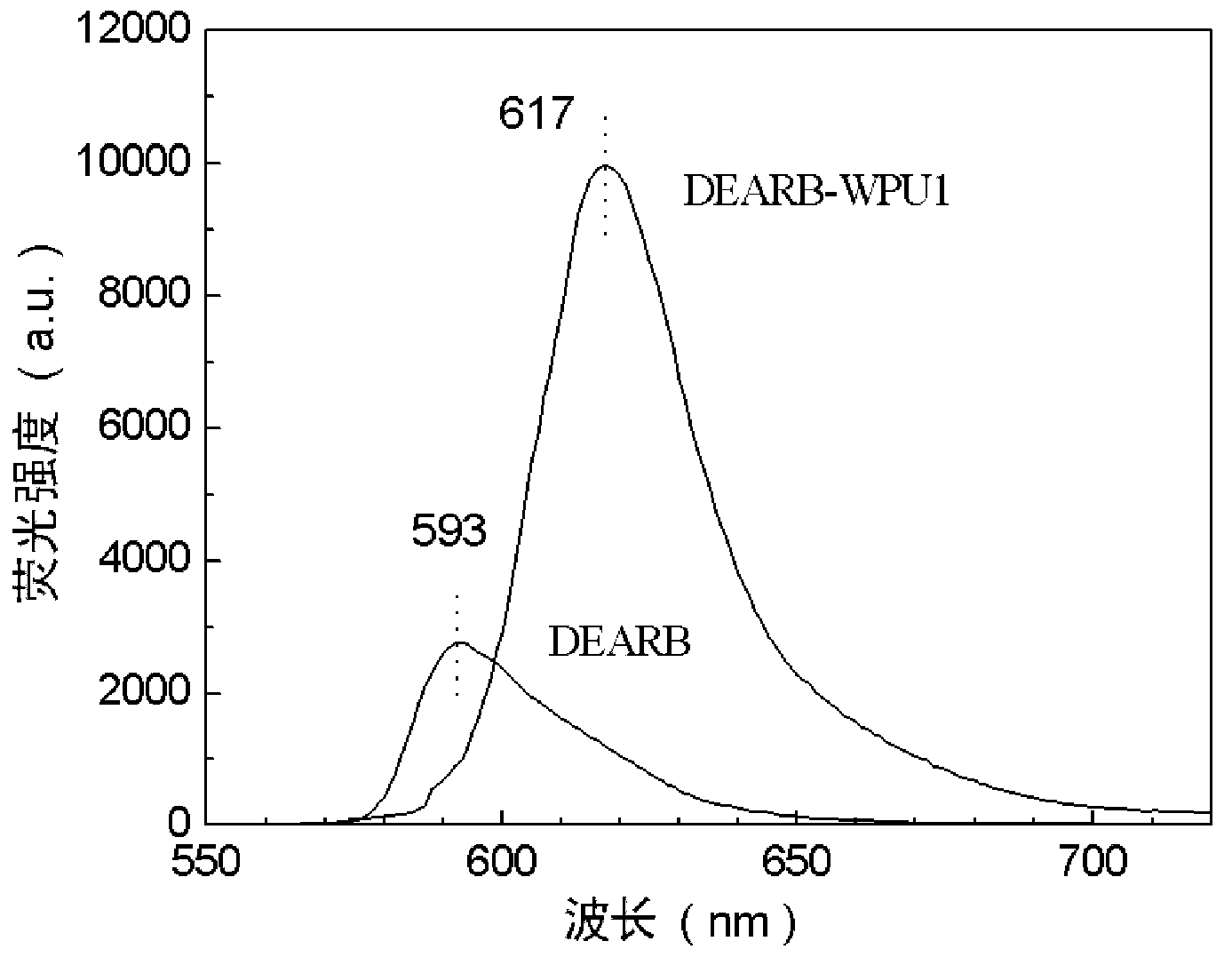

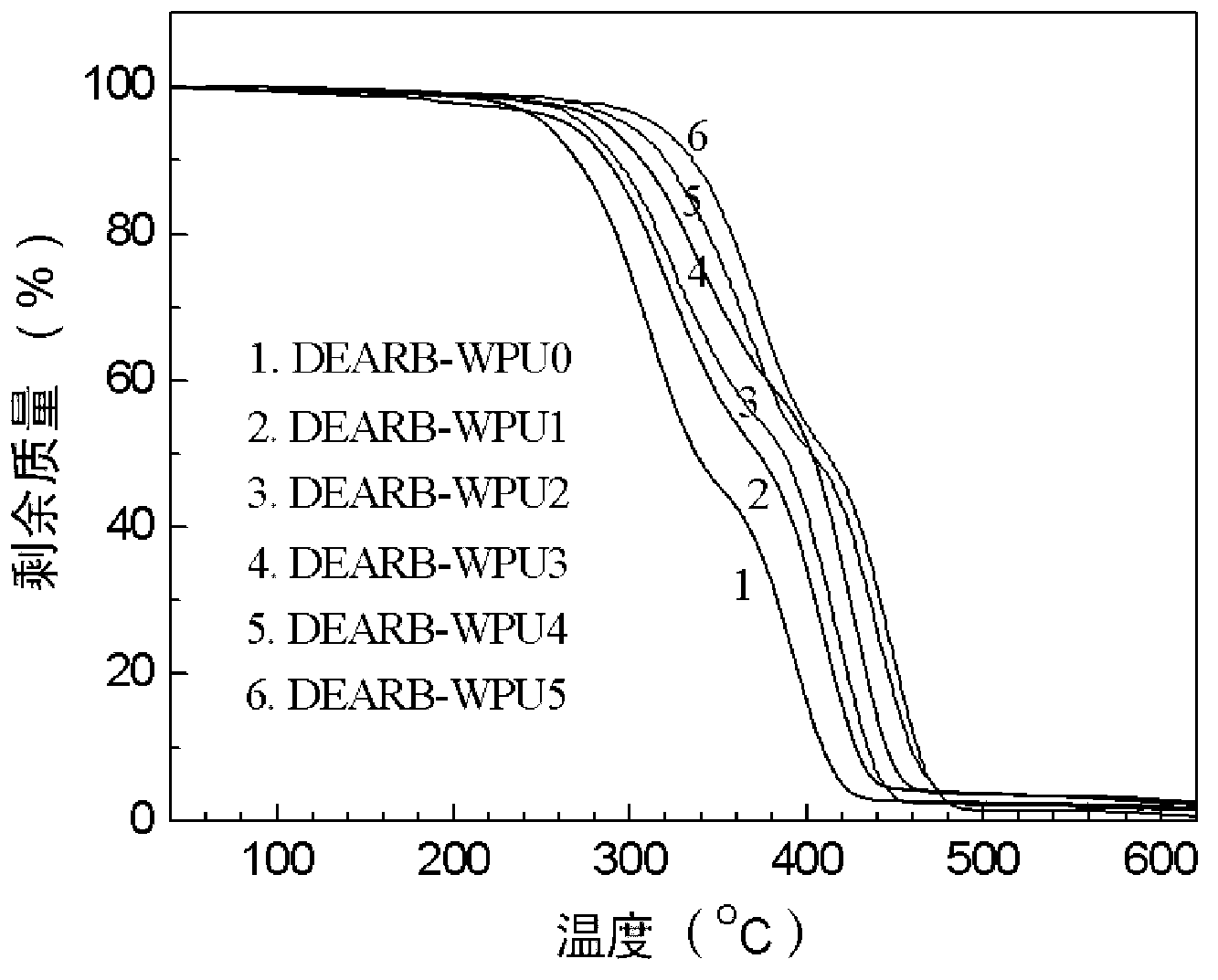

A water-based polyurethane, fluorescent technology, applied in luminescent materials, chemical instruments and methods, etc., can solve problems such as exudation, migration, and deterioration of material fluorescence, and achieve the effects of uniform distribution, difficult migration, and enhanced fluorescence intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

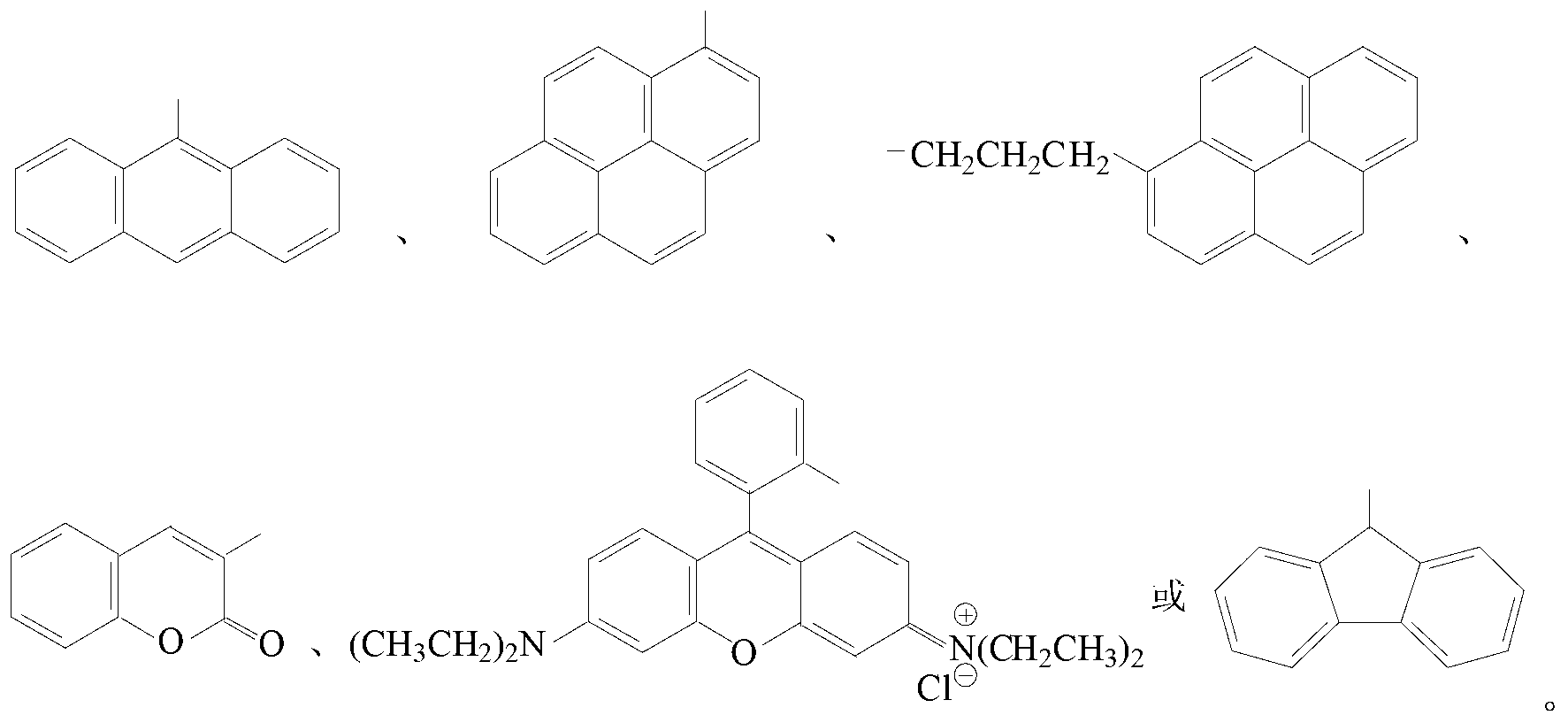

[0056] 110 grams of dimethyl sulfoxide, 30.5 grams of potassium carbonate, 13.9 grams of diethanolamine and 1.0 grams of sodium iodide were put into a three-necked flask, and 5 grams of 9-chloromethyl anthracene and 15 grams of dimethyl anthracene were added dropwise under magnetic stirring. The solution formed by sulfone was heated to 80°C, kept for 2 hours, then added 300 grams of water, filtered to obtain a precipitate, and recrystallized with ethyl acetate and anisole (volume ratio: 1:1) to obtain the fluorescent diol DEAA, structural formula for:

[0057]

[0058] Mix 50 grams of PPG (M n =2000) into a 500mL three-neck flask, dehydrated at 110°C for 1 hour and then cooled to 50°C. Take 12.90 grams of TDI into a three-necked flask, stir and react at 80°C for 2 hours, then add 1.33 grams of the above-prepared fluorescent diol DEAA, 4 grams of DMPA, 0.50 grams of DEG, 0.02 grams of DBTDL and 50.00 grams of butanone, and keep the temperature at 70°C After stirring and re...

Embodiment 2

[0060] Add 13.00 grams of 9-chloromethylanthracene and 100 milliliters of acetone into a 250-mL three-neck flask, add 7.92 grams of potassium carbonate and 18.00 grams of dimethyl 5-hydroxyisophthalate, heat up to 56°C under magnetic stirring, and reflux for 30 hours , cooled to 20°C, filtered to obtain the filtrate, distilled under reduced pressure to remove acetone, washed with methanol three times, and dried in vacuo to obtain an ether solid;

[0061] Mix 4.32 grams of lithium aluminum hydride and 30 milliliters of tetrahydrofuran at 0°C to form a suspension, add dropwise a tetrahydrofuran solution (100 g / L) of ether solids to the suspension, react at room temperature for 10 hours after the addition is complete, and add a small amount of Stir the water for 10 minutes after no gas is generated, filter to obtain the filtrate, distill under reduced pressure to remove the solvent, recrystallize with n-hexane, filter and vacuum-dry to constant weight to obtain the fluorescent dio...

Embodiment 3

[0065] Weigh 2.0 grams of 9-anthracene formic acid into a one-necked flask, add 40 grams of dichloromethane as a solvent under magnetic stirring conditions until the 9-anthracene formic acid is completely dissolved, add 3 grams of oxalyl chloride dropwise to the one-necked flask, and then add 0.02 grams of N,N'-Dimethylformamide, react at 20°C for 5 hours, then add 30 grams of n-hexane to the system, and distill under reduced pressure to remove n-hexane (oxalyl chloride will be taken out when distilling n-hexane under reduced pressure), Repeated three times to obtain intermediate 1;

[0066] Add 10 grams of dichloromethane in the obtained intermediate 1 to obtain the dichloromethane solution of intermediate 1, dissolve 2.52 grams of diethanolamine in 20 grams of dichloromethane to obtain the dichloromethane solution of diethanolamine, and then the intermediate The dichloromethane solution of 1 was added dropwise to the dichloromethane solution of diethanolamine, and reacted at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com