Patents

Literature

74results about How to "Weak" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

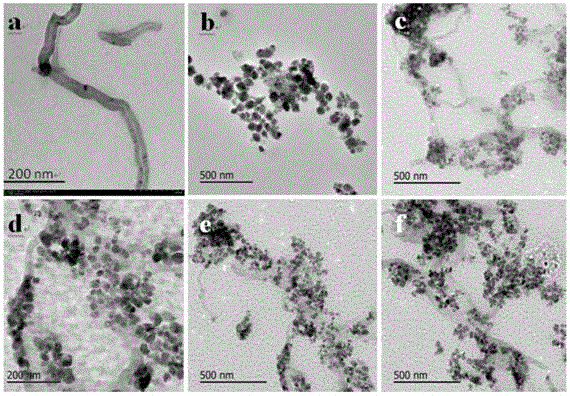

Method of resin sealing permanent magnets in laminated rotor core

ActiveUS20090189309A1Decrease in temperatureEasy to cleanMagnetic circuitManufacturing stator/rotor bodiesMagnetEngineering

Owner:MITSUI HIGH TEC INC

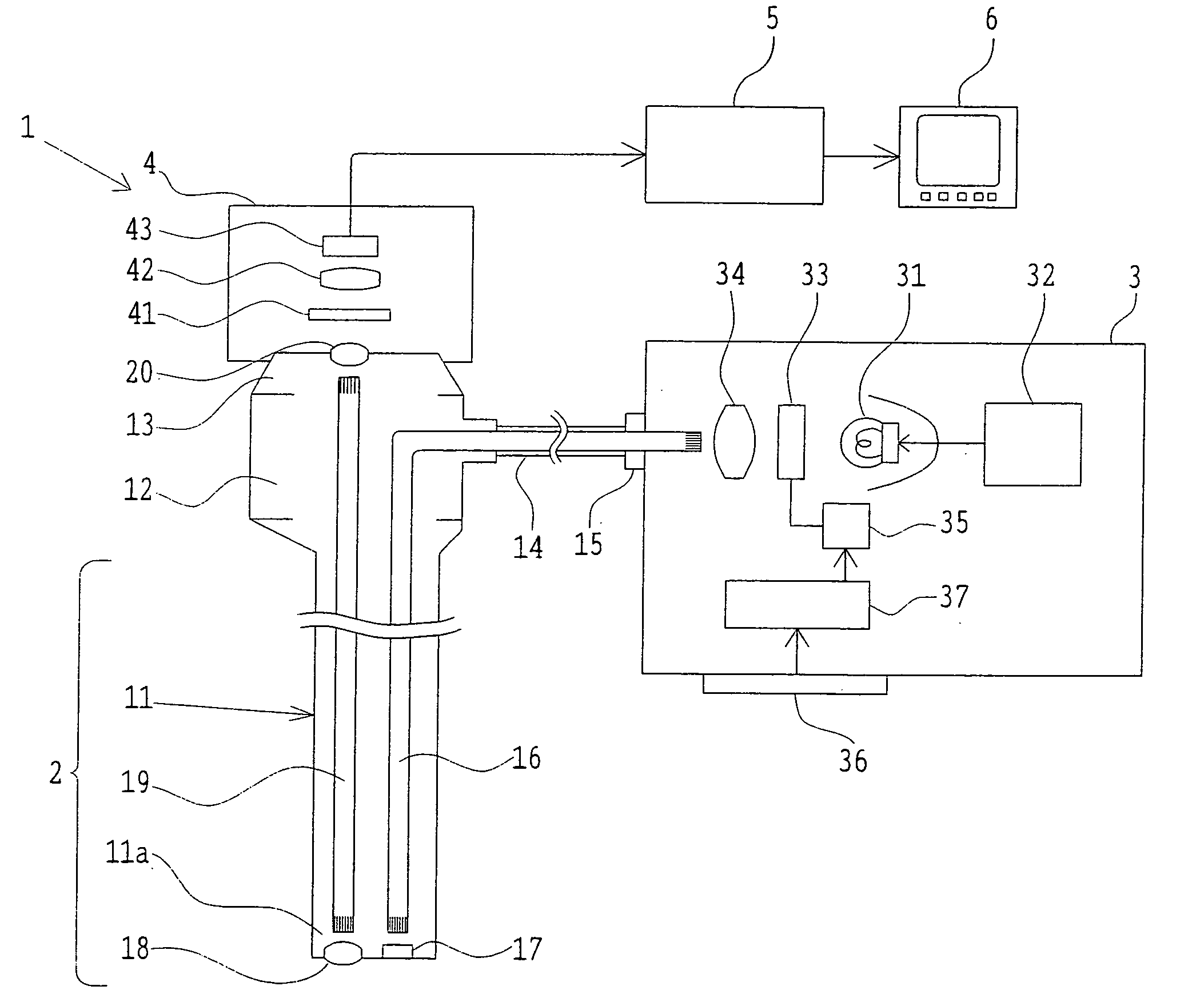

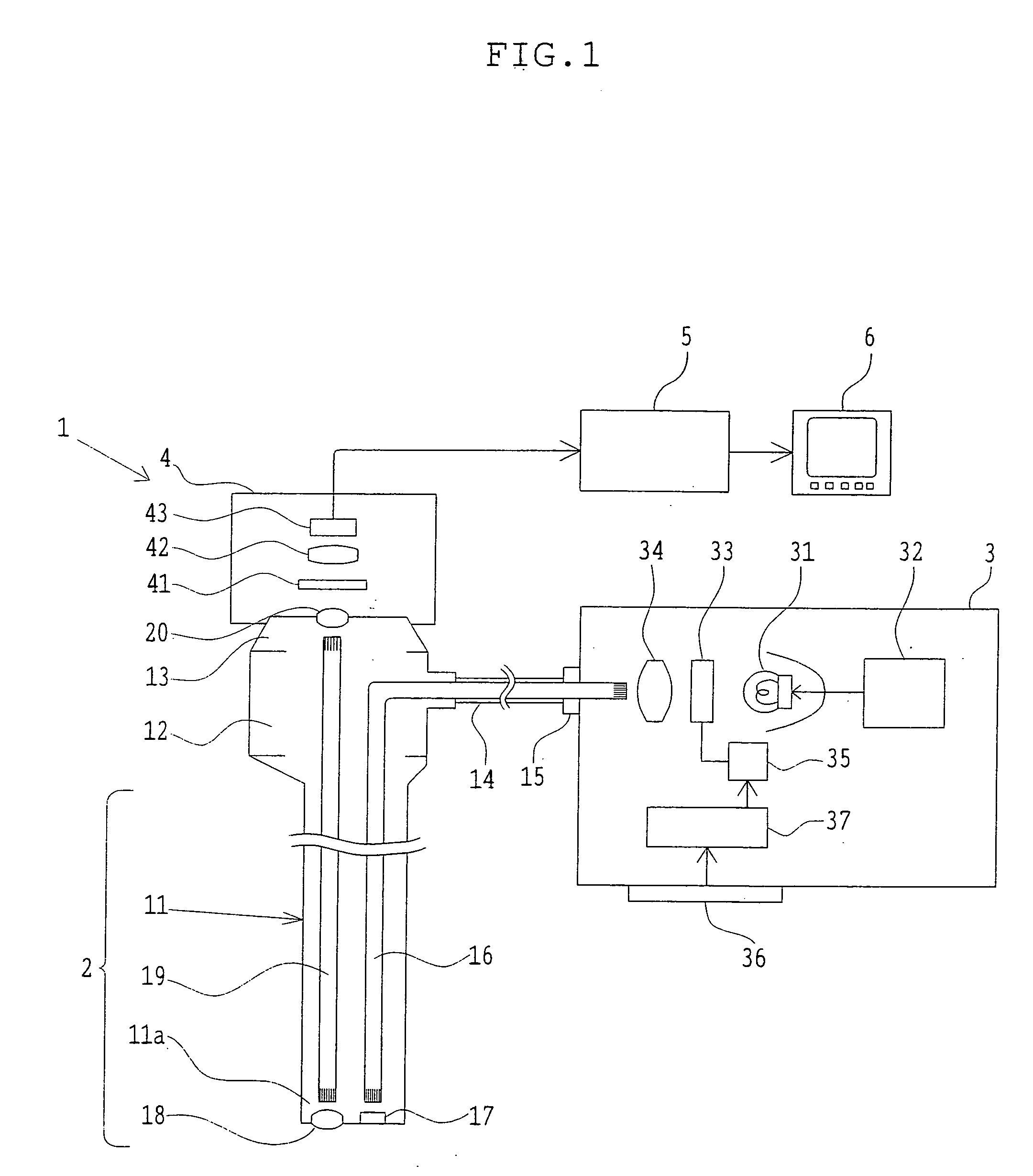

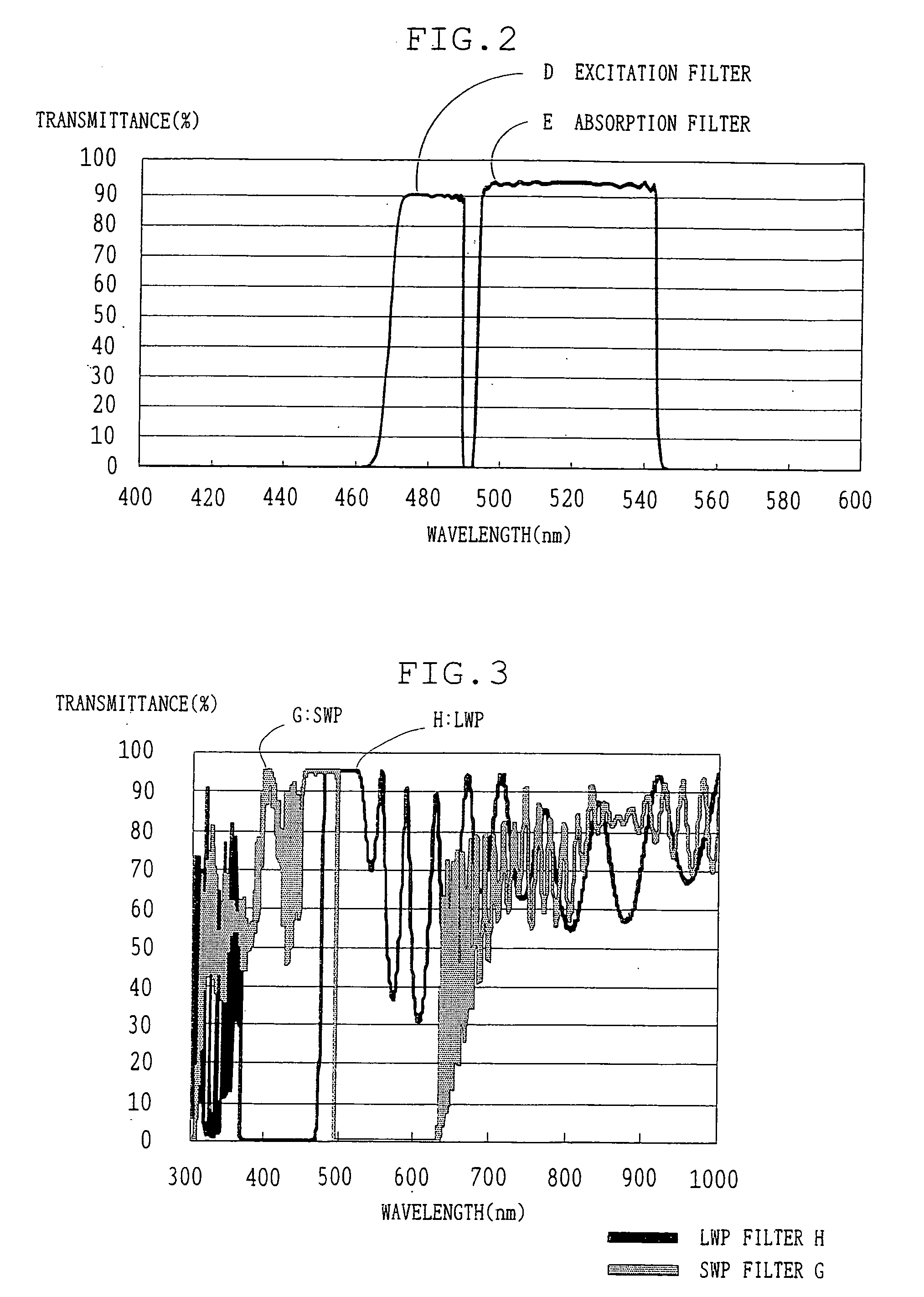

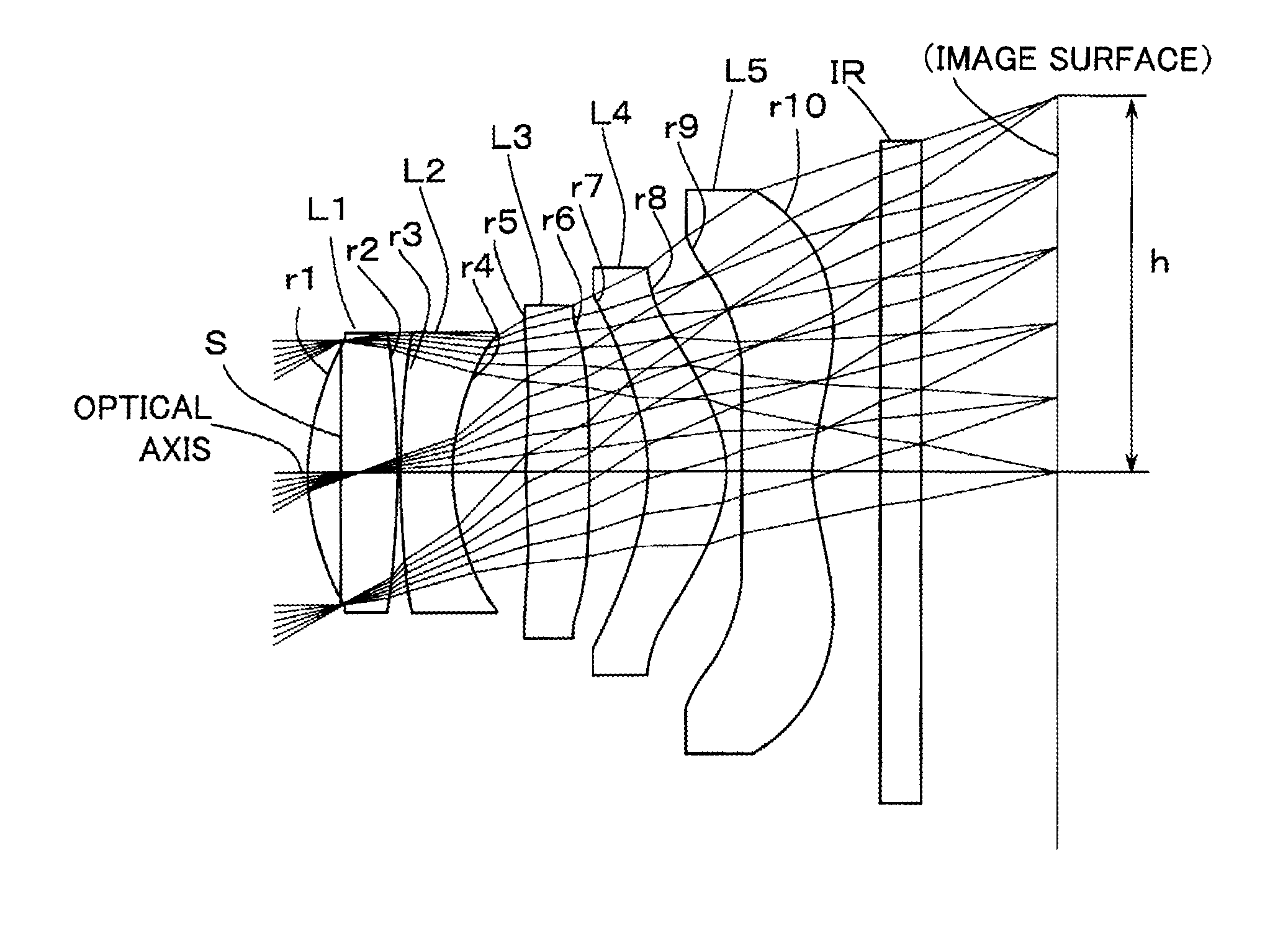

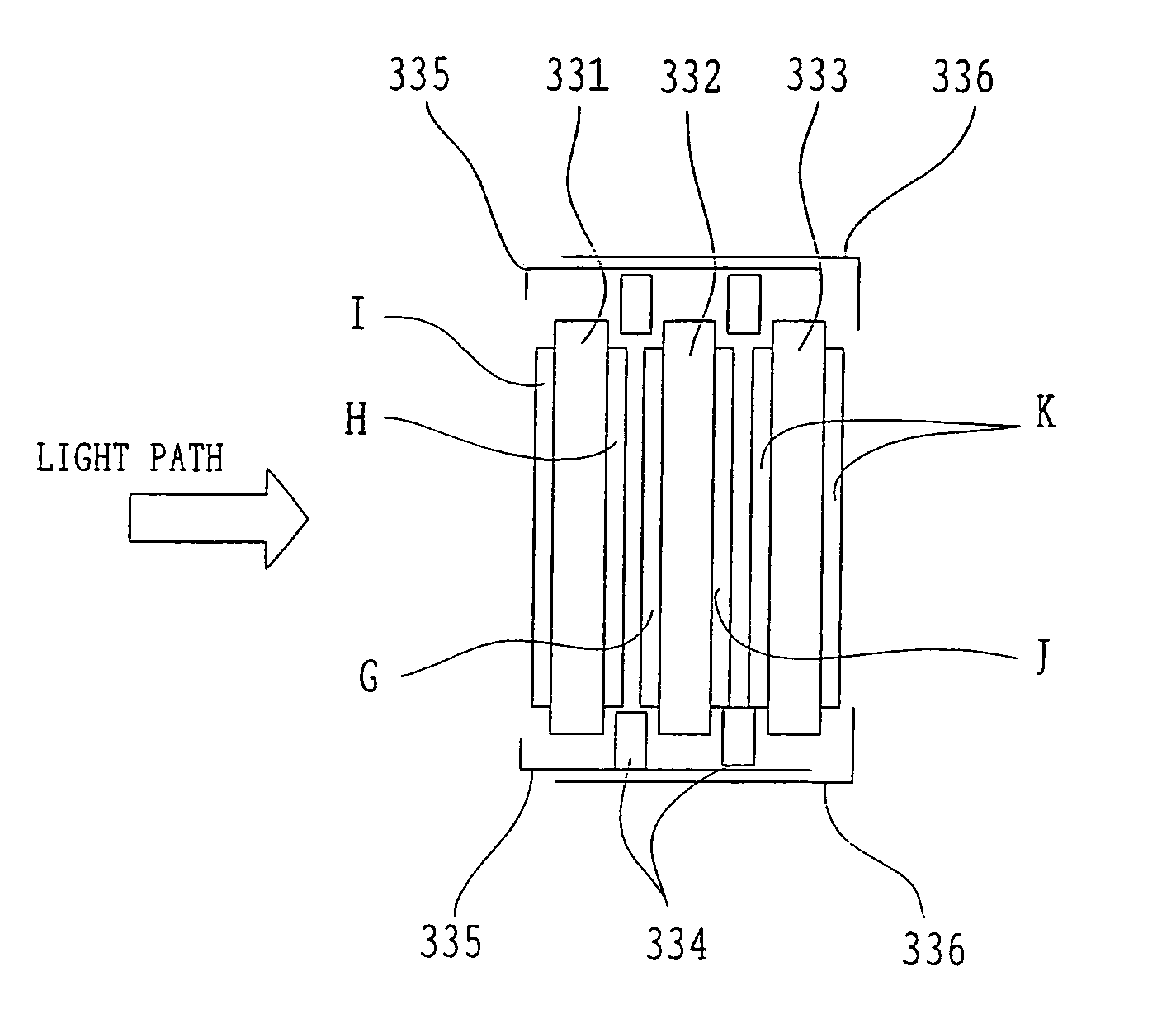

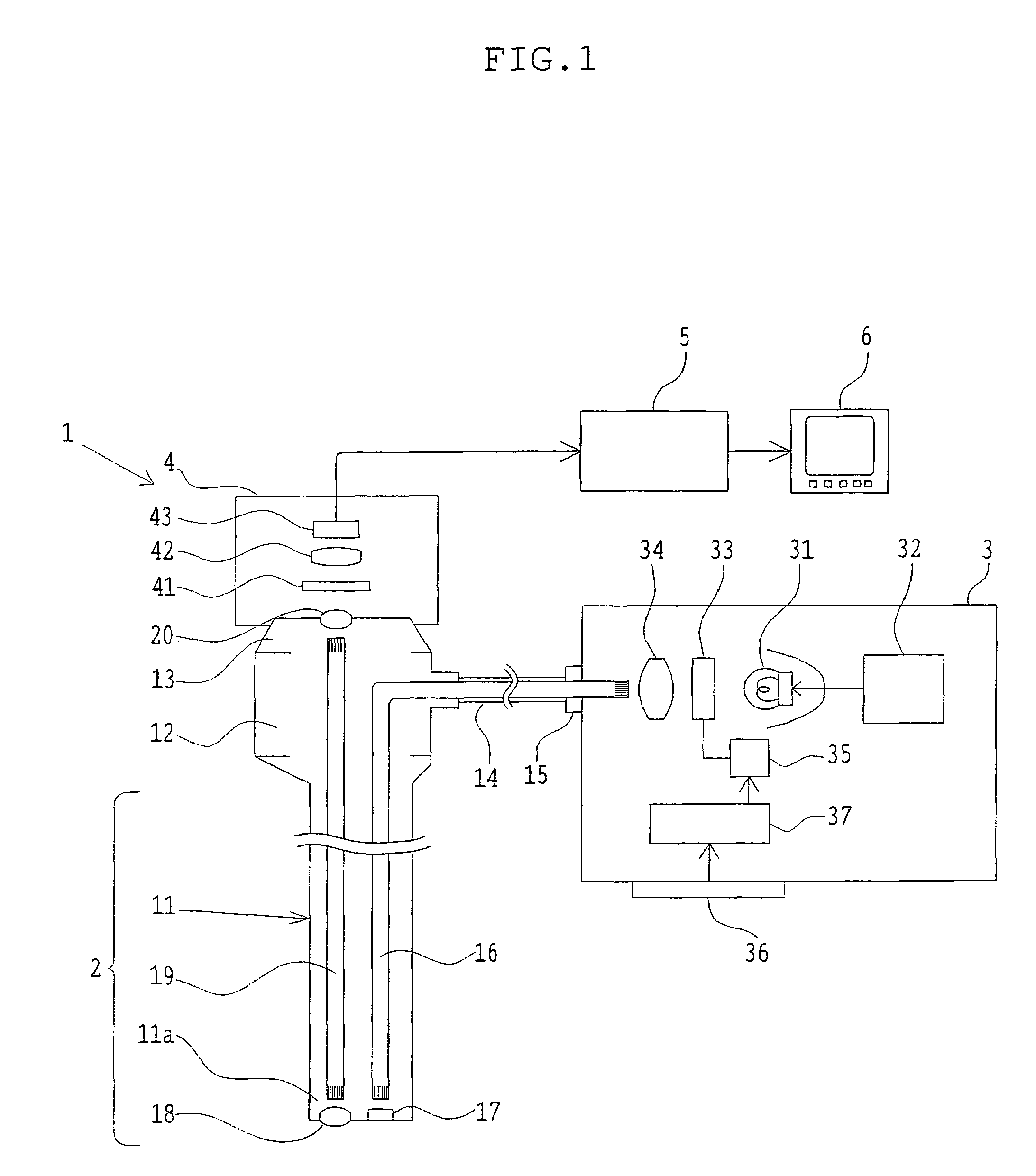

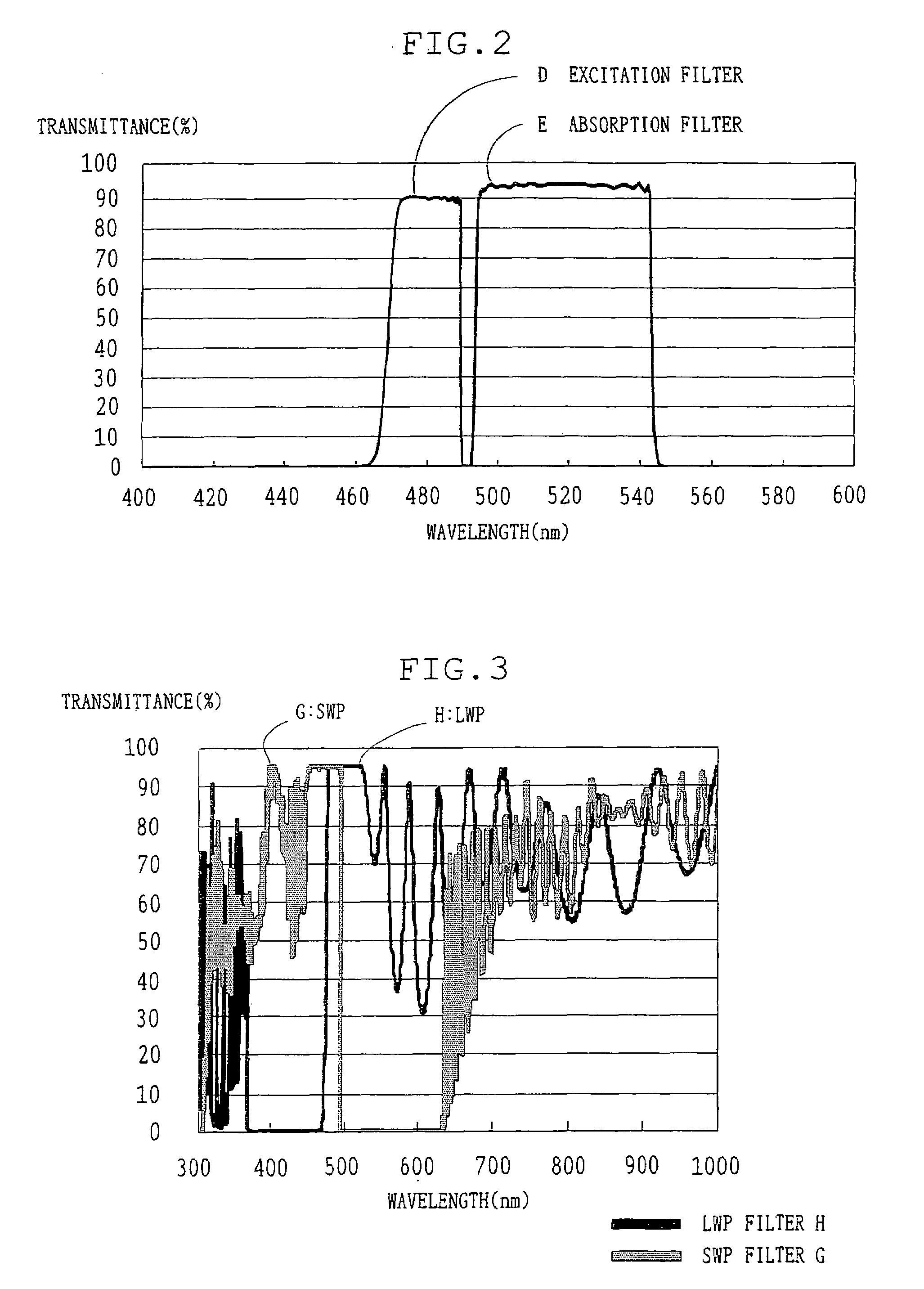

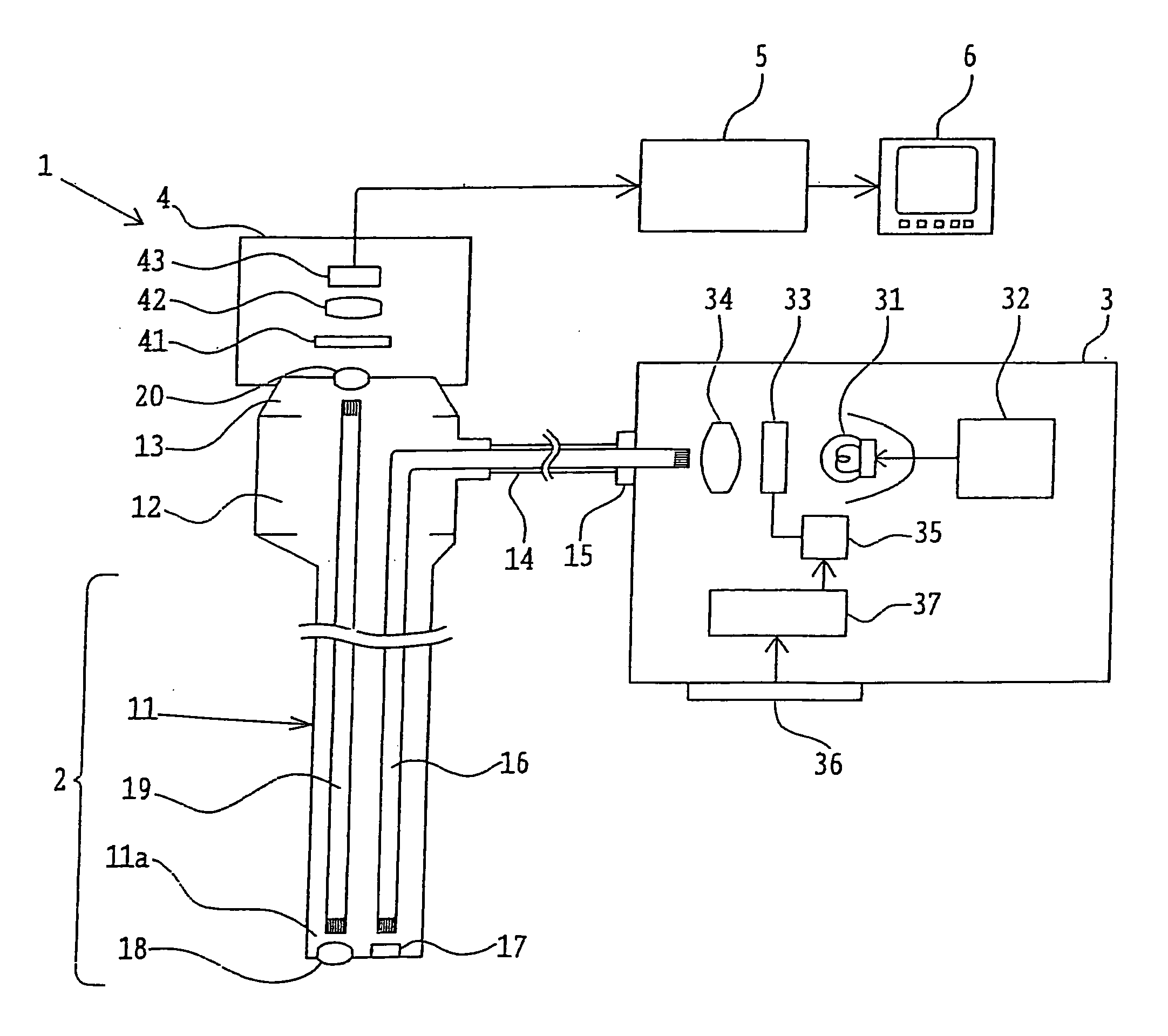

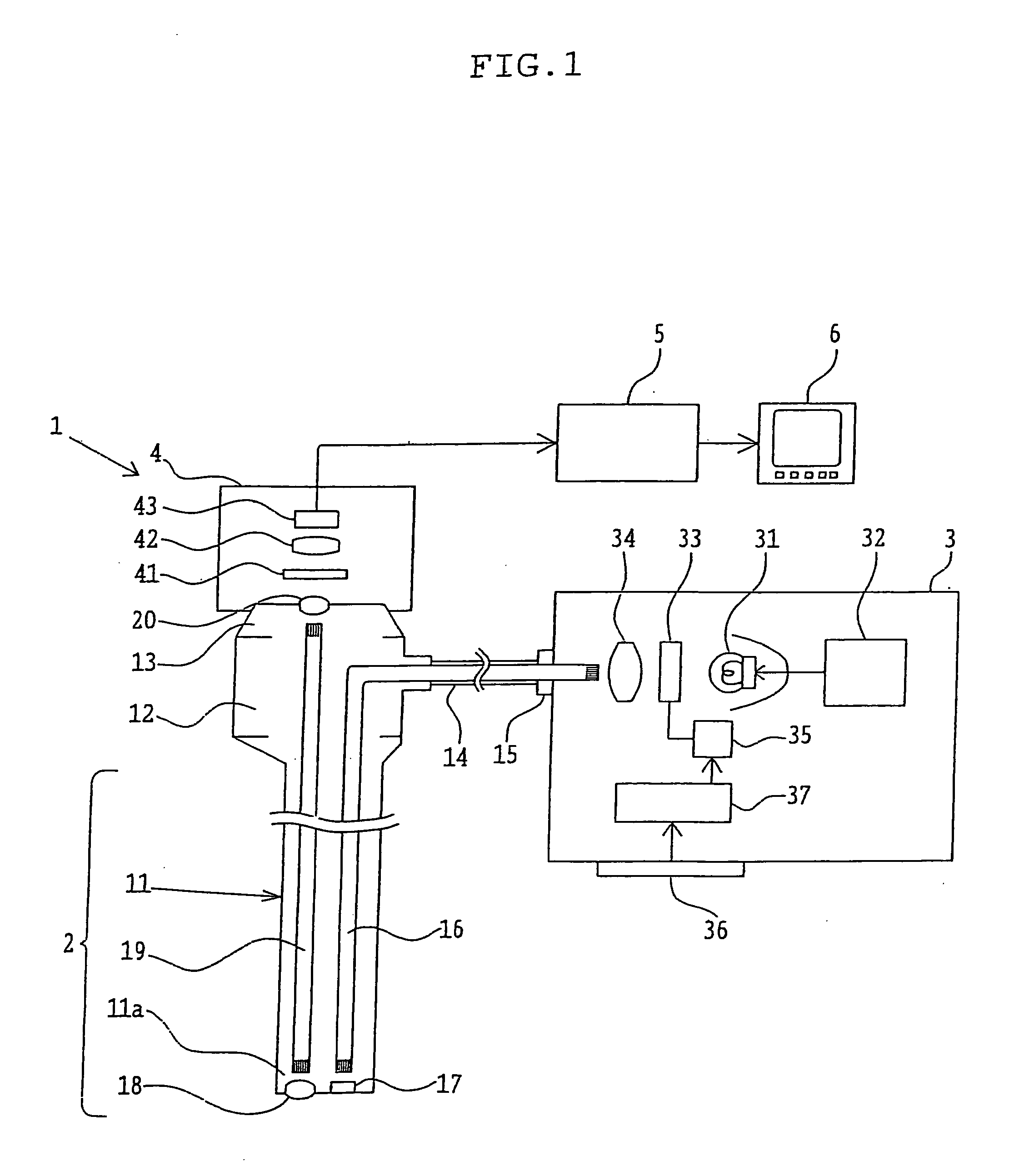

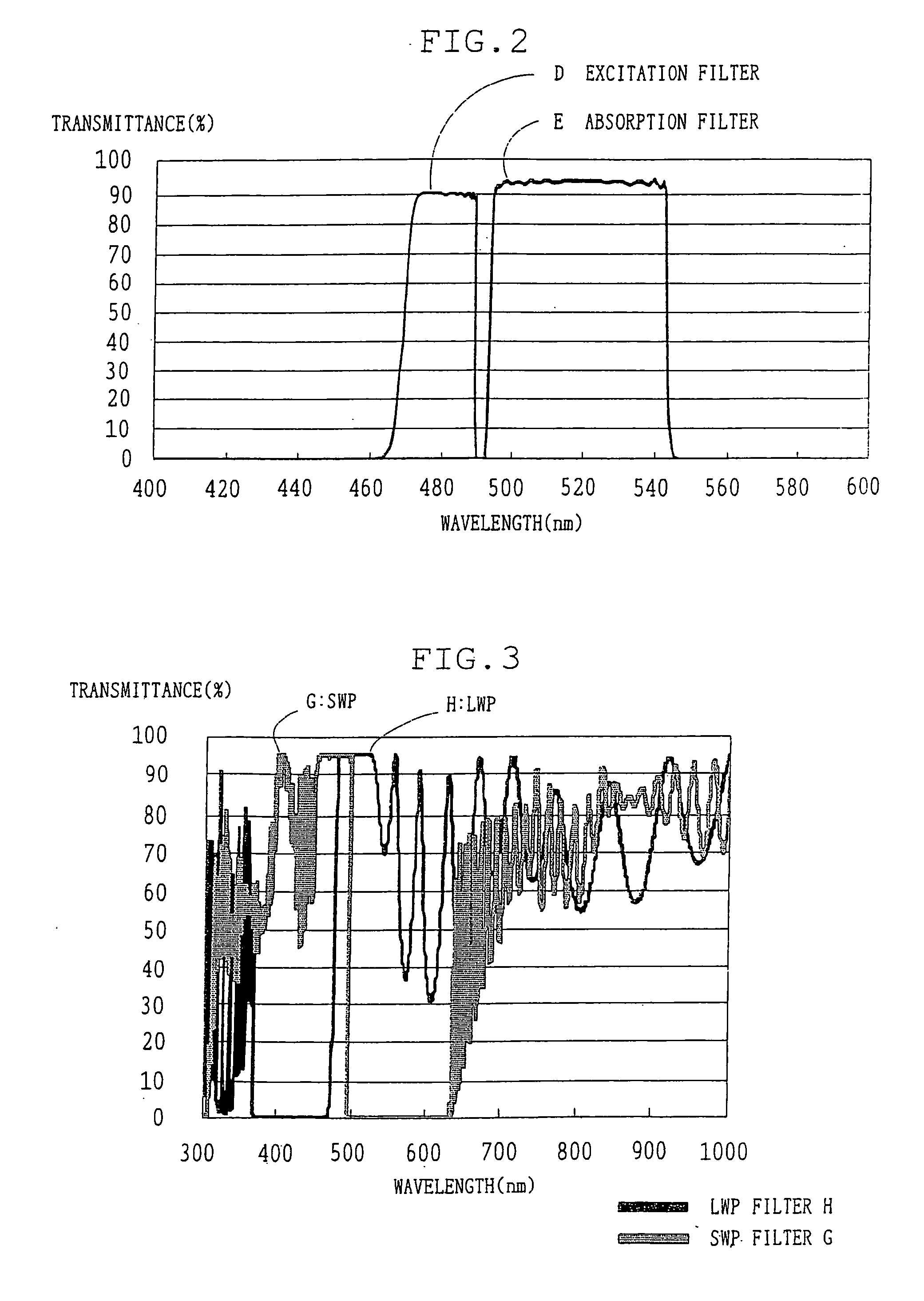

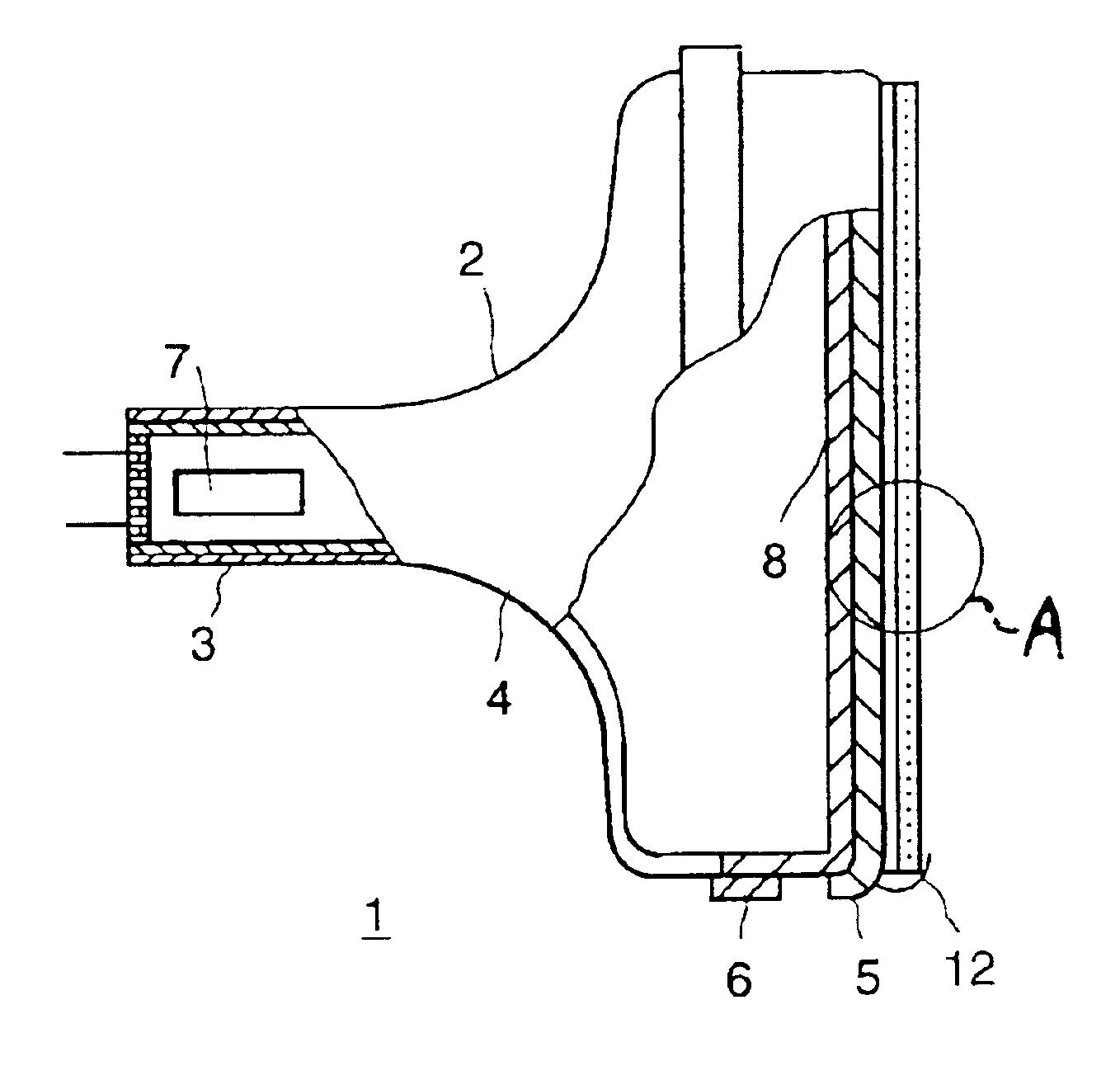

Flourescence observation equipment

ActiveUS20060017913A1High fluorescence intensityWeakOptical radiation measurementForce measurement by measuring optical property variationPhysicsFluorescence

An apparatus for fluorescence observation includes an excitation filter which transmits only exciting light of an specific wavelength among illumination light, and an absorption filter which blocks the exciting light and transmits only fluorescence generated from a specimen when the exciting light is irradiated to the specimen. Here, an interval of a half-value wavelength at a long-wavelength side of the excitation filter and a half-value wavelength at a short-wavelength side of the absorption filter is in a width between 1 nm to 6 nm, and change of the half-value wavelength of the excitation filter and the absorption filter when humidity changes from 10% to 95%, is 0.5 nm or less.

Owner:EVIDENT CORP

Auxiliary material combination for improving atomizing and drying process of traditional Chinese medicine granules and application thereof

ActiveCN101862458AReduce dosageHigh softening pointGranular deliveryMacromolecular non-active ingredientsFlavorMedicine

The invention relates to an auxiliary material combination for improving atomizing and drying process of traditional Chinese medicine granules and an application thereof. The auxiliary material combination comprises 10 to 90 percent of betadex and 10 to 90 percent of maltodextrin or dextrine. The application of the auxiliary material combination is: after being dissolved in hot water, the auxiliary material combination is added into extract obtained by extracting Chinese medicine or is directly added into extract to be uniformly mixed and to be atomized and dried; when adding the auxiliary material combination, the temperature of the extract is 50 to 100 DEG C, relative density of the extract is 1.02 to 1.20 (60 DEG C), air inlet temperature for atomizing drying is 140 to 190 DEG C, and the air outlet temperature is 75 to 100 DEG C. by adopting the auxiliary material combination, under the same atomizing and drying condition, the consumed quantity of the auxiliary material is less, the consumption quantity of the auxiliary material can be reduced by more than 30 percent, the auxiliary material with the same quantity is added for atomizing and drying, the softening point of the extract can be improved during the atomizing and drying process, the wall is difficult to be adhered during the atomizing process, the fluidity of the atomizing and drying powder is good, the atomizing and drying powder is difficult to be moistened, the dispersion of the flavor can be effectively prevented during the atomizing and drying process, and the original flavor of the extract is maintained.

Owner:陇西一方制药有限公司

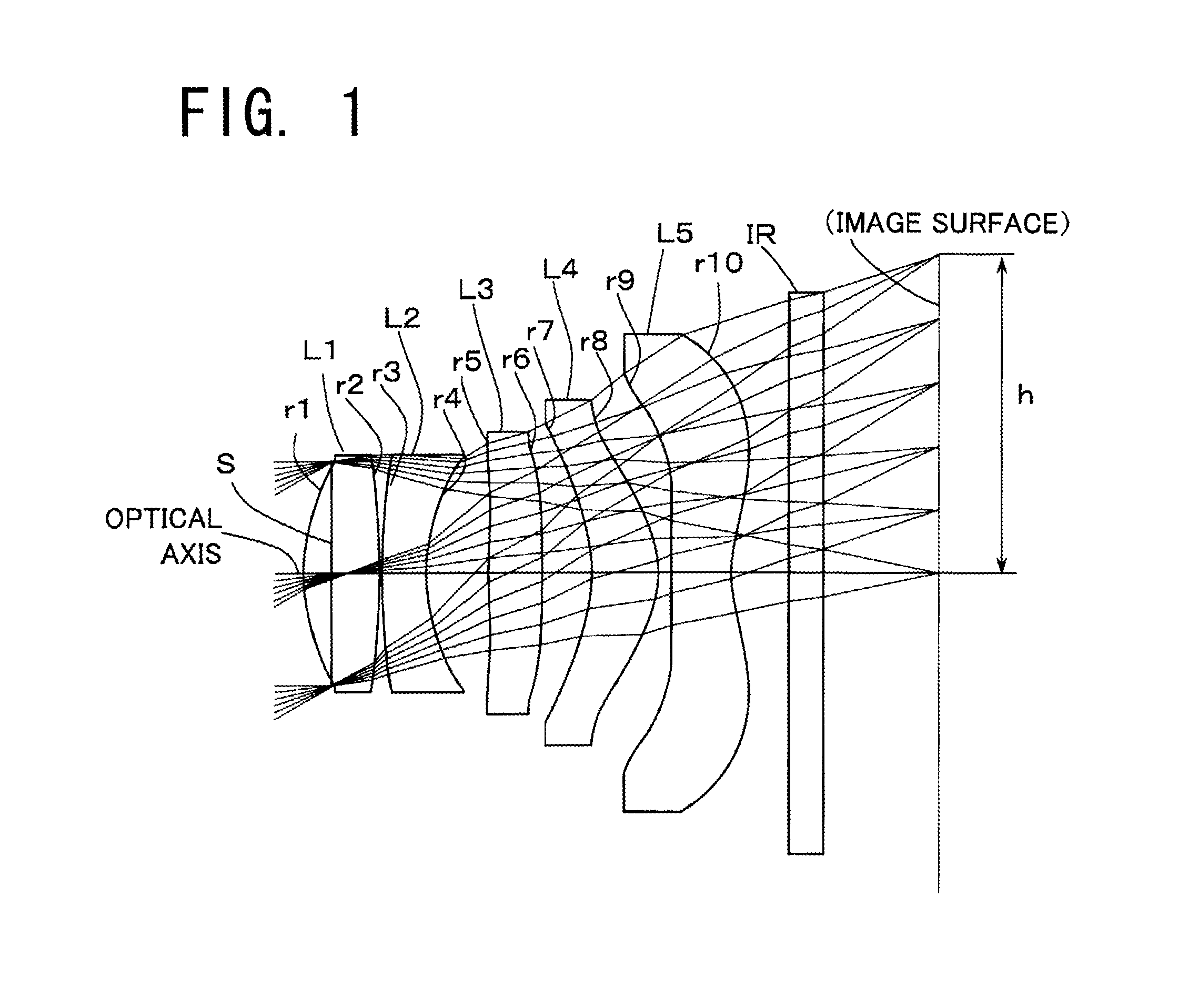

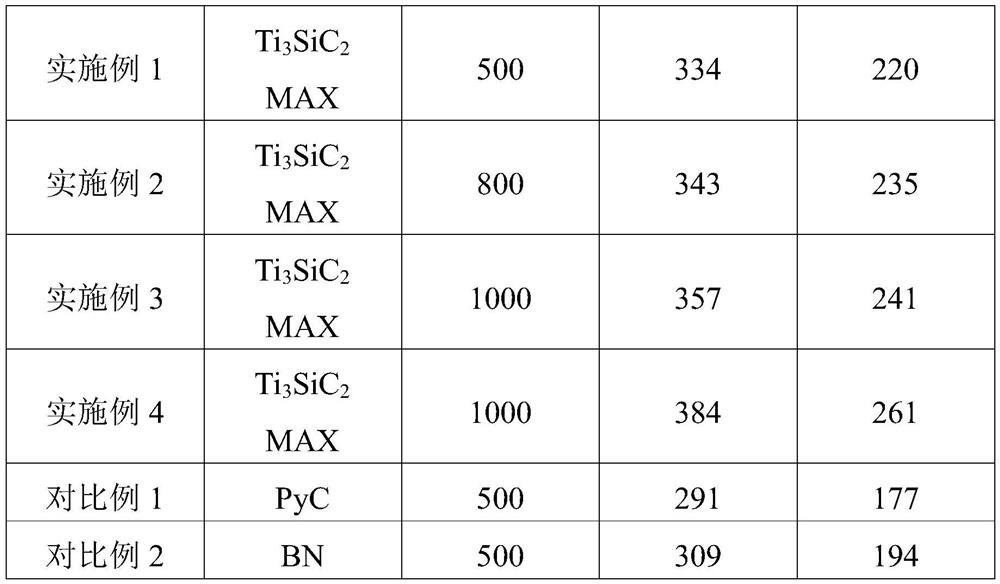

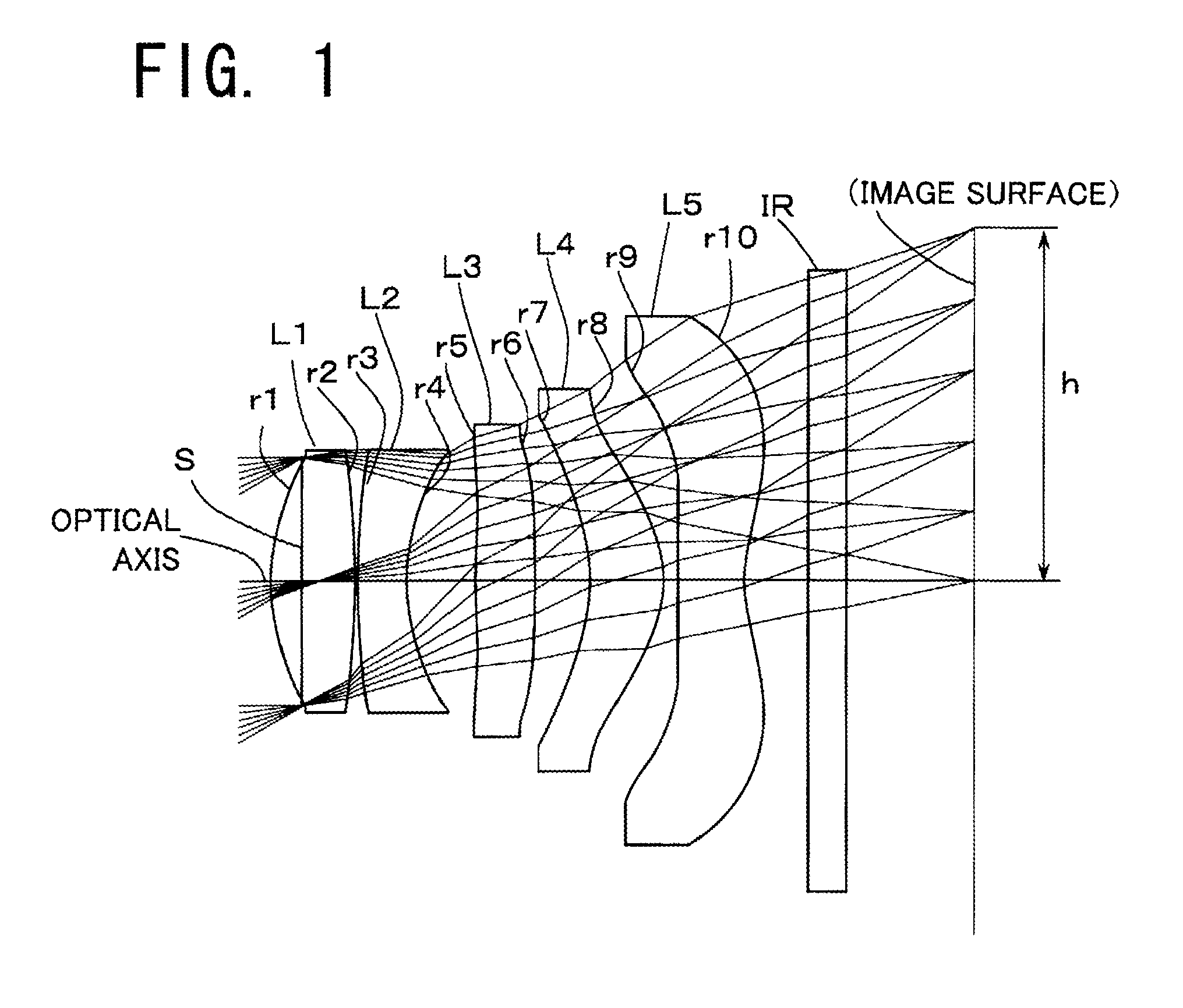

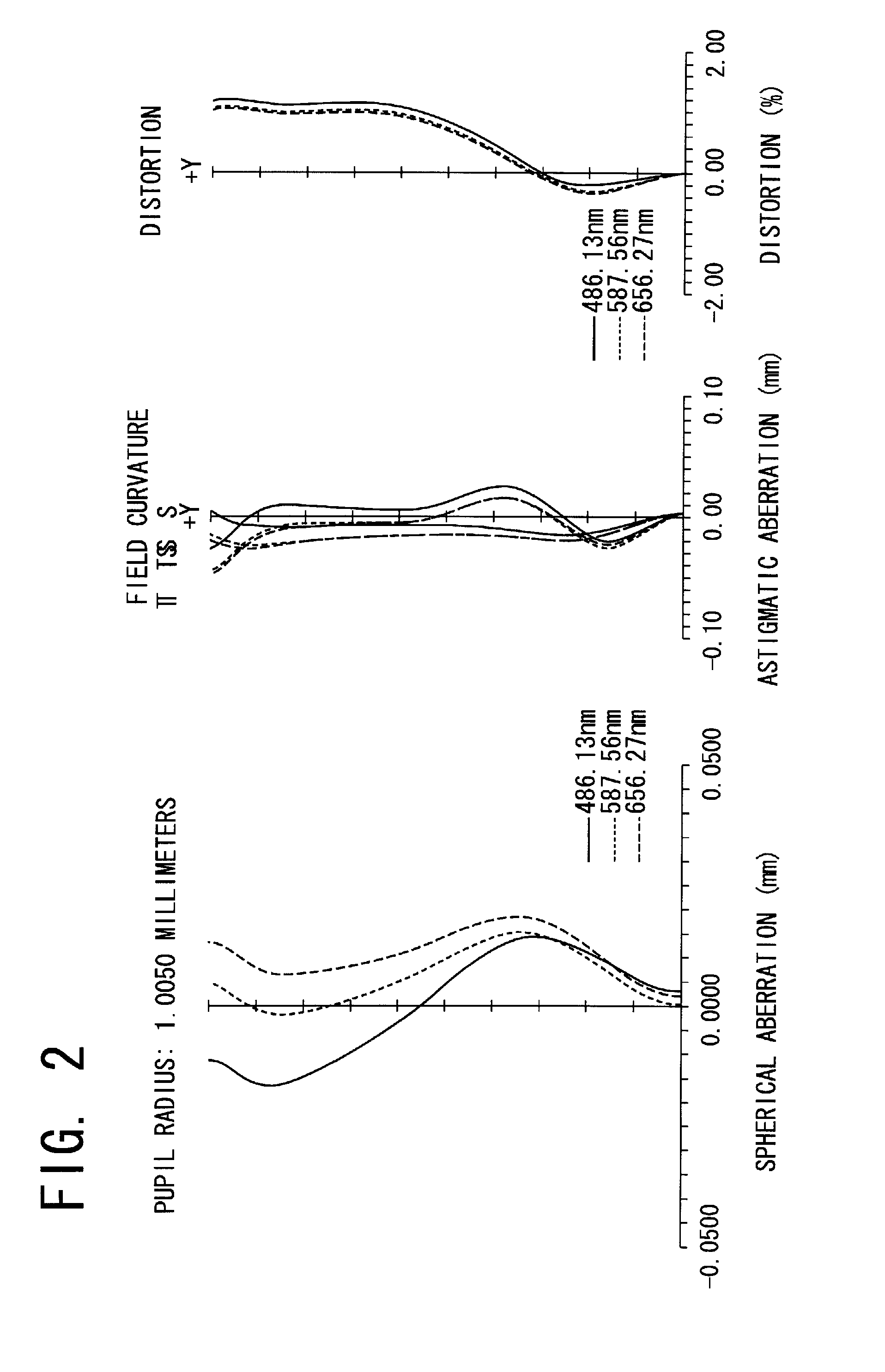

Imaging lens

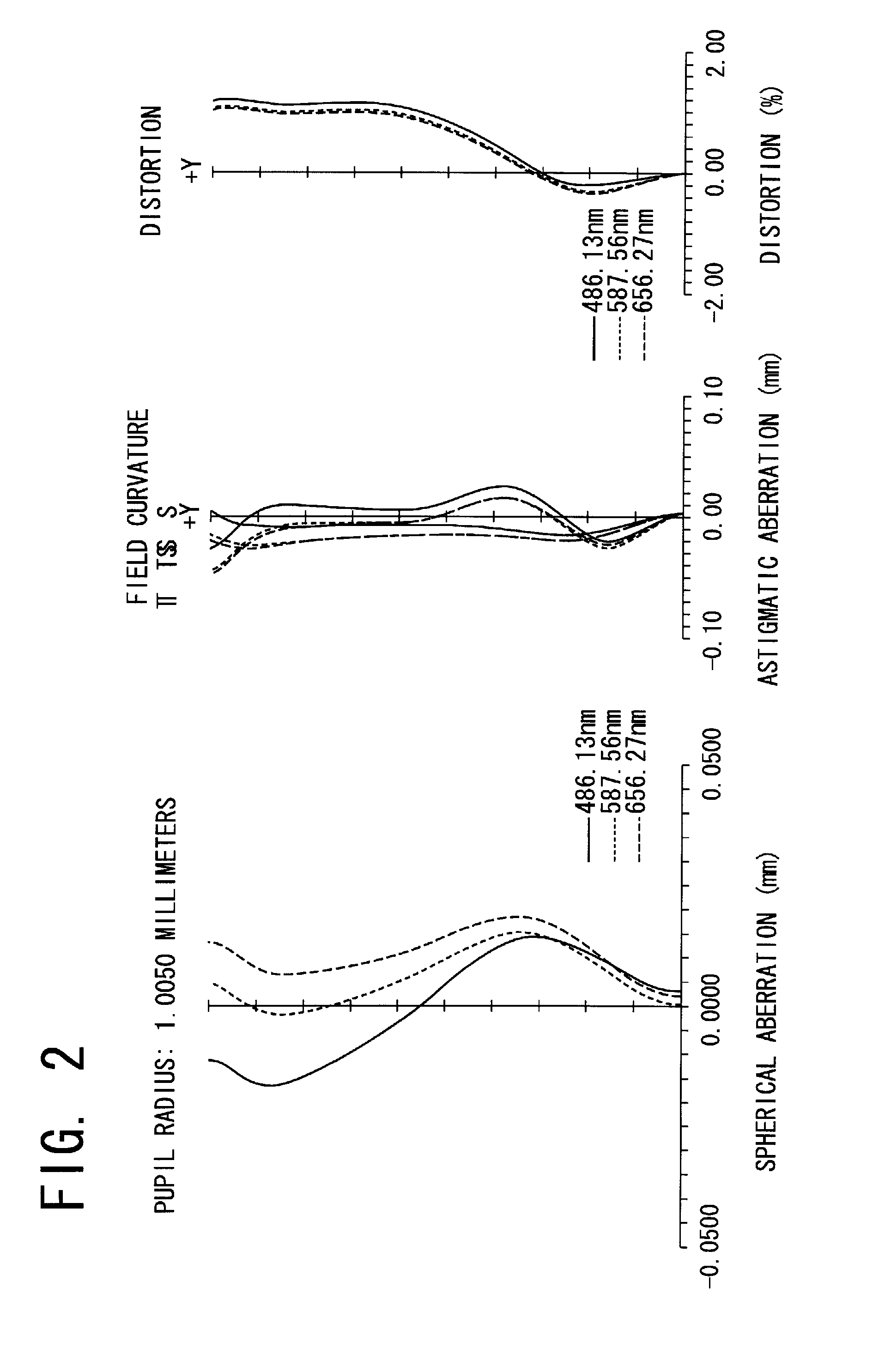

ActiveUS20120250167A1Small and high-performanceCorrected spherical aberrationLensCamera lensConditional expression

An imaging lens includes: an aperture stop; a biconvex first lens directing convex surfaces toward an object and an image; a second lens directing a convex surface toward the object near the optical axis and having negative refractive power; a biconvex third lens directing convex surfaces toward the object and the image near the optical axis; a fourth lens directing a concave surface toward the object near the optical axis and having positive refractive power; and a fifth lens directing a convex surface toward the object near the optical axis and having negative refractive power. The aperture stop and the first to fifth lenses are arranged in this order from the object side, and a conditional expression 1 being 0.50<f1 / f<0.76 is satisfied, where f1 represents the focal length of the first lens and f represents the focal length of the entire imaging lens.

Owner:TOKYO VISIONARY OPTICS CO LTD

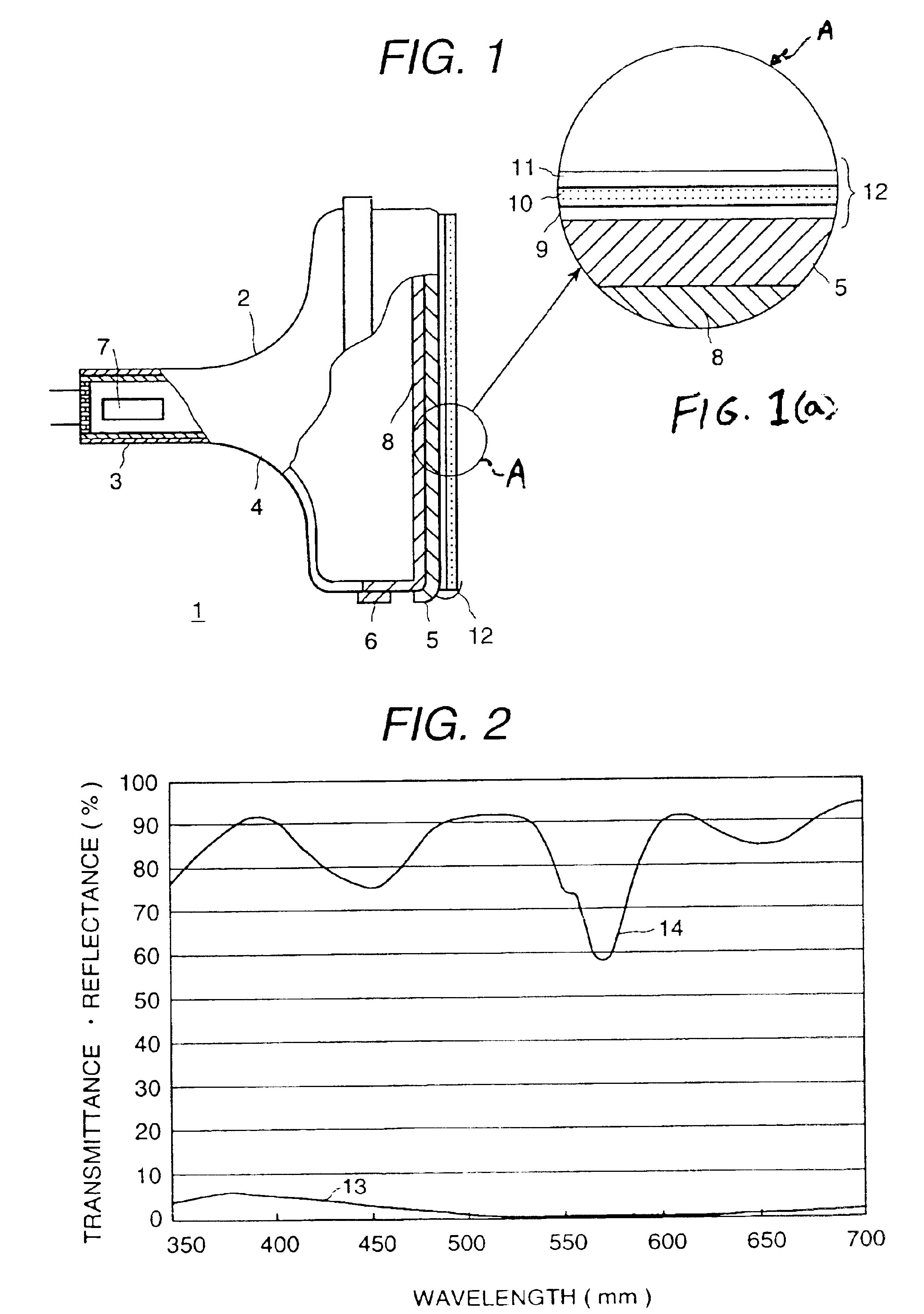

Fluorescence observation equipment

InactiveUS7453568B2WeakHigh fluorescence intensityOptical radiation measurementForce measurement by measuring optical property variationAbsorption filterTransmission illumination

An apparatus for fluorescence observation includes an excitation filter which transmits only exciting light of an specific wavelength among illumination light, and an absorption filter which blocks the exciting light and transmits only fluorescence generated from a specimen when the exciting light is irradiated to the specimen. Here, an interval of a half-value wavelength at a long-wavelength side of the excitation filter and a half-value wavelength at a short-wavelength side of the absorption filter is in a width between 1 nm to 6 nm, and change of the half-value wavelength of the excitation filter and the absorption filter when humidity changes from 10% to 95%, is 0.5 nm or less.

Owner:EVIDENT CORP

Natural plant health drink

InactiveCN1377611AGood anti-fatigue effectImprove fatigue resistanceUnknown materialsFood scienceLycium barbarum fruitDigestion

The present invention provides a kind of natural plant health drink prepared with haw, date and mulberry as basic medicinal material; and lotus leaf and wolfberry fruit, or chrysanthemum and fresh reed rhizome, or Xianggu mushroom as supplementary material, and through decoction, enzymolysis, clairification, disinfection, filtering to obtain filtrate, and adding citric acid, cane sugar, vitamin Cand stabilizer. The natural plant health drink has the health functions of aiding digestion, reducing blood fat, invigorating vital energy, nourishing blood, relaxing the bowels, nourishing Yin, etc.

Owner:姚力克

Green tea beverage for reinforcing immunity, reducing blood fat, losing weight and clearing away summer heat

InactiveCN101658221AImprove antioxidant capacityImprove immunityPre-extraction tea treatmentAdditive ingredientTrace element

The invention provides a green tea beverage for reinforcing immunity, reducing blood fat, losing weight and clearing away summer heat, comprising the following main components in parts by weight: 3 to30 parts of fiveleaf gynostemma herb, 1 to 10 parts of lotus leaves and 1 parts of green tea. The fiveleaf gynostemma herb is leaves of curcurbitaceae sweet gynostemma pentaphylla, grows in west areas of Hubei Province, and specially contains trace element selenium. The green tea beverage is used for solving susceptible fatigue and other diseases caused by low immunity, can simultaneously and effectively regulate blood fat and lose weight if the beverage is drunk for long time, has simple manufacture process, less equipment investment and low product cost, and is applicable to industrial andspecialized production in large scale.

Owner:张鸿毓

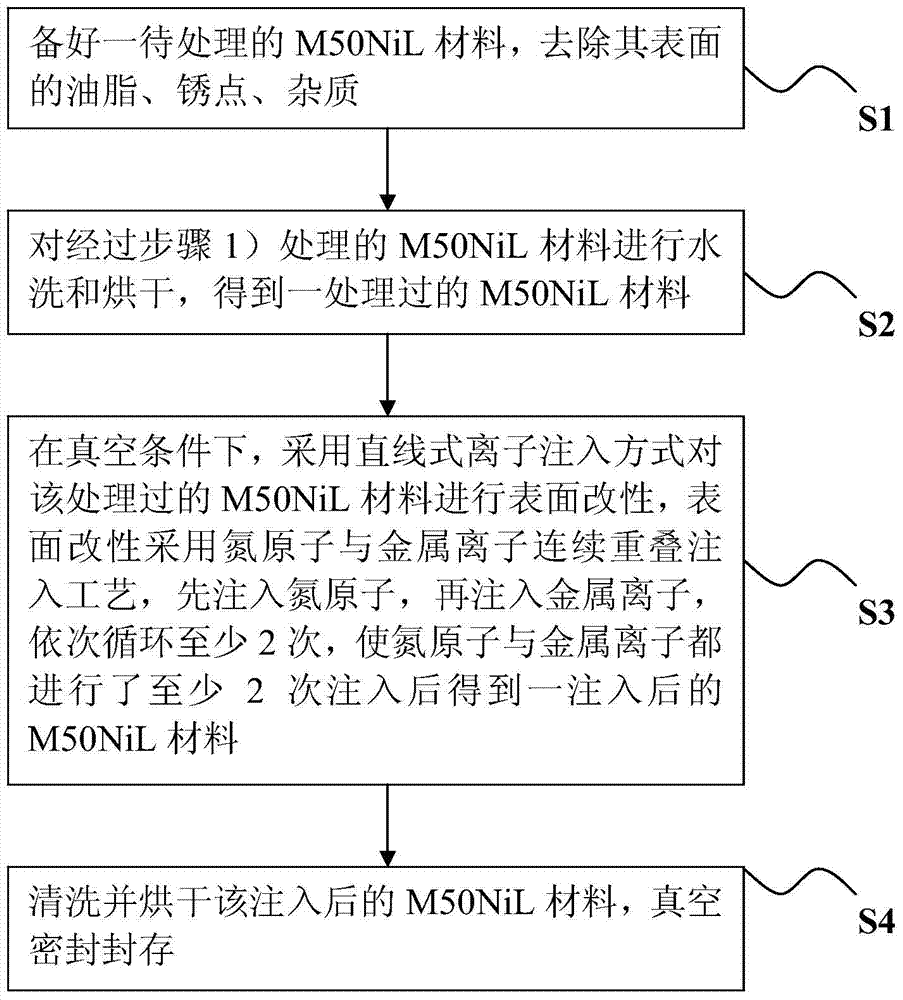

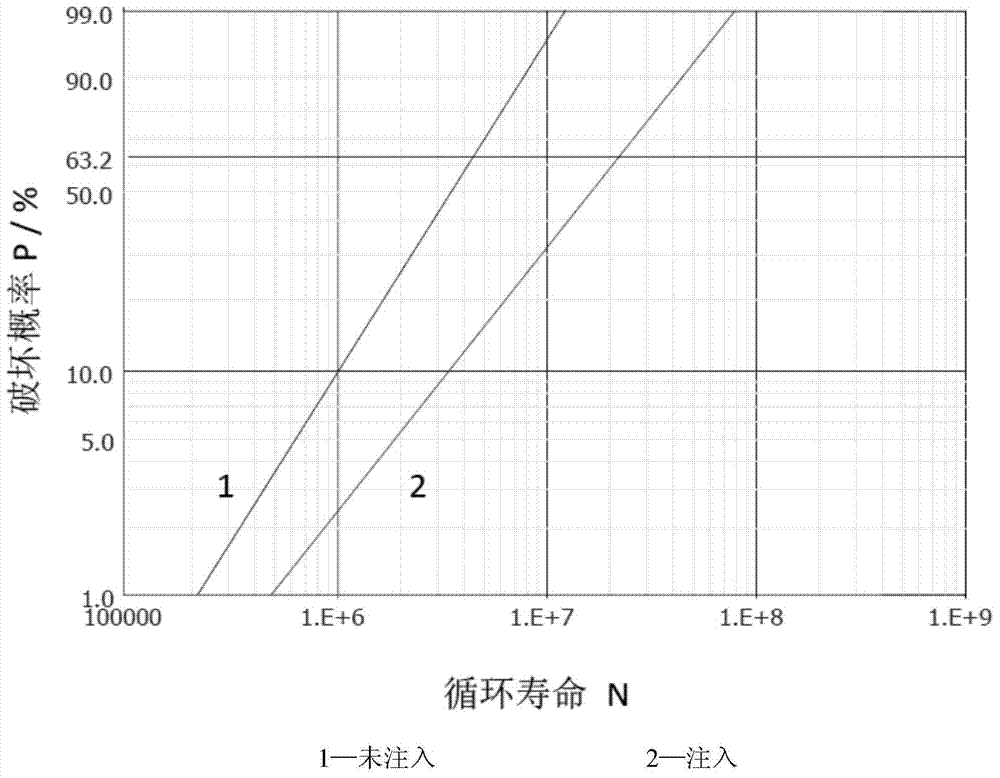

Linear ion implantation surface modification method of M50NiL material

ActiveCN103757598AImprove surface conditionImproved slip characteristicsVacuum evaporation coatingSputtering coatingNitrogenIon implantation

The invention discloses a linear ion implantation surface modification method of an M50NiL material. The method comprises the following steps: carrying out surface modification on M50NiL material by adopting a linear ion implantation mode, carrying out continuous overlapping injection by adopting nitrogen ions and metal ions for surface modification; firstly, injecting the nitrogen ions, then injecting the metal ions, and orderly circulating at least twice, so that the nitrogen ions and the metal ions are injected at least twice. By adopting the linear ion implantation surface modification method of the M50NiL material and the surface-modified M50NiL material disclosed by the invention, the surface of the modified M50NiL material has good contact fatigue resistance.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

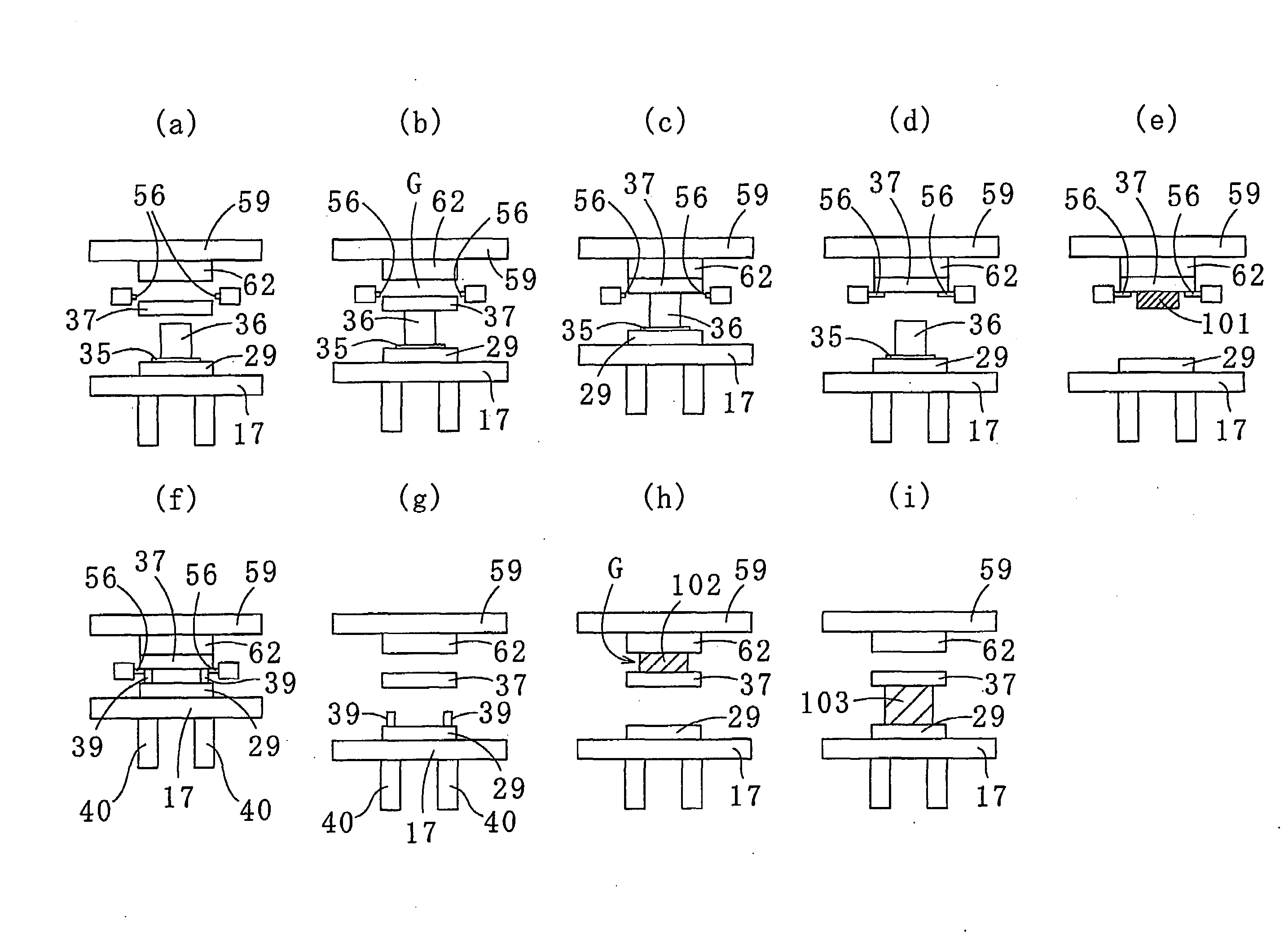

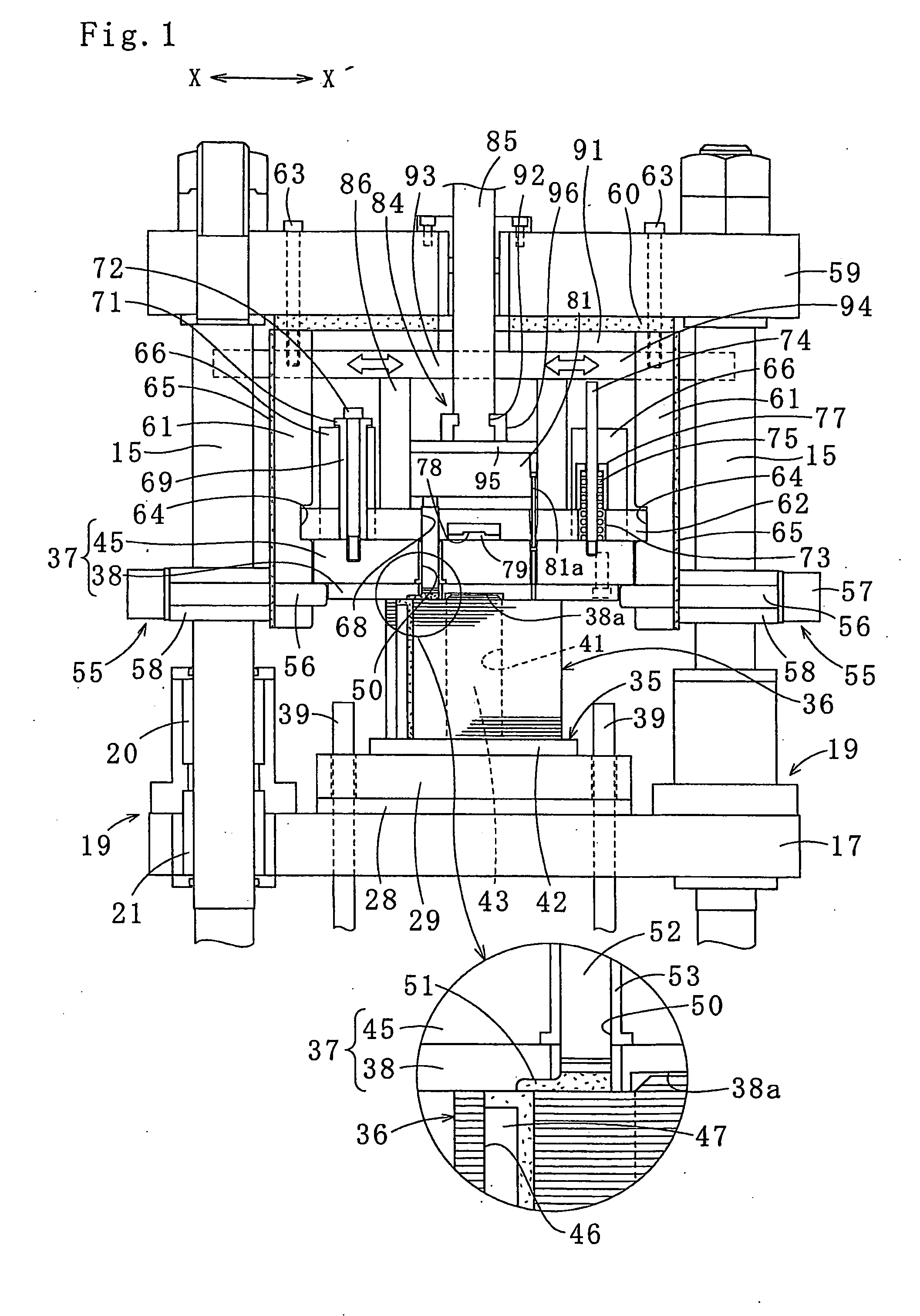

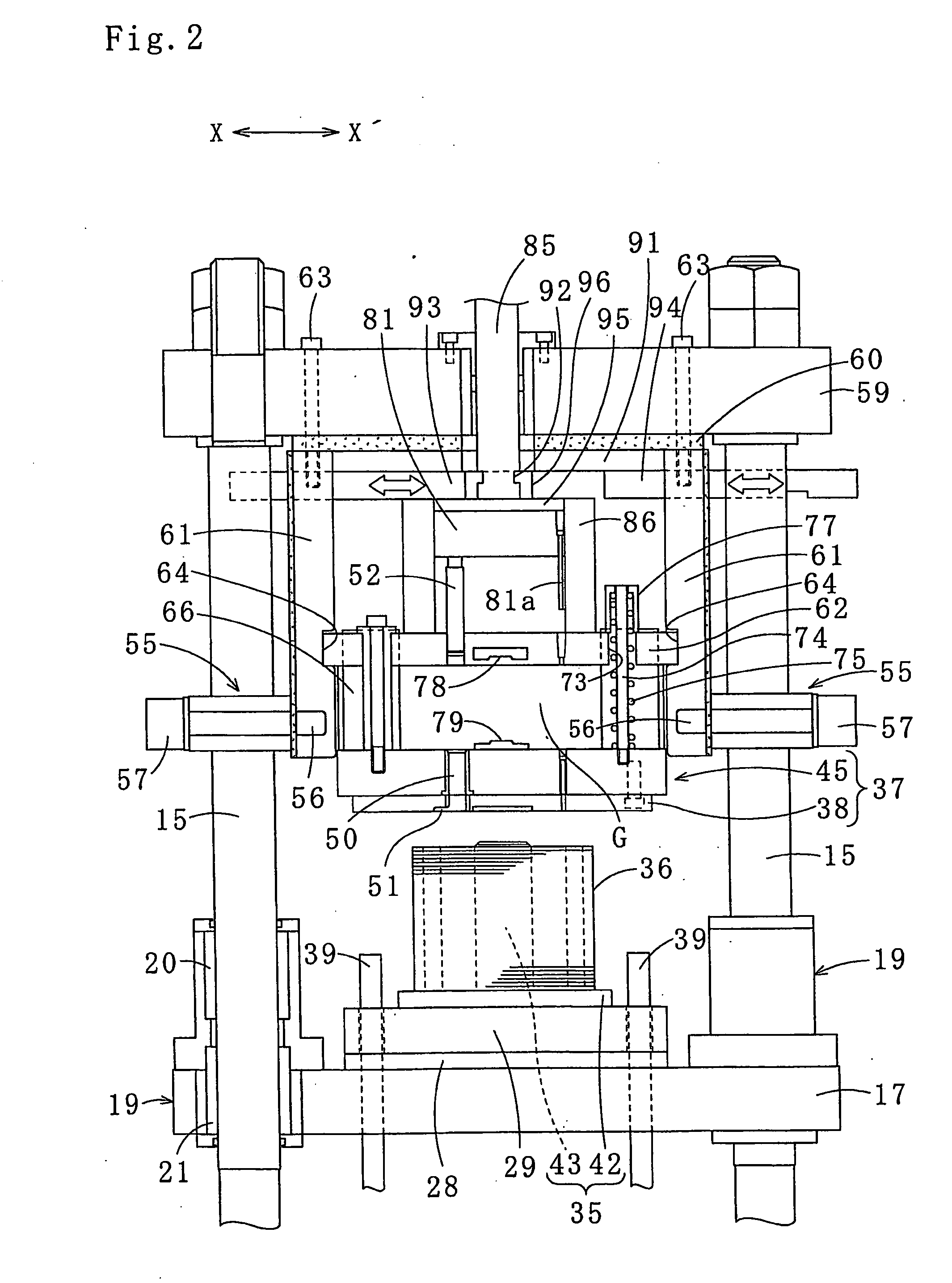

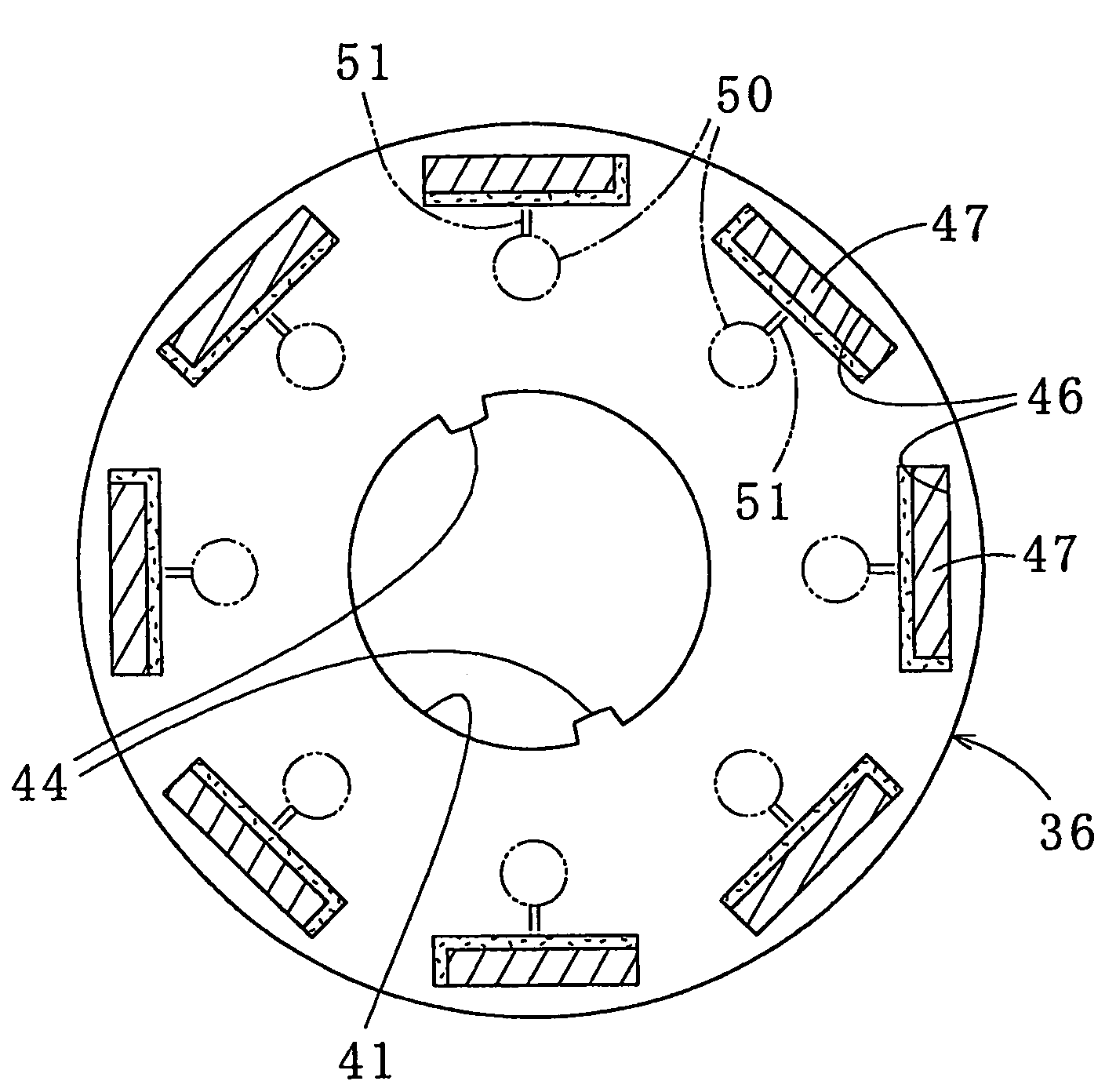

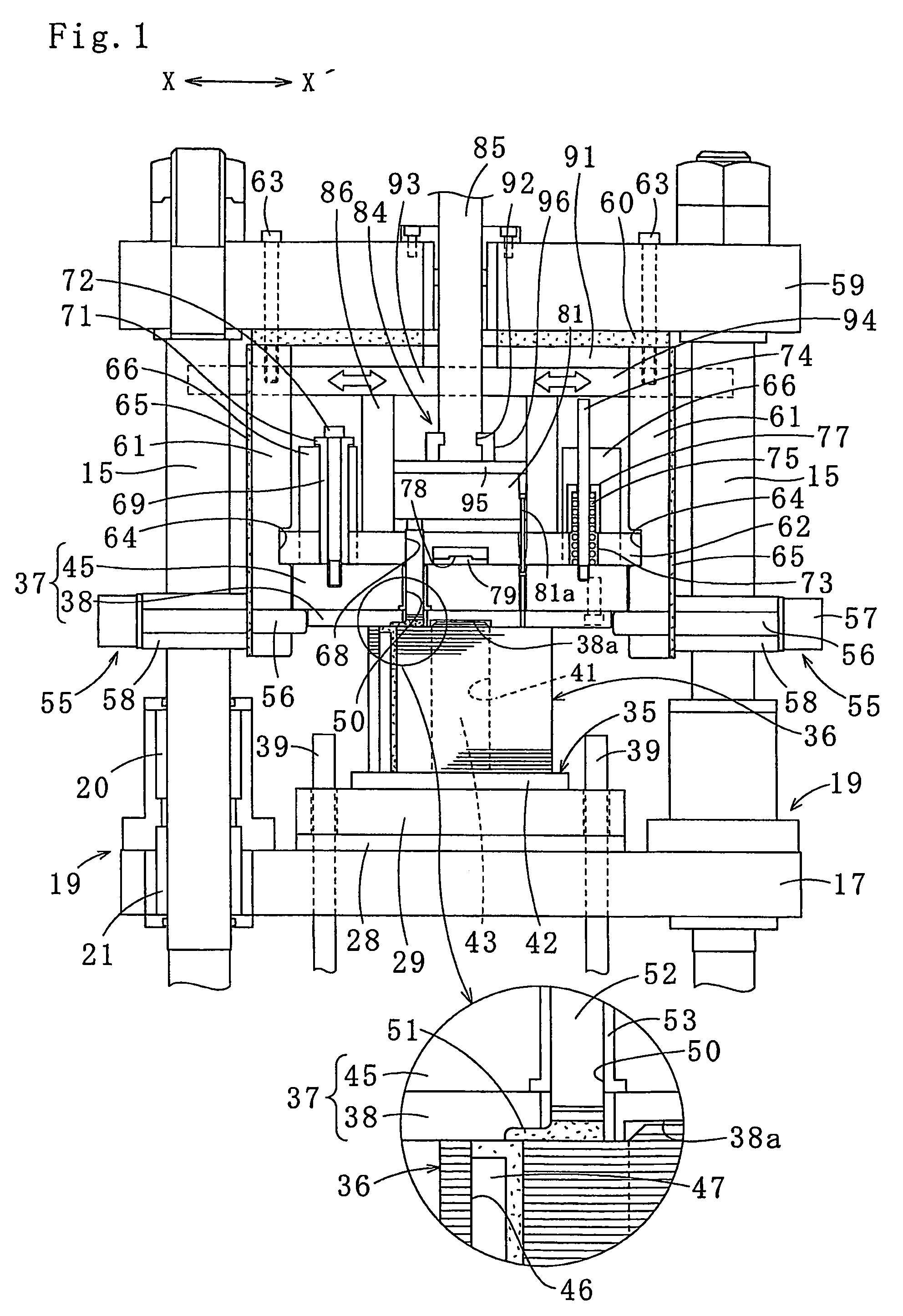

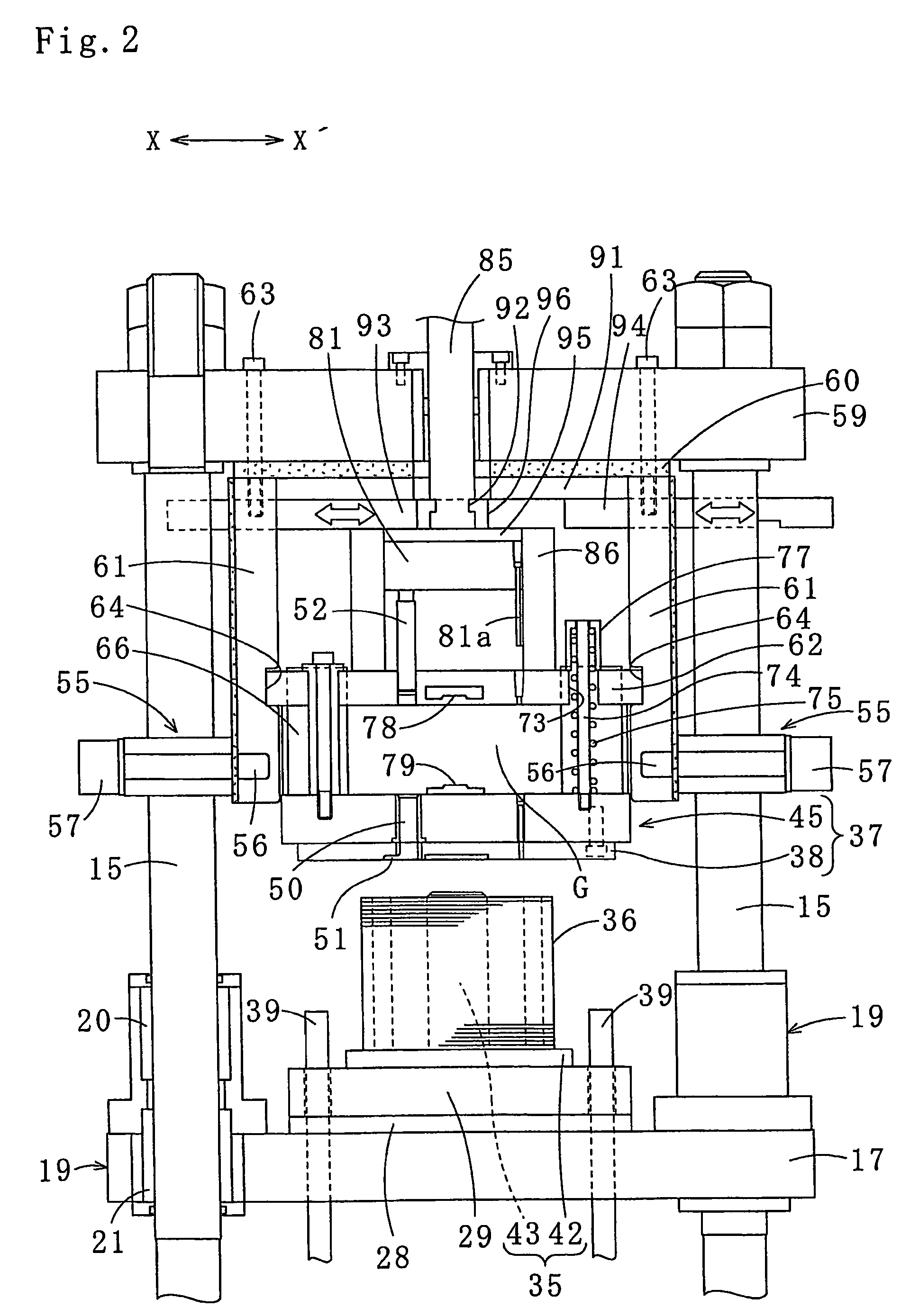

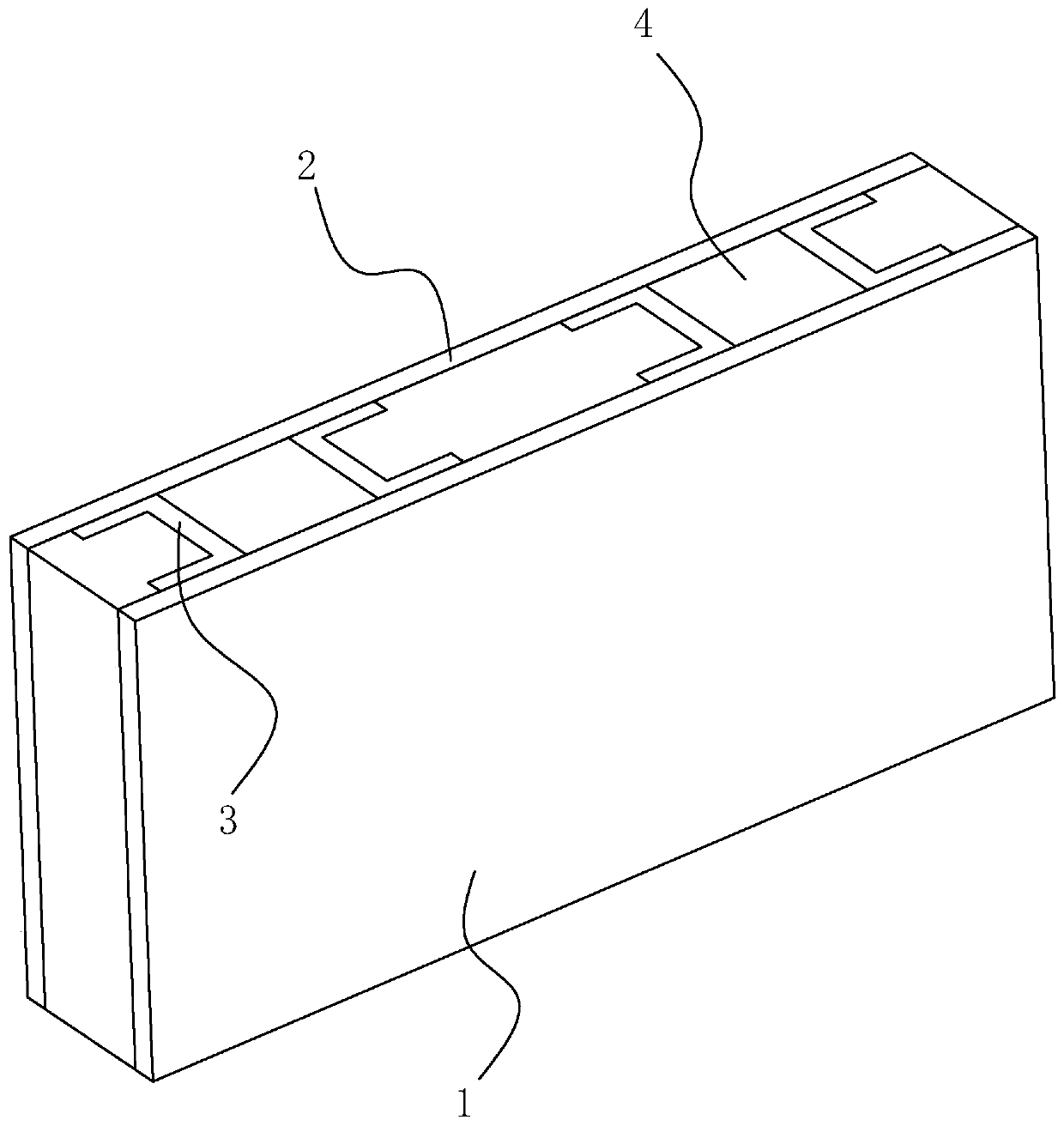

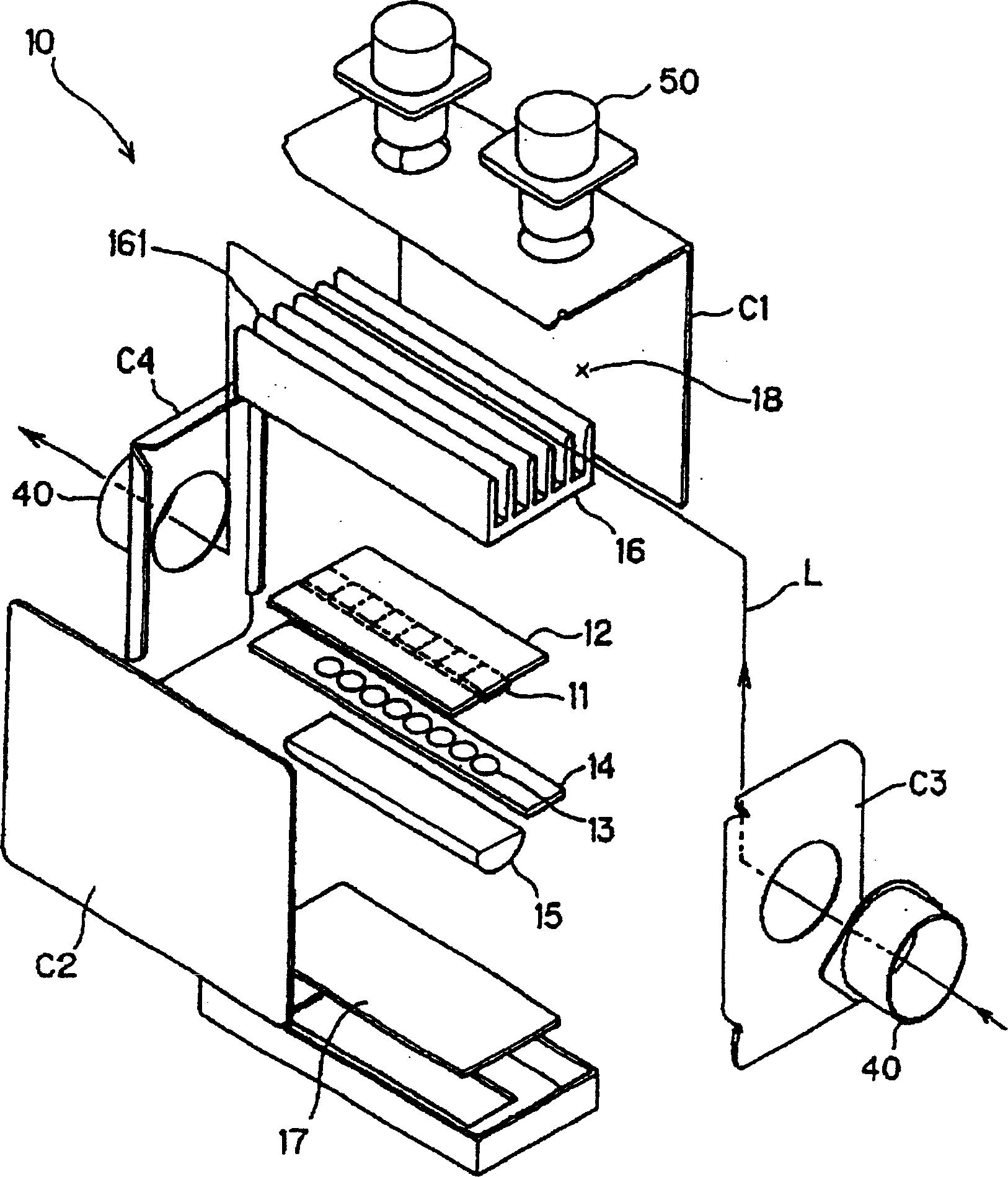

Method of resin sealing permanent magnets in laminated rotor core

ActiveUS7897089B2Easy to cleanEasy to disassembleMagnetic circuitManufacturing stator/rotor bodiesEngineeringPlunger

A laminated rotor core (36) wherein permanent magnets (47) are inserted in respective magnet insertion holes (46) is disposed between and pressed by an upper die (37) and a lower die (29). The upper die (37) has resin reservoir pots (50) provided above the laminated rotor core (36) and at positions corresponding to the respective magnet insertion holes (46). Raw resin material put in the resin reservoir pots (50) is heated by the upper die (37). Subsequently, the resin material in a liquefied state is ejected from the resin reservoir pots (50) by plungers (52) that are inserted and moves vertically in the resin reservoir pots (50) and is directly filled in the magnet insertion holes (46). Consequently, the respective magnet insertion holes (46) are filled with the resin material more evenly and highly reliable products can be supplied at low cost.

Owner:MITSUI HIGH TEC INC

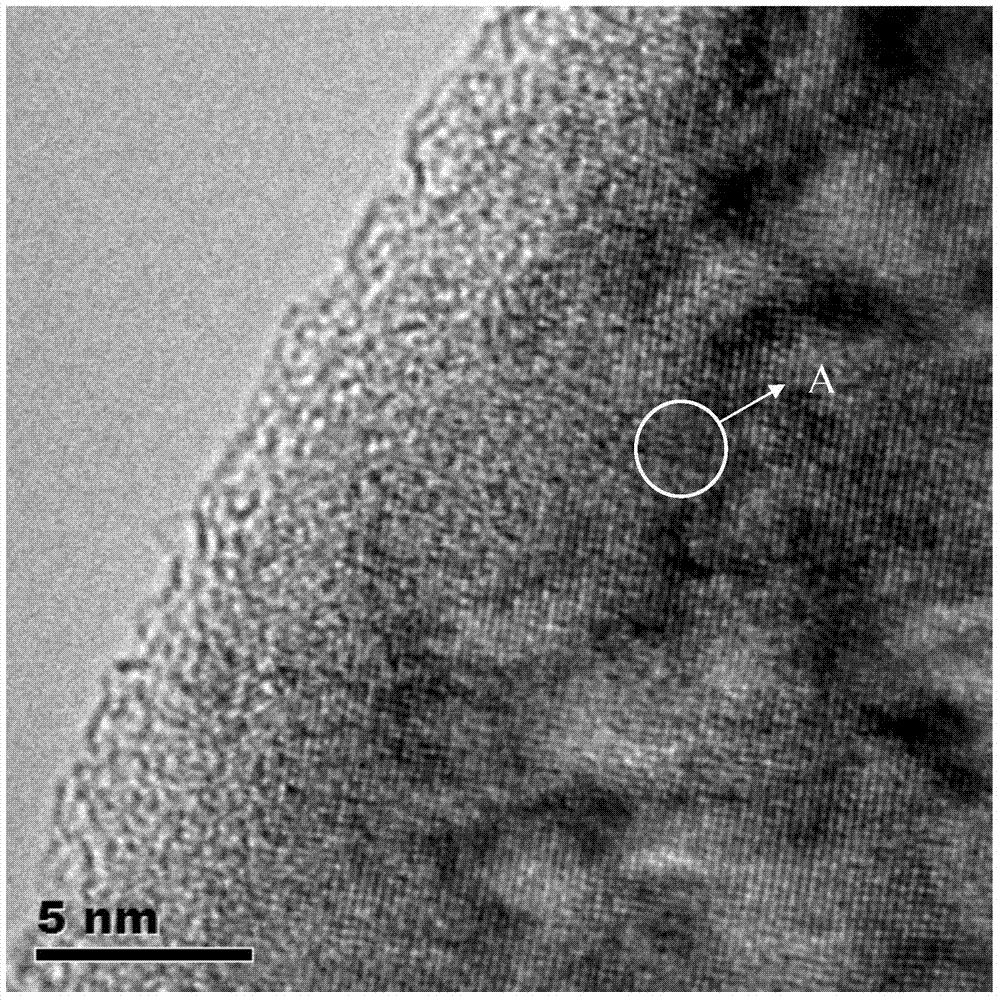

Thermal deformation strengthening method of rare-earth magnesium alloy

The invention provides a thermal deformation strengthening method of a rare-earth magnesium alloy, relating to the fields of metal material formation and processing. The method comprises the following steps: carrying out homogenizing treatment on an ingot blank, which is prepared by metal mold gravity casting, at 525 DEG C for 10-24 hours, cooling with water, and removing the shell; preheating the shelled ingot blank at 400-500 DEG C for 0.5-2 hours, and carrying out extrusion twice according to an extrusion ratio of (5-30):1 at the extrusion speed of 0.1-10 m / min in a forward extrusion mode, wherein the temperatures of the extrusion mold and the extrusion cylinder are kept at 380-420 DEG C in the extrusion process; and holding the extruded rare-earth magnesium alloy at 450-560 DEG C for 10-24 hours, carrying out water quenching solution treatment, and holding at 180-250 DEG C for 10-45 hours to perform aging heat treatment. The method is simple and easy to control, can produce difficult-to-form metal materials, can implement continuous large-scale production, effectively lowers the production cost, and can greatly enhance the mechanical properties of the rare-earth magnesium alloy.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

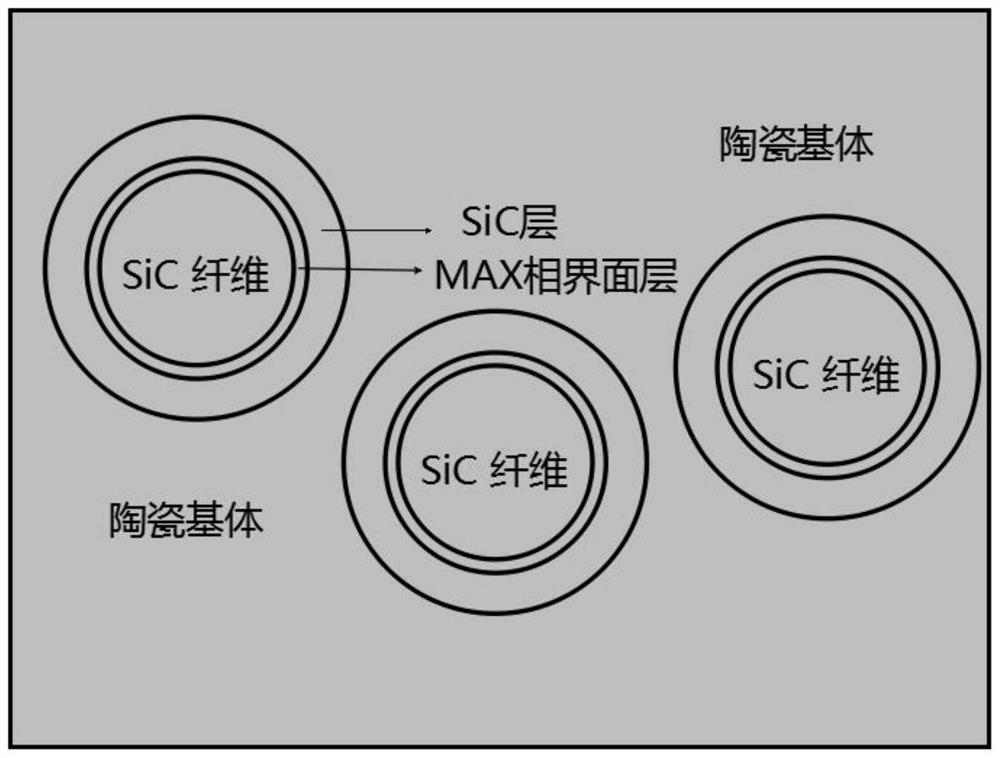

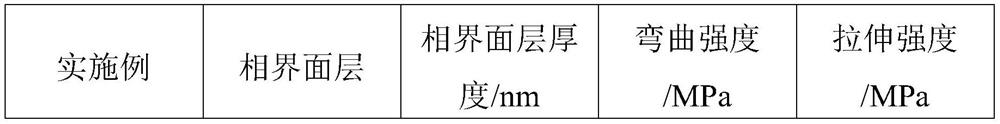

Ti3SiC2MAX phase interface layer modified SiC/SiC composite material and preparation method thereof

The invention relates to a preparation method of a Ti3SiC2 MAX phase interface layer modified SiC / SiC composite material, and belongs to the field of aerospace material preparation processes. A chemical vapor deposition method is adopted, a Ti3SiC2 MAX phase interface layer is deposited on the fiber surface in a SiC fiber prefabricated body, and the thickness is 200-1200 nm. And then, a SiC interface layer is deposited on the outer side of the Ti3SiC2 MAX phase interface layer through a chemical vapor deposition method, and the Ti3SiC2 MAX phase interface layer is completely coated with the SiC interface layer with the thickness ranging from 3 micrometers to 5 micrometers. Then a proper resin precursor for repeated dipping, curing and cracking treatment is selected to obtain a green body containing a porous carbon matrix; and finally, liquid silicon melting reaction is performed in a high-temperature infiltration furnace to obtain the SiC / SiC composite material. The Ti3SiC2 MAX phase has excellent chemical stability, heat-conducting property and friction property so that the performance of the SiC / SiC composite material under a high-temperature condition can be effectively improved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Imaging lens

ActiveUS8531784B2Small and high-performanceCorrected spherical aberrationLensOptical axisConditional expression

Owner:TOKYO VISIONARY OPTICS CO LTD

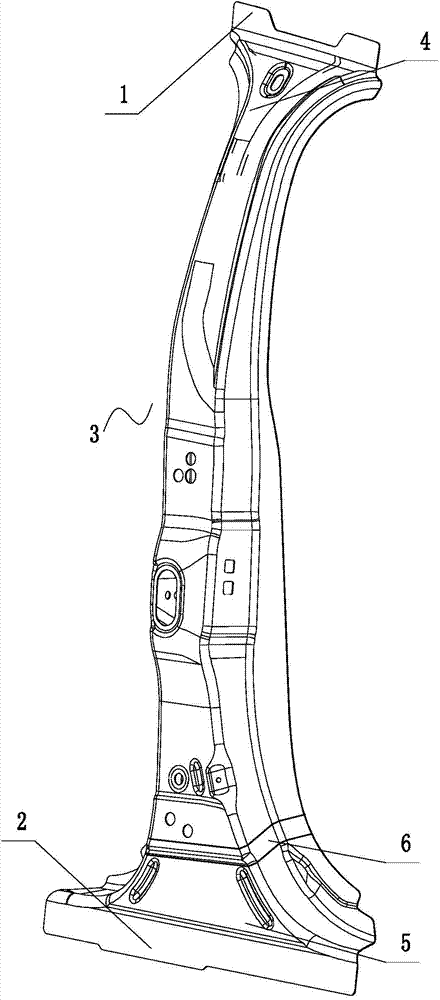

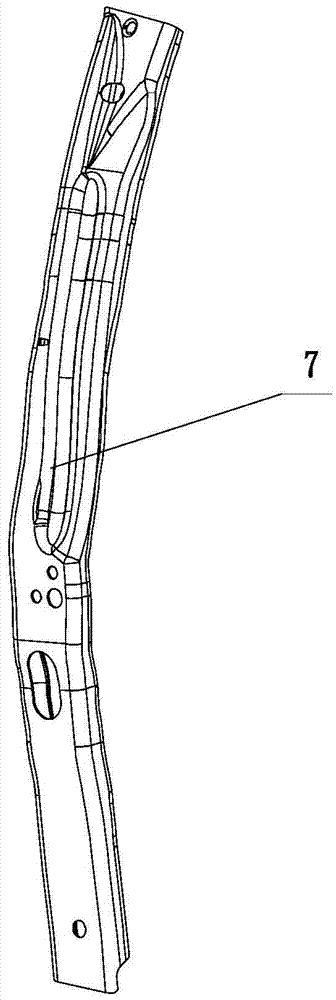

B column on vehicle and manufacturing method

The invention relates to a B column on a vehicle and a manufacturing method. The B column comprises a B column body, an upper fixed portion fixed to a roof is arranged at the top of the B column body, and a lower fixed portion fixed to a threshold is arranged at the bottom of the B column body. The B column is characterized in that a hard area is arranged on the upper portion of the B column body, a soft area is arranged on the lower portion of the B column body, a transition area is arranged between the hard area and the soft area, a reinforcing pipe is arranged on the hard area, the hard area is a martensitic structure prepared by an ultrahigh-strength steel hot forming process, the strength of the martensitic structure is 1300-1500MPa, the soft area is a ferrite and pearlite structure or bainite structure prepared by slow cooling in an ultrahigh-strength steel hot forming process, the strength of the ferrite and pearlite structure or bainite structure is 500-700MPa, the reinforcing pipe is a hollow pipe prepared by a hydraulic forming process, and the wall thickness of the reinforcing pipe is 1.8mm+ / -30%. The sectional design of the reinforcing pipe can be flexibly changed according to the shape of the B column, so that the load of each section is more uniform, and the requirement of the vehicle for light weight is met.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

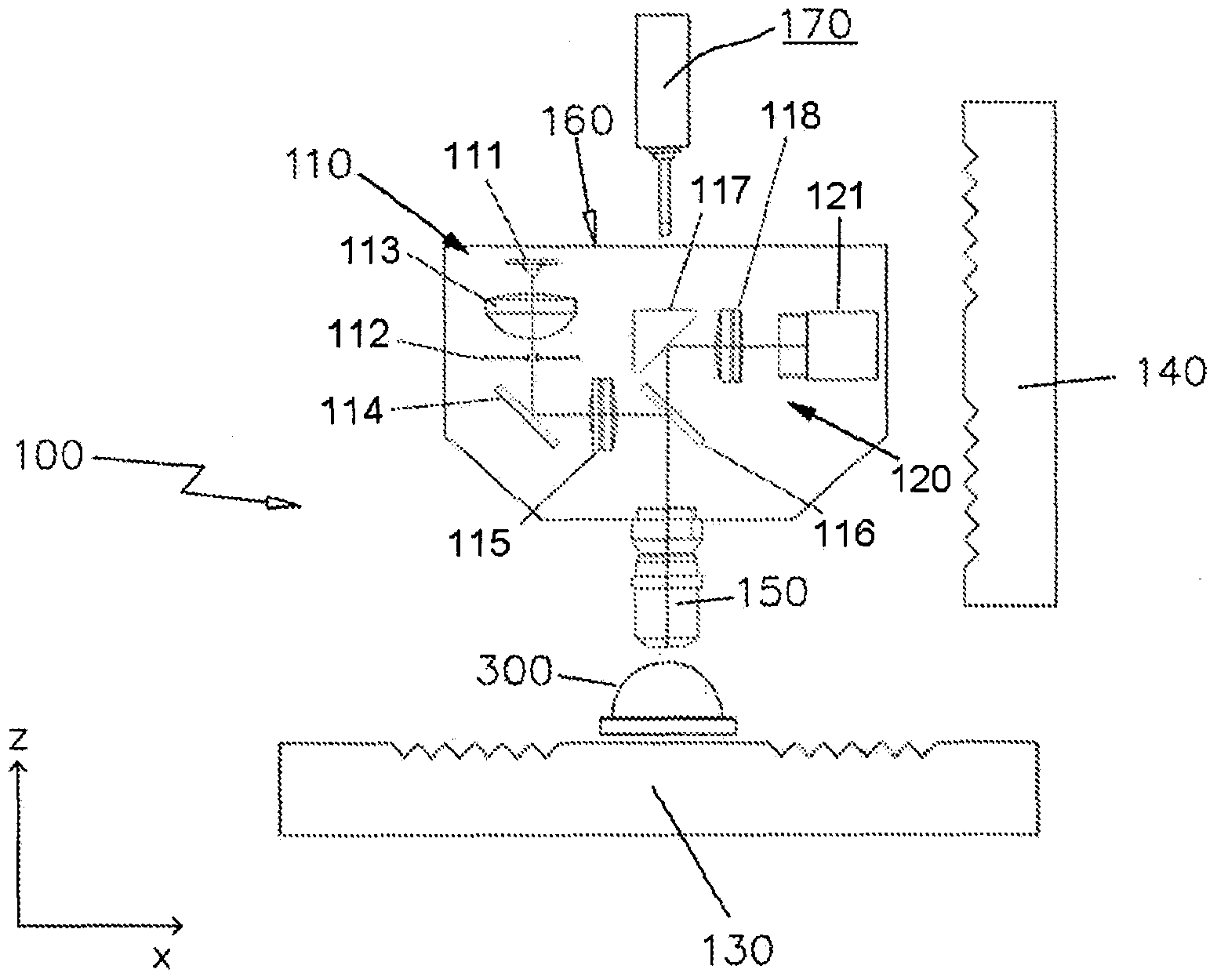

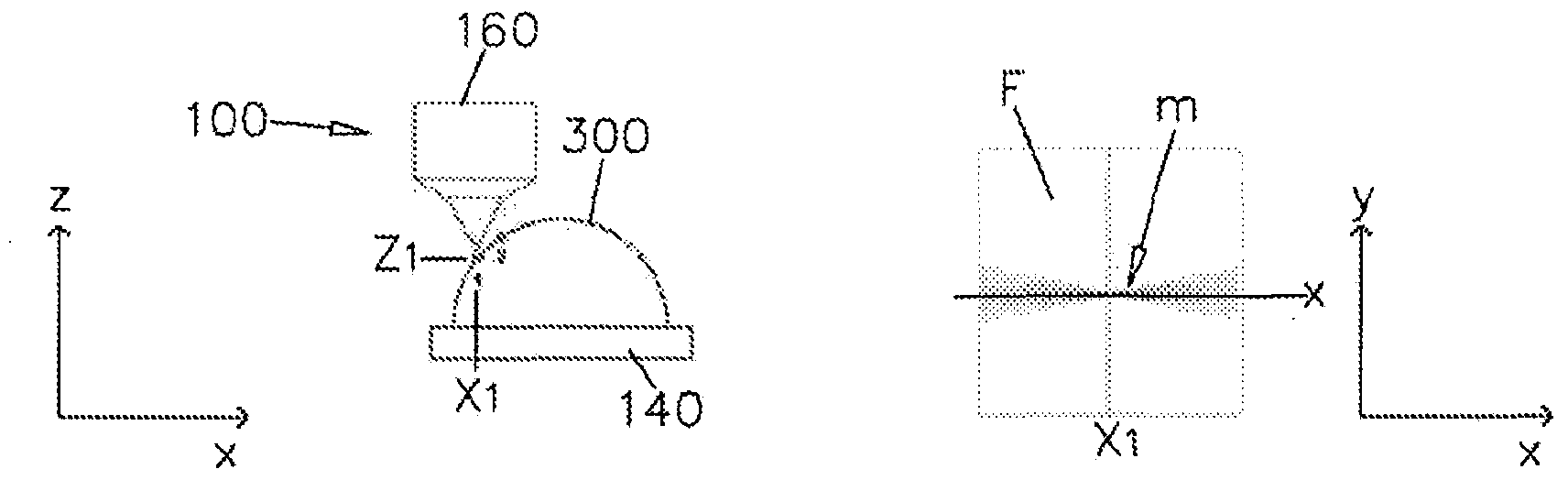

Method and device for non-contact measuring surfaces

ActiveCN103547883AHigh depth partitioning capabilityAccurately determineMicroscopesUsing optical meansPhysicsVertical axis

A slit (m) is projected onto an object surface in which reference point (X1) is in a horizontal axis (x) closest to best in focus position (P). One image of a field of view area (F) is acquired after reflection of light comprising said reference point (X1). Position (Z1) of the object (300) in a vertical axis (z) is determined. Images of respective field of view areas (F) are acquired after reflection of light having reference points (X2, X3... Xn) by simultaneously moving the object (300) along axis (z) to maintain reference points (X2, X3... Xn) closest to best in focus position (P). Positions (Z2, Z3... Zn) in which images were acquired are determined. The best in focus position (P) along horizontal axis (x) is determined for each image. A correction differential (?1, ?2...?n) between best in focus position (P) and reference points (X1, X2.. Xn) is calculated.

Owner:UNIV POLITECNICA DE CATALUNYA

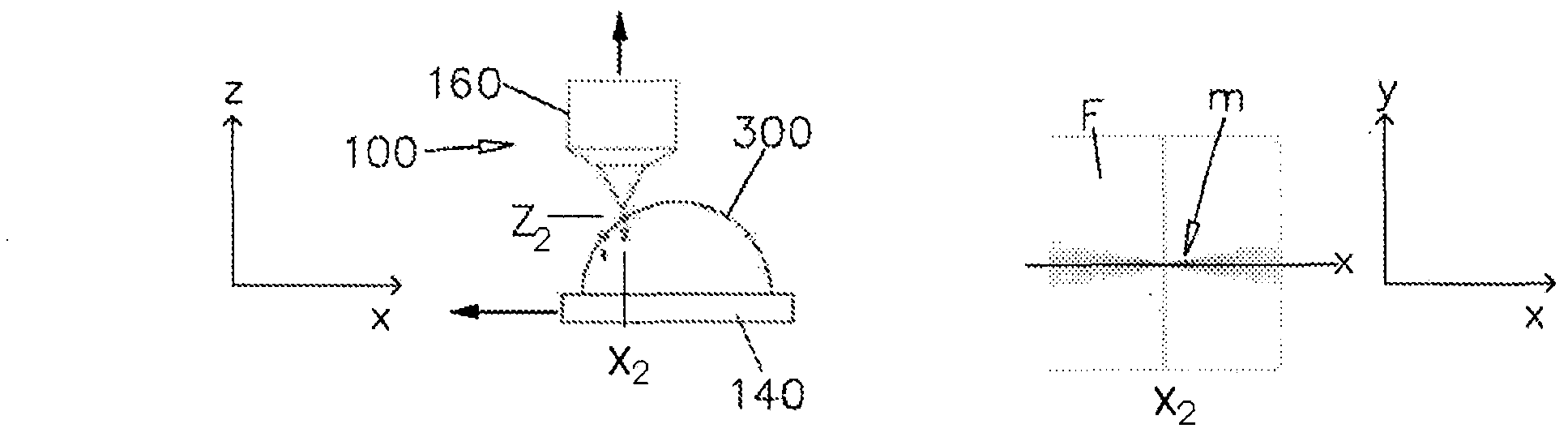

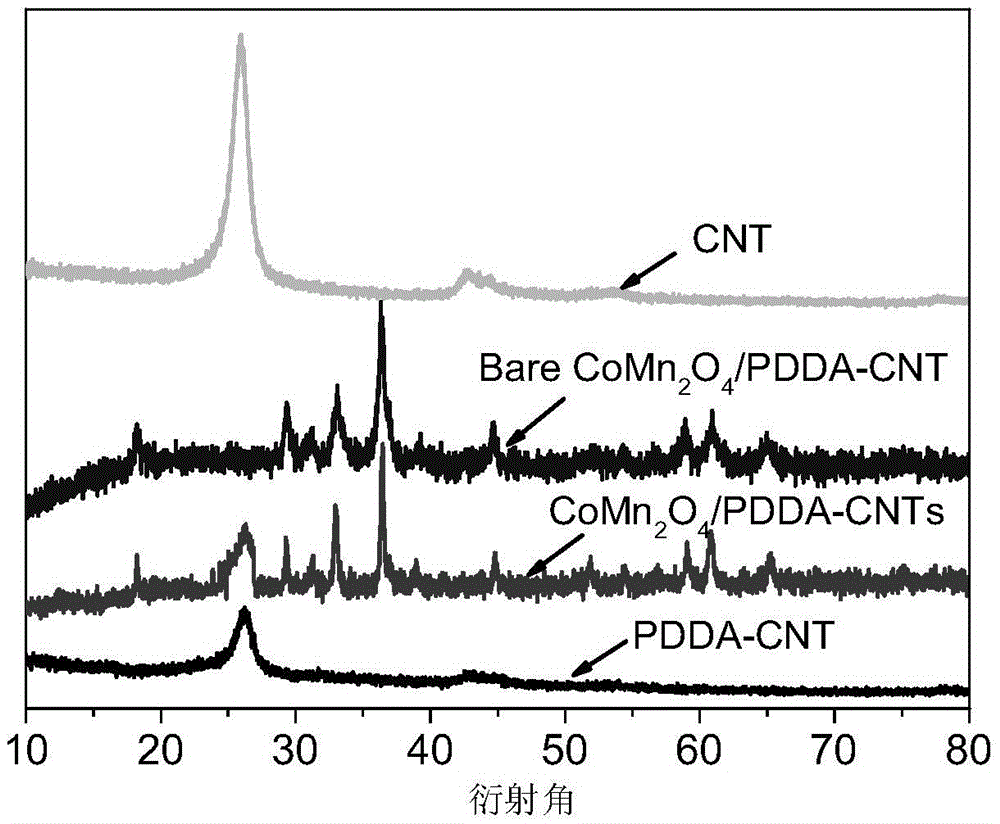

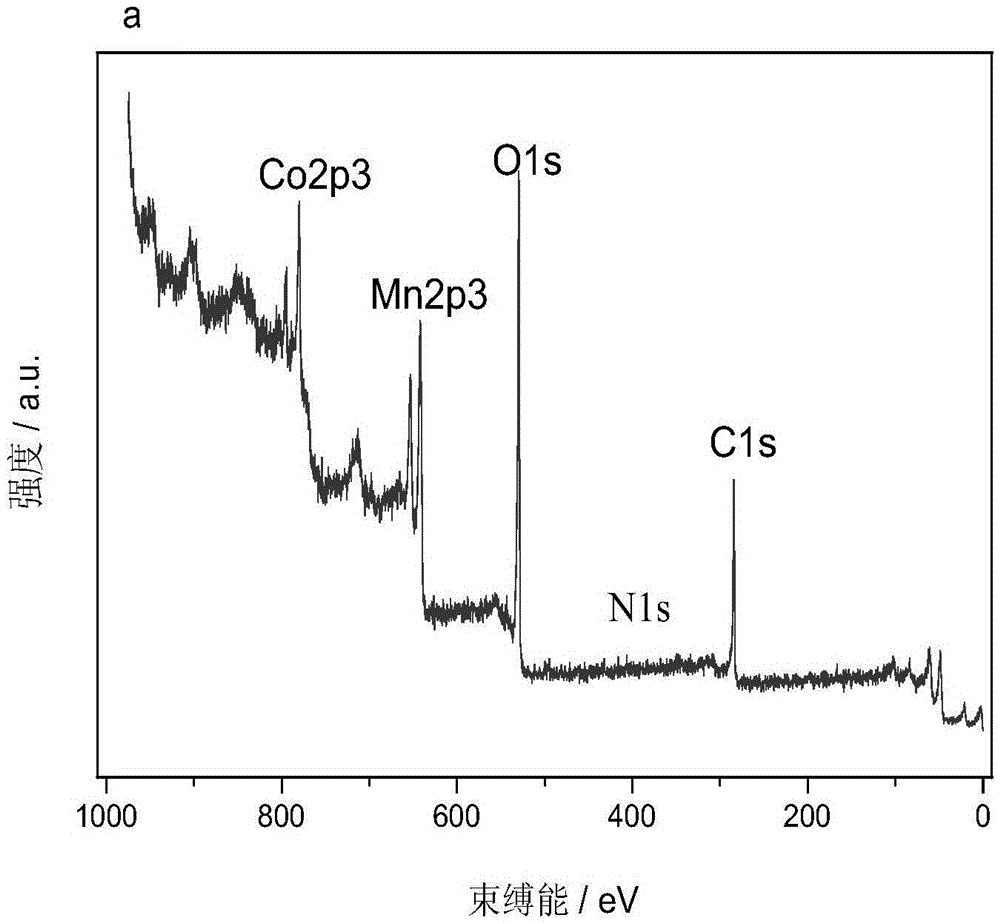

Modified cobalt-manganese-oxide-doped carbon nanotube catalyst as well as preparation method and application thereof

InactiveCN105552391AImprove solubility and dispersibilityImprove solubilityCell electrodesIonManganese oxide

The invention discloses a modified cobalt-manganese-oxide-doped carbon nanotube catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: (1), putting carbon nanotubes in a PDDA aqueous solution and carrying out ultrasonic dispersion, thereby obtaining a homogeneous solution; (2), firstly dispersing the obtained homogeneous solution in deionized water, adding a dimethylformamide solution and carrying out ultrasonic dispersion; then, dissolving Co2+ and Mn2+ in the mixed solution according to a molar ratio of 1 : (2-2.5), and slowly stirring till obtaining black precipitate; (3), washing the black precipitate by utilizing the deionized water, putting the washed precipitate in a polytetrafluoroethylene high-pressure reactor, heating for 8-10 hours at 160-180 DEG C, and finally drying the processed black precipitate, thereby obtaining the modified cobalt-manganese-oxide-doped carbon nanotube catalyst. The modified cobalt-manganese-oxide-doped carbon nanotube catalyst can successfully starts MFC and shortens a starting period of the MFC; compared with a comparison group Pt / C, the modified cobalt-manganese-oxide-doped carbon nanotube catalyst has better performance, and following the reduction of CoMn2O4 load, the performance of the MFC is also gradually improved.

Owner:SOUTH CHINA UNIV OF TECH

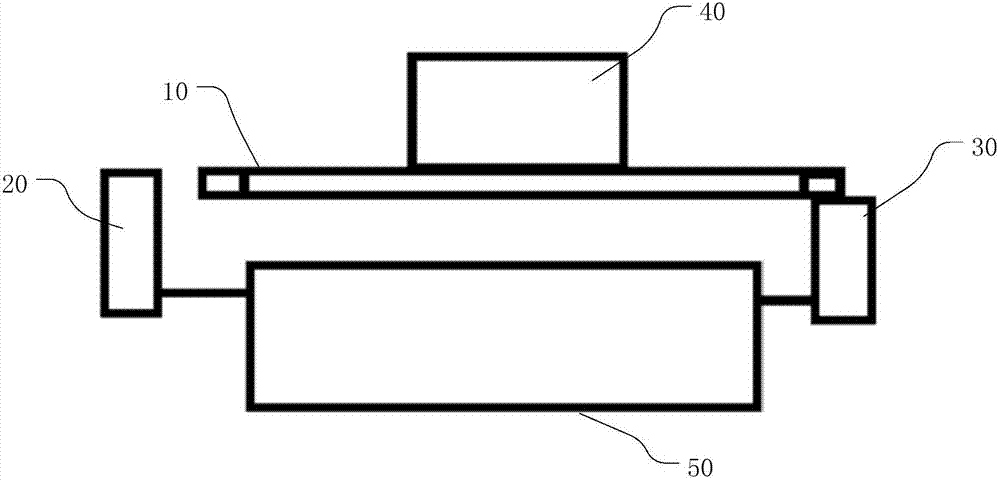

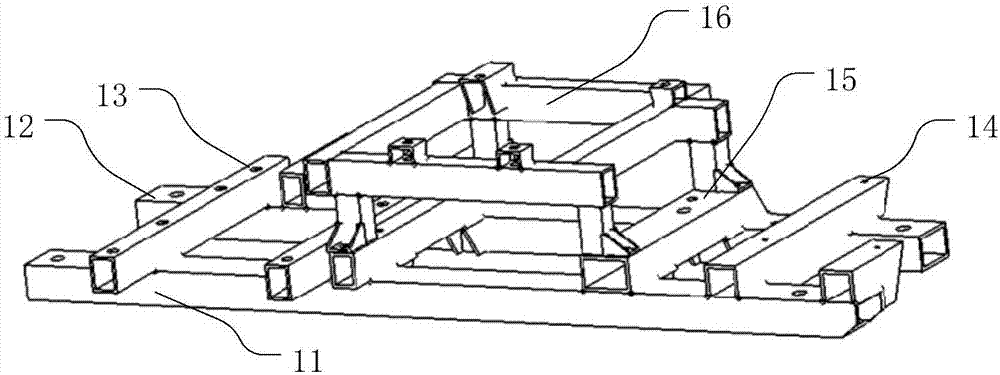

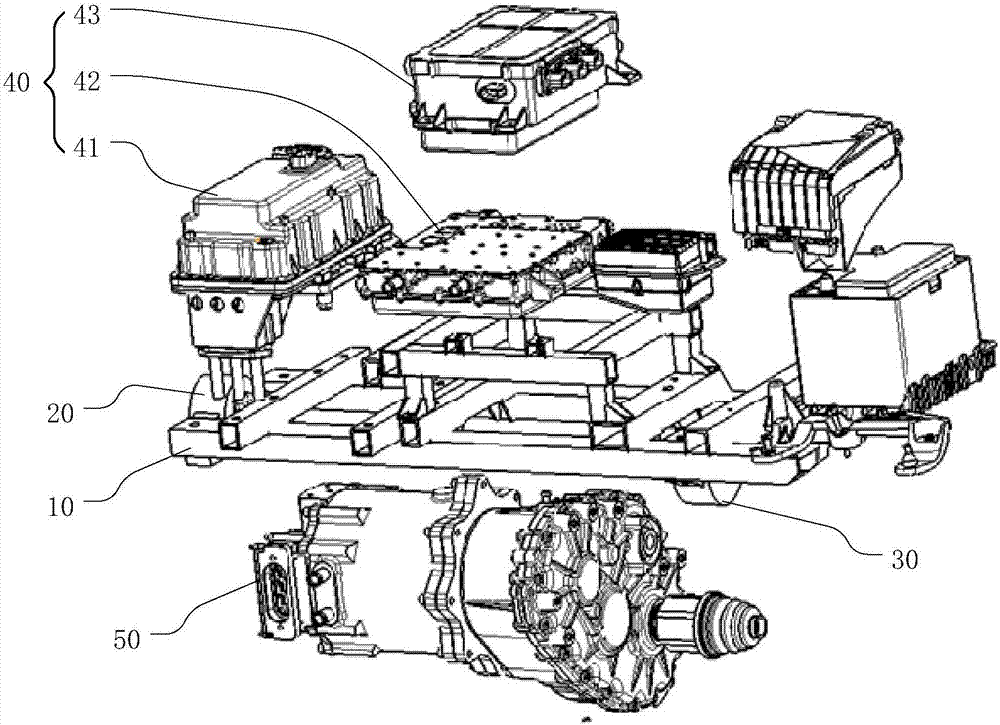

Support suspension system and electric car

InactiveCN106864231AWeakReduce adverse effectsElectric propulsion mountingUnderstructuresCurrent electricElectric machine

The embodiment of the invention provides a support suspension system and an electric car, and is applied to carrying high-voltage electric components and a drive motor of the electric car. The system comprises a motor left suspension mount, a motor right suspension mount and an electrical bracket. The two ends of the electrical bracket are respectively fixed on a left longitudinal beam and a right longitudinal beam; the high-voltage electrical component is fixed on the upper part of the electrical bracket; the motor left suspension mount is fixed on the left longitudinal beam; the motor right suspension mount is fixed on the fixed end of the electrical bracket with the right longitudinal beam; the two ends of the drive motor are respectively fixed on the motor left suspension mount and the motor right suspension mount and are located below the electrical bracket. When a collision occurs, part of the force spread through the motor left suspension mount, the drive motor and the motor right suspension mounts, the force borne by the drive motor decreases the adverse effects on high-voltage electrical components, so that in the event of collisions the high-voltage electrical components can be well protected, so as to resolve the issue of poor safety of the high-voltage electrical components in current electric cars when in collisions.

Owner:FAFA AUTOMOBILE (CHINA) CO LTD

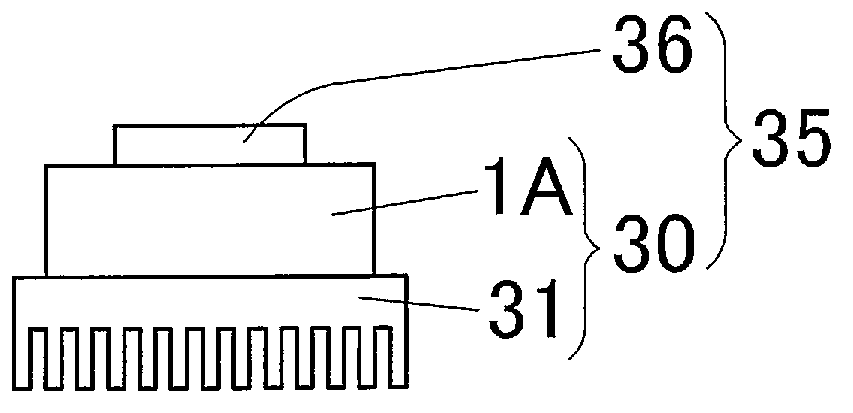

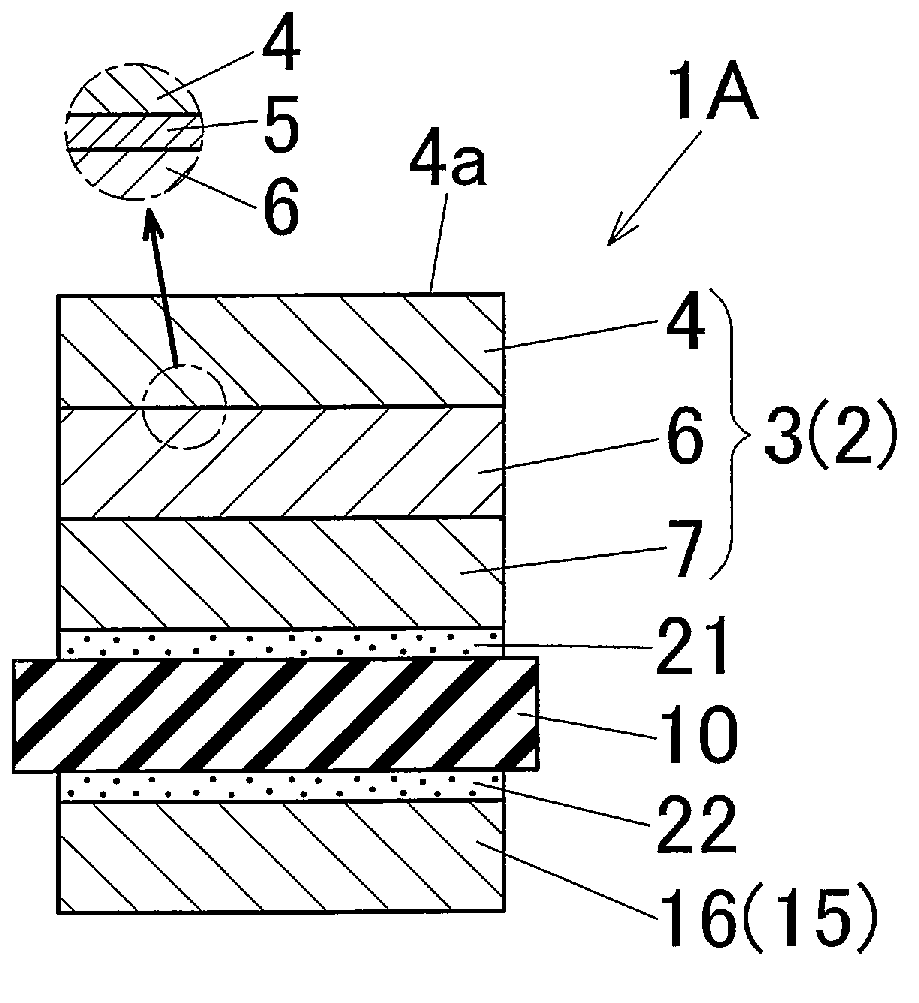

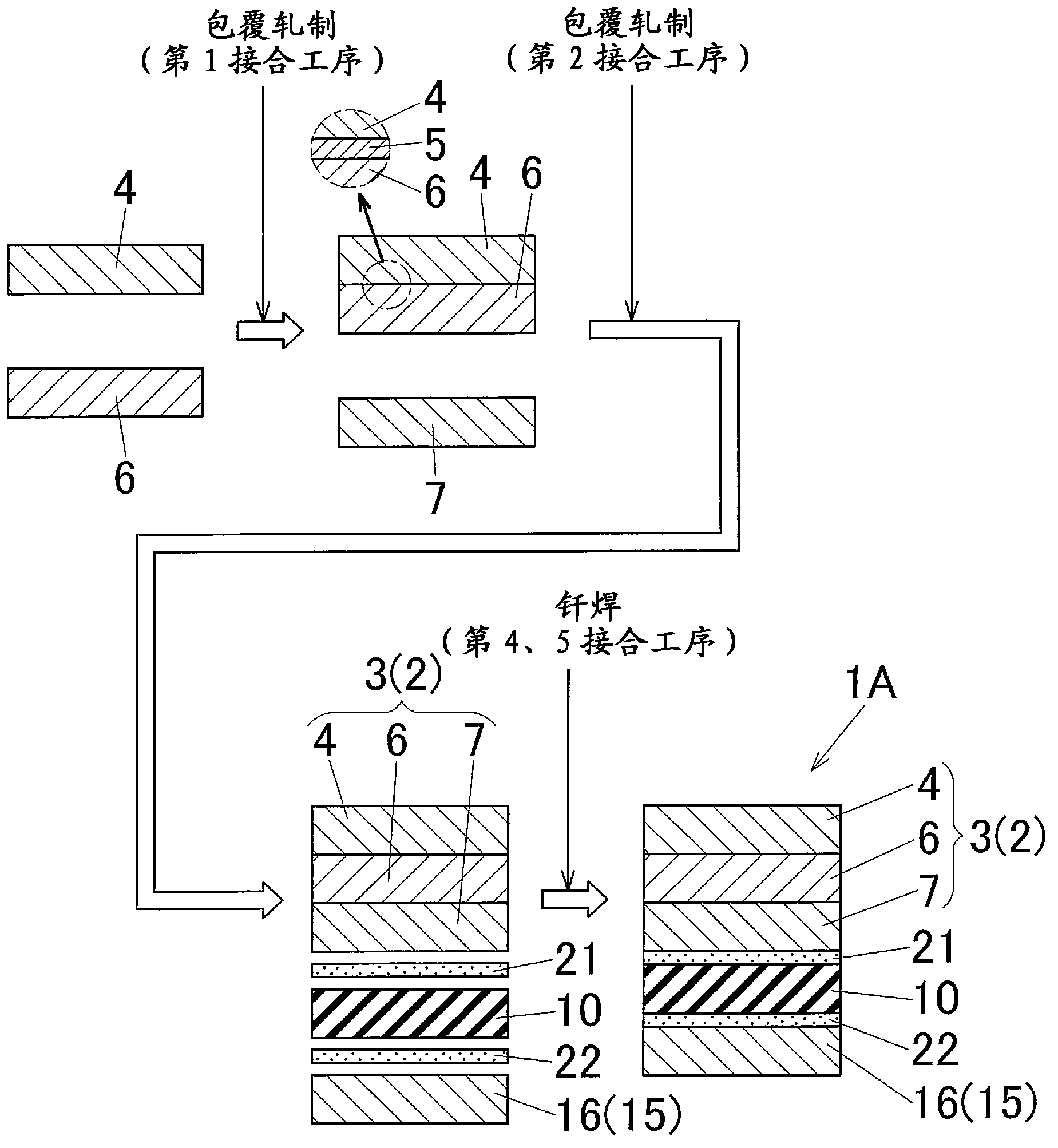

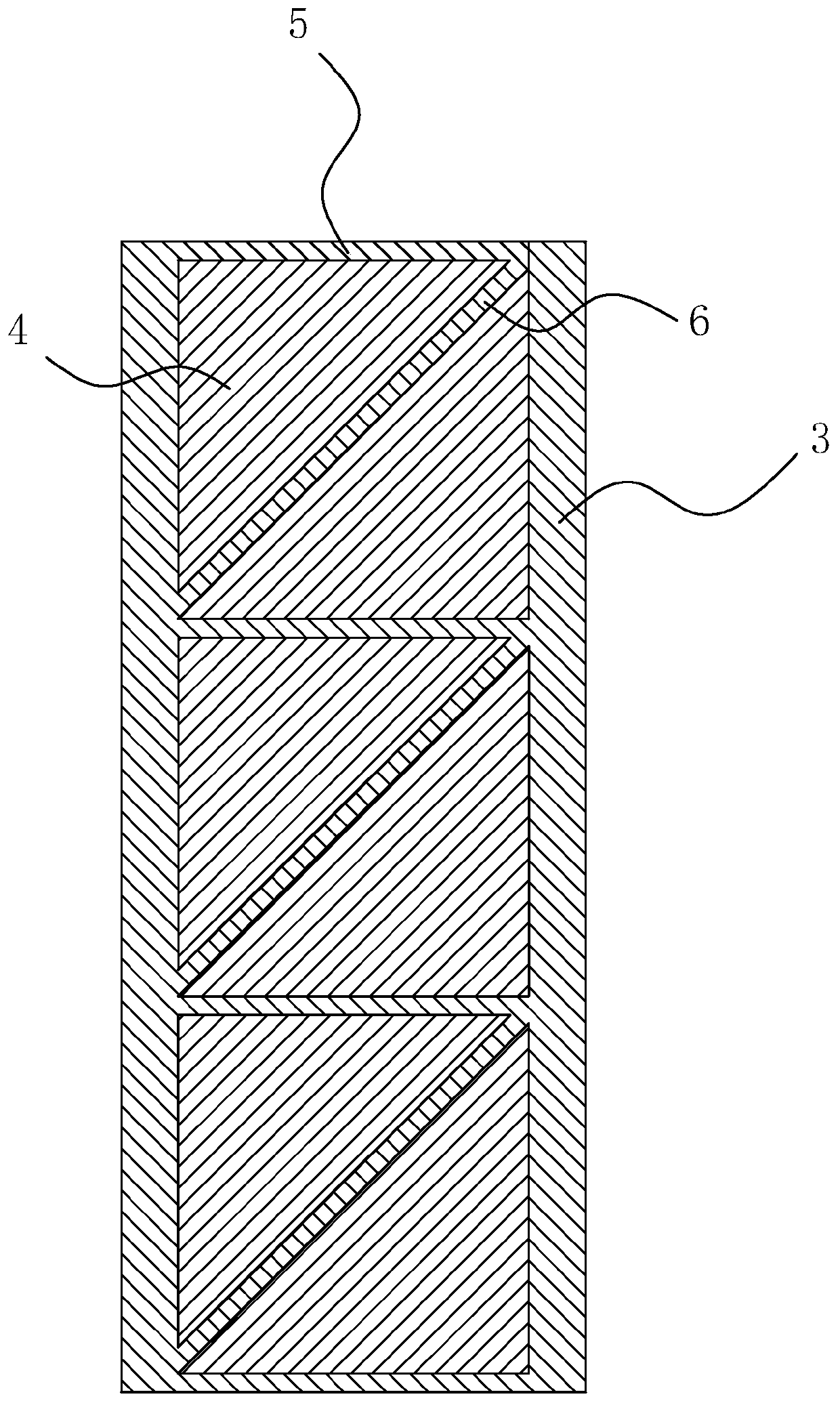

Cladding material for insulated substrates

InactiveCN103210488ARelieve heat stressWeakSemiconductor/solid-state device detailsSolid-state devicesMetallurgyAlloy

A cladding material (1A) is provided with: a Ni layer (4) made from Ni or a Ni alloy; a Ti layer (6) formed from Ti or a Ti alloy and positioned on one side of the Ni layer (4); and a first Al layer (7) formed from Al or Al alloy and positioned on the other side of the Ti layer (6) to which the Ni layer (4) is positioned. The Ni layer (4) and Ti layer (6) are joined by cladding rolling. A Ni-Ti superelastic layer (5) formed by alloying at least the Ni of the constituent elements of the Ni layer (3) and at least the Ti of the constituent elements of the Ti layer (6) is interposed between the Ni layer (4) and the Ti layer (6). The Ti layer (6) and the first Al layer (7) adjoin one another and are joined by cladding rolling.

Owner:SHOWA DENKO KK

Apparatus for fluorescence observation

InactiveUS20080296511A1WeakHigh fluorescence intensitySurgeryEndoscopesAbsorption filterFluorescence

An apparatus for fluorescence observation includes an excitation filter which transmits only exciting light of an specific wavelength among illumination light, and an absorption filter which blocks the exciting light and transmits only fluorescence generated from a specimen when the exciting light is irradiated to the specimen. Here, an interval of a half-value wavelength at a long-wavelength side of the excitation filter and a half-value wavelength at a short-wavelength side of the absorption filter is in a width between 1 nm to 6 nm, and change of the half-value wavelength of the excitation filter and the absorption filter when humidity changes from 10% to 95%, is 0.5 nm or less.

Owner:OLYMPUS CORP

Washing method of high-calcium phosphorous-removed silicon

InactiveCN102602935BEasy to erodeReduce generationSilicon compoundsPhysical chemistryCombustible gas

The invention discloses a washing method of high-calcium phosphorous-removed silicon. According to the invention, high-calcium metal silicon is crushed into particles; the particles are subject to grinding and sieving, such that powder is obtained; the powder is sampled, and the calcium content is determined; the powder is soaked by using a hydrochloric acid solution; the mixture is stirred, and is subject to solid-liquid separation; the mixture is washed by using deionized water, such that primary mixed powder is obtained; the primary mixed powder is soaked by using an alkali solution; the mixture is stirred, and is subject to solid-liquid separation; the mixture is washed by using deionized water, such that secondary mixed powder is obtained; the secondary mixed powder is soaked by using a mixed acid solution of sulfuric acid and hydrofluoric acid; the mixture is stirred, and is subject to solid-liquid separation; the mixture is washed by using deionized water, such that tertiary mixed powder is obtained; the tertiary mixed powder is soaked by using a mixed acid solution of hydrochloric acid and hydrofluoric acid; the mixture is stirred, and is subject to solid-liquid separation; the mixture is washed by using deionized water, such that quaternary mixed powder is obtained; the quaternary mixed powder is subject to vacuum drying, such that low-phosphorous silicon powder is obtained. With the washing method provided by the invention, on a basis that impurities such as calcium and phosphorous are effectively removed, the generations of flammable and combustible gases are reduced, such that production can be safely preceded.

Owner:刘荣隆

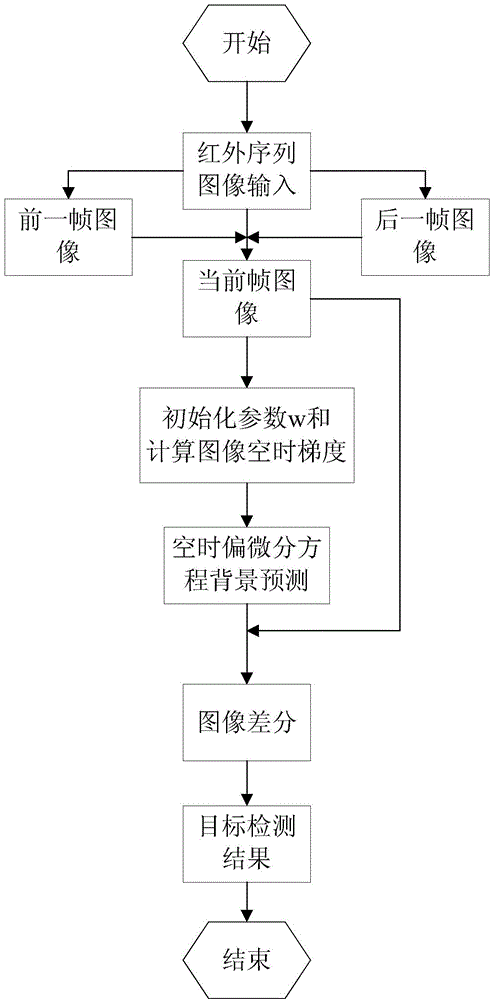

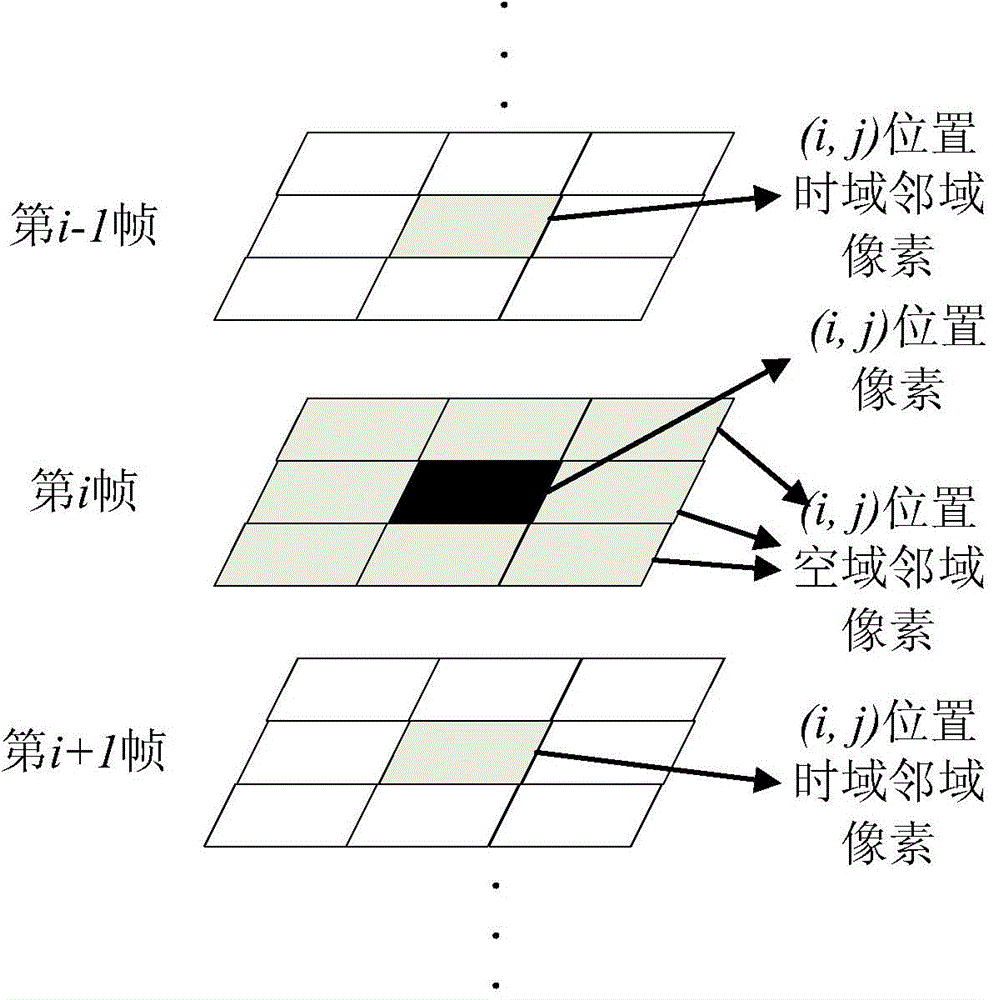

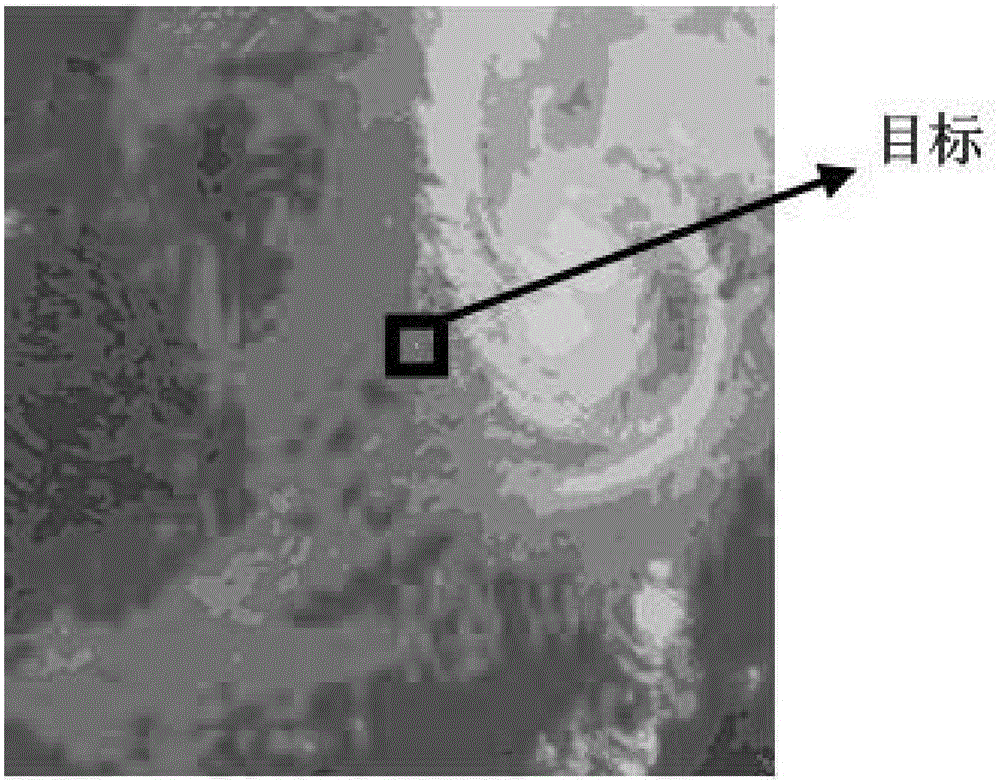

Method for detecting weak and small target based on space-time partial differential equation

ActiveCN104616299AWeak geometryWeakImage enhancementImage analysisPattern recognitionMatrix differential equation

The invention discloses a method for detecting a weak and small target based on a space-time partial differential equation. The method comprises the steps of (1) reading adjacent three frame images with image sequence to be processed; (2) initializing parameters w and calculating the time-space gradients of the images by the formula in the specification; (3) predicating the backgrounds of the images through the space-time partial differential equation; (4) differentiating the current frame image and the background predicating result to obtain the detection result of the weak and small target. According to the method, the background of a far infrared image is predicated through the space-time partial differential equation, and thus the weak and small target can be detected through the algorithm; the method provides technical support to image guidance, safety monitoring, and space monitoring, and is relatively high in practical value.

Owner:NANJING UNIV OF POSTS & TELECOMM

Construction method of fabricated light steel structure composite outer wall plate

InactiveCN111042432AHigh strengthStable supportWallsBuilding material handlingThermal insulationMechanical engineering

The invention discloses a construction method of a fabricated light steel structure composite outer wall plate, relates to the technical field of prefabricated wallboard, and solves the problem that the hoisting operation is inconvenient due to the weight of an existing prefabricated wallboard. According to the technical scheme, the construction method comprises the following steps of a, performing wall structure design; b, performing waterproof design; c, performing component manufacturing; d, performing component inspection; e, conveying and stacking the component; f, performing installationconstruction; g, performing joint waterproof construction; and h, performing mass acceptance. According to the construction method, an inner blade wall and an outer blade wall are connected through C-shaped steel, the space between the inner blade wall and the outer blade wall is filled with a thermal insulation material, the weight of the wall itself is greatly reduced, the hoisting constructioncan be carried out without using large hoisting equipment, so that hoisting construction is more convenient.

Owner:青岛泰合洋房建设有限公司

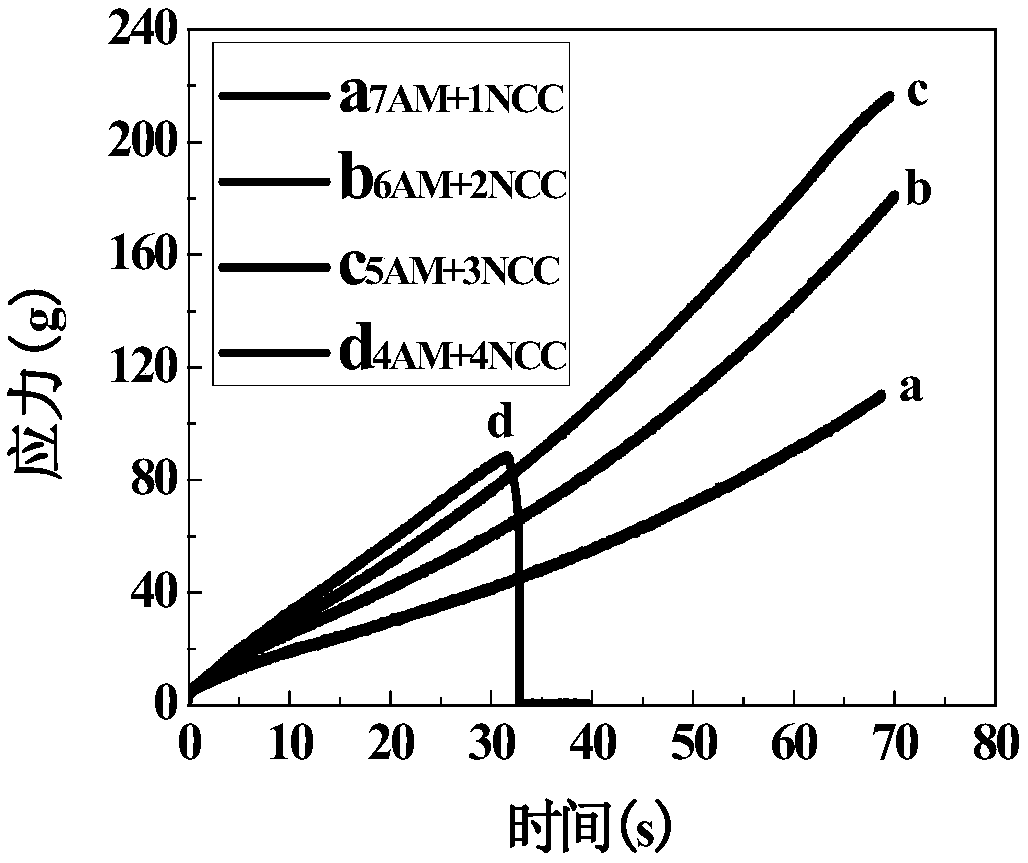

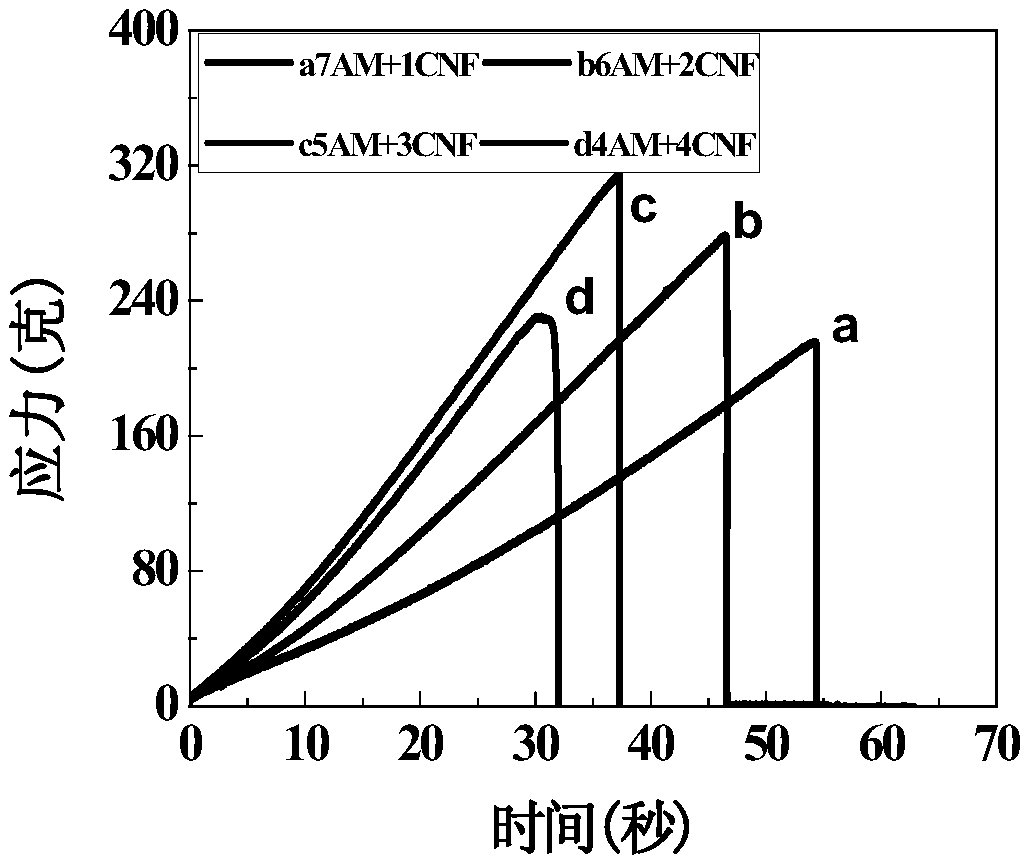

Acrylamide/nano cellulose composite gel and preparation method thereof

The invention discloses acrylamide / nano cellulose composite gel and a preparation method thereof. The preparation method comprises the following steps: adding acrylamide, an initiator and a crosslinking agent into a suspension of nano cellulose, and carrying out gelatinization to obtain the acrylamide / nano cellulose composite gel. As conventional polymer gel is of a three-dimensional hole networkstructure which takes water molecules as a main component, the gel is loose in chain structure and relatively low in intensity, has certain flowability, and cannot reach the intensity required by a gel valve applied to an oil field; particularly for a high-pressure stratum, the conventional polymer gel cannot effectively prevent overflowing of oil gas; in view of the problem, an effect of increasing the intensity of the composite gel is achieved by adding the nano cellulose into the polymer gel, so that the mechanical intensity of the gel valve is increased, and the performance of the gel valve in a sleeve is improved. According to the acrylamide / nano cellulose composite gel, the interaction between the nano cellulose and a polymer is also investigated, and the action mechanism of the nanocellulose for increasing the gel intensity is researched; the acrylamide / nano cellulose composite gel has an instruction significance on improving the mechanical property of the gel valve.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

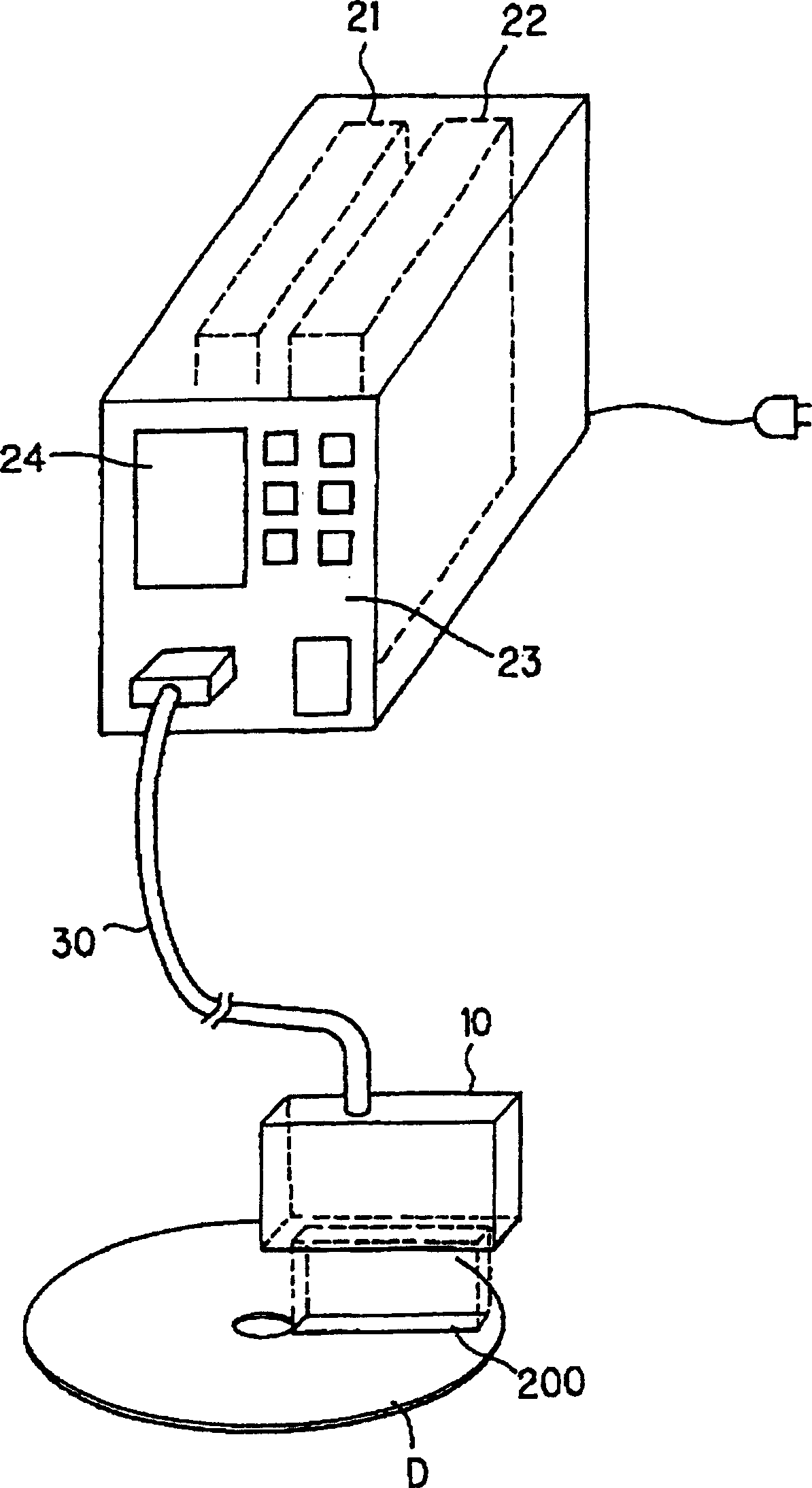

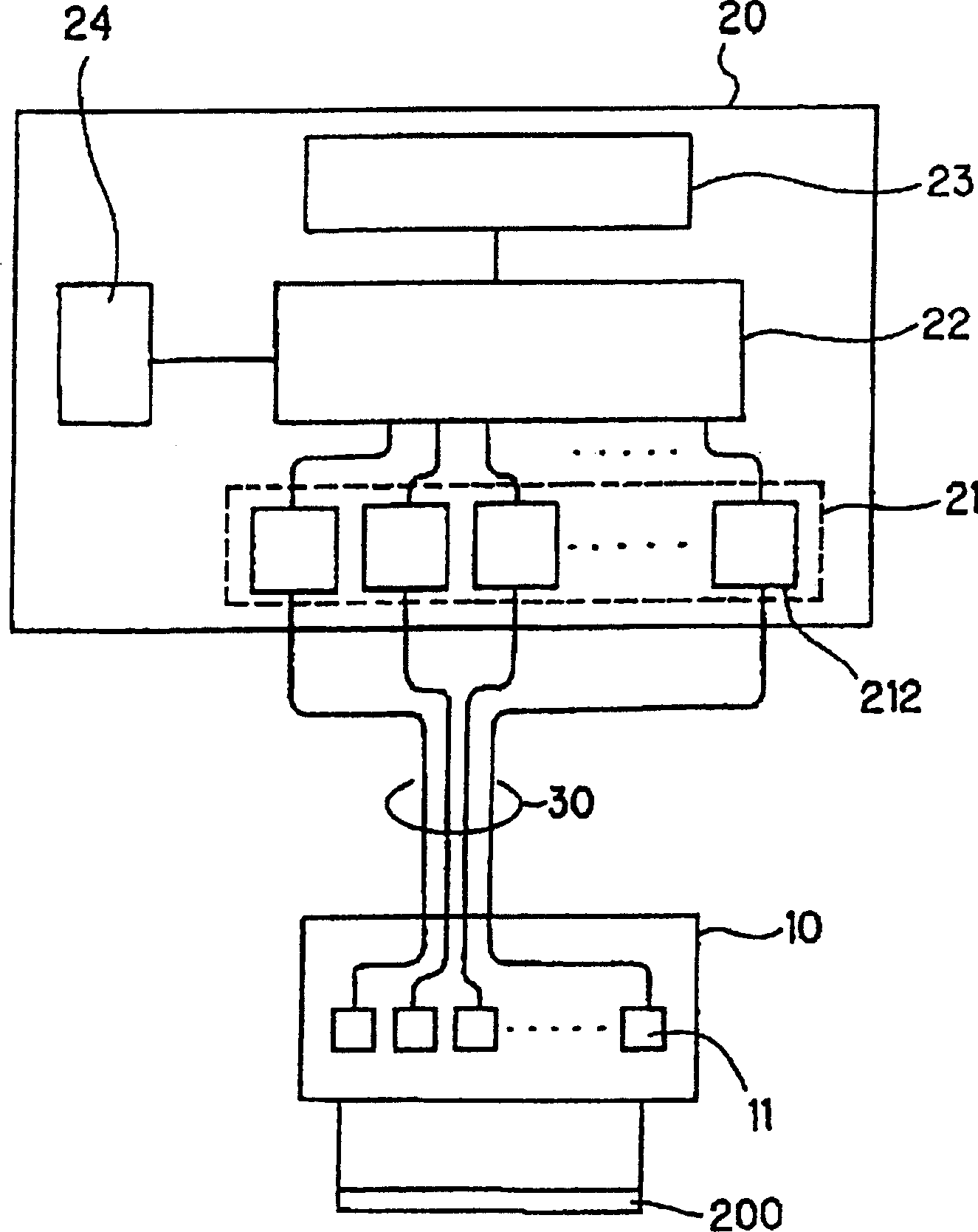

Ultraviolet irradiation device

InactiveCN1896670AChange light intensityWeakDrying solid materials with heatPhotomechanical exposure apparatusLight irradiationControl power

An ultraviolet irradiating apparatus is provided to control power supplied to each light emitting diode by disposing an ultraviolet light emitting diode of a line type as an ultraviolet source for forming a light irradiation region of a thin and long shape emitted from an ultraviolet irradiating apparatus and by independently supplying power to each ultraviolet light emitting diode. An ultraviolet irradiating apparatus includes an ultraviolet irradiating part(10) for irradiating ultraviolet rays, a power part for supplying power to the ultraviolet irradiating part, and a control part for supplying a control signal to the power part. The ultraviolet irradiating part includes a plurality of ultraviolet light emitting diode and a plurality of convex lenses(13). The plurality of ultraviolet light emitting diodes are disposed in parallel with each other on a print substrate(12), made of a line type. The plurality of convex lenses are disposed at the light emitting part of the plurality of ultraviolet light emitting diodes, corresponding to each ultraviolet light emitting diode. Power is independently supplied from the power part to the plurality of ultraviolet light emitting diode, and the power is controlled by the control part. A cylindrical lens(15) is installed at the light emission part of the convex lens, collecting the light collected by the convex lens in one direction.

Owner:USHIO DENKI KK

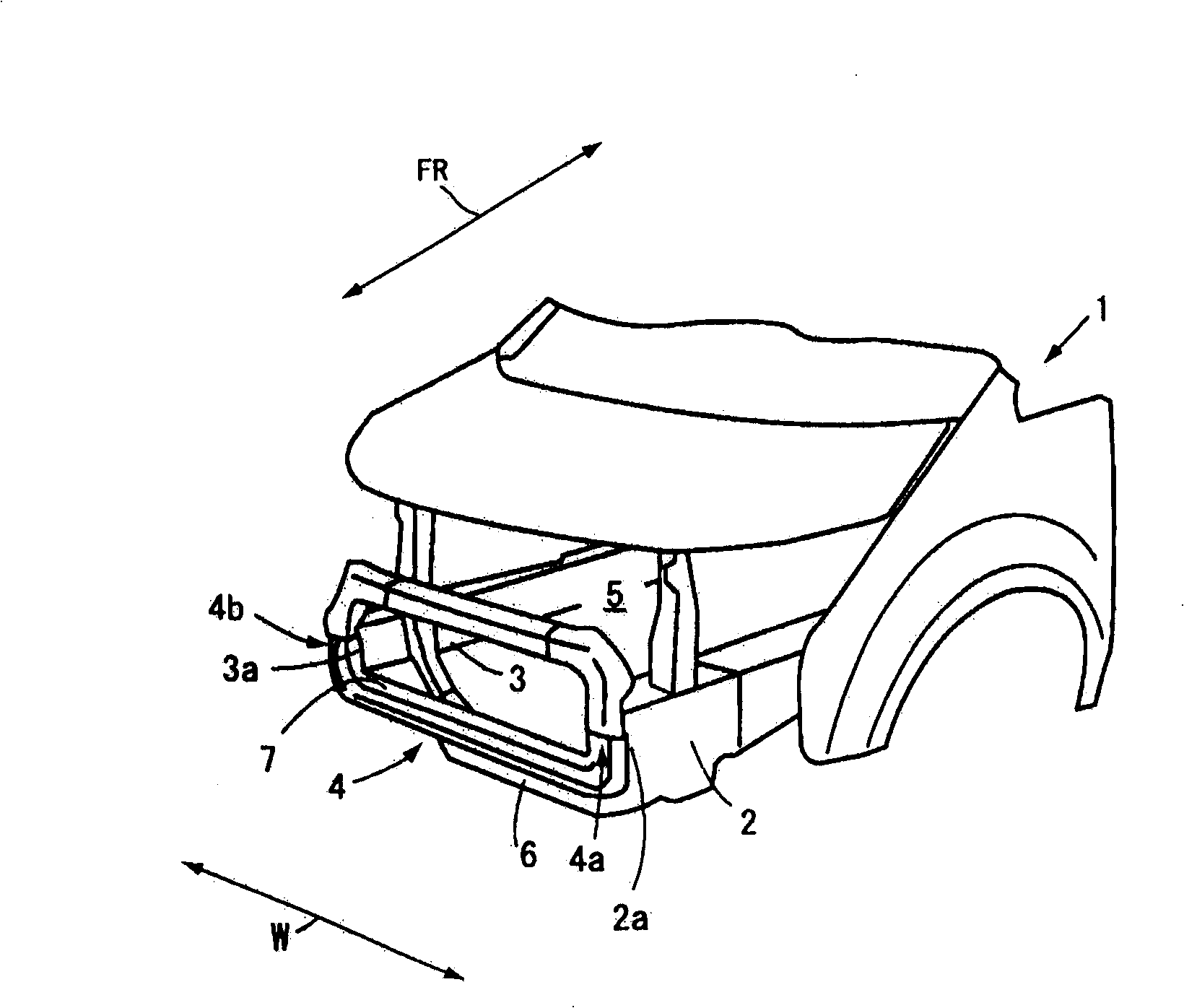

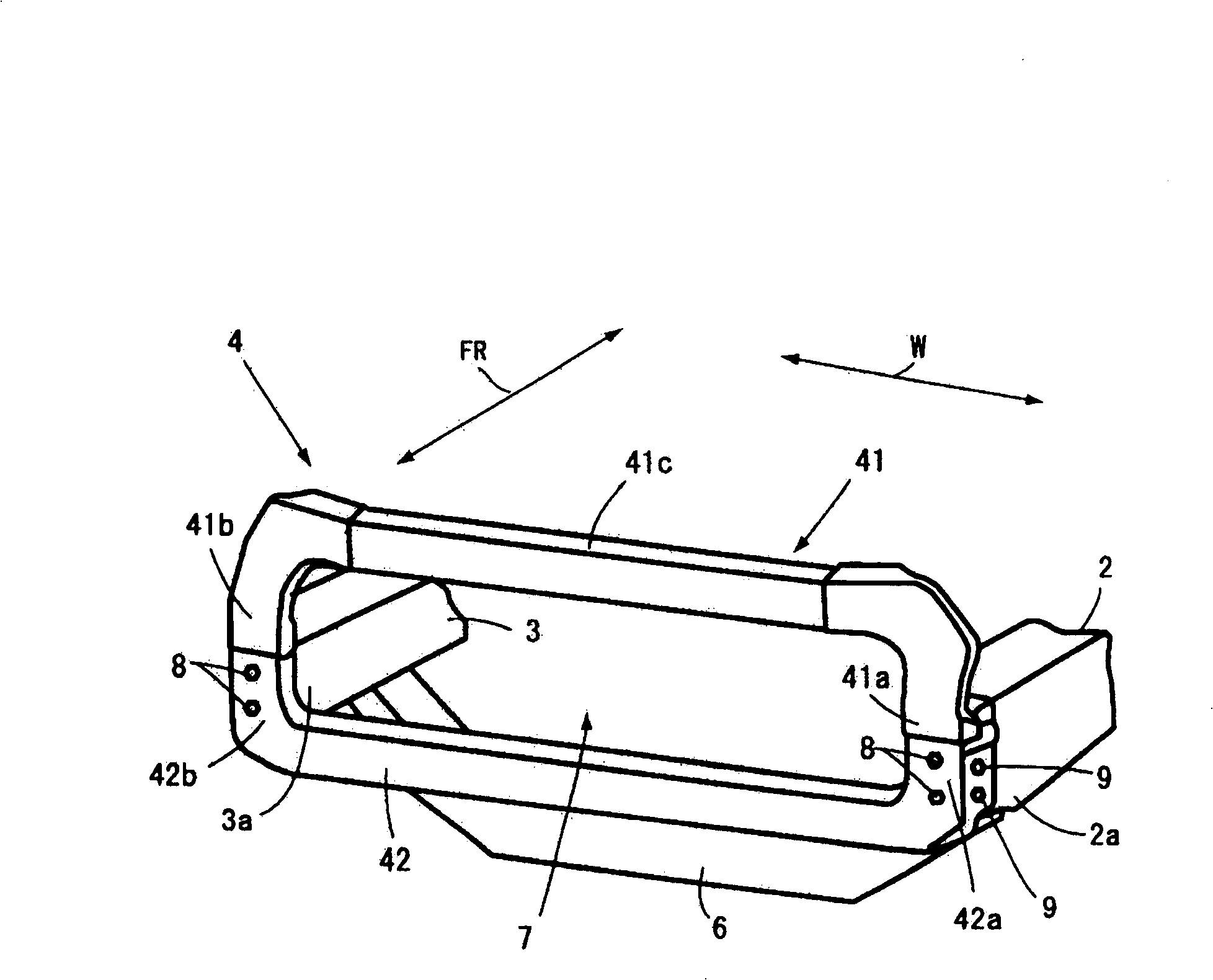

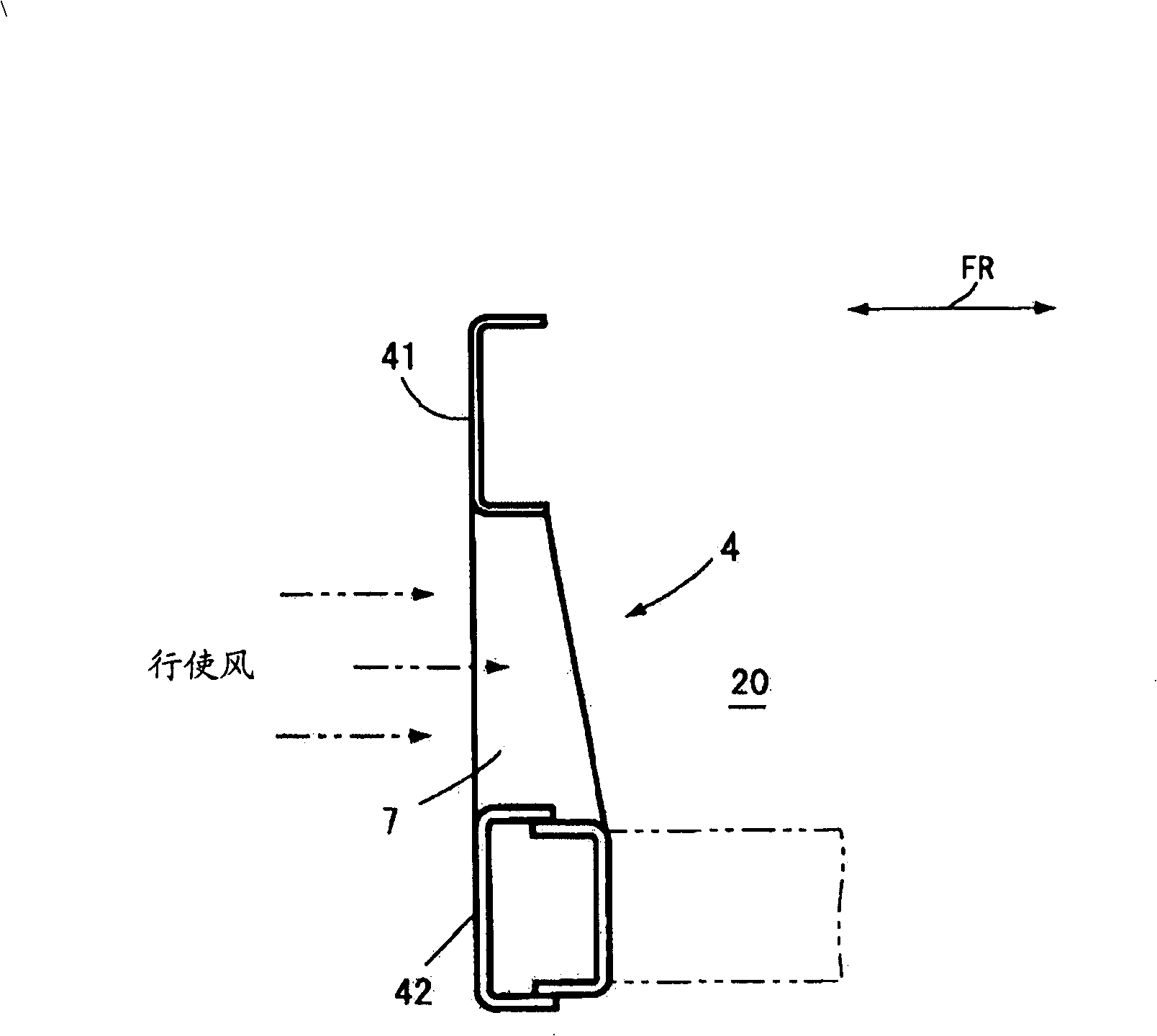

Vehicle body structure

InactiveCN101254768AGuaranteed Cooling PerformanceNot easily deformedSuperstructure subunitsBumpersEngineeringPedestrian

The invention provides a vehicle body structure effective for protection of a pedestrian and absorption of the collision load while ensuring the cooling performance. The vehicle body structure comprises a lower member (42) connected to fore ends (2a, 3a) of a pair of front side members (2, 3) extending in the back and forth direction FR of a vehicle body and arranged in the vehicle width direction W, and a bumper beam (4) located above the lower member (42) and forming an opening part (7) by an upper member (41) connected to the fore ends (2a, 3a). The strength of the upper member 41 is set to be lower than that of the lower member (42).

Owner:MITSUBISHI MOTORS CORP

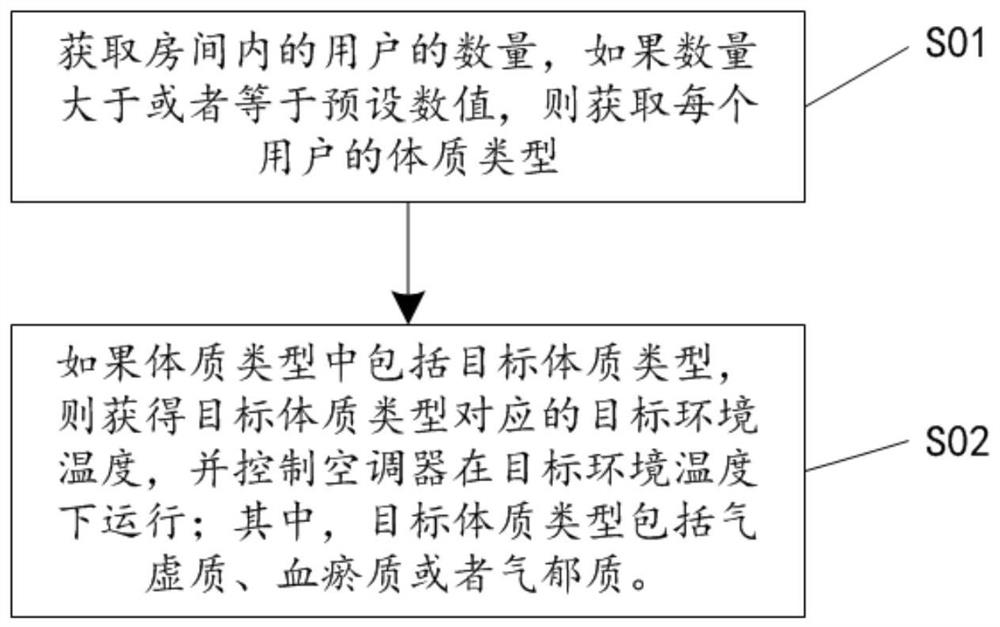

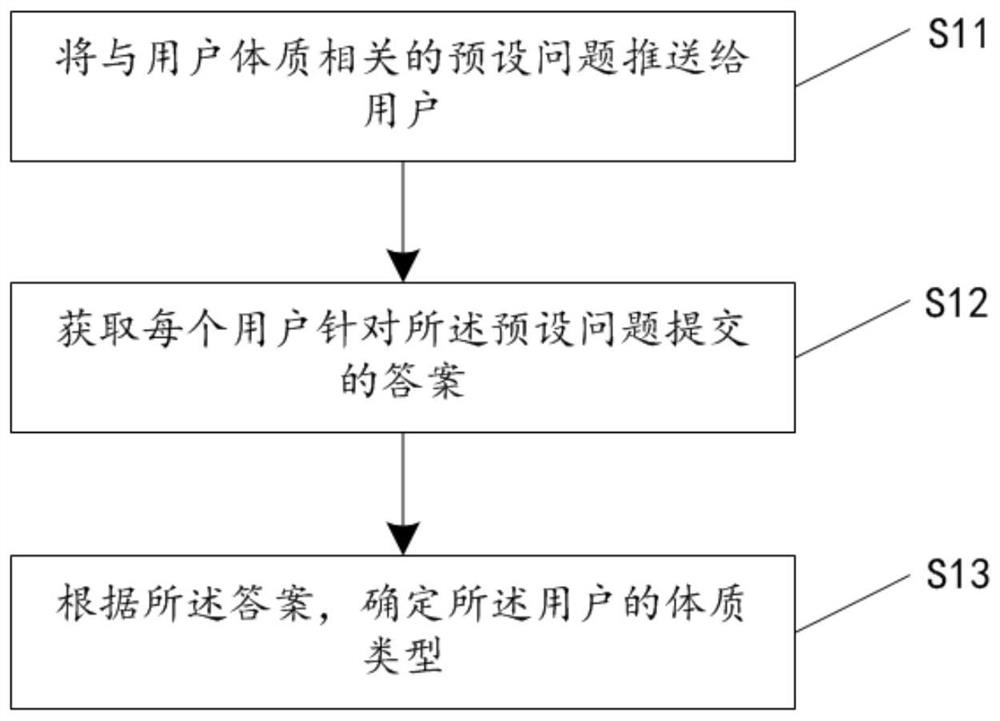

Control method and control device for air conditioner and air conditioner

ActiveCN113375307AWeakMechanical apparatusSpace heating and ventilation safety systemsPhysical medicine and rehabilitationEngineering

The invention relates to the technical field of intelligent air conditioners, and discloses a control method for an air conditioner. The control method comprises the following steps that the number of users in a room is acquired, and the physique type of each user is acquired if the number is greater than or equal to a preset value; and if the physique types comprise a target physique type, a target environment temperature corresponding to the target physique type is obtained, and the air conditioner is controlled to operate at the target environment temperature; wherein the target physique type comprises qi deficiency constitution, blood stasis constitution or qi depression constitution. In a multi-user scene, the air conditioner can control the running temperature of the air conditioner according to the physique type of the user with weak physique, and the use requirements of people are met. The invention further discloses a control device for the air conditioner and the air conditioner.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

Method for determining gas channeling of unit nitrogen flooding in fractured-vuggy reservoir and method for preventing channeling in injection and production

The invention relates to a method for determining gas channeling of unit nitrogen flooding in a fractured-vuggy reservoir and a method for preventing channeling in injection and production. The methodfor determining gas channeling comprises the following steps of step 1, gas channeling determination principles: (1) the nitrogen content in produced gas of a production well is greater than 10%, andthe nitrogen content when nitrogen flooding is not implemented is not greater than 5%, which are both volume fractions; and (2) the gas production of the production well is greater than 1.5 times that when nitrogen flooding is not implemented; and step 2, determination that gas channeling occurs in the unit nitrogen flooding when the unit nitrogen flooding with high gas channeling risks at leastsatisfies any gas channeling determination principle, wherein the unit nitrogen flooding with the high gas channeling risks comprises at least one easy gas channeling factor that there are cross-wellfracture zones or secondary fractures between wells, the injection-production relationship is low injection and high production, and there is no structural high point or dip angle in a local structural form between the wells. If the gas channeling of the unit nitrogen flooding is determined by the above-mentioned method for determining gas channeling, the method for preventing channeling in the mode of first dynamically adjusting channeling prevention and then automatically preventing channeling or automatically preventing channeling directly is used based on the characteristics of gas channeling and the degree of gas channeling of the unit nitrogen flooding.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for judging gas channeling in nitrogen flooding in a fractured-vuggy reservoir unit and a method for preventing channeling during injection and production

The present invention relates to a method for judging gas channeling in fractured-cavity reservoir units with nitrogen drive and an anti-channeling method for injection and production. 10%, and the nitrogen content is not more than 5% when nitrogen flooding is not implemented, both are volume fractions; ②The gas production of production wells is greater than 1.5 times that of when nitrogen flooding is not implemented; Step 2, when nitrogen flooding in units with high gas channeling risks If any gas channeling judgment principle is met, it is judged that gas channeling has occurred in unit nitrogen flooding, and unit nitrogen gas flooding with high risk of gas channeling includes at least one easy gas channeling factor: there is a cross-well fault zone or secondary fault between wells, and the injection-production relationship is low There is no structural high point or a dip in the local structural form between high injection and production wells. If gas channeling in unit nitrogen drive is judged by the above gas channeling determination method, then based on the gas channeling characteristics and gas channeling degree of unit nitrogen drive, first dynamically adjust the anti channeling method, followed by active channeling prevention or direct active channeling prevention method.

Owner:CHINA PETROLEUM & CHEM CORP +1

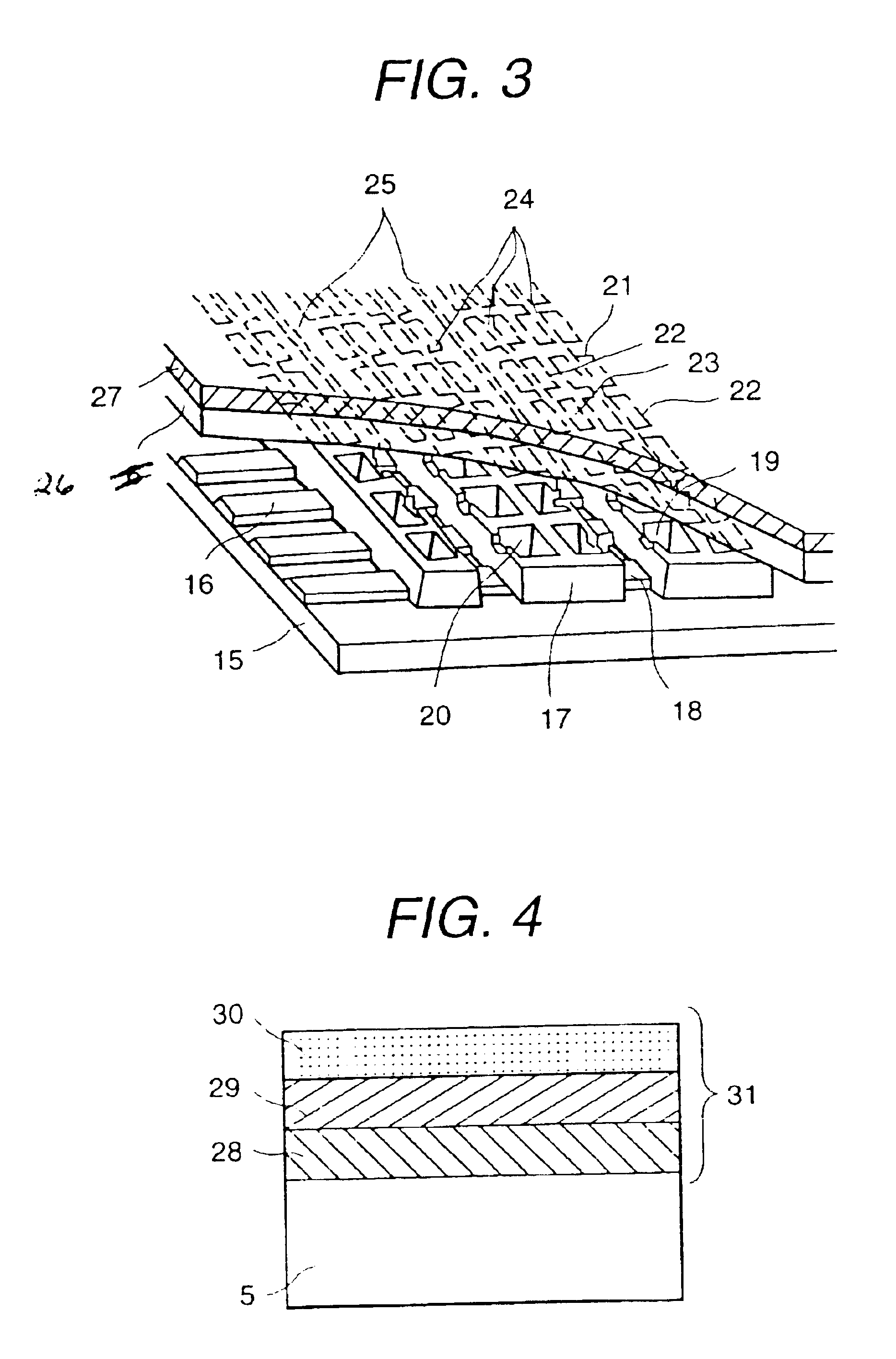

Display apparatus with a multi-layer absorption, conduction and protection film

InactiveUS6992425B1Lower refractive indexDifferenceCathode-ray/electron-beam tube electrical connectionIncadescent screens/filtersTectorial membraneDisplay device

A high definition display apparatus having a wavelength selective absorption effect and an anti-static and anti-reflection effect is provided by thin films having a low resistance and a high refractive index. The high definition display apparatus has an anti-static and anti-reflection film composed of laminated oxide or metallic thin films, wherein at least three layers of oxide or metallic films having different reflectance from each other are laminated onto the front surf ace of the display apparatus, and the laminated films are composed such that an absorbing film containing coloring material is arranged under a high reflectance film as seen from the outer surface of the laminated films.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Light treatment bar

The invention discloses a light treatment bar. The light treatment bar comprises a peripheral body, a light source and a power supply module, wherein an accommodation space is formed at the peripheral body to accommodate a treated object, an inner side of the peripheral body is equipped with a light source, the light source comprises one or more OLED light sources, the OLED light sources are used for emitting irradiation light with different wavelength scopes, and the power supply module is connected with the light source and is used for providing electric energy for the light source. According to the light treatment bar, low energy consumption OLEDs are taken as the light sources, the OLED light sources are cold light sources, radiation heat is quite low, and energy consumption is small; the OLED light sources are surface light sources, an irradiation coverage area is large, uniform light emission is realized, light is soft and does not hurt eyes, harmful blue light is weak, damage to the eyes can be effectively reduced, and the light treatment bar further has functions of convenient carrying, self power supply, data transmission and multi-media playing.

Owner:长春若水科技发展有限公司

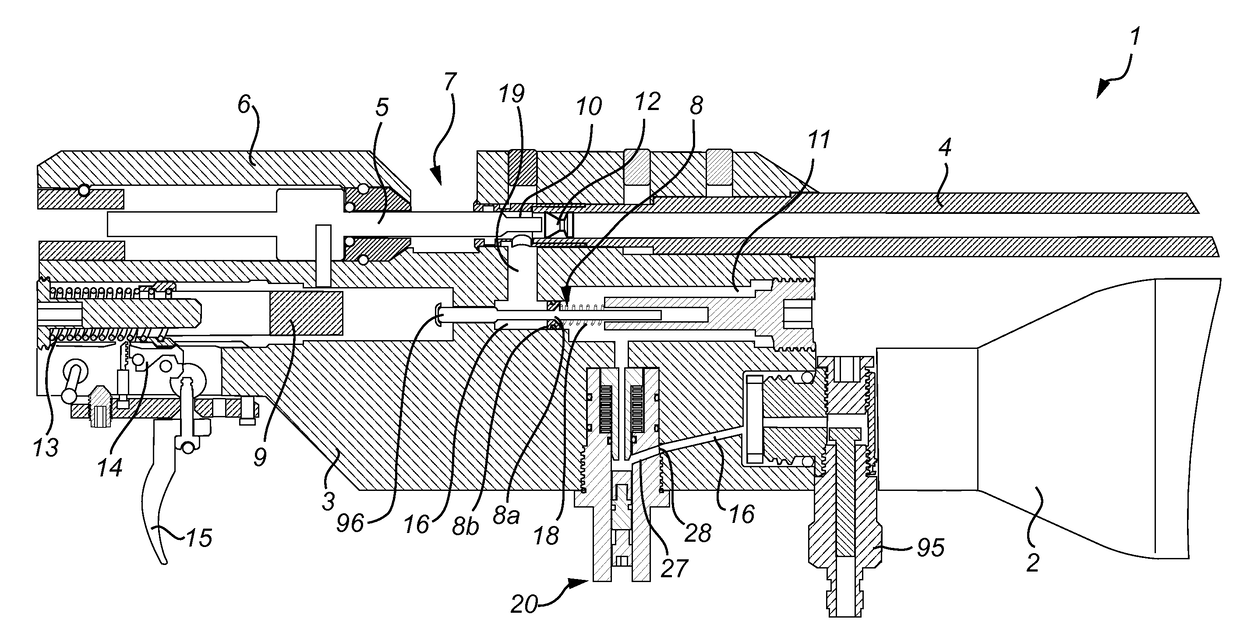

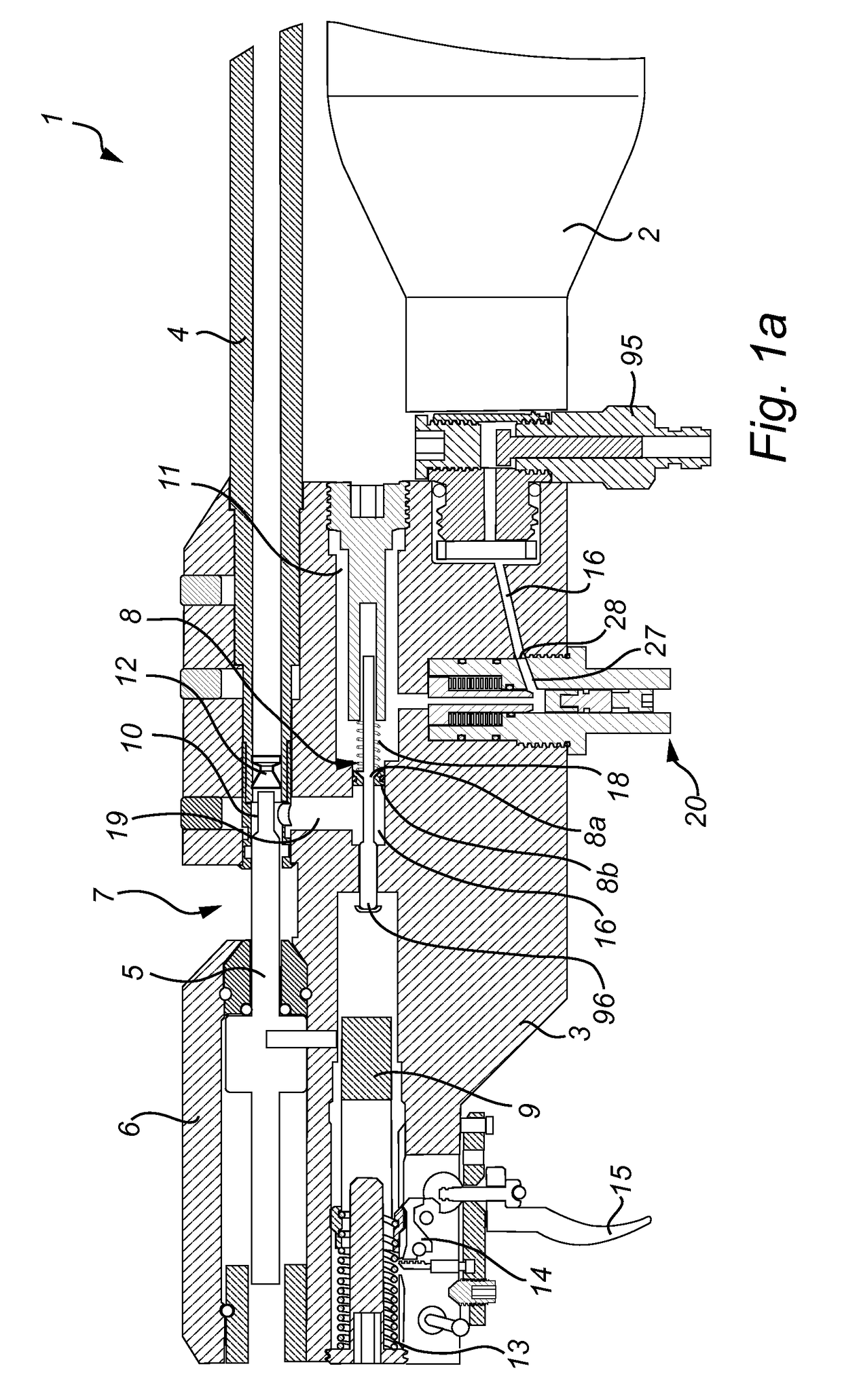

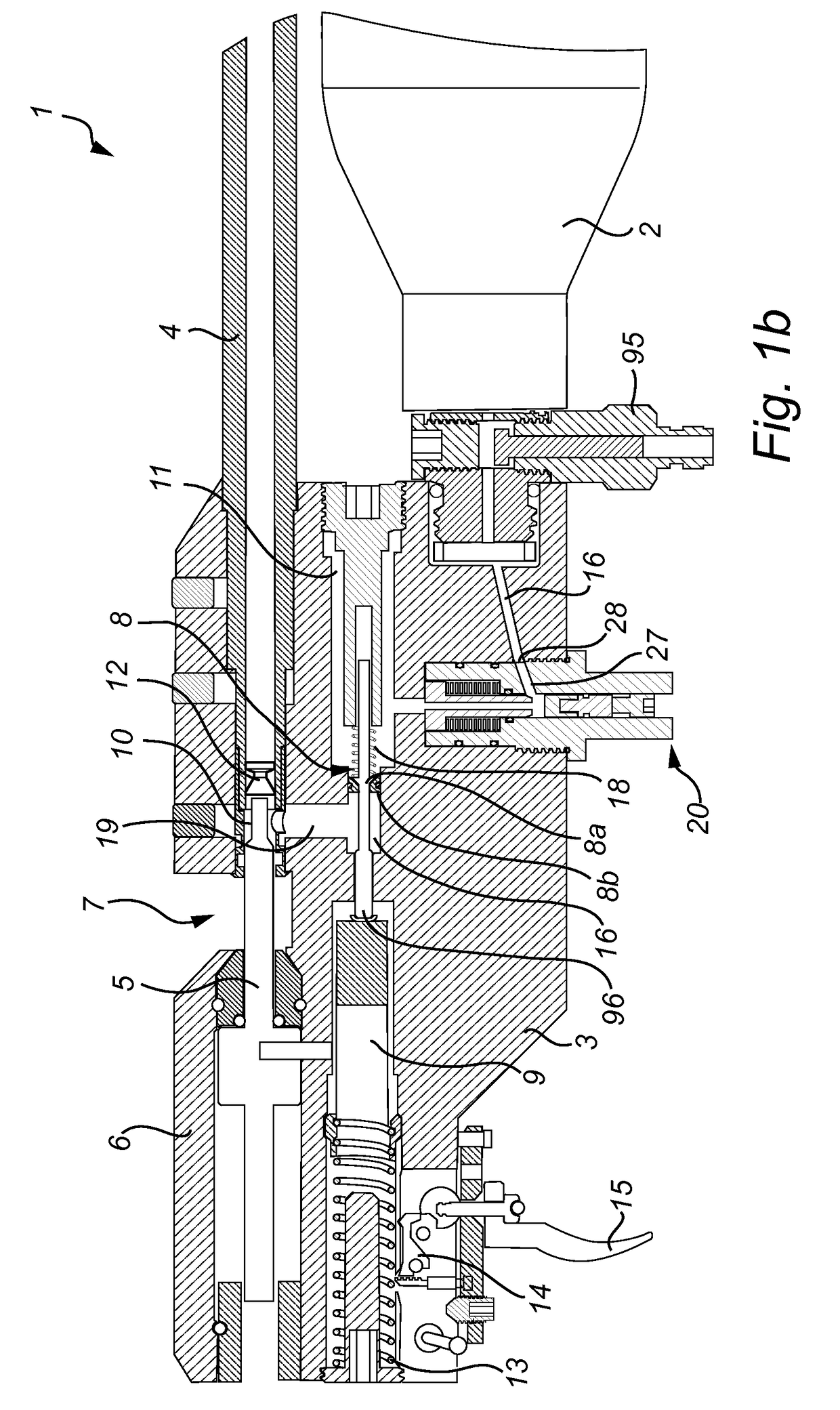

Gas powered gun and a pressure tube for a gas powered gun

A gas powered gun and a pressure tube for a gas powered gun each comprises a gas regulator between a pressure chamber and a source of compressed gas. The gas regulator comprises a body forming first and second cylindrical portions connected to each other. The first cylindrical portion is in fluid connection with the pressure chamber. A piston is mounted for sliding movement in the first and second cylindrical portions. A valve seat is in the second cylindrical portion. An intermediate chamber is in the second cylindrical portion between the piston and the valve seat and in fluid connection with the source of compressed gas. A passageway through the piston connects the pressure chamber with the intermediate chamber. A biasing member presses the piston resiliently away from the valve seat. A valve seat adjusting mechanism is accessible to a user for adjusting a position of the valve seat.

Owner:FX AIRGUNS AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com