Modified cobalt-manganese-oxide-doped carbon nanotube catalyst as well as preparation method and application thereof

A cobalt oxide manganese oxide catalyst, carbon nanotube technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low active site, small specific surface area, limited catalytic activity, etc., to increase solubility and dispersibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 (CoMn 2 o 4 / PDDA-CNT catalyst preparation)

[0051] 1. Use PDDA to further functionalize carbon nanotubes to increase the solubility and dispersibility of carbon nanotubes. Specifically, place 0.1g of carbon nanotubes in a 200mL beaker and add 2mL of 1wt% PDDA aqueous solution for ultrasonic dispersion for 1h , a stable black solution can be obtained.

[0052] 2. Prepare by Hummer method, firstly disperse PDDA-CNT in 20mL deionized water, add 100mL dimethylformamide (DMF) solution, and ultrasonicate together for 0.5h. Second, 3.792gCo(OAc) 2 ·6H 2 O and 7.477gMn(OAc) 2 ·6H 2 O was dissolved into the mixture at a molar ratio of 1:2, and stirred slowly for 0.5 hours to obtain a black precipitate.

[0053] 3. Wash 0.03g of the precipitated black solid with deionized water, put the precipitate into a polytetrafluoroethylene autoclave, heat it at 180°C for 10h, and finally place the black precipitate in an oven at 80°C for 24h to obtain 30 %CoMn 2 o 4...

Embodiment 2

[0055] Embodiment 2 (CoMn 2 o 4 / TEM characterization of PDDA-CNT)

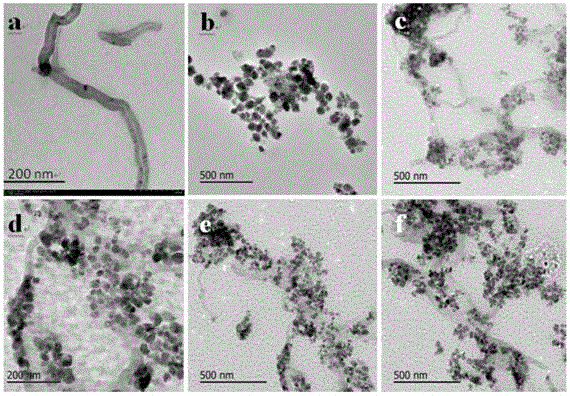

[0056] The surface morphology of the catalyst was observed with a Transmission Electron Microscope (TEM) (HITACHIH-7650, Japan).

[0057] TEM analysis was used to observe as pure CNT and CoMn 2 o 4 / Surface morphology of PDDA-CNT catalyst, the test voltage is 80kV.

[0058] Through this example for pure CNT and CoMn 2 o 4 / PDDA-CNT catalyst TEM observation, it can be seen that the formed black nano-scale particles are evenly attached to the CNT surface. Moreover, with the increase of loading amount, the number of particles loaded on the surface of carbon tubes also increases. Nanostructured PDDA-CoMn 2 o 4 / CNT compounds can effectively increase the specific surface area of the catalyst, thereby increasing the oxygen adsorption and CoMn 2 o 4 catalytic performance. That is, the reduction of the specific surface area will limit the interaction between oxygen and the catalyst, thereby limiting th...

Embodiment 3

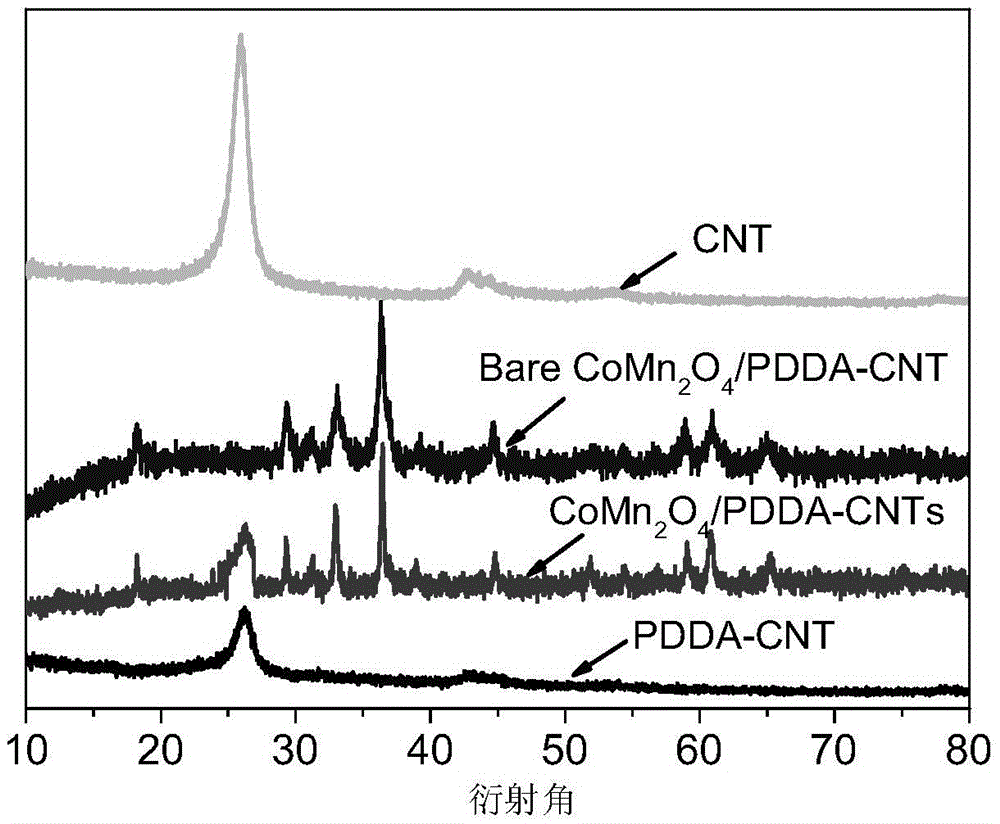

[0059] Embodiment 3 (CoMn 2 o 4 / XRD characterization of PDDA-CNT and PDDA-CNT)

[0060] XRD analysis: used to analyze the elemental composition of NiO / CNT catalyst, the test process is realized on the D8ADVANCE instrument, the test conditions are copper target, incident ray λ=0.15418nm, Ni filter, tube pressure 40KV, tube flow 40mA; scan The step length is 0.02 degrees, the scanning speed is 0.1 seconds / step; the slit DS0.5°RS8mm (corresponding to the LynxExe array detector). Using the Scherrer formula to estimate the average particle size of NiO, the average particle size Where λ is the wavelength of X-rays, β 1 / 2 is the half-peak width, and θ is the angle of the NiO(200) diffraction peak.

[0061] According to the Raman spectrum, the prepared compound has a tetragonal spinel crystal structure and the XRD peaks are obvious, indicating that the prepared compound has a significant crystal structure. Besides, with the standard CoMn 2 o 4 Compared with the peaks, the pea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com