Temperature-sensitive polymer modified carbon nanotube composite material and preparation method thereof

A technology of carbon nanotubes and composite materials, which is applied in the directions of multi-walled carbon nanotubes, carbon compounds, chemical instruments and methods, etc., can solve the problems of limiting application fields and performance, maintain physical properties, and improve solubility and dispersibility. , the effect of strong binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

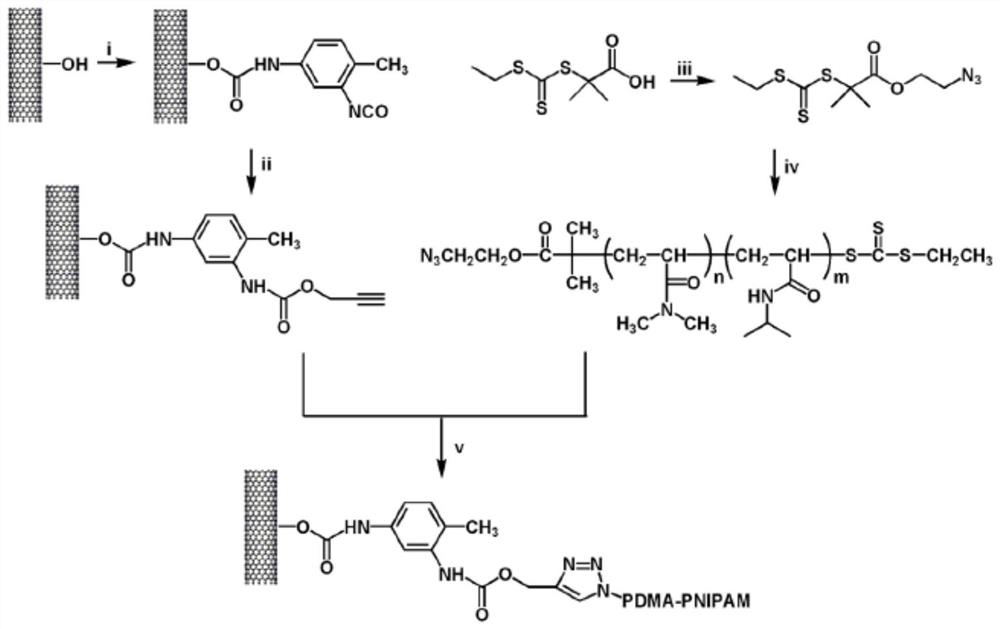

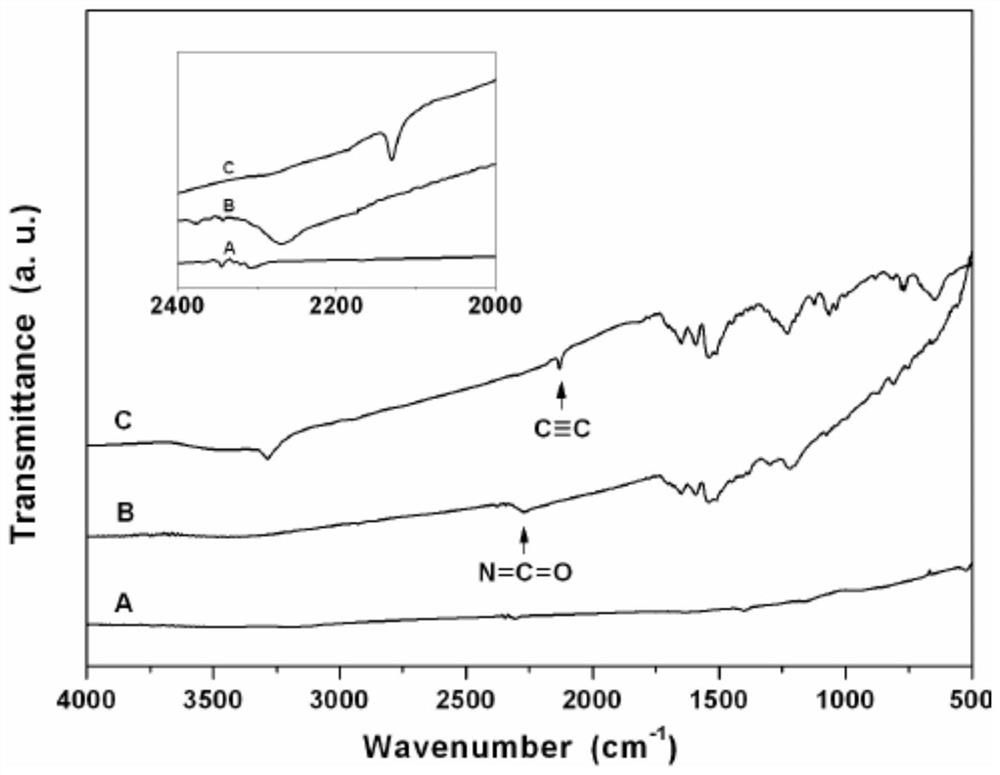

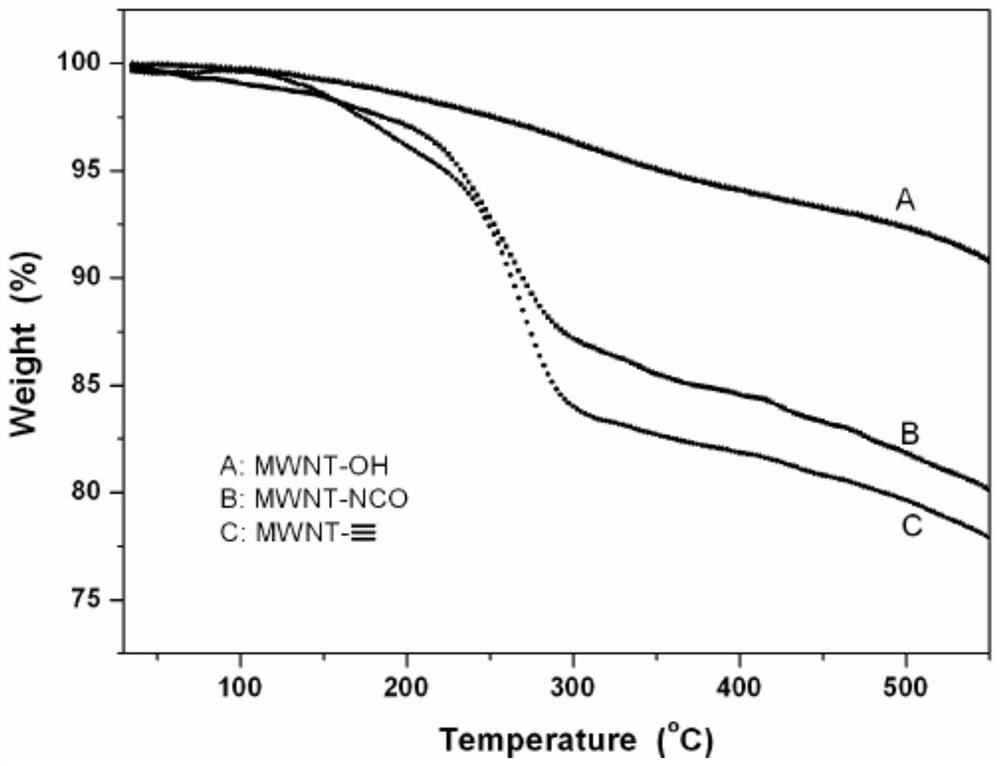

[0029] Embodiment 1, the reaction process of the present embodiment is as figure 1 shown.

[0030] 1. Disperse 1-100mg of multi-walled (layers 2-100) carbon nanotubes (referred to as MWNT-OH) with hydroxyl groups on the surface in 1-50mL of toluene-2,4-diisocyanate (TDI), under nitrogen protection React at 70°C to 90°C for 72 hours, filter the reaction product with a polytetrafluoroethylene membrane (PTFE membrane, 200nm pore size), wash with anhydrous toluene several times to remove residual TDI, and then vacuum at 30°C to 50°C Dry for 24h to obtain TDI-modified multi-walled carbon nanotubes, denoted as MWNT-NCO;

[0031] 2. Add 1 to 100 mg of the MWNT-NCO in a 100 mL round bottom flask, inject 1 to 15 mL of anhydrous toluene with a syringe under nitrogen protection, add 1 to 6 mL of propynyl alcohol (PPL) after ultrasonic dispersion for 30 min, and dissolve at 90 Reflux reaction at ℃~110℃ for 48h. After the reaction, filter with 200nm PTFE membrane, wash with tetrahydrofur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com