Preparation device for improving fluidity of polyurethane color master batch

A technology for preparing device and color masterbatch, which is applied in the field of preparation device for improving the fluidity of polyurethane color masterbatch, can solve the problems of unguaranteed solubility and dispersibility, poor fluidity, etc., so as to avoid leakage and improve solubility. and dispersibility, the effect of promoting stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Color masterbatch is also called color masterbatch. It is composed of three basic elements: pigment or dye, carrier and additive. Its tinting strength is higher than that of the pigment itself. When processing, a small amount of color masterbatch and uncolored resin is mixed to achieve the colored resin or product with the designed pigment concentration.

[0032] At present, in the preparation process of color masterbatch, its solubility and dispersibility cannot be guaranteed, which in turn causes the problem of poor fluidity.

[0033] In view of the above problems, the present invention provides a preparation device for improving the fluidity of polyurethane color masterbatch.

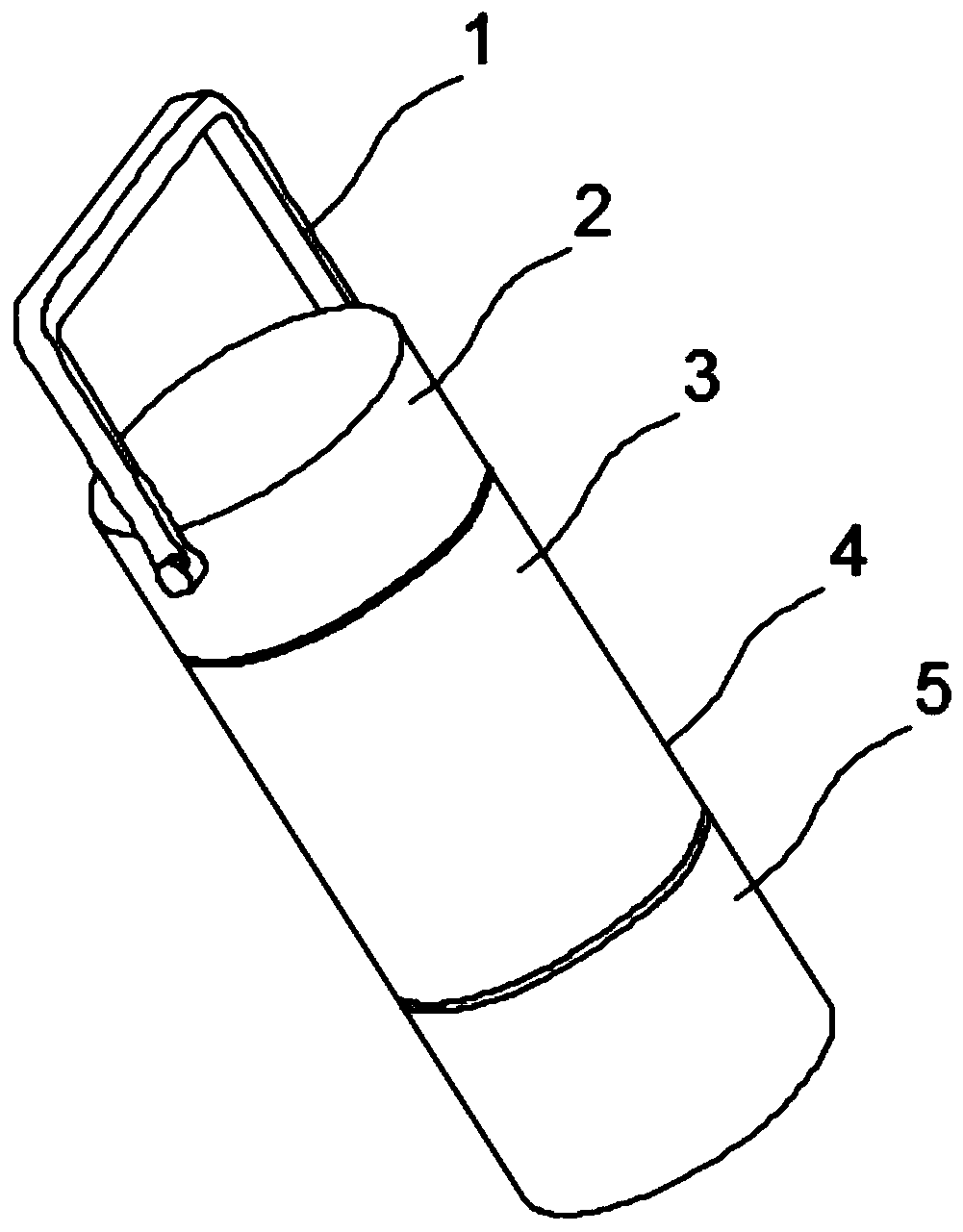

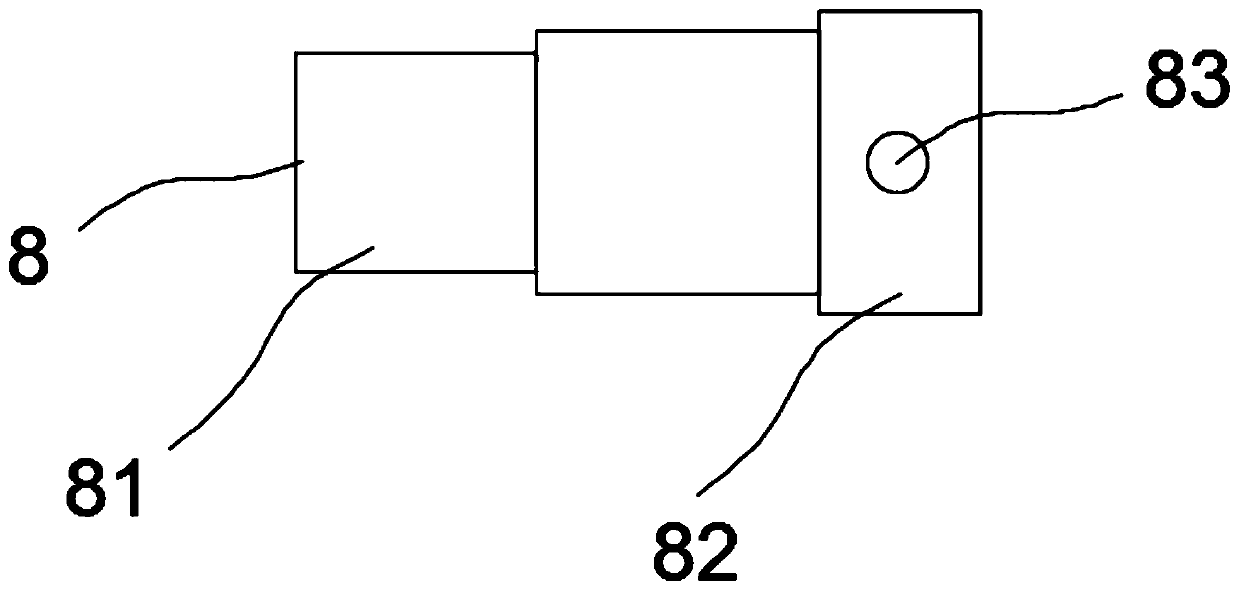

[0034] Specific as Figure 1~3 As shown, a preparation device for improving the fluidity of polyurethane masterbatches includes a cylinder 4 with a top cover 3 installed, and the cylinder 4 is composed of a cylinder wall 3 and a base 5 arranged at the bottom of the cylinder wall 3; Describe...

Embodiment 2

[0043] The embodiment of the present invention is further limited on the basis of embodiment 1.

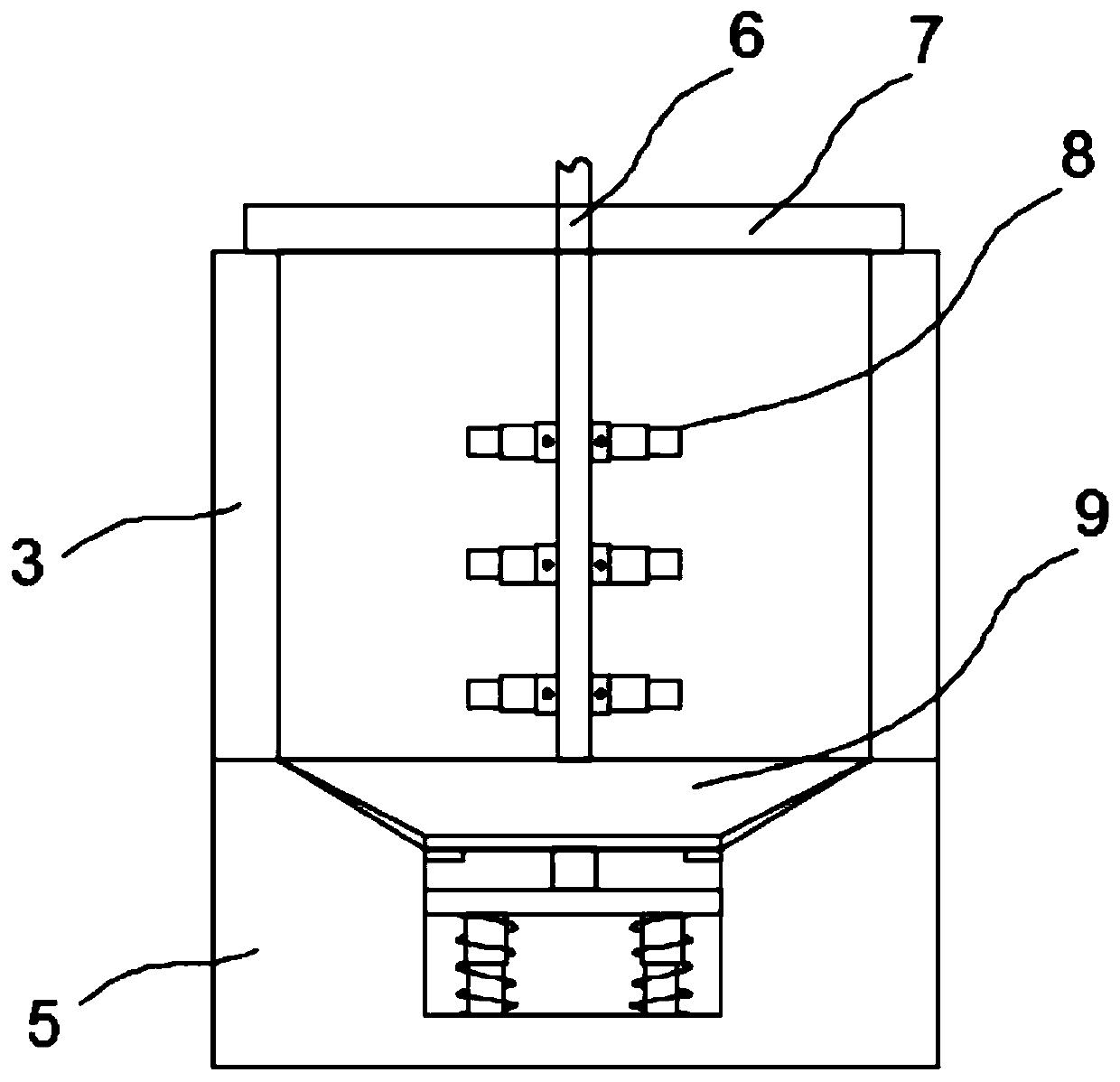

[0044] see figure 2 and Figure 4 , a bottom plate 9 is placed inside the base 5 .

[0045] Optimally, a connecting column 56 is provided at the bottom of the bottom plate 9 , and a lifting plate 54 is fixed at the lower end of the connecting column 56 , and a plurality of elastic members 51 arranged in an array are arranged at the lower end of the lifting plate 54 .

[0046] Optimally, the elastic member 51 is composed of a telescopic rod 53 and a spring 54 sleeved on the telescopic rod 53 .

[0047] Optimally, a backing plate 57 is provided between the bottom plate 9 and the connecting column 56 , and a limiting ring 55 is fixed at the lower end of the backing plate 57 .

[0048] Furthermore, when the bottom plate 9 is lifted and discharged, the elastic member 51 can lift the lifting plate 54 to the limit ring 55 to seal to avoid leakage.

[0049] The working principle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com