Viscous fine mineral powder fluidization reactor

A reactor and fluidization technology, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problem of insufficient surface renewal, unfavorable viscous fine mineral powder fluidization quality, improvement of reactor efficiency, air flow shear Low cutting force and other issues, to achieve the effect of low operation and maintenance costs, avoid adhesion, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

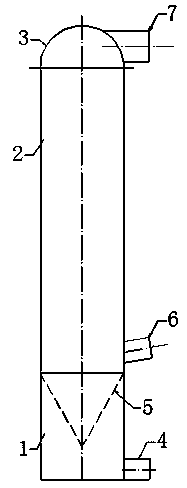

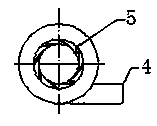

[0017] see figure 1 , The viscous fine mineral powder fluidized reactor of the present invention includes a gas flow distribution chamber 1, a reactor body 2 and a furnace roof 3, and the upper part of the reactor body 2 is connected to the furnace roof 3. The outer wall of the gas flow distribution chamber 1 is provided with a reaction gas inlet 4 through which the gas flow enters tangentially. The lower end of the outer wall of the main body of the reactor is provided with an inlet 6 for fine mineral powder and recycled materials. The furnace top 3 is provided with an outlet 7 for gas and unreacted fine powder. It is discharged through the outlet; the gas distribution chamber is communicated with the reactor body through a gas distributor. The gas distributor 5 is a conical cylinder with the top facing down, and the apex angle of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com