Patents

Literature

114results about How to "Long fermentation route" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

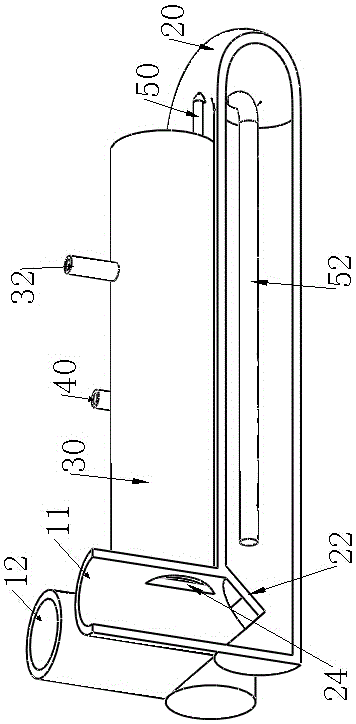

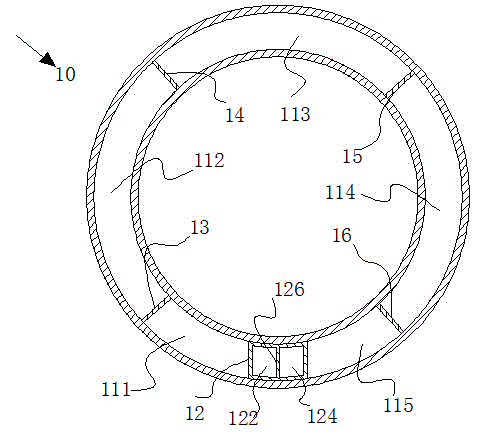

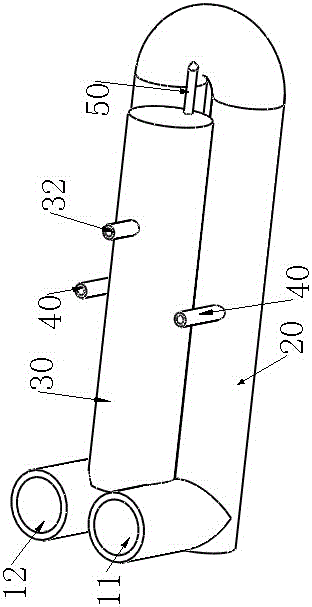

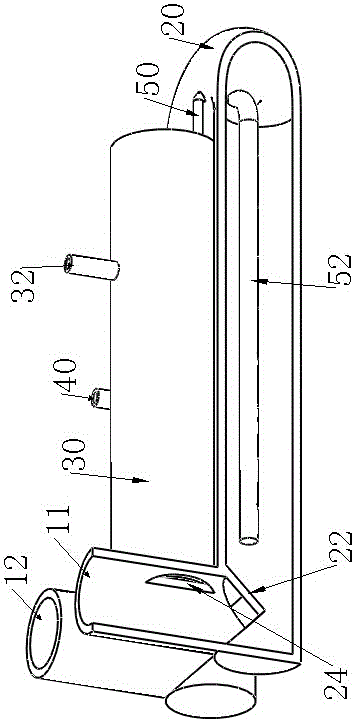

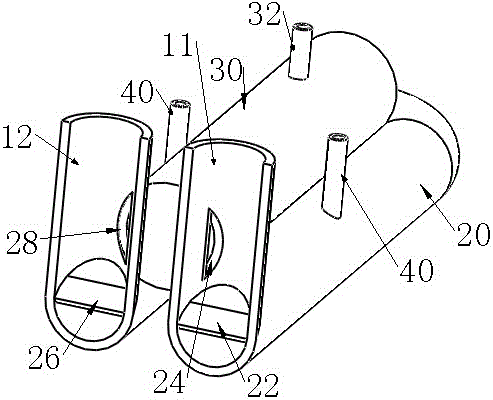

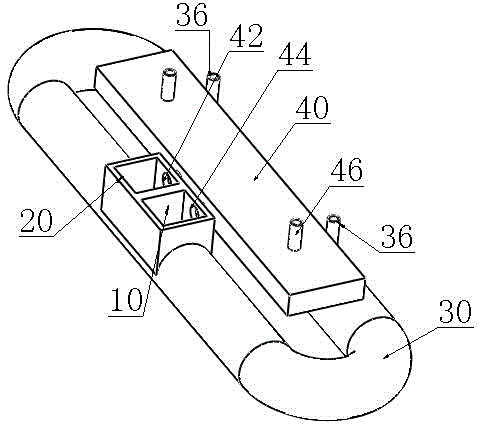

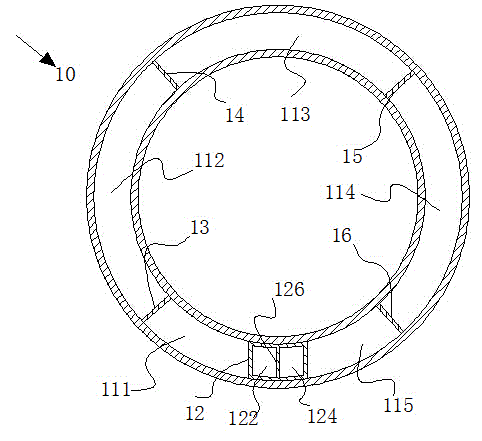

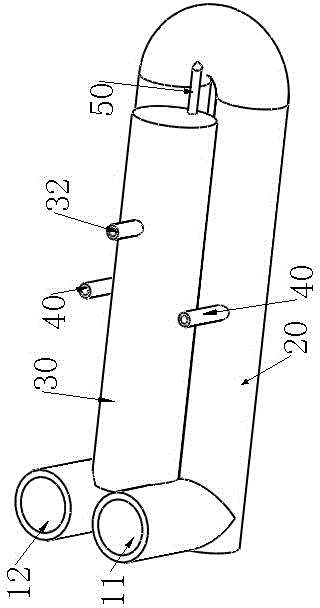

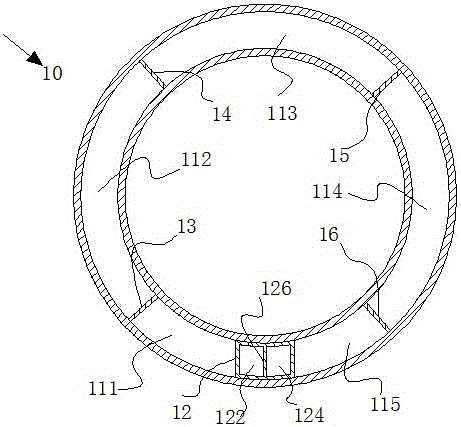

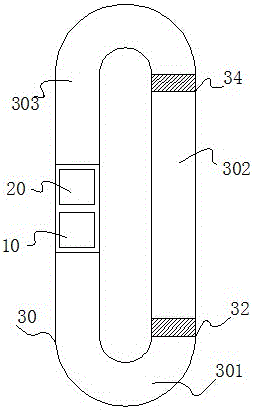

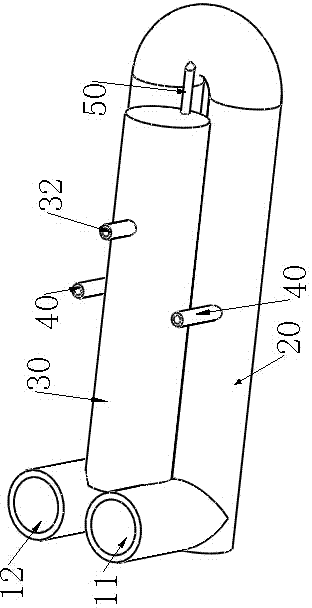

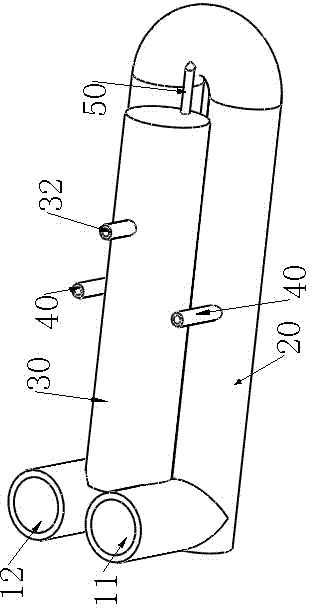

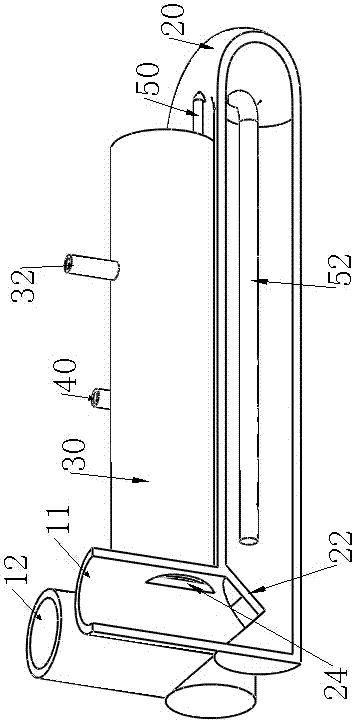

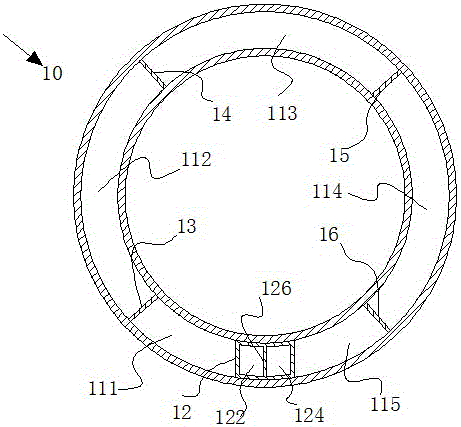

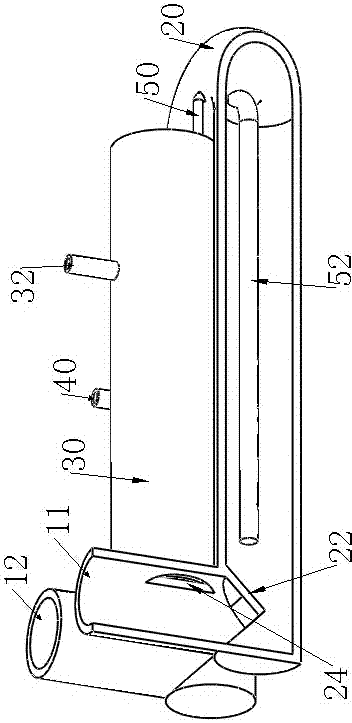

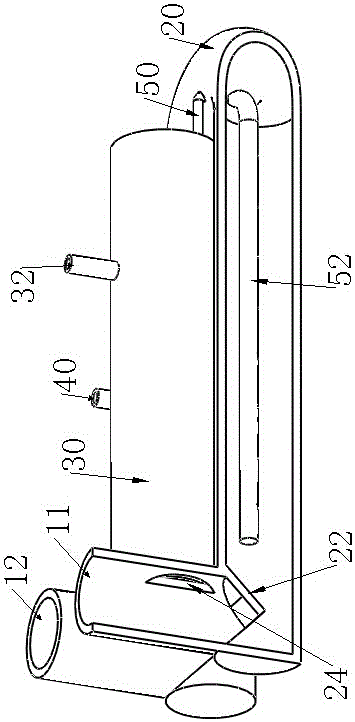

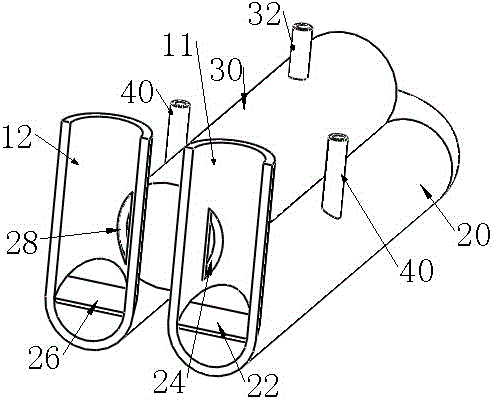

Double cylinders bundled type straw biogas digester

InactiveCN104371913AEasy feedingLong fermentation routeGas production bioreactorsWaste based fuelGlass fiberPlastic materials

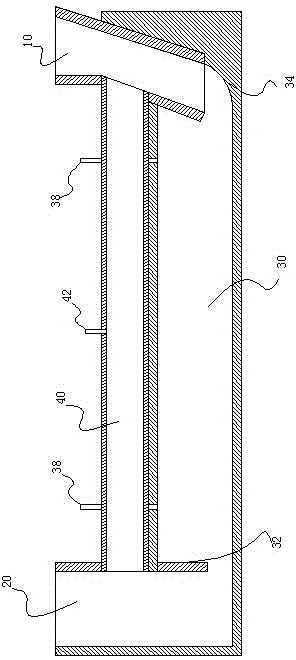

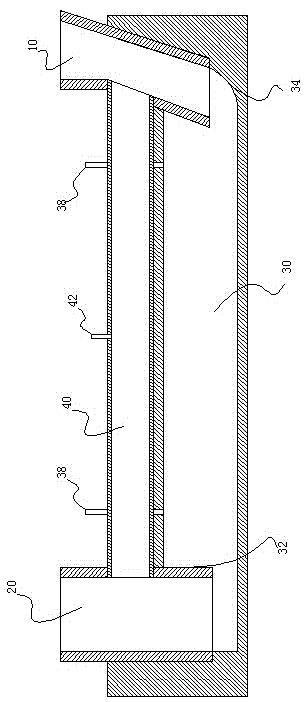

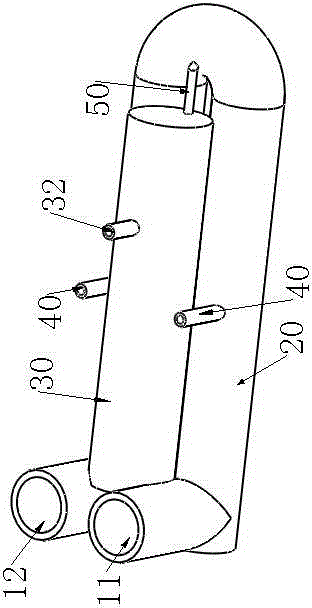

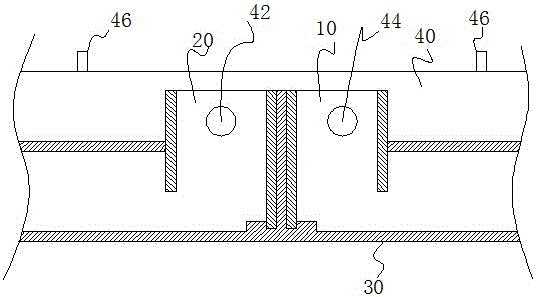

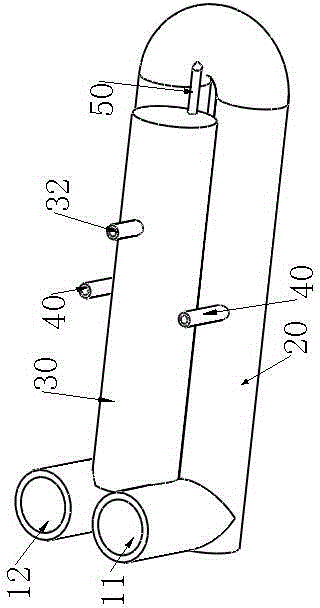

The invention discloses a double cylinders bundled type straw biogas digester. A biogas digester body is composed of a feed pipe, a discharge pipe, a fermentation pipeline and a hydraulic pressure chamber. The fermentation pipeline is horizontally arranged. The feed pipe inclines to be connected with the fermentation pipeline. The discharge pipe is vertically arranged to be connected with the fermentation pipeline. The hydraulic pressure chamber with two ends communicated is arranged at the top of the fermentation pipeline along the center axis of the fermentation pipeline and is communicated with the side wall of the feed pipe and the side wall of the discharge pipe. Air ducts are communicated with the fermentation pipeline. According to the arrangement, straws are conveniently fed in, due to the straight cylinder type fermentation pipeline, a fermentation path of the straws is prolonged, biogas is smoothly exhausted through the air ducts, and blocking never occurs; structure is reasonable, and the whole biogas digester is made of glass fiber reinforced plastic material or made by connecting PVC (polyvinyl chloride) pipelines.

Owner:陆永成

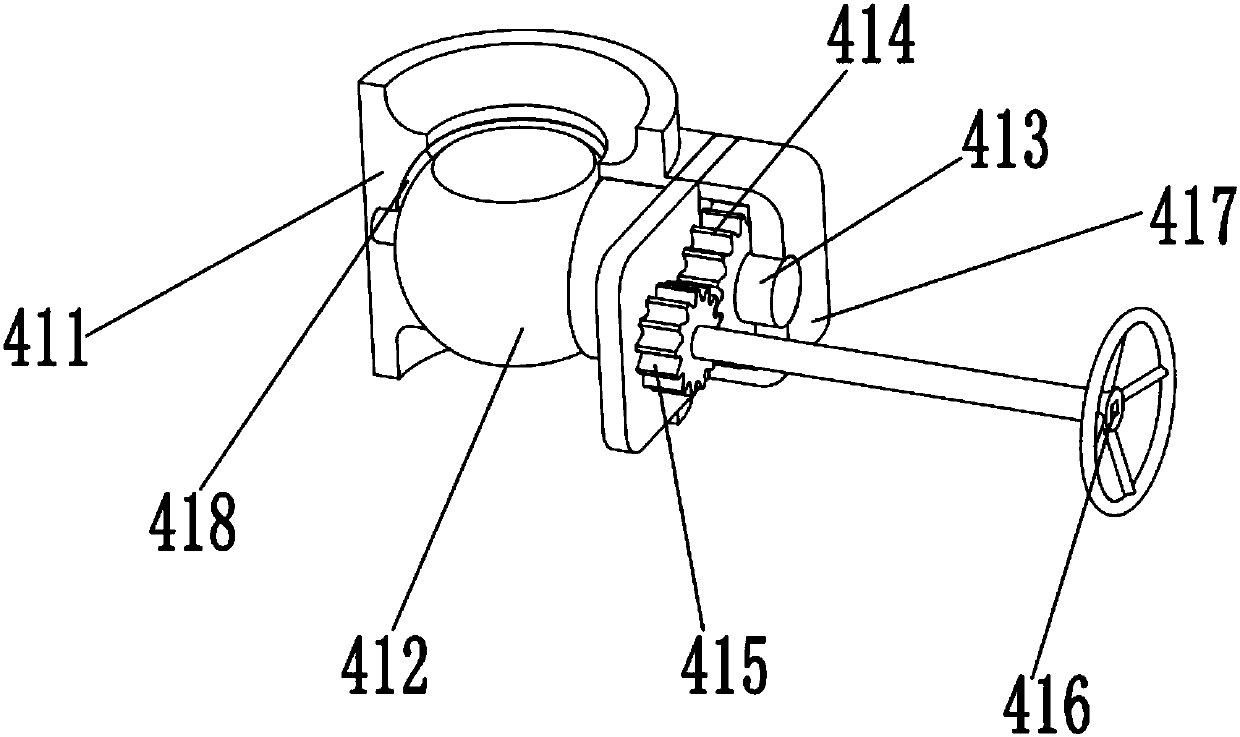

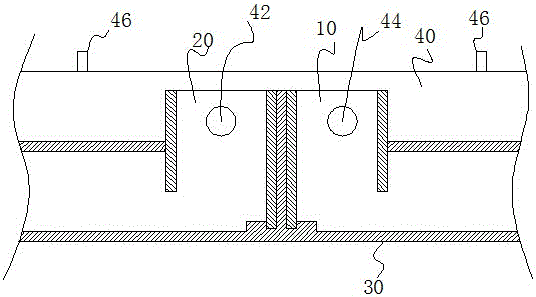

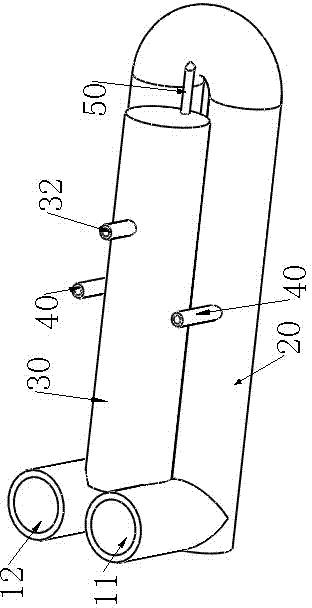

Method for producing biogas by biogas slurry reflux stirring device of auger type biogas generation system

ActiveCN104531513AGood convection stirring effectImprove distributionGas production bioreactorsWaste based fuelProcess engineeringSlurry

The invention discloses a method for producing biogas by a biogas slurry reflux stirring device of an auger type biogas generation system. The method comprises the steps of pouring fermentation raw materials from a feeding pipe, fermenting in a fermentation pipeline to produce biogas, respectively gathering the biogas in fermentation areas formed between the feeding pipe / discharging pipe and adjacent gas blocking plates or between the adjacent gas blocking plates, enabling the biogas to occupy the space in the fermentation area, extruding biogas slurry to realize convection, and enabling the biogas slurry to flow to the feeding pipe, the discharging pipe and a bacteria distribution device, wherein the biogas slurry in the fermentation pipe flows into a water pressure room through a drainage hole of the feeding pipe, the drainage hole of the discharging pipe and a drainage pipe of the bacteria distribution device as the liquid level of the biogas slurry in the feeding pipe, the discharging pipe and the bacteria distribution device rises; and using the biogas stored in any one fermentation area, wherein the gas pressure of the biogas stored in the fermentation area is reduced, the biogas slurry in the adjacent fermentation area flows into the fermentation area, and the biogas slurry stored in the water pressure room flows back into the fermentation pipeline through the drainage hole of the feeding pipe, the drainage hole of the discharging pipe and the drainage pipe of the bacteria distribution device to supplement the reduced biogas space, thereby completing the circulating flow of the biogas slurry.

Owner:六安皖智知识产权运营有限公司

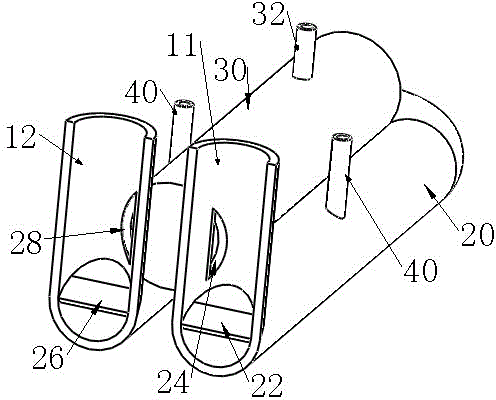

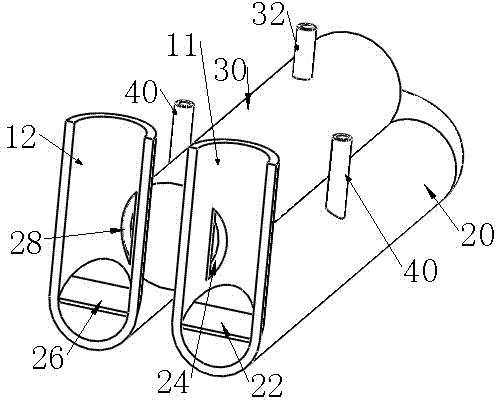

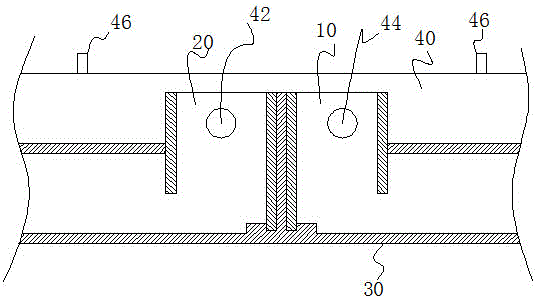

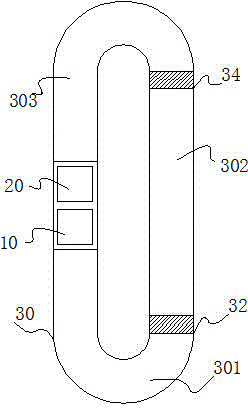

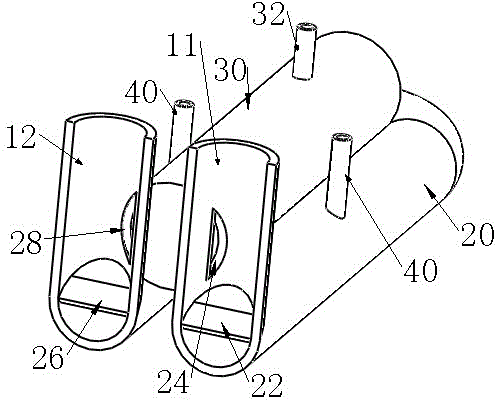

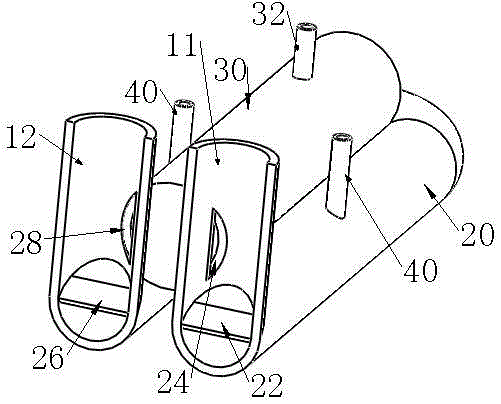

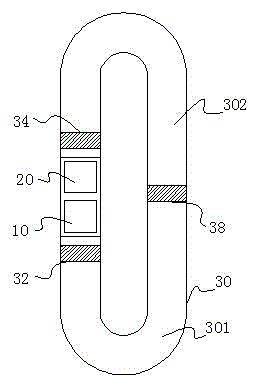

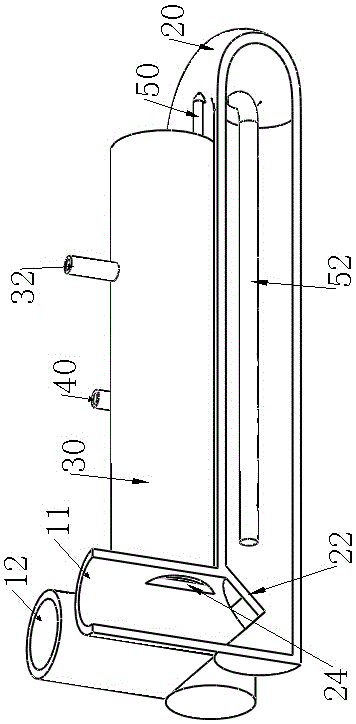

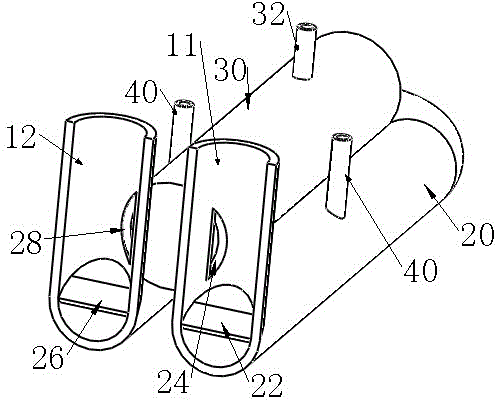

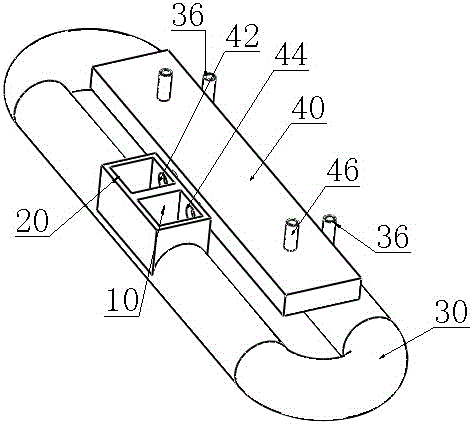

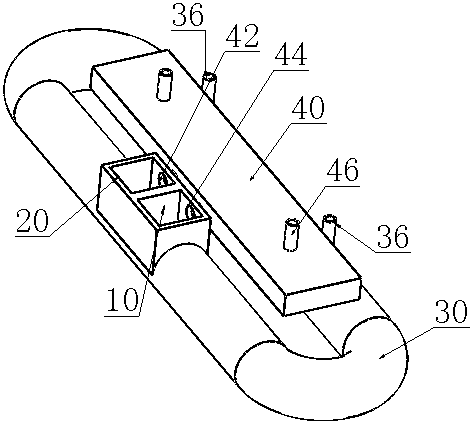

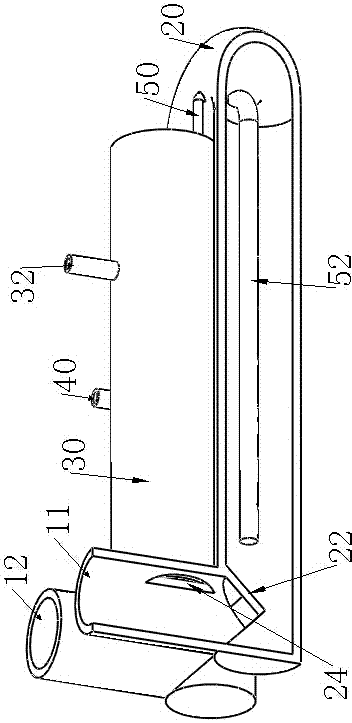

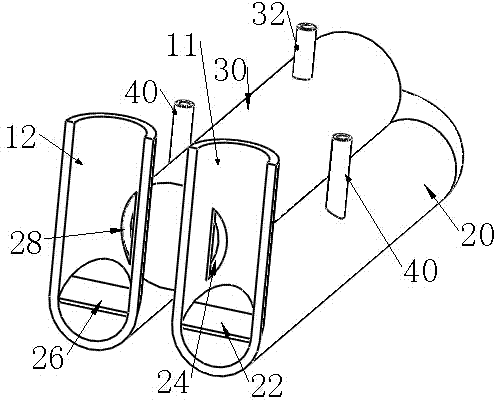

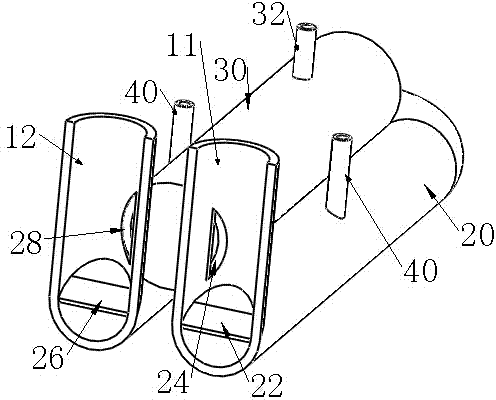

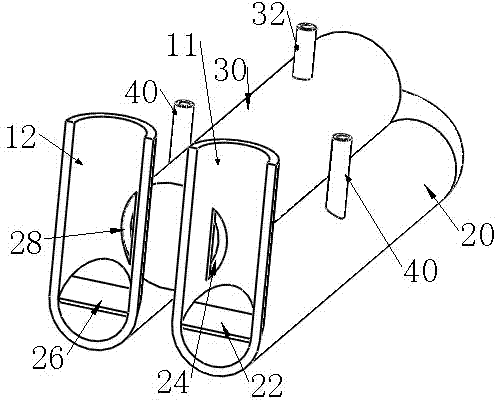

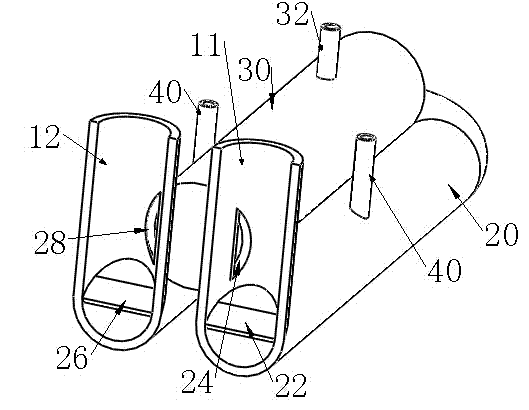

Device for promoting biogas slurry return flow agitation in intertwined biogas generation system

InactiveCN104498340AGood convection stirring effectImprove distributionGas production bioreactorsWaste based fuelProcess engineeringSlurry

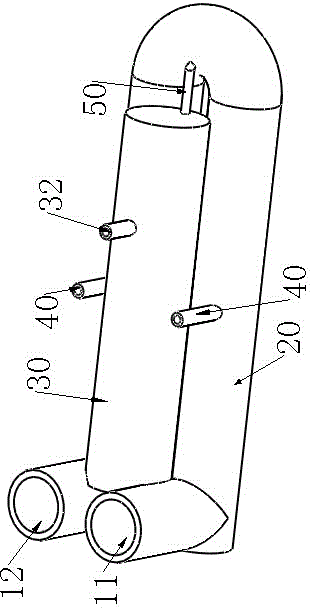

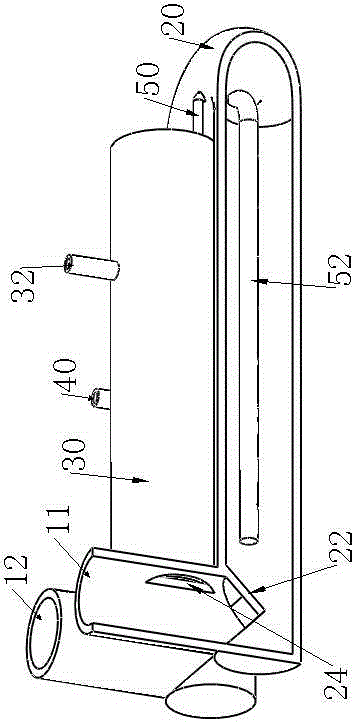

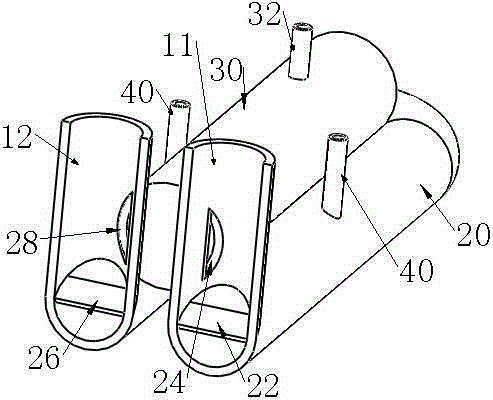

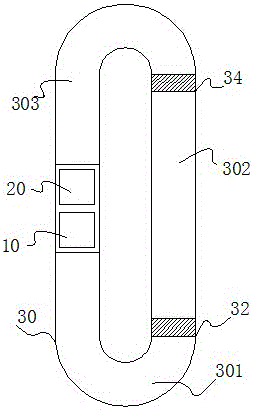

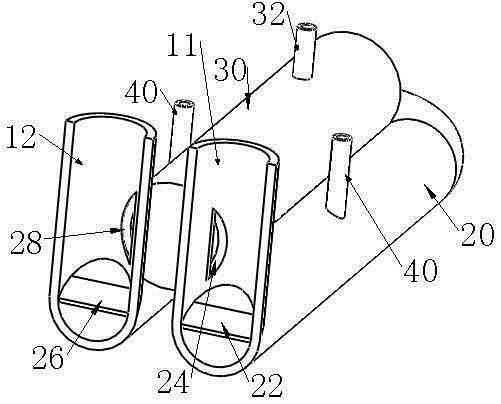

A device for promoting biogas slurry return flow agitation in an intertwined biogas generation system comprises a feeding pipe, a discharging pipe and a U-shaped fermentation pipeline. The U-shaped fermentation pipeline is horizontally placed, the feeding pipe and the discharging pipe are vertically connected with two end sides of the U-shaped fermentation pipeline, a water pressure space is formed on the U-shaped fermentation pipeline, a feeding pipe drain hole is formed in the joint of the water pressure space and the feeding pipe, a discharging pipe drain hole is formed in the joint of the water pressure space and the discharging pipe, a feeding pipe gas baffle plate is arranged at the joint of the U-shaped fermentation pipeline and the feeding pipe, a discharging pipe gas baffle plate is arranged at the joint of the U-shaped fermentation pipeline and the discharging pipe, at least one gas baffle plate is arranged between the discharging pipe gas baffle plate and the feeding pipe gas baffle plate, a fermentation area is formed among the feeding / discharging pipe and the adjacent gas baffle plates or between the adjacent gas baffle plates, an independent gas collecting pipe is arranged at the top of each fermentation area, the top of each fermentation area is connected with the independent gas collecting pipe, and a valve is arranged on each gas collecting pipe. A U-shaped channel-type fermentation device is used, a fermentation path is long, biogas slurry sufficiently flows in the system by control of water pressure difference and one-way valves, bacteria are driven to be uniformly distributed, crusting is effectively prevented, and gas generating rate is high.

Owner:程阳 +6

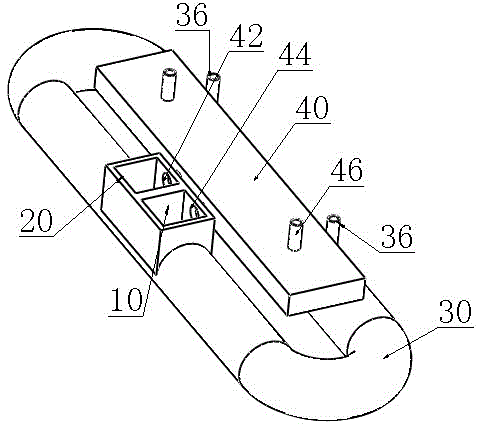

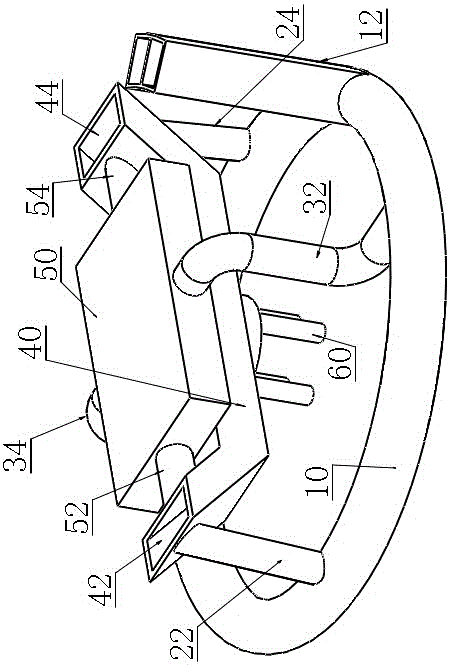

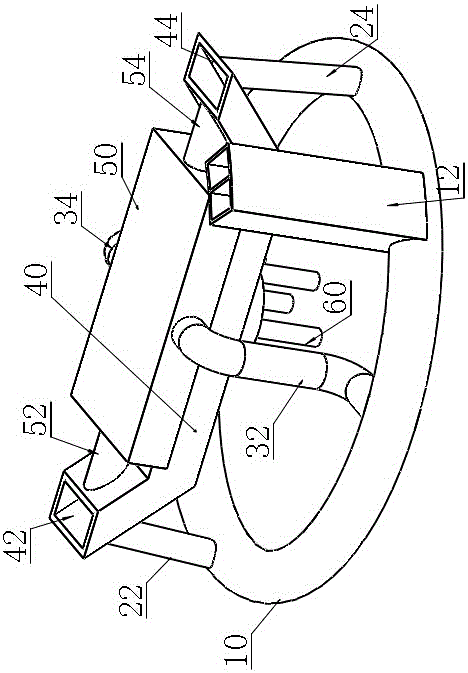

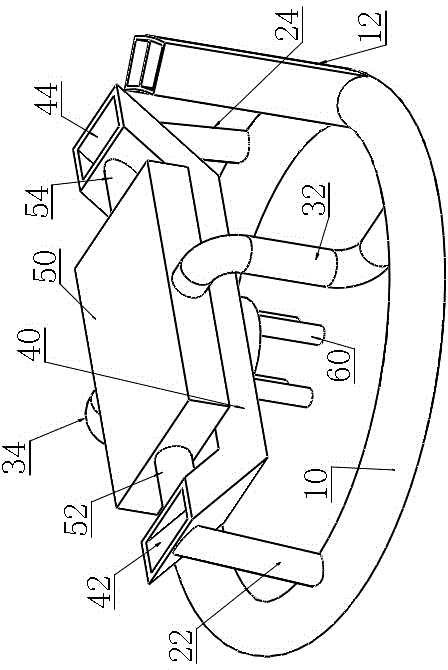

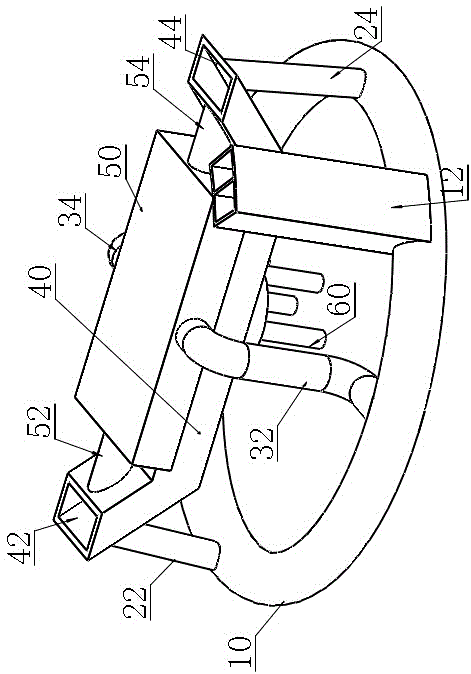

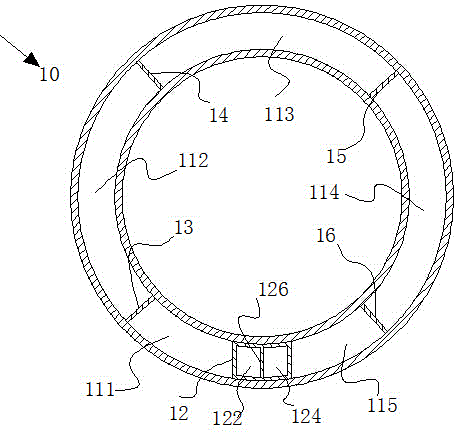

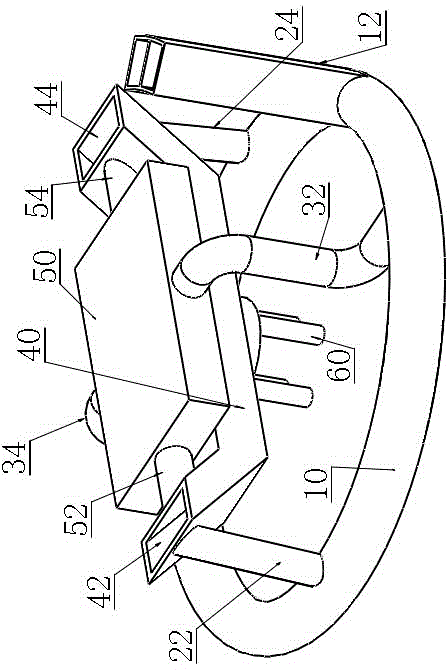

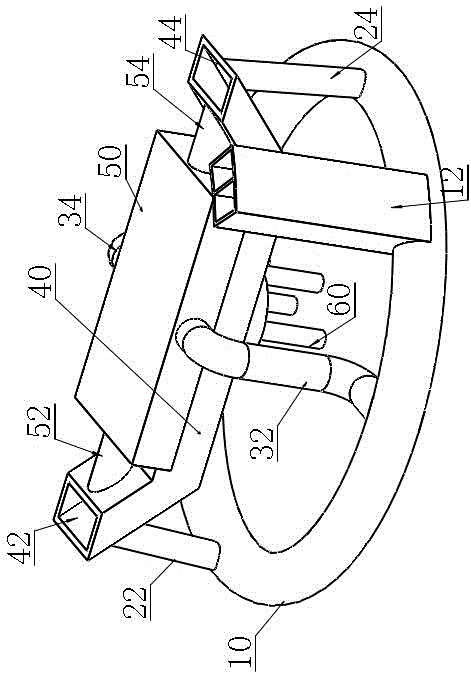

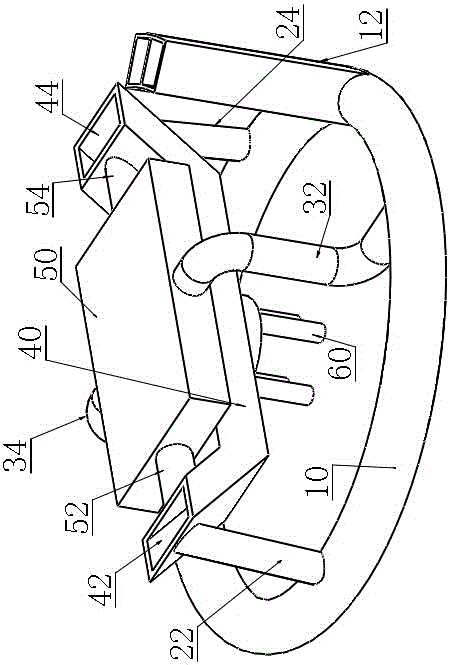

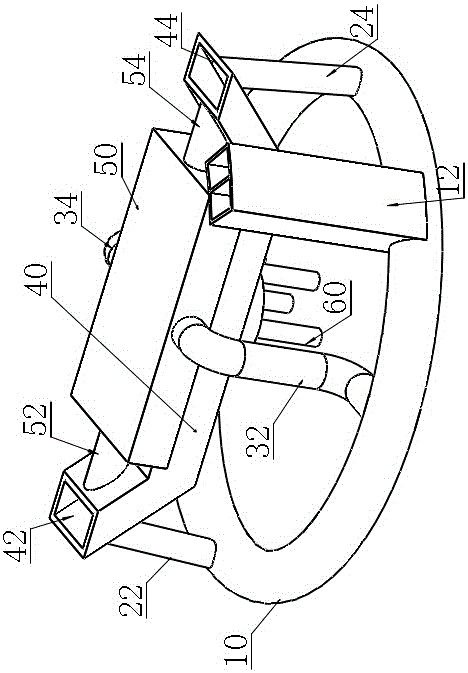

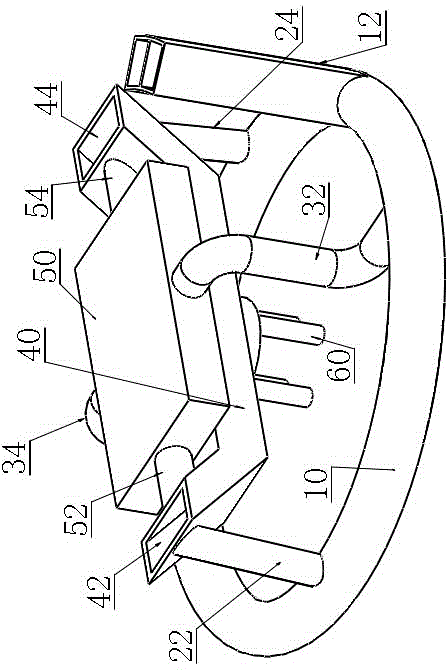

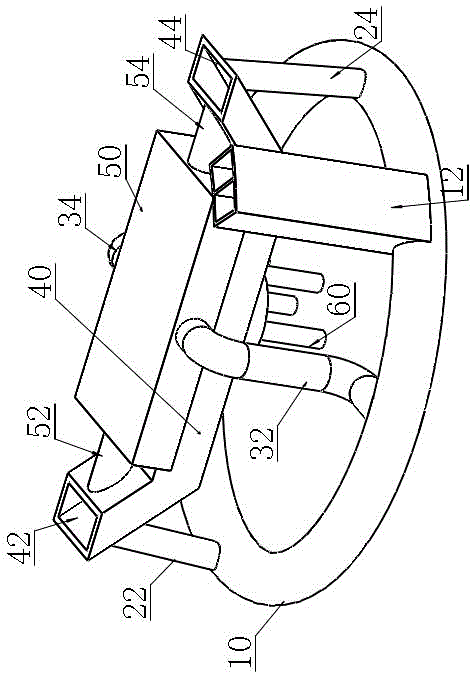

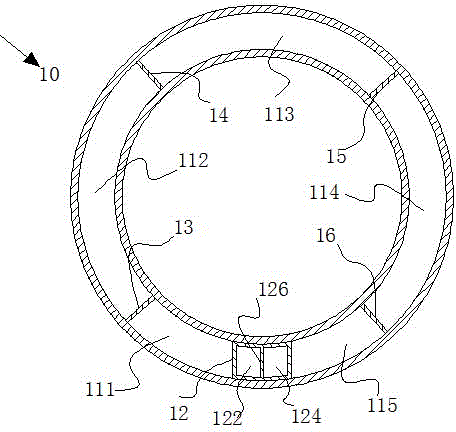

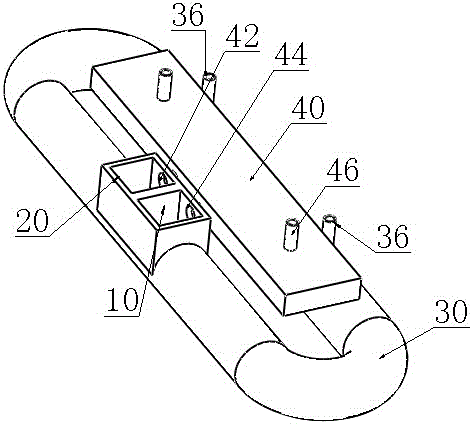

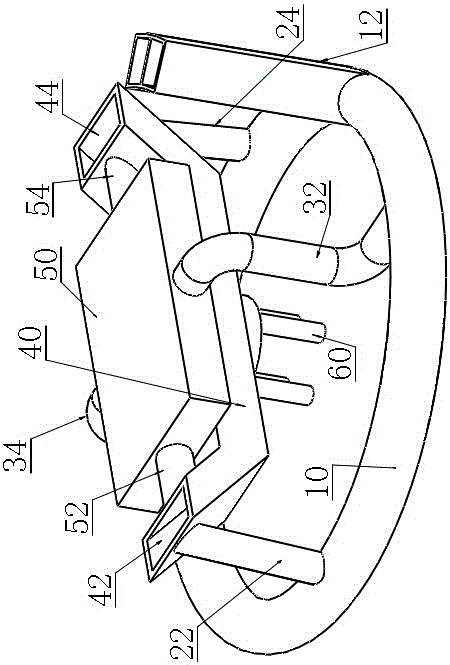

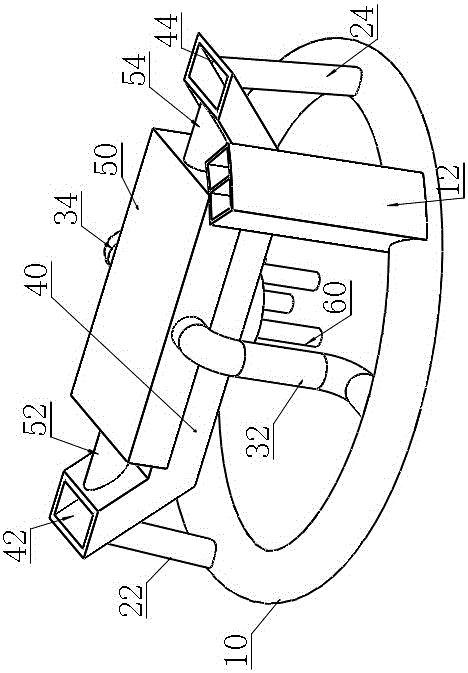

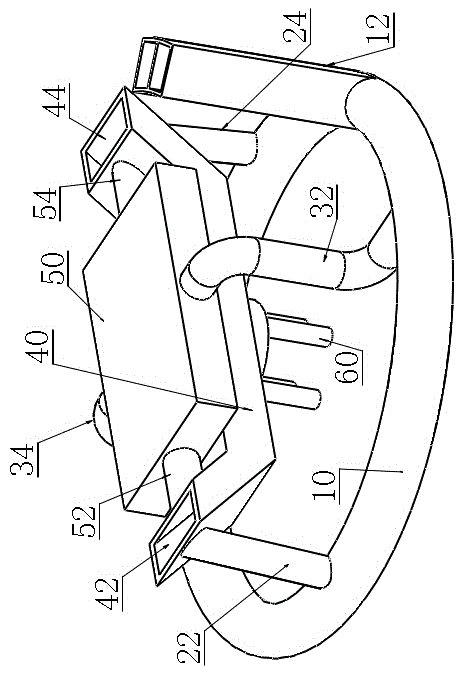

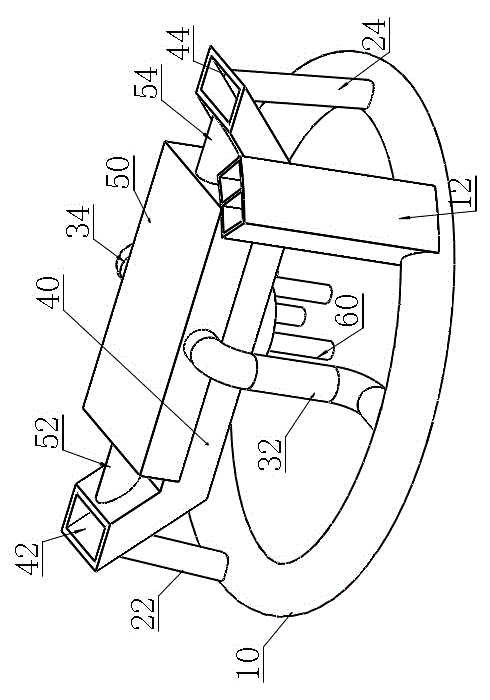

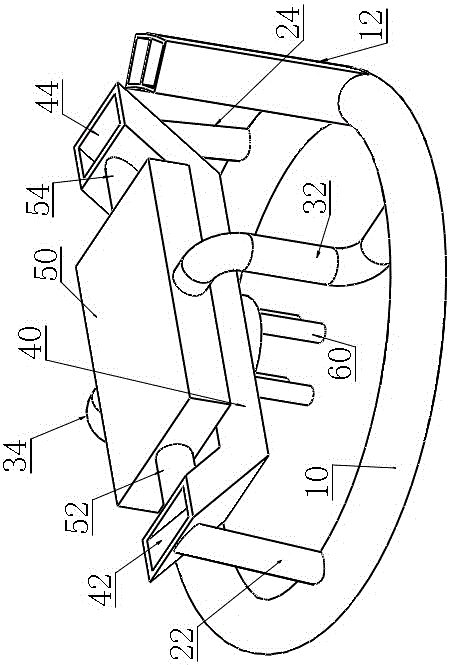

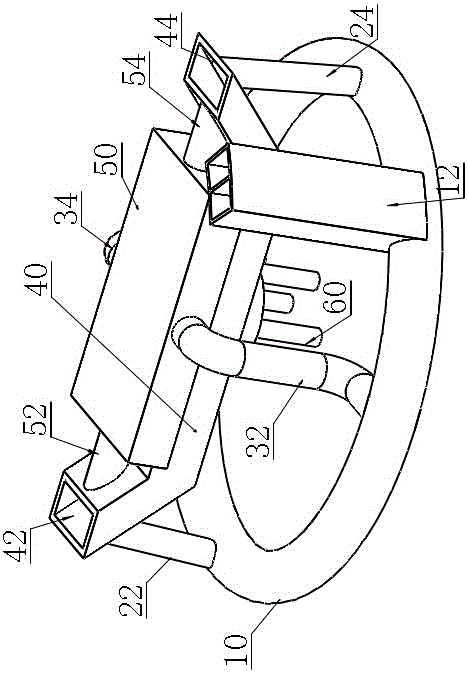

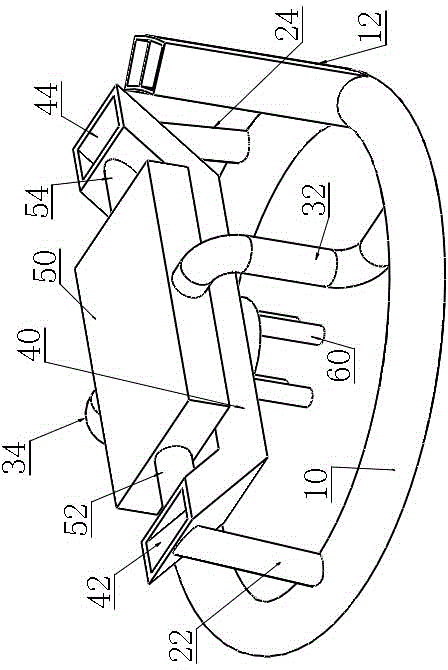

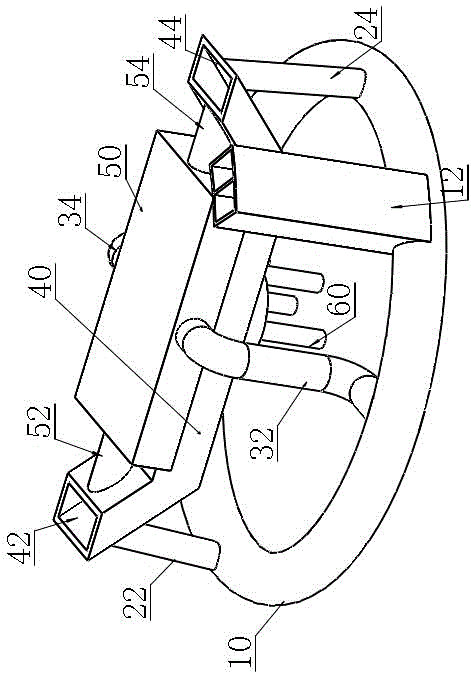

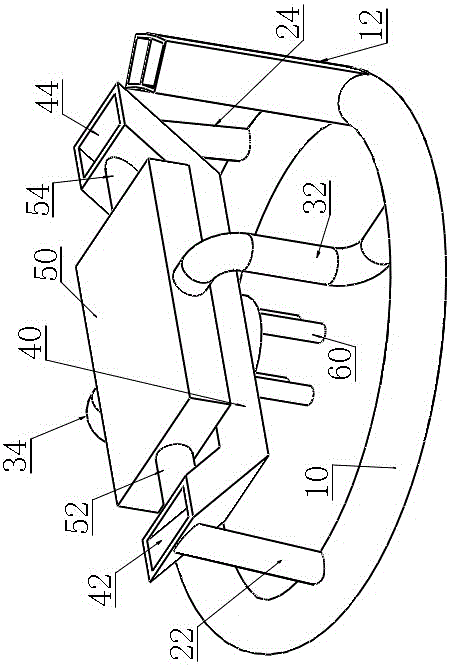

Detachable combined novel energy generating device

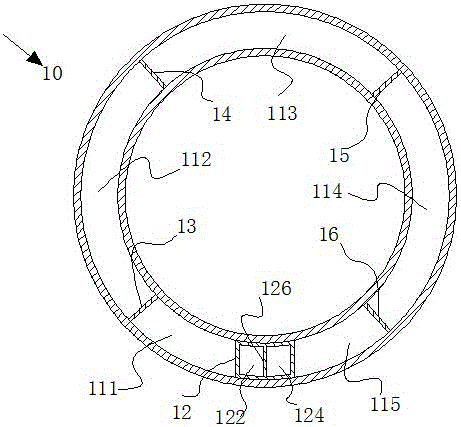

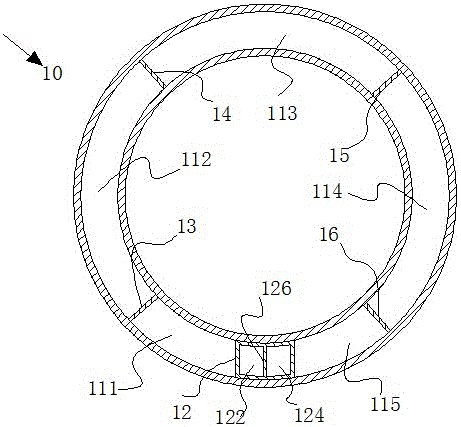

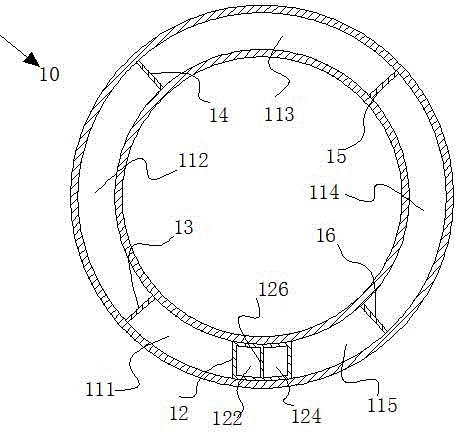

InactiveCN104593234ALong fermentation routeImprove fermentation efficiencyGas production bioreactorsEngineeringMechanical engineering

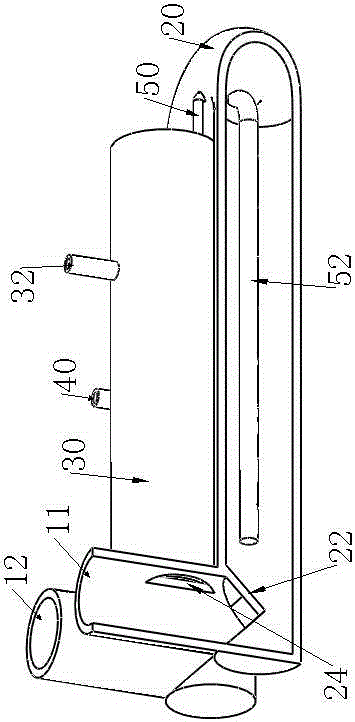

The invention discloses a detachable combined novel energy generating device. The detachable combined novel energy generating device comprises a feeding pipe, a discharging pipe, a fermenting pipeline and a water pressure chamber, wherein the fermenting pipeline is an annular fermenting pipeline, the water pressure chamber is arranged on the top of the annular fermenting pipeline, an opening is formed in the annular fermenting pipeline, a partition board which extends to the bottom of the annular fermenting pipeline is formed in the central position of the opening, the feeding pipe and the discharging pipe are respectively inserted into two sides of the partition board, and the side walls of the feeding pipe and the discharging pipe extend below the liquid level of biogas slurry of the annular fermenting pipeline; a feeding pipe draining pipe is connected between the water pressure chamber and the feeding pipe, a discharging pipe draining pipe is connected between the water pressure chamber and the discharging pipe, at least one gas baffle is arranged in the annular fermenting pipeline, one fermenting region is formed between every two adjacent gas baffles, independent gas guide pipes are arranged on the tops of the fermenting regions, and valve bodies are arranged on the gas guide pipes. By virtue of an annular fermenting system, a fermenting route is long, and the adequate fermentation is guaranteed; by dividing the fermenting system into multiple fermenting regions by virtue of multiple gas baffles, and the flow of the biogas slurry, strains and fermenting raw materials is promoted by virtue of air pressure difference, so that the fermenting efficiency is improved.

Owner:张玲玲

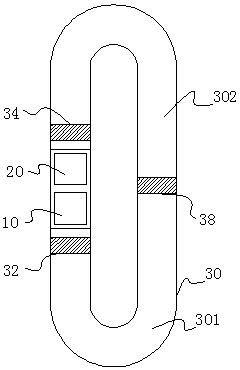

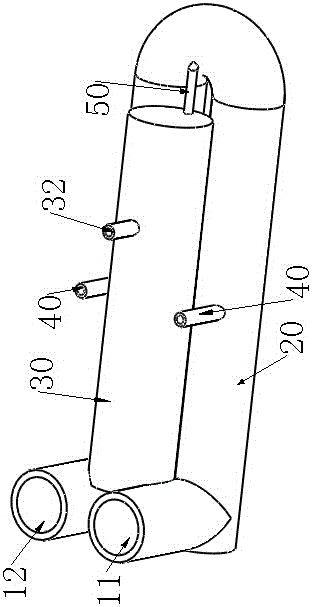

Ultra-efficient methane generation system with curved pneumatic extrusion biogas slurry flow and agitation

ActiveCN104498343BGood convection stirring effectImprove distributionGas production bioreactorsWaste based fuelSlurryProcess engineering

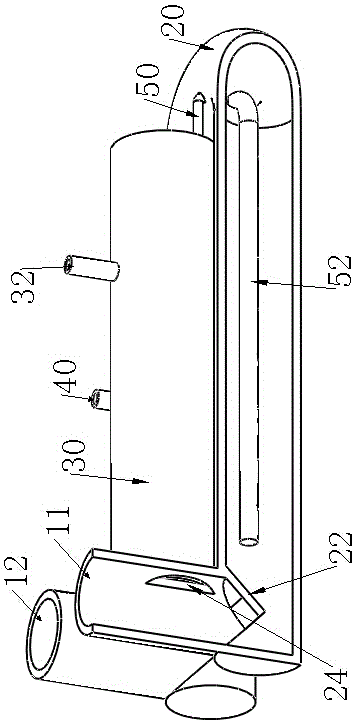

The invention discloses a bend type pneumatic extrusion biogas fluid stirred flow super efficient methane generation system. The bend type pneumatic extrusion biogas fluid stirred flow super efficient methane generation system comprises a feed pipe, a discharge pipe and a U-shaped fermentation pipeline, the U-shaped fermentation pipeline is horizontally placed, the feed pipe and the discharge pipe are vertically connected with two end sides of the U-shaped fermentation pipeline, a hydraulic pressure room is located at the upper part of the U-shaped fermentation pipeline, the connection part between the hydraulic pressure room and the feed pipe is the feed pipe drain hole, the connection part between the hydraulic pressure room and the discharge pipe is the discharge pipe drain hole, the connection part between the U-shaped fermentation pipeline and the feed pipe is provided with a feed pipe gas baffle plate, the connection part between the U-shaped fermentation pipeline and the discharge pipe is provided with a discharge pipe gas baffle plate, at least one gas baffle plate is formed between the discharge pipe gas baffle plate and the feed pipe gas baffle plate, a fermentation region is formed between the feed pipe / discharge pipe and the adjacent gas baffle plate or between the adjacent gas baffle plates, an independent gas collecting pipe is arranged at the top of each fermentation region; the top of each fermentation region is connected with the independent gas collecting pipe and the independent gas collecting pipe is provided with a valve body; the fermentation line is long by adopting the U-shaped channel-type fermentation device, the biogas fluid can flow in the system for driving the bacteria to be evenly distributed through the control of the water pressure difference and the one-way valve, the crusting phenomenon can be effectively prevented and the gas yield is high.

Owner:六安皖智知识产权运营有限公司

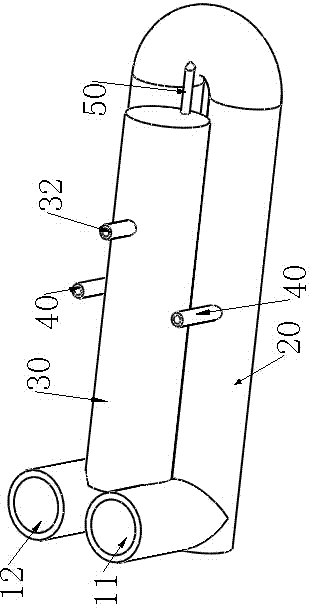

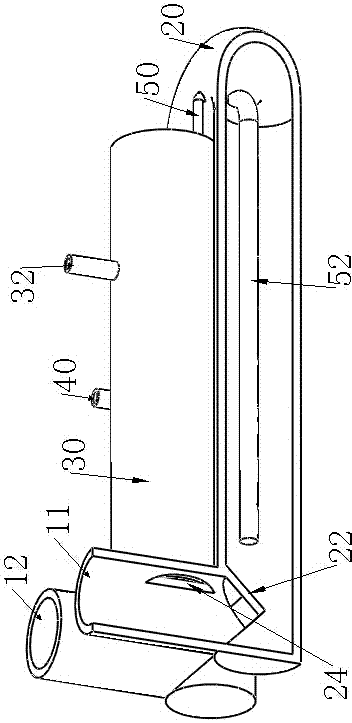

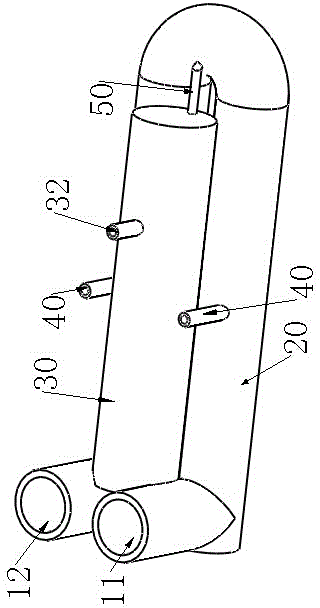

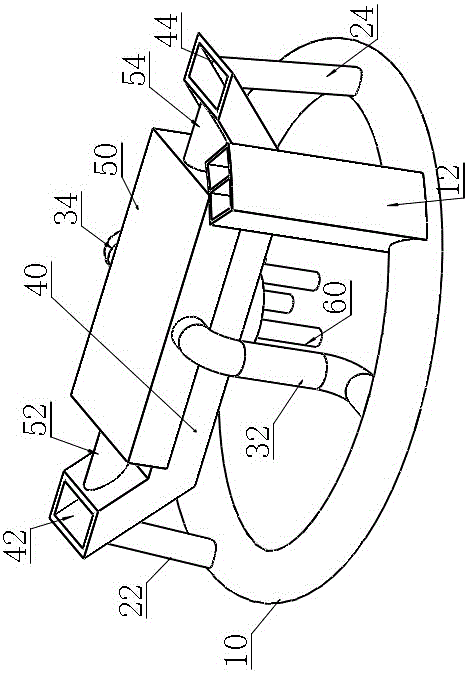

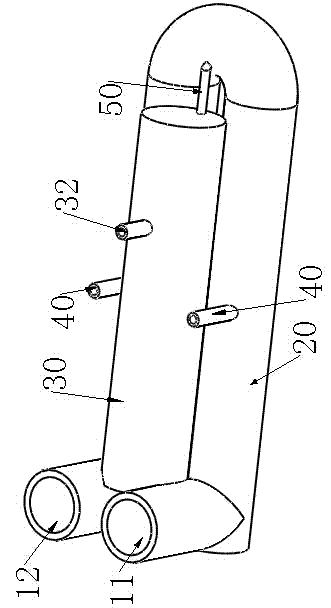

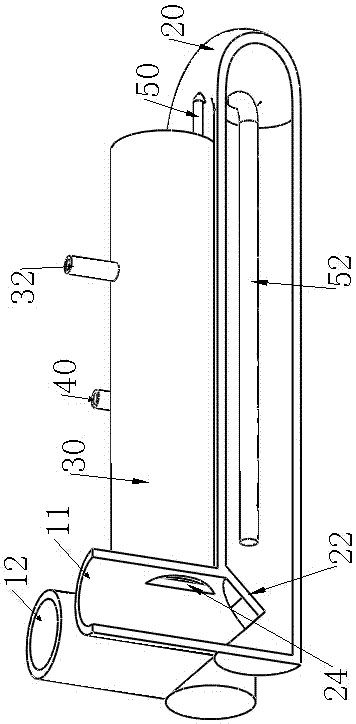

Tower-type two-stage linkage fermentation system to promote uniform distribution of bacteria

ActiveCN104611211BPromote circulationStir wellGas production bioreactorsWaste based fuelAgricultural engineeringSlurry

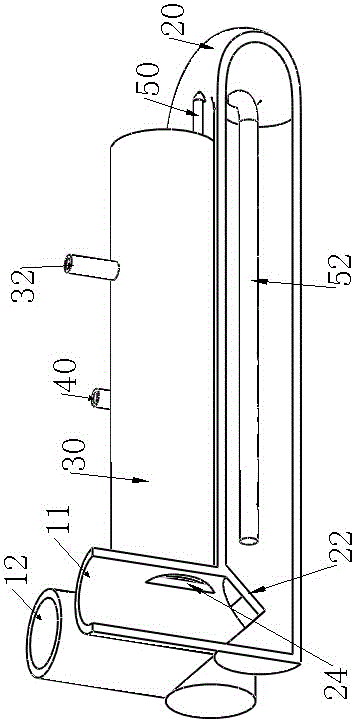

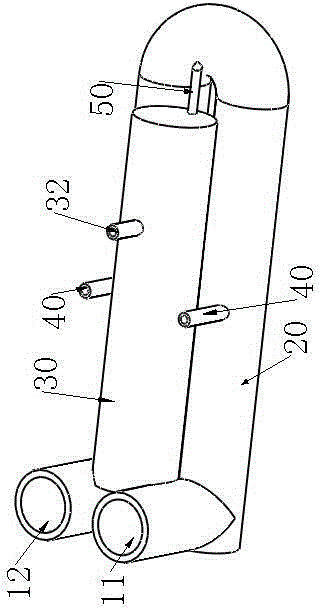

The invention discloses a tower-type two-stage linkage fermentation system for promoting uniform distribution of strains, which includes a primary fermentation system and a secondary fermentation system, the installation position of the secondary fermentation system is higher than that of the primary fermentation system, the primary fermentation system and the secondary fermentation system The first-stage fermentation systems are connected by aqueducts, the secondary feed pipes and / or discharge pipes are connected with the first-stage fermentation pipes, and the water pressure rooms are connected with the first-stage fermentation pipes; the first-stage The fermentation system adopts a circular fermentation pipeline with a long fermentation route. The synchronous fermentation of the primary fermentation system and the secondary fermentation system promotes the circulation of the biogas slurry in the system, effectively promotes the stirring of the biogas slurry, and drives the uniform distribution of bacteria. Improve the fermentation efficiency in the system.

Owner:北京航天恒丰科技股份有限公司

A device for improving the turbulence effect of biogas slurry in the curved methane generation system

InactiveCN104498338BImprove flowGood convection stirring effectGas production bioreactorsWaste based fuelProcess engineeringSlurry

A device for improving the turbulence effect of biogas slurry in a curved methane generation system, which includes: feed pipe, discharge pipe, U-shaped fermentation pipe, the U-shaped fermentation pipe is placed horizontally, and the feed pipe and discharge pipe are vertically connected to the U-shaped fermentation pipe. On both ends of the pipeline, a water pressure room is placed on the upper part of the U-shaped fermentation pipeline. A feed pipe air baffle is set at the connection position between the pipeline and the feed pipe, a discharge pipe air baffle is set at the connection position between the U-shaped fermentation pipeline and the discharge pipe, the discharge pipe air baffle and the feed pipe air baffle There is also at least one air baffle between them, and a fermentation area is formed between the inlet / outlet pipe and the adjacent air baffle or between the adjacent air baffles, and the top of each fermentation area is provided with an independent collector Trachea; the top of each fermentation area is connected to an independent gas collection pipe, and the gas collection pipe is equipped with a valve body; the U-shaped channel fermentation device is adopted, the fermentation route is long, and the biogas slurry is realized by using the control of water pressure difference and one-way valve It flows fully in the system and drives the uniform distribution of bacteria, effectively preventing crusting and high gas production rate.

Owner:佛山市高科气体有限公司

Method for producing methane in secondary synchronous methane fermentation system

ActiveCN104560682APromote circulationStir wellGas production bioreactorsWaste based fuelMethane fermentationSlurry

The invention discloses a method for producing methane in a secondary synchronous methane fermentation system. The method comprises the following steps: fermenting to produce biogas in a primary fermentation system, and gathering the biogas in the side walls of a charging / discharging barrel and adjacent gas baffles or in a fermentation area formed between adjacent gas baffles; extruding the biogas slurry in a primary fermentation pipeline to flow to a first water guide pipe and a second water guide pipe, and finally allowing the biogas slurry to flow into a secondary fermentation pipeline; fermenting to produce biogas in a secondary fermentation system, and gathering the biogas between the side walls of a secondary feeding / discharging pipe and adjacent gas baffles or in a fermentation area formed between the adjacent gas baffles, allowing the biogas slurry to flow into a water pressure room in a one-way mode by virtue of a secondary discharging pipe, and allowing the biogas slurry in the secondary fermentation pipeline to flow into the water pressure room by virtue of a drainage pipe of a bacteria distribution device when the liquid level of the biogas slurry in the water pressure room reaches the lowest position of the upper part of the drainage pipe of the bacteria distribution device.

Owner:徐州金港起重机制造有限公司

Large capacity storage methane fermentation system

InactiveCN104560685APromote circulationStir wellGas production bioreactorsWaste based fuelMass storageMethane fermentation

The invention discloses a large capacity storage methane fermentation system which comprises a primary fermentation system and a secondary fermentation system, wherein the mounting position of the secondary fermentation system is higher than that of the primary fermentation system; the primary fermentation system and the secondary fermentation system are connected by virtue of a water guide pipe; the water guide pipe is connected between a secondary feeding pipe and / or discharging pipe and a primary fermentation pipeline; and a water guide pipe is connected between a water pressure room and the primary fermentation pipeline. An annular fermentation pipeline is adopted in the primary fermentation system, the fermentation route is long, circular flow of biogas slurry in the system is promoted by virtue of simultaneous fermentation of the primary fermentation system and the secondary fermentation system, stirring of the biogas slurry is effectively promoted, uniform culture distribution is promoted, and the fermentation efficiency in the system is improved.

Owner:罗小华

Method for producing methane in a system with tower-type two-stage linkage fermentation to promote uniform distribution of strains

InactiveCN104630047BPromote circulationStir wellGas production bioreactorsWaste based fuelTowerBiology

The invention discloses a method for producing methane by using a system used for promoting uniform distribution of strains in a tower-type two-stage linkage fermentation way. The method comprises following steps: fermentation is performed in a first-stage fermentation system to generate methane and the generated methane is accumulated in a fermentation region formed between the side wall of a charge / discharge barrel and an adjacent gas blocking plate or between adjacent gas blocking plates; then, biogas slurry in a first-stage fermentation pipeline is pressed to flow into a first water guide pipe and a second water guide pipe and finally flow into a second-stage fermentation pipeline; methane is produced through fermentation in a second-stage fermentation system, is accumulated in a fermentation region formed between the side wall of a second-stage charge / discharge tube and an adjacent gas blocking plate or between adjacent gas blocking plates and finally flows into a hydraulic pressure room through the second-stage discharge pipe in a unidirectional way.

Owner:孙俊艳

Biogas Fermentation System of Panlong-style Cloth Bacteria in Several Partitions

ActiveCN104513789BGood convection stirring effectImprove distributionGas production bioreactorsWaste based fuelEnvironmental engineeringMechanical engineering

Owner:河北德瑞环保设备有限公司

Multistage linked fermentation system capable of improving biogas slurry turbulence effect

InactiveCN104593245APromote circulationStir wellGas production bioreactorsWaste based fuelSlurryEngineering

The invention discloses a multistage linked fermentation system capable of improving a biogas slurry turbulence effect. The fermentation system comprises a primary fermentation system and a secondary fermentation system, wherein the installation position of the secondary fermentation system is higher than that of the primary fermentation system; the primary fermentation system is connected with the secondary fermentation system by use of a water guide pipe; a water guide pipe is connected between a secondary feed pipe and / or a discharge pipe and a primary fermentation pipeline, and a water guide pipe is also connected between a water pressure chamber and the primary fermentation pipeline. The primary fermentation system adopts an annular fermentation pipeline, so that the fermentation route is long; biogas slurry can be promoted to circularly flow in the system by virtue of the synchronous fermentation of the primary fermentation system and the secondary fermentation system, and therefore, the biogas slurry can be stirred favorably, a bacterial strain can be distributed evenly, and the fermentation efficiency in the system can be improved.

Owner:胡秀红

Method for producing biogas in disordered turbulent biogas fermentation system

ActiveCN104673651BSpeed up the flowLong fermentation routeGas production bioreactorsWaste based fuelContinuous fermentationSlurry

The invention discloses a method for producing biogas through a disordered turbulence type super-high-efficiency biogas fermentation system. The method is characterized by comprising the steps: pushing biogas slurry to flow to an adjacent fermentation area when the biogas is produced in a fermentation area between the side wall of a feeding / discharging pipe and a gas baffle or a fermentation area formed between adjacent gas baffles in an annular fermentation pipeline; allowing the biogas produced by continuous fermentation to flow into an adjacent fermentation area which is not filled with biogas until the fermentation areas are communicated with one another when the fermentation area is filled with biogas; allowing the biogas produced by continuous fermentation to overflow from the fermentation system and discharge into atmosphere when the liquid level of the biogas slurry in the annular fermentation pipeline reaches the lowest position of the side wall of the feeding pipe or discharging pipe; and allowing the liquid level of biogas slurry in the feeding pipe, the discharging pipe and the bacteria distribution device to continuously ascend in the process of producing biogas in the annular fermentation pipeline, and allowing the biogas slurry to flow into the water pressure room by virtue of the drainage pipe of the feeding pipe, the drainage pipe of the discharging pipe and the bacteria distribution device.

Owner:谭家湾遗址公园运营管理(桐乡乌镇)有限公司

Ultra-efficient biogas generation device that promotes the circulation of biogas slurry by air pressure

ActiveCN104496142BFull flowEvenly distributedWaste based fuelBiological sludge treatmentProcess engineeringEnvironmental engineering

The invention discloses an ultra-high-efficiency biogas generating device that air pressure promotes biogas slurry circulation, which includes a feed pipe, a discharge pipe, and a U-shaped fermentation pipe. The U-shaped fermentation pipe is placed horizontally, and the feed pipe and the discharge pipe are connected vertically. At both ends of the U-shaped fermentation pipeline, a water pressure room is placed on the upper part of the U-shaped fermentation pipeline. The connection between the water pressure room and the feed pipe is the drain hole of the feed pipe, and the connection between the water pressure room and the discharge pipe is the discharge hole of the discharge pipe. A feed pipe air baffle is set at the connection position between the U-shaped fermentation pipeline and the feed pipe, and a discharge pipe air baffle is set at the connection position between the U-shaped fermentation pipeline and the discharge pipe; the U-shaped fermentation pipeline is provided with a gas collecting pipe. The drain hole of the feed pipe is provided with a one-way valve to control the one-way flow of the biogas slurry in the water pressure chamber into the feed pipe. The fermentation route is long, using the control of water pressure difference and one-way valve to realize the full flow of biogas slurry in the system, and to drive the uniform distribution of bacteria, effectively prevent crusting, high gas production rate, suitable for large-scale production.

Owner:广东新科迪环保科技有限公司

Multi-stage linkage fermentation system

ActiveCN104611212BPromote circulationStir wellGas production bioreactorsWaste based fuelAgricultural engineeringSlurry

The invention discloses a multi-level interaction type fermentation system which comprises a primary fermentation system and a secondary fermentation system, wherein the mounting position of the secondary fermentation system is higher than that of the primary fermentation system; the primary fermentation system and the second fermentation system are connected by virtue of a water guide pipe; a water guide pipe is connected between a secondary feeding pipe and / or discharging pipe and a primary fermentation pipeline; and a water guide pipe is connected between a water pressure room and the primary fermentation pipeline. The primary fermentation system adopts an annular fermentation pipeline, the fermentation route is long, circulating flow of a biogas slurry in the system is promoted by virtue of synchronous fermentation of the primary fermentation system and the second fermentation system, stirring of the biogas slurry is effectively promoted, uniform distribution of strains is driven, and the fermentation efficiency in the system is improved.

Owner:谭家湾遗址公园运营管理(桐乡乌镇)有限公司

Method for producing biogas employing super-effective biogas fermentation system

InactiveCN104673840ASpeed up the flowFacilitates flow and agitationGas production bioreactorsWaste based fuelProcess engineeringBiogas production

The invention discloses a method for producing biogas employing a super-effective biogas fermentation system. The method comprises the following steps: a fermentation raw material is poured into a feeding pipe, wherein a plurality of fermentation zones in an annular fermentation pipeline generate different biogases in quantity; the fermentation zone with relatively high atmospheric pressure prompts biogas slurry to flow towards the fermentation zone with relatively low atmospheric pressure; when the biogas is fully collected in the fermentation zone with relatively high atmospheric pressure, the biogas generated by further fermentation flows towards the adjacent fermentation zone which is not full of the biogas; in the biogas production process in the annular fermentation pipeline, the biogas slurry is extruded in the fermentation pipeline into a feeding pipe, a discharge pipe and a bacteria distribution device; firstly, the biogas slurry in the fermentation pipeline is extruded into a water pressure room through the bacteria distribution device; and when the liquid level of the biogas slurry in the water pressure room reaches the lowest liquid levels of a feeding pipe drain pipe and a discharge pipe drain pipe, the biogas slurry flows into the water pressure room through the feeding pipe drain pipe, and flows into the water pressure room through the discharge pipe drain pipe in a one-way.

Owner:潘显敏

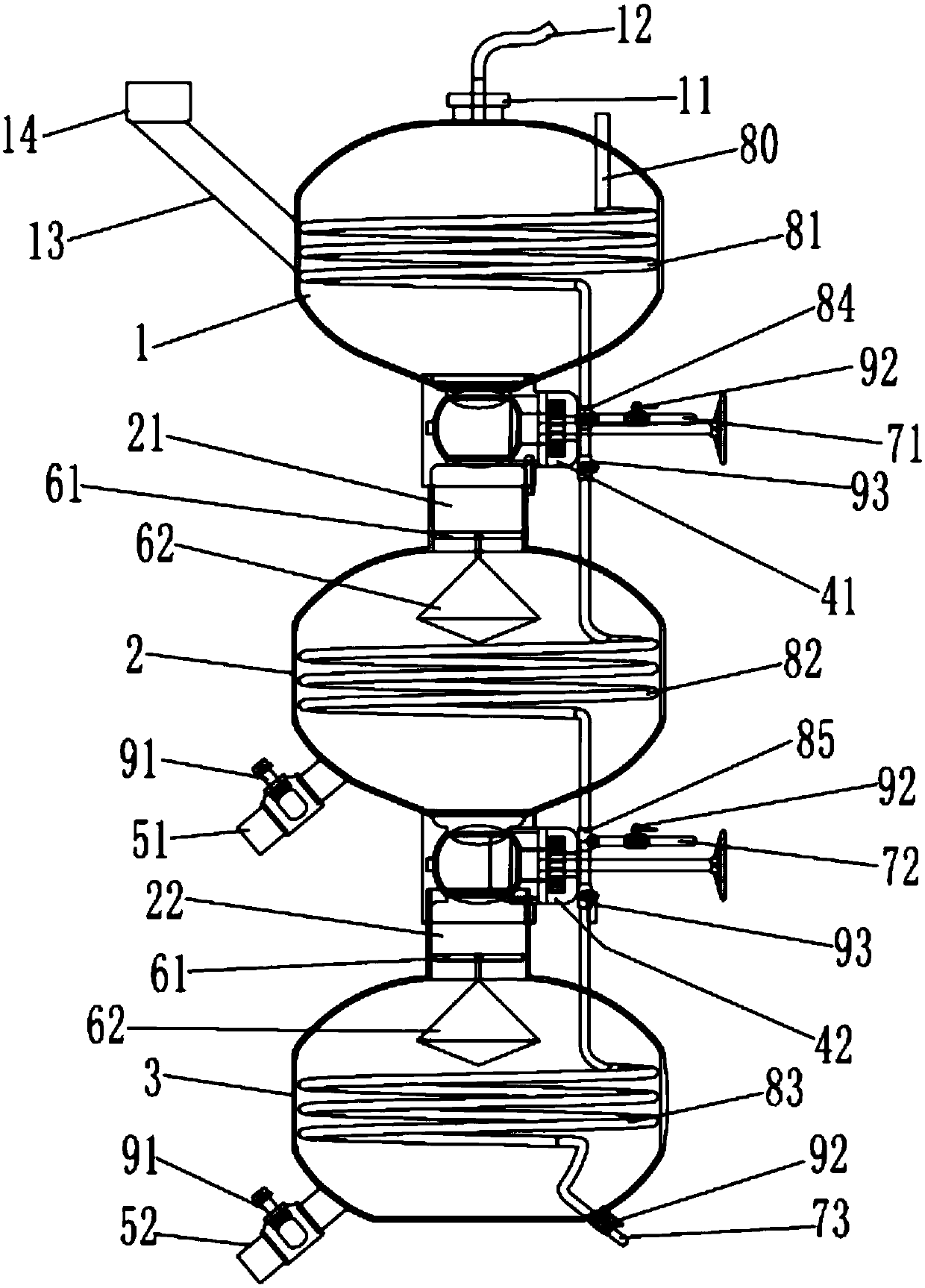

Separate floating cover type novel methane fermentation device

InactiveCN107815411AImprove fermentation efficiencyIncrease biogas outputBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasGas pipeline

The invention discloses a novel biogas fermentation device of separation floating cover type, which comprises a first fermentation room (1), a second fermentation room (2) and a third fermentation room (3) which are sequentially connected from top to bottom. A fermentation room (1) is provided with a steam input pipe (80), a valve is provided between two adjacent fermentation rooms, and a valve is provided in the second fermentation room (2) and the third fermentation room (3). There is a diffusion device; the three fermentation rooms are equipped with annular air pipes, and each of the annular air pipes passes through the corresponding fermentation room, and the annular air pipes between two adjacent fermentation rooms protrude The ends are connected to each other, and the corresponding steam pipes are externally connected to the connected positions. The present invention is provided with three fermentation rooms connected from top to bottom, and is equipped with a diffusion device, and an annular air pipe connected to a steam conduit, while controlling the temperature, it can also discharge materials in a timely manner without affecting the continuity of fermentation. The fermentation efficiency is improved, and the output of biogas is increased.

Owner:CHONGQING UNIV OF ARTS & SCI

Method for generating methane by using device capable of promoting multistage fermentation with barometric disturbance

ActiveCN104593241APromote circulationStir wellGas production bioreactorsWaste based fuelSlurryAtmospheric pressure

The invention discloses a method for generating methane by using a device capable of promoting multistage fermentation with barometric disturbance, which comprises the following steps: biogas is generated by fermentation in a primary fermentation system and accumulated in a fermentation which is formed between the side wall of an inlet / outlet charging barrel and the adjacent gas barrier or between the adjacent gas barriers, and biogas slurry in a primary fermentation pipeline is forced to flow to a first water manifold and a second water manifold and finally flow into a secondary fermentation pipeline; biogas is generated by fermentation in a secondary fermentation system and accumulated in a fermentation region which is formed between the side wall of a secondary inlet / outlet charging barrel and the adjacent gas barrier or between the adjacent gas barriers, and flows into a water pressure chamber through a discharge line drainage pipe; and when the secondary fermentation pipeline is used for storing the biogas, the biogas slurry stored in the water pressure chamber unidirectionally flows into the secondary fermentation pipeline through a drainage pipe of a bacterium distributor.

Owner:临泉县白良电子信息技术有限责任公司

Method for Promoting Biogas Generation System with Evenly Distributed Bacterial Species by Bacteria Spreading Device

InactiveCN104529118BAchieve circular flowImprove filtration efficiencyWaste based fuelBiological sludge treatmentDraining tubeEngineering

The invention discloses a method for producing biogas by use of a biogas generation system with a bacterium distributor for promoting even distribution of bacteria. The method comprises the following steps that: fermentation raw materials are poured into a U-shaped fermentation pipeline via a feed pipe and fermented to produce biogas, the biogas is gathered in the space between a feed pipe gas baffle plate and a discharge pipe gas baffle plate in the U-shaped fermentation pipeline so as to occupy the space in the fermentation pipeline and push the biogas slurry in the fermentation pipeline to flow into the feed pipe, the discharge pipe and the bacterium distributor and further flow into a water pressure chamber unidirectionally via a discharge pipe drain hole and flow into the water pressure chamber via the drain pipe of the bacterium distributor; and when the biogas stored in the fermentation pipeline is output to the outside via a gas collecting pipe, the pressure of the biogas in the fermentation pipeline drops and the biogas stored in the water pressure chamber unidirectionally flows into the fermentation pipeline via the feed pipe drain hole and returns to the fermentation pipeline via the drain pipe of the bacterium distributor, and therefore, circular flow of the biogas slurry is completed.

Owner:康洪祥

Large-capacity storage methane fermentation system

InactiveCN104560685BPromote circulationStir wellGas production bioreactorsWaste based fuelMass storageMethane fermentation

The invention discloses a large capacity storage methane fermentation system which comprises a primary fermentation system and a secondary fermentation system, wherein the mounting position of the secondary fermentation system is higher than that of the primary fermentation system; the primary fermentation system and the secondary fermentation system are connected by virtue of a water guide pipe; the water guide pipe is connected between a secondary feeding pipe and / or discharging pipe and a primary fermentation pipeline; and a water guide pipe is connected between a water pressure room and the primary fermentation pipeline. An annular fermentation pipeline is adopted in the primary fermentation system, the fermentation route is long, circular flow of biogas slurry in the system is promoted by virtue of simultaneous fermentation of the primary fermentation system and the secondary fermentation system, stirring of the biogas slurry is effectively promoted, uniform culture distribution is promoted, and the fermentation efficiency in the system is improved.

Owner:罗小华

A method for producing biogas in a fermentation system with evenly distributed strains driven by turbulent flow of biogas slurry in multiple regions

ActiveCN104673656BSpeed up the flowLong fermentation routeGas production bioreactorsWaste based fuelEngineeringAtmosphere

The invention discloses a method for generating marsh gas in fermentation system driving even distribution of strains by multi-zone marsh liquid turbulence. The method comprises the following steps that: fermentation raw materials are poured into a feeding pipe, when a fermentation zone formed between a feeding / discharging pipe sidewall and a gas blocking plate or a fermentation zone formed between the adjacent gas blocking plates in a ring-shaped fermentation pipeline generates marsh gas, the marsh liquid is pushed to flow to the adjacent fermentation zone, and is further pushed into the feeding pipe, the discharging pipe and a strain distribution device; when the fermentation is full of the marsh gas, the marsh gas generated by further fermentation flows to the adjacent fermentation zones which is not full, until each fermentation zones is intercommunicated; when the liquid level of the marsh liquid in the ring-shaped fermentation pipeline reaches the lowest position of the sidewall of the feeding pipe or the discharging pipe, the marsh gas generated by further fermentation overflows from the fermentation system and is discharged into the atmosphere.

Owner:重庆博视知识产权服务有限公司

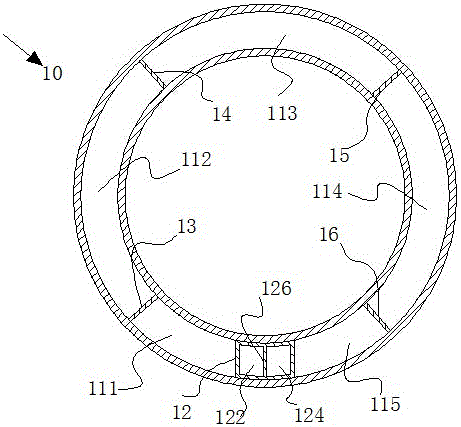

Circular Biogas Fermentation System with Multi-zone Biogas Slurry Circulation and Flow Stirring

InactiveCN104673646BReduce air pressureSpeed up the flowGas production bioreactorsWaste based fuelSlurryMechanical engineering

The invention discloses an annular biogas fermentation system with multi-area biogas slurry circulation and stirring. The main body of the biogas fermentation system is composed of an inlet and outlet barrel, an annular fermentation pipeline, and a hydraulic room. The inlet and outlet barrels are vertically connected to the annular fermentation pipeline. Feed pipe and discharge pipe, the feed pipe and discharge pipe are separated by a partition extending vertically to the bottom of the fermentation pipe, the water pressure room is installed on the top of the water pressure room, and the water pressure room is connected to the feed pipe There is a feed pipe drain pipe, a discharge pipe drain pipe is connected between the water pressure room and the discharge pipe, a feed pipe air baffle is set at the connection position between the ring-shaped fermentation pipe and the feed pipe, and the ring-shaped fermentation pipe and the discharge pipe A discharge pipe air baffle is arranged at the connection position, at least one air baffle is arranged between the feed pipe air baffle and the discharge pipe air baffle, and a fermentation zone is formed between adjacent air baffles.

Owner:王斌

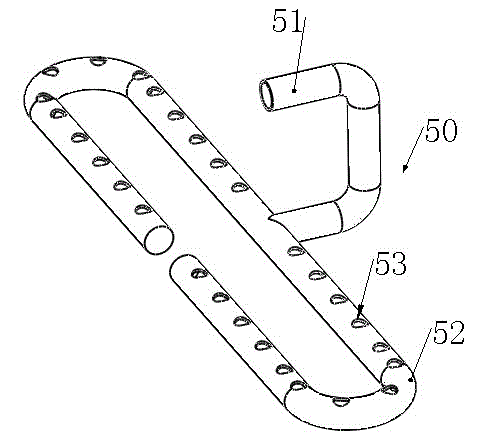

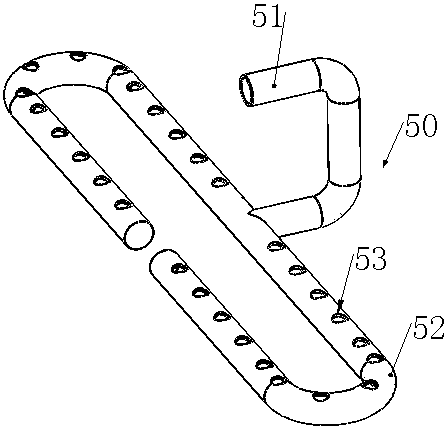

Super-efficient biogas generation system with function of promoting biogas liquid flowing and bacterial distribution under gas pressure

ActiveCN104512992AAchieve circular flowImprove filtration efficiencyWaste based fuelBiological sludge treatmentProcess engineeringEnvironmental engineering

The invention discloses a super-efficient biogas generation system with a function of promoting biogas liquid flowing and bacterial distribution under the gas pressure. The biogas generation system is characterized in that a feeding pipe and a discharging pipe are vertically connected to the two sides of a U-shaped fermentation pipeline; a water pressure chamber is formed in the upper part of the U-shaped fermentation pipeline; a feeding pipe water outlet is formed in the joint of the water pressure chamber and the feeding pipe; a discharging pipe water outlet is formed in the joint of the water pressure chamber and the discharging pipe; a feeding pipe gas baffle is arranged at the joint of the U-shaped fermentation pipeline and the feeding pipe; a discharging pipe gas baffle is arranged at the joint of the U-shaped fermentation pipeline and the discharging pipe; a gas collecting pipe is arranged on the U-shaped fermentation pipeline; the water pressure chamber is connected with a bacterial distribution device; a water discharge pipe of the bacterial distribution device is connected to one side, deviating from the feeding pipe and the discharging pipe, of the water pressure chamber; the other side of the water discharge pipe is connected and fixed to a U-shaped bacterial distribution pipe in the fermentation pipeline; the U-shaped bacterial distribution pipe is matched with the fermentation pipeline in shape and extends into the fermentation pipeline; a plurality of bacterial distribution holes are vertically formed in the U-shaped bacterial distribution pipe.

Owner:六安皖智知识产权运营有限公司

Method for generating biogas in intertwined partitioned super-efficient bacteria distribution biogas fermentation system

InactiveCN104498344AGood convection stirring effectImprove distributionGas production bioreactorsWaste based fuelProcess engineeringSlurry

The invention discloses a method for generating biogas in an intertwined partitioned super-efficient bacteria distribution biogas fermentation system. The method includes the steps: pouring fermentation raw materials from a feeding pipe and fermenting the raw materials in a fermentation pipeline to generate the biogas; using the biogas stored in an optional fermentation area. The biogas is respectively gathered in fermentation areas formed among the feeding / discharging pipe and adjacent gas baffle plates or between the adjacent gas baffle plates, occupies space in the fermentation areas, squeezes biogas slurry in convection and flows towards the feeding pipe and the discharging pipe, and the biogas slurry in the fermentation pipeline flows into a water pressure space through a drain hole of the discharging pipe along with rise of the liquid level of the biogas slurry in the feeding pipe and the discharging pipe. The pressure of the biogas stored in the optional fermentation area is reduced, the biogas slurry in an adjacent fermentation area flows towards the optional fermentation area, and the biogas slurry stored in the water pressure space unidirectionally flows into the fermentation pipeline through a drain hole of the feeding pipe and flows back into the fermentation pipeline through the drain hole of the discharging pipe to supplement reduced biogas space, so that circulating flow of the biogas slurry is finished.

Owner:陆永柱

Super-efficient fermentation system for promoting biogas slurry convective stirring by virtue of synchronous fermentation

ActiveCN104630046ALong fermentation routePromote stirringGas production bioreactorsWaste based fuelBiogasWater pipe

The invention discloses a super-efficient fermentation system for promoting biogas slurry convective stirring by virtue of synchronous fermentation. The super-efficient fermentation system comprises a primary fermentation system and a secondary fermentation system, wherein the mounting position of the secondary fermentation system is higher than that of the primary fermentation system; the primary fermentation system is connected with the secondary fermentation system by virtue of a water guide pipe; a water guide pipe is connected between a secondary feed pipe and / or discharge pipe and a primary fermentation pipeline; a water guide pipe is connected between a water pressure chamber and the primary fermentation pipeline; and the primary fermentation system adopts an annular fermentation pipeline, the fermentation route is long, and the synchronous fermentation of the primary fermentation system and the secondary fermentation system promotes biogas slurry to flow circularly in the system, so that stirring of the biogas slurry is effectively promoted, the uniform distribution of strains is driven, and the fermentation efficiency in the system is improved.

Owner:重庆博视知识产权服务有限公司

Hydraulic double-pipe channel type biogas generator

InactiveCN104496144BAchieve circular flowImprove filtration efficiencyWaste based fuelBiological sludge treatmentTube drainageProcess engineering

The invention discloses a hydraulic double-pipe channel type biogas generating device, which includes a feed pipe, a discharge pipe, and a U-shaped fermentation pipe. The U-shaped fermentation pipe is placed horizontally, and the feed pipe and the discharge pipe are vertically connected to the U-shaped fermentation pipe. At both ends of the pipeline, a water pressure room is placed on the upper part of the U-shaped fermentation pipeline. A feed pipe air baffle is set at the connection position between the pipeline and the feed pipe, and a discharge pipe air baffle is set at the connection position between the U-shaped fermentation pipeline and the discharge pipe; The position of the drainage hole is provided with a one-way valve to control the one-way flow of the biogas slurry in the fermentation pipeline into the water pressure room, and the one-way valve is set on the drain hole of the feed pipe to control the one-way flow of the biogas slurry in the water pressure room into the feed pipe; The channel-type fermentation device has a long fermentation route, and uses the control of water pressure difference and one-way valve to realize the full flow of biogas slurry in the system, and to drive the uniform distribution of bacteria, effectively preventing crusting, high gas production rate, suitable for Large-scale production.

Owner:徐幸利 +2

Method for producing methane in two-stage synchronous methane fermentation system

ActiveCN104560682BPromote circulationStir wellGas production bioreactorsWaste based fuelMethane fermentationSlurry

The invention discloses a method for producing methane in a secondary synchronous methane fermentation system. The method comprises the following steps: fermenting to produce biogas in a primary fermentation system, and gathering the biogas in the side walls of a charging / discharging barrel and adjacent gas baffles or in a fermentation area formed between adjacent gas baffles; extruding the biogas slurry in a primary fermentation pipeline to flow to a first water guide pipe and a second water guide pipe, and finally allowing the biogas slurry to flow into a secondary fermentation pipeline; fermenting to produce biogas in a secondary fermentation system, and gathering the biogas between the side walls of a secondary feeding / discharging pipe and adjacent gas baffles or in a fermentation area formed between the adjacent gas baffles, allowing the biogas slurry to flow into a water pressure room in a one-way mode by virtue of a secondary discharging pipe, and allowing the biogas slurry in the secondary fermentation pipeline to flow into the water pressure room by virtue of a drainage pipe of a bacteria distribution device when the liquid level of the biogas slurry in the water pressure room reaches the lowest position of the upper part of the drainage pipe of the bacteria distribution device.

Owner:徐州金港起重机制造有限公司

Methane generation system hydraulically and pneumatically promoting uniform bacteria distribution

ActiveCN104498339AGood convection stirring effectImprove distributionGas production bioreactorsWaste based fuelSlurryMechanical engineering

A methane generation system hydraulically and pneumatically promoting uniform bacteria distribution comprises a feeding pipe, a discharging pipe and a U-shaped fermentation pipeline. The U-shaped fermentation pipeline is horizontally placed, the feeding pipe and the discharging pipe are vertically connected with two end sides of the U-shaped fermentation pipeline, a water pressure space is formed on the U-shaped fermentation pipeline, a feeding pipe drain hole is formed in the joint of the water pressure space and the feeding pipe, a discharging pipe drain hole is formed in the joint of the water pressure space and the discharging pipe, a feeding pipe gas baffle plate is arranged at the joint of the U-shaped fermentation pipeline and the feeding pipe, a discharging pipe gas baffle plate is arranged at the joint of the U-shaped fermentation pipeline and the discharging pipe, at least one gas baffle plate is arranged between the discharging pipe gas baffle plate and the feeding pipe gas baffle plate, a fermentation area is formed among the feeding / discharging pipe and the adjacent gas baffle plates or between the adjacent gas baffle plates, an independent gas collecting pipe is arranged at the top of each fermentation area, the top of each fermentation area is connected with the independent gas collecting pipe, and a valve is arranged on each gas collecting pipe. A U-shaped channel-type fermentation device is used, a fermentation path is long, biogas slurry sufficiently flows in the system by control of water pressure difference and one-way valves, bacteria are driven to be uniformly distributed, crusting is effectively prevented, and gas generating rate is high.

Owner:海门名驰工业设计有限公司

Method for generating methane with a methane generating device with a curved ultra-long fermentation path

ActiveCN104498335BFull flowEvenly distributedGas production bioreactorsWaste based fuelMethane fermentationSlurry

The invention discloses a method for generating methane in a methane generation device with a bent super-long fermentation path. The method includes the steps: pouring fermentation raw materials from a feeding pipe and fermenting the raw materials in a fermentation pipeline to generate the methane; using the methane stored in an optional fermentation area. The methane is respectively gathered in fermentation areas formed among the feeding / discharging pipe and adjacent gas baffle plates or between the adjacent gas baffle plates, occupies space in the fermentation areas, squeezes biogas slurry in convection and flows towards the feeding pipe, the discharging pipe and a bacteria distribution device, and the biogas slurry in the fermentation pipeline unidirectionally flows into a water pressure space through a drain hole of the discharging pipe and flows into the water pressure space through a drain pipe of the bacteria distribution device along with rise of the liquid level of the biogas slurry in the feeding pipe, the discharging pipe and the bacteria distribution device. The pressure of the methane stored in the optional fermentation area is reduced, the biogas slurry in an adjacent fermentation area flows towards the optional fermentation area, and the biogas slurry stored in the water pressure space unidirectionally flows back into the feeding pipe through a drain hole of the feeding pipe and flows back into the fermentation pipeline through the drain pipe of the bacteria distribution device to supplement reduced methane space, so that circulating flow of the biogas slurry is finished.

Owner:六安皖智知识产权运营有限公司

U-shaped biogas fermentation system

ActiveCN104496143AReduce air pressureFull flowWaste based fuelBiological sludge treatmentProcess engineeringEnvironmental engineering

The invention discloses a U-shaped biogas fermentation system. The U-shaped biogas fermentation system comprises a feed pipe, a discharge pipe, a U-shaped fermentation pipeline, wherein the U-shaped fermentation pipeline is arranged horizontally; the feed pipe and the discharge pipe are vertically connected to the two end sides of the U-shaped fermentation pipeline; a water pressure chamber is arranged on the upper part of the U-shaped fermentation pipeline; a feed pipe drain hole is formed in the connection position of the water pressure chamber and the feed pipe, while a discharge pipe drain hole is formed in the connection position of the water pressure chamber and the discharge pipe; a feed pipe gas stop plate is arranged at the connection position of the U-shaped fermentation pipeline and the feed pipe, while a discharge pipe gas stop plate is arranged at the connection position of the U-shaped fermentation pipeline and the discharge pipe; a gas collecting pipe is arranged on the U-shaped fermentation pipeline; a one-way valve for controlling the biogas slurry in the U-shaped fermentation pipeline to flow into the water pressure chamber in one direction is arranged at the position of the discharge pipe drain hole; a U-shaped channel-type fermentation device is adopted and the fermentation path is long; sufficient flowing of the biogas slurry in the system is realized by virtue of the water pressure difference and the control of the one-way valve; besides, bacteria are distributed evenly to effectively prevent crusting; the U-shaped biogas fermentation system is high in gas generation rate and suitable for large-scale production.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com