Separate floating cover type novel methane fermentation device

A biogas fermentation, a new type of technology, applied in biochemical cleaning equipment, enzymology/microbiology equipment, bioreactor/fermentation tank combination, etc., can solve the problems of reducing gas production, difficult stirring, and inconvenient discharge of biogas tanks, etc. Achieve the effect of improving fermentation efficiency and increasing biogas output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

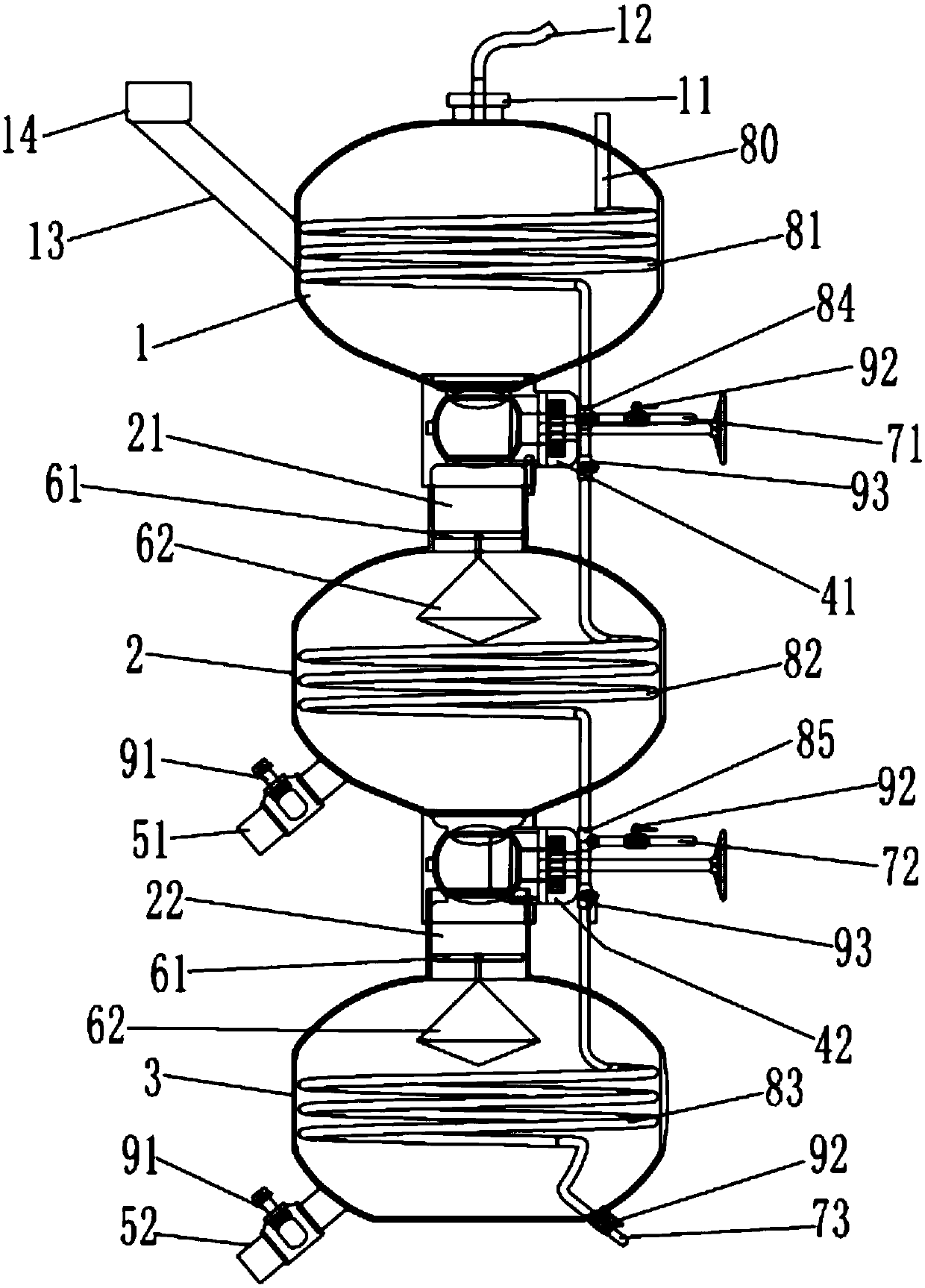

[0018] Such as figure 1 with figure 2 As shown, the present invention is composed of the first fermentation room 1, the second fermentation room 2 and the third fermentation room 3 etc. which are sequentially connected from top to bottom. A movable top cover 11 is provided on the first fermentation room 1. The movable top cover 11 is pierced with an air duct 12, and one side of the first fermentation room 1 is provided with a steam input pipe 80 pierced in, and the other side is connected with a feed pipe 13, and the feed pipe 13 is also connected with the feed room 14, the second fermentation room 2 is provided with a first discharge pipe 51, and the third fermentation room 3 is provided with a second discharge pipe 52.

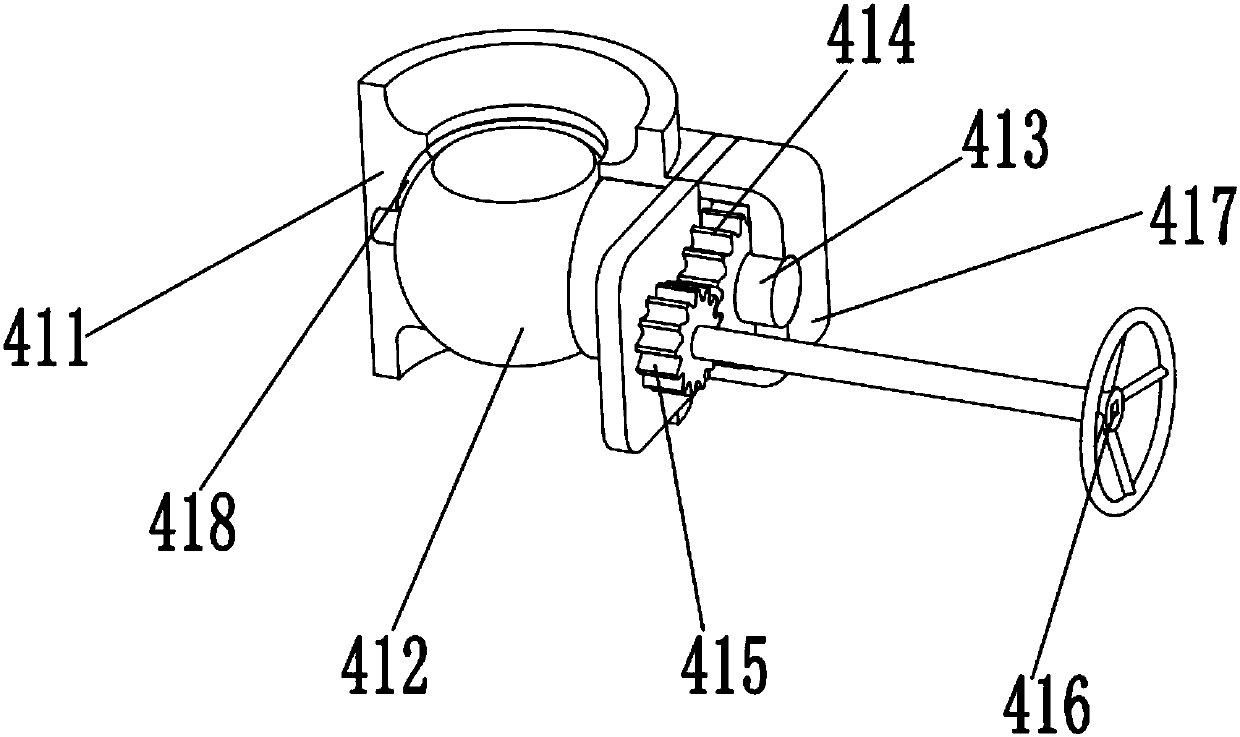

[0019] A first connecting pipe 21 is provided between the first fermentation room 1 and the second fermentation room 2, a second connecting pipe 22 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com