Patents

Literature

460results about "Fertiliser treatment heating/cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

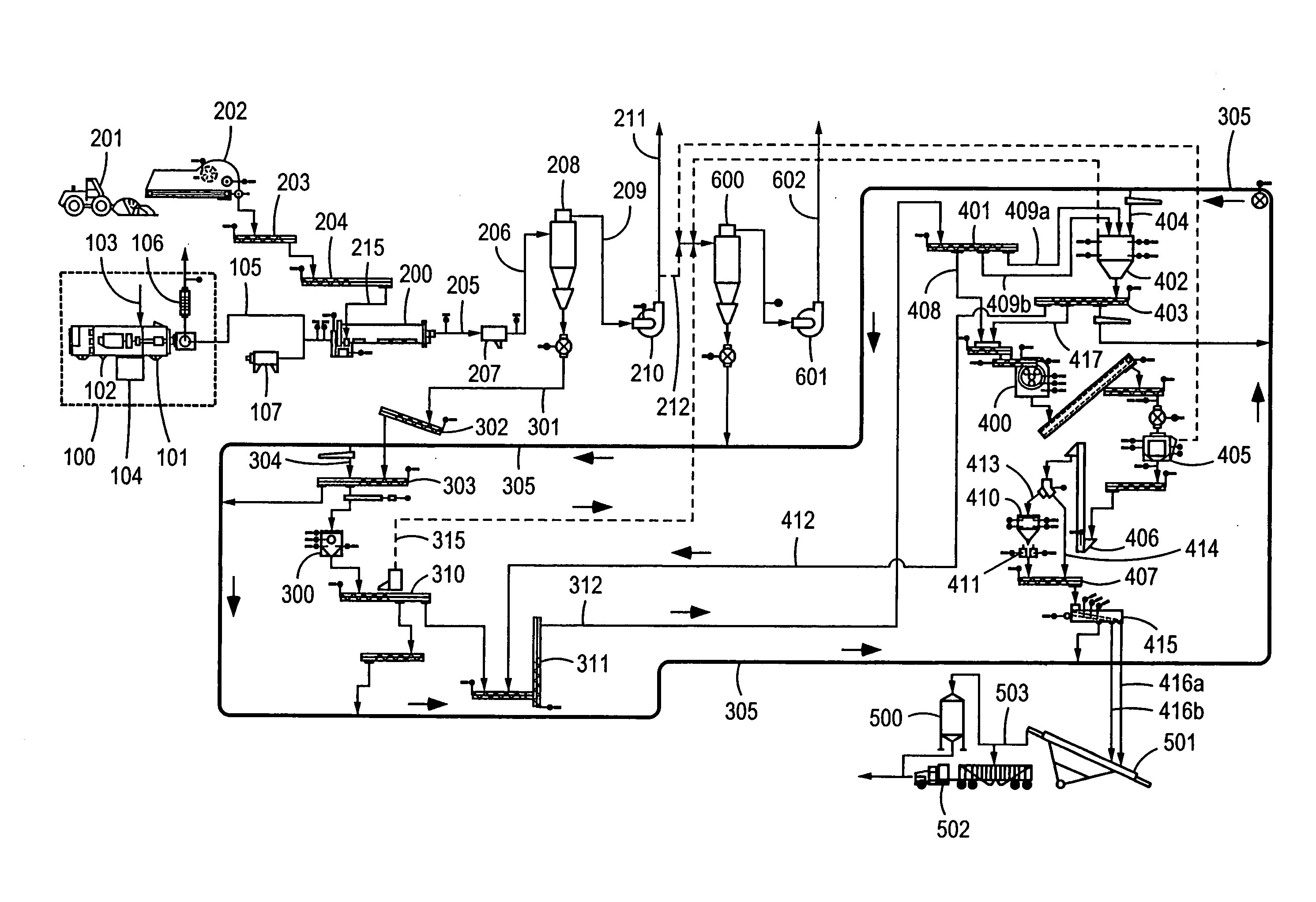

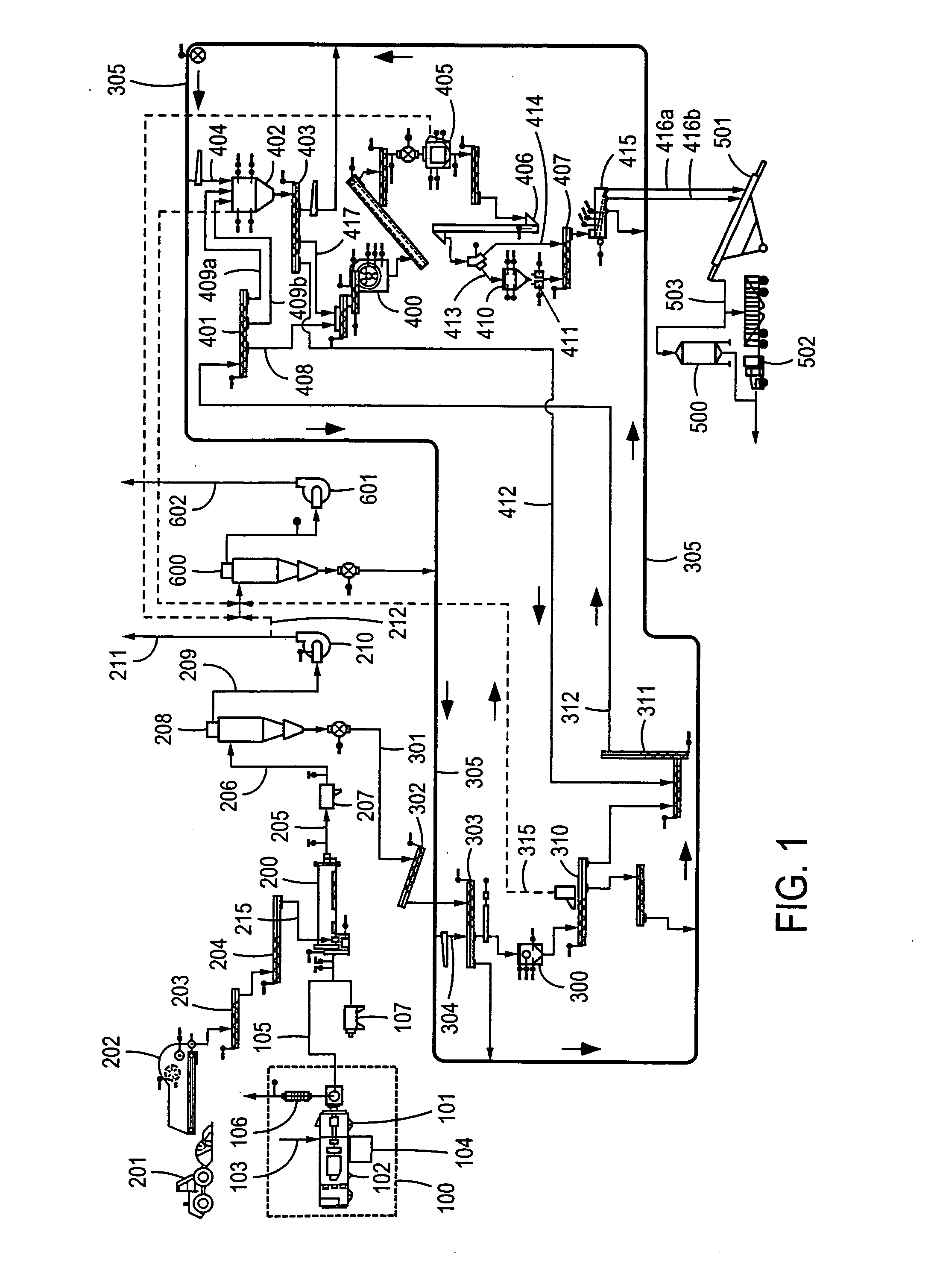

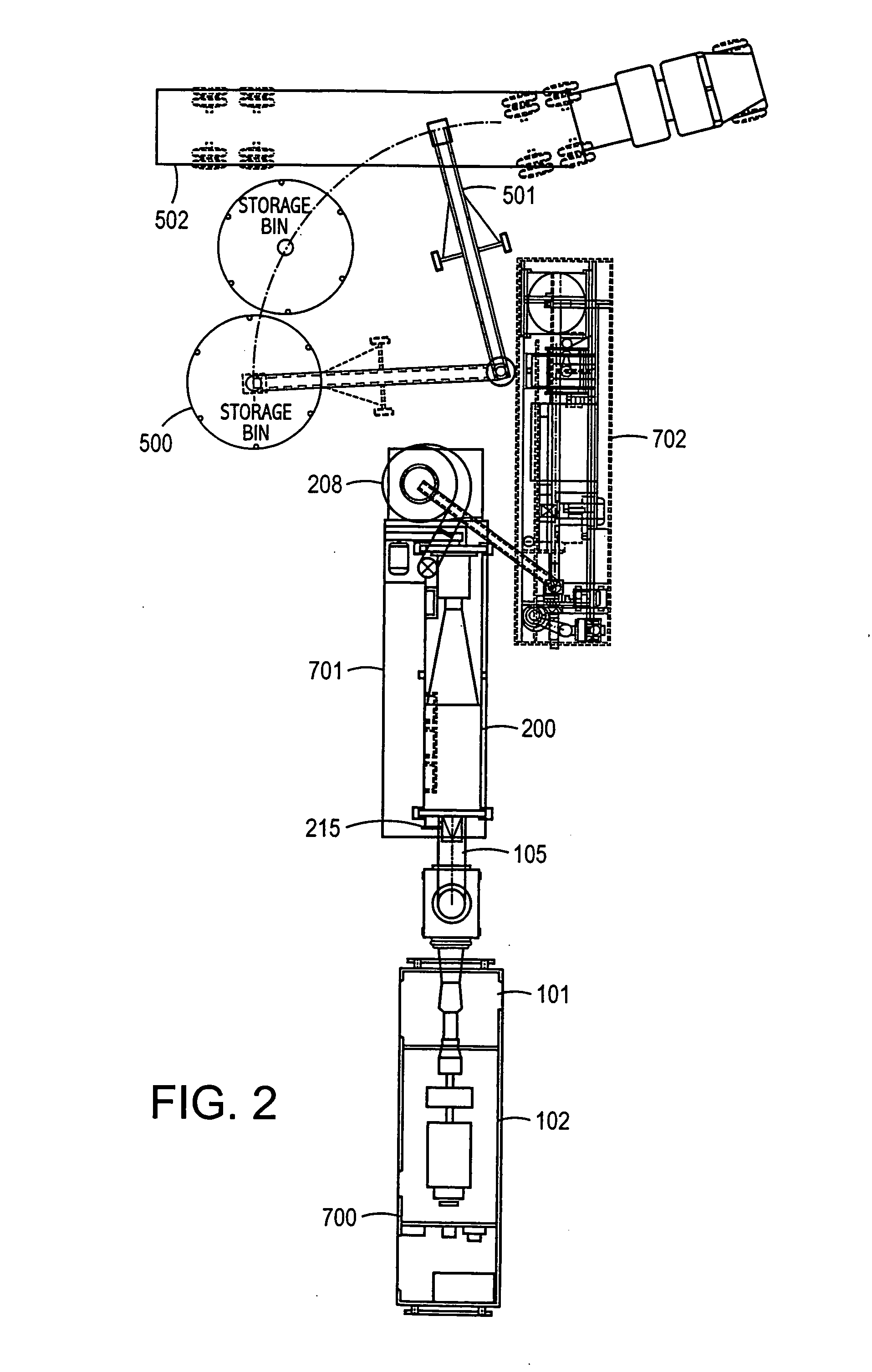

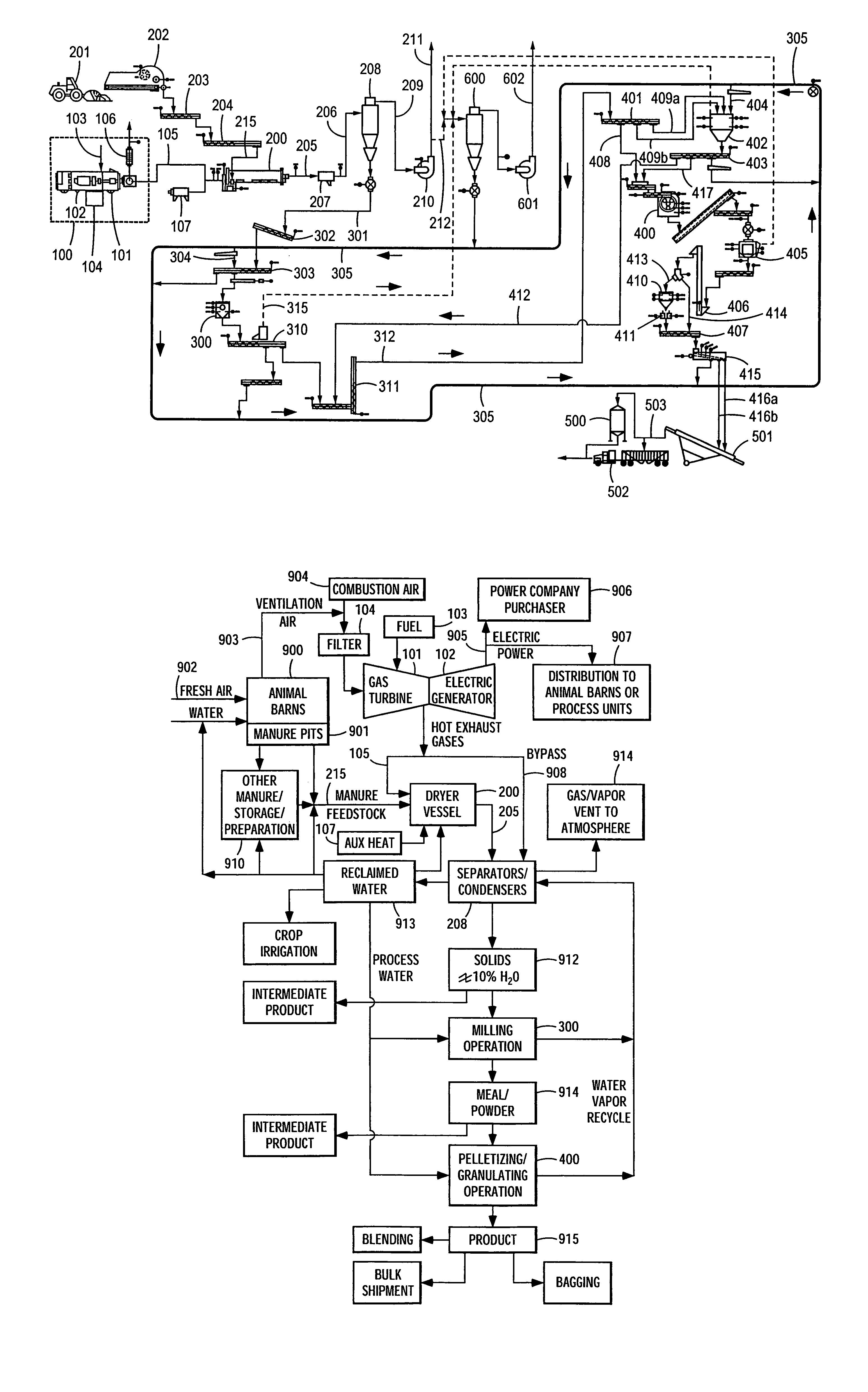

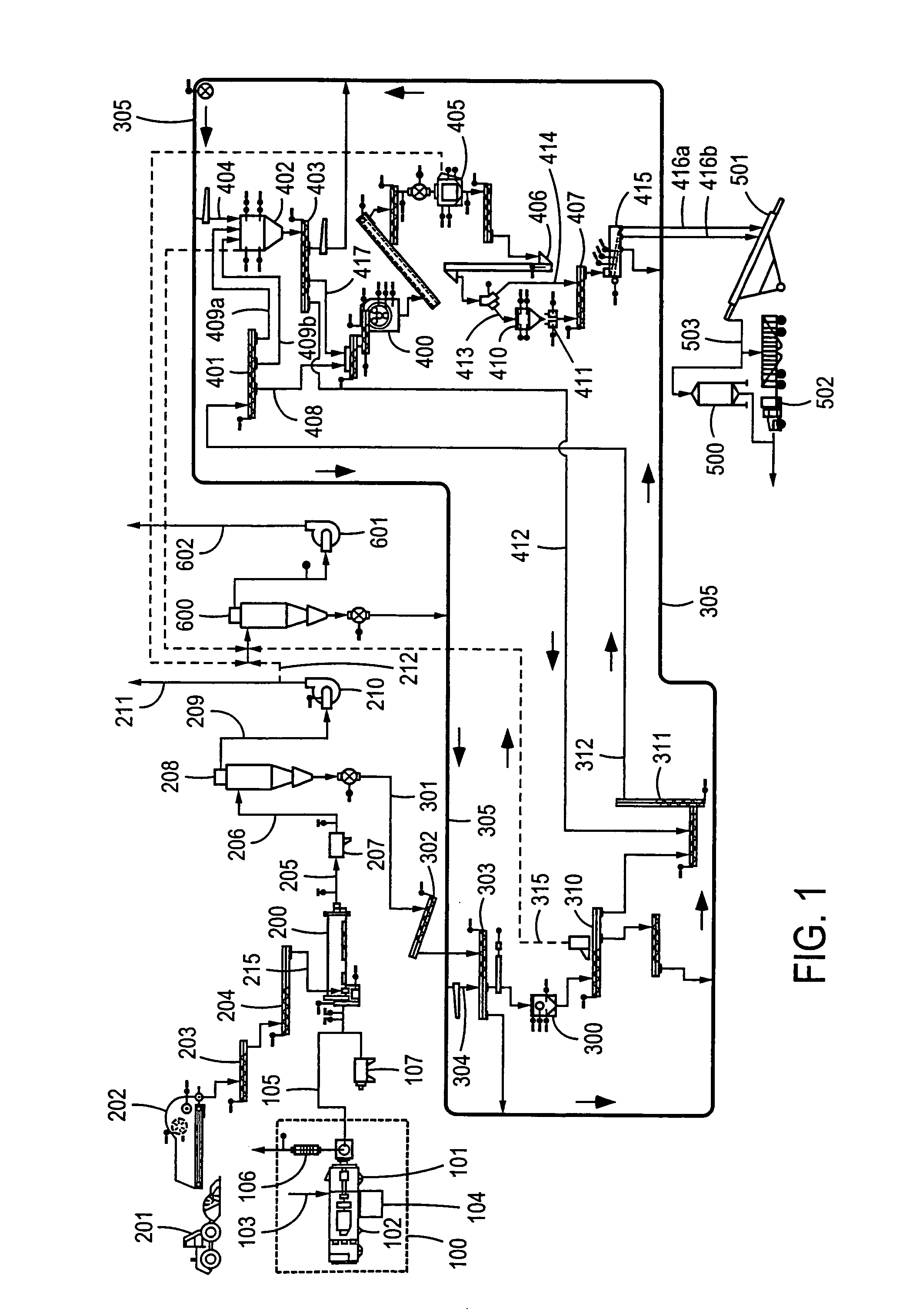

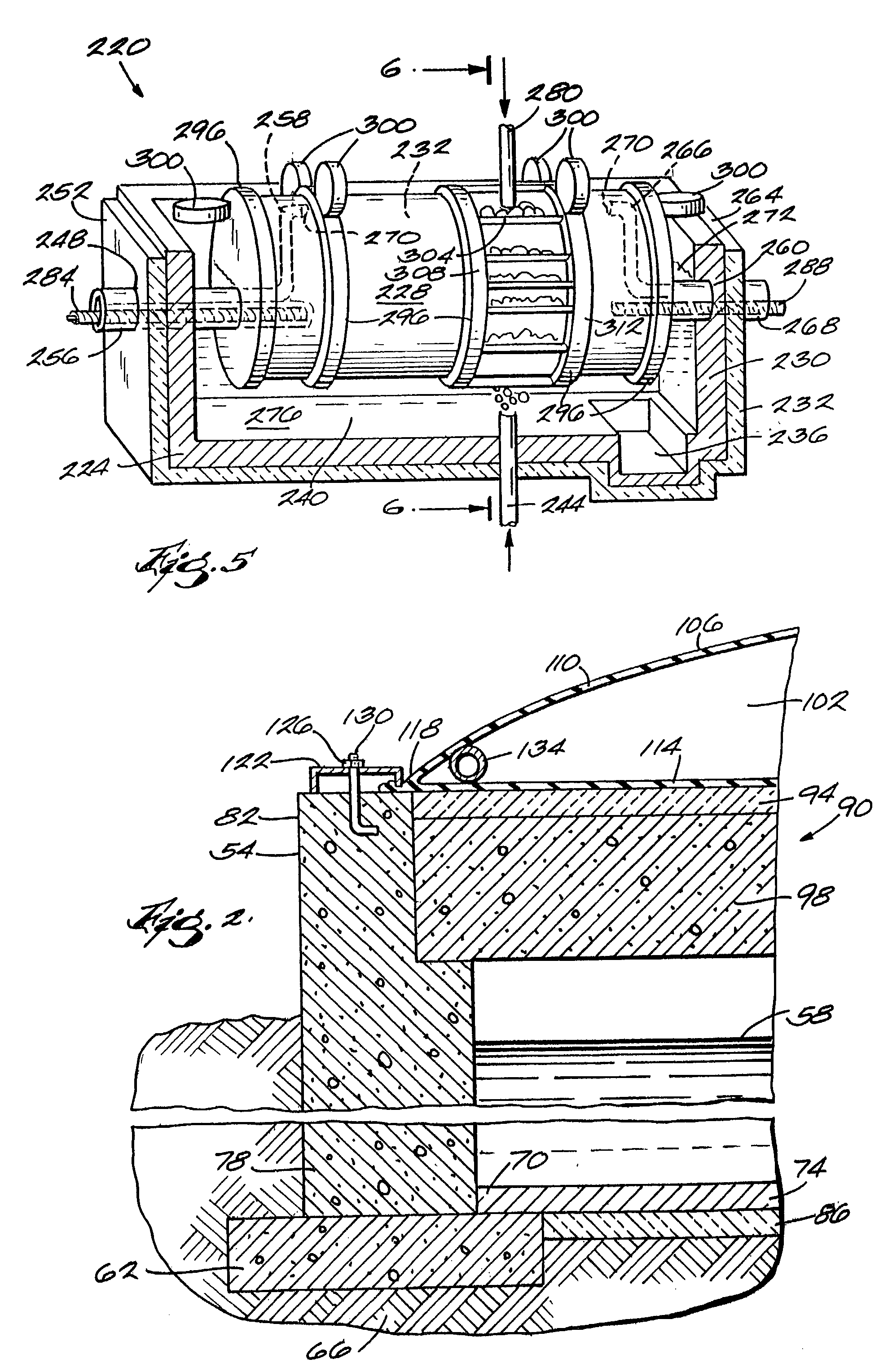

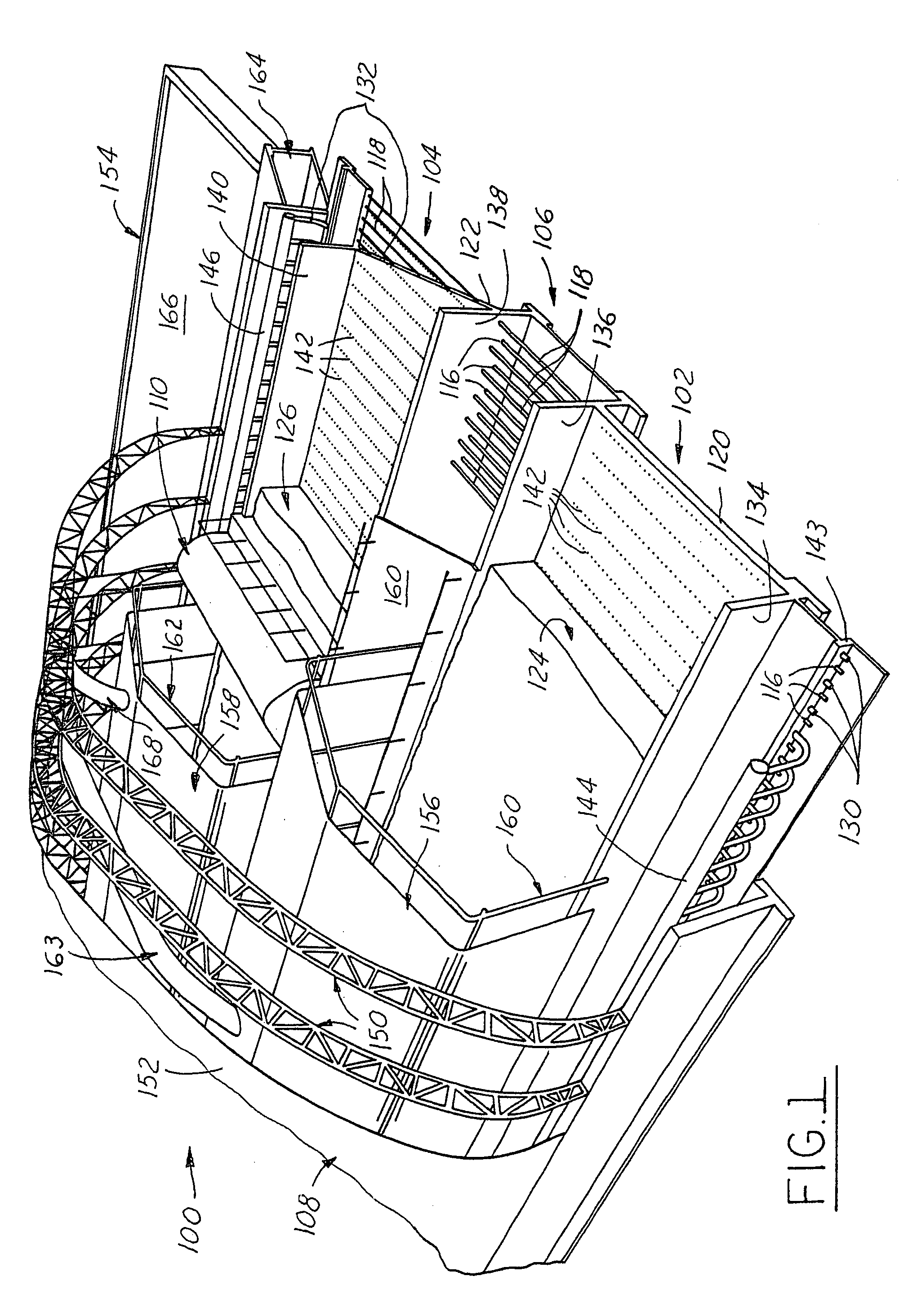

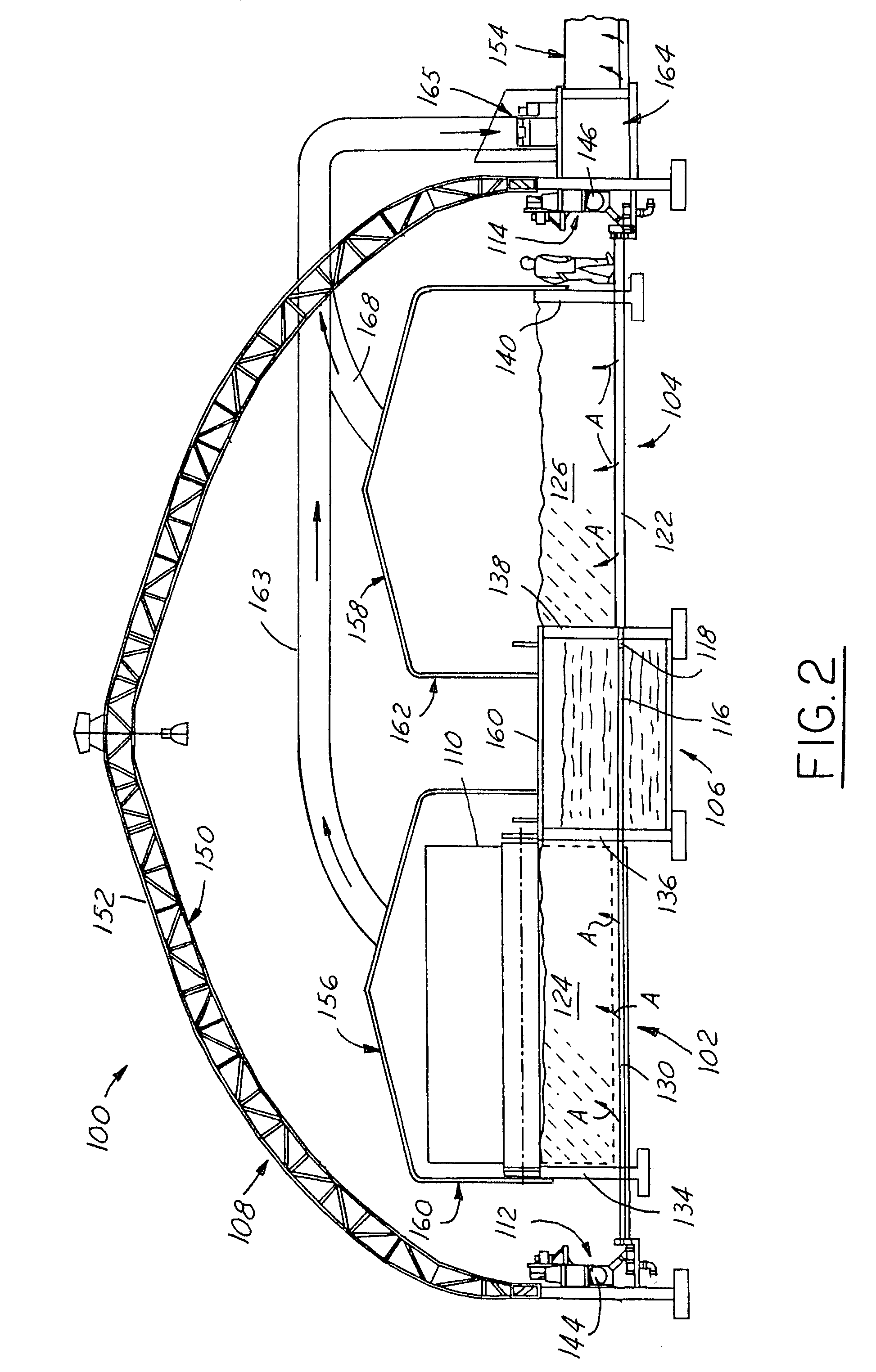

Process and apparatus for manufacture of fertilizer products from manure and sewage

InactiveUS20060010712A1Drying using combination processesBio-organic fraction processingOrganic farmingSewage

This invention discloses systems and methods for conversion of manure to novel fertilizer and / or soil builder products useful as input for organic farming operations. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel. The dryer vessel receives the manure for contact with the turbine exhaust gases to convert the manure to a dry material, which is passed to the processing unit where it is formed into granules, pellets or other desired form for the final dry fertilizer product. The method comprises drying, heating and converting the manure to form novel self binding fertilizer and soil builder type products for organic farming and other uses.

Owner:EARTHRENEW INC

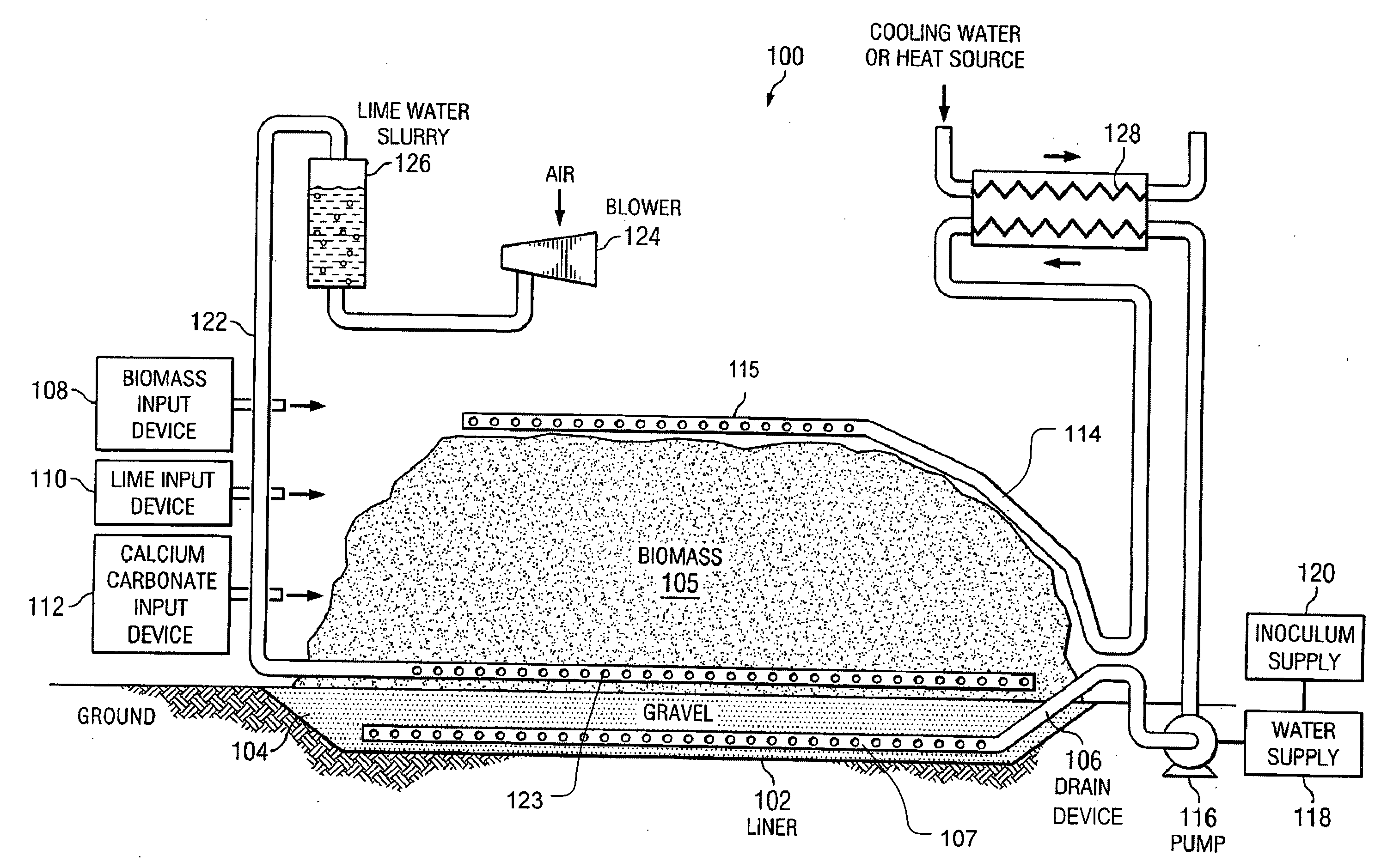

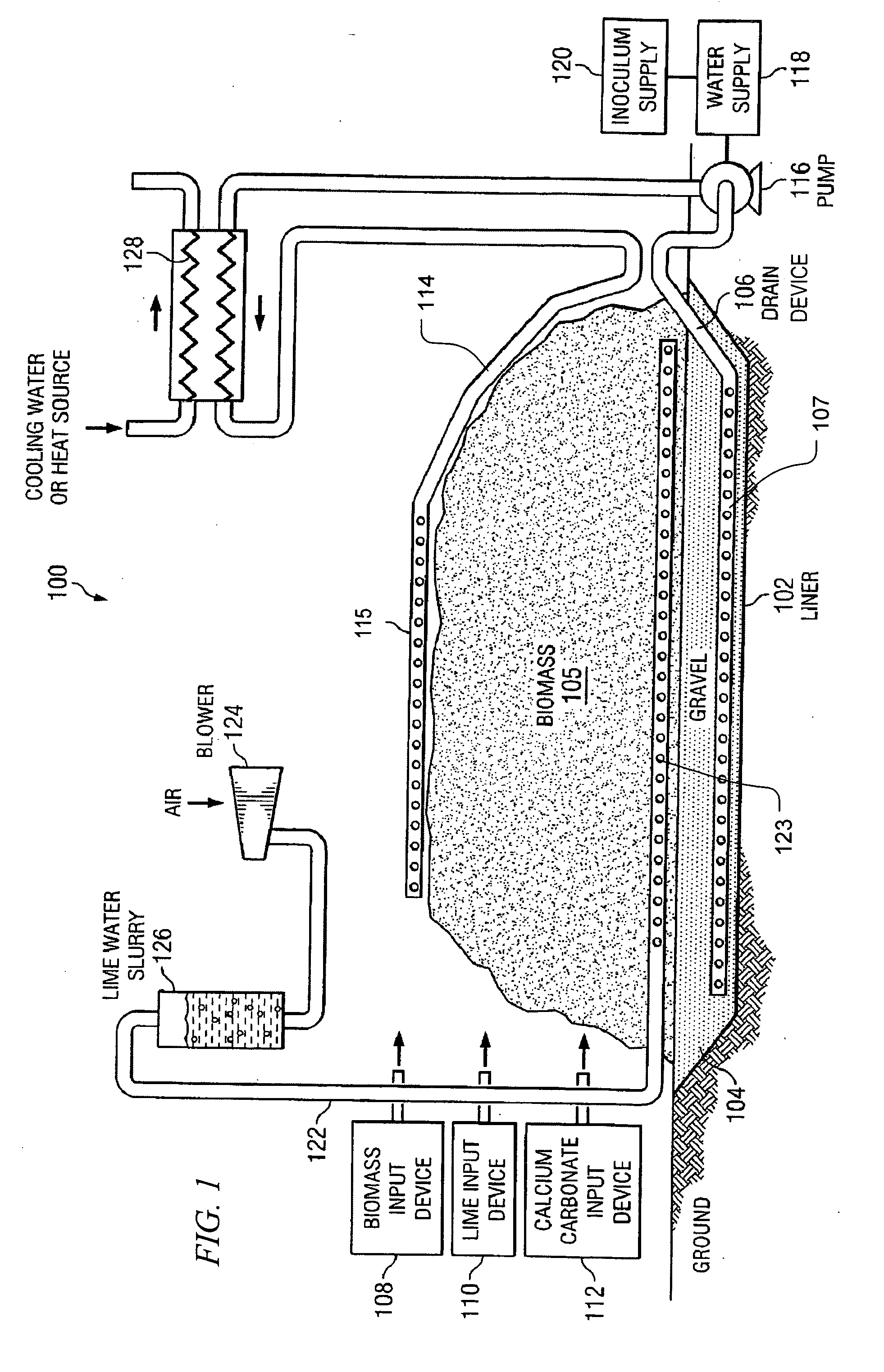

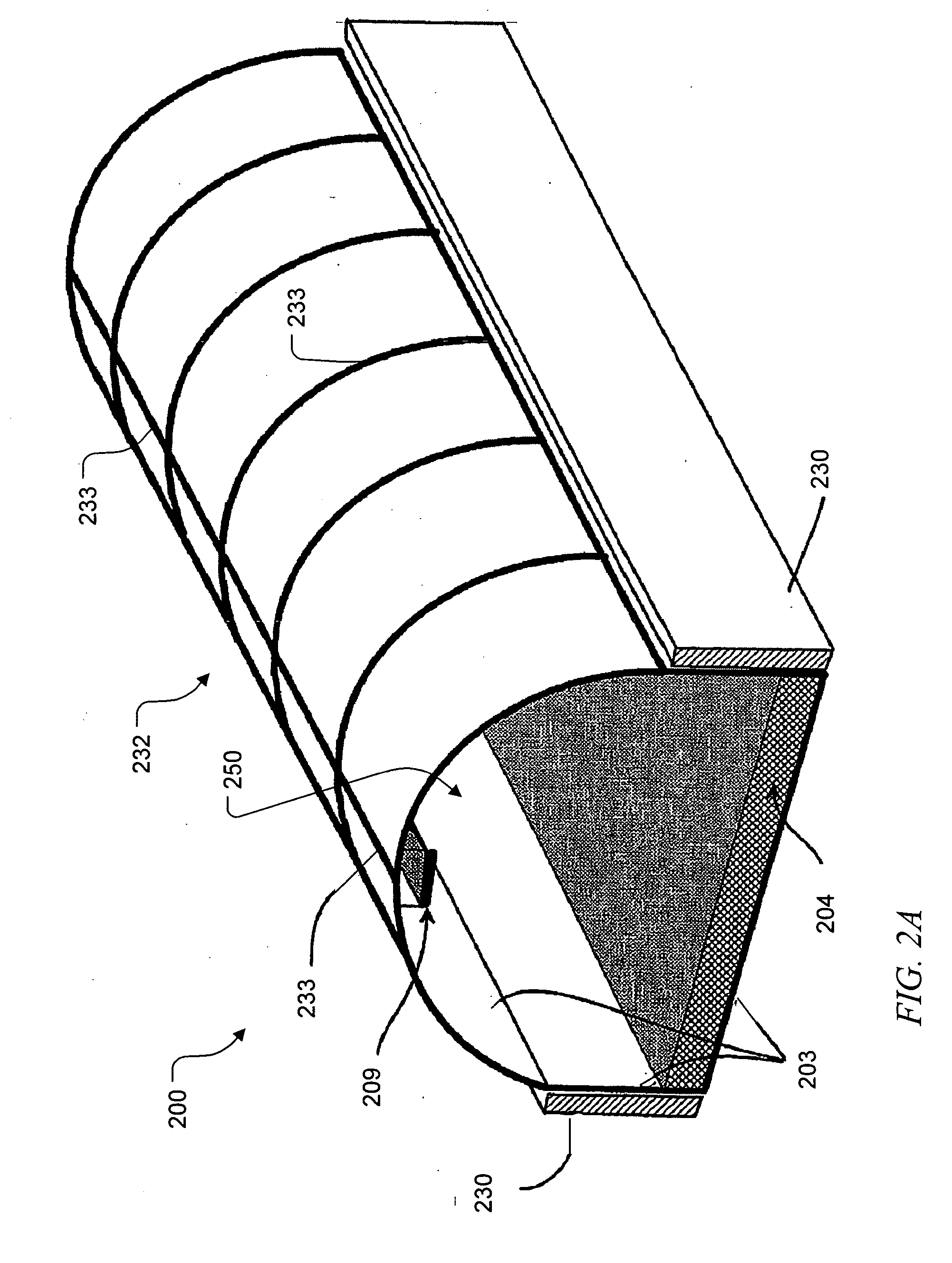

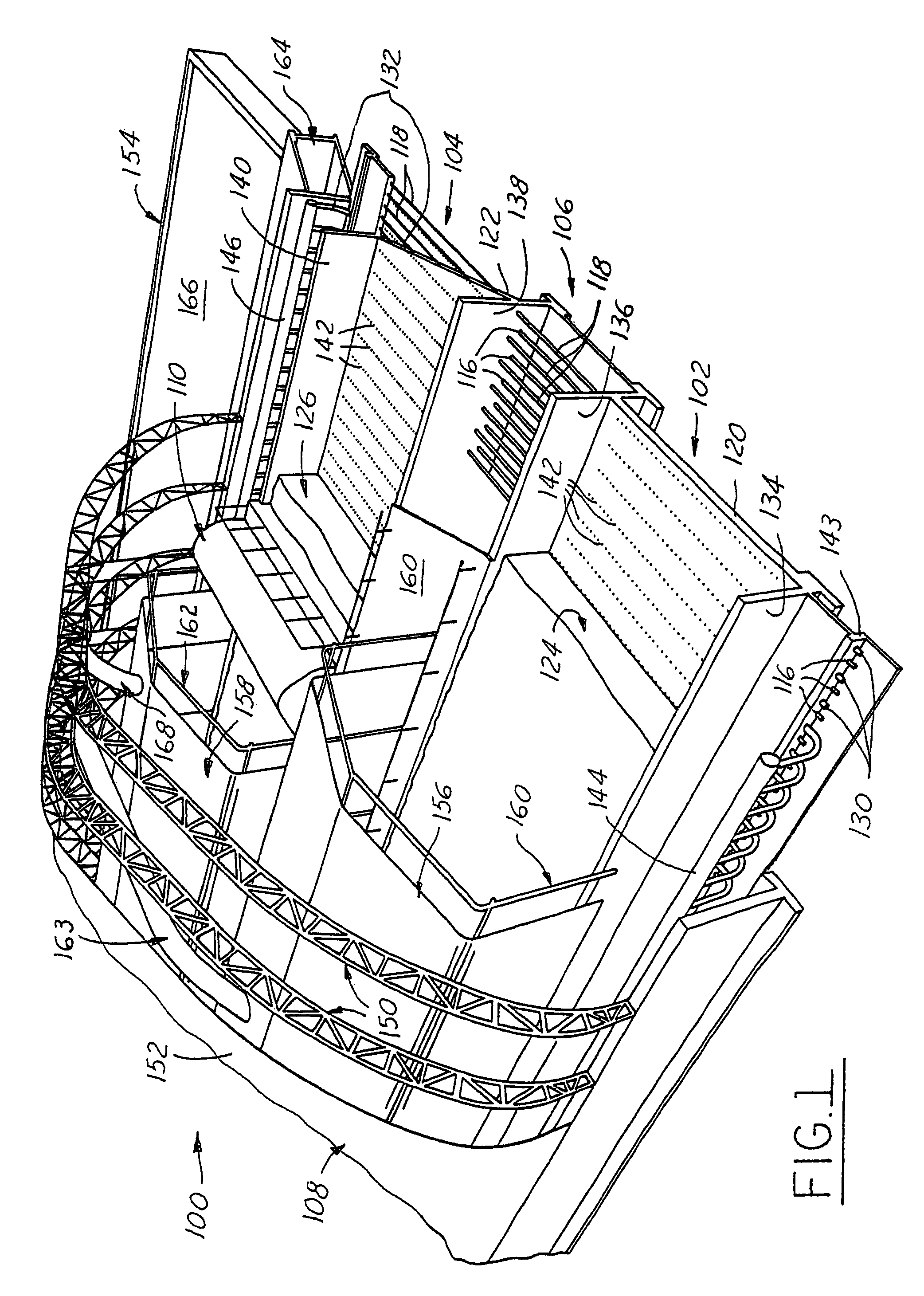

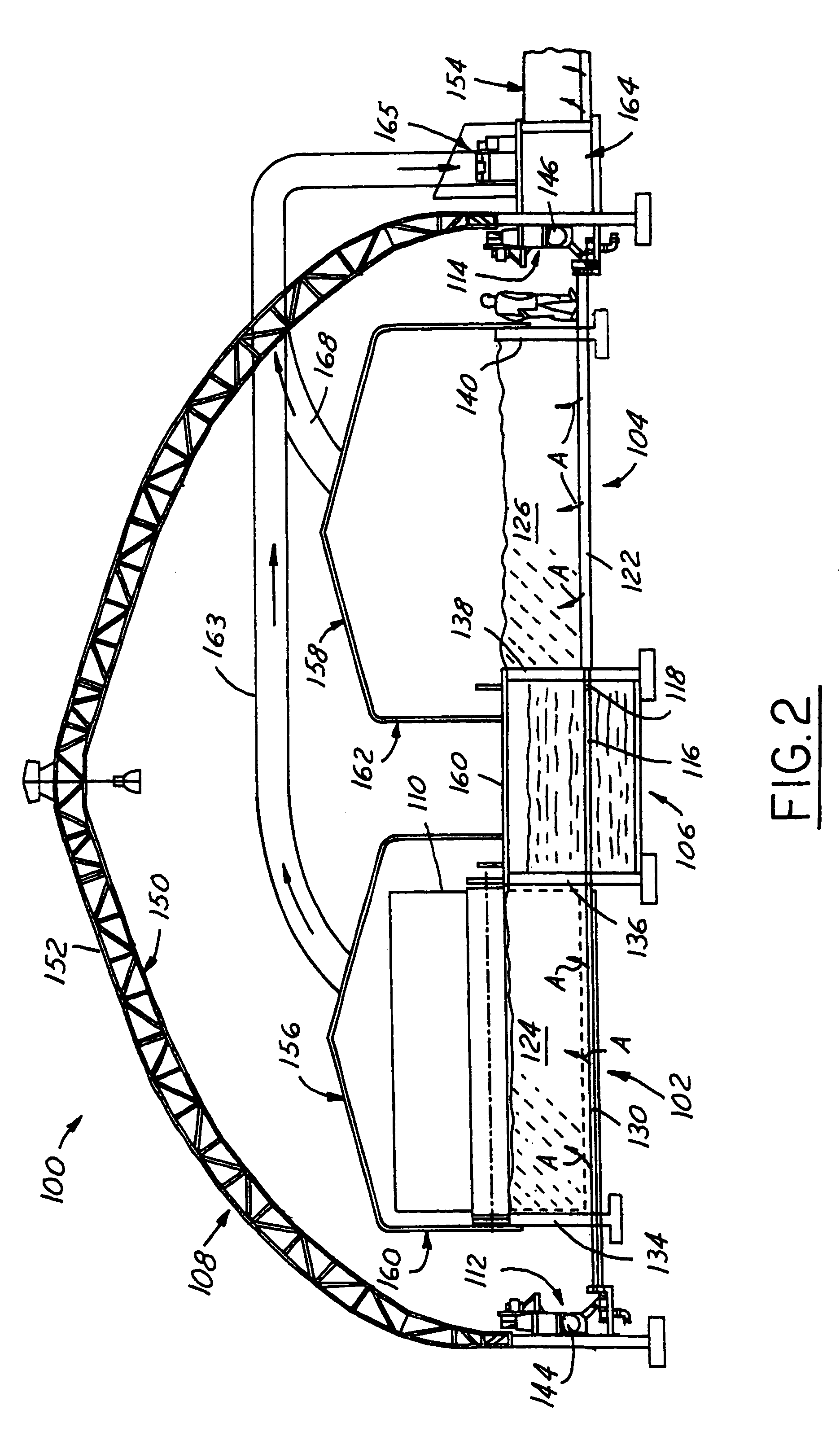

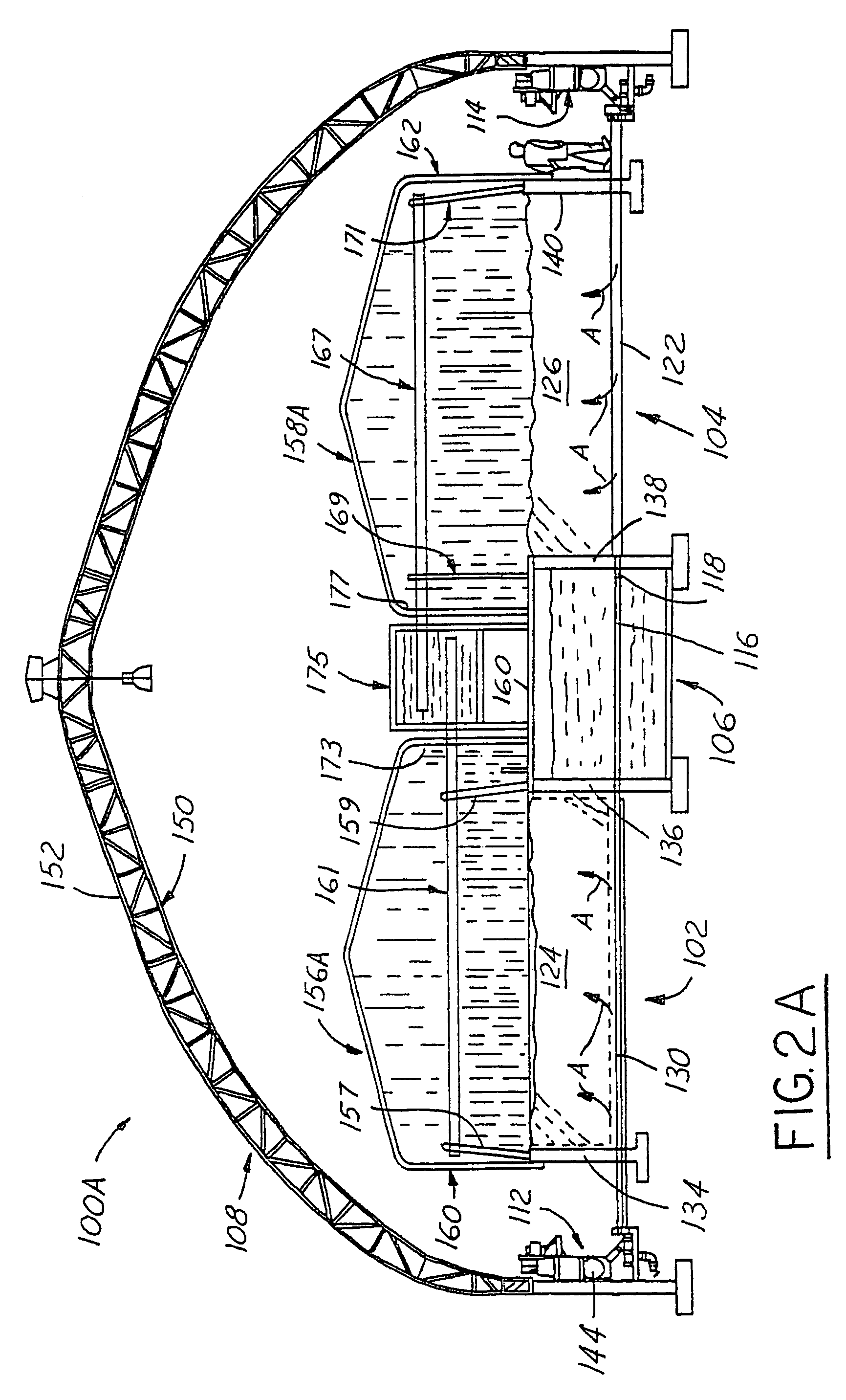

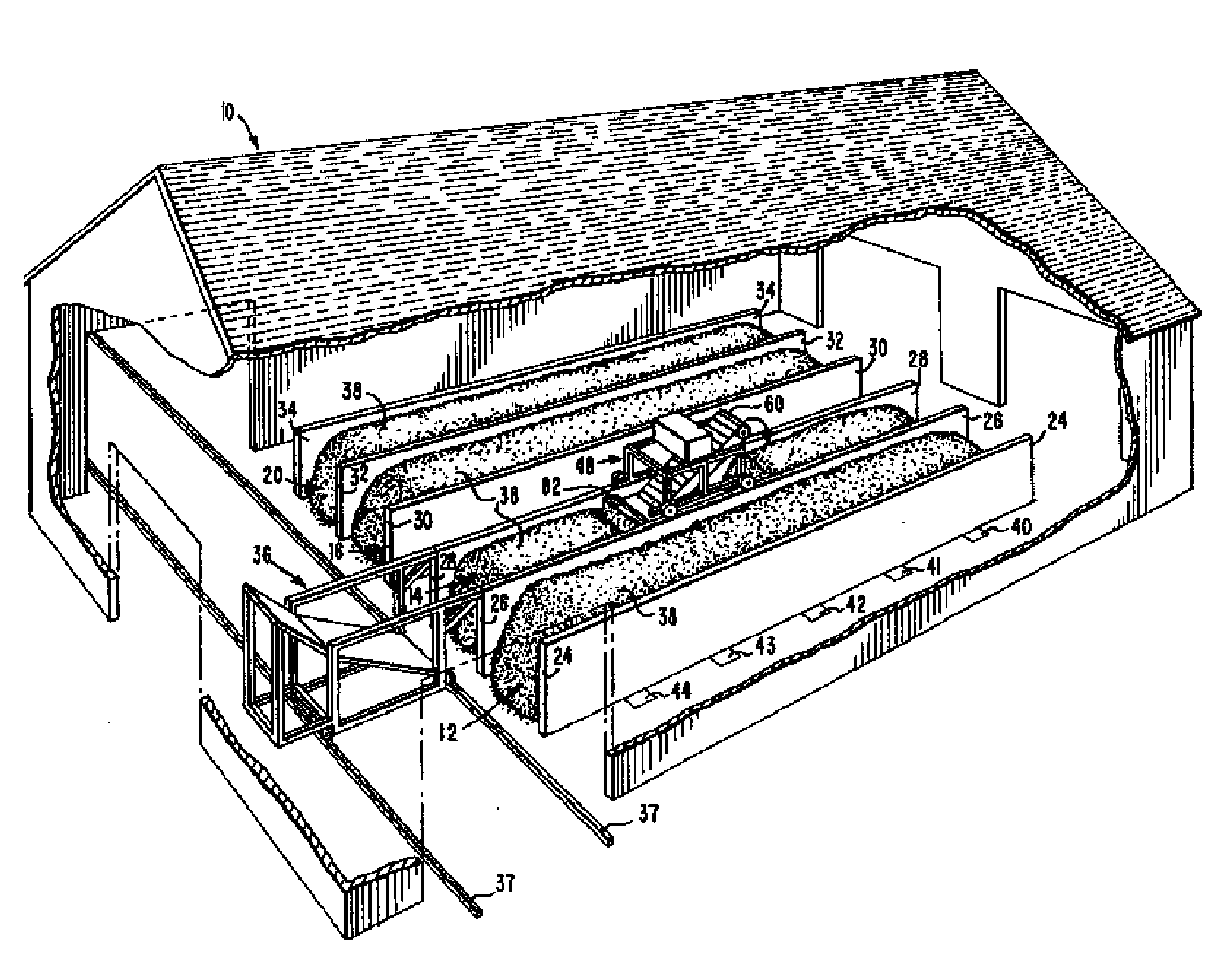

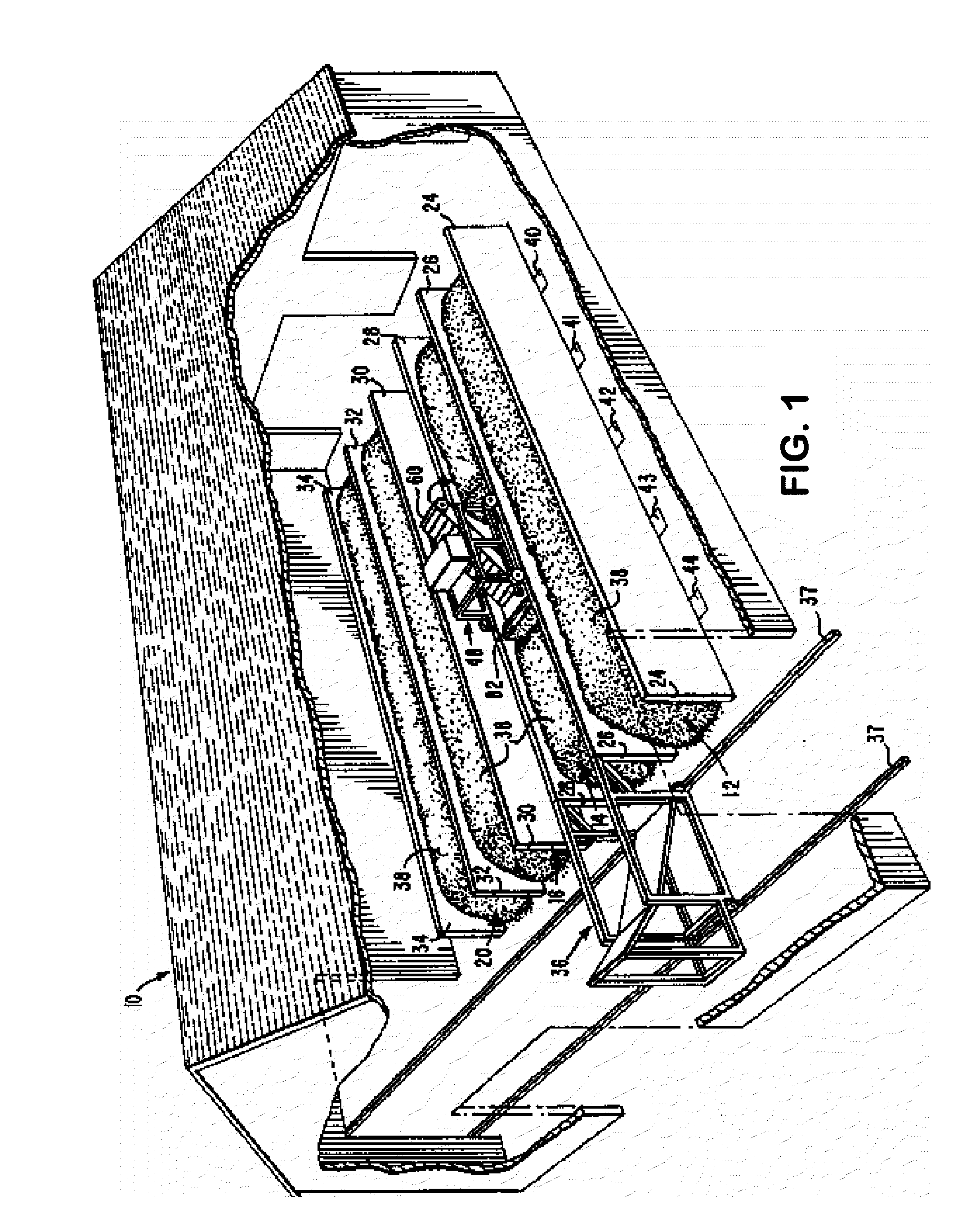

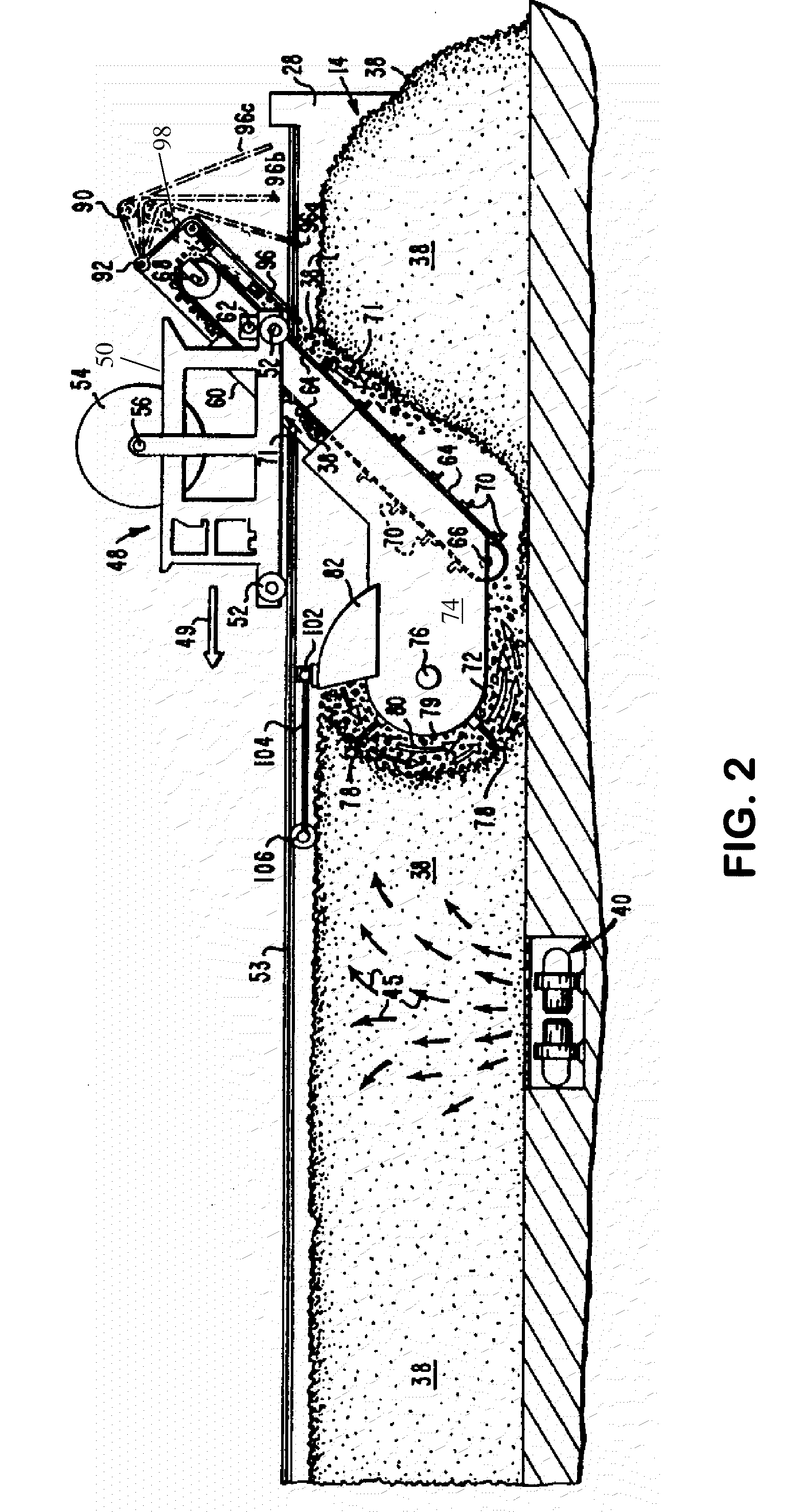

System and method for processing biomass

InactiveUS20060188980A1Low costBioreactor/fermenter combinationsBio-organic fraction processingEngineeringFluid input

According to one embodiment of the invention, a system for processing biomass comprises a chamber, a biomass input device, a fluid input device, and a retrieval device. The chamber is defined by at least a bottom, at least one wall, and a cover supported by the at least one wall. The biomass input device operable to deliver biomass into the chamber to form a biomass pile. The fluid input device is operable to deliver fluid into the chamber to the biomass pile. The retrieval device operable to receive fluid from the chamber.

Owner:TEXAS A&M UNIVERSITY

Process and apparatus for manufacture of fertilizer products from manure and sewage

InactiveUS7024796B2Drying using combination processesBio-organic fraction processingAgricultural scienceOrganic farming

This invention discloses systems and methods for conversion of manure to novel fertilizer and / or soil builder products useful as input for organic farming operations. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel. The dryer vessel receives the manure for contact with the turbine exhaust gases to convert the manure to a dry material, which is passed to the processing unit where it is formed into granules, pellets or other desired form for the final dry fertilizer product. The method comprises drying, heating and converting the manure to form novel self binding fertilizer and soil builder type products for organic farming and other uses.

Owner:EARTHRENEW INC

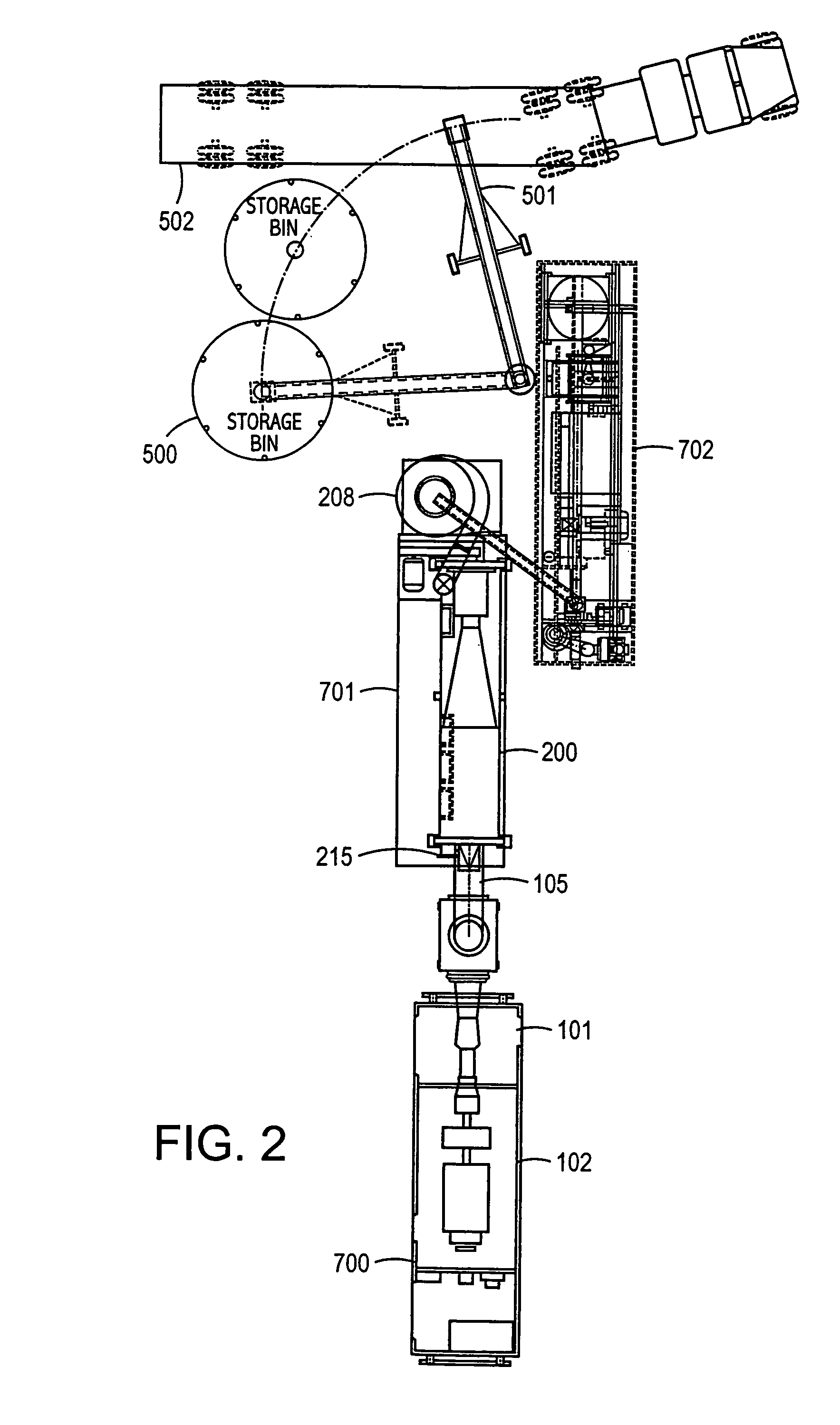

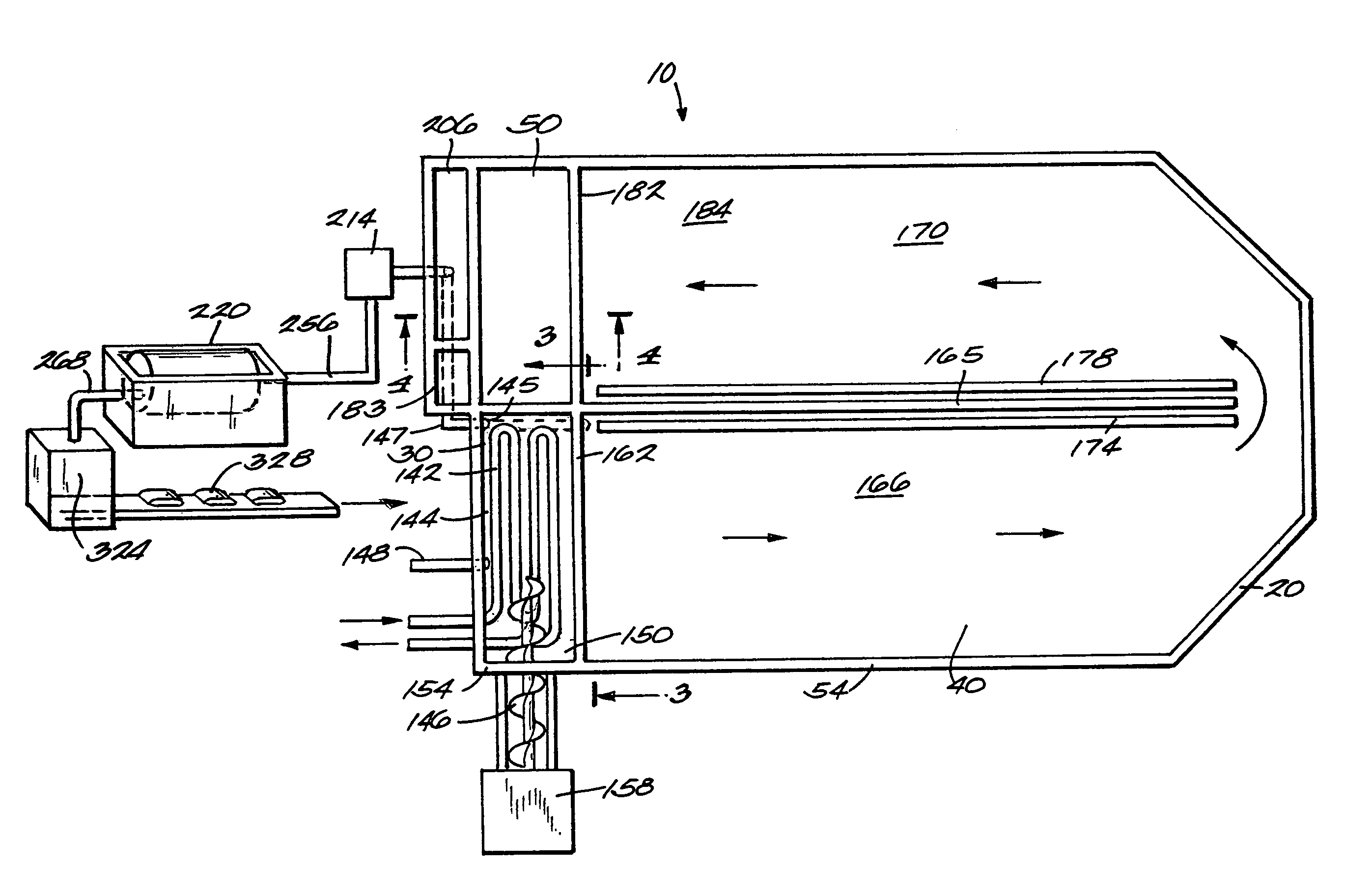

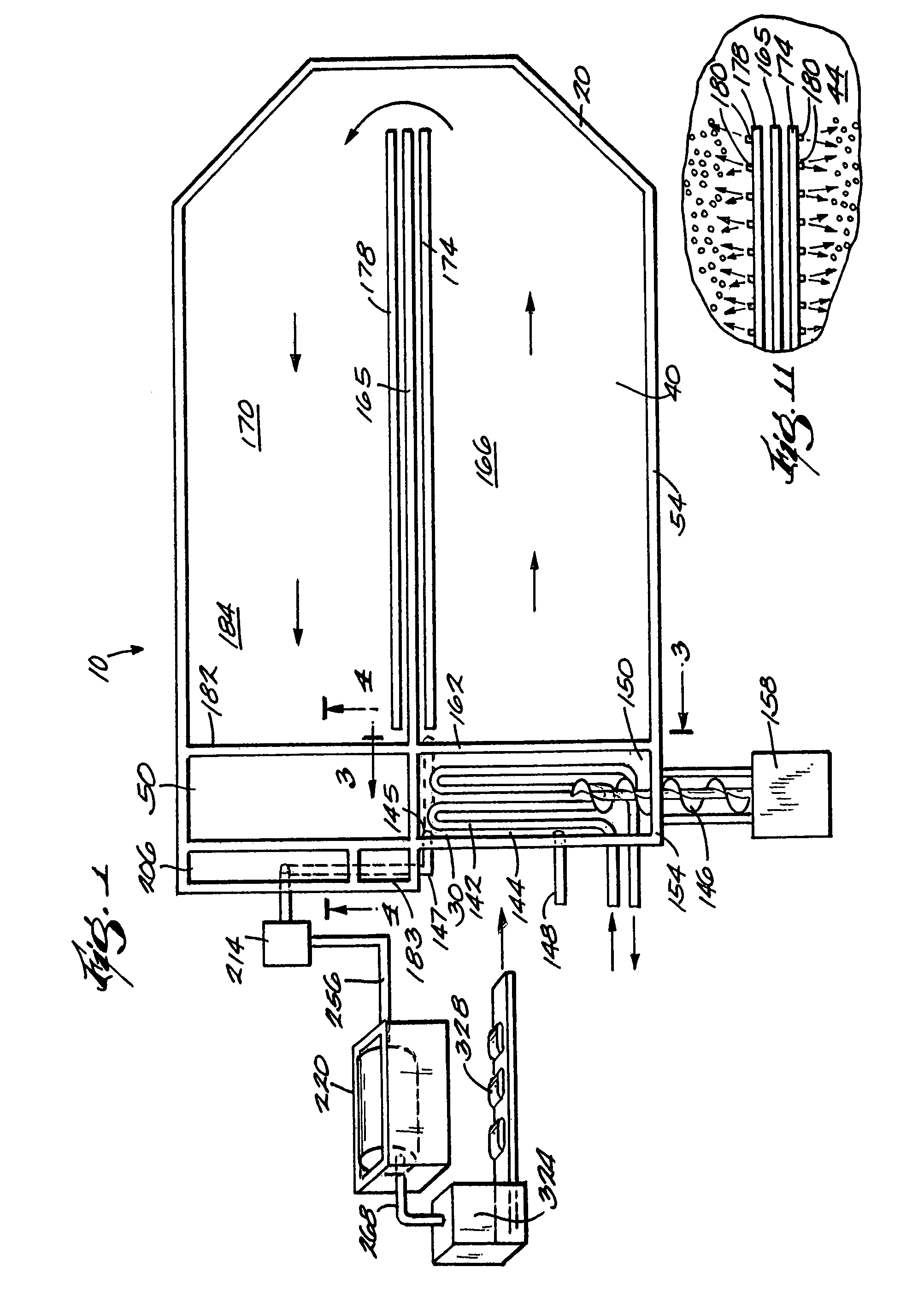

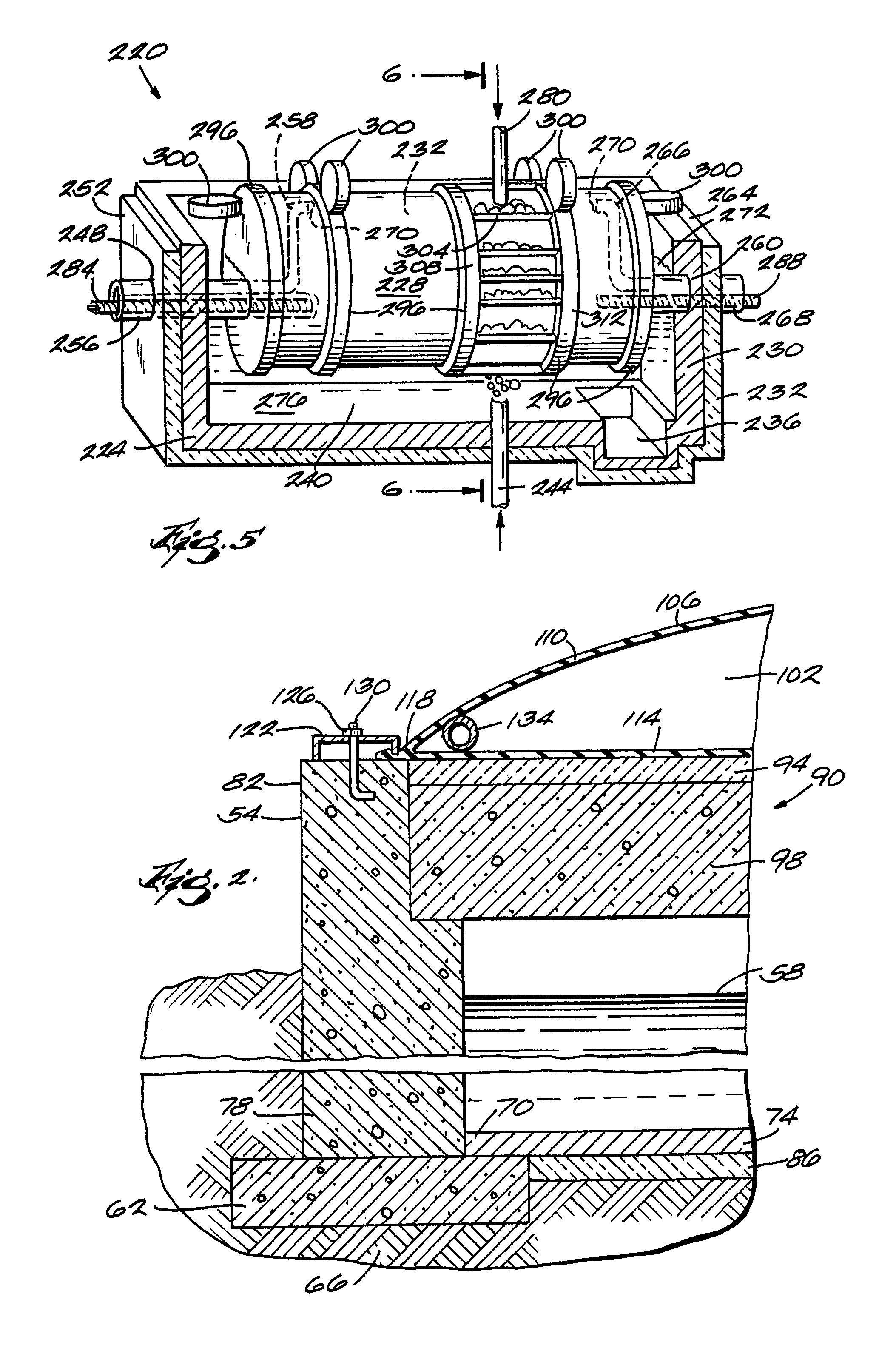

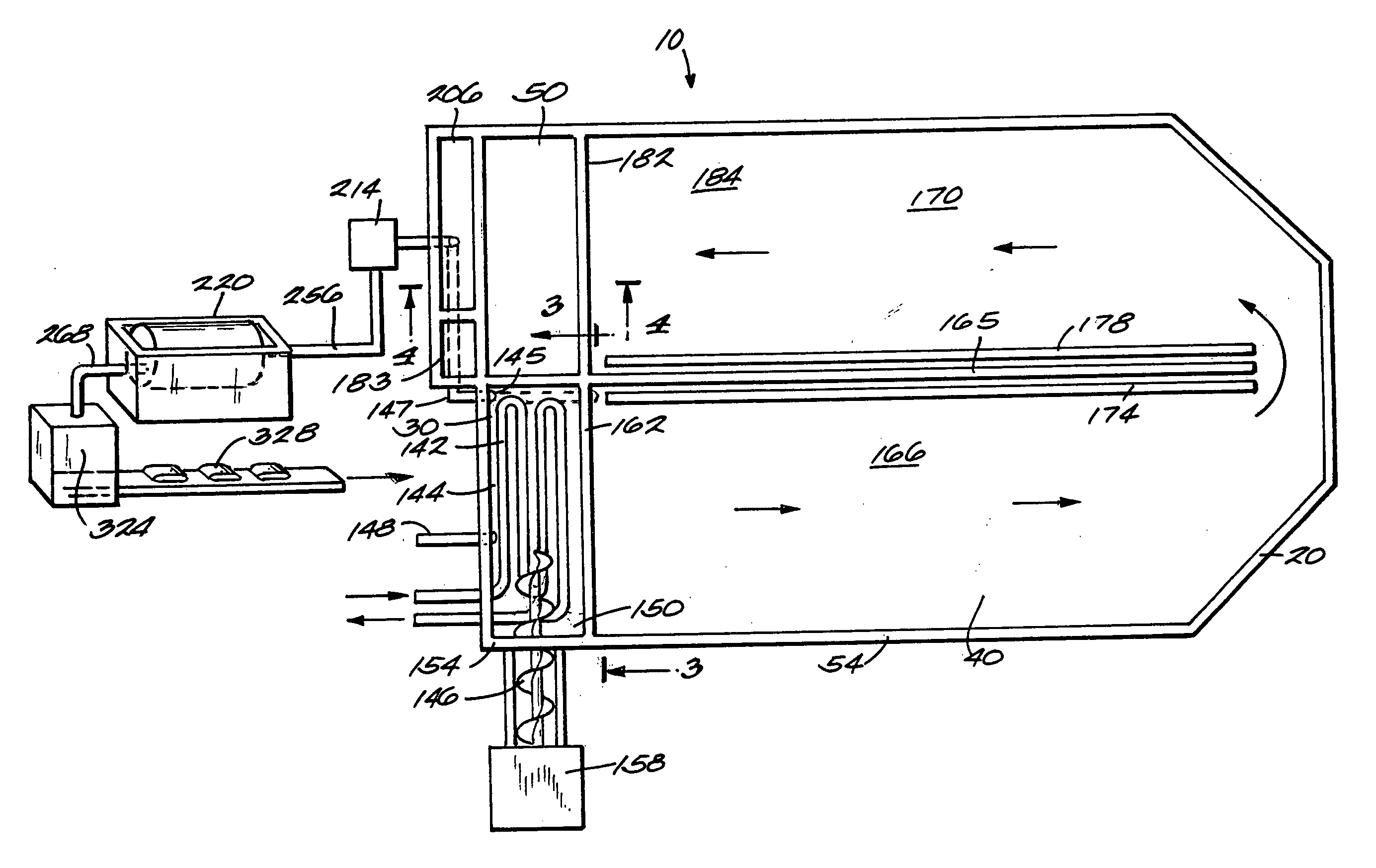

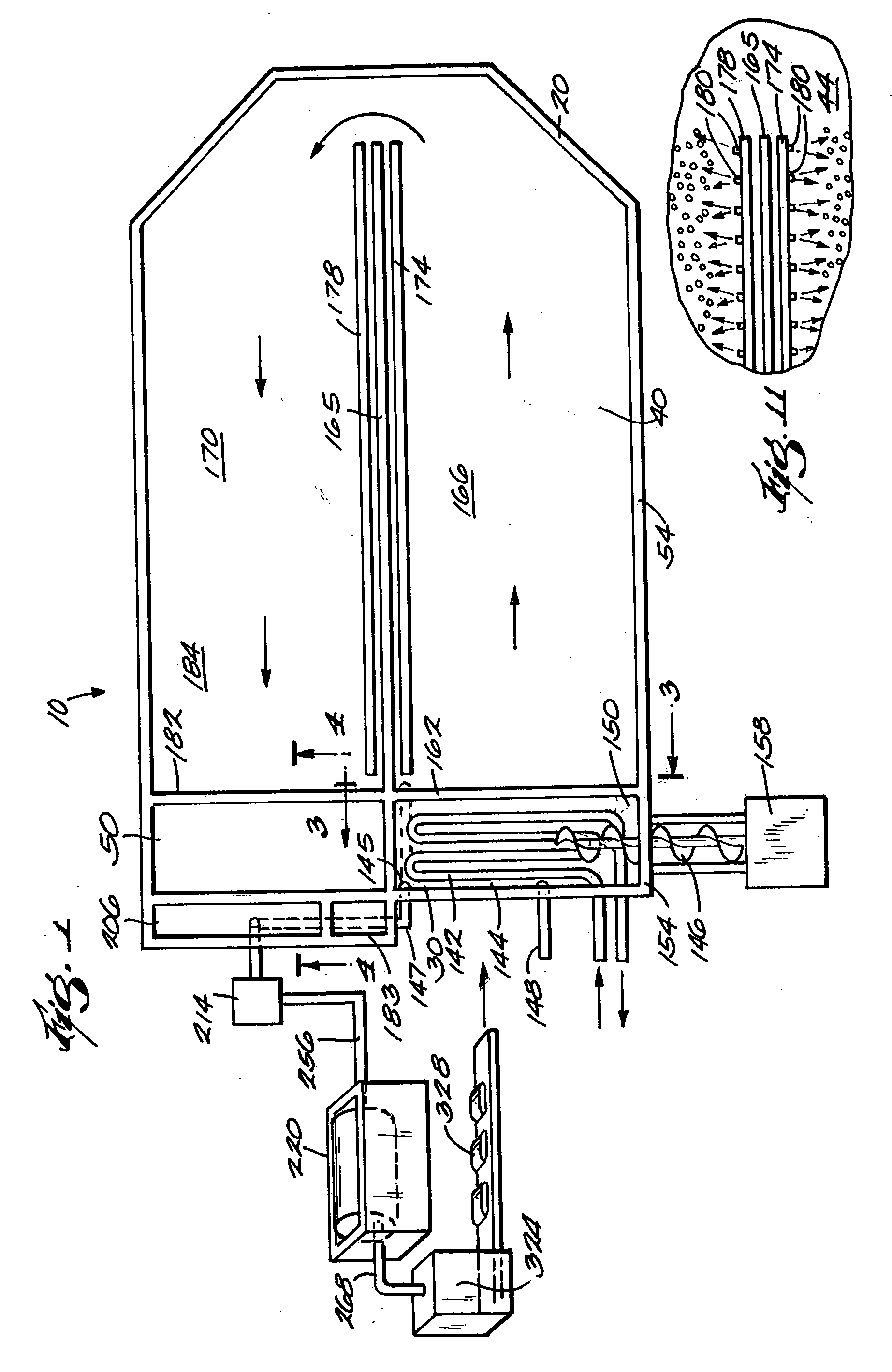

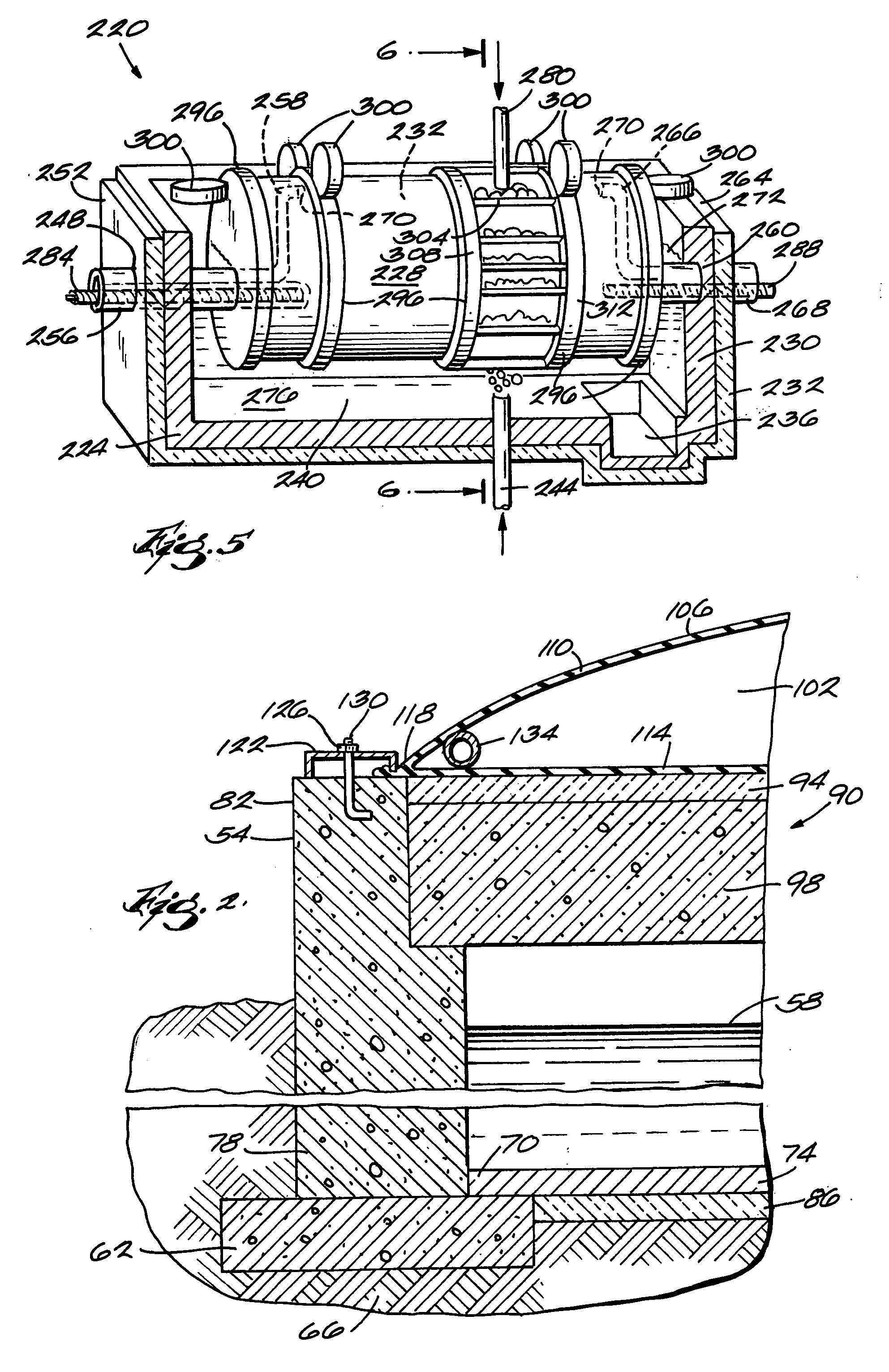

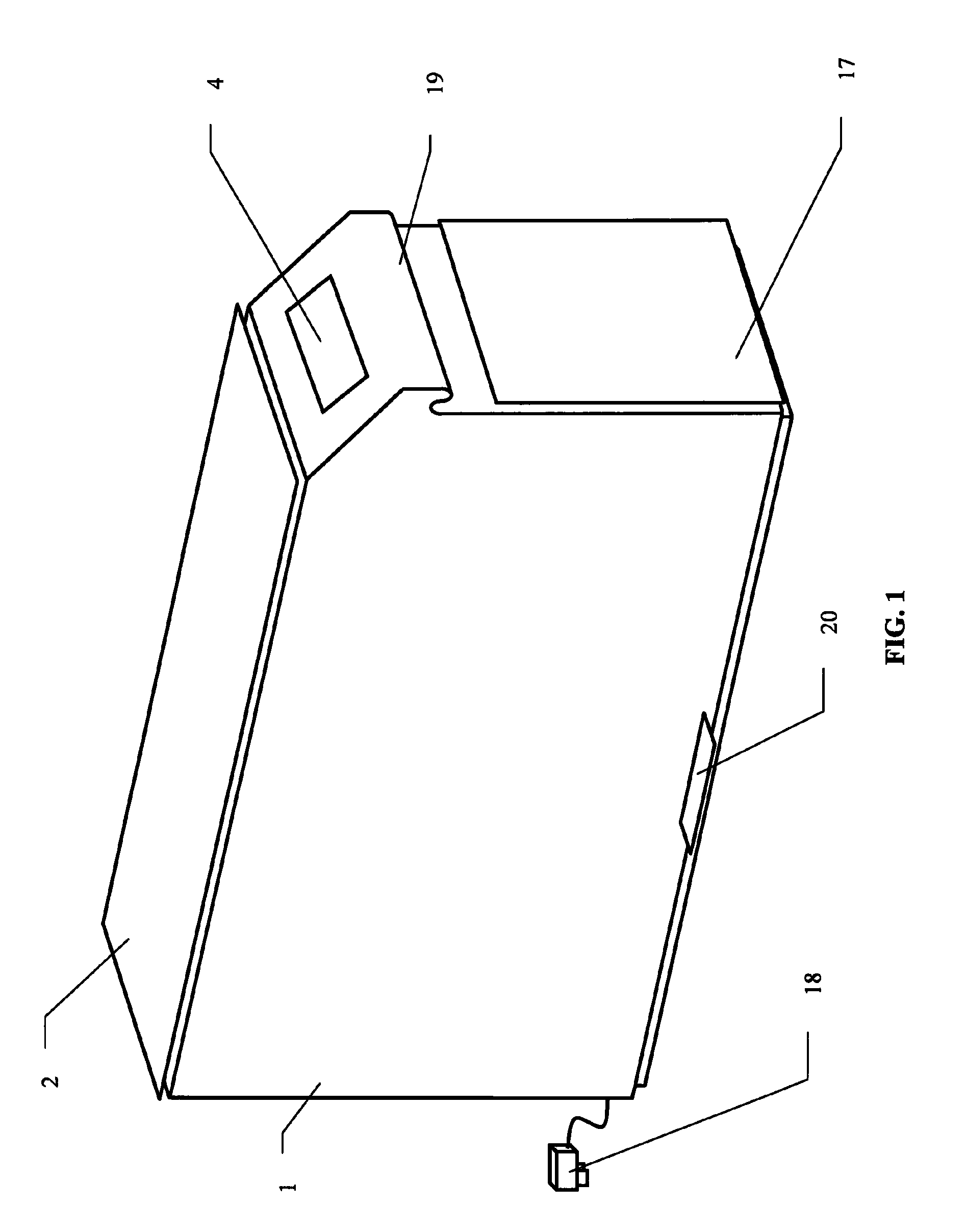

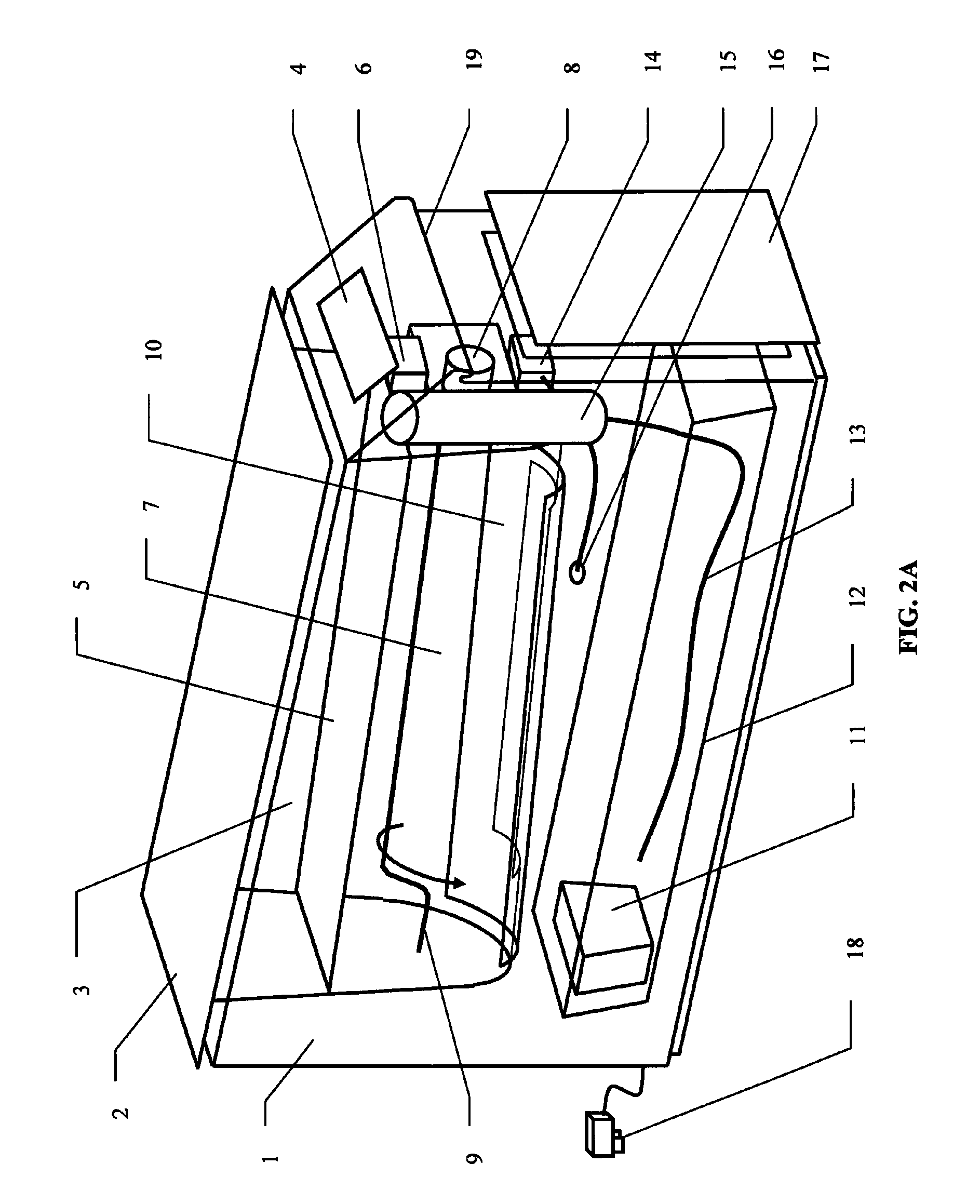

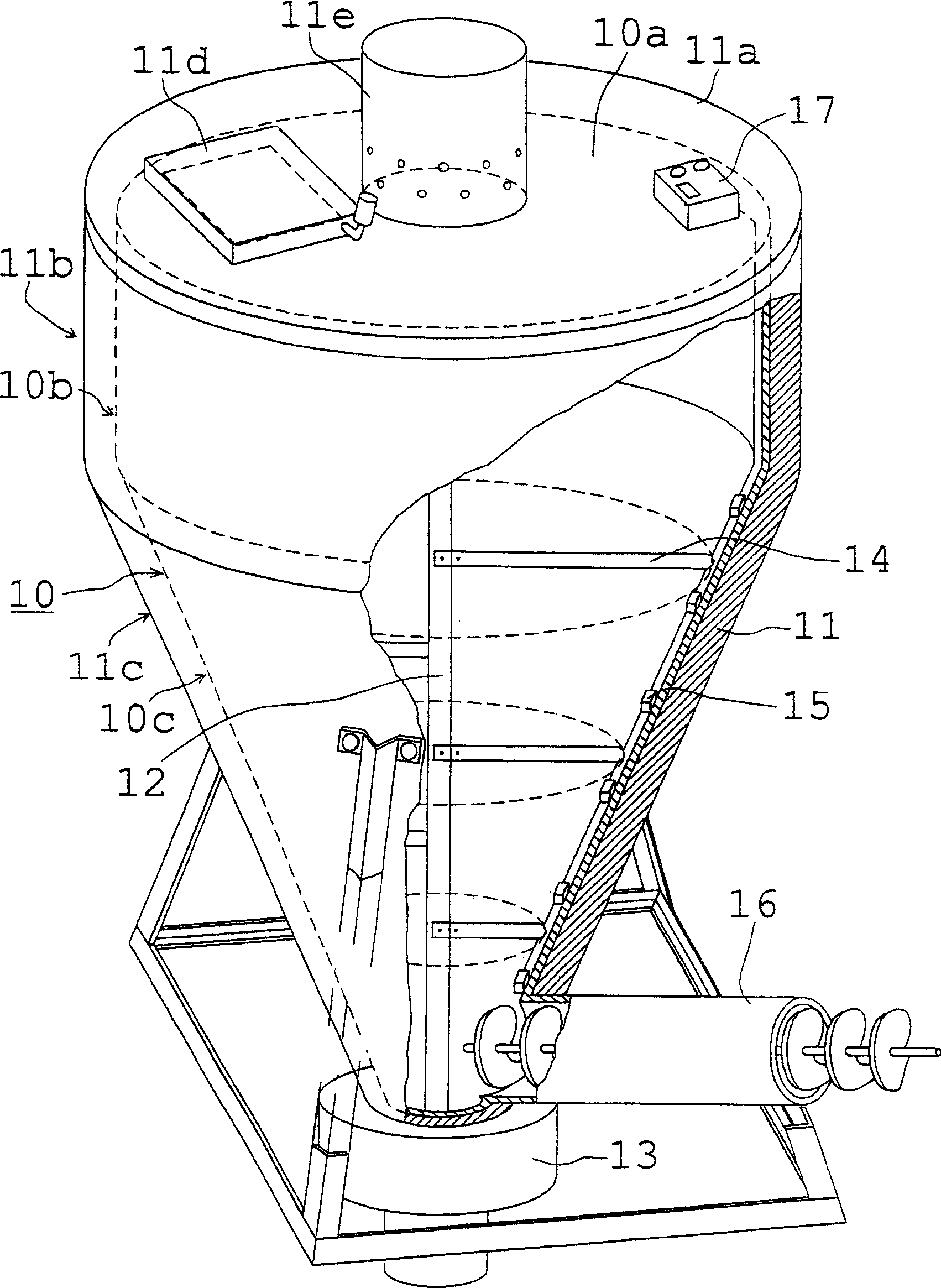

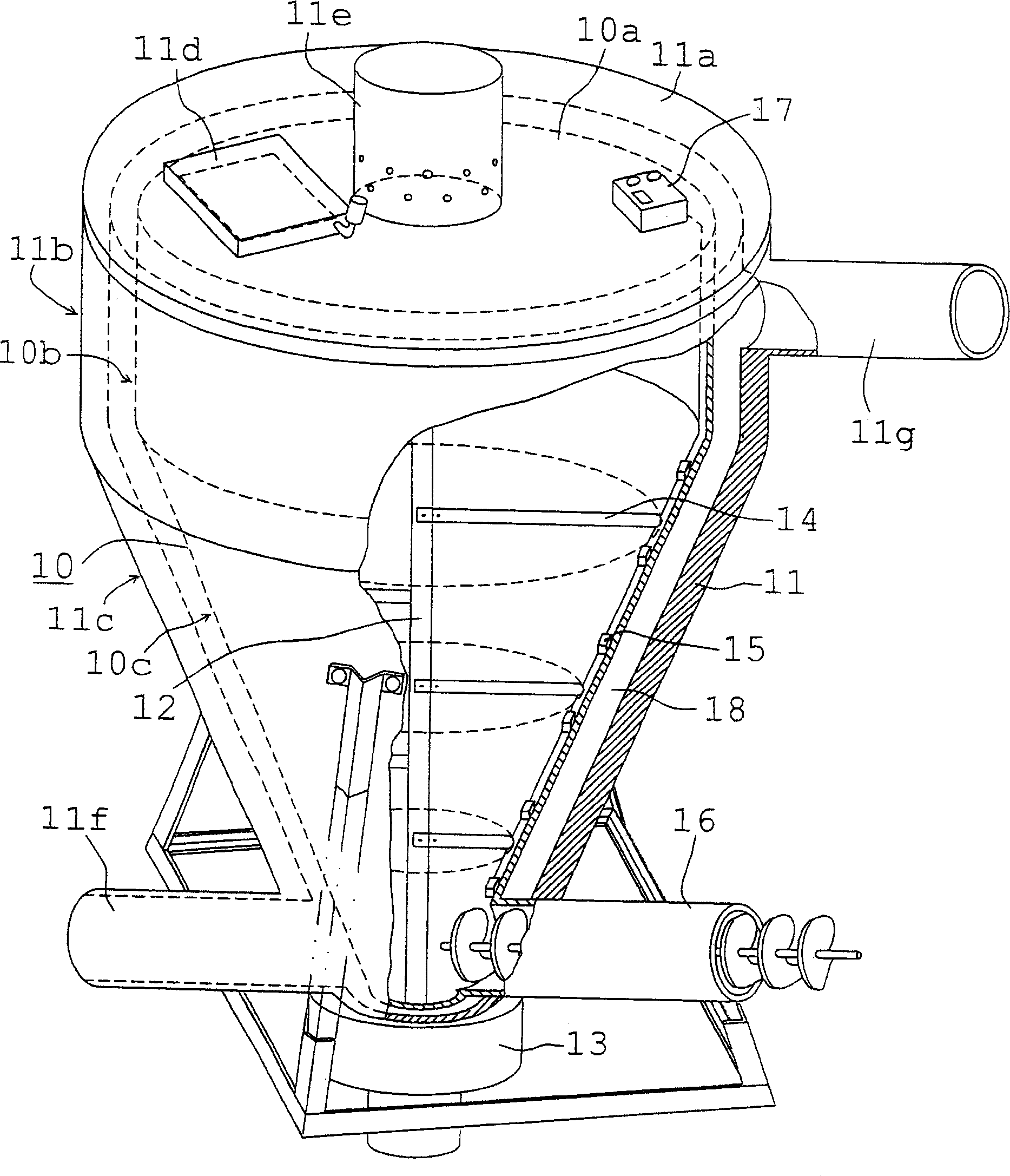

Method and apparatus for solids processing

InactiveUS7078229B2Minimize end waste productMaximize energy efficiencyBioreactor/fermenter combinationsBio-organic fraction processingWaste processingProcess engineering

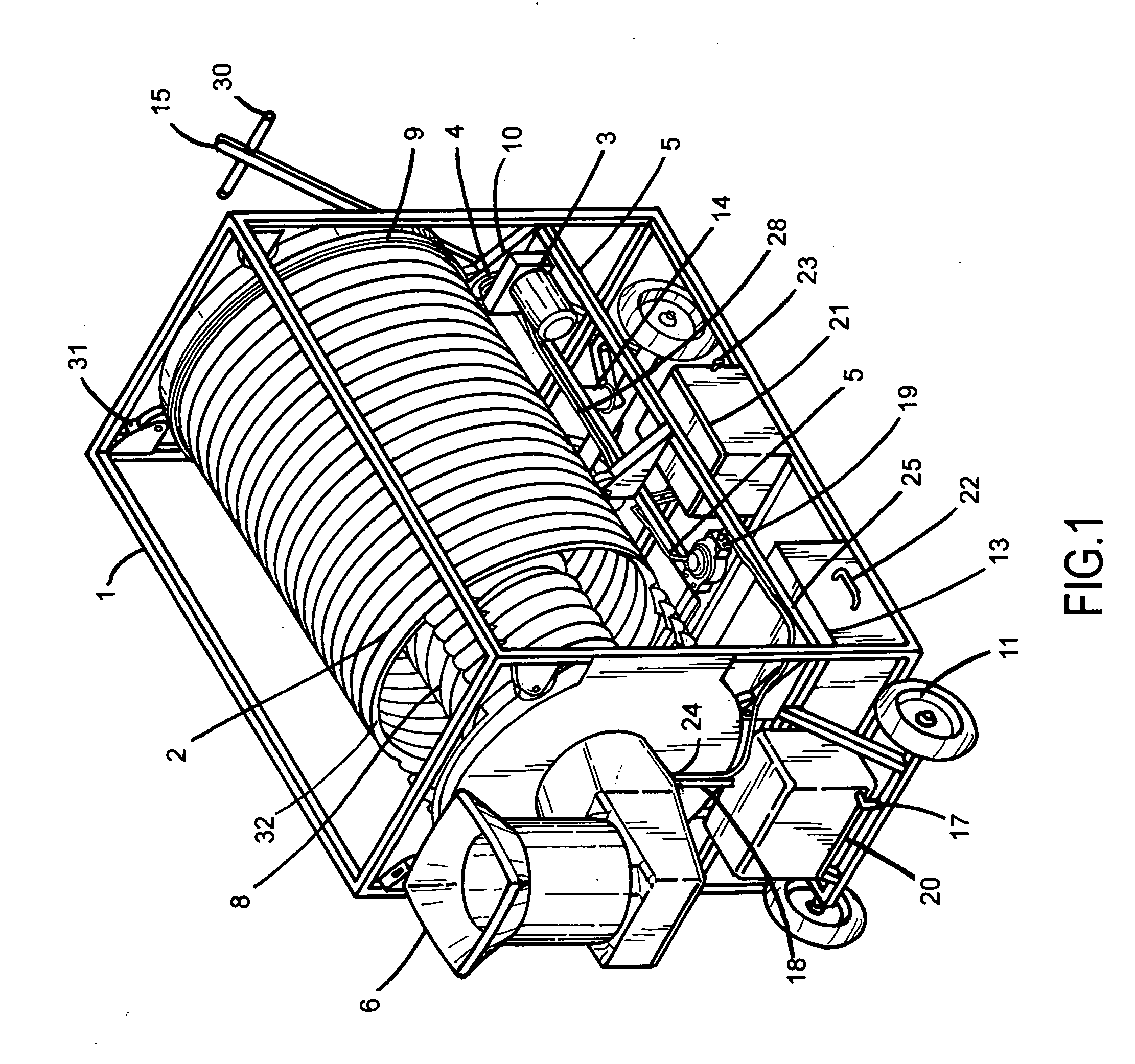

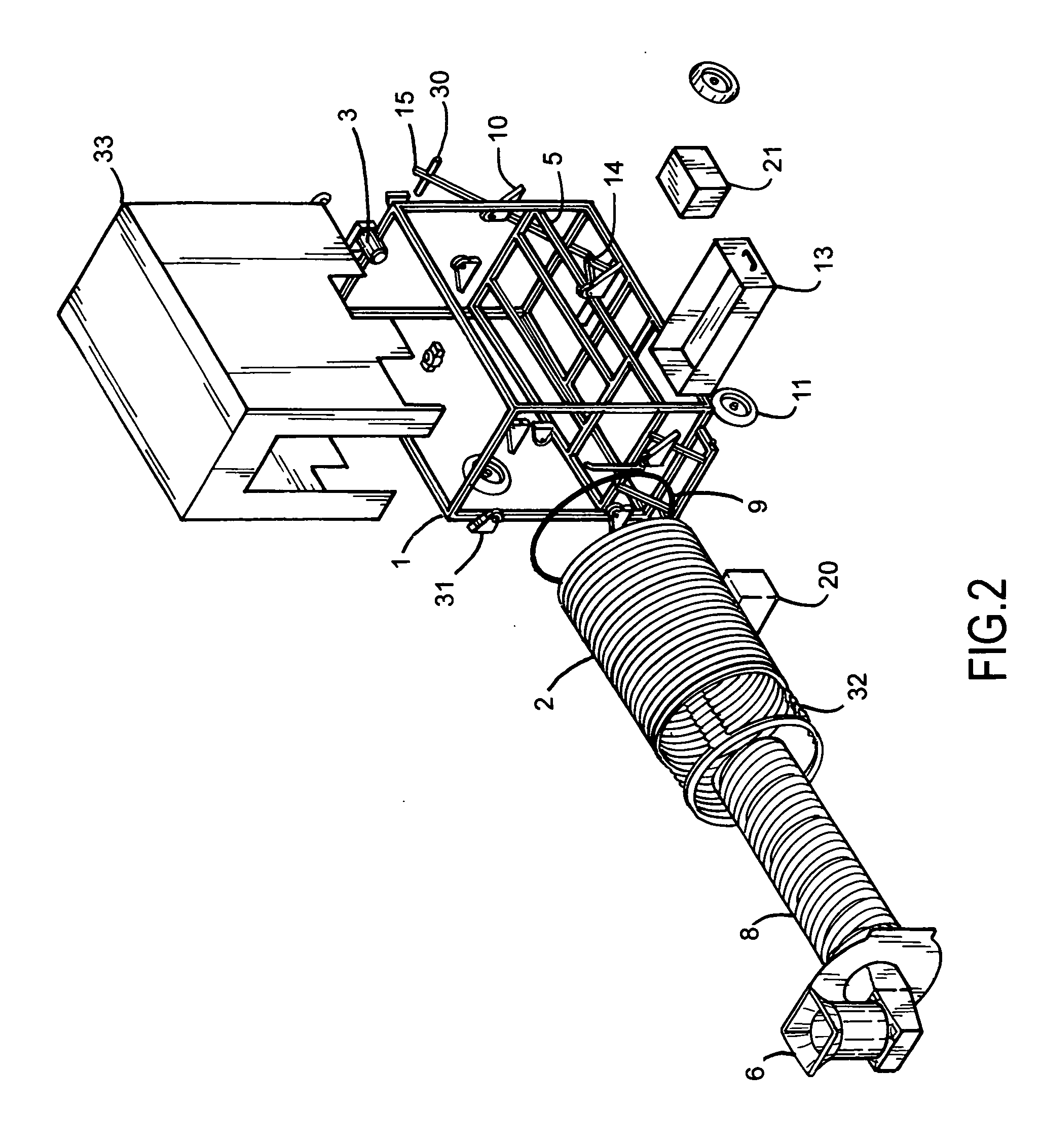

This invention provides a waste-processing system capable of processing high-solids wastes such as manure. This invention provides a compact U-shaped digester that allows for recycling of activated sludge to improve the efficiency of the process. Efficiency is also improved through a sludge heating design that creates a current in the digester and efficiently heats the sludge. A composter is provided to further process the sludge through aerobic digestion to create usable fertilizer. Finally, one embodiment provides a turbine that is fueled by biological gases from the digester to generate heat and electricity to be used by the system.

Owner:DVO LICENSING

Method and apparatus for solids processing

InactiveUS7179642B2Bioreactor/fermenter combinationsBio-organic fraction processingAnaerobic digestionWaste management

Owner:DVO LICENSING

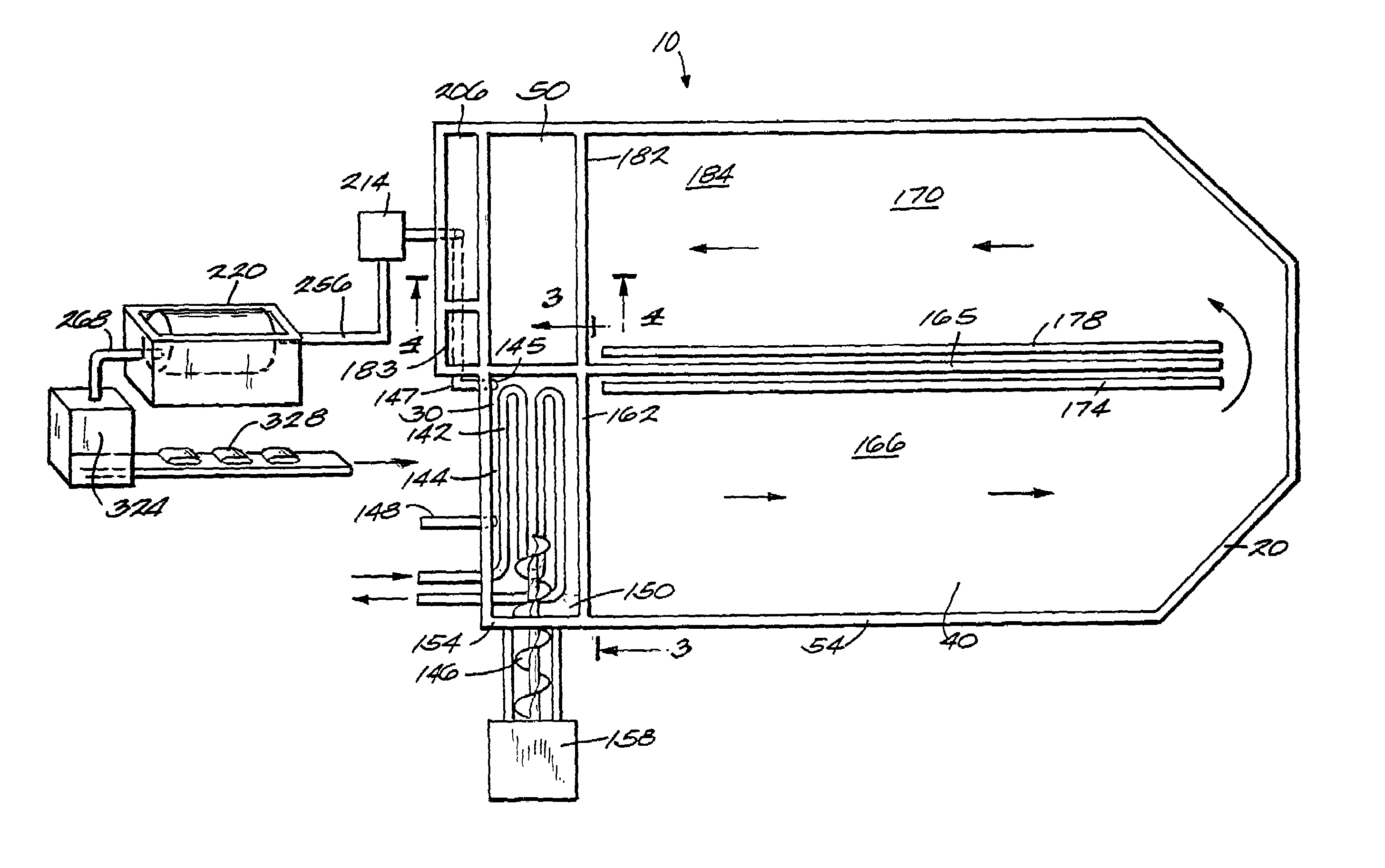

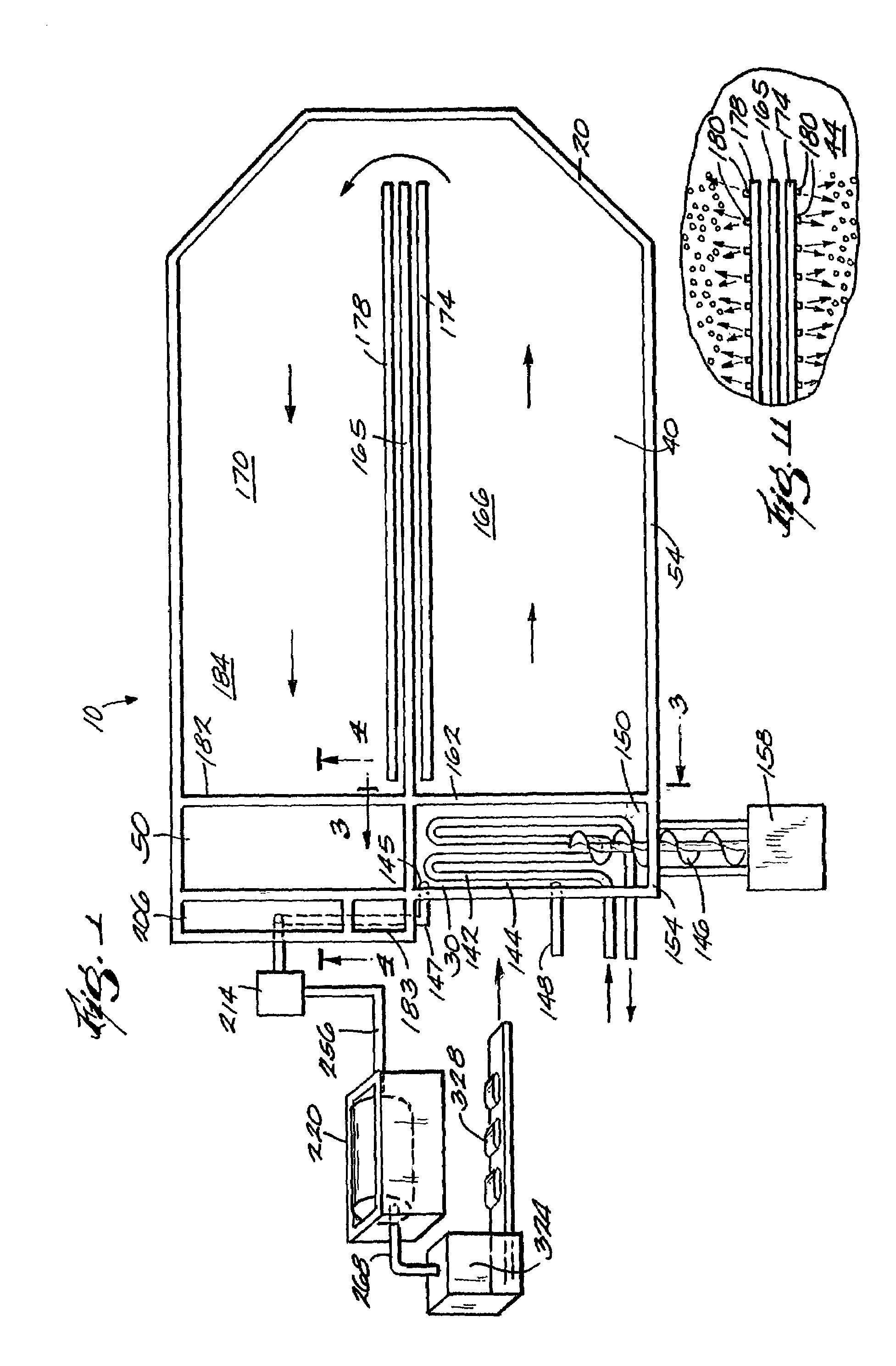

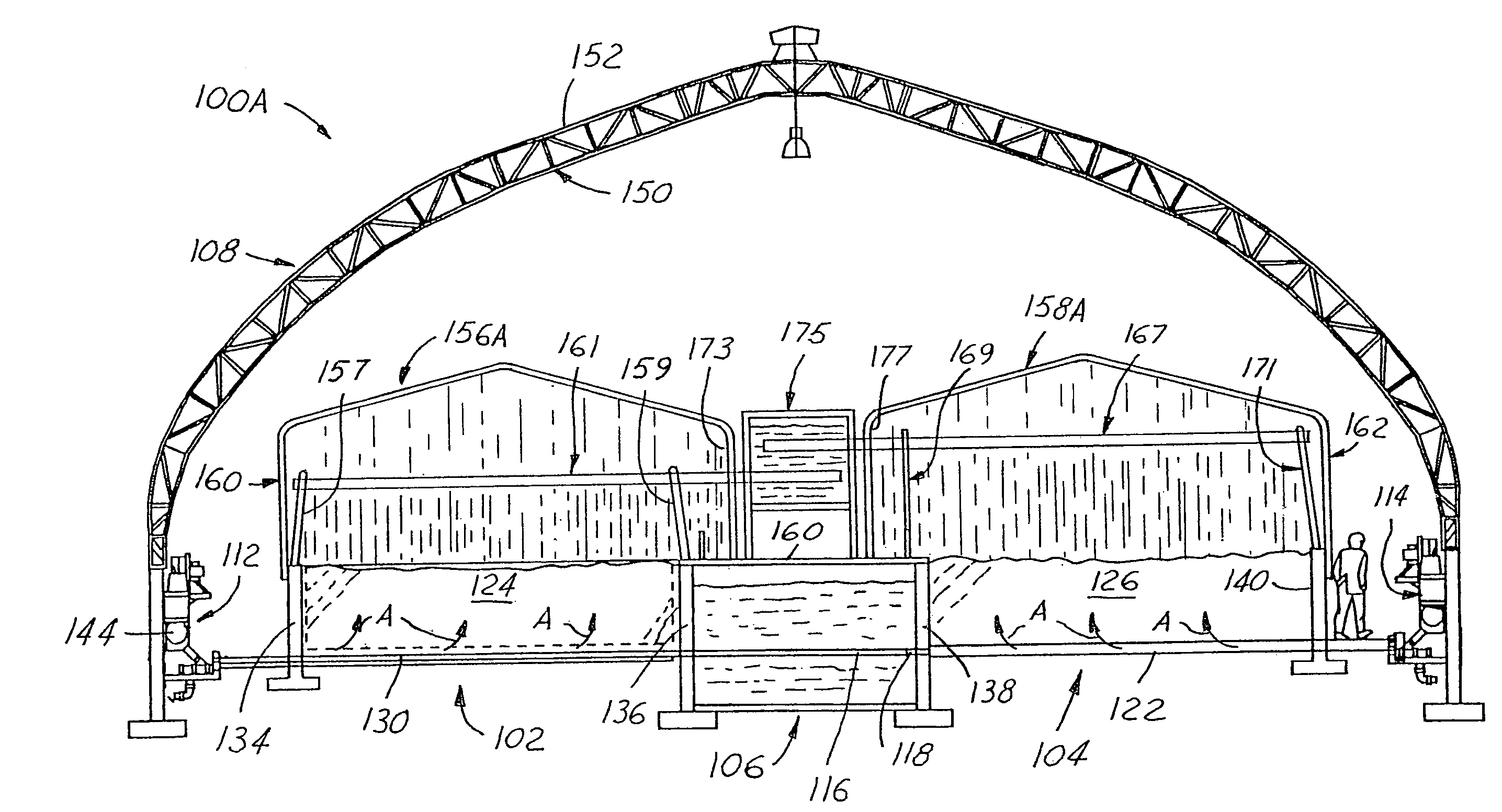

Biomass heating system

InactiveUS7135332B2Improve heating effectMaximize biomass decomposition service lifetimeBioreactor/fermenter combinationsBio-organic fraction processingBasementGrowth plant

Improved systems, methods, apparatus and compositions for generating, extracting and distributing the renewable heat energy produced by microbial decomposition of organic biomass within a contained and controlled environment. This heat energy is preferably transferred and distributed, preferably by the use of heat pipes, to the interior of a greenhouse or other structure to be heated, either directly or via heat exchange apparatus such as hot water heating systems. In one embodiment heat transfer and distribution mechanism customized to the application requirements of a greenhouse heating batch-type process is disclosed, along with a recipe for a readily available biomass material composition that will slowly decompose while it generates a substantial quantity of usable heat energy to be consumed in the elevation of temperature in a separated greenhouse basement confinement area. Additional continuous and batch process embodiments of biomass heating systems are also disclosed that extract heat energy from decomposing biomass for heating uses. In some embodiments gaseous products generated in a biological decomposition process, primarily CO2, are utilized to enhance plant growth in the greenhouse environment.

Owner:AGRILAB TECH INC

Method and apparatus for solids processing

InactiveUS20040087011A1Bioreactor/fermenter combinationsBio-organic fraction processingWaste managementAnaerobic digestion

Apparatuses and methods for anaerobic digestion of high-solids waste are provided. The methods may include and the apparatuses may be used for moving the solid waste in a corkscrew-like fashion through a closed container. The method may further include moving the high-solids waste into contact with a heating device to facilitate the corkscrew-like movement. Other methods and apparatuses may use at least one of a partition and a conduit from which liquid or gas is discharged.

Owner:DVO LICENSING

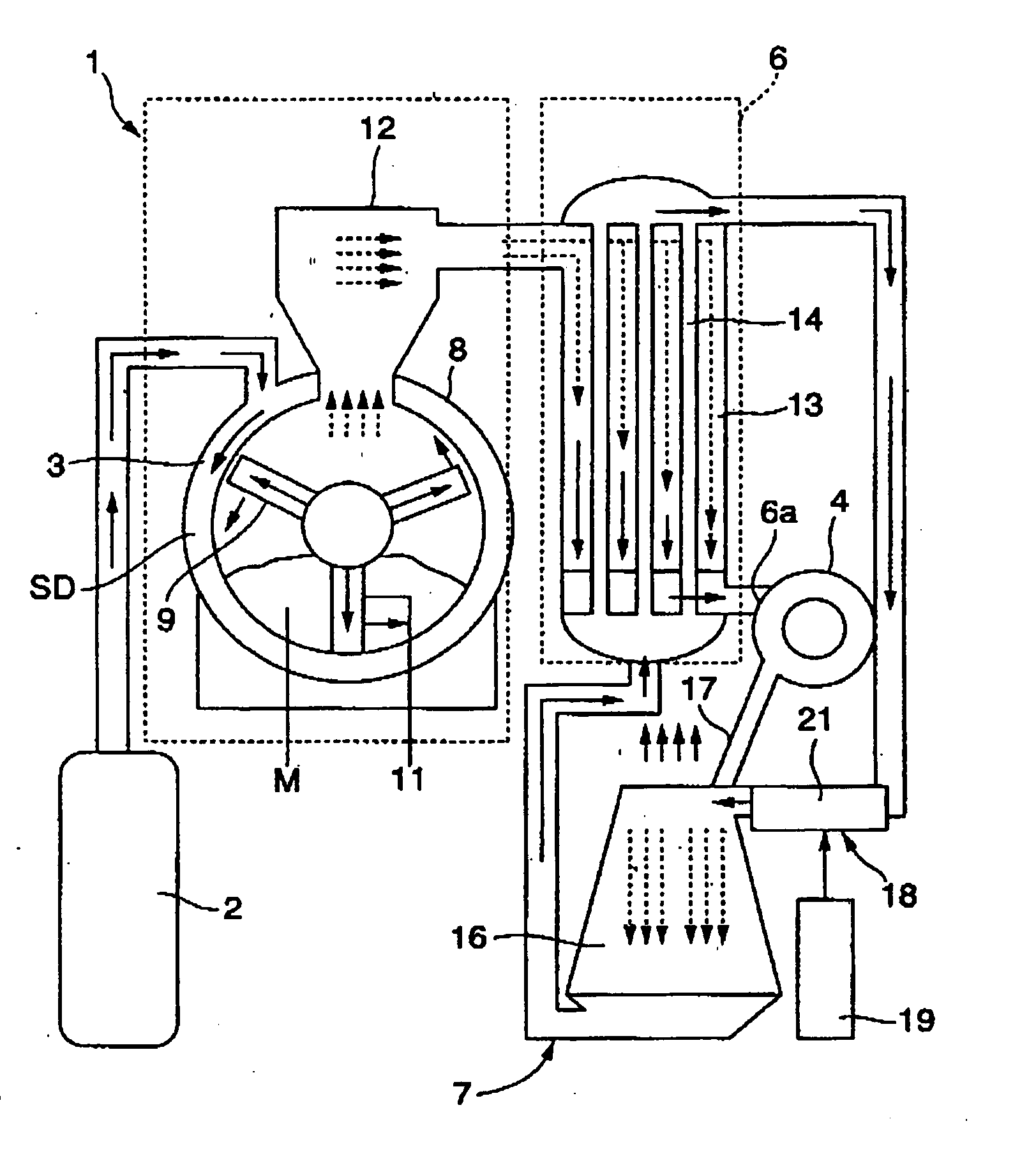

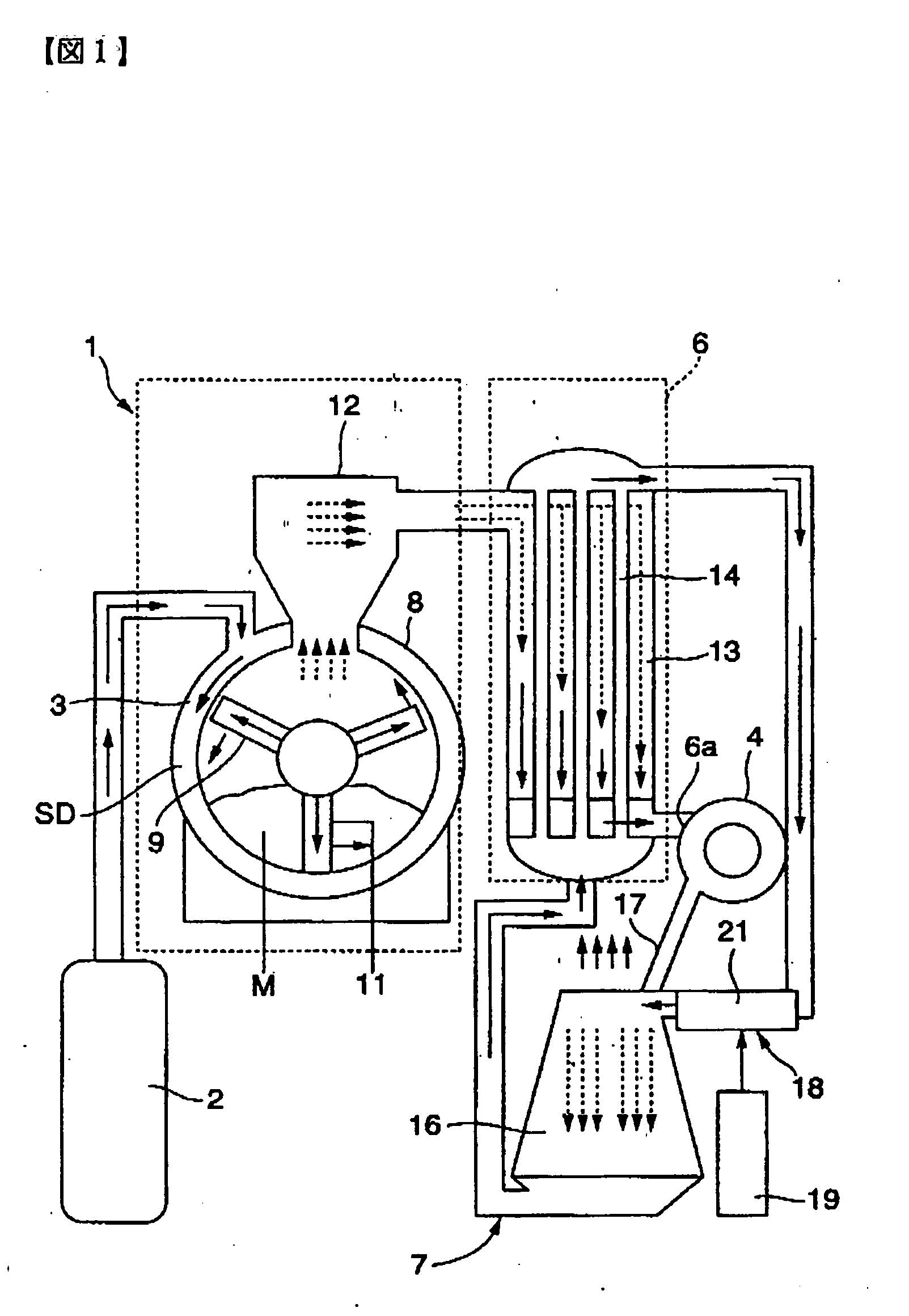

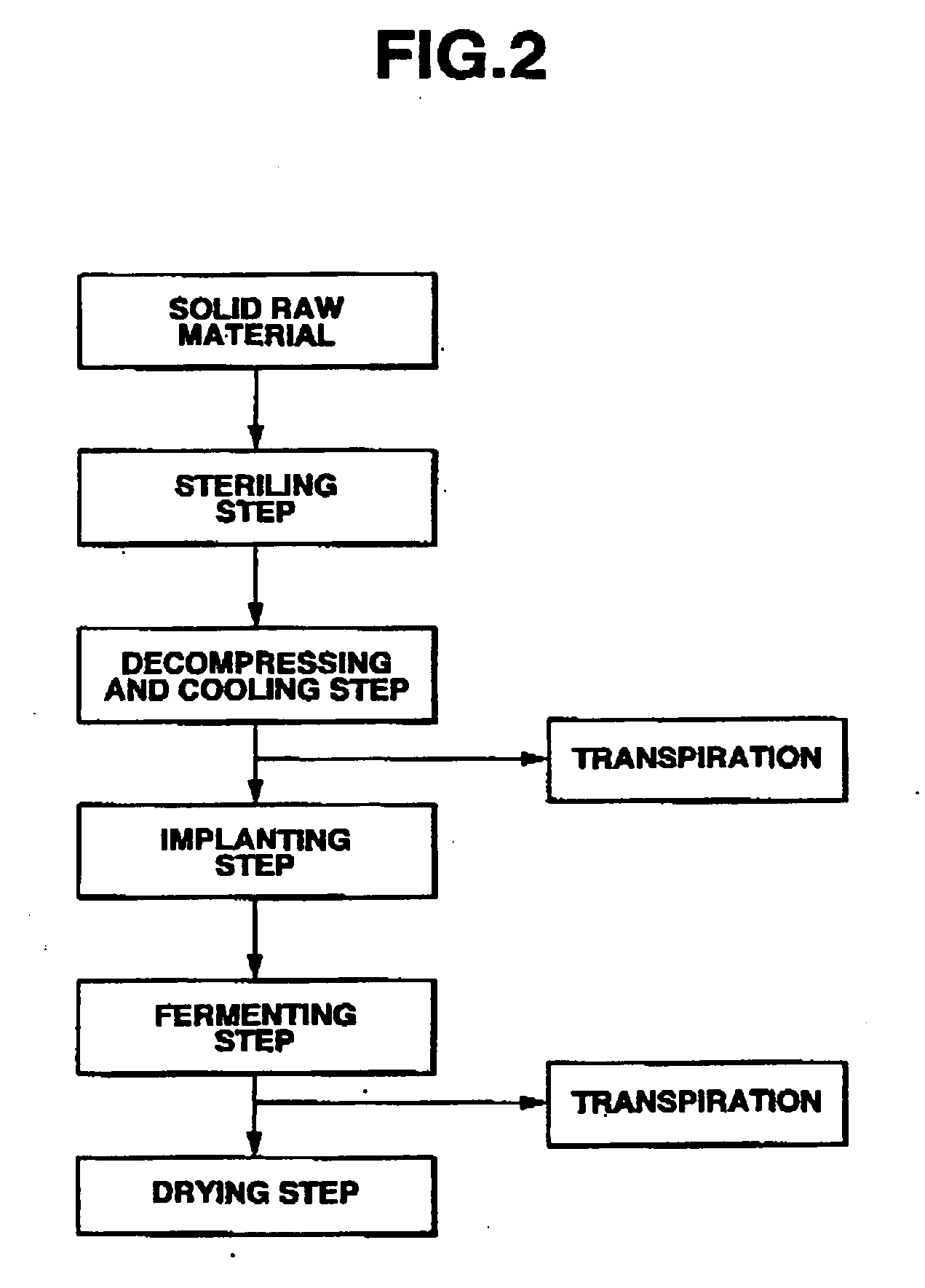

Method and apparatus for producing organic fertilizer

InactiveUS20050044911A1Short timeImprove efficiencyBioreactor/fermenter combinationsBio-organic fraction processingBoiling pointDecomposition

Disclosed is an manufacturing method of organic fertilizer of the present invention, wherein moisturized organic wastes and microbe, which decomposed organic materials so as to compost, are mixedly contained in a container (3) which can be sealed but also freely opened and closed, the container (3) is heated as well as decompressed by closing the container (3), the boiling point of water in the container (3) is set below the fermentation heat of the organic wastes caused by the microbe in decomposing the organic materials, and the moisture in the organic wastes in the container (3) ins vaporized and exhausted, whereby an organic fertilizer is manufactured by the decomposition of the organic materials. Thereby, a technique where the process to manufacture the organic fertilizer from organic wastes is efficiently conducted in a short period of time is provided.

Owner:JAPAN NOBLE SYST

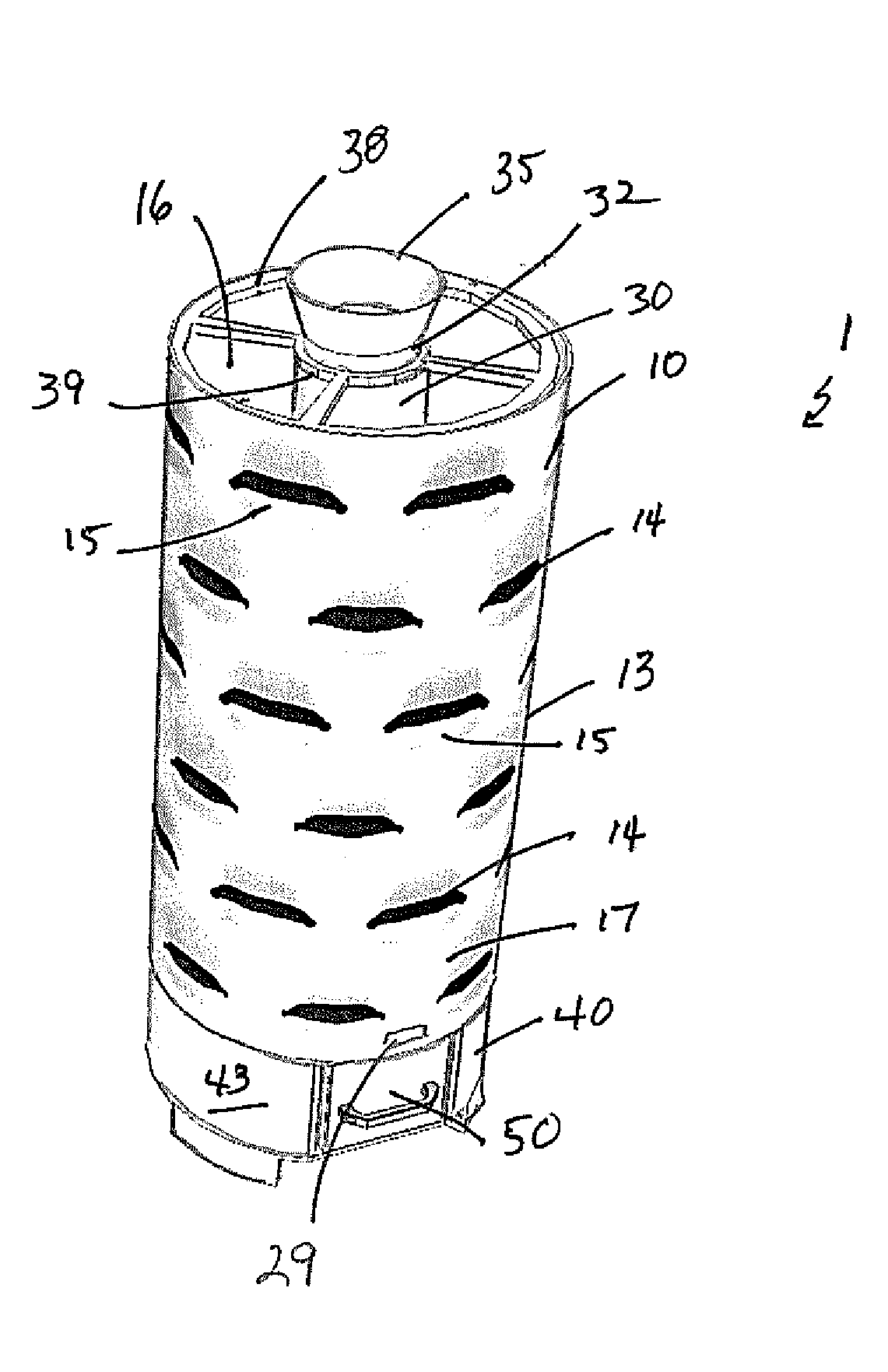

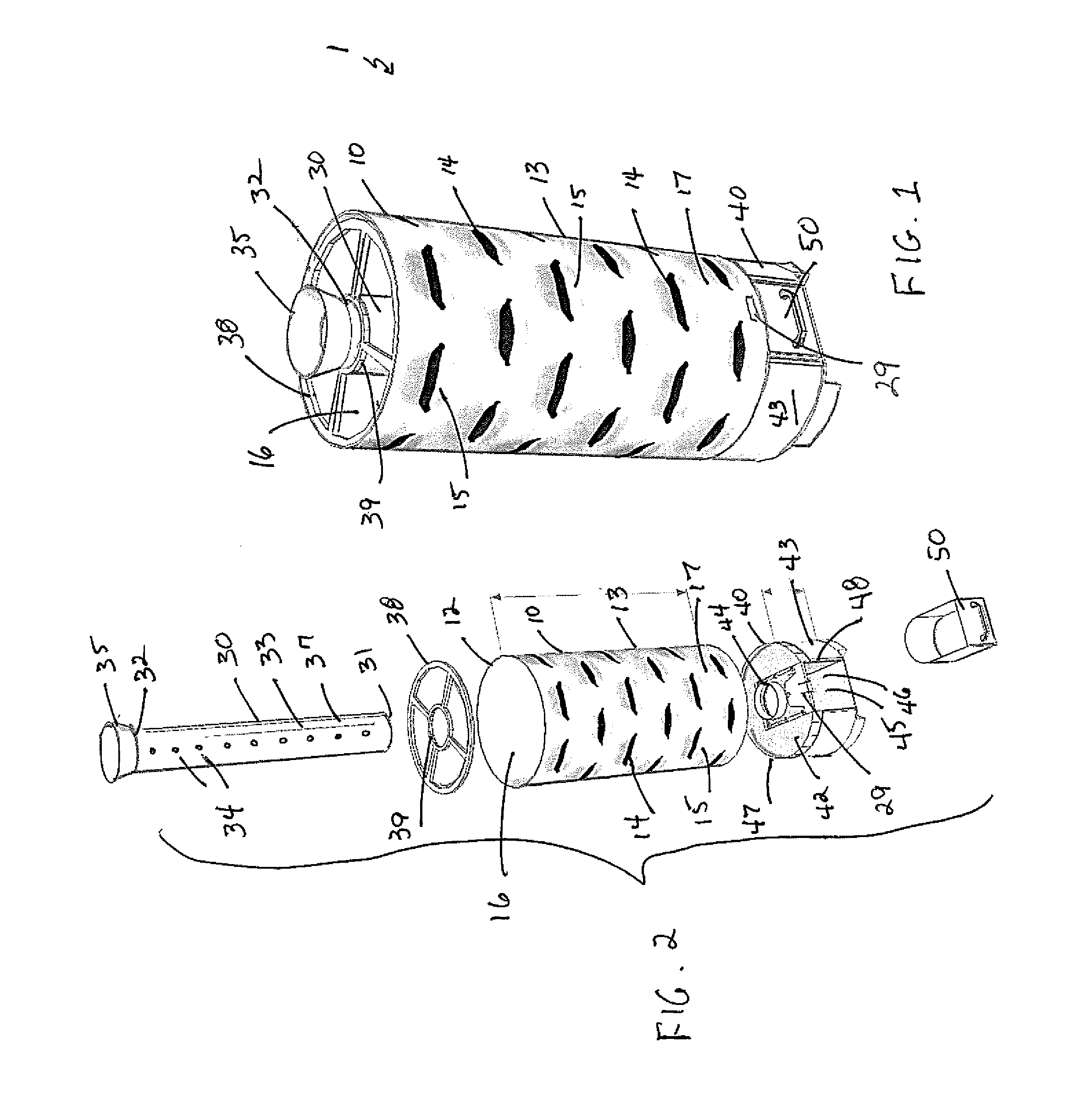

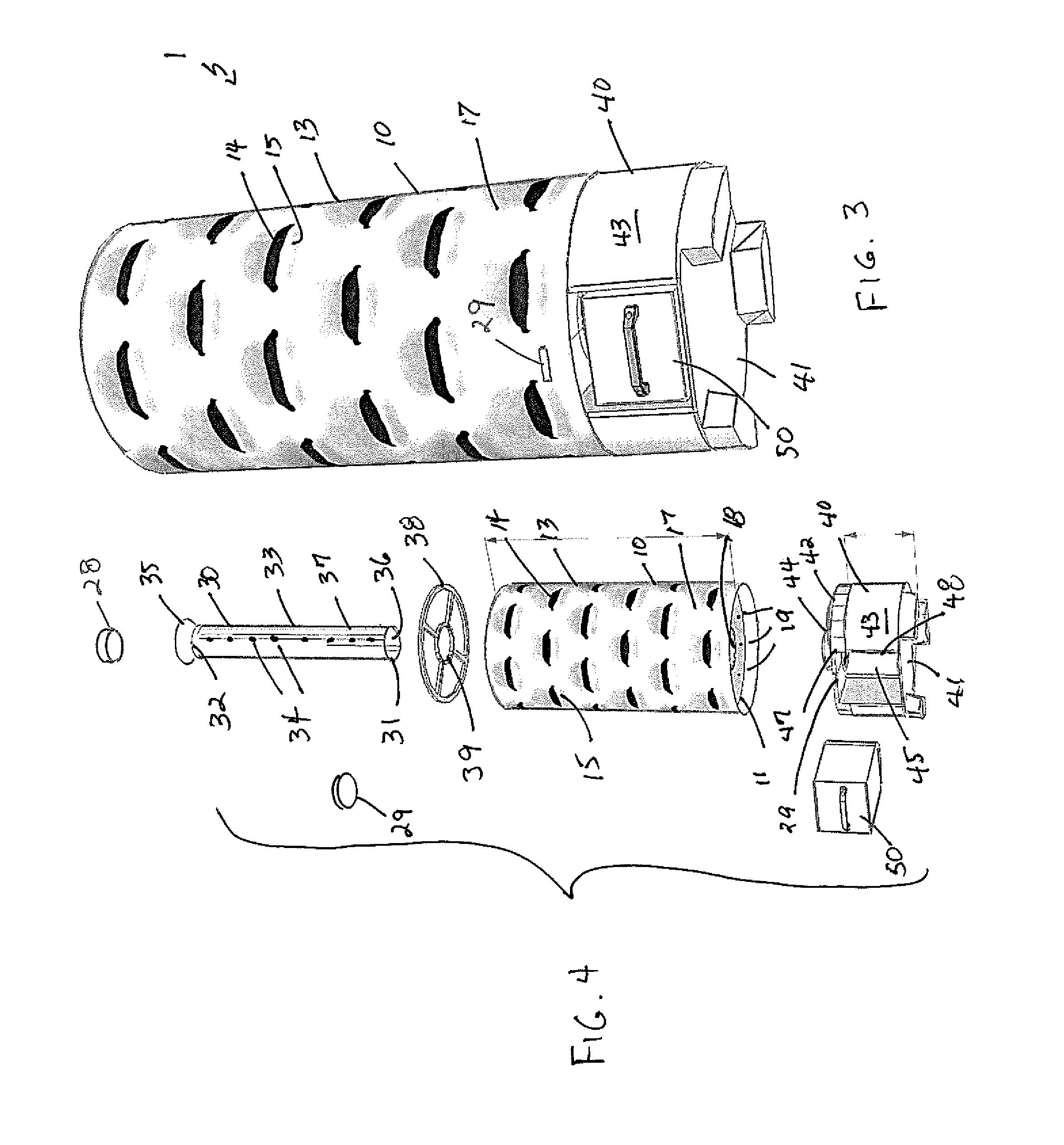

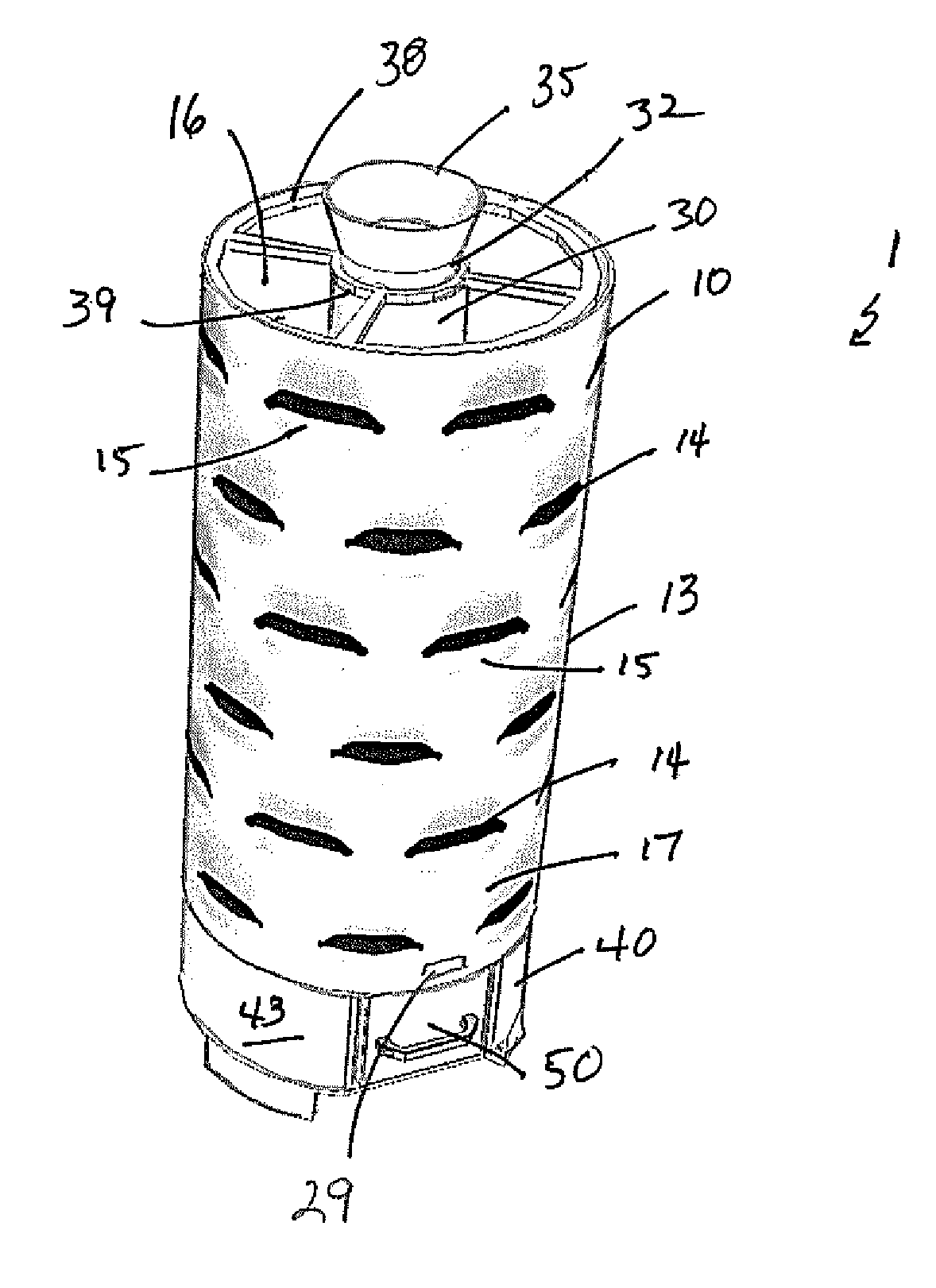

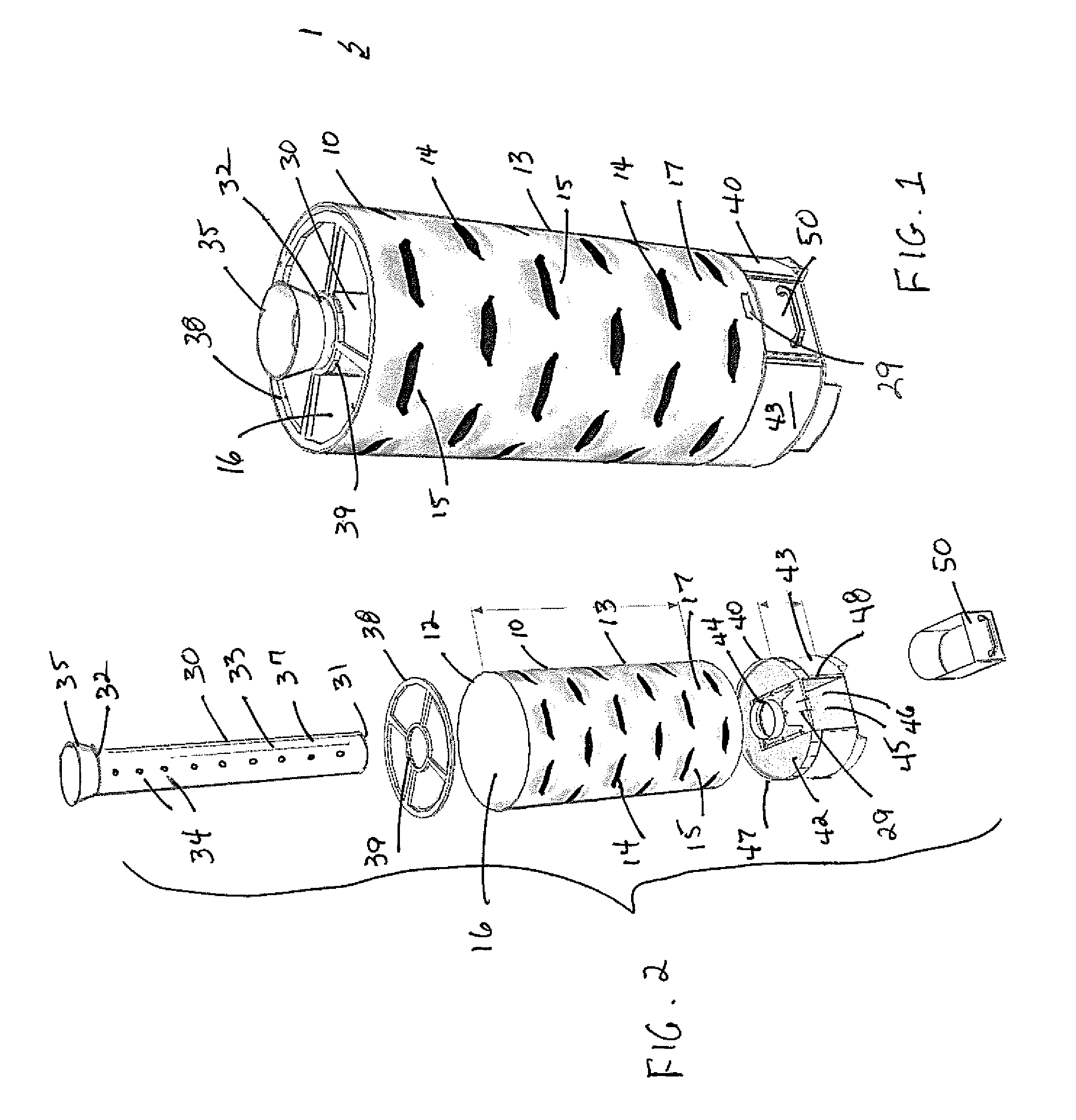

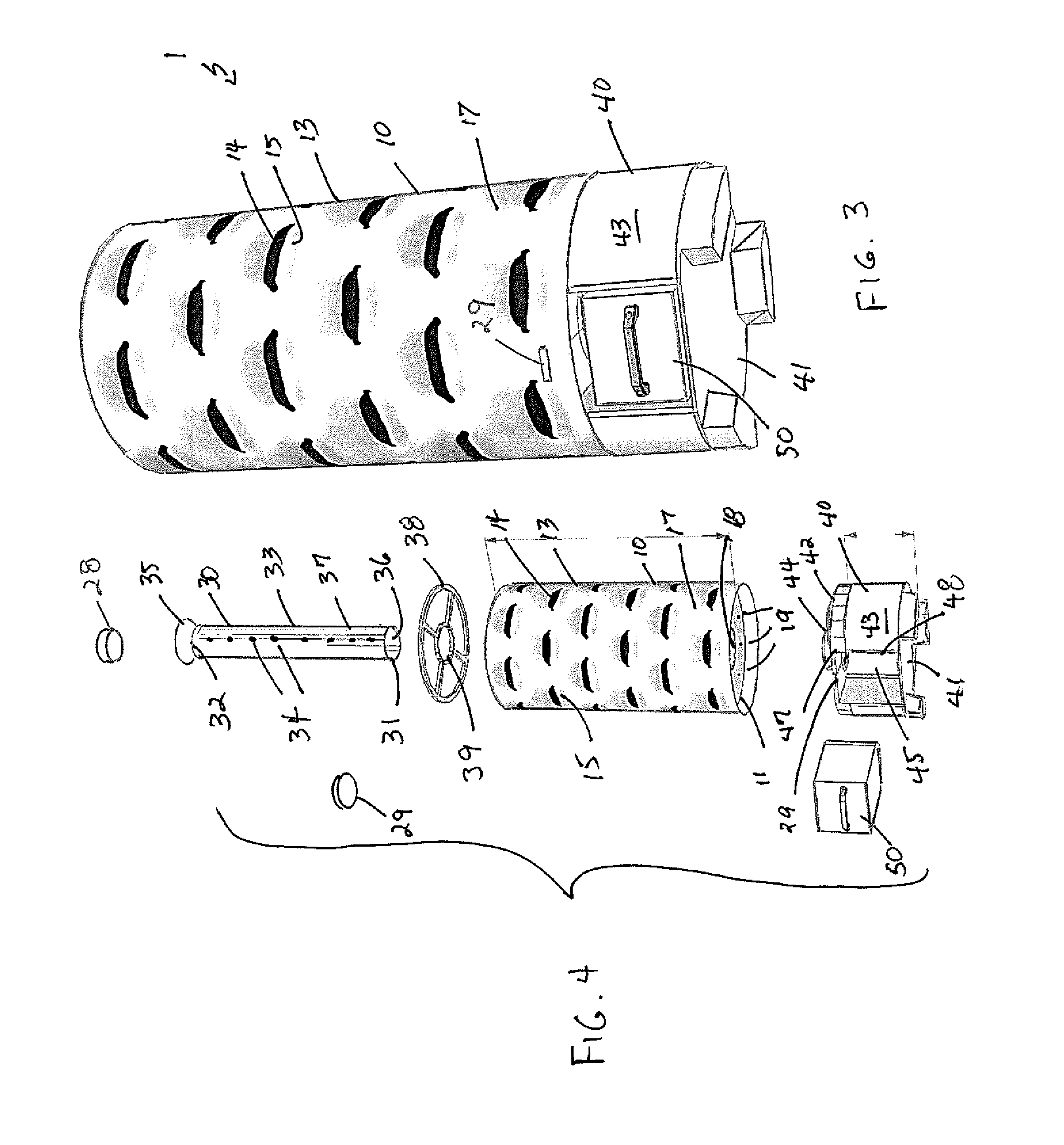

Composting Garden Container

A planter in the form of a tower planter having an internal vertical composting capability is provided. The planter has a hollow, vertical, outer cylindrical barrel with a plurality of openings formed about its cylindrical side. A hollow inner cylindrical composting tube having a plurality of perforations formed in its cylindrical wall is provided. The space formed between the inner tube and barrel wall is filled with growing medium. The inner tube is filled with compost material. A removable container is placed at the bottom of the tube and barrel, said container adapted to capture water draining out from the tube and barrel, as well, as periodically receiving compost from the compost tube.

Owner:CUDMORE COLIN

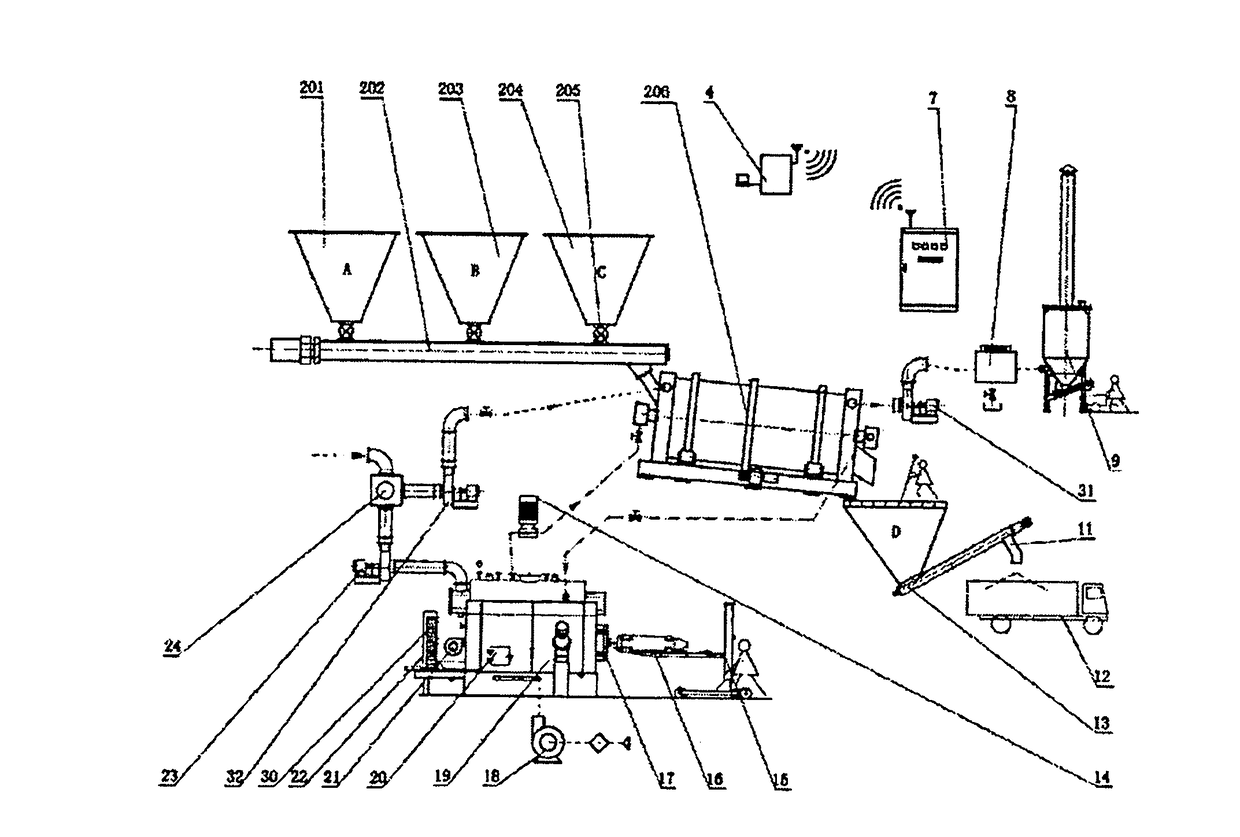

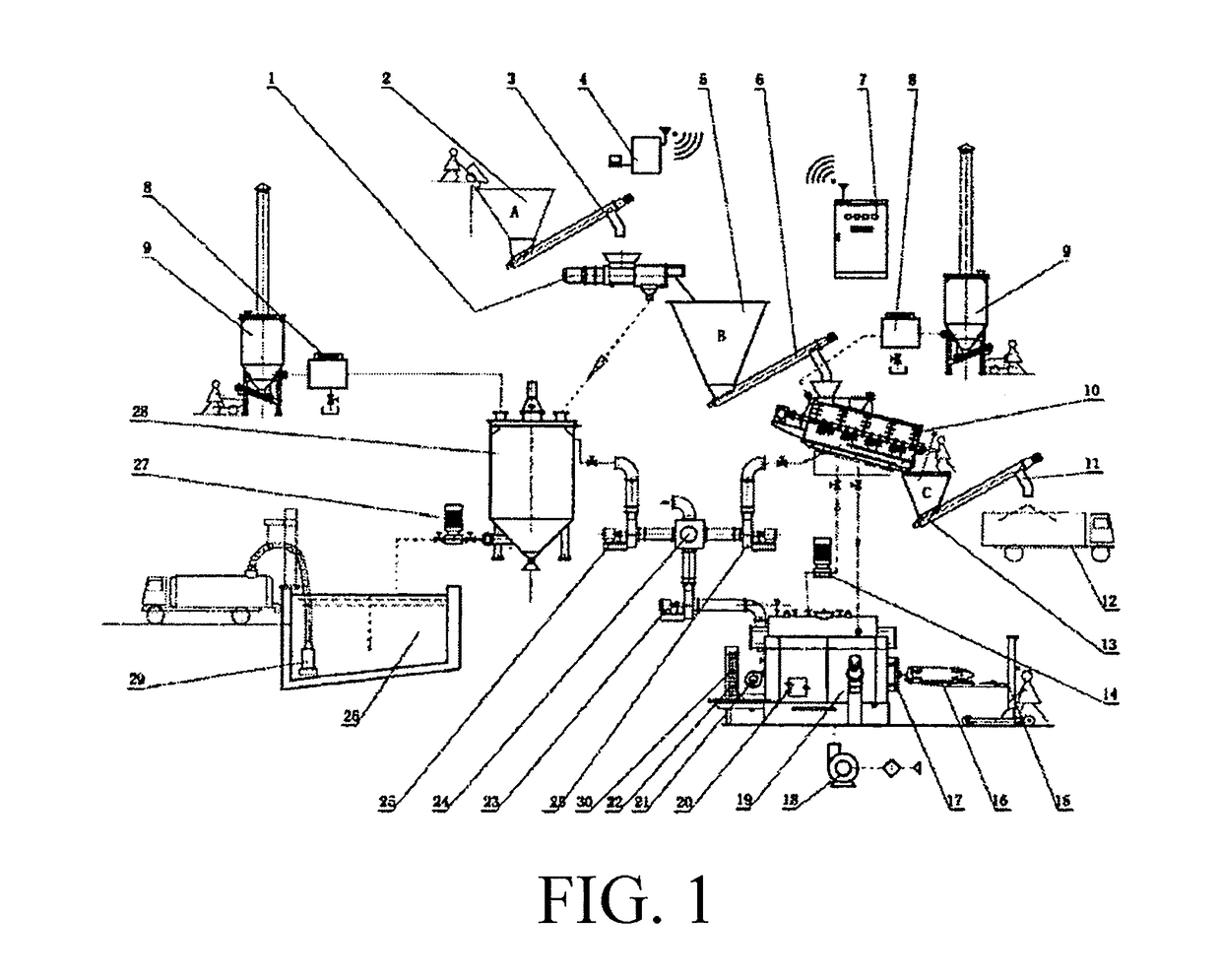

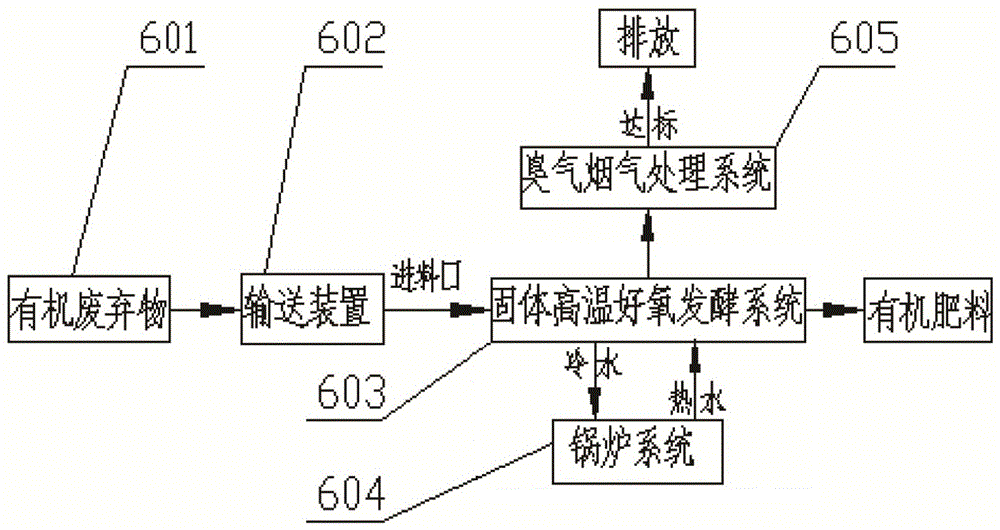

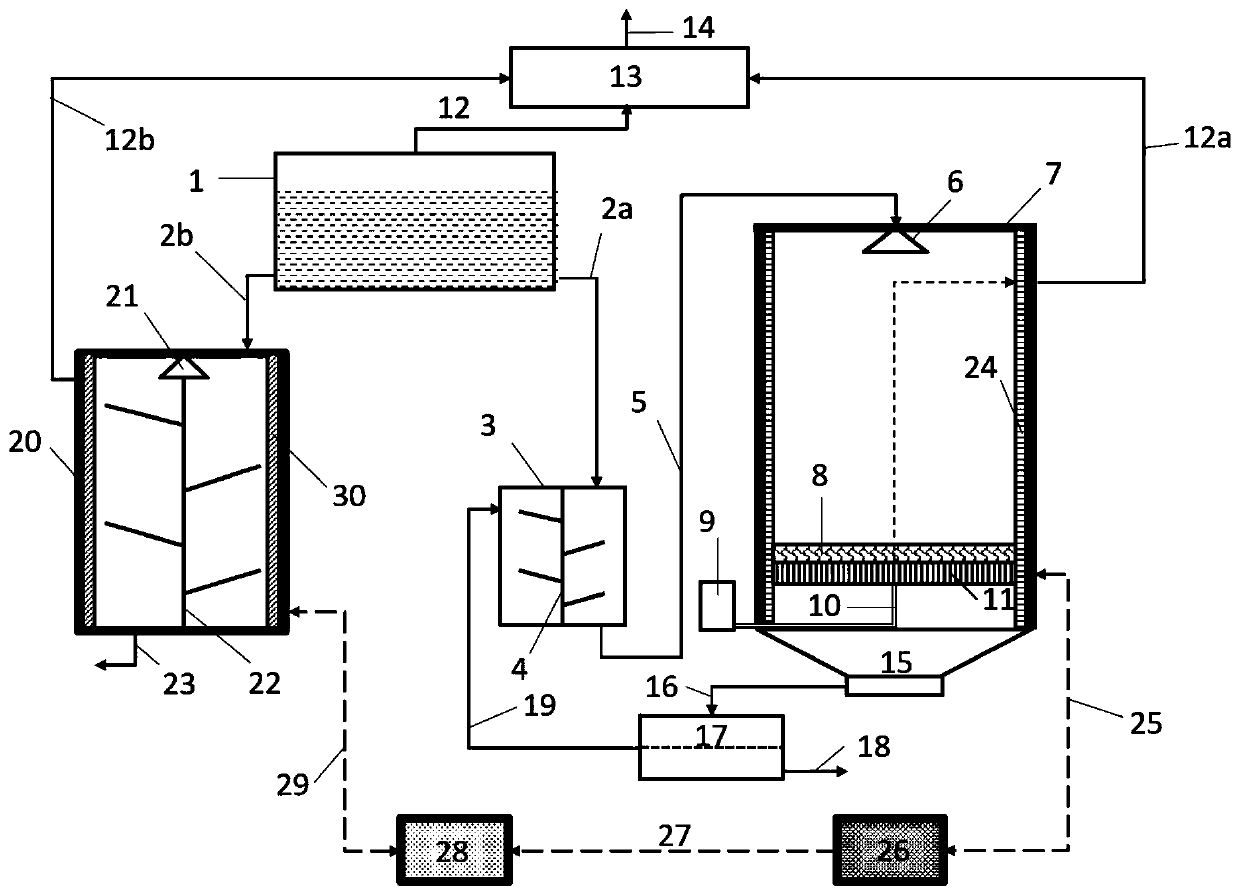

Rural bulk organic waste pollutant source comprehensive treatment system and method

ActiveUS20180148389A1Keep healthyProtect environmentBio-organic fraction processingSolid waste disposalOxygenFermentation

A rural bulk organic waste pollutant source comprehensive treatment system including a solid high-temperature aerobic fermentation reactor, a liquid high-temperature aerobic fermentation reactor and a multifunctional boiler is provided. A rural bulk organic waste pollutant source comprehensive treatment method. For excretion waste of a livestock farm adopting the technology of manure cleaning by urine submerging, a solid-liquid separation is firstly performed thereto, wherein solid is conveyed to the solid high-temperature aerobic fermentation reactor and fermented to produce solid organic fertilizers, and liquid is conveyed to the liquid high-temperature aerobic fermentation reactor and fermented to produce liquid organic fertilizers. For dry collection manure of a livestock and poultry farm, carbon-containing auxiliary materials, residues left after dead animals and household waste being incinerated by the multifunctional boiler, and ash generated by straw burning are added thereto, and then the mixture is conveyed to the solid high-temperature aerobic fermentation reactor and fermented to produce solid organic fertilizers. Exhaust fume and hot water produced by the multifunctional boiler pass through the solid high-temperature aerobic fermentation reactor and the liquid high-temperature aerobic fermentation reactor to heat the reactors and keep the reactors warm.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

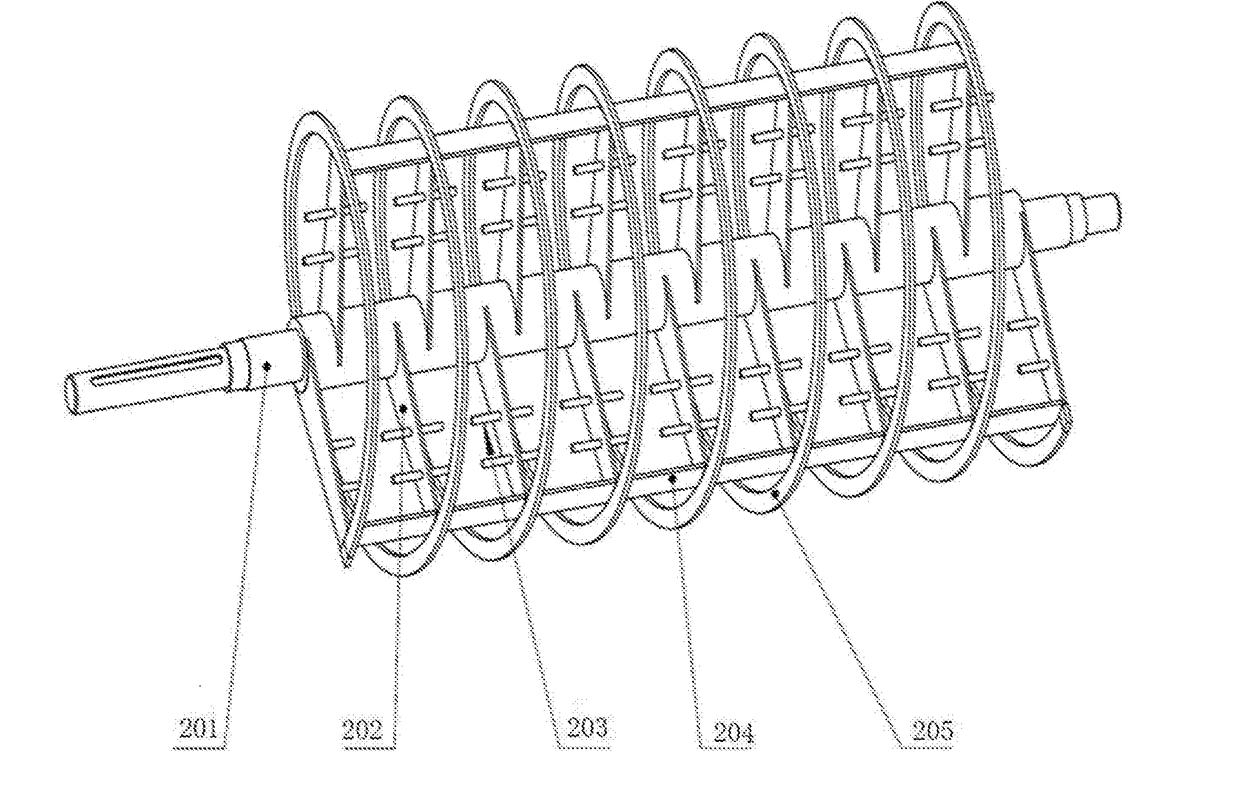

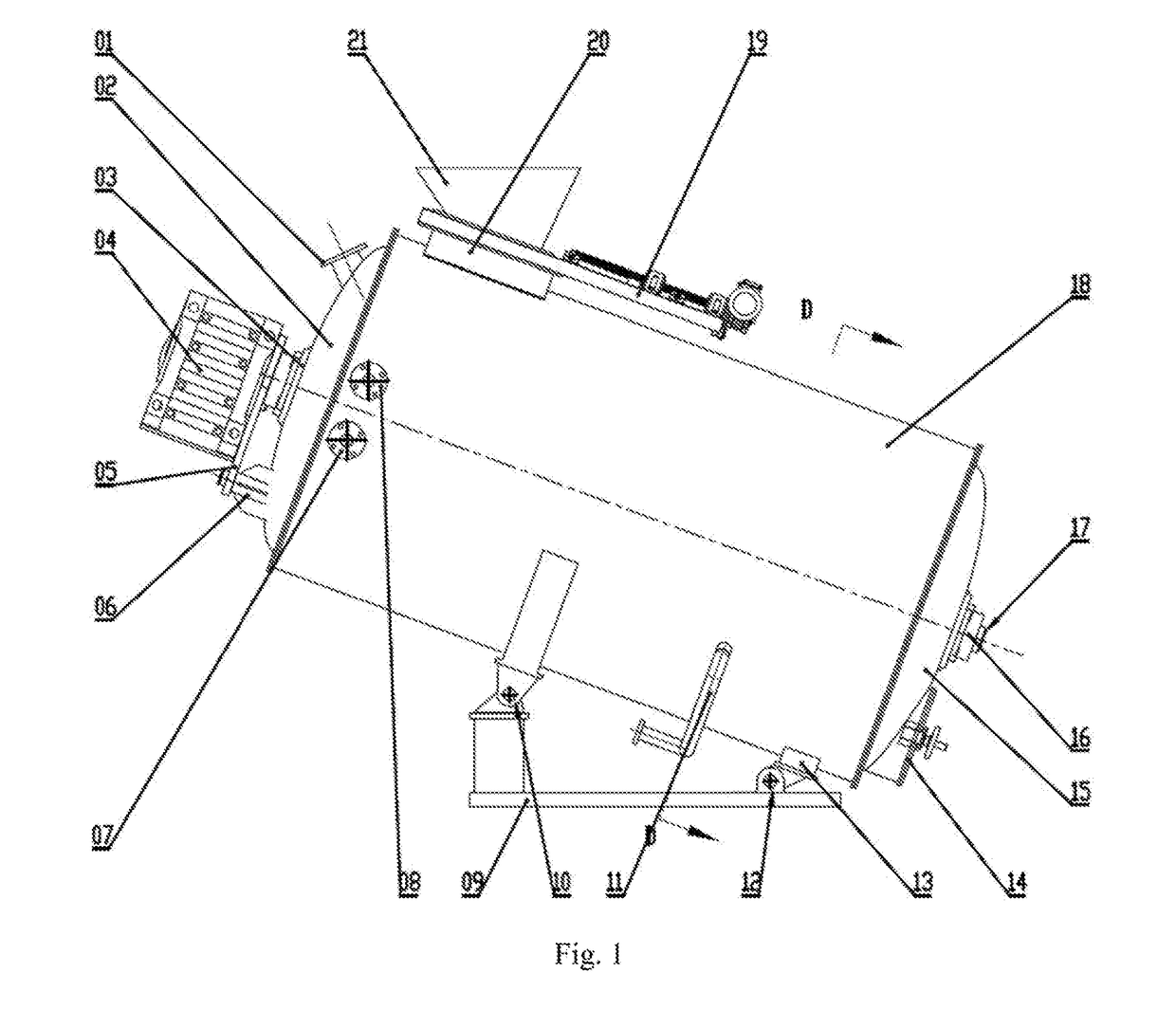

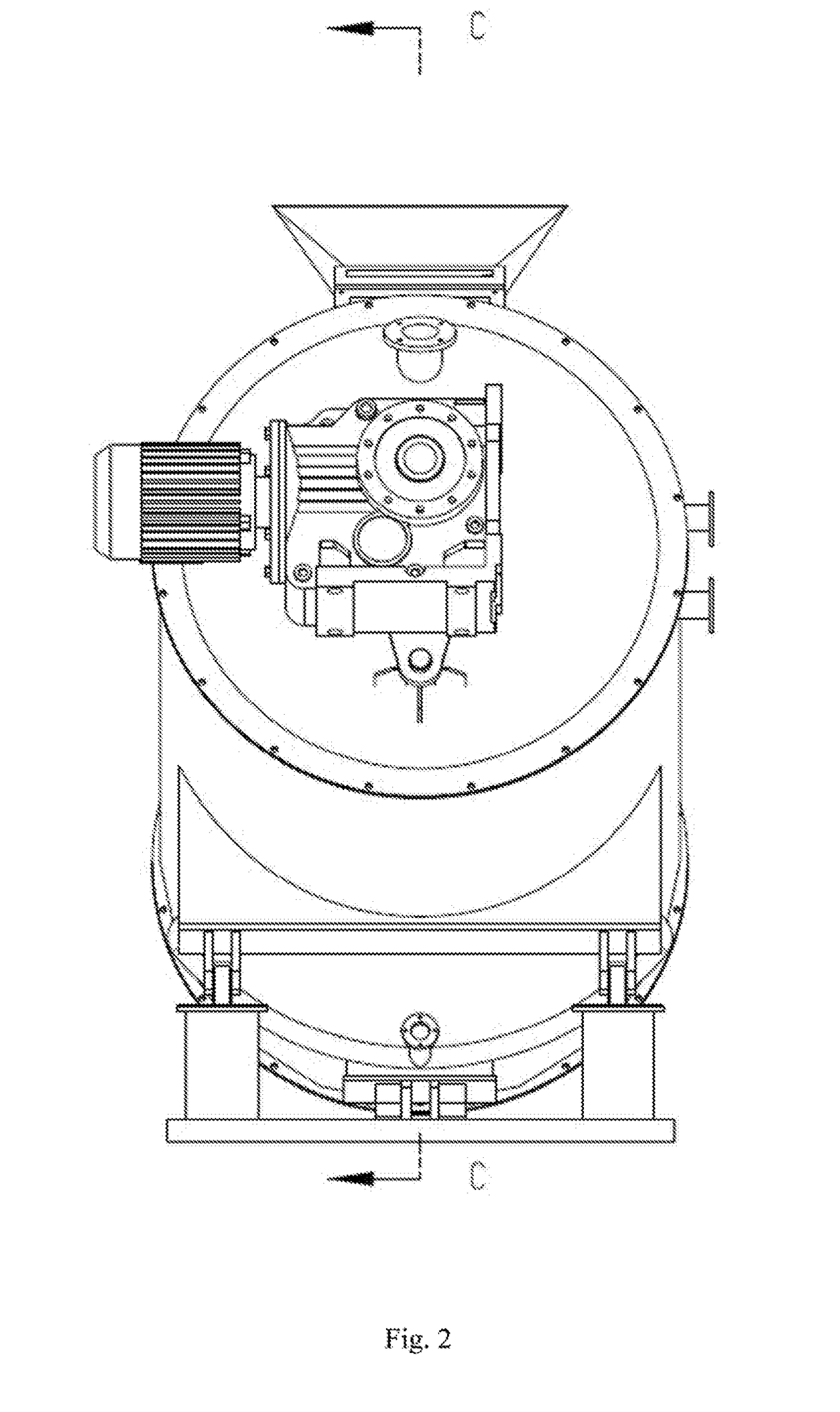

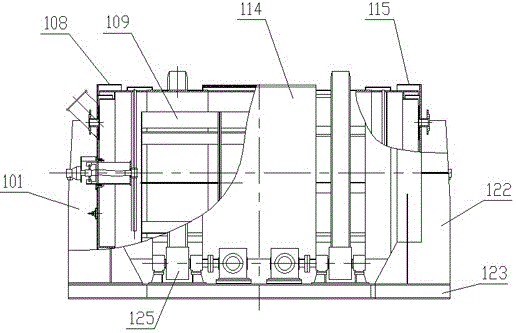

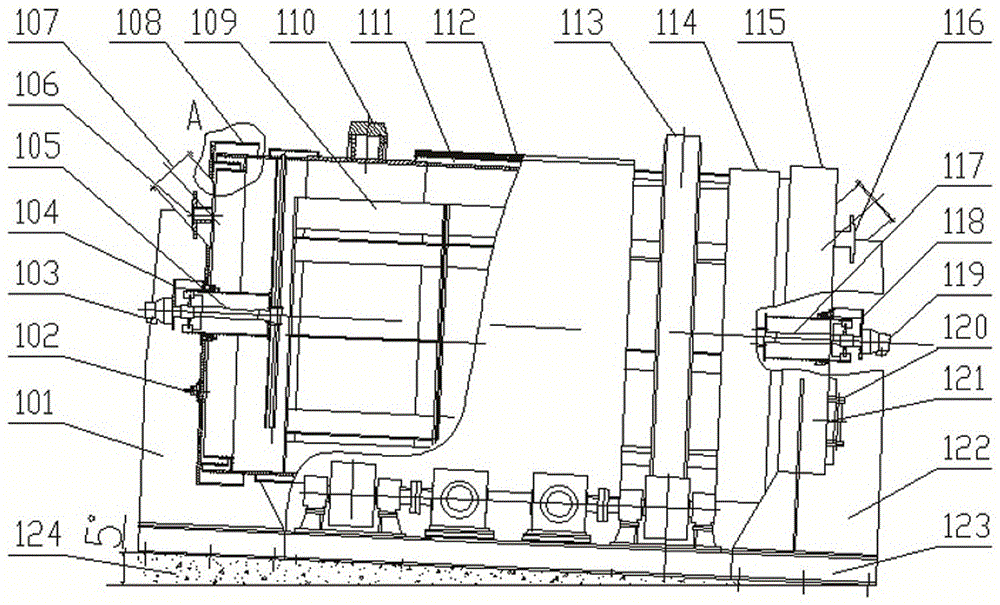

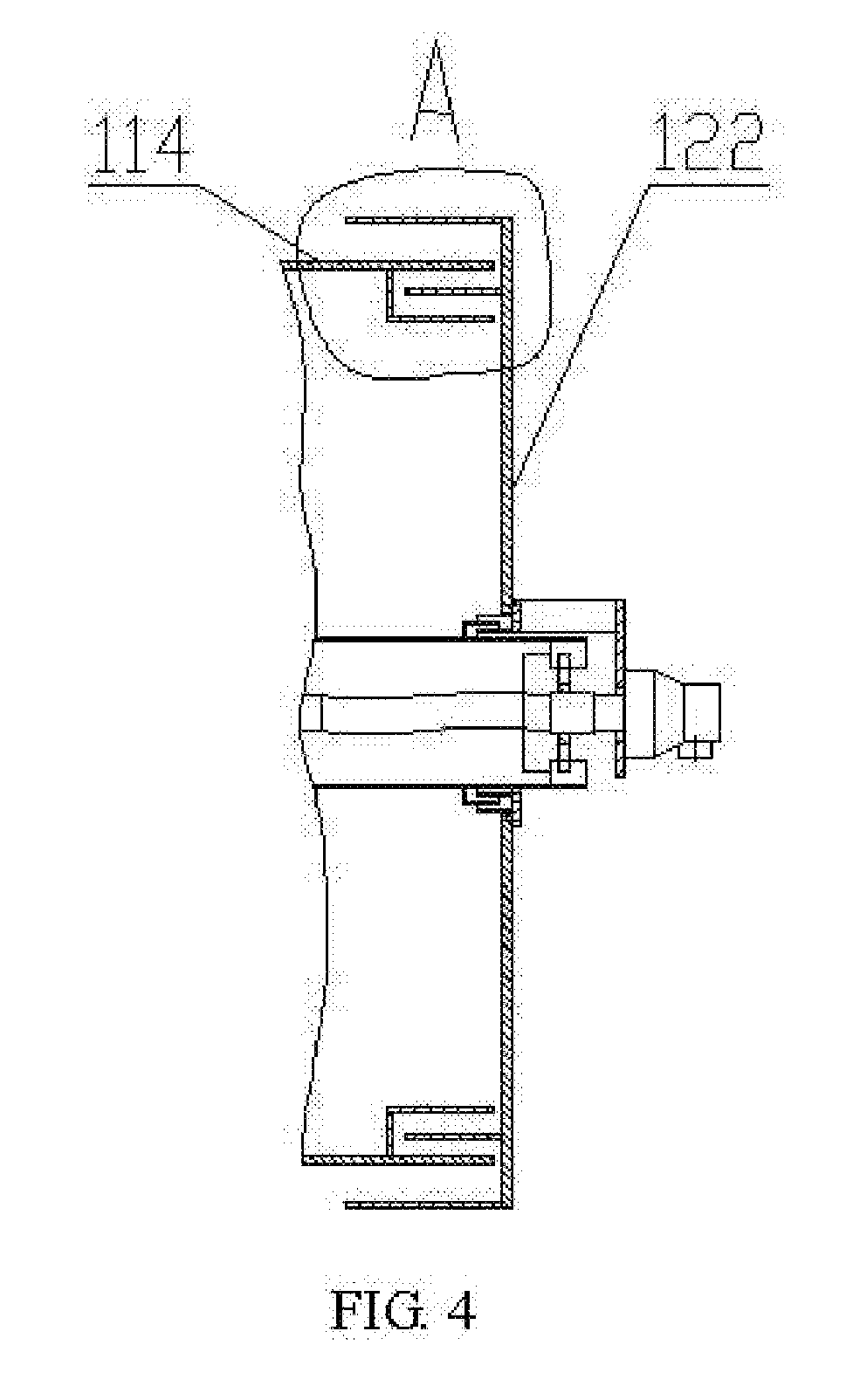

Inclined reactor of bottom gas-inlet type for aerobic fermentation and method for aerobic fermentation

ActiveUS20170226023A1Increase speedSufficient oxygenBioreactor/fermenter combinationsBio-organic fraction processingHeight differenceOxygen

An inclined reactor of bottom gas-inlet type for aerobic fermentation and a method for aerobic fermentation are provided, a fermenter is provided with a circular inner tank, end covers and a jacket; an airtight fermentation space is formed in the fermenter by the inner tank, an upper end cover and a lower end cover; a feed opening and an exhaust outlet are arranged at an upper part of the fermenter, and a discharge opening is arranged at a lower part of the lower end cover of the fermenter; a length of the fermenter is greater than or equal to a diameter of the fermenter, the fermenter is fixed on a base having a height difference and is hence in an inclined state; an energy-saving stirrer is mounted in the fermenter, and the energy-saving stirrer is formed by connecting several groups of tangential plates or a spiral combination of tangential plates, a radial rod, a stirring rod and a stirring shaft; several groups of air chambers are arranged at an external wall at the bottom of the inner tank of the fermenter, the air chambers are arranged inside the jacket, several aeration nozzles are defined on an inner side of each air chamber, and the aeration nozzles are close to the inner tank.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD

Biomass heating system

InactiveUS7744671B1Produced economicallyPromote and sustain plant growthBioreactor/fermenter combinationsBio-organic fraction processingGrowth plantDecomposition

Improved systems, methods, apparatus and compositions for generating, extracting and distributing the renewable heat energy produced by microbial decomposition of organic biomass within a contained and controlled environment. This heat energy is preferably transferred and distributed, preferably by the use of heat pipes, to the interior of a greenhouse or other structure to be heated, either directly or via heat exchange apparatus such as hot water heating systems. In one embodiment heat transfer and distribution mechanism customized to the application requirements of a greenhouse heating batch-type process is disclosed, along with a recipe for a readily available biomass material composition. Additional continuous and batch process embodiments of biomass heating systems are also disclosed that extract heat energy from decomposing biomass for heating uses. In some embodiments gaseous products generated in a biological decomposition process, primarily CO2, are utilized to enhance plant growth in the greenhouse environment.

Owner:AGRILAB TECH INC

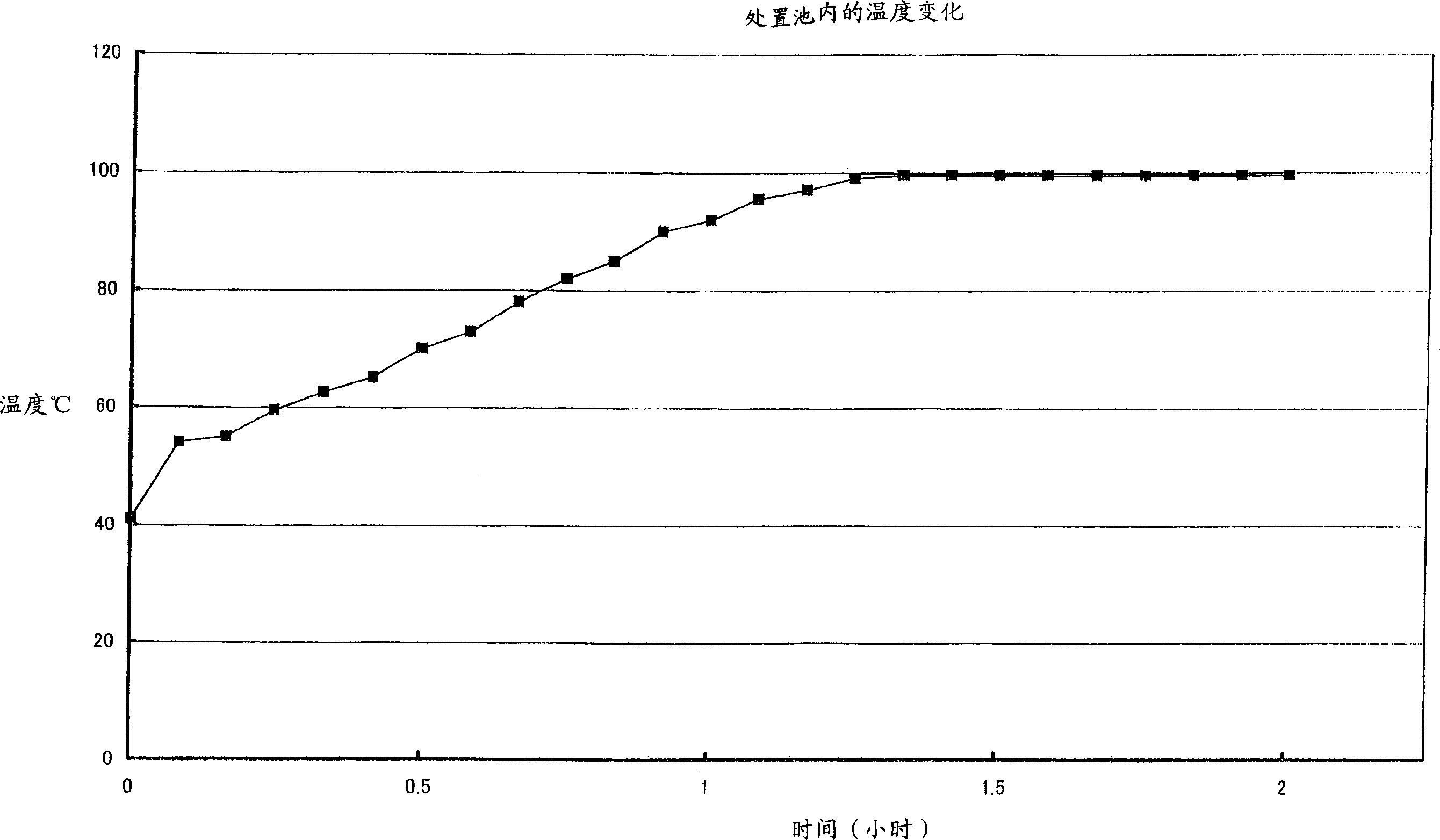

Superhigh-temperature composting method for livestock and poultry manure

InactiveCN107162656AAvoid pollutionEasy to storeBio-organic fraction processingExcrement fertilisersDecompositionAnimal feces

The invention discloses a superhigh-temperature composting method for livestock and poultry manure. The method comprises the following steps: adjusting the water content of livestock and poultry manure to 45 to 60% by using a conditioning agent and then adding a decomposition bacterial strain for organic materials; then heating a mixed material, allowing the temperature of the mixed material to rise to 80 to 85 DEG C within 1 to 2 h and maintaining the superhigh temperature for 16 to 24 h to accomplish composting fermentation, wherein a high-pressure fan carries out aeration or stirring on the material for oxygen supply during fermentation; and after completion of fermentation, allowing the water content of an obtained composting product to fall to 20 to 30%, wherein the composting product allows the germination rate of seeds to reach 95% or above. The composting method provided by the invention can realize rapid decomposition of livestock and poultry manure, and the prepared composting product is thorough in inactivation of pathogenic organisms and low in loss of carbon and nitrogen and has substantially better fertilizer efficiency compared with traditional composting products.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Compositing apparatus and method

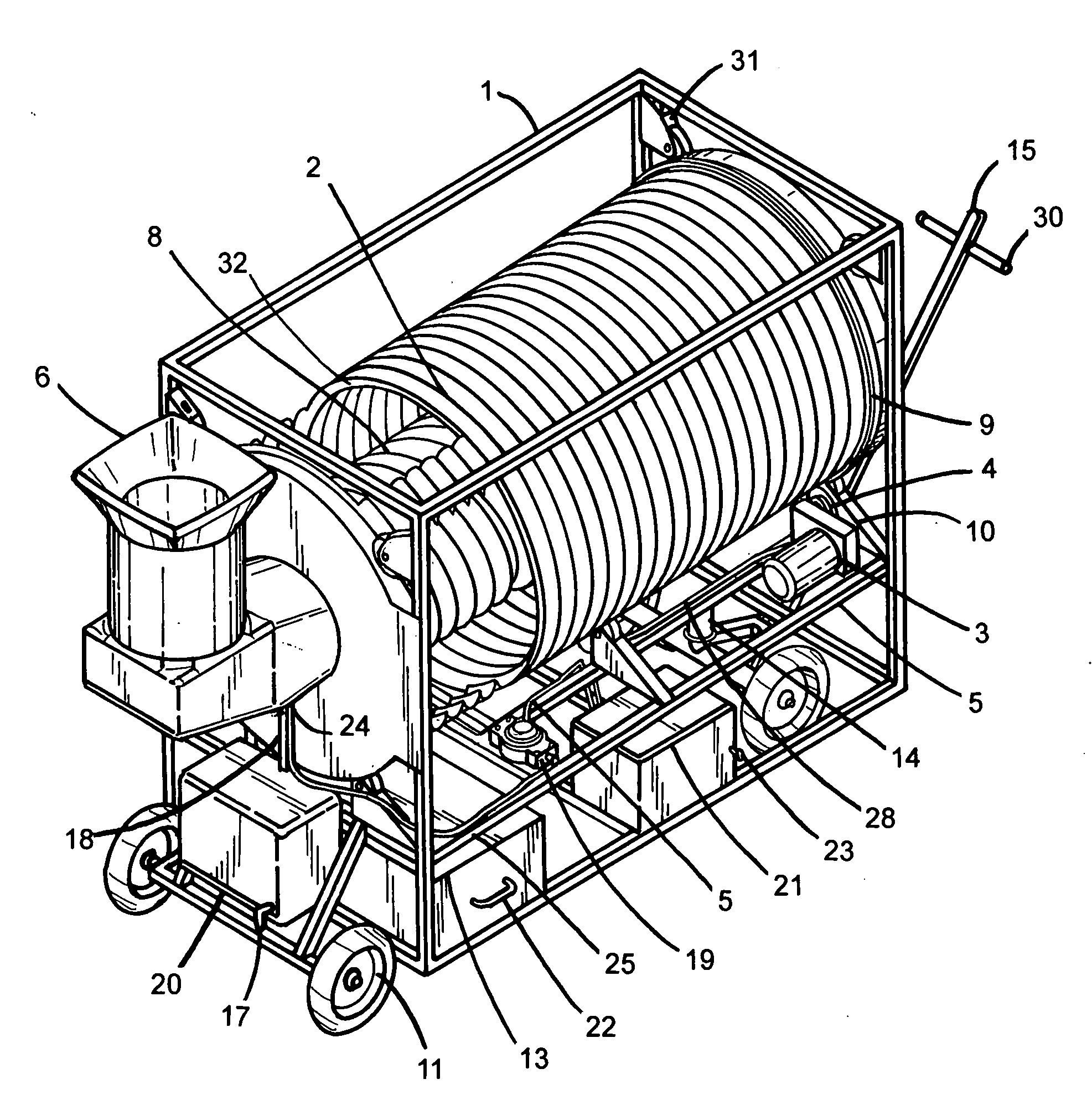

InactiveUS20130263786A1Simple and effective and highly efficientSimple, effective and highly efficient vermicompostingBio-organic fraction processingProductsReduction driveEngineering

A composting apparatus and method utilizing a vessel for receiving organic material which is rotatably supported. In a preferred embodiment, the vessel has a two corrugated conduits of different diameters and the one of smaller diameter is axially aligned inside the larger conduit to move and agitate the material in two different lateral directions. The worm vermicompositing takes place in the inside of the smaller diameter conduit, dropped into the outlet larger conduit where it is dried and collected. In another embodiment, the vessel is fabricated from secured end-to-end at their top ends. The vessel is rotated by an electric motor with a gear reduction drive sprocket engaging a peripheral track on the exterior of the larger diameter conduit. Water can be added during the vermicompositing to make and collect worm tea.

Owner:MEISEL III EDWARD CHARLES +3

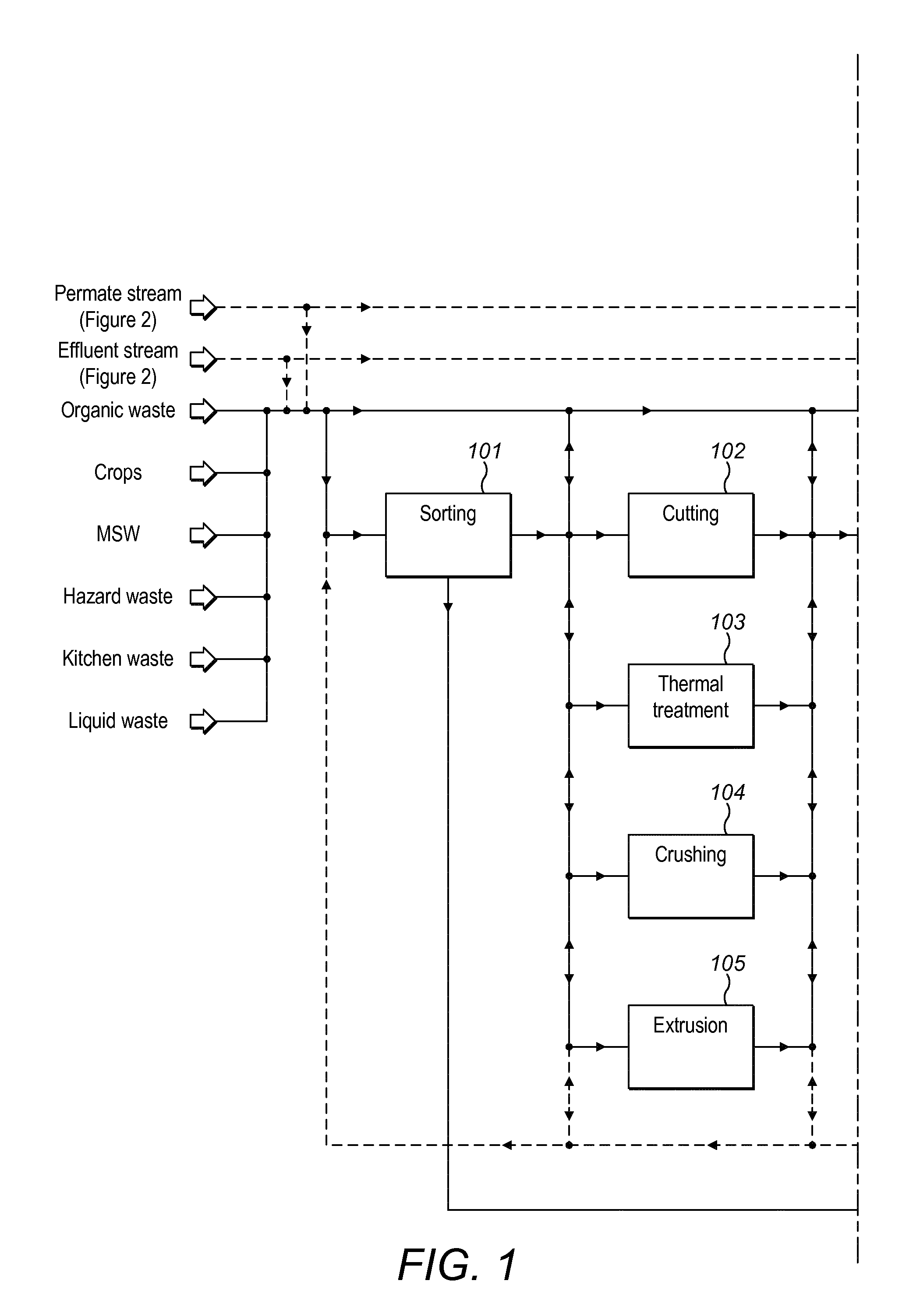

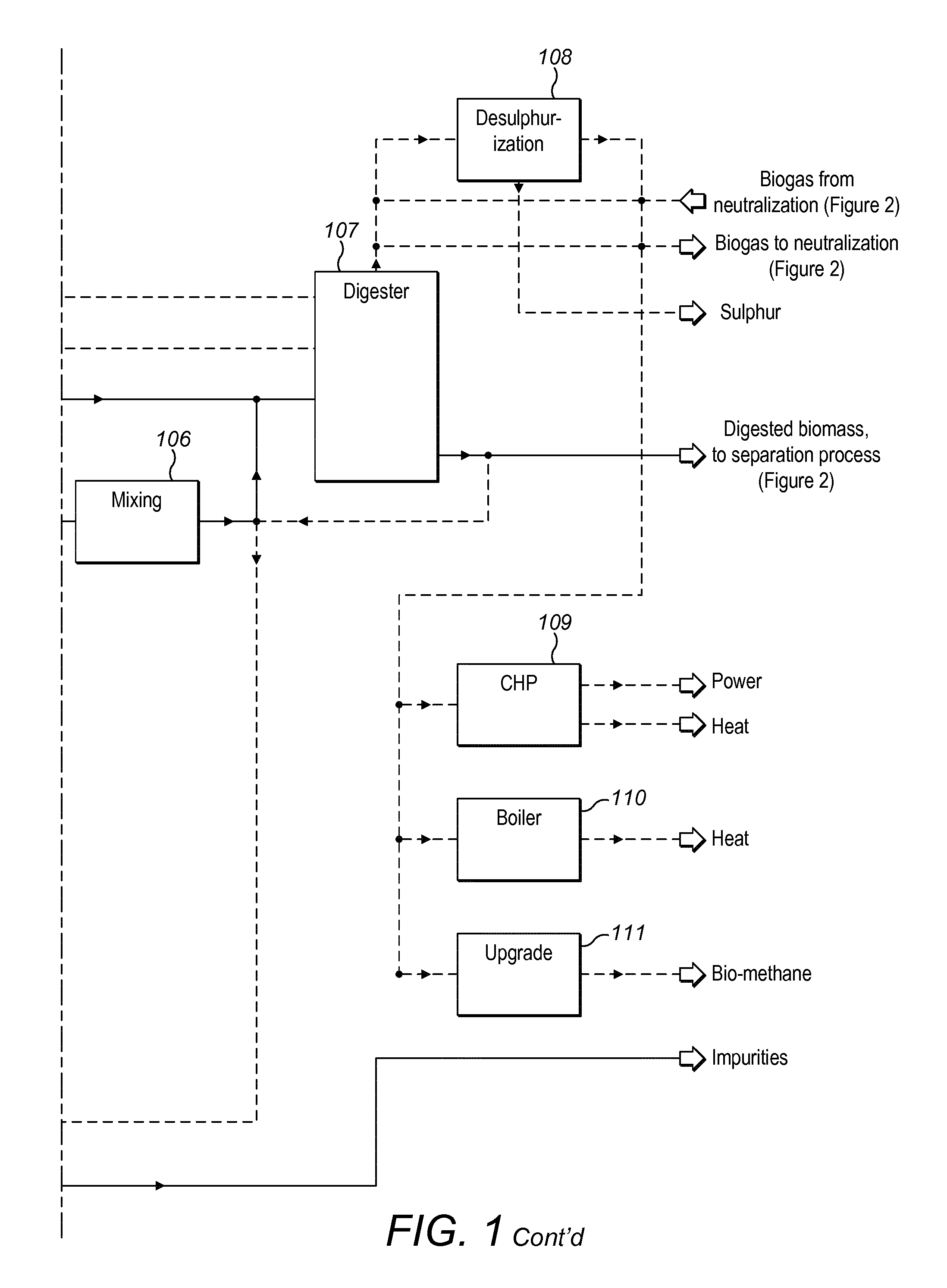

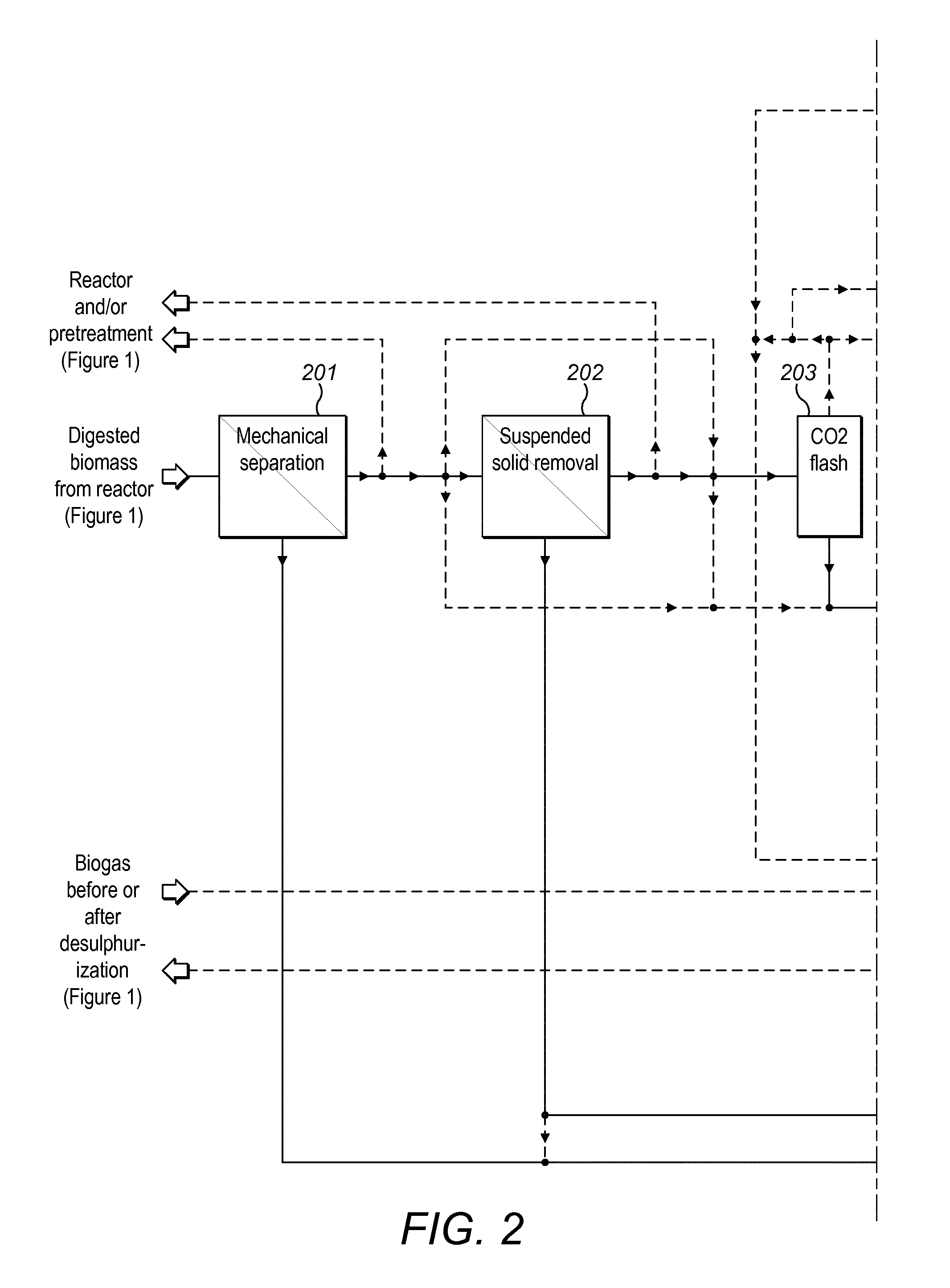

Method and plant for treatment of organic waste

ActiveUS20160176768A1Increasing biogasCost effectiveBioreactor/fermenter combinationsBio-organic fraction processingBoiling pointAmmonia

The present invention relates to methods and plants for the treatment of an organic waste material, wherein waste is subjected to anaerobic fermentation in a biogas digester; effluent is mechanically separated from the biogas digester into a concentrated fraction and a liquid fraction; the liquid fraction is heated to a high temperature below the boiling point of the liquid; the heated liquid is introduced to a flash column to partially remove volatile carbon dioxide, the pH of the liquid is elevated and ammonia is removed from the liquid.

Owner:RENEW ENERGY USA LLC +1

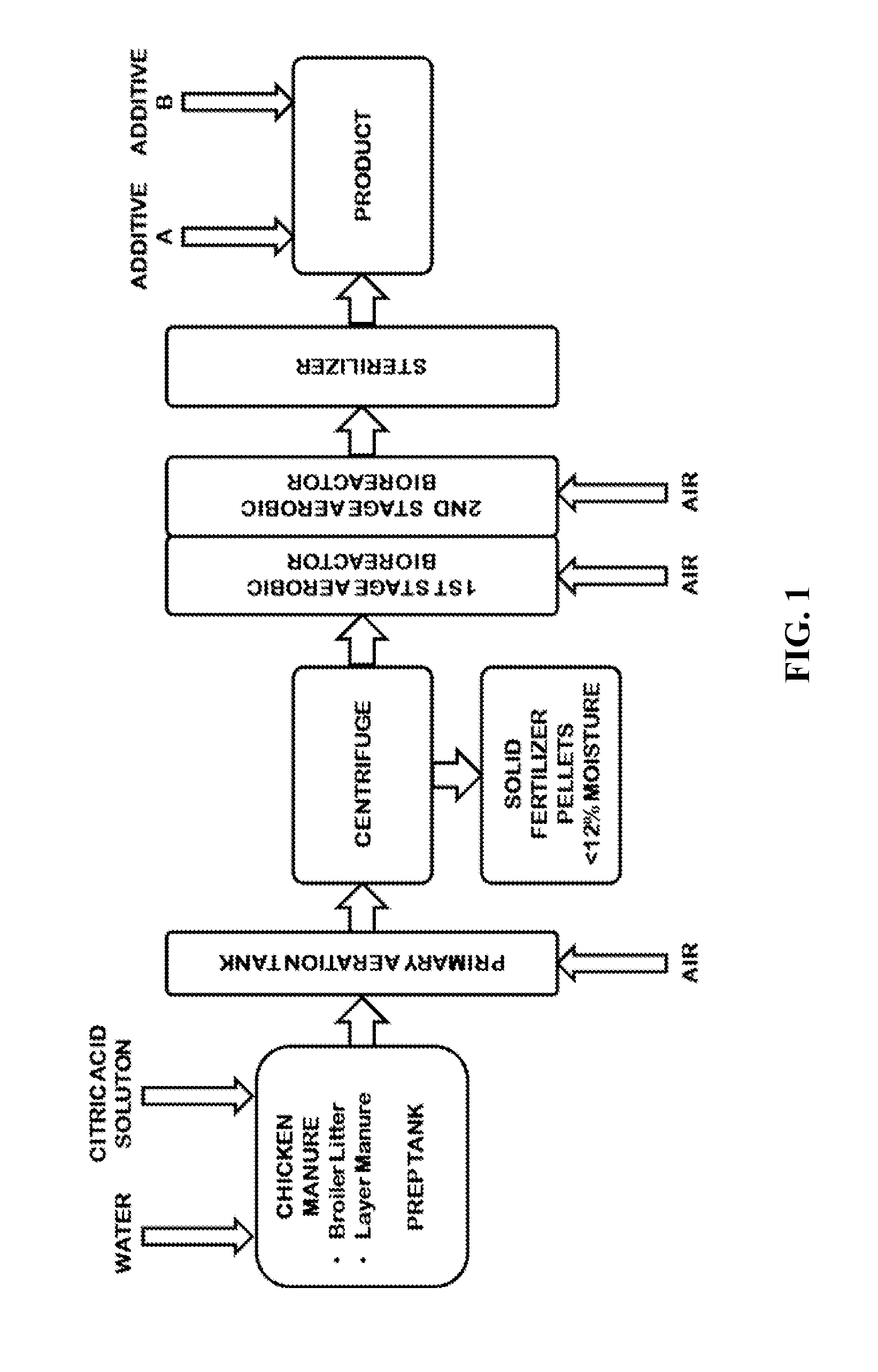

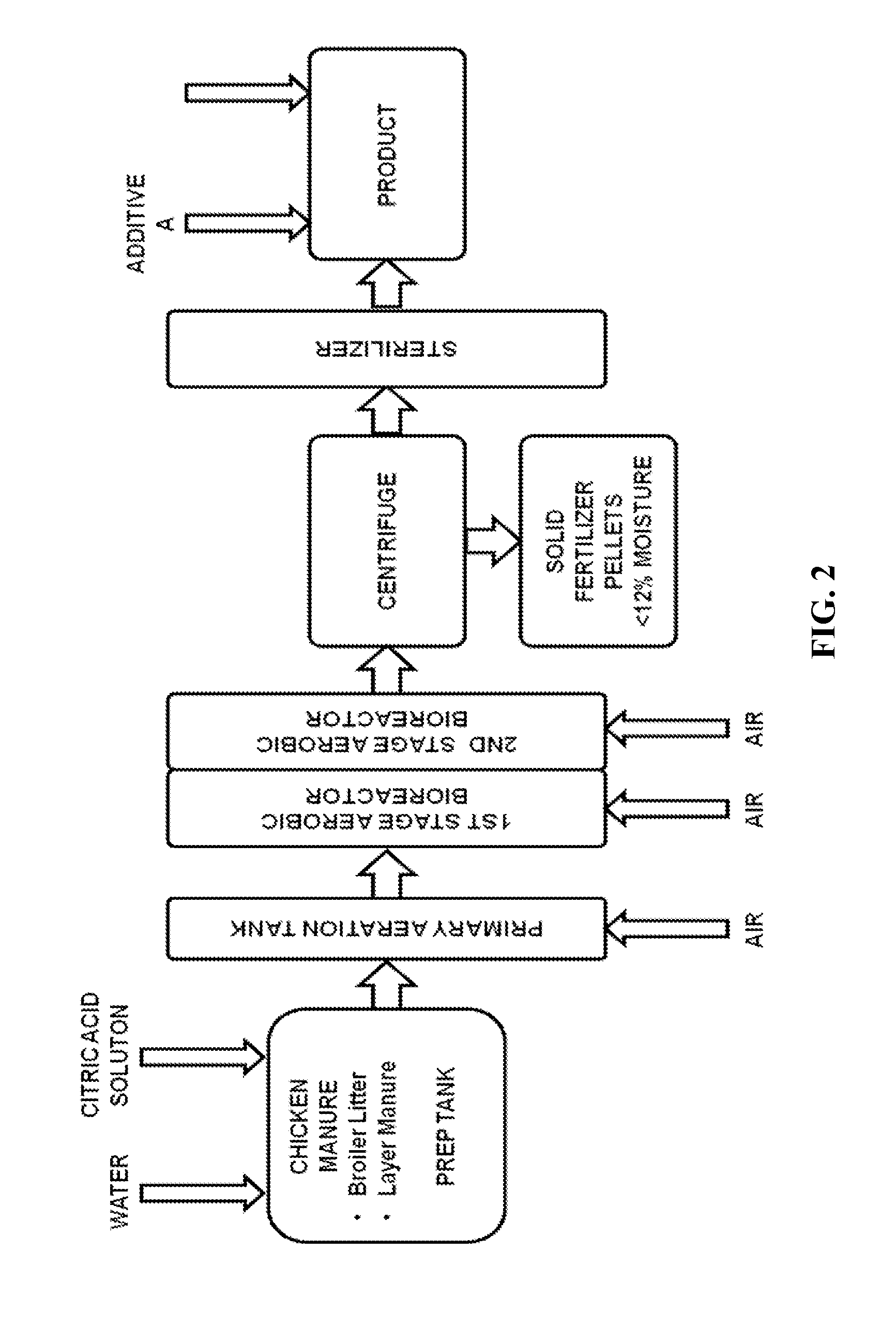

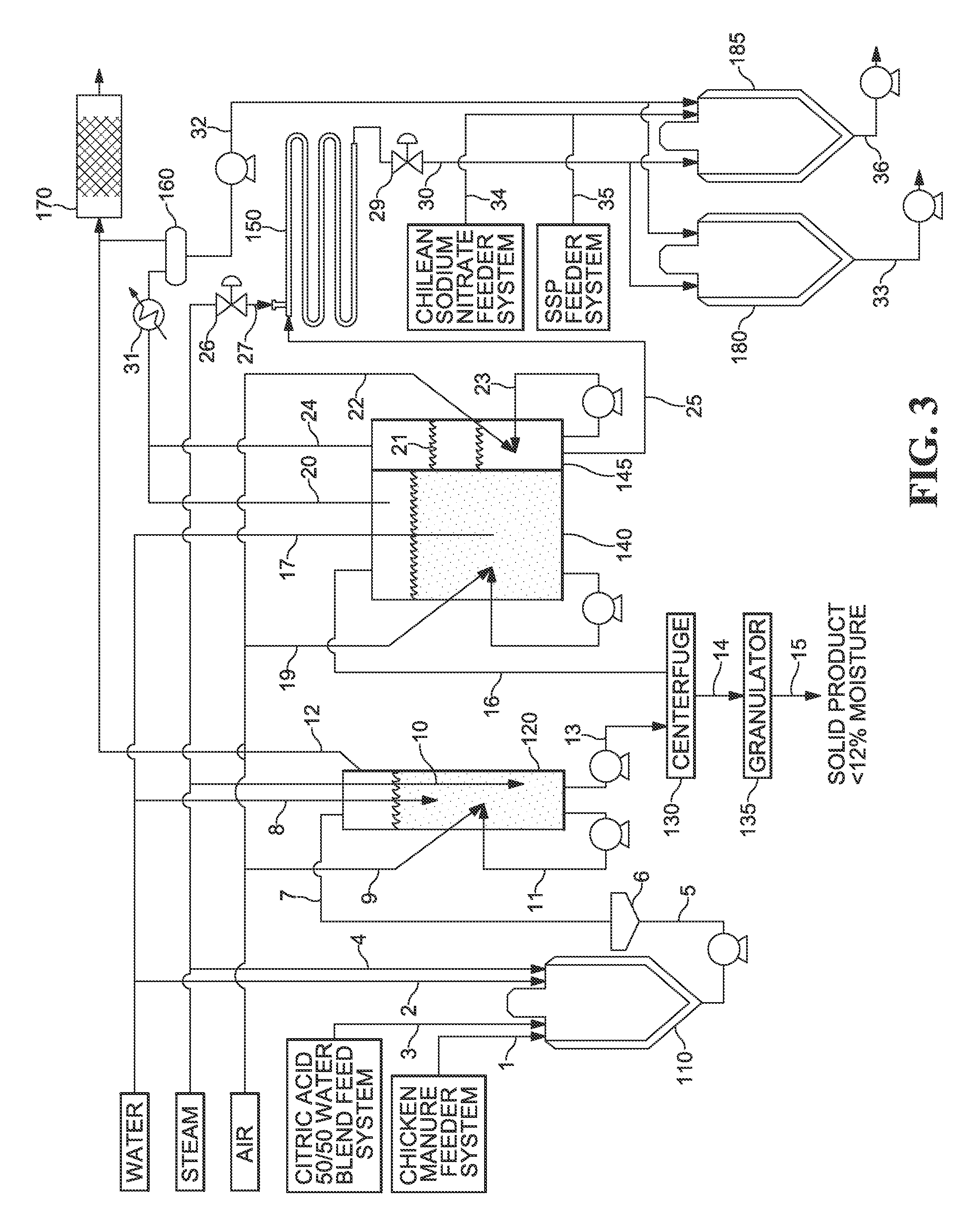

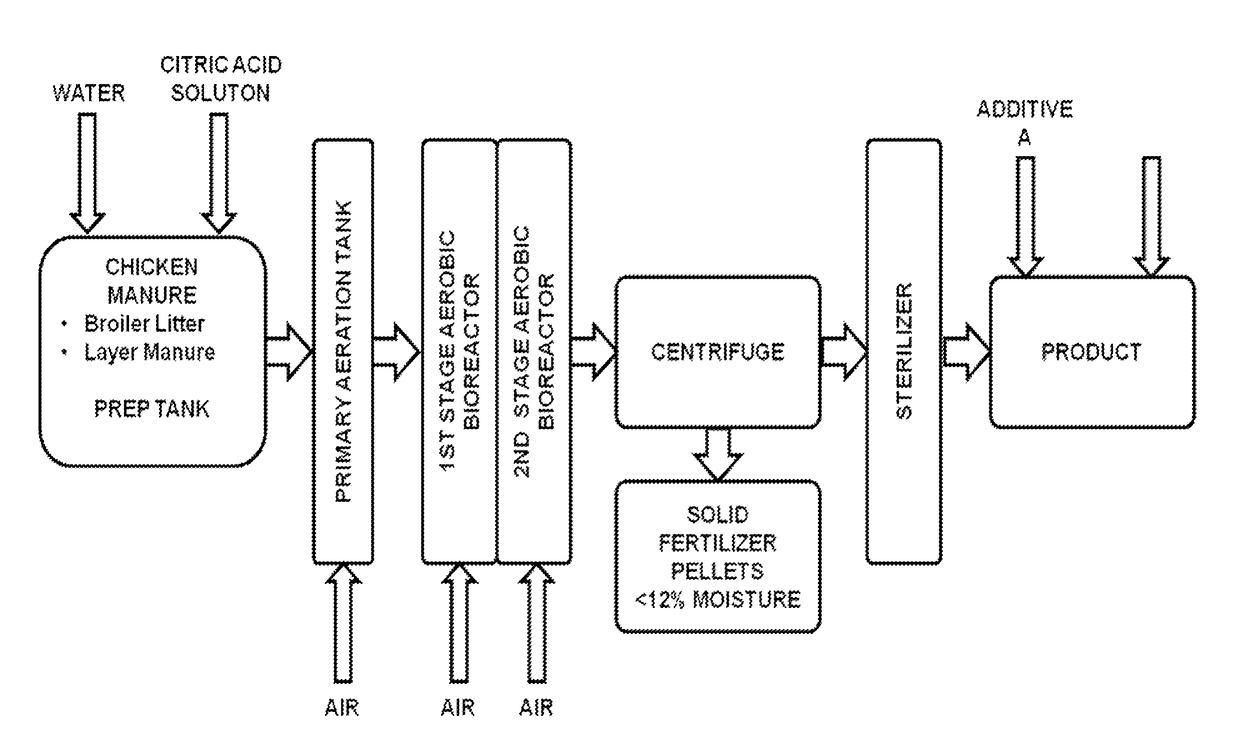

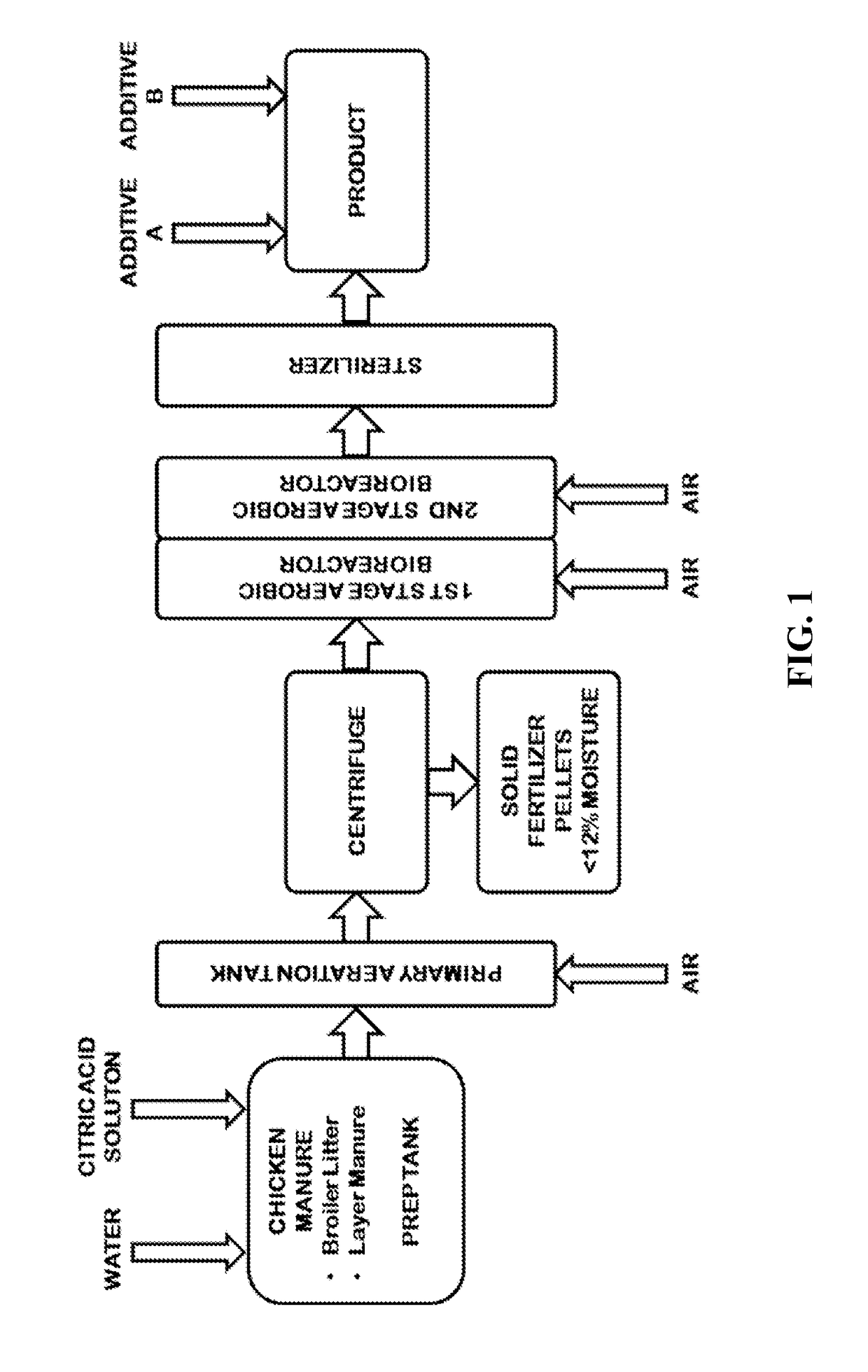

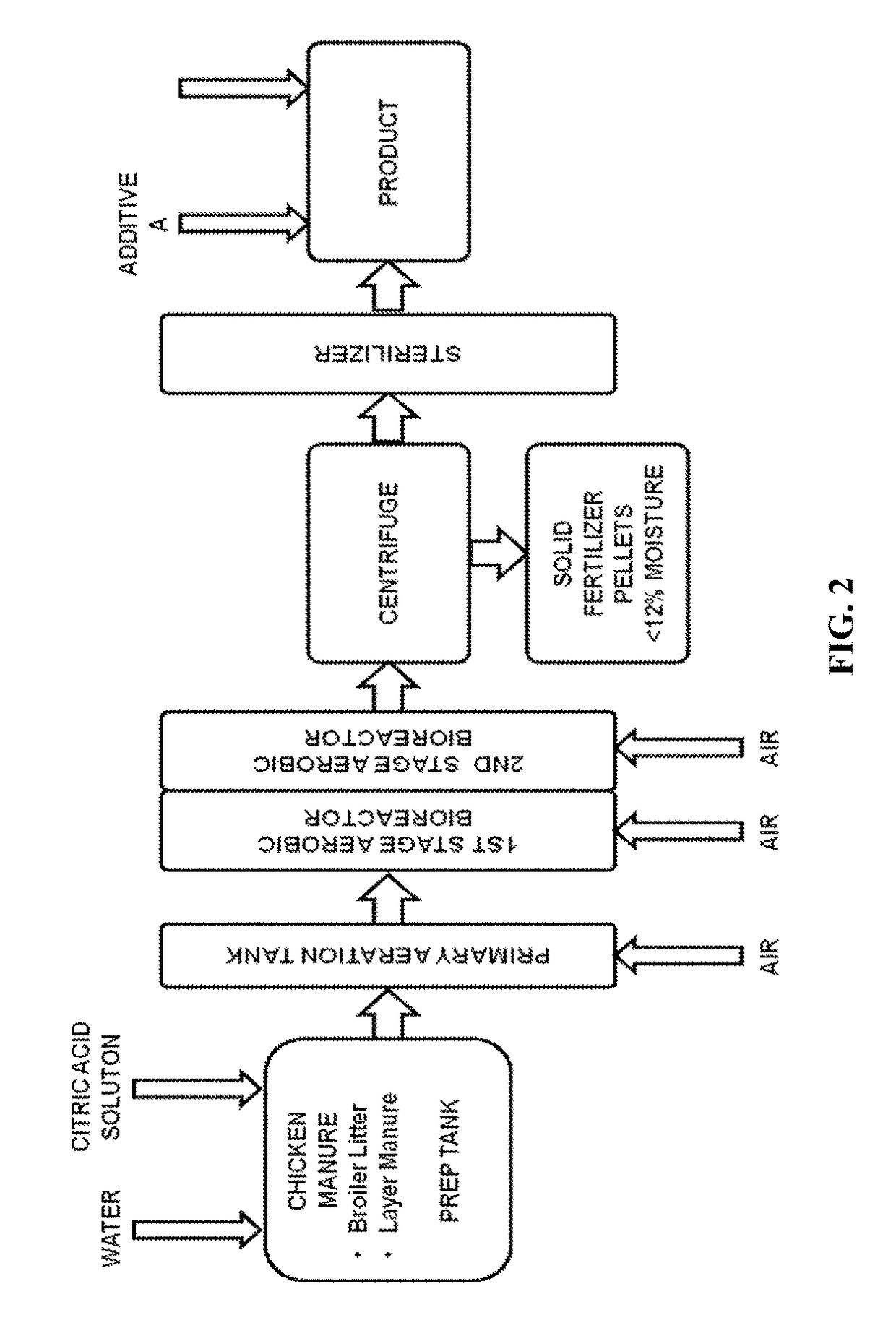

Process for manufacturing liquid and solid organic fertilizer from animal waste

Processes for manufacturing organic fertilizer products, such as liquid and solid organic fertilizer, from animal manure are disclosed, together with the fertilizer products produced therefrom.

Owner:ENVIROKURE

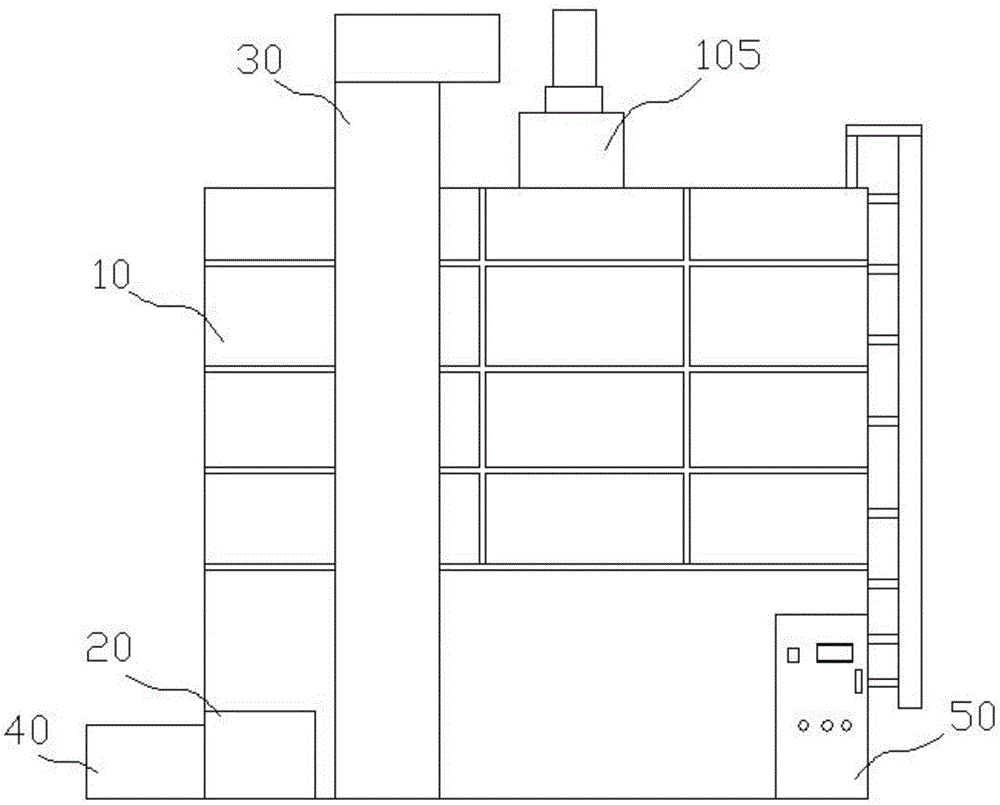

Solid high-temperature aerobic fermentation reaction system and method

ActiveCN106119105AAvoid stickingEasy to use and maintainBioreactor/fermenter combinationsBio-organic fraction processingEnvironmental resistanceSmall footprint

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

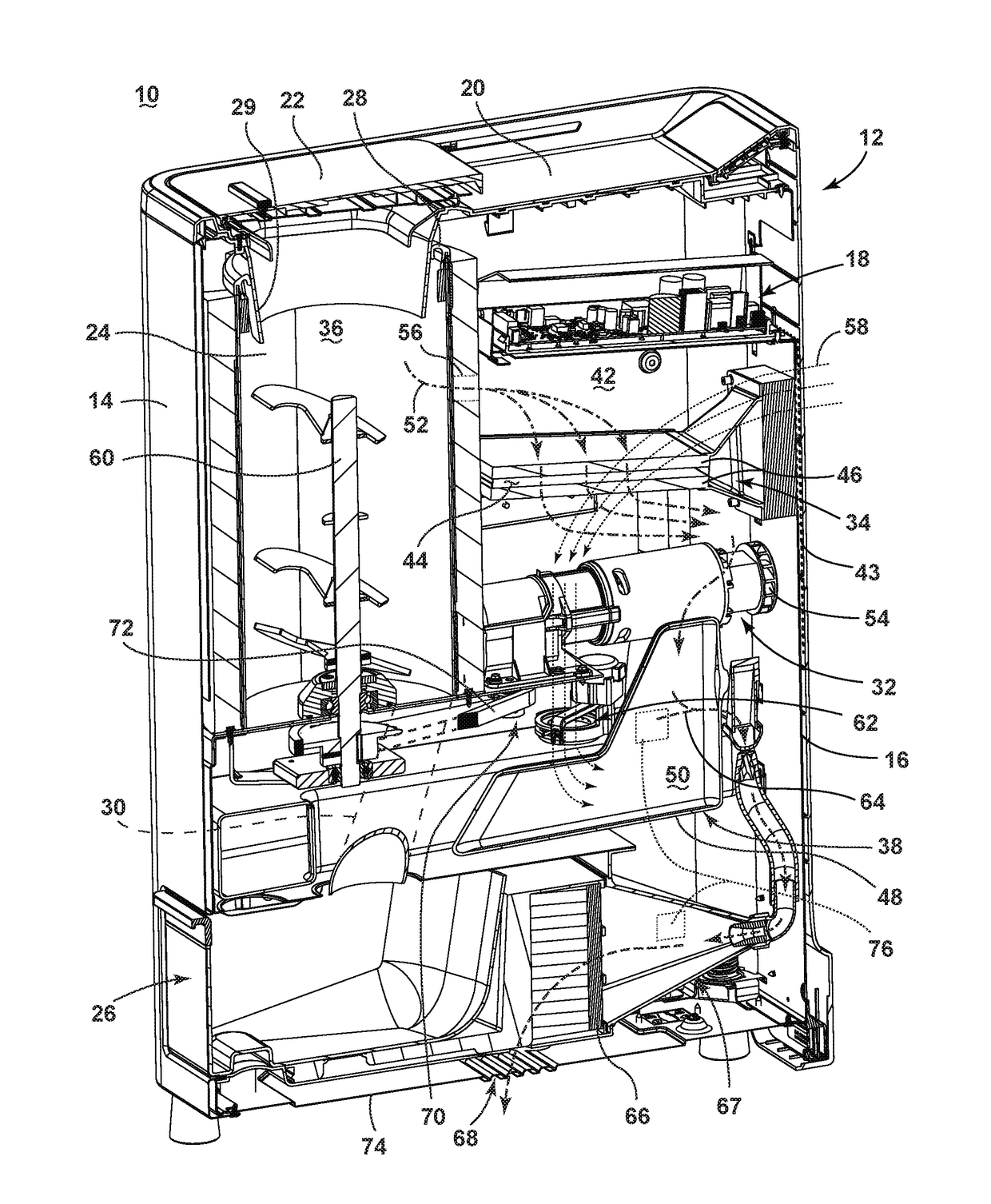

Composting systems and methods

InactiveUS8129177B2Bioreactor/fermenter combinationsBio-organic fraction processingElectronic controllerEngineering

Systems and methods for automated, rapid composting are disclosed. An air-tight housing prevents odors from leaking out. The housing is thermally insulated to enable the compost to achieve sufficient temperatures for rapid composting. A chambered system, generally including an optional hopper, a reactor, and a cure tray, physically shields odorous material from the external environment. A mixing wand mechanically mixes and / or breaks up the compost material and enhances air flow therethrough. A drip tray segregates liquid byproducts from the solid compost material. An air pump draws in air, while a carbon filter may absorb odors before returning the air to the external environment. A motor provides mixing, and facilitates opening and closing of the two trap doors separating the chambers. An electronic controller automates the composting process while allowing certain settings to be adjusted.

Owner:RSF MEZZANINE FUND

Process for manufacturing liquid and solid organic fertilizer from animal waste

Processes for manufacturing organic fertilizer products, such as liquid and solid organic fertilizer, from animal manure are disclosed, together with the fertilizer products produced therefrom.

Owner:ENVIROKURE

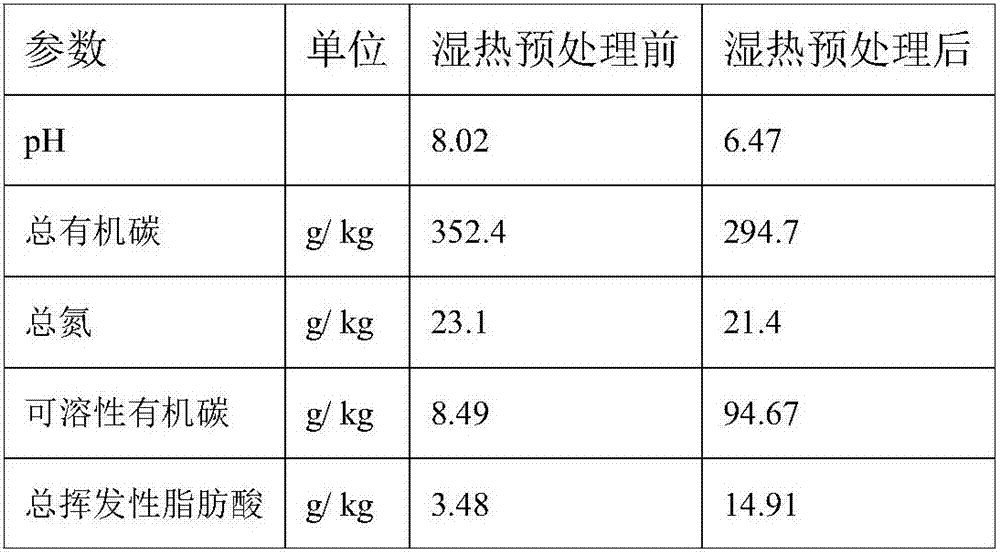

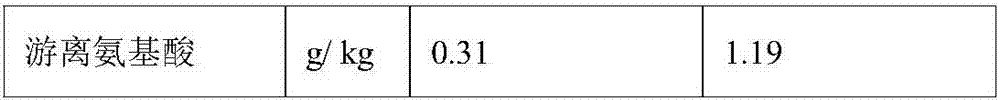

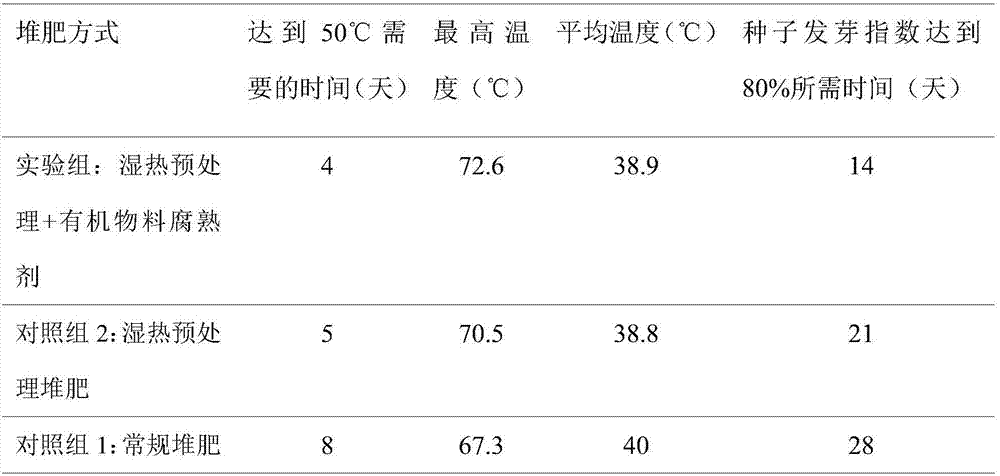

Composting method capable of carrying out damp and hot preprocessing to accelerate composting of livestock excrement

ActiveCN107141047AHeating up fastShorten the maturity cycleBio-organic fraction processingExcrement fertilisersFecesHydrogen

The invention discloses a composting method capable of carrying out damp and hot preprocessing to accelerate the composting of livestock excrement. The composting method comprises the following specific steps: firstly, mixing the livestock excrement with conditioner to regulate a moisture content, a carbon nitrogen ratio and a pH (Potential of Hydrogen) value; then, heating, and maintaining damp and hot preprocessing for 1-4h after the temperature of materials is raised to 80-95 DEG C; after the materials are cooled to 50 DEG C, inoculating organic material decomposition agent to carry out secondary aerobic composting, and ensuring that the materials are completely composted until a fermentation temperature is lowered to environment temperature and does not change. Compared with conventional composting which does not carry out the damp and hot preprocessing, the composting method disclosed by the invention is characterized in that the damp and hot preprocessing is combined with organic material decomposition agent inoculation, so that composting temperature can be obviously improved, a composting period is shortened, meanwhile, nitrogen losses in a composting process can be reduced, a composting humification course is accelerated, the content of humus is improved, and the quality of the composting product is guaranteed.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Amendment-free sludge composting

ActiveUS20100184131A1Increase speedPromote formationBioreactor/fermenter combinationsBio-organic fraction processingSludge compost

A composting system for promoting aerobic microbial activity in a composting bed. The system includes at least one composting bay for receiving composting material and an agitator for aerating and displacing composting material as it travels through the composting bay. Compost produced by the system is used in place of traditional woody amendment material for mixing with incoming material to be composted.

Owner:EVOQUA WATER TECH LLC

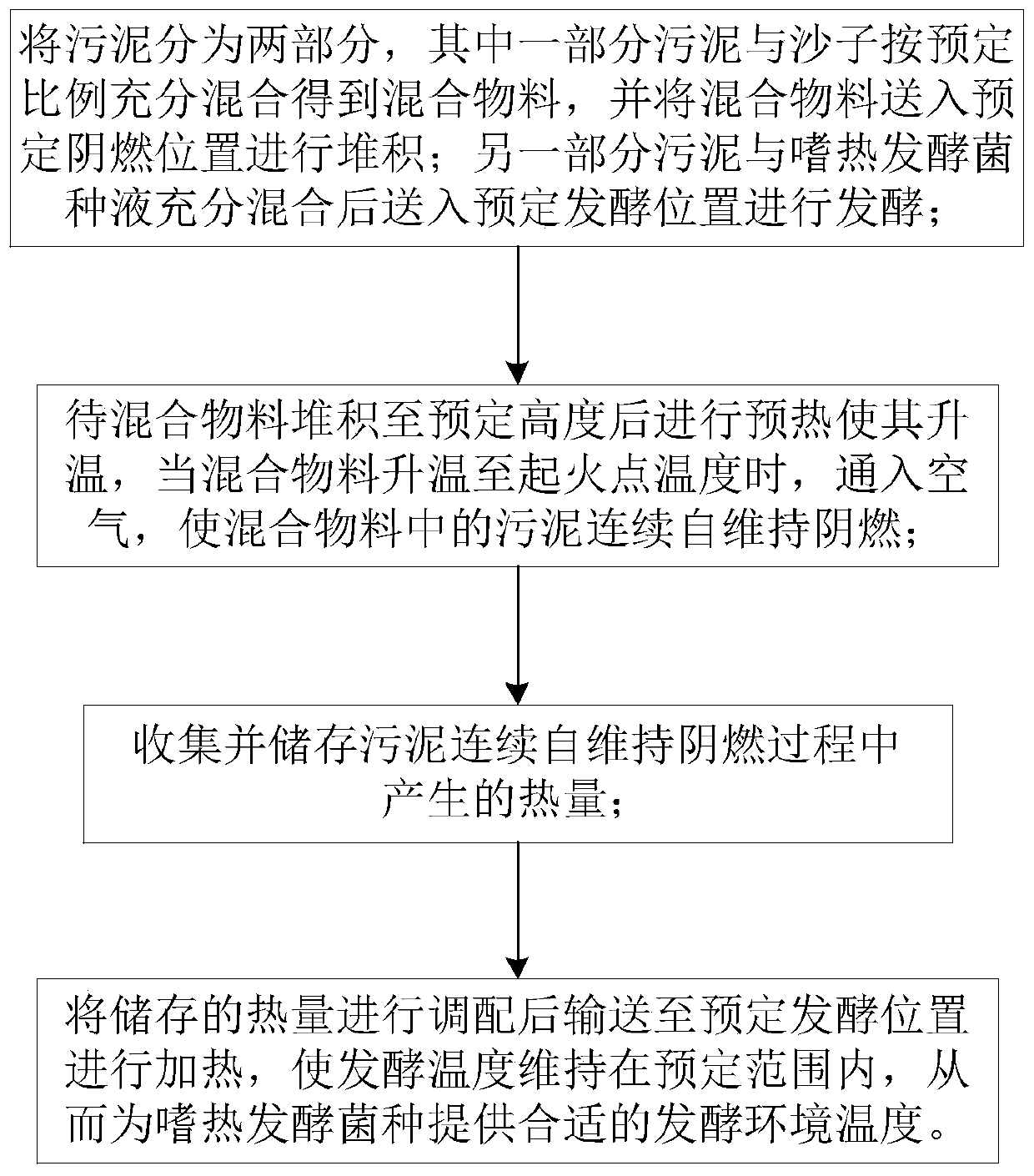

Self-sustaining smoldering and high-temperature aerobic fermentation composite disposal process and equipment for sludge

ActiveCN111425868AReduce energy consumptionIncrease processing rateBio-organic fraction processingClimate change adaptationSludgeEngineering

The invention discloses a self-sustaining smoldering and aerobic biological fermentation composite disposal process and equipment for sludge, belongs to related technical processes in the field of domestic waste disposal, and mainly aims at harmless resource disposal of the municipal sludge and other high-water-content low-calorific-value organic wastes. The self-sustaining smoldering and aerobicbiological fermentation composite disposal process for the sludge is characterized in that two disposal technologies of self-sustaining smoldering and aerobic fermentation composting are combined, sothat the sludge disposal capacity is improved, the energy consumption in the aerobic biological fermentation process is reduced and advantage complementation among the technologies is realized; and sludge ashes generated by smoldering and organic fertilizers generated by fermentation can be combined for use, so that the sludge disposal rate is increased, meanwhile, the energy consumption of a sludge disposal system is reduced, the biological fermentation period is shortened, and the diversity of sludge resource products is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

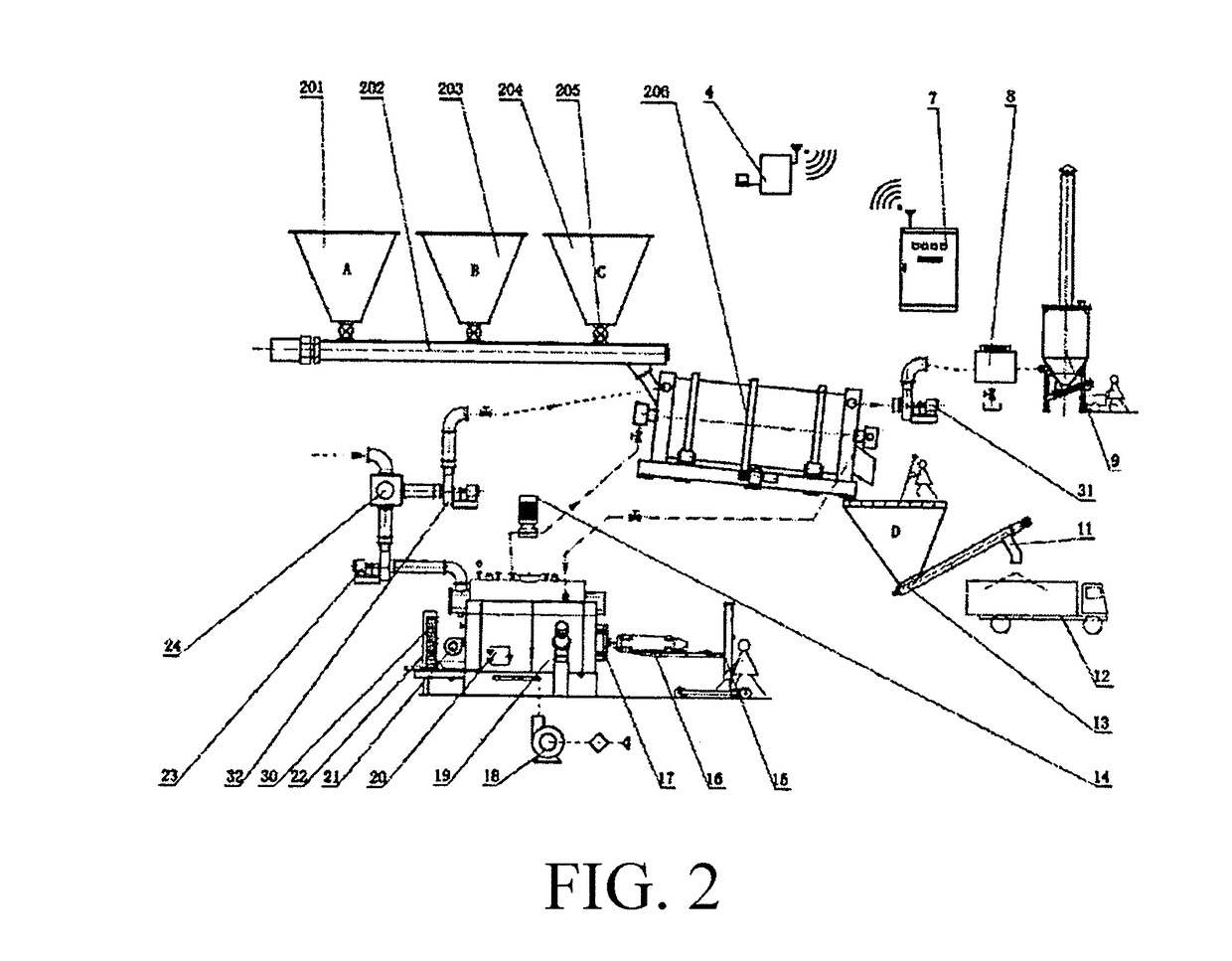

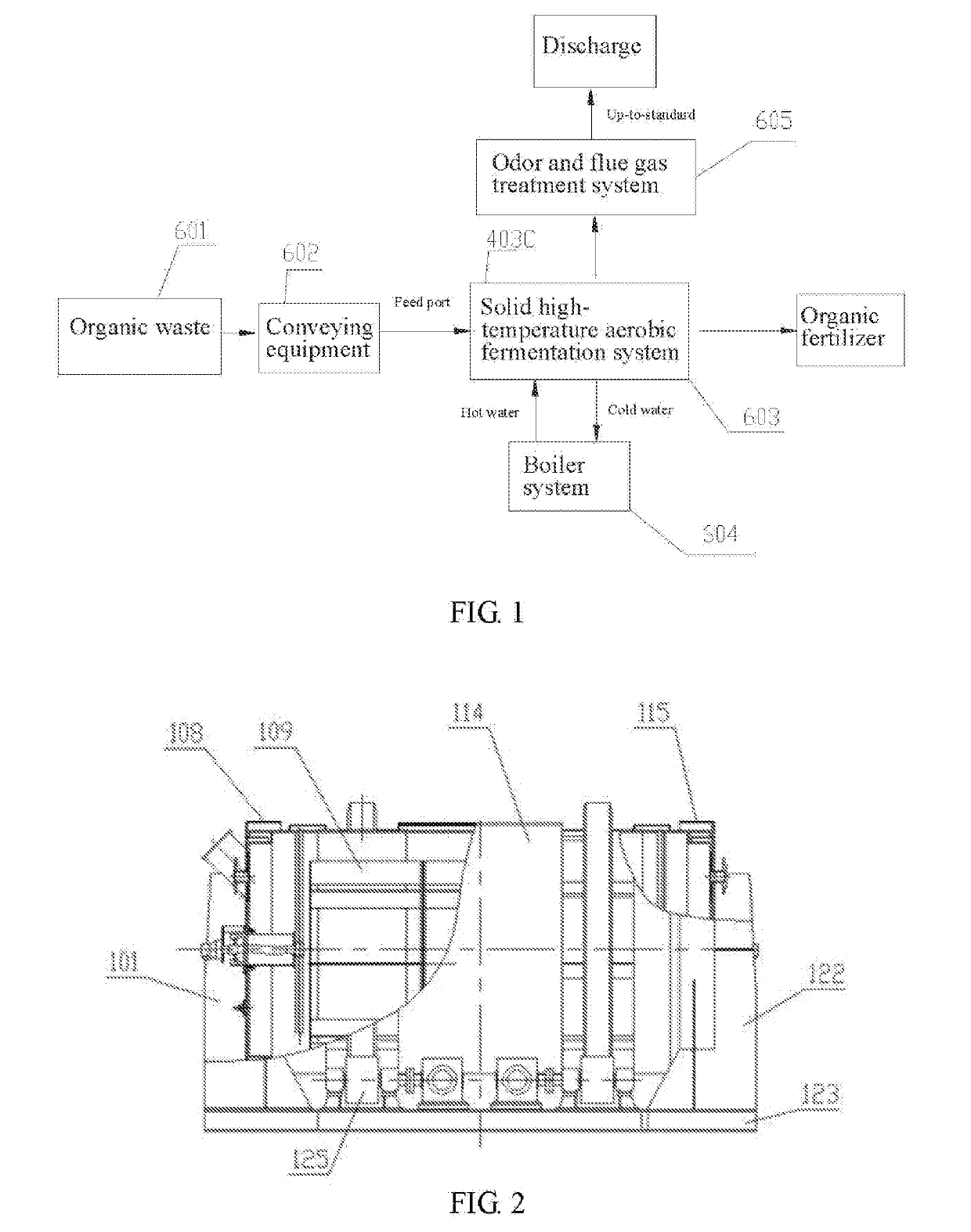

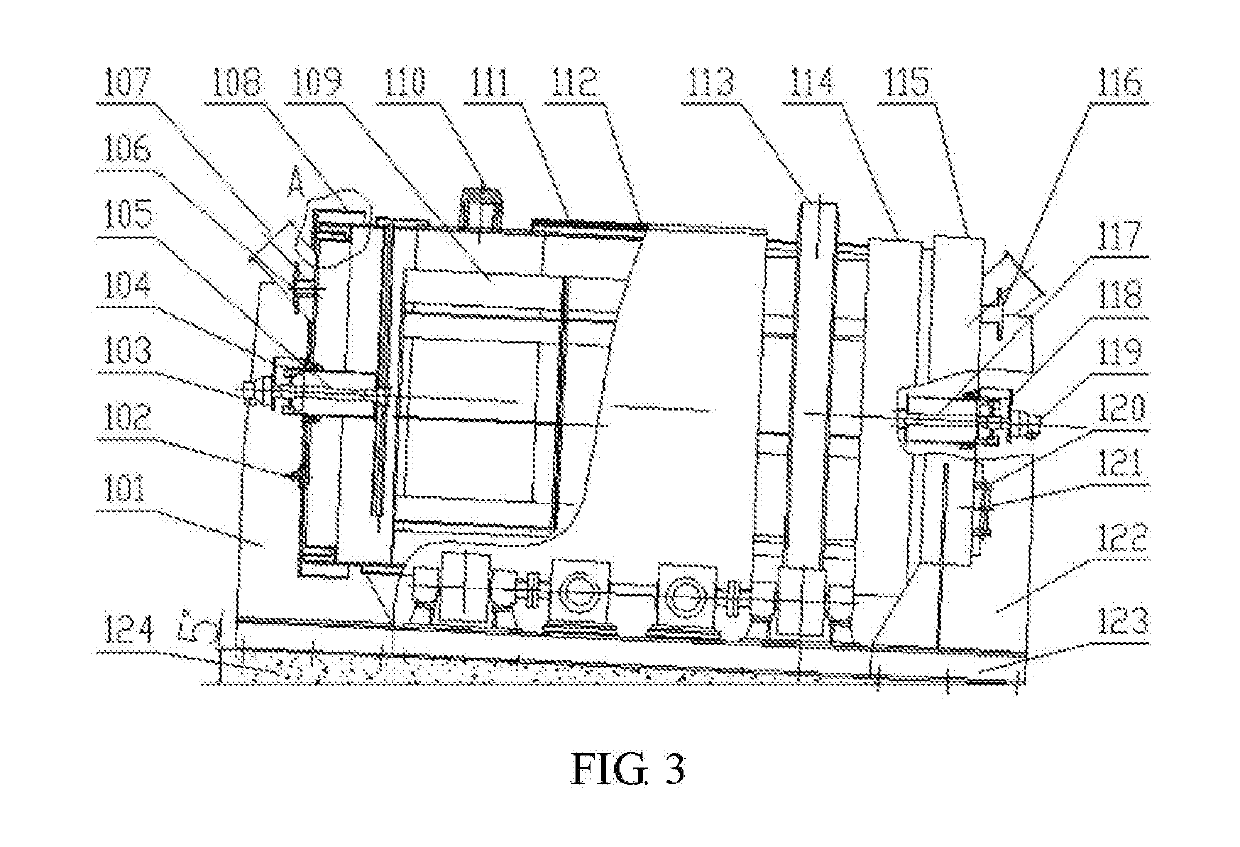

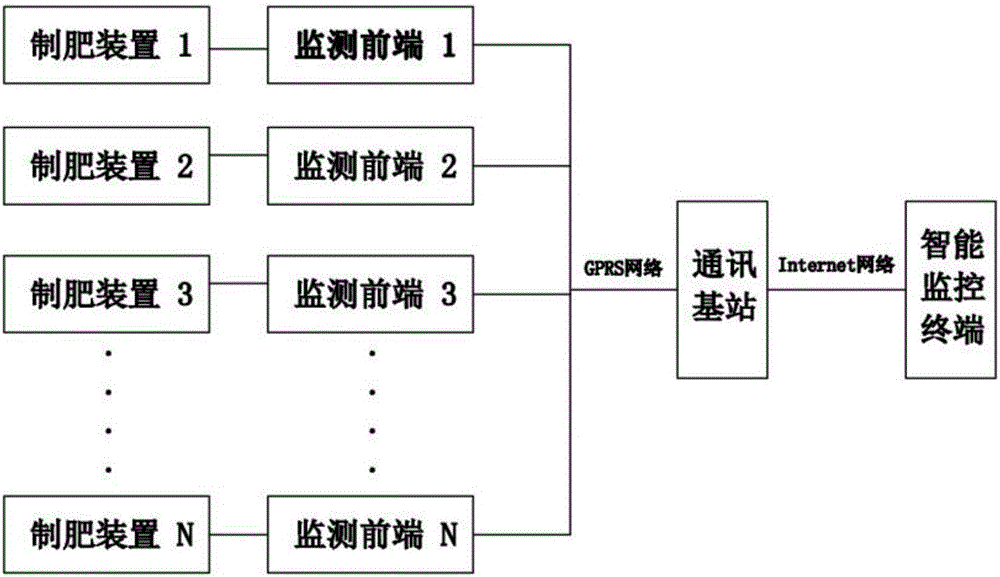

Solid high-temperature aerobic fermentation reaction system and method

PendingUS20190144353A1Easy to useMeet convenient maintenanceBioreactor/fermenter combinationsBio-organic fraction processingFlue gasControl system

A solid high-temperature aerobic fermentation reaction system includes a solid high-temperature aerobic fermentation system, a boiler system, an odor and flue gas treatment system, and a test and control system. The solid high-temperature aerobic fermentation system includes 1 to X solid high-temperature aerobic fermentation reactors. Each solid high-temperature aerobic fermentation reactor includes an inclined horizontal drum, a feed side sealing cover labyrinth sealing device, discharge side sealing cover labyrinth sealing device, a power supporting wheel set, a stirring and anti-sticking device and an integrated base. A water jacket is arranged outside the horizontal drum. The stirring and anti-sticking device is positioned in the horizontal drum which is disposed on the power supporting wheel set. The boiler system includes a shot water boiler, a circulating water pump, a three-way electric regulation valve and an electromagnetic valve.

Owner:WANG SHEN +1

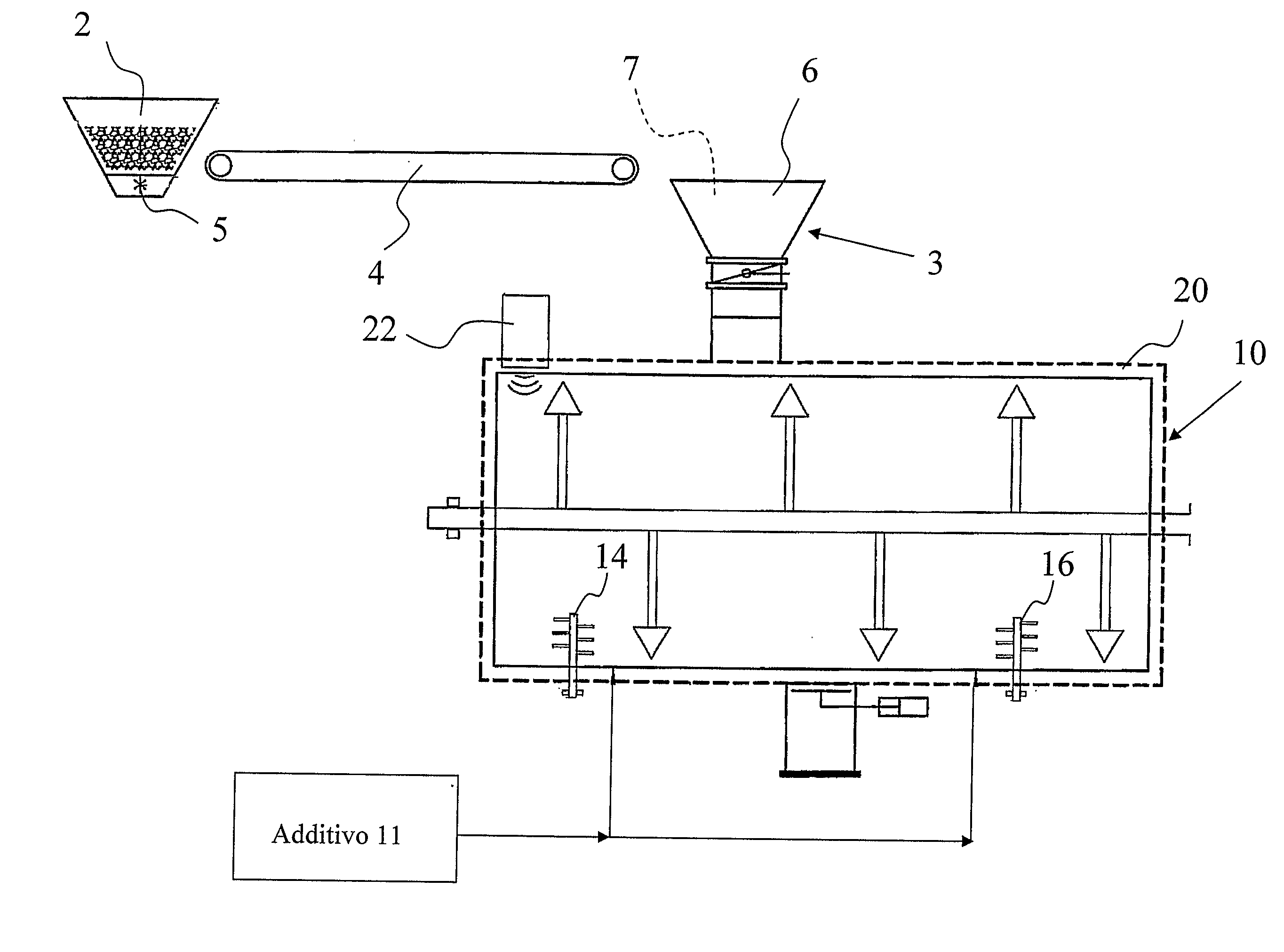

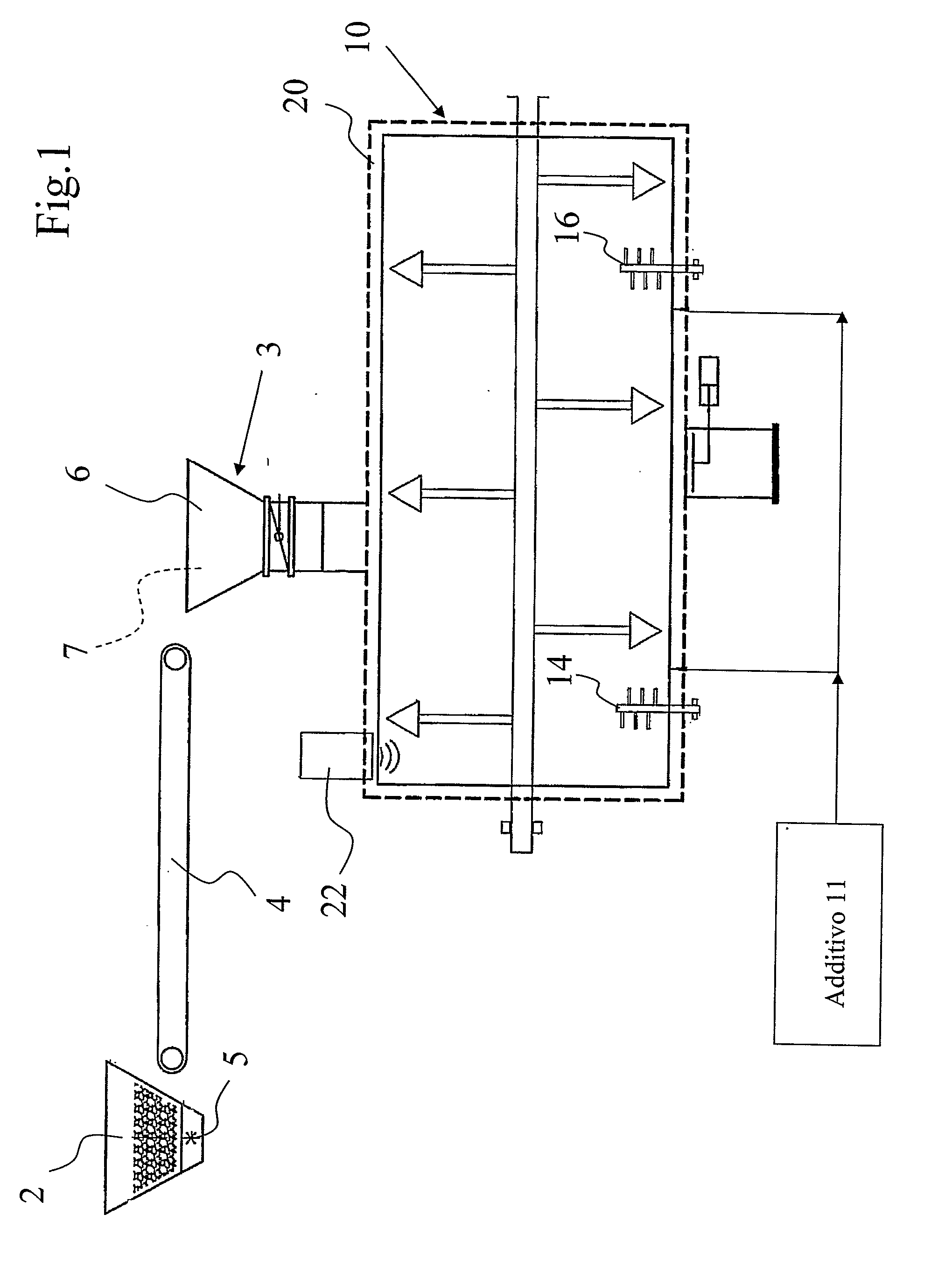

Plant and process for transformation of organic material

InactiveUS20100058821A1Improve both the soilIncrease productionProductsBio-organic fraction processingMicrowaveReaction chamber

A transformation process of organic material (2), for the production of a fertiliser substrate, comprising the steps of grinding said organic material (2) and fermenting, in a reaction chamber, said ground organic material (6) and is characterised in that a microwave source (22) is involved in the removal of the bacterial load. The invention moreover comprises a plant for the actuation of the aforesaid process.

Owner:TECNOIMPIANTI

Special fermenting device for high-value development of multifunctional fertilizer by utilizing straws

ActiveCN106747742ARealize automatic heat exchangeMake up for the lack of slow onsetCalcareous fertilisersBio-organic fraction processingDecompositionEngineering

The invention discloses a special fermenting device for high-value development of a multifunctional fertilizer by utilizing straws. The special fermenting device comprises a double-tower fermenting tank, a crushing mechanism, an automatic feeding mechanism and an automatic discharging mechanism; one end of the automatic feeding mechanism is connected with a material outlet end of the crushing mechanism; the other end of the automatic feeding mechanism is connected with a material inlet section of the double-tower fermenting tank; the automatic discharging mechanism is connected with the bottom of the double-tower fermenting tank; an interlayer is arranged in an outer shell of the double-tower fermenting tank; the interlayer is connected with first heat exchange equipment; a heat exchange pipe is arranged in the first heat exchange equipment; the heat exchange pipeline is loaded with a refrigerant internally; an outlet of the heat exchange pipeline is connected with second heat exchange equipment. The overall equipment is high in automation degree and low in energy consumption, and can realize continuous scale production; the product decomposition period is short; the cost is low; the yield is high; the fertilizer efficiency is high; the technology is mature; the process is environment-friendly.

Owner:ANHUI JULI MACHINERY MFG

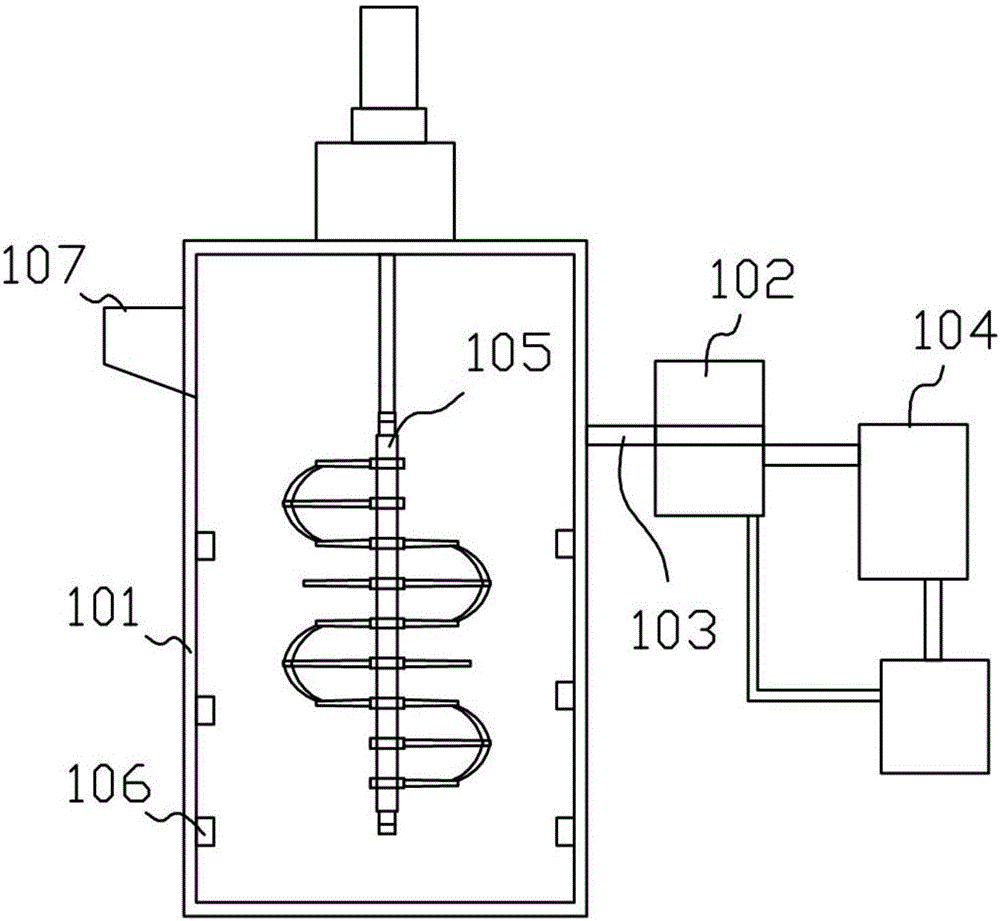

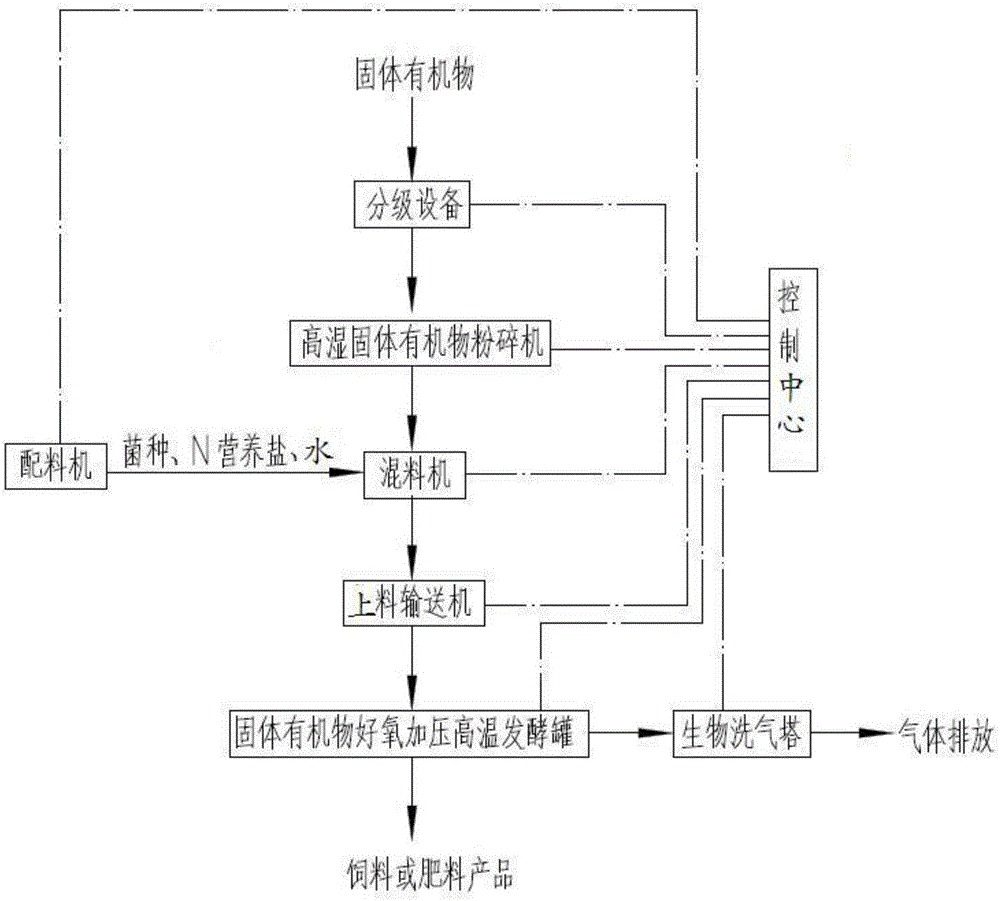

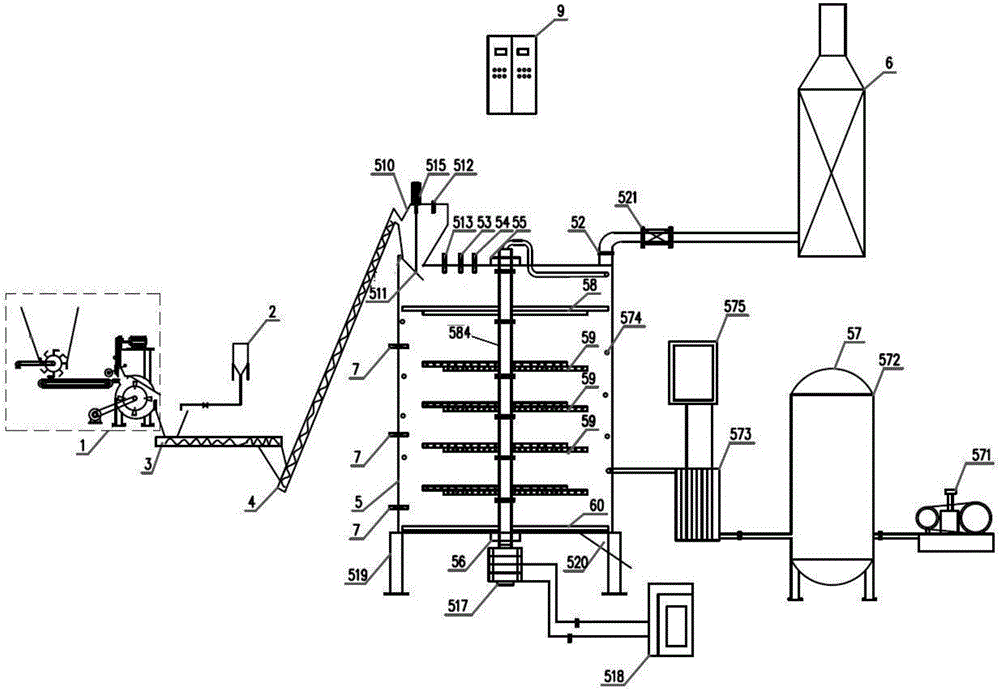

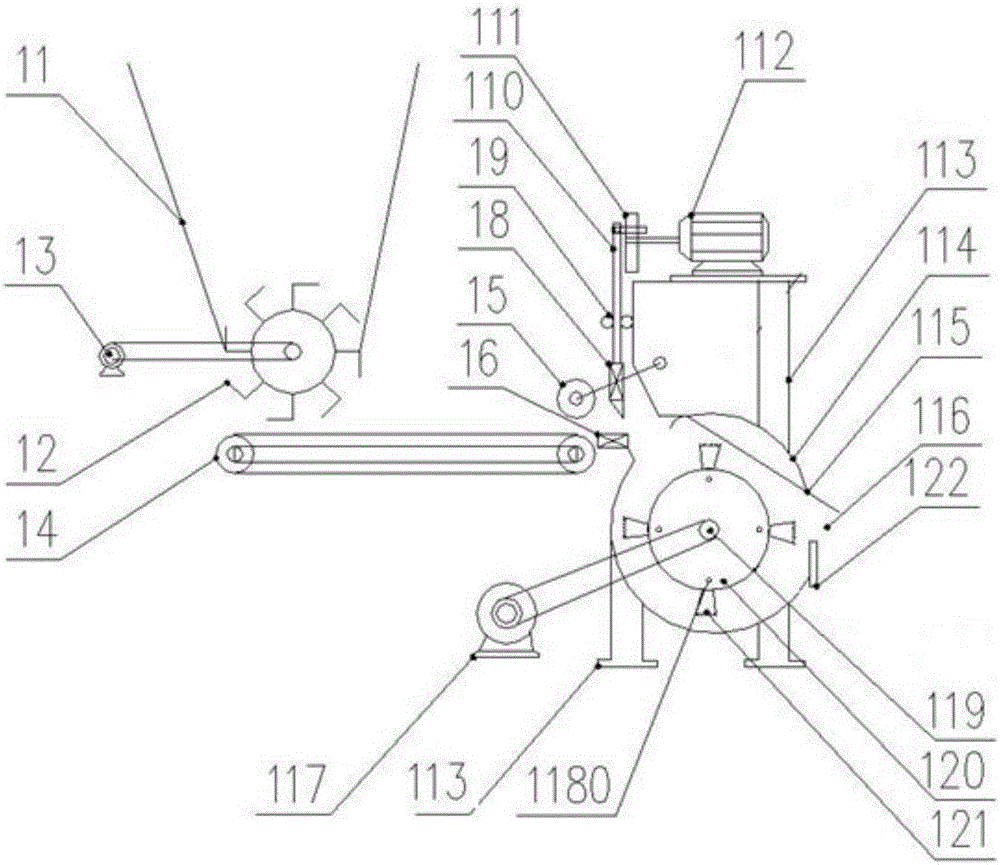

Method and device for aerobic pressurization and high-temperature fermentation of solid organic substances

InactiveCN106278436ABroaden the way of resource utilizationLow costBio-organic fraction processingFeeding-stuffFiberDecomposition

The invention discloses a method and device for aerobic pressurization and high-temperature fermentation of solid organic substances. The method comprises the following steps: classifying solid organic substances through a classifying apparatus; transferring long-fiber solid organic substances into a high-humidity solid organic substance pulverizer, pulverizing, and transferring into a mixer; adding fermentation inocula, N nutritive salts and water into the mixer through a dispenser, uniformly mixing, transferring into a tank for aerobic pressurization and high-temperature fermentation of solid organic substances, and fermenting; and finally, discharging the materials as feeds, organic fertilizers or biological organic fertilizers for use. Gas discharged from the tank for aerobic pressurization and high-temperature fermentation of solid organic substances is purified in a biological gas washing tower, thus solving the tail gas treatment problem. According to the method disclosed by the invention, the solid organic substances with various water contents can be smoothly pulverized; the method is low in cost, high in yield and stable in fermentation temperature, realizes faster and more thorough decomposition and harmless treatment, shortens the fermentation period and improves the efficiency; the device realizes modularization and automation, is small in occupied space and lowers the labor intensity; and multiple devices can be connected in parallel for use.

Owner:南宁绿智环保科技有限公司

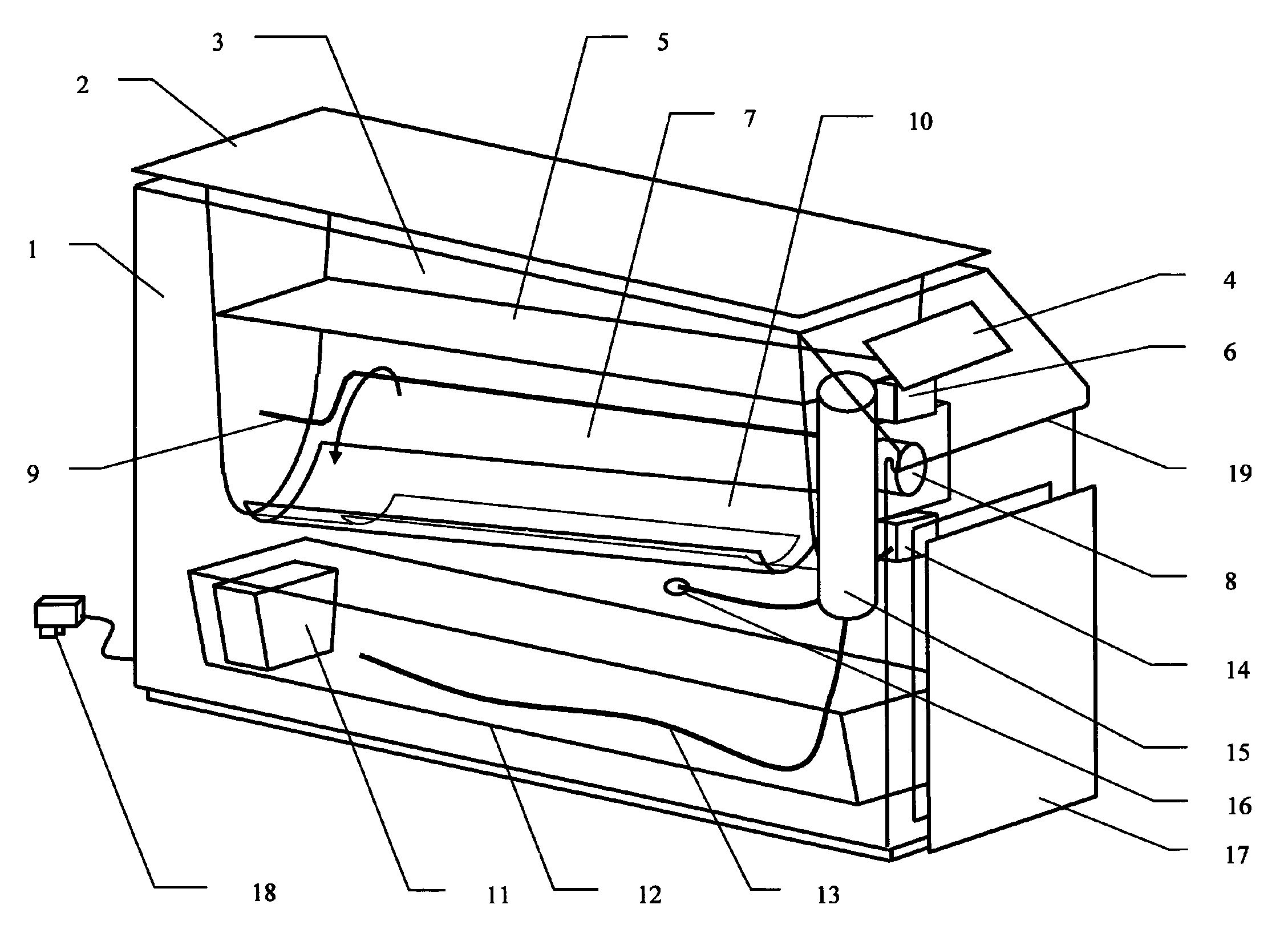

Organic waste fermentatively-processing device

InactiveCN1487860AEfficient use ofBioreactor/fermenter combinationsBio-organic fraction processingMicroorganismHigh pressure

An organic waste fermentatively-processing device, which is capable of fermentatively processing organic waster, such as leftovers and kitchen garbage, to convert it into composite, effectively in a short time. The organic waste fermentatively-processing device stores a fermentation accelerator having a fermentative microorgqanism inoculated thereinto and organic waste in a processing tank and fermentatively decomposes the organic waste by the fermentation microorganism, and is characterized in that a heat insulator covers the tank to prevent leakage of the fermentation heat gengrated by fermentation of the organin waste. The device is further characterized by including heat exchange means capable of absorbing the excess heat generated in the processing tank and conveying it outside the processing tank and sealing means for maintaining the interior of the processing tank under high temperature high pressure conditions against the pressure of the vapor produced by fermentation of the orgain waste.

Owner:JAPAN LIFE CENT +1

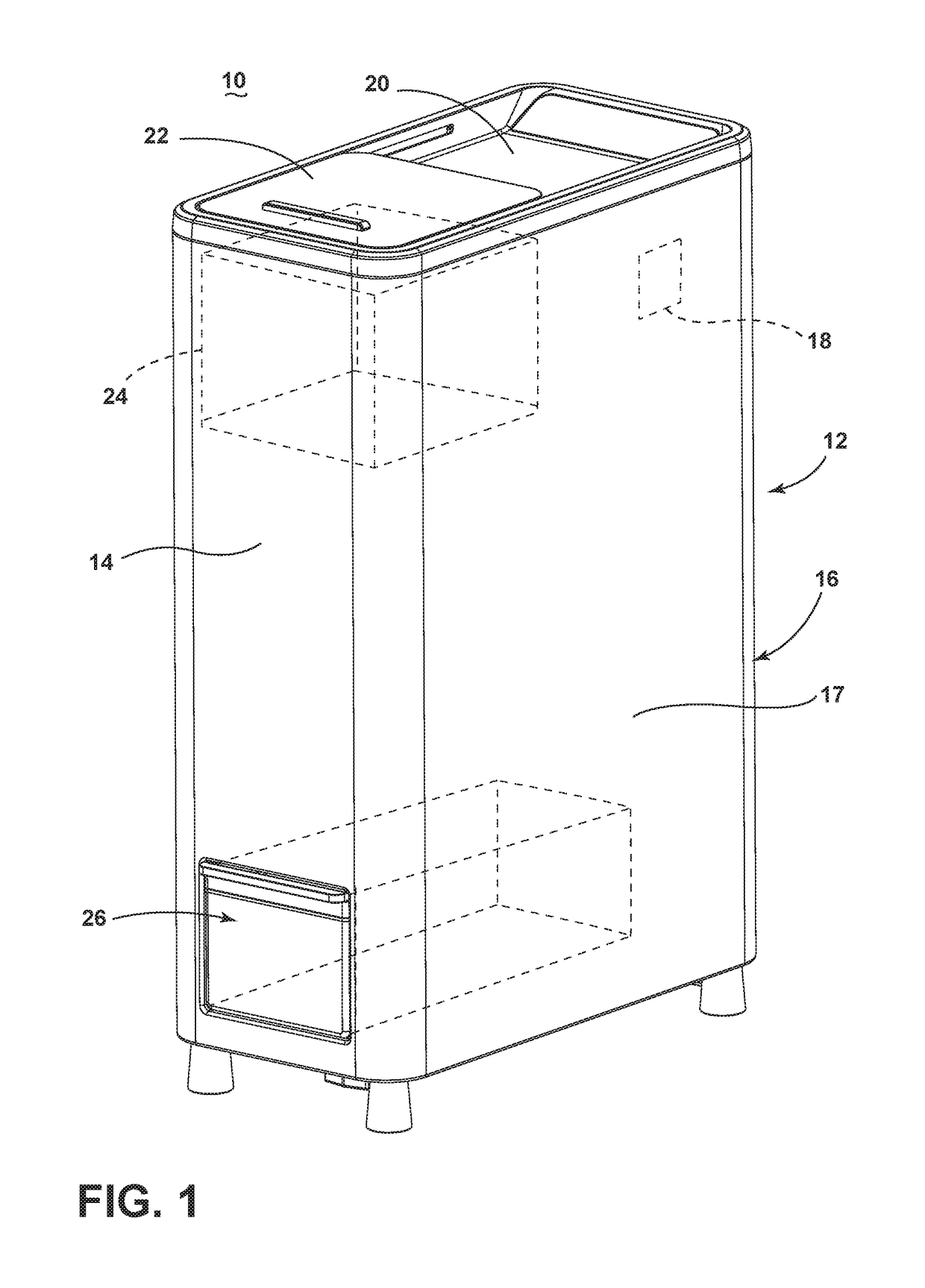

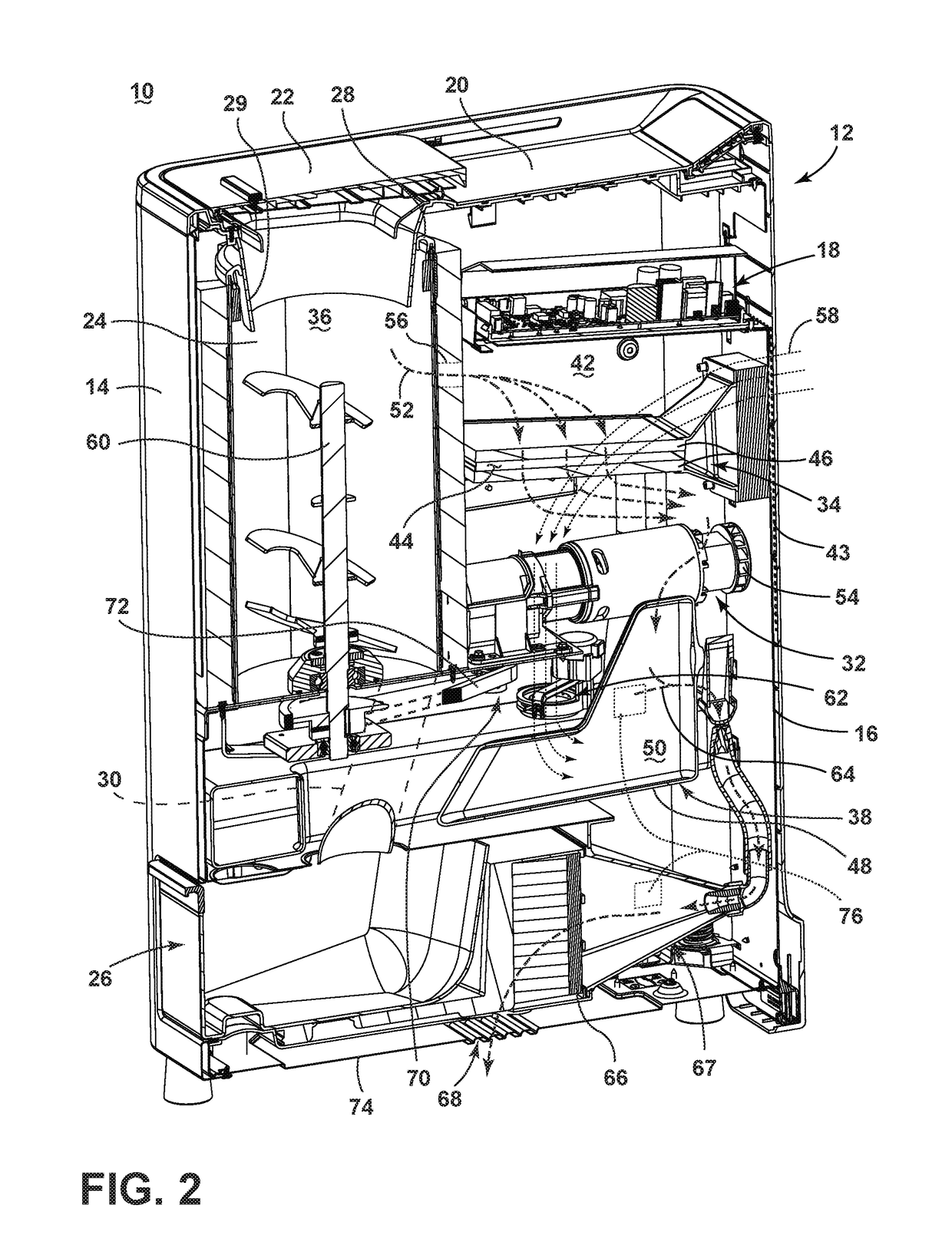

Method and apparatus for operating a composter device

A method and apparatus for operating a composter device includes a compost container, a condensate reservoir, a first fluid pathway fluidly coupling the composting chamber and the condensate reservoir, and a fan moving air from the composting chamber to the condensate reservoir along the first fluid pathway to define a first airflow.

Owner:WHIRLPOOL CORP

Organic compound fertilizer produced by using sludge with water content of 80% and production method

PendingCN109851451AShort processing timeGood effectCalcareous fertilisersMagnesium fertilisersChlorine dioxideResource utilization

The invention relates to an organic compound fertilizer produced by using sludge with a water content of 80% and a production method. The production method is characterized by comprising the steps ofadopting the sludge with the water content of 80%, coal ash, agricultural waste, quick lime, ferrous sulfate, magnesium sulfate, polyacrylamide and chlorine dioxide for even mixing, using a belt conveyor for transporting a mixture to a sealed high-temperature fermentation machine, elevating temperature in the fermentation machine to 100 DEG C through oil-electric heat conduction, maintaining an outage for 2 hours, maintaining temperature at 60 DEG C, adding high-temperature-loving active compound bacteria for fermentation, adjusting a stirring system of the fermentation machine to turn on an intermittent stirring function, and enabling fermentation time of the sludge in the fermentation machine to be 12 hours to effectively kill harmful microorganisms, eggs, weed seeds and pathogenic bacteria in the sludge; and ageing, crushing and screening a fermented cooked material to produce powder, and using an automatic electronic weighing and packaging machine for packaging the powder to produce an organic compound fertilizer product. Therefore, the problem of treating the sludge with the water content of 80% is solved, resource utilization of the sludge is achieved, and pollution to the natural environment is reduced.

Owner:李健

Composting garden container

A planter in the form of a tower planter having an internal vertical composting capability is provided. The planter has a hollow, vertical, outer cylindrical barrel with a plurality of openings formed about its cylindrical side. A hollow inner cylindrical composting tube having a plurality of perforations formed in its cylindrical wall is provided. The space formed between the inner tube and barrel wall is filled with growing medium. The inner tube is filled with compost material. A removable container is placed at the bottom of the tube and barrel, said container adapted to capture water draining out from the tube and barrel, as well as periodically receiving compost from the compost tube.

Owner:CUDMORE COLIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com