Self-sustaining smoldering and high-temperature aerobic fermentation composite disposal process and equipment for sludge

An aerobic fermentation and sludge technology, applied in biological sludge treatment, lighting and heating equipment, sewage/sludge fertilizer, etc. The effect of reducing biological fermentation cycle, increasing disposal rate and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

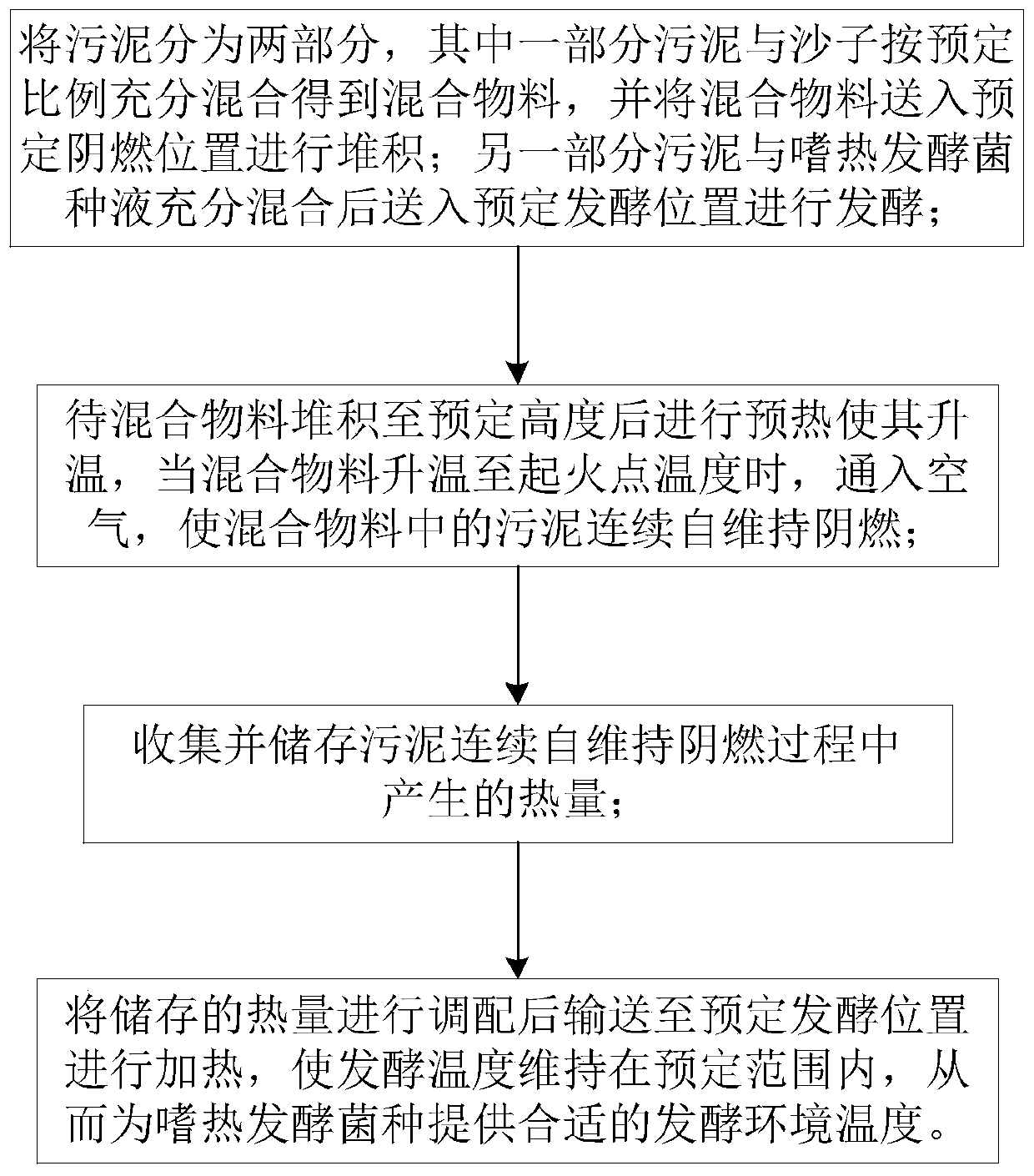

[0057] (1) Divert the introduced sludge, a part of it is fully mixed with sand at a weight ratio of 1:4.5, and the mixed material is sent to a predetermined smoldering device for accumulation; the other part of the sludge is fully mixed with the thermophilic fermentation bacterial seed liquid Then it is sent to the predetermined fermentation position to be fermented;

[0058] (2) After the mixed material has accumulated to a predetermined height, the smoldering device is preheated and heated. When the temperature of the bottom mixed material rises to 250°C, air is introduced so that the Darcy flow rate of the air in the smoldering device is 3.3cm / s, and the mixed material The sludge in it starts to smolder;

[0059] (3) Collect and store the heat generated during the continuous self-sustaining smoldering process of sludge;

[0060] (4) Prepare the stored heat and transport it to the predetermined fermentation position for heating, so that the fermentation temperature is maint...

Embodiment example 2

[0063] (1) Divert the introduced sludge, a part of it is fully mixed with sand in a weight ratio of 1:9, and the mixed material is sent to a predetermined smoldering device for accumulation; the other part of the sludge is fully mixed with the thermophilic fermentation bacterial seed liquid Then it is sent to the predetermined fermentation position to be fermented;

[0064] (2) After the mixed material has accumulated to a predetermined height, the smoldering device is preheated and heated. When the temperature of the bottom mixed material rises to 300°C, air is introduced so that the Darcy flow rate of the air in the smoldering device is 4.5cm / s, and the mixed material The sludge in it starts to smolder;

[0065] (3) Collect and store the heat generated during the continuous self-sustaining smoldering process of sludge;

[0066] (4) Prepare the stored heat and transport it to the predetermined fermentation position for heating, so that the fermentation temperature is maintai...

Embodiment example 3

[0069] (1) Divide the introduced sludge, a part of it is fully mixed with sand at a weight ratio of 1:5, and the mixed material is sent to a predetermined smoldering device for accumulation; the other part of the sludge is fully mixed with the thermophilic fermentation bacterial seed liquid Then it is sent to the predetermined fermentation position to be fermented;

[0070] (2) After the mixed material has accumulated to a predetermined height, the smoldering device is preheated and heated up. When the temperature of the bottom mixed material rises to 250°C, air is introduced so that the Darcy flow rate of the air in the smoldering device is 6.0cm / s, and the mixed material The sludge in it starts to smolder;

[0071] (3) Collect and store the heat generated during the continuous self-sustaining smoldering process of sludge;

[0072] (4) Prepare the stored heat and transport it to the predetermined fermentation position for heating, so that the fermentation temperature is main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com