Patents

Literature

56results about How to "Realize resource disposal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

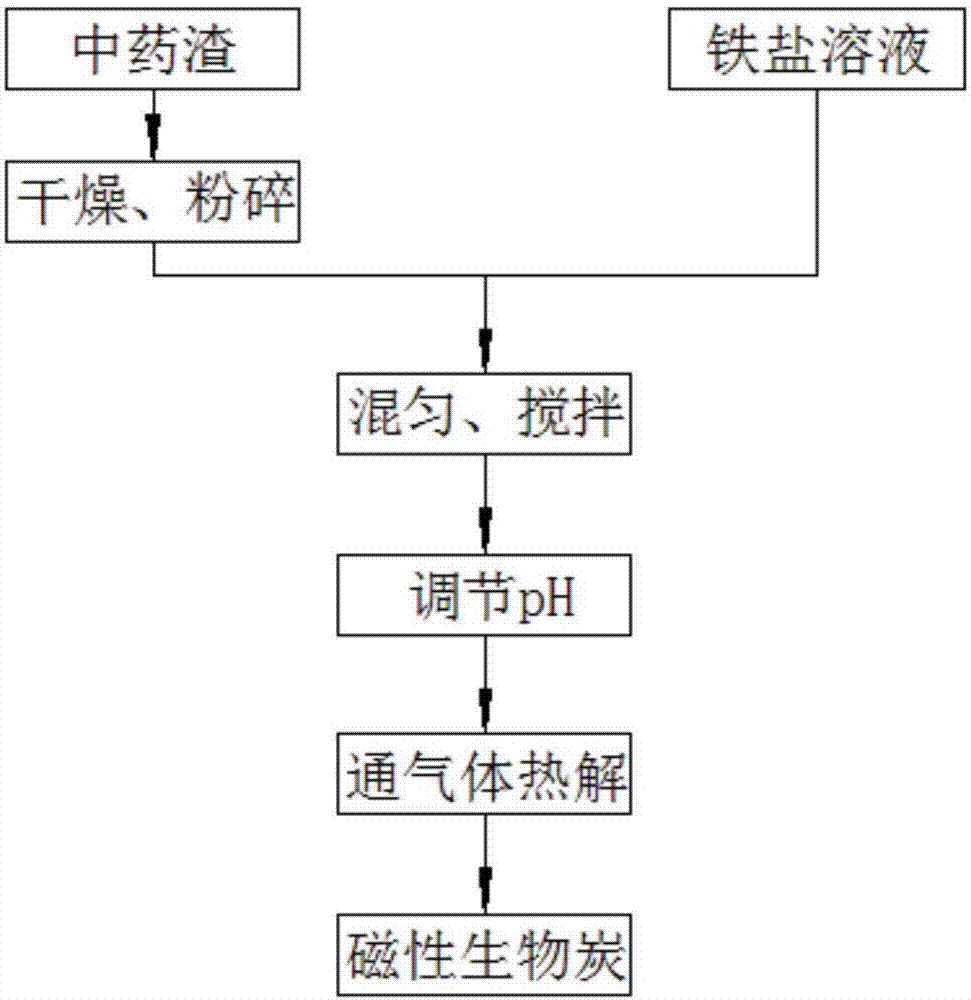

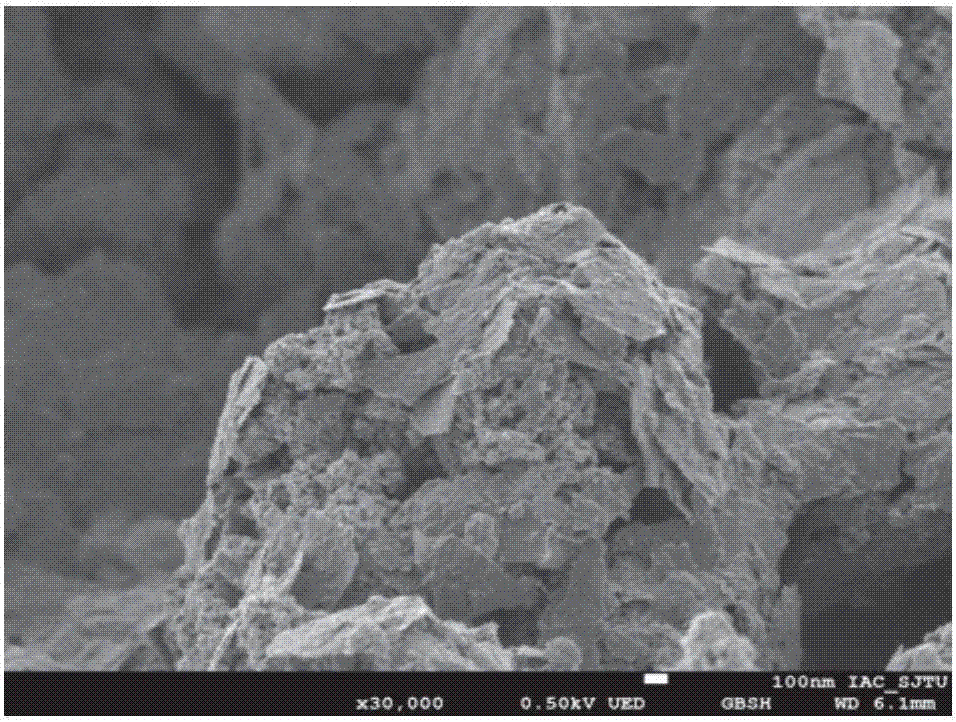

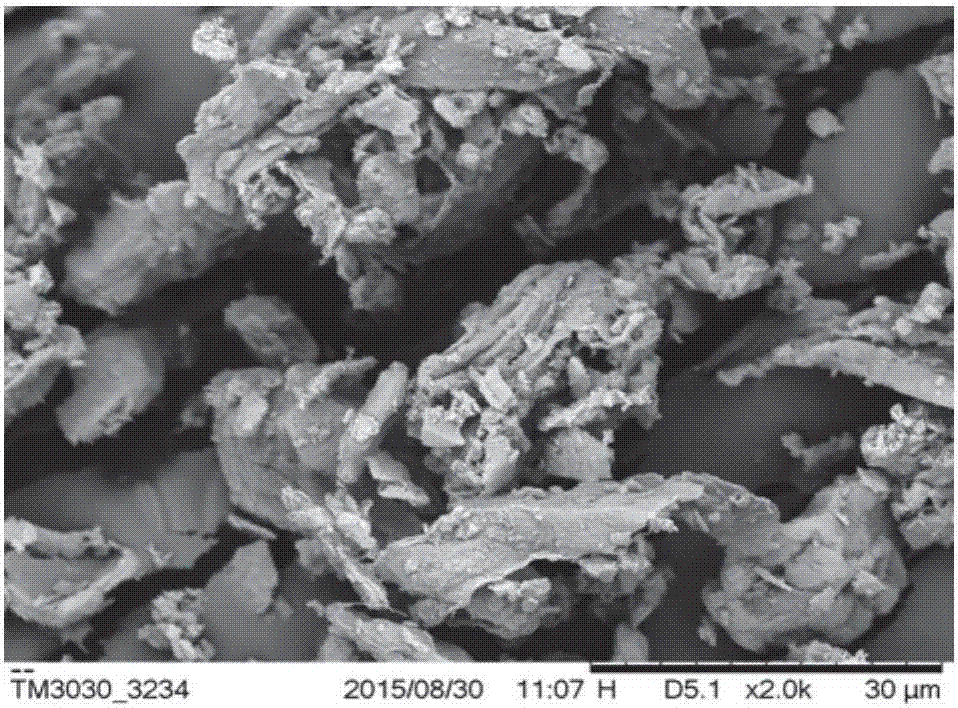

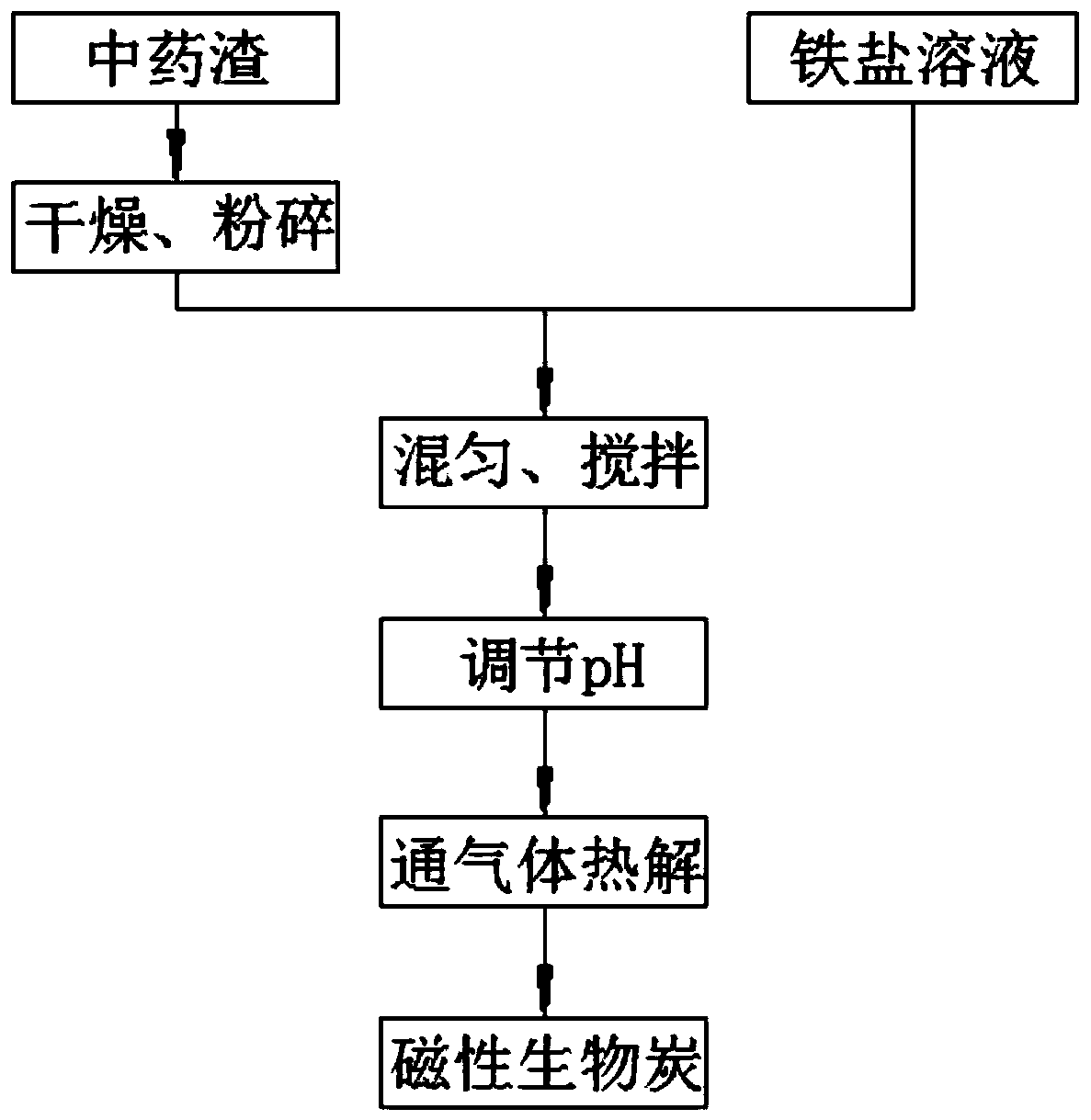

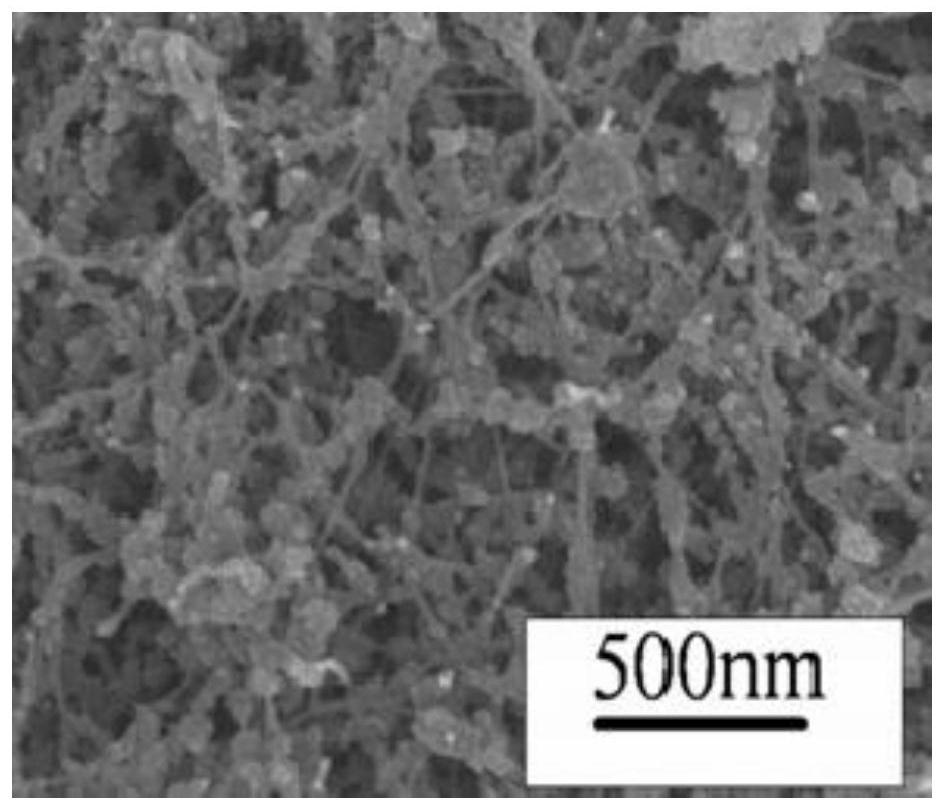

Method for preparing magnetic biological carbon by utilizing traditional Chinese medicine residues, magnetic biological carbon and application thereof

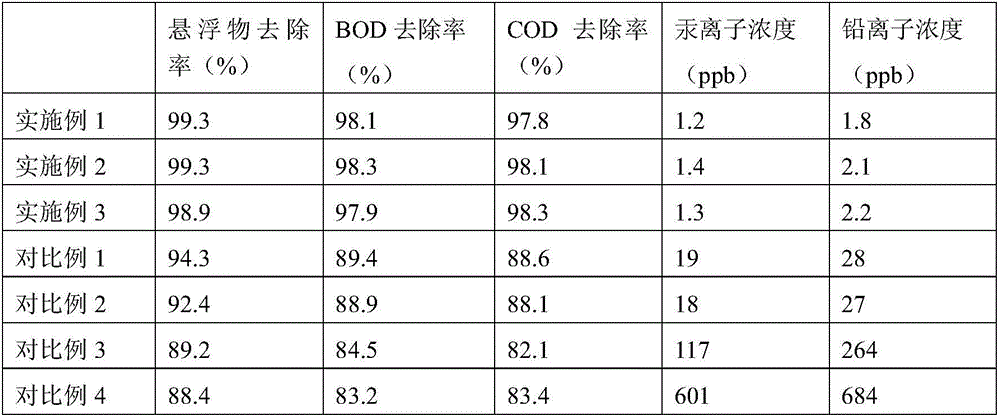

ActiveCN107096500ARealize resource disposalSolve the problem of low added valueOther chemical processesWater contaminantsSocial benefitsResource utilization

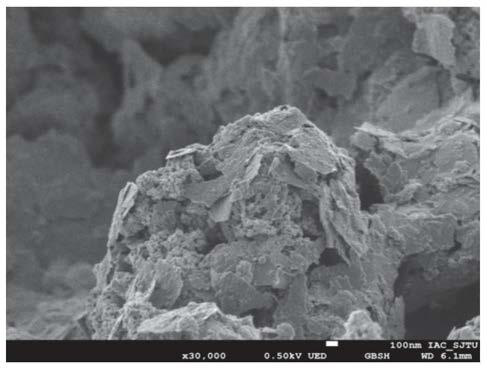

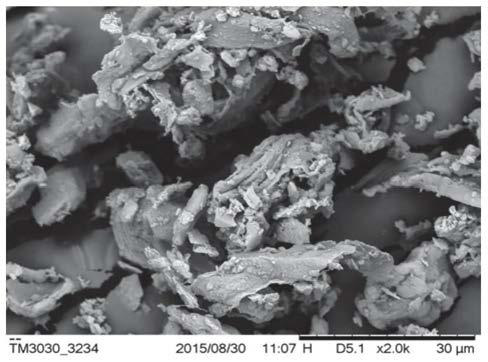

The invention discloses a method for preparing magnetic biological carbon by utilizing traditional Chinese medicine residues, the magnetic biological carbon and application thereof and belongs to the field of biomass resource utilization. The method comprises the following steps: after impregnation pretreatment of the traditional Chinese medicine residues and sodium carbonate, performing ion salt impregnation and high-temperature anaerobic activation, washing, drying and the like to obtain the magnetic biological carbon. The method has the characteristics of being simple in production process, highly available in raw materials, high in product solid-liquid efficiency and the like. The method disclosed by the invention realizes the resource of the traditional Chinese medicine residues, has great significances in expanding the use of wastes extracted from the traditional Chinese medicines and expanding the source and the application scope of biological carbon adsorbents and can be widely applied to the water treatment field, thereby having good economic benefits and social benefits.

Owner:CHINA PHARM UNIV

Sewage flocculant

InactiveCN103663729AReduce turbidityImprove processing efficiencyBiological water/sewage treatmentFlocculationSodium Bentonite

The invention discloses a sewage flocculant. The sewage flocculant comprises polyacrylamide, citric acid, compound microorganisms, polyferric trichloride and bentonite. The flocculant has good flocculation and can reduce the sewage turbidity and improve the sewage treatment efficiency.

Owner:SHANDONG JIANZHU UNIV

Traditional Chinese medicine dreg charcoal adsorbent carrying vulcanization nano zero-valent iron and preparation method and application of adsorbent

PendingCN109908863AEasy to handleEfficient removalOther chemical processesWater contaminantsVulcanizationWastewater

The invention discloses a traditional Chinese medicine dreg charcoal adsorbent carrying vulcanization nano zero-valent iron and a preparation method and application of the adsorbent in wastewater treatment. Traditional Chinese medicine dregs are adopted to prepare charcoal and are used as a carrier of vulcanization nano zero-valent iron, the defect that a nano material is liable to aggregate is alleviated, the dispersibility and the reaction activity of the nano material can be improved, and the purpose of treating wastes with wastes can be achieved. The method is simple to operate, easy in raw material obtaining, low in price and good in effect, novel ways for recycling of traditional Chinese medicine dregs can be developed, and novel ideas are provided for treatment on organic and heavymetal wastewater.

Owner:CHINA PHARM UNIV

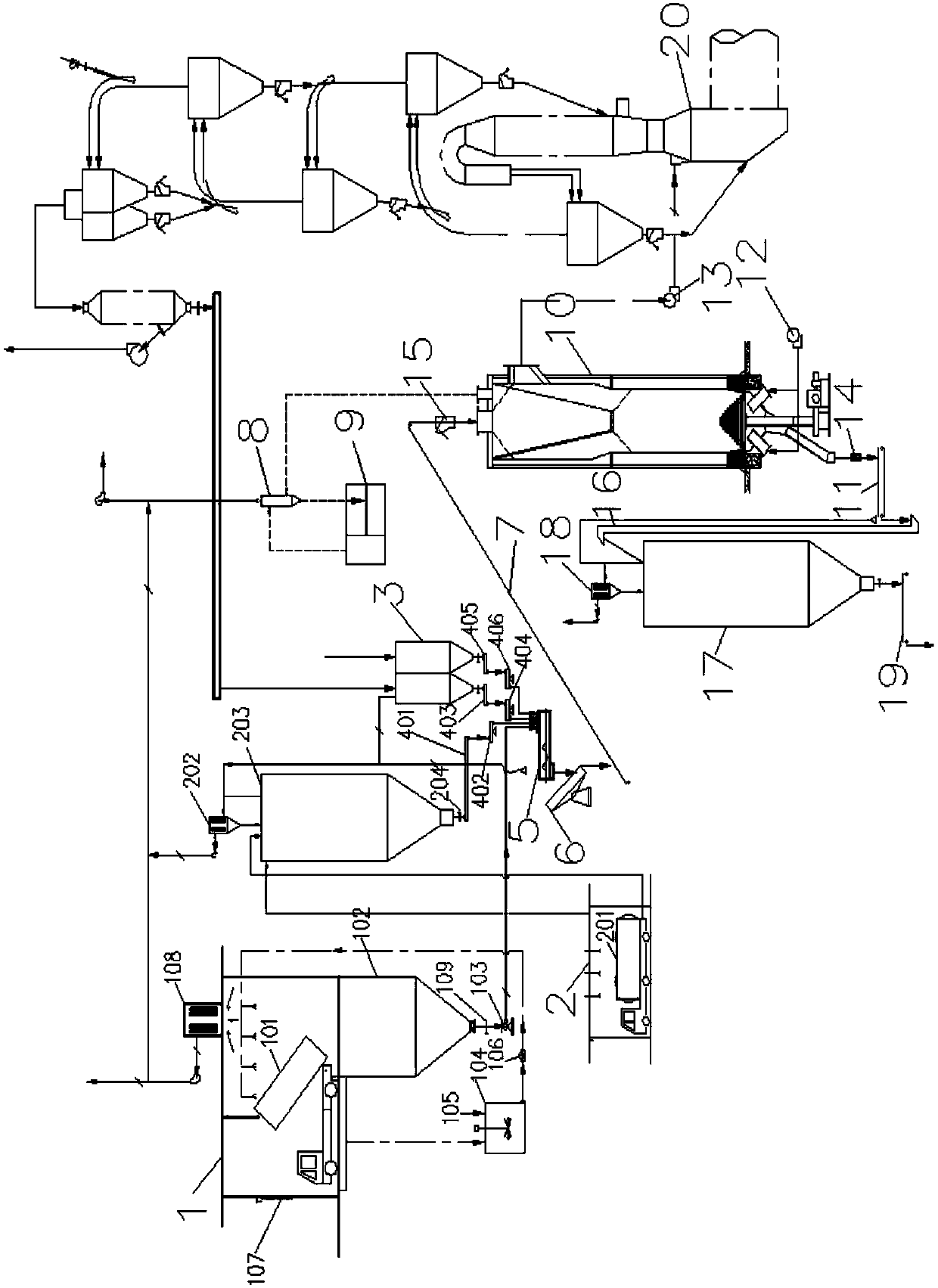

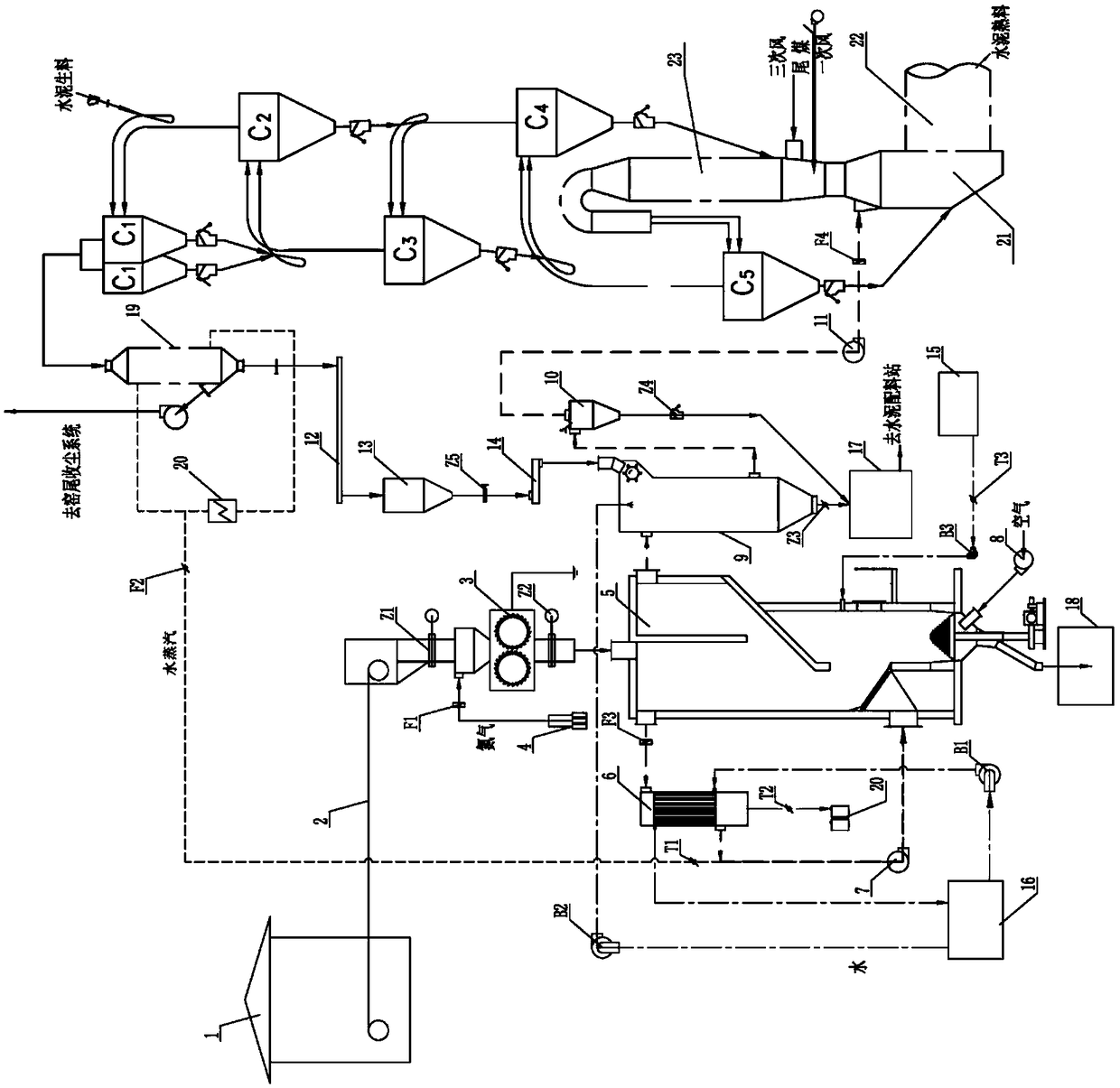

System and method for producing ecological cement through garbage fly ash and sludge cooperative mixed combustion in cement kiln

PendingCN108036323AAvoid harmEliminate poisonous propertiesCement productionIncinerator apparatusCombustionSludge

Owner:长沙中硅环保科技有限公司

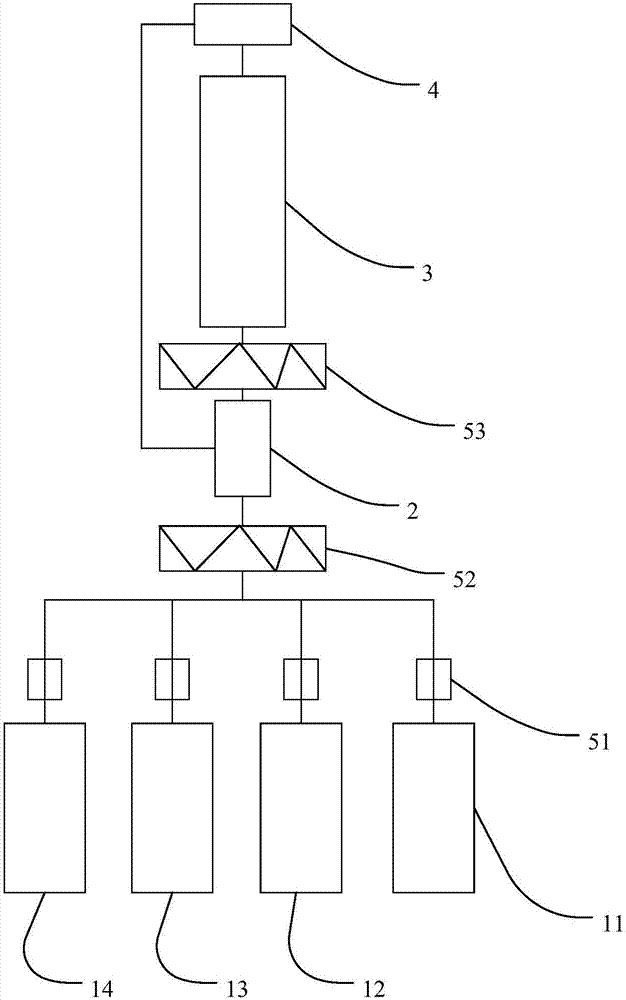

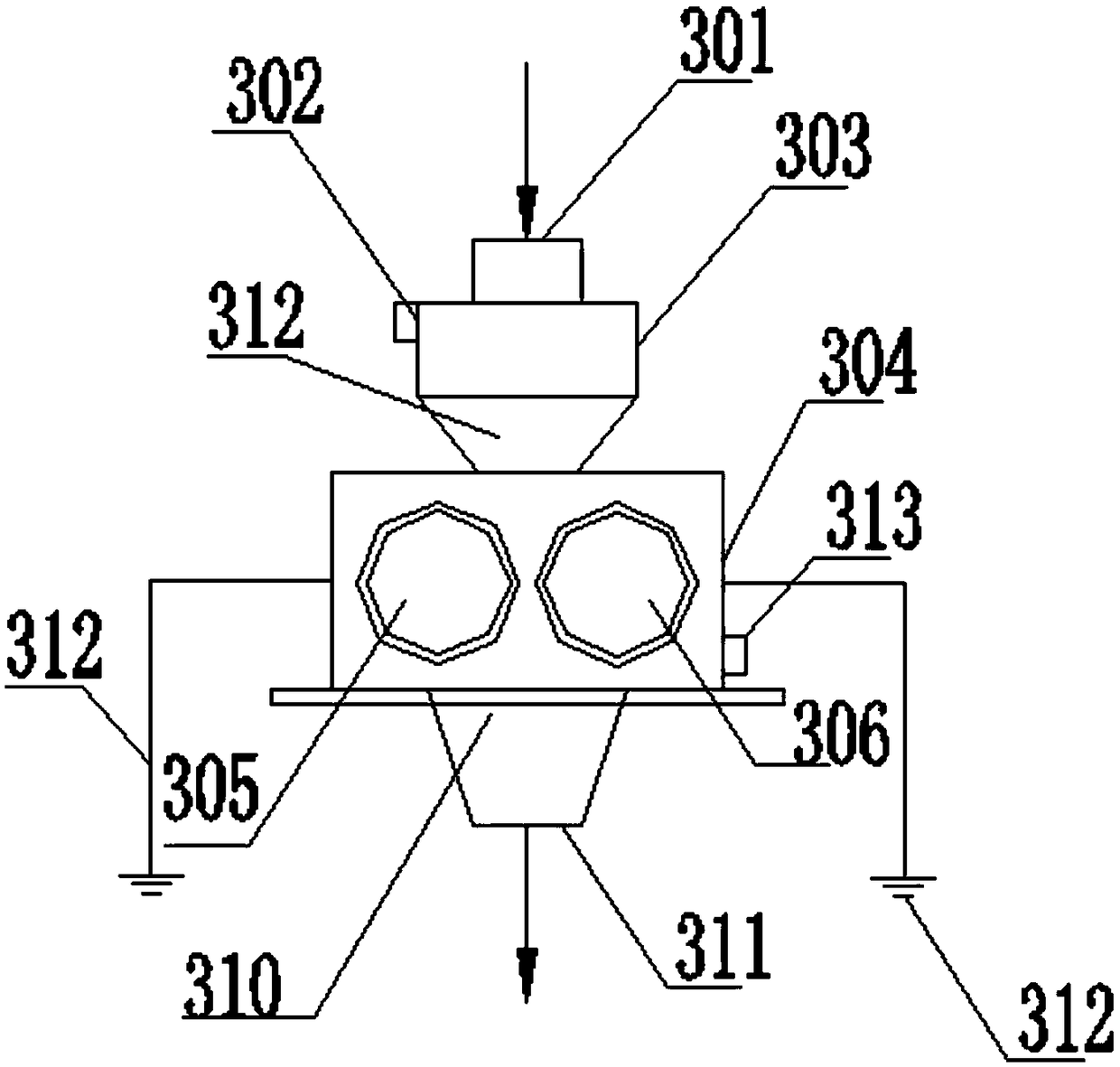

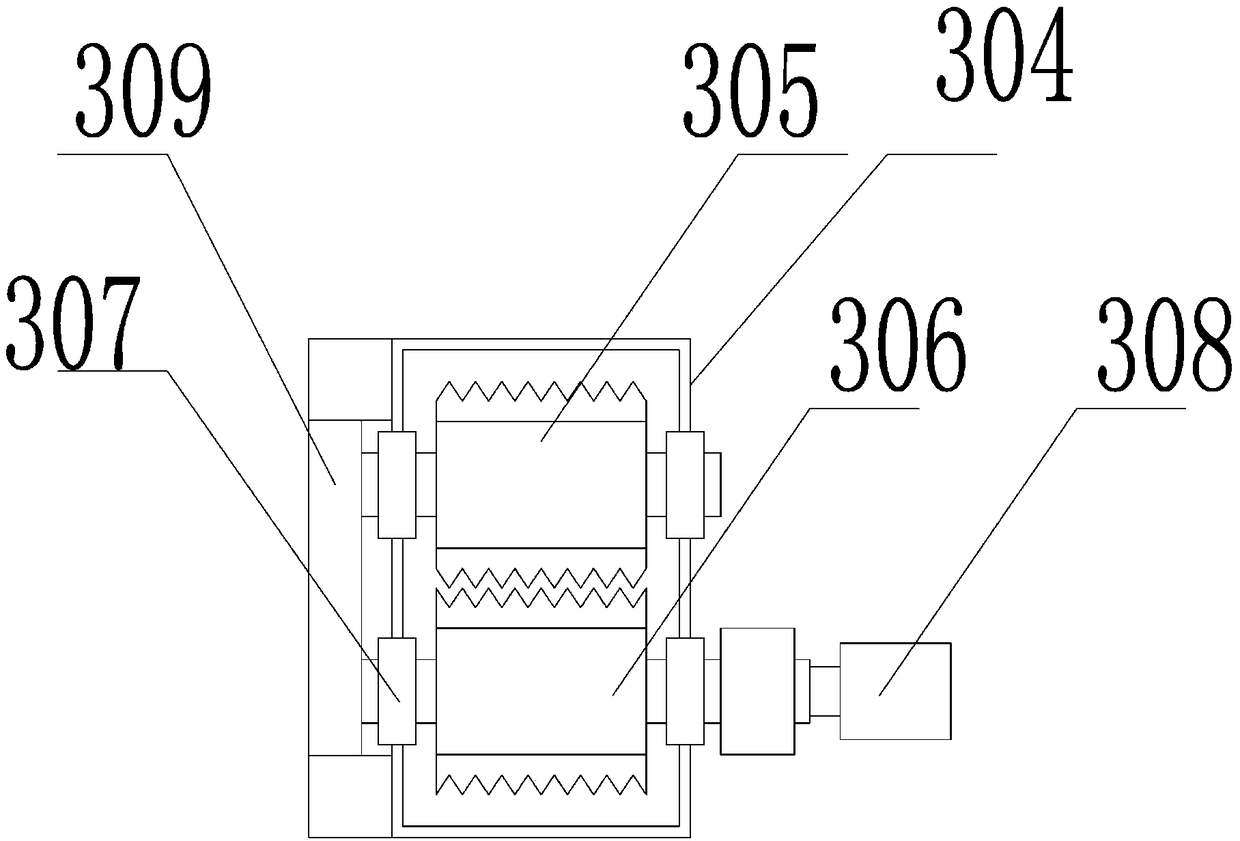

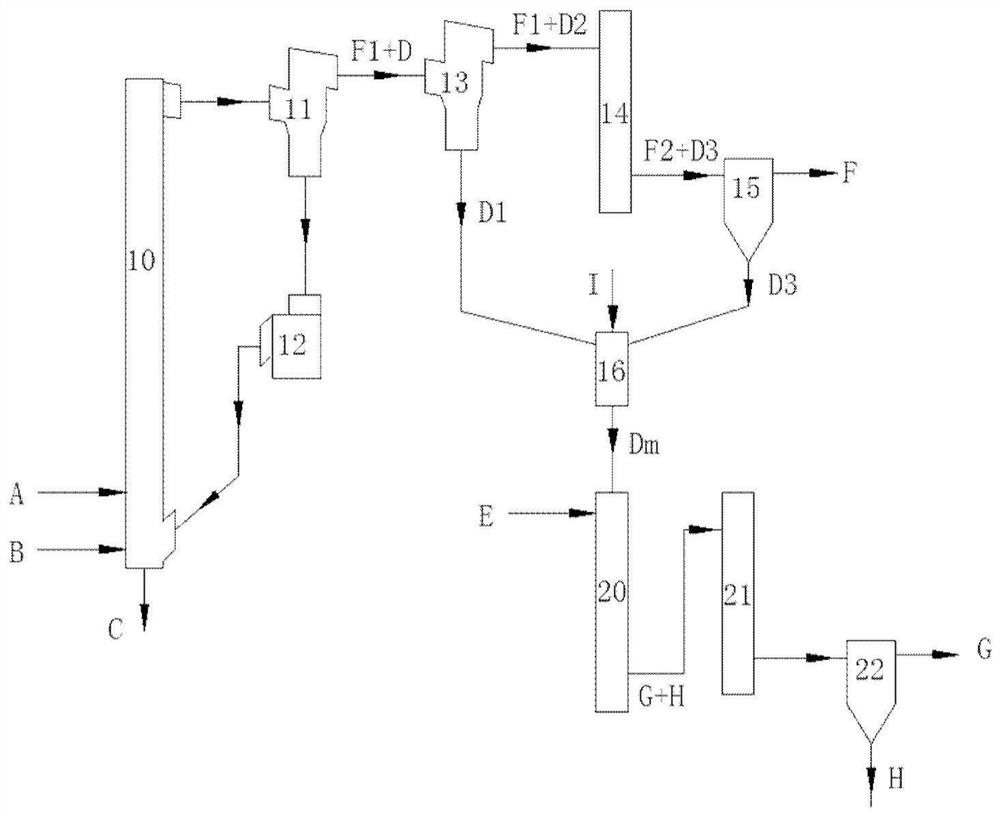

Compressive handling equipment and process for organic solid waste

InactiveCN106862246ARealize resource utilizationWay out no problemSolid waste disposalPulp and paper industryIntegrated processing

The invention discloses compressive handling equipment and process for organic solid waste. The equipment comprises multiple material storage bins, a first mixer, a material compounding device, a fermentation box and a screening device. The multiple material storage bins are connected with a feeding opening of the first mixer and used for storing waste materials to be handled in a classified manner. A discharging opening of the first mixer is connected with the material compounding device. The discharging end of the material compounding device is connected with the feeding end of the fermentation box. The discharging end of the fermentation box is connected with the discharging end of the screening device. The material compounding device receives multiple types of waste materials. The multiple types of waste materials comprise waste materials from the first mixer. After all the types of received waste materials are added in proportion through the material compounding device, the waste materials are conveyed to the fermentation box for fermentation, and waste materials obtained after the fermentation effect is completed are conveyed to the screening device for screening treatment. By means of the equipment and process, automated and efficient operation of all links in the organic solid waste handling process can be achieved; the waste fermentation process is effectively monitored and adjusted in time; and handling efficiency and the handling effect are greatly improved.

Owner:北京华清博雅环保工程有限公司

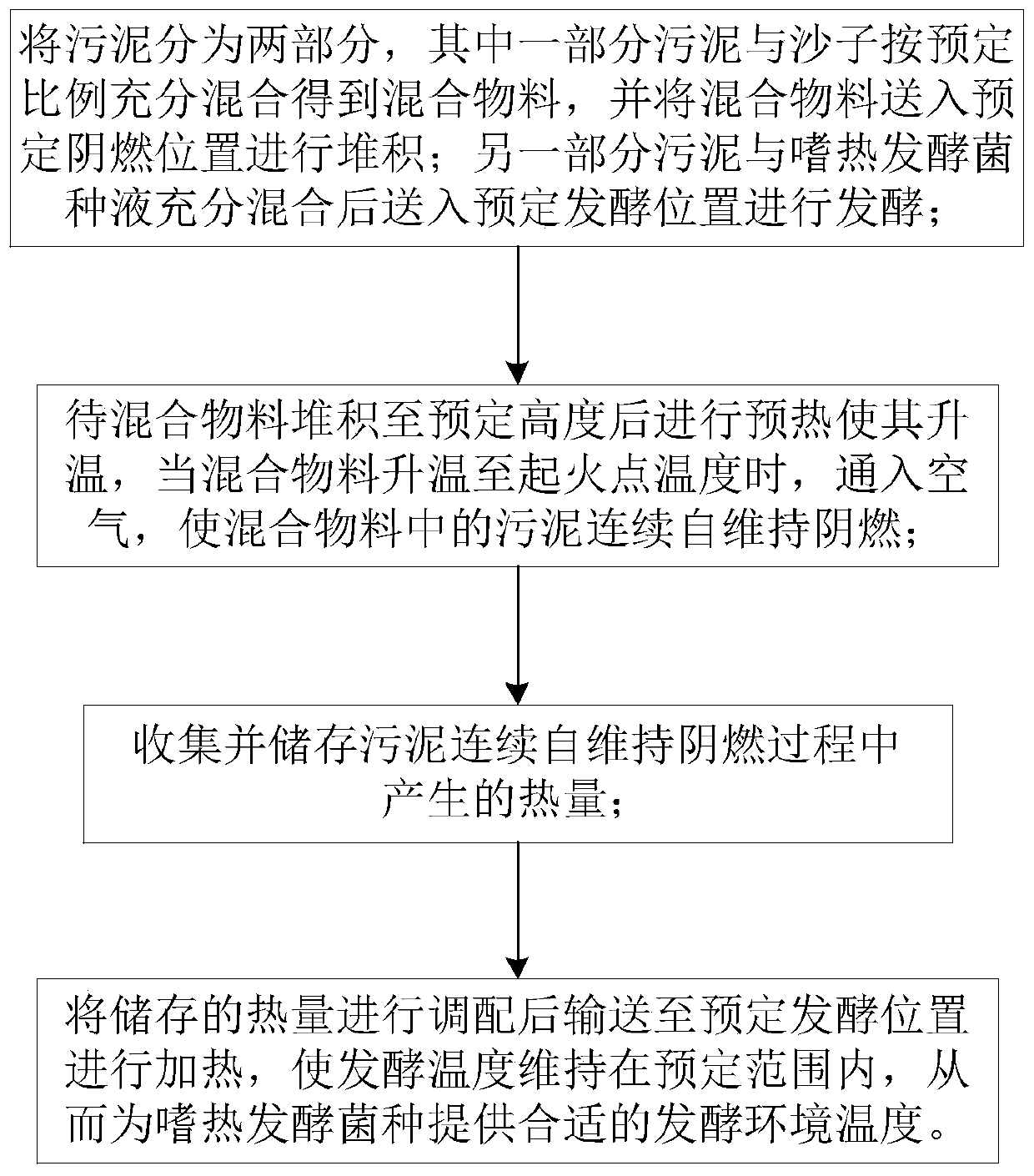

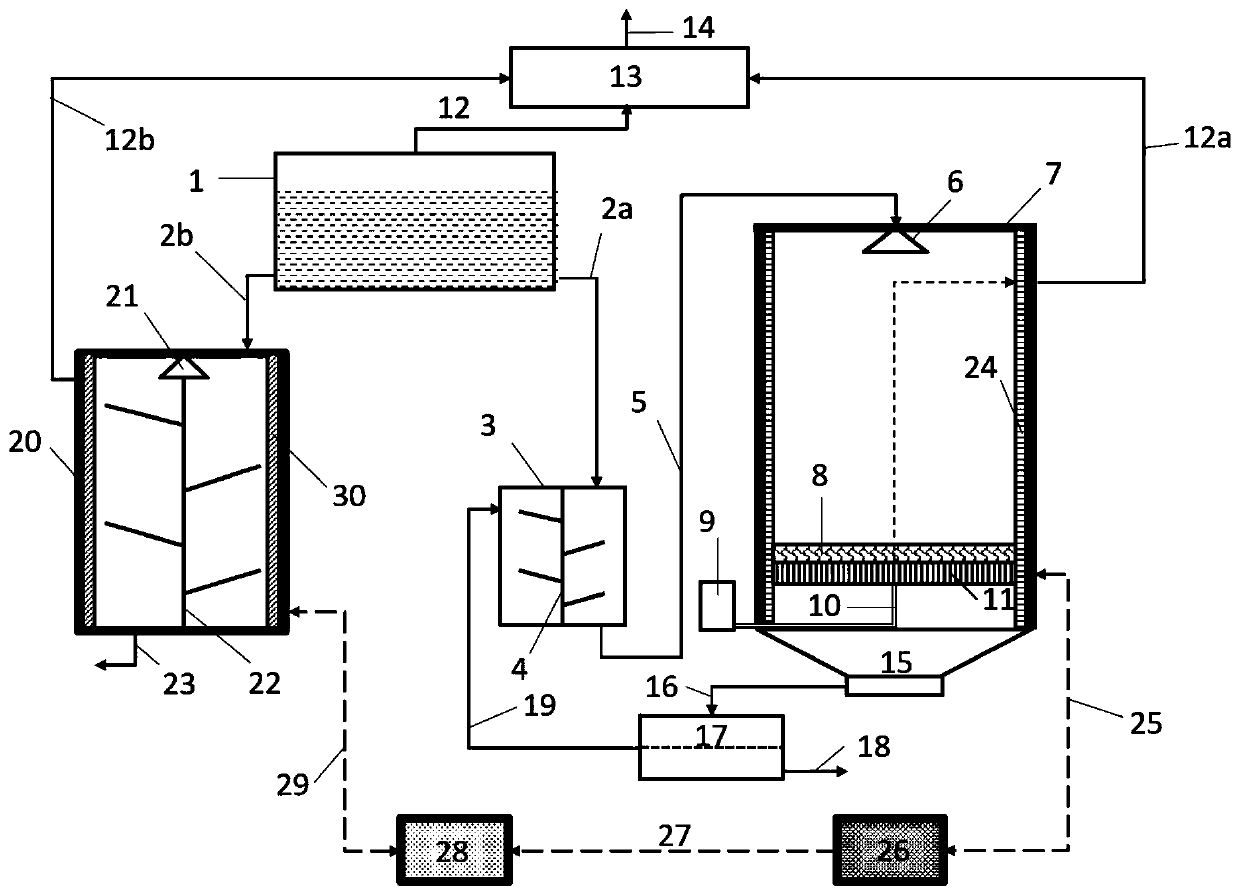

Self-sustaining smoldering and high-temperature aerobic fermentation composite disposal process and equipment for sludge

ActiveCN111425868AReduce energy consumptionIncrease processing rateBio-organic fraction processingClimate change adaptationSludgeEngineering

The invention discloses a self-sustaining smoldering and aerobic biological fermentation composite disposal process and equipment for sludge, belongs to related technical processes in the field of domestic waste disposal, and mainly aims at harmless resource disposal of the municipal sludge and other high-water-content low-calorific-value organic wastes. The self-sustaining smoldering and aerobicbiological fermentation composite disposal process for the sludge is characterized in that two disposal technologies of self-sustaining smoldering and aerobic fermentation composting are combined, sothat the sludge disposal capacity is improved, the energy consumption in the aerobic biological fermentation process is reduced and advantage complementation among the technologies is realized; and sludge ashes generated by smoldering and organic fertilizers generated by fermentation can be combined for use, so that the sludge disposal rate is increased, meanwhile, the energy consumption of a sludge disposal system is reduced, the biological fermentation period is shortened, and the diversity of sludge resource products is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

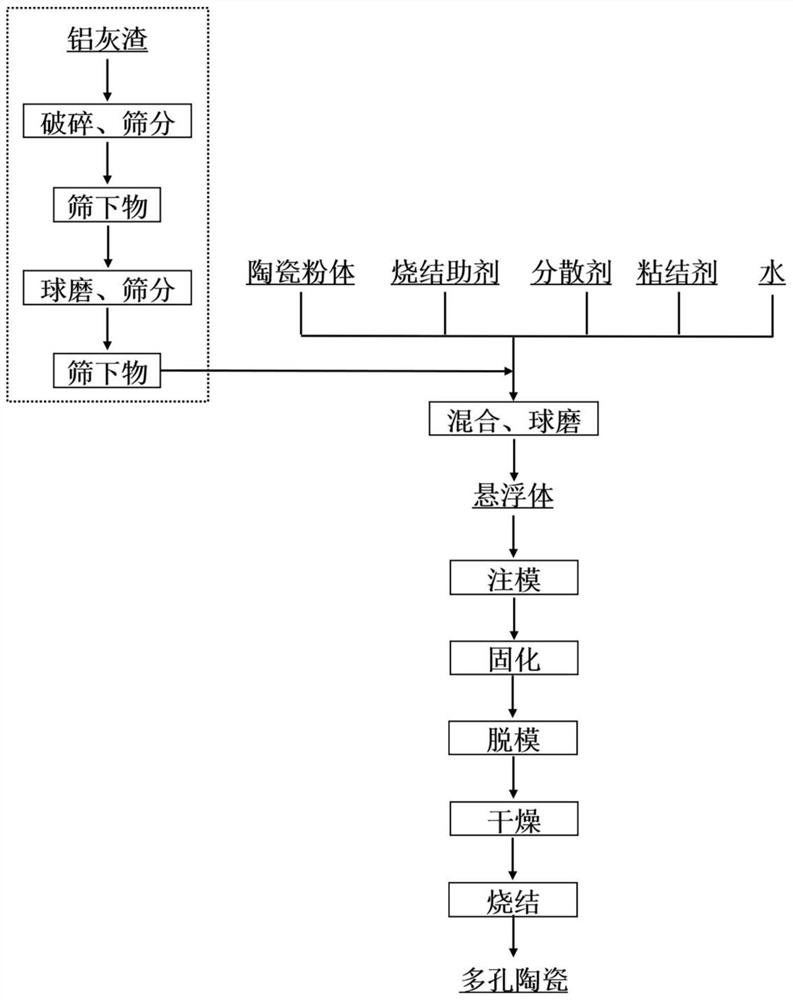

Method for preparing porous ceramic by in-situ curing molding of water-based slurry containing aluminum ash

ActiveCN113563102AAchieve in-situ curingAchieving a self-foaming joint effectCeramic materials productionCeramicwareAluminium hydroxideSlurry

The invention discloses a method for preparing porous ceramic through in-situ curing molding of water-based slurry containing aluminum ash, and belongs to the technical field of solid waste green treatment and resource utilization. The method comprises the following steps: adding a dispersing agent, a binder, a sintering aid and water into the aluminum ash or a mixture of the aluminum ash and ceramic powder, and uniformly mixing to obtain solid-liquid mixed phase slurry; heating and curing the slurry in a mold, demolding after molding, drying and sintering to obtain porous ceramic. In the curing process of the slurry, the material containing the Al component is subjected to hydrolysis reaction to play a dual role; aluminum hydroxide sol generated by the hydrolysis reaction fixes the ceramic particles in the raw material components in the aluminum hydroxide sol; gas generated by the reaction forms a porous structure in a green body, so that in-situ curing and self-foaming are realized. The method effectively solves the problems of green treatment and recycling of the aluminum ash by utilizing the component characteristics of the aluminum ash, and has the characteristics of low cost, simple process, high controllability, no need of expensive equipment and easiness in industrial production.

Owner:UNIV OF SCI & TECH BEIJING

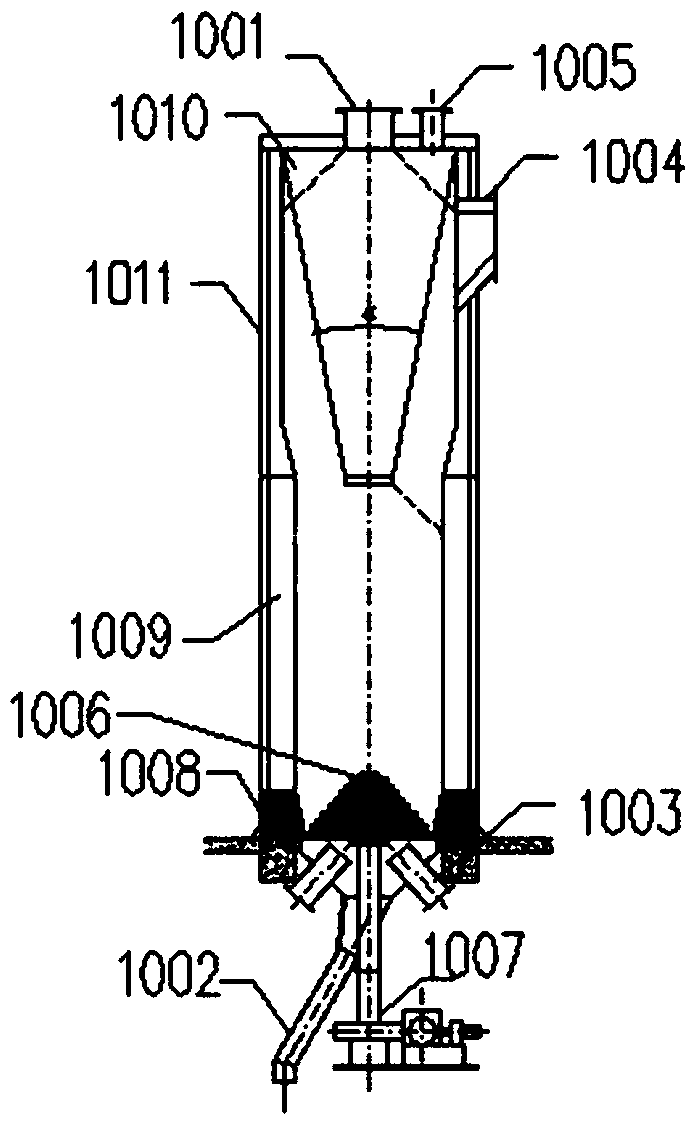

System and method for synergistic disposal of waste lithium ion batteries in cement kiln

PendingCN108772407AHarmlessRealize resource disposalSolid waste disposalTransportation and packagingDecompositionSlag

The present invention provides a system and a method for synergistic disposal of waste lithium ion batteries in a cement kiln. The system is based on the characteristics of substances contained in thewaste lithium ion batteries and aims at the problems existing in the prior art. The system includes a waste lithium ion battery storage device, an anhydrous and anaerobic biaxial crusher, a verticalpyrolysis furnace, a neutralization tower, a valuable element extraction system and a cement kiln system; the disposal method is as follows: classified pretreatment of the waste lithium ion batteries,anhydrous and anaerobic breakdown, evaporation decomposition sintering in the vertical pyrolysis furnace into solid mixed slag, and extracting of valuable elements from the solid mixed slag; neutralization of fluorine-containing and phosphorus-containing compound gases, high-temperature incineration of combustible waste gases in the cement kiln, and disposal of all waste residues, and clean production and environmental protection can be achieved. The system has simple device structure, can realize the maximum utilization of resources and energy in the whole system, and can realize the low cost recovery of the valuable elements by a simple method.

Owner:长沙中硅环保科技有限公司 +1

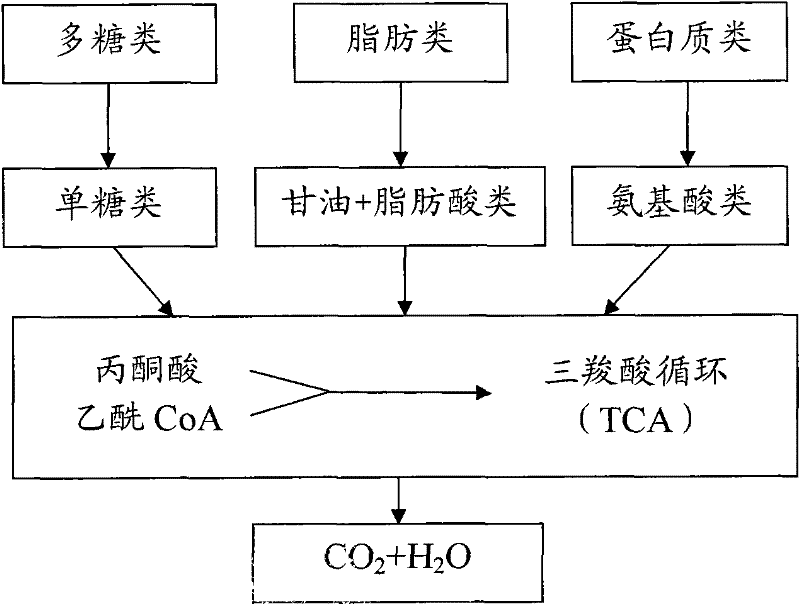

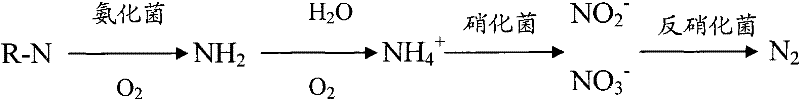

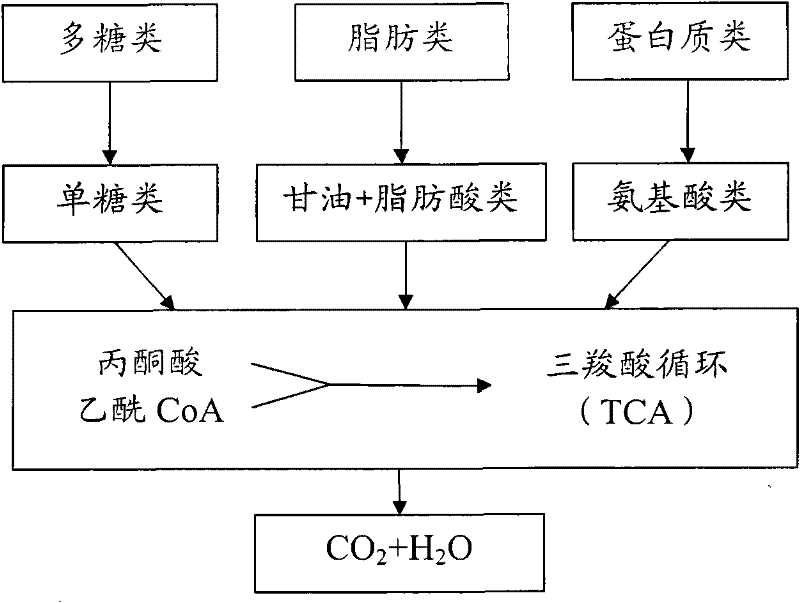

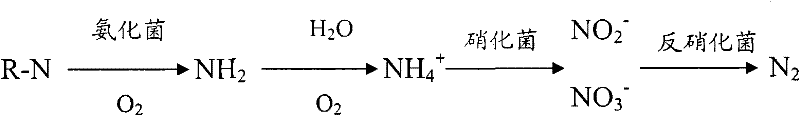

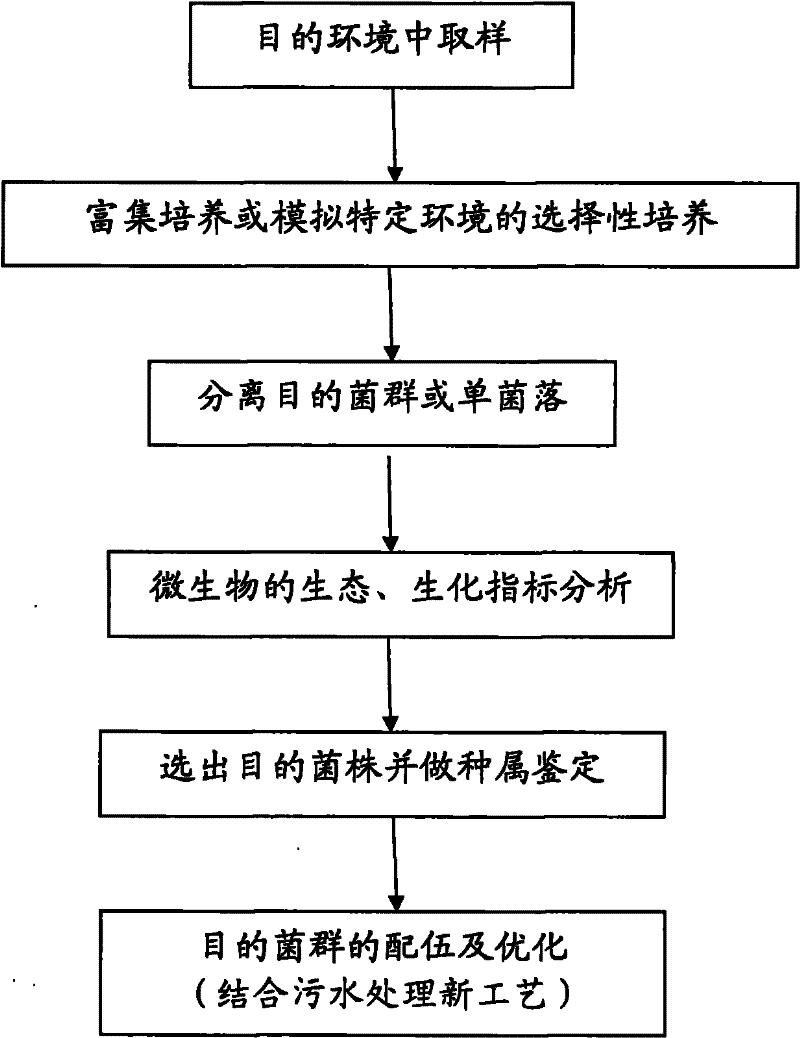

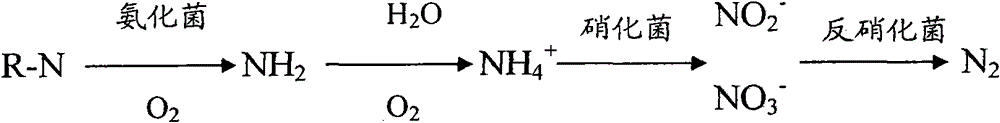

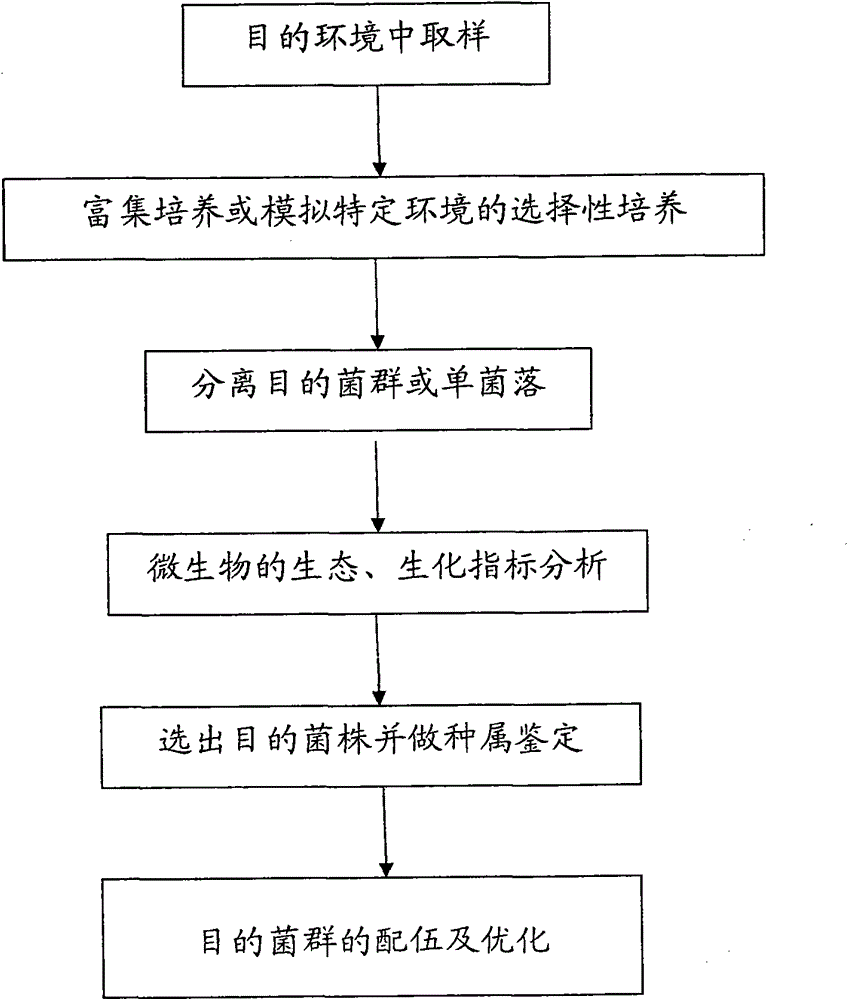

High-efficiency combined functional bacteria for sludge treatment

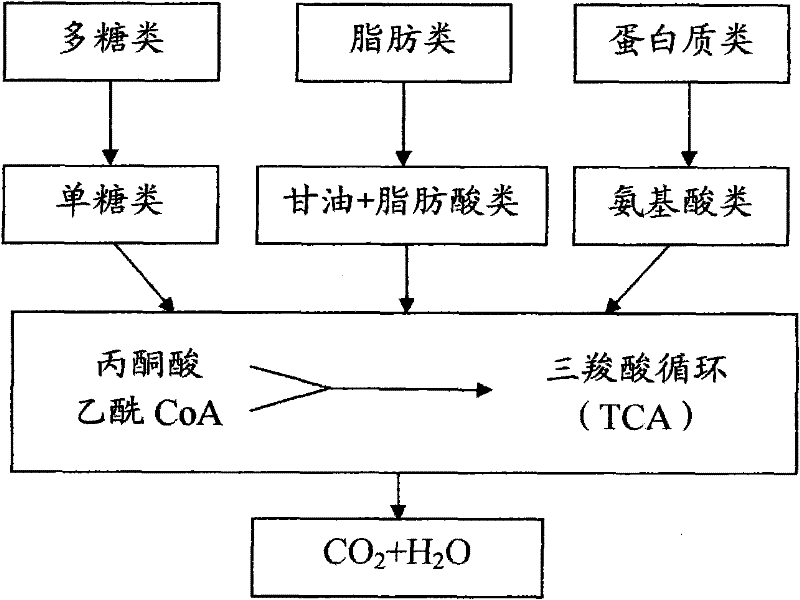

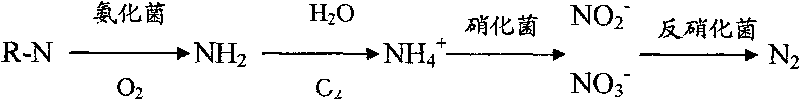

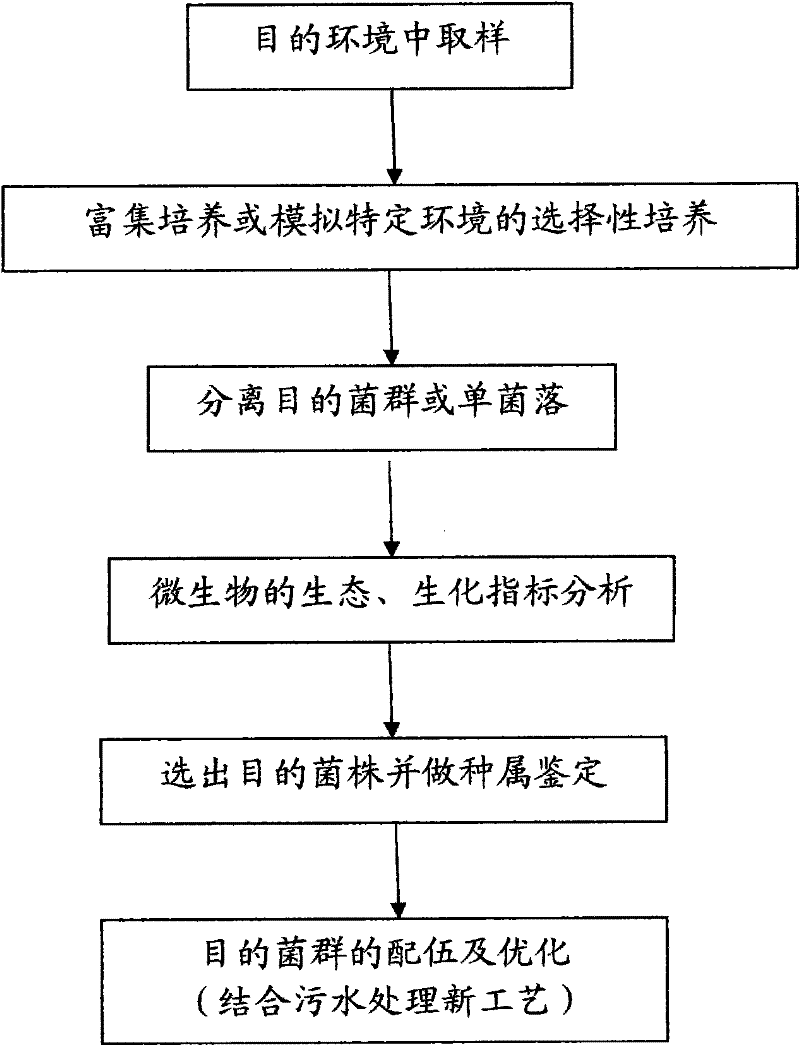

InactiveCN102234615AEmission reductionRealize ecologyBacteriaMicroorganism based processesBacillus licheniformisBacillus megaterium

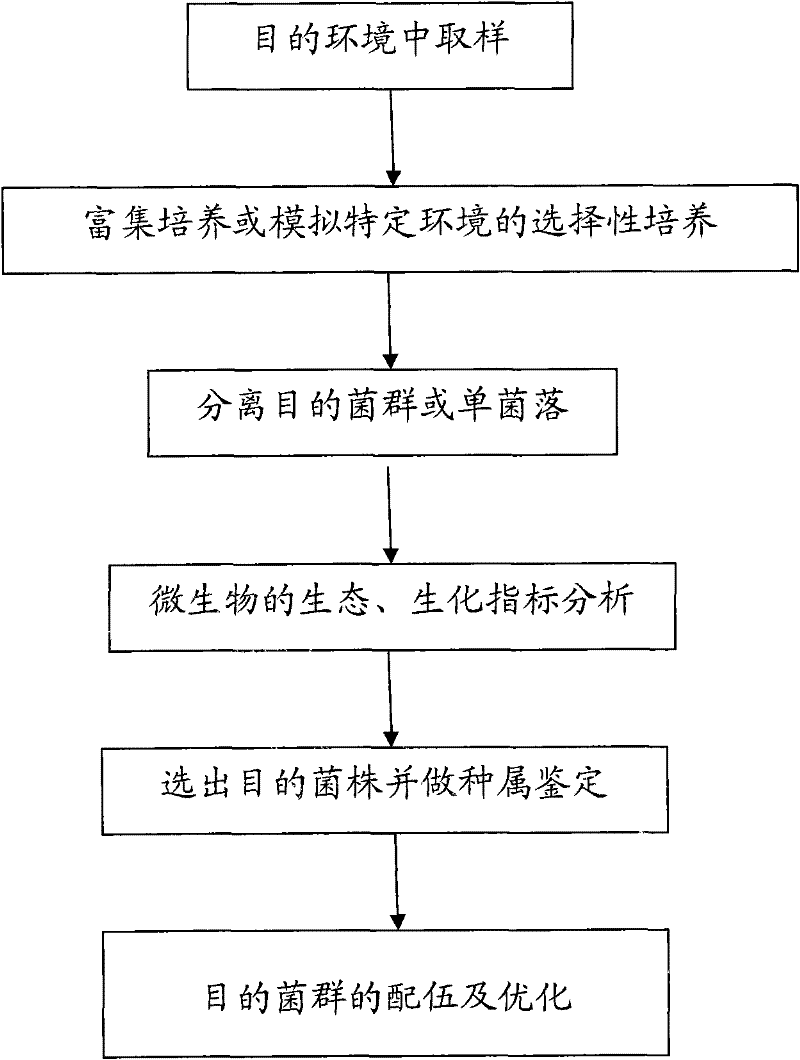

The invention discloses high-efficiency combined functional bacteria for sludge treatment. The high-efficiency combined functional bacteria comprise the following six microbes: bacillus licheniformis, bacillus subtilis, bacillus lentus, bacillus megaterium, bacillus thuringiensis and bacillus cereus. A culture method for the microbes comprises the following steps of: sampling; culturing in a culture medium; separating target strains; performing index analysis on the separated strains; identifying species; mixing; and optimizing. The functional bacteria are quick in multiplication and have obvious effect of removing phosphorus from sludge in the process of decomposing organic matters, so that the sludge treatment effect ensures that the sludge reaches the national emission standard, and the sludge discharge can be greatly reduced.

Owner:JIANGSU TONGREN ENVIRONMENTAL PROTECTION TECH

Combined treatment process of copper smelting electric dust acid leaching solution and arsenic sulfide slag

InactiveCN109055759ARealize resource disposalSolve processing problemsPhotography auxillary processesProcess efficiency improvementVulcanizationSlag

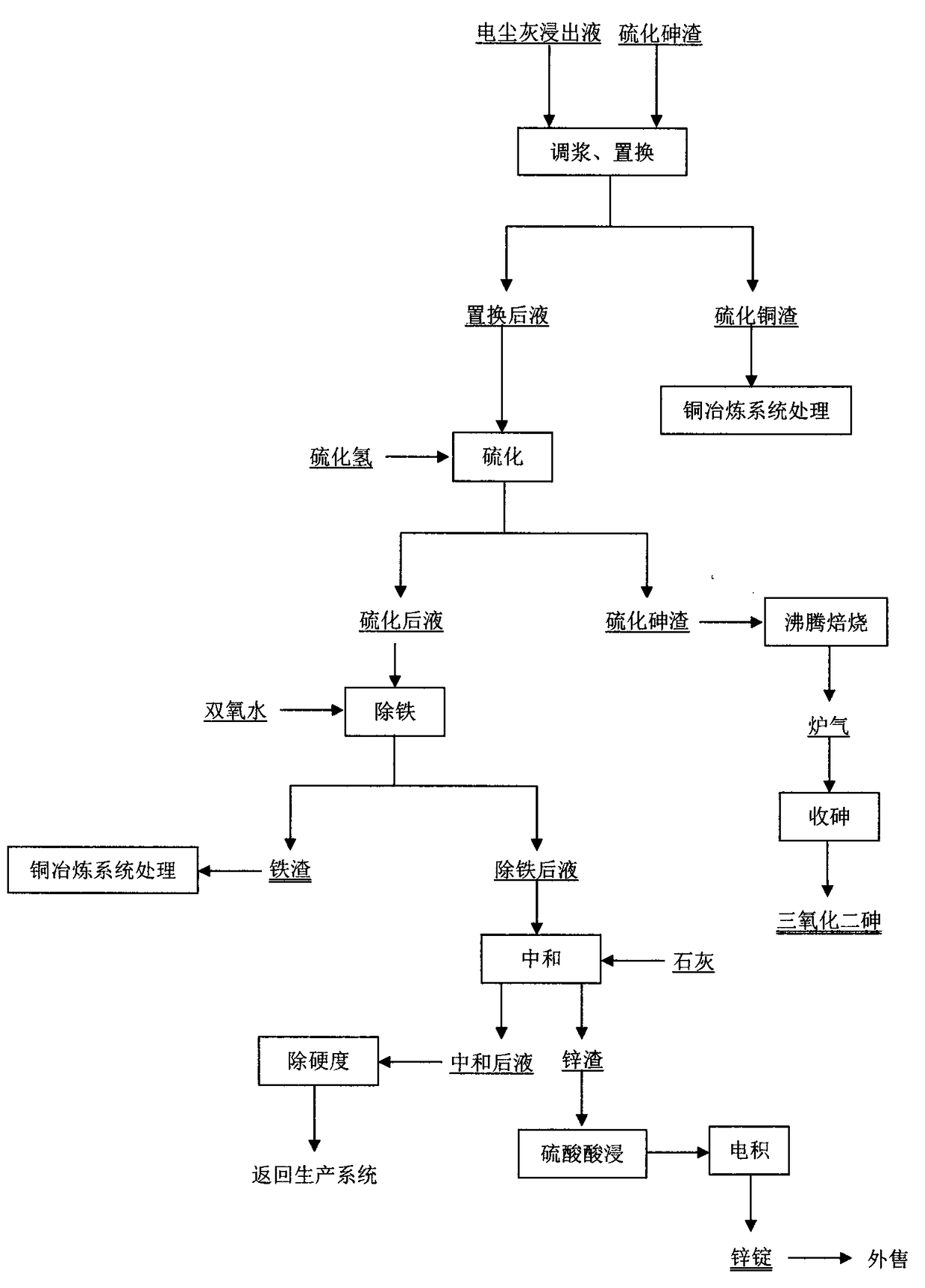

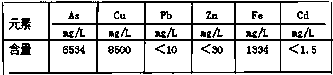

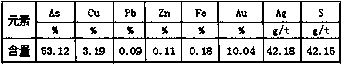

The invention provides a combined treatment process of a copper smelting electric dust acid leaching solution and arsenic sulfide slag. The process comprises the following process steps that the arsenic sulfide slag is subjected to copper smelting electric dust acid leaching liquid blending, and replacement to obtain an after-replacement solution and the copper sulfide slag, the copper sulfide slag returns to a copper smelting system for treatment, the after-replacement solution is subjected to vulcanization to obtain the arsenic sulfide slag and a vulcanized solution, the arsenic sulfide slagis subjected to two-stage roasting and furnace gas collecting arsenic to produce arsenic trioxide products for selling, after the vulcanized solution is subjected to oxidation iron removal and zinc extraction, the iron slag is produced for selling, and the after-neutralizing solution returns to a production system for reuse after the hardness removal, and zinc slag is subjected to sulfuric acid leaching and electrodeposition process to produce zinc ingots. According to the process, the process flow is simple, indexes are easy to control, the closed cycle is realized, no three wastes are discharged, the arsenic in the treated vulcanized liquid is less than 0.15 mg / L, the copper in the treated vulcanized liquid is less than 0.01 mg / L, the treatment problem of the arsenic sulfide slag can beeffectively solved, and resource treatment of arsenic, copper, iron and zinc is realized so as to realize using waste to treat waste.

Owner:SHANDONG HUMON SMELTING

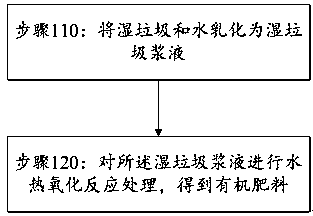

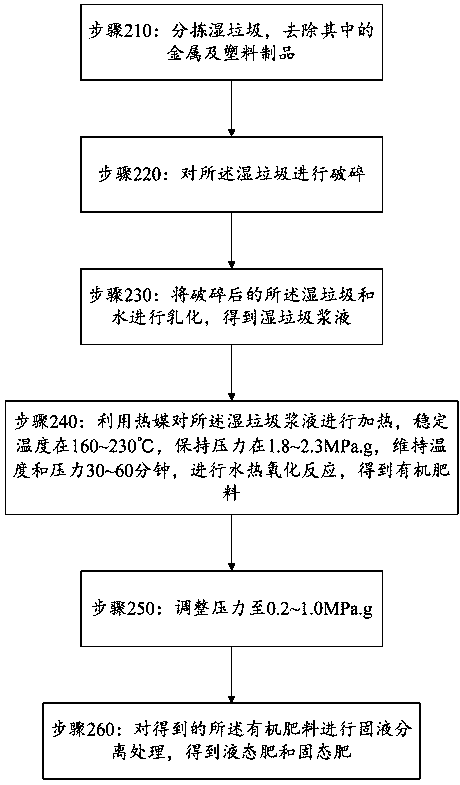

Wet garbage treatment method and system

InactiveCN110759756ARealize resource disposalClimate change adaptationOrganic fertilisersEnvironmental chemistryRefuse Disposals

Embodiments of the invention disclose a wet garbage treatment method and a system. The wet garbage treatment method comprises the steps: emulsifying wet garbage and water, so as to obtain wet garbageslurry; and subjecting the wet garbage slurry to hydrothermal oxidation reaction treatment, thereby obtaining an organic fertilizer. Thus, the wet garbage is converted into the organic fertilizer, andthe resource-converting treatment of the garbage is achieved.

Owner:上海臻漫环保设备有限公司

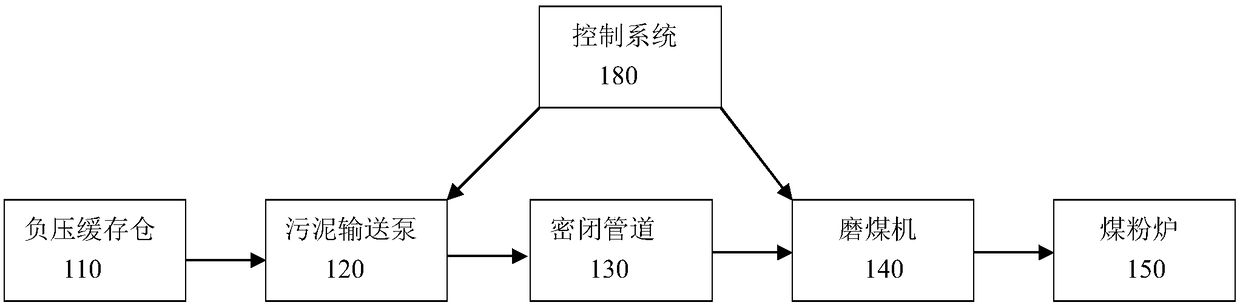

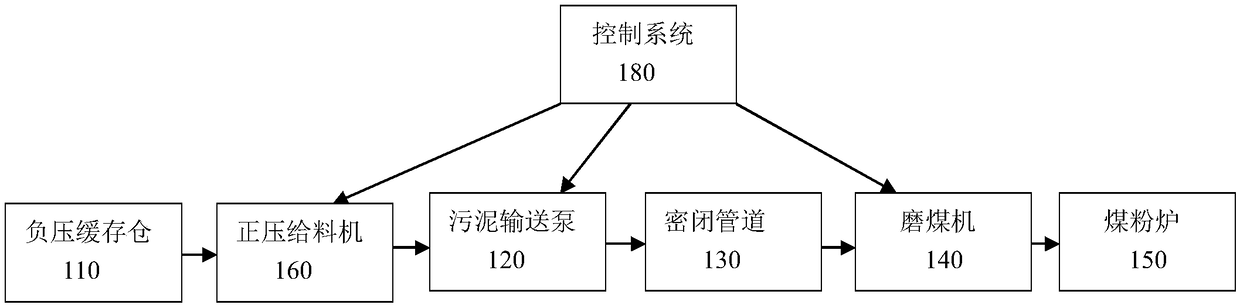

Environment-friendly method for directly mix-burning sludge in pulverized coal furnace

PendingCN108395072AAchieve reductionHarmlessSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeControl system

The invention provides an environmental-friendly method for directly mix-burning sludge in a pulverized coal furnace. The method is characterized by directly inputting the sludge into a coal mill through a pumping manner, mixing with fire coal, drying, powdering, and feeding into the pulverized coal furnace for mix-burning for generating power. A negative pressure caching bin, a sludge conveying pump, an airtight pipeline, the coal mill, the pulverized coal furnace and a control system connected sequentially are arranged corresponding to the mix-burning system; the negative pressure caching bin is used for caching sludge; the sludge conveying pump directly conveys the sludge to the coal mill through the airtight pipeline; the sludge has no need to be specially dried or dewatered before entering the coal mill; the coal mill is used for mixing, drying and powdering the sludge and the fire coal conveying into the coal mill; the sludge and powdered granulated mixtures of the fired coal areconveyed to the pulverized coal furnace so as to be used for burning and generating power. The method provided by the invention can be used for treating the sludge in a reduction, harmless and recycling way, is simple, convenient, efficient and low in energy consumption, and meets the emission standards; a sludge pumping room and pipelines are arranged flexibly and compactly and are less in investment.

Owner:光大清洁技术股份有限公司

A New Chromatographic Carrier Device for the Degradation Treatment of Urban Sewage by Functional Bacteria

InactiveCN102267761AEmission reductionRealize ecologyTreatment with aerobic and anaerobic processesBiofilmSludge

The invention discloses a new chromatographic carrier device for the degradation treatment of functional bacteria in urban sewage, including a soft carrier for adsorbing functional bacteria, a carrier bracket supporting the soft carrier, and a high-efficiency biochemical device for accommodating the soft carrier and the carrier bracket. pool, the soft carrier is absorbed by functional bacteria to form a biofilm structure composed of aerobic zone, facultative zone and anaerobic zone, in which the layer of microorganisms close to the surface area of the carrier forms an anaerobic zone, and the middle layer is shallow The outer layer of the carrier forms an aerobic zone. The chromatographic carrier device of the present invention combines high-efficiency functional microbial flora, so that the treatment effect of sewage can reach the national discharge standard, and the amount of sludge discharge can be greatly reduced.

Owner:姚维华

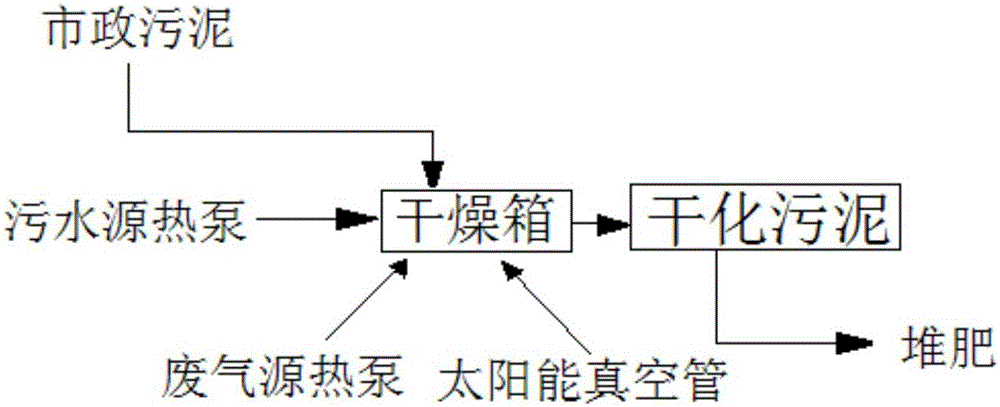

Municipal sludge treatment method and heat pump and solar energy coupling system for implementing method

InactiveCN106007285AGood economic valueRealize resource disposalSolar heating energyBio-organic fraction processingSludgeEnergy coupling

The invention relates to the field of municipal sludge drying, in particular to a municipal sludge treatment method and a heat pump and solar energy coupling system for implementing the method. The municipal sludge treatment method comprises the steps that municipal sludge is dried, wherein heat used for drying comes from heat, collected by a wastewater source heat pump, of wastewater, heat collected by a gas source heat pump after waste gas generated in the wastewater treatment process is heated with solar energy and heat collected by solar vacuum pipes; the sludge is dried until the water content is 68-72%, closed fermentation is carried out, and fertilizer is obtained. The invention further provides the heat pump and solar energy coupling system for implementing the method. According to the municipal sludge treatment method and the heat pump and solar energy coupling system for implementing the method, energy is generated with the resources in a wastewater plant and solar energy, dried sludge is composted and turned into wealth, the obtained fertilizer is inorganic fertilizer and can be widely applied, and remarkable economic value is achieved.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of composite flocculant

InactiveCN104828922AReduce turbidityImprove processing efficiencyWater/sewage treatment by flocculation/precipitationAluminium chlorideMeth-

The invention discloses a preparation method of a composite flocculant. The composite flocculant comprises crystalized aluminum chloride, sulfuric acid, sodium hydrogen sulfite, amine persulfate, acrylamide and N, N-dimethyl-N- octadecyl benzemethanaminium chloride and octadecyl trimethyl ammonium chloride and MMH. The raw materials are subjected to ternary starch graft copolymer synthesis and crushed to obtain the composite flocculant. When the composite flocculant is matched with an existing sewage treatment system, sewage treatment effect can reach notational emission standards, sludge emission is reduced greatly, ecologicalization, reduction and recycling treatment of city industry and domestic sewage is achieved.

Owner:谢秋鸿

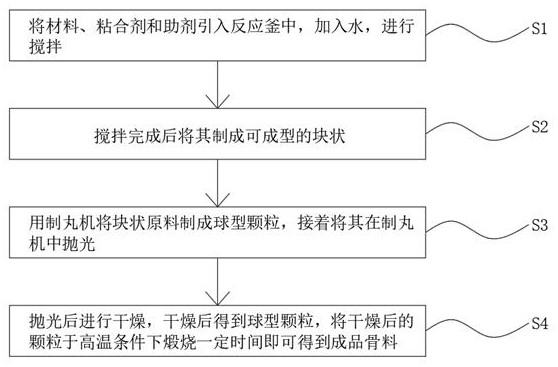

Preparation method of 3D printing building material aggregate

ActiveCN111635156ASolve the scaleSolve high valueAdditive manufacturing apparatusAdhesiveArchitectural engineering

The invention discloses a preparation method of 3D printing building material aggregate. The preparation method comprises the following steps: S1, introducing a material, an adhesive and an assistantinto a reaction kettle, adding water, and stirring; S2, after stirring is completed, manufacturing the mixture into a moldable block; S3, preparing the blocky raw materials into spherical particles byusing a pill making machine, and then polishing the spherical particles in the pill making machine; S4, drying after polishing, drying to obtain spherical particles; calcining the dried particles fora certain time under a high-temperature condition to obtain a finished product aggregate; the structure is scientific and reasonable, the preparation method of the 3D printing building material aggregate is simple, safe and convenient to use, a new preparation scheme of the 3D printing building material aggregate is provided, a new choice is provided for 3D printing building materials, solid waste is recycled, and large-scale, high-valued and resourceful treatment of the solid waste is achieved.

Owner:SHANGHAI RUIHUI ENVIRONMENTAL PROTECTION TECH

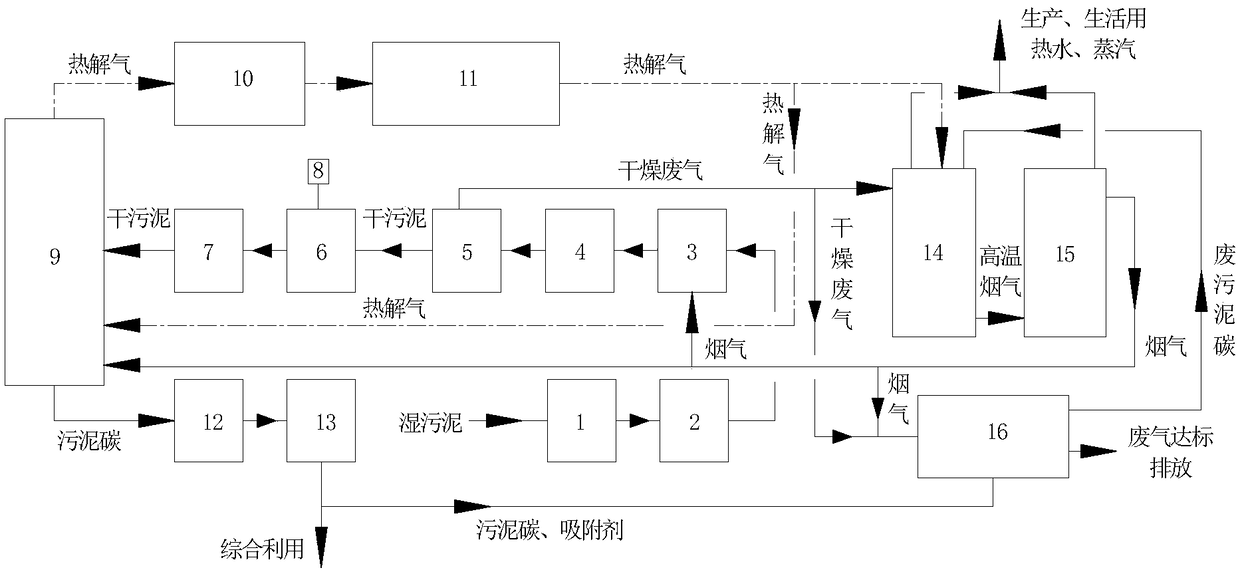

Comprehensive utilization device and method for sludge

InactiveCN108640471AAvoid secondary pollutionReduce consumptionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeEngineering

The invention provides a comprehensive utilization device for sludge. The comprehensive utilization device for sludge is utilized for sludge treatment, no pollutants are discharged in the overall process of the sludge treatment, so that the problem of secondary pollution of an existing sludge treatment technology is solved, and a new clean and environment-friendly sludge recycling treatment technology is provided; the sludge as a renewable resource is taken as a raw material for producing pyrolysis gas, gas fuel is provided for industrial production and can replace existing non-renewable fossil fuel such as coal, petroleum and the like, and the production cost of an enterprise is reduced while resource consumption is reduced; safe, harmless, clean and recycling treatment of the sludge is realized.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

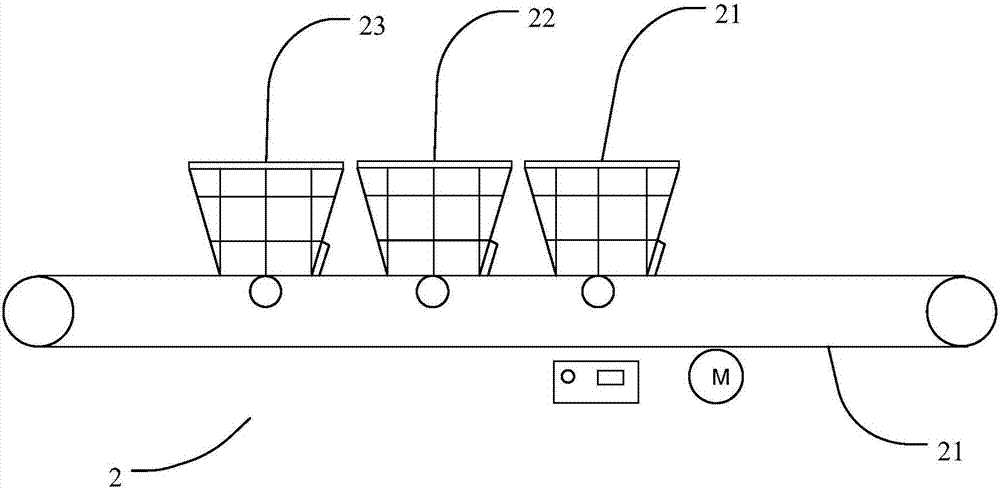

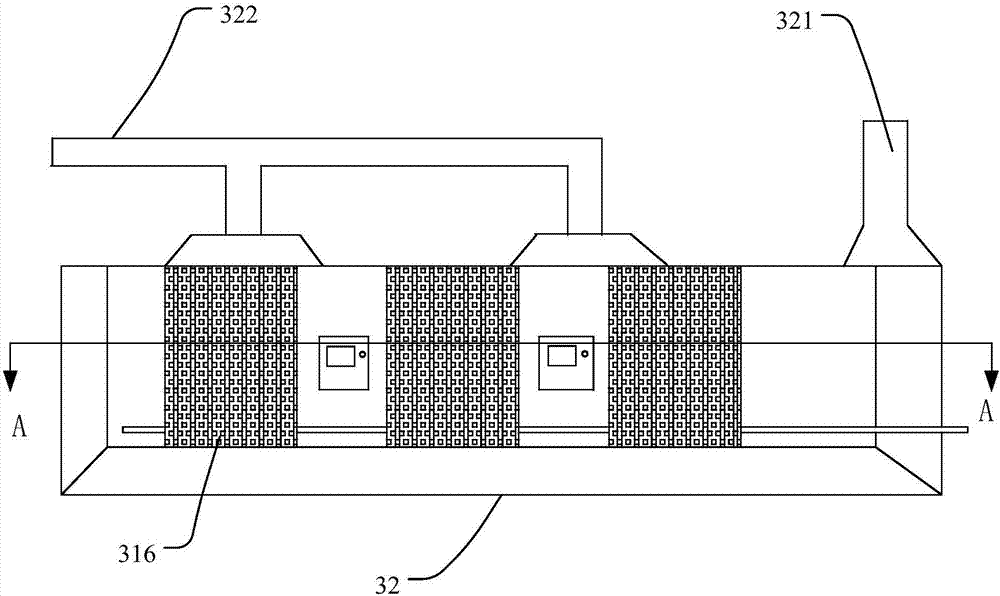

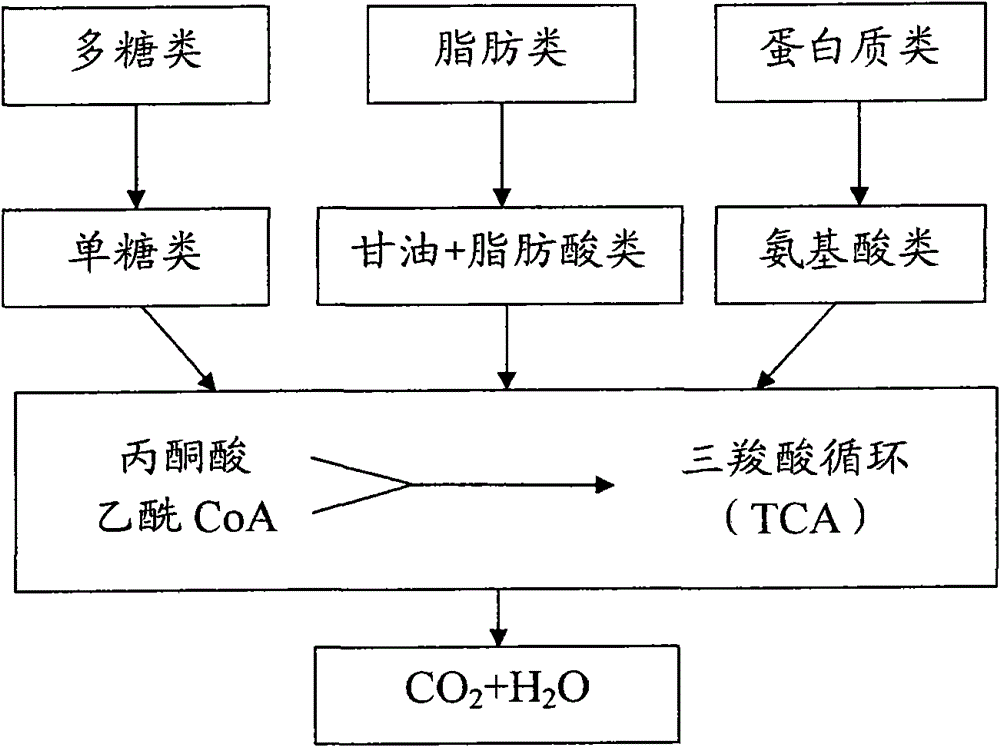

Resourceful treatment system and method for anaerobic fermentation biogas residues

InactiveCN113620732AConducive to environmental protection and sustainable developmentReduce processing timeBio-organic fraction processingMethane capturePhysicsBiogas

The invention discloses a resourceful treatment system and method for anaerobic fermentation biogas residues. The resourceful treatment system comprises a solar greenhouse, a solar heat collector, a mixer, a biological drying bed, a material conveying belt, a fermentation bed and a drying device, a mixer, a biological drying bed, a material conveying belt, a fermentation bed and a drying device are arranged in the solar greenhouse, and a solar heat collector is arranged at the upper part of the solar greenhouse; the solar heat collector is respectively connected with the biological drying bed and the lower part of the fermentation bed through a circulating pump, and the biological drying bed and the lower part of the fermentation bed are respectively connected with the solar heat collector through the drying device to form a circulating loop; the mixer is connected with the biological drying bed and is used for drying materials; the biological drying bed is connected with the fermentation bed through a material conveying belt and is used for fermenting dried materials; and a biological filter is connected with the drying device and is used for treating secondary pollution odor and condensate water in the solar greenhouse. According to the invention, the resource treatment of the anaerobic fermentation biogas residue is realized, and the sustainable development is facilitated.

Owner:CHINA TIANYING +1

Novel chromatographic carrier reactor for sewage disposal

InactiveCN102211812AEmission reductionRealize ecologyTreatment with aerobic and anaerobic processesSludgeSewage treatment

The invention discloses a novel reactor chromatographic carrier for sewage disposal, comprising a flexible carrier for absorbing functional bacteria, a carrier support for supporting the flexible carrier and a high-efficiency biochemical basin for containing the flexible carrier and the carrier support; after the flexible carrier absorbs the functional bacteria, a biomembrane structure consisting of an aerobic zone, a faculative zone and an anaerobic zone is formed on the flexible carrier, wherein the anaerobic zone is formed by the layer of microorganisms tightly close to the surface of the carrier, the middle layer is the superficial layer faculative zone, and the aerobic zone is formed on the outer layer of the carrier. The novel chromatographic carrier reactor for sewage disposal is combined with the high-efficiency functional microorganism flora so that the sewage disposal effect can reach the sewage discharging standard in China and the discharge of sludge is greatly reduced.

Owner:JIANGSU AIDONG GROUP

Enrichment purification method of SO2 in flue gas

InactiveCN103288057ALow concentration of effluxRealize resource disposalDispersed particle separationSulfur compoundsPurification methodsFlue gas

The invention discloses an enrichment purification method of SO2 in flue gas. The method is characterized by comprising the technique steps of: SO2 in the flue gas is absorbed and desulfurized by a macromolecular organic absorbent, the pregnant solution resolves when the absorption liquid enriches to certain concentration, and the resolved and purified SO2 can be used for producing sulfuric acid or liquid sulfur dioxide; when the SO2 is resolved, such impurity ions as SO42 in the macromolecular organic absorbent enriches to certain concentration to affect the absorption of the SO2, the impurity ions are filtered and removed through an ion exchange membrane, and the purified macromolecular organic absorbent is recycled in the procedures. The method is capable of comprehensively utilizing the resources, simple to allocate equipment, stable to operate, convenient to control and capable of lowering the production cost, the absorbent can be recycled, and the emission concentration of the tail gas SO2 is much lower than that of the national standard.

Owner:SHANDONG HUMON SMELTING

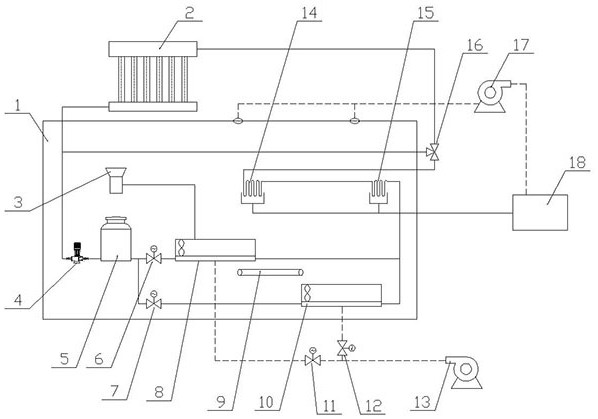

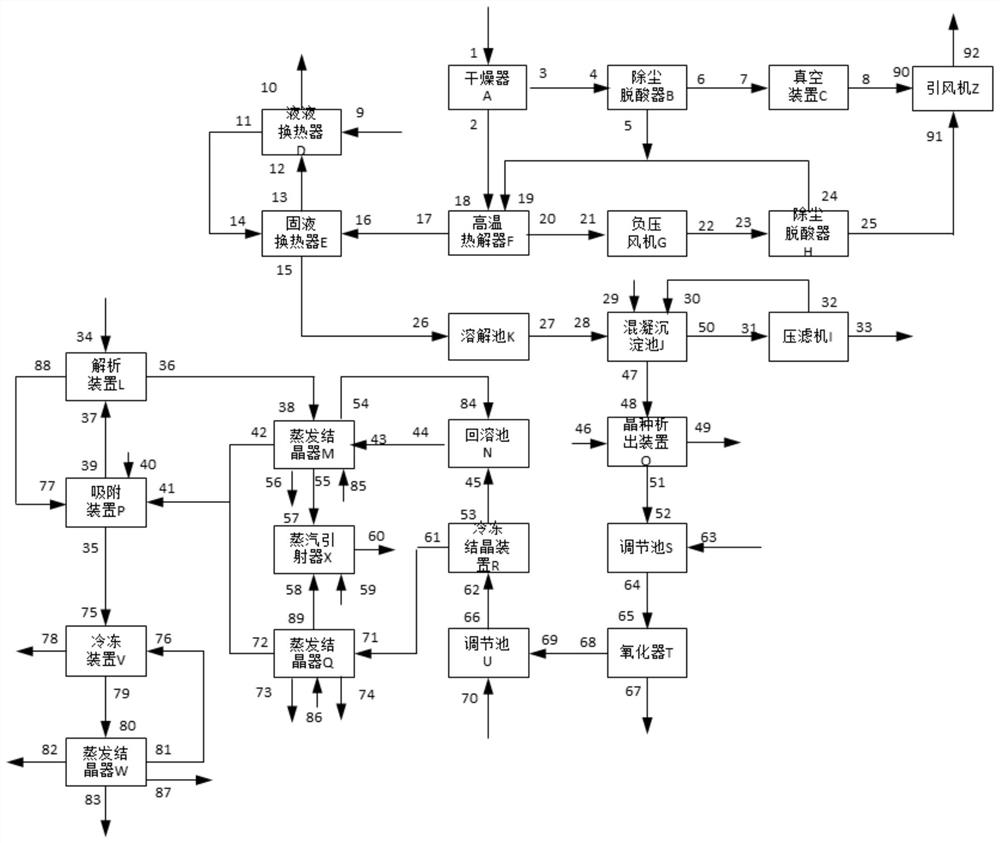

Waste salt recycling system and method based on thermal power plant energy saving and environment protection integration

PendingCN111672879AReduce disposal costsRealize secondary recyclingAlkali metal sulfites/sulfates preparation formDispersed particle filtrationDust controlFilter press

The invention relates to a waste salt recycling system and method based on thermal power plant energy saving and environment protection integration. The system comprises a dryer A, a dust removal deacidification device B, a vacuum device C, a liquid-liquid heat exchanger D, a solid-liquid heat exchanger E, a high-temperature pyrolyzer F, a negative-pressure draught fan G, a dust removal deacidification device H, a dissolving pond K, a coagulative precipitation tank J, a filter press I, a seed crystal precipitation device O, an adjusting pond S, an oxidizer T, an adjusting pond U, a freezing crystallization device R, a re-dissolution pond N, an evaporation crystallizer M, a steam ejector X, an evaporation crystallizer Q, a resolver L, an adsorption device P, a freezing device V, an evaporation crystallizer W and an induced draft fan Z. Harmful and recycling treatment of danger waste salt generated during industrial production can be achieved on the basis of energy gradient utilization and waste heat recycling thermotechnical processes, accompanying dioxin, danger waste smoke and other secondary pollution are eliminated, and the danger waste salt recycling treatment effective runningenergy consumption and danger waste salt treatment cost are obviously reduced.

Owner:北京赫宸智慧能源科技股份有限公司 +3

Environment-friendly sewage treating agent

InactiveCN105776407AEasy to handleEfficient separationWater contaminantsWater/sewage treatment by flocculation/precipitationTherapeutic effectPollution

The invention discloses an environment-friendly sewage treating agent which is prepared from the following components: polyepoxysuccinic acid, tetrabutyl titanate, polysilicate ferric chloride, acidized silver-loaded active carbon, 2,6-xylenol, organic amine, polyaspartic acid, kaolin, soluble metal salt and a dispersing agent. The provided treating agent is high in adsorption capacity, stable in heavy metal adsorption and free of secondary pollution, has high speed and good adsorption, flocculation and treatment effects, can meet the discharging standard, is stable in treating effect and is environment-friendly and non-toxic.

Owner:SUZHOU NENGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

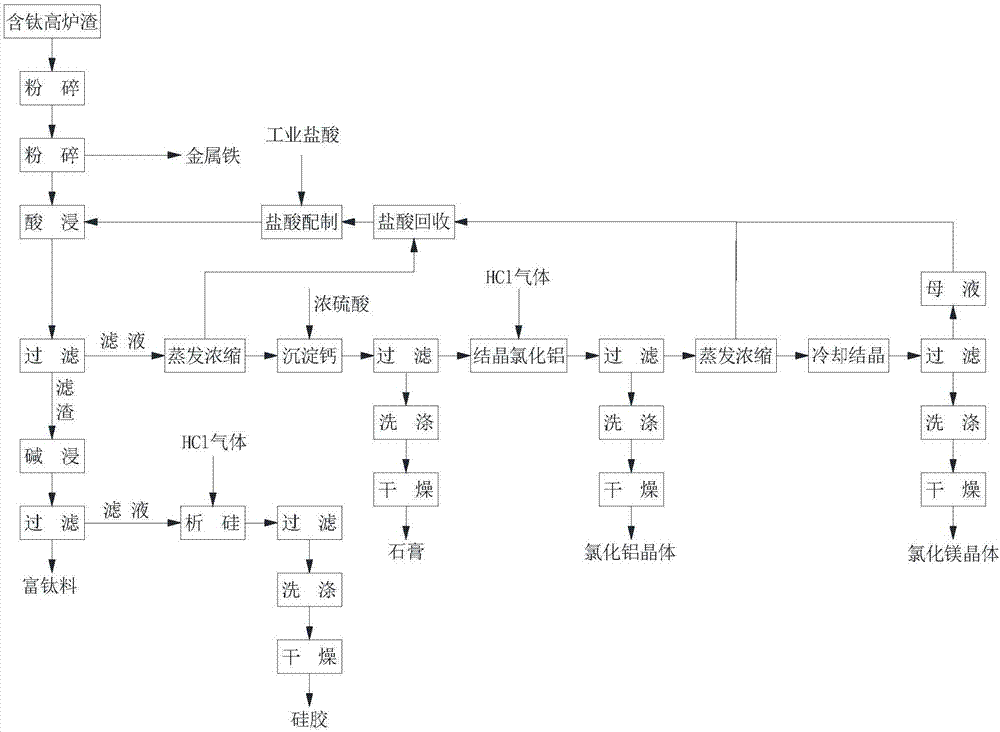

Resource treatment method of titanium-bearing blast furnace slag and rich-titanium material acquiring method

InactiveCN107354252AReduce acid consumptionReduce concentrationSilicaMagnesium chloridesMineral SourcesSlag

The invention discloses a method for gathering TiO2 in titanium-bearing blast furnace slag and a resource treatment method of the titanium-bearing blast furnace slag and belongs to the technical field of comprehensive utilization of mineral resources. The method is implemented specifically according to the following steps that the titanium-bearing blast furnace slag is smashed to be 150-250 [mu]m, magnetic separation is conducted to remove iron, and blast furnace slag powder is obtained; the blast furnace slag powder is added into a hydrochloric acid solution with the concentration being 18-22% according to the solid-liquid rate of 1:2.5-3.5, the mixture is leached for 3.5-4 hours at the temperature of 85-92 DEG C and then filtered, and filtrate and acid-leaching filter residues are obtained; and the acid-leaching filter residues are added into a NaOH solution according to the solid-liquid rate of 1:1.0-1.5, the mixture is subjected to a reaction for 2-3 hours at the heating temperature of 48-55 DEG C and then filtered, filter residues are separated out, and the filter residues are a rich-titanium material. According to the method, titanium in the titanium-bearing blast furnace slag is gathered through an acid and alkali combined technology with high efficiency, low pollution and small acid consumption, the rich-titanium material with the high titanium content is prepared, and meanwhile other products are prepared.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Micro-porous sludge water-retaining nutrient polymer and preparation method thereof

PendingCN110002915AHarmlessAchieve stabilizationSewage/sludge fertilisersFertiliser formsCelluloseDewatered sludge

The invention belongs to the technical field of comprehensive utilization of solid wastes, and concretely relates to a micro-porous sludge water-retaining nutrient polymer and a preparation method thereof. The micro-porous sludge water-retaining nutrient polymer comprises an inner layer efficient water-retaining humus nutrient base solution and an outer layer micro-porous sludge solidification block. The preparation method of the micro-porous sludge water-retaining nutrient polymer comprises the following steps: 1, celluloses in wood processing residues are extracted and modified to obtain sodium carboxymethylcellulose; 2, humic acid in weathered coal is extracted and modified; 3, an efficient water-retaining humus base solution is prepared; 4, the efficient water-retaining humus nutrientbase solution is prepared; 5, the outer layer micro-porous sludge solidification block is prepared; and 6, the prepared efficient water-retaining humus nutrient base solution is poured into the curedmicro-porous sludge solidification block. Dewatered sludge, processing residues of woods such as barks and branches, weathered coal, fly ash and other materials are combined by physical and chemical processes to prepare the efficient water-retaining nutrient polymer in order to achieve the purpose of treating wastes with wastes.

Owner:TAIYUAN UNIV OF TECH

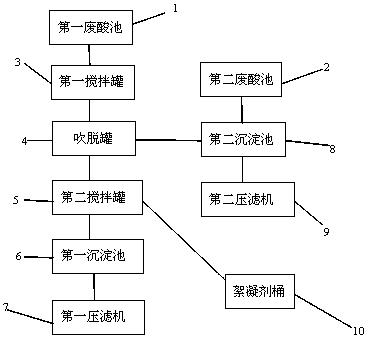

Acidic wastewater treatment system and technological method

ActiveCN107777802ASmall footprintLarge amount of processingWaste water treatment from metallurgical processMultistage water/sewage treatmentAluminum IonSludge

The invention discloses an acidic wastewater treatment system and an acidic wastewater treatment technological method. The acidity is reduced by adding a natural mineral material, the pH is adjusted by adding alkali, and aluminum ions are produced into aluminum hydroxide; while the acidity is reduced, calcium in the natural mineral material is converted into calcium ions and the calcium ions reactwith sulfuric acid or phosphoric acid in waste acid to produce calcium sulfate or calcium phosphate; the aluminum hydroxide, the calcium sulfate and the calcium phosphate are recycled; the acidic wastewater treatment system occupies a small floor area, has a large treatment amount and saves the civil engineering cost and the equipment investment cost; by the acidic wastewater treatment technological method, the amount of produced sludge is small, and huge waste as well as formation of a large amount of waste slag, which are caused by underutilization of lime are avoided; by the acidic wastewater treatment technological method, the aluminum hydroxide, the calcium sulfate and the calcium phosphate can be recycled, resource disposal of wastewater is achieved, formation of secondary pollutionis avoided, and the environment-friendly effect is outstanding.

Owner:SHANGHAI JIANGZHE ENVIRONMENT ENG TECH CO LTD

A method for preparing magnetic biochar from traditional Chinese medicine residue, magnetic biochar and application

ActiveCN107096500BRealize resource disposalSolve the problem of low added valueOther chemical processesWater contaminantsBiochemical engineeringEconomic benefits

The invention discloses a method for preparing magnetic biological carbon by utilizing traditional Chinese medicine residues, the magnetic biological carbon and application thereof and belongs to the field of biomass resource utilization. The method comprises the following steps: after impregnation pretreatment of the traditional Chinese medicine residues and sodium carbonate, performing ion salt impregnation and high-temperature anaerobic activation, washing, drying and the like to obtain the magnetic biological carbon. The method has the characteristics of being simple in production process, highly available in raw materials, high in product solid-liquid efficiency and the like. The method disclosed by the invention realizes the resource of the traditional Chinese medicine residues, has great significances in expanding the use of wastes extracted from the traditional Chinese medicines and expanding the source and the application scope of biological carbon adsorbents and can be widely applied to the water treatment field, thereby having good economic benefits and social benefits.

Owner:CHINA PHARM UNIV

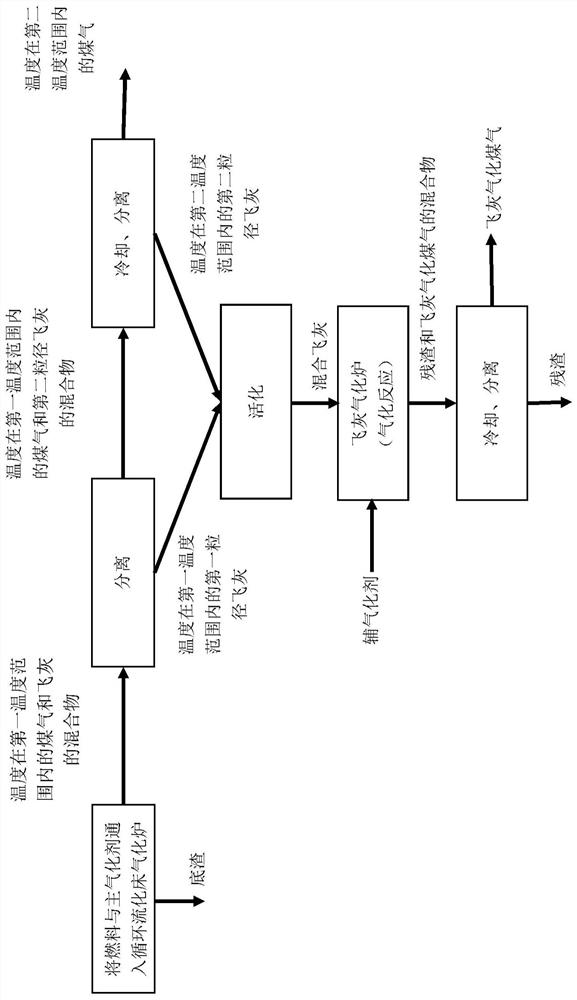

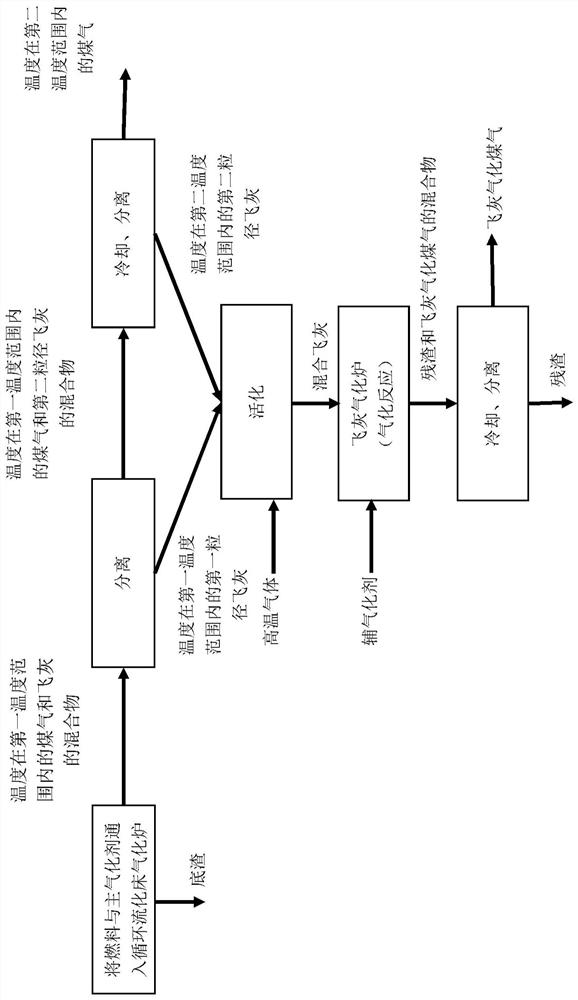

Gasification method and system with fly ash regasification

ActiveCN113462434AEnables direct disposalSimplified coolingGranular/pulverulent flues gasificationFuel gasificationFluidized bed

The invention relates to the technical field of fuel gasification, in particular to a gasification method and system with fly ash regasification. The gasification method with fly ash regasification comprises the following steps: introducing fuel and a main gasification agent into a circulating fluidized bed gasification furnace for gasification reaction to generate a mixture of coal gas and fly ash with the temperature within a first temperature range; separating the mixture of the coal gas and the fly ash within the first temperature range to obtain fly ash with a first particle size within the first temperature range and a mixture of the coal gas and the fly ash with a second particle size within the first temperature range; introducing a mixture of the coal gas with the temperature within the first temperature range and the fly ash with the second particle size into a main cooling dust removal system to be cooled and separated, and obtaining the coal gas with the temperature within the second temperature range and the fly ash with the second particle size within the second temperature range; and introducing the first particle size fly ash with the temperature within the first temperature range and the second particle size fly ash with the temperature within the second temperature range into a fly ash activator.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

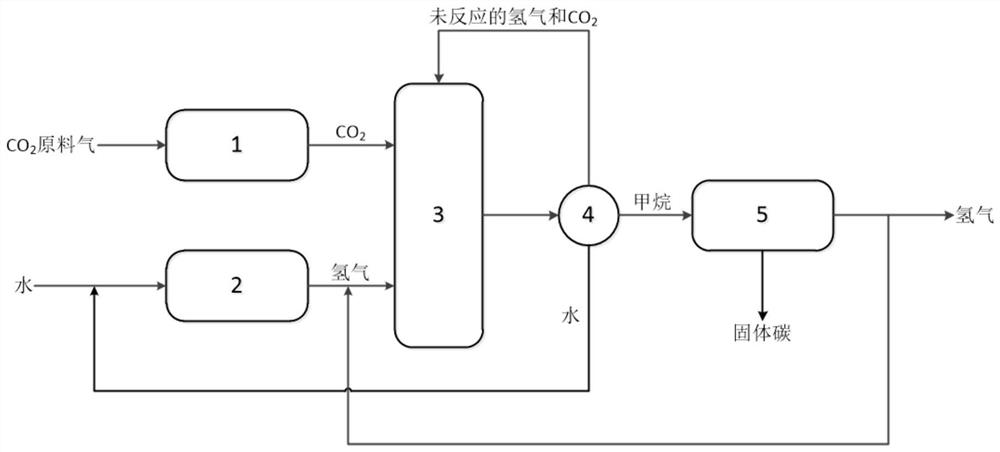

Carbon dioxide resource treatment system and method

PendingCN113086968ALower carbon dioxide levelsRealize resource disposalElectrolysis componentsEnergy inputSolid carbonEnvironmental engineering

The invention belongs to the field of environmental protection, and particularly relates to a carbon dioxide resource treatment system and method. The system provided by the invention comprises a methane synthesis device, methane separation equipment and a thermal cracking device, the methane synthesis device takes hydrogen and CO2 as reaction raw materials to catalyze and prepare methane; the methane separation equipment is used for separating reaction products conveyed by the methane synthesis device to respectively obtain methane, water and unreacted raw materials, and a feeding hole of the methane separation equipment is connected with a reaction product outlet of the methane synthesis device; and the thermal cracking device is used for carrying out catalytic cracking on methane and preparing hydrogen and solid carbon materials, and a feeding hole of the thermal cracking device is connected with a methane outlet of the methane separation equipment. According to the system provided by the invention, CO2 can be converted into a solid carbon material, CO2 recycling is realized, the content of carbon dioxide in the atmospheric environment is reduced fundamentally, and the system has good environmental benefits and economic benefits.

Owner:WEICHAI POWER CO LTD +1

Combined strain

InactiveCN102796677AReduce sludge dischargeEmission reductionBacteriaMicroorganism based processesSpecies identificationBacillus cereus

The invention discloses a combined strain. The combined strain comprises the following six kinds of microorganisms: Bacillus licheniformis, Bacillus subtilis, Bacillus lentus, Bacillus megaterium, Bacillus thuringiensis and Bacillus cereus. The cultivation of the microorganisms comprises the following steps of: sampling, culturing in a culture medium, separating target strains, performing index analysis on the separated strains, performing species identification, compatibilizing and optimizing. The functional strain can proliferate quickly in the process of decomposing organic matter, has a remarkable effect of dephosphorizing sludge, ensures that the treatment effect of the sludge meets the national emission standard, and can greatly reduce the discharge amount of the sludge.

Owner:陈玉

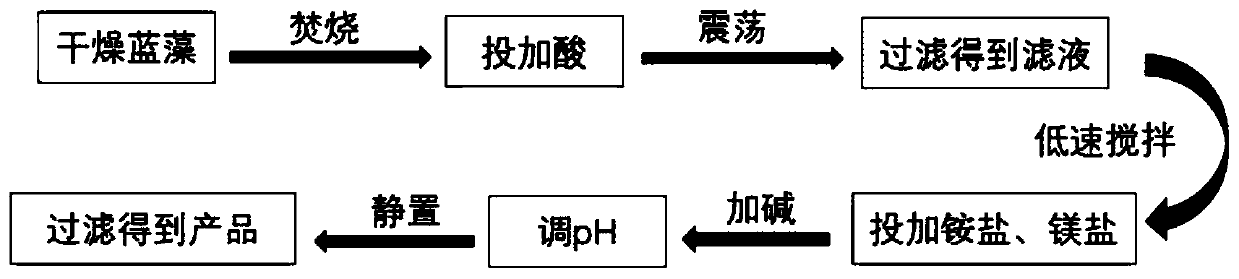

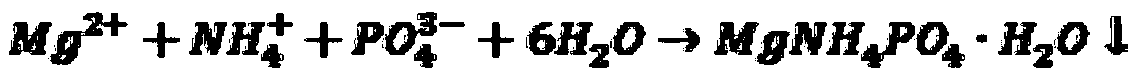

Method for recovering phosphorus in blue-green algae in struvite form

InactiveCN111348636AReduce generationAchieve reductionPhosphorus compoundsMagnesium saltStruvite Crystals

The invention discloses a method for recovering phosphorus in blue-green algae in a struvite form, which comprises the following steps: drying blue-green algae, crushing, and carrying out ashing combustion in an incinerator to obtain blue-green algae incineration ash; dissolving out phosphorus in the blue-green algae by using an acid leaching method, and filtering to obtain filtrate for later use;adding ammonium salt and magnesium salt into the filtrate while stirring at a low speed; and adding alkali liquor to adjust the pH value of a reaction solution to 8.0-10.5, filtering and recovering aprecipitate, and drying to obtain a struvite crystal product. The whole steps are simple and easy to operate, the reaction period is short, the whole phosphorus recovery process is closed, odor is reduced to the maximum extent, the prepared product struvite can be used as an efficient slow-release fertilizer and a medical raw material while phosphorus is recovered, and finally reduction, harmlessand resource treatment of salvaged blue-green algae is achieved.

Owner:JIANGSU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com