System and method for synergistic disposal of waste lithium ion batteries in cement kiln

A lithium ion battery and ion battery technology, which are applied in chemical instruments and methods, battery recycling, solid waste removal, etc., can solve the problems of ineffective treatment of waste residue, secondary pollution, and undisclosed complete process of waste lithium battery treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

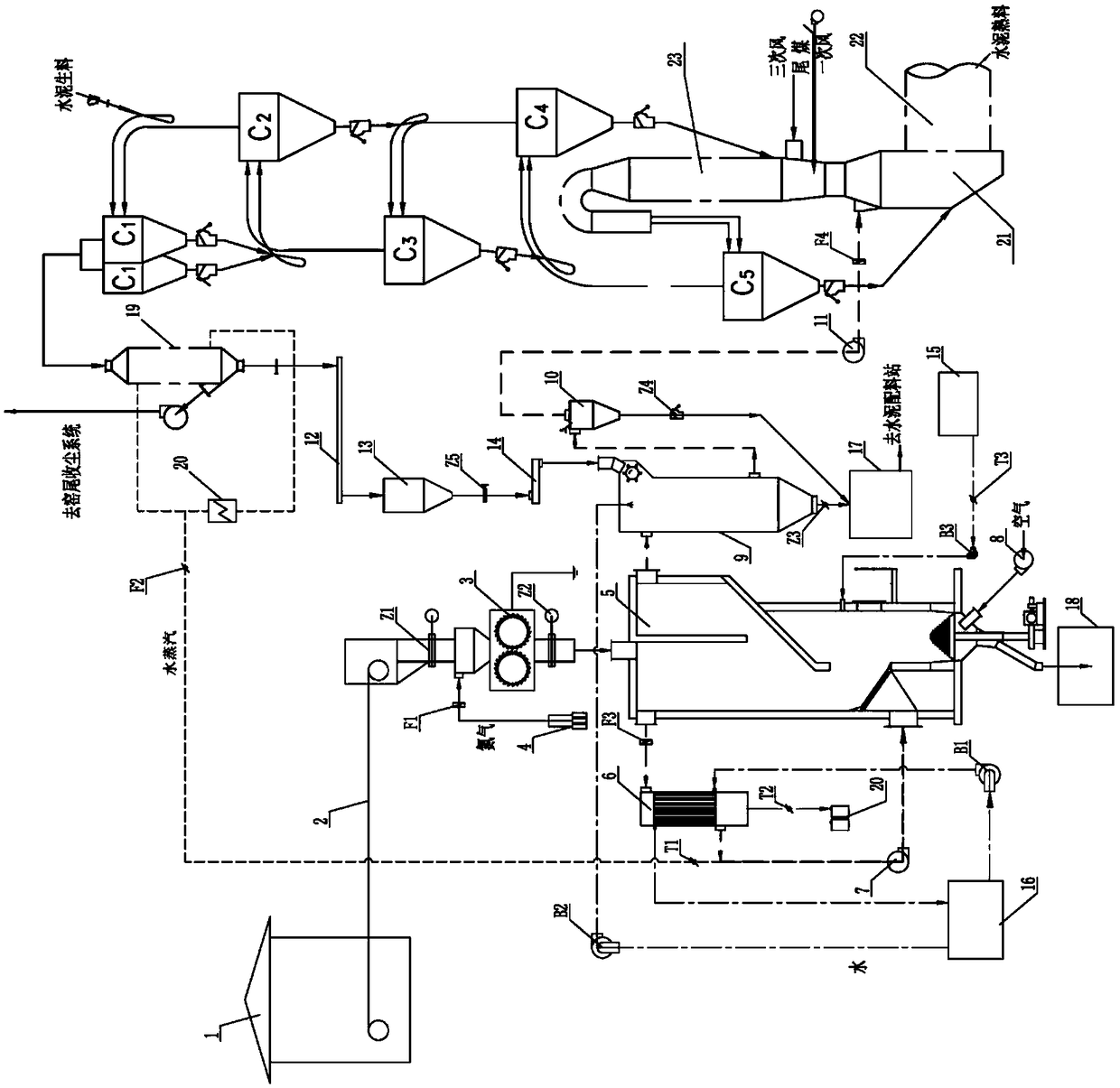

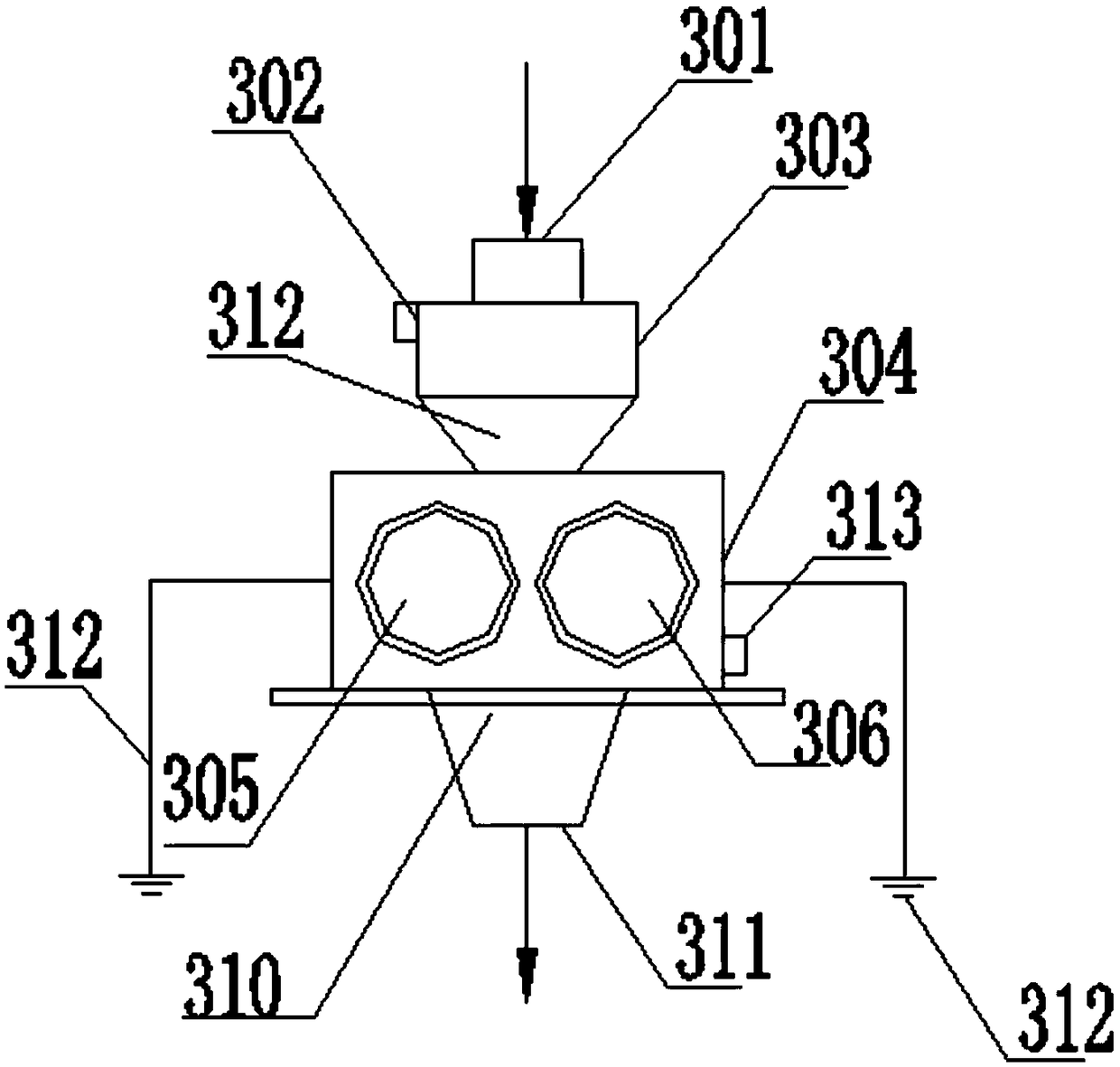

[0122] Such as Figure 1-4 7. As shown in 7-8, this embodiment provides a cement kiln co-processing system for waste lithium-ion batteries, which specifically includes: stack shed 1, anhydrous and oxygen-free biaxial crusher 3, vertical pyrolysis furnace 5, neutralization Tower 9, the extraction system of valuable elements and the cement kiln system; the shed 1 is connected to the feed inlet 301 of the anhydrous and oxygen-free double-shaft crusher 3 through the belt conveyor 2; the outlet of the anhydrous and oxygen-free double-shaft crusher 3 The feed port 311 is connected to the slag material inlet 501 of the vertical pyrolysis furnace 5; the flue gas outlet 506 of the vertical pyrolysis furnace 5 is connected to the neutralization tower 9; the mixed slag outlet 502 of the vertical pyrolysis furnace 5 passes through the feed pipe It is connected with the valuable element extraction system; the deacidification flue gas outlet of the neutralization tower 9 is connected with the...

Embodiment 2

[0156] The difference between this embodiment and embodiment 1 is that:

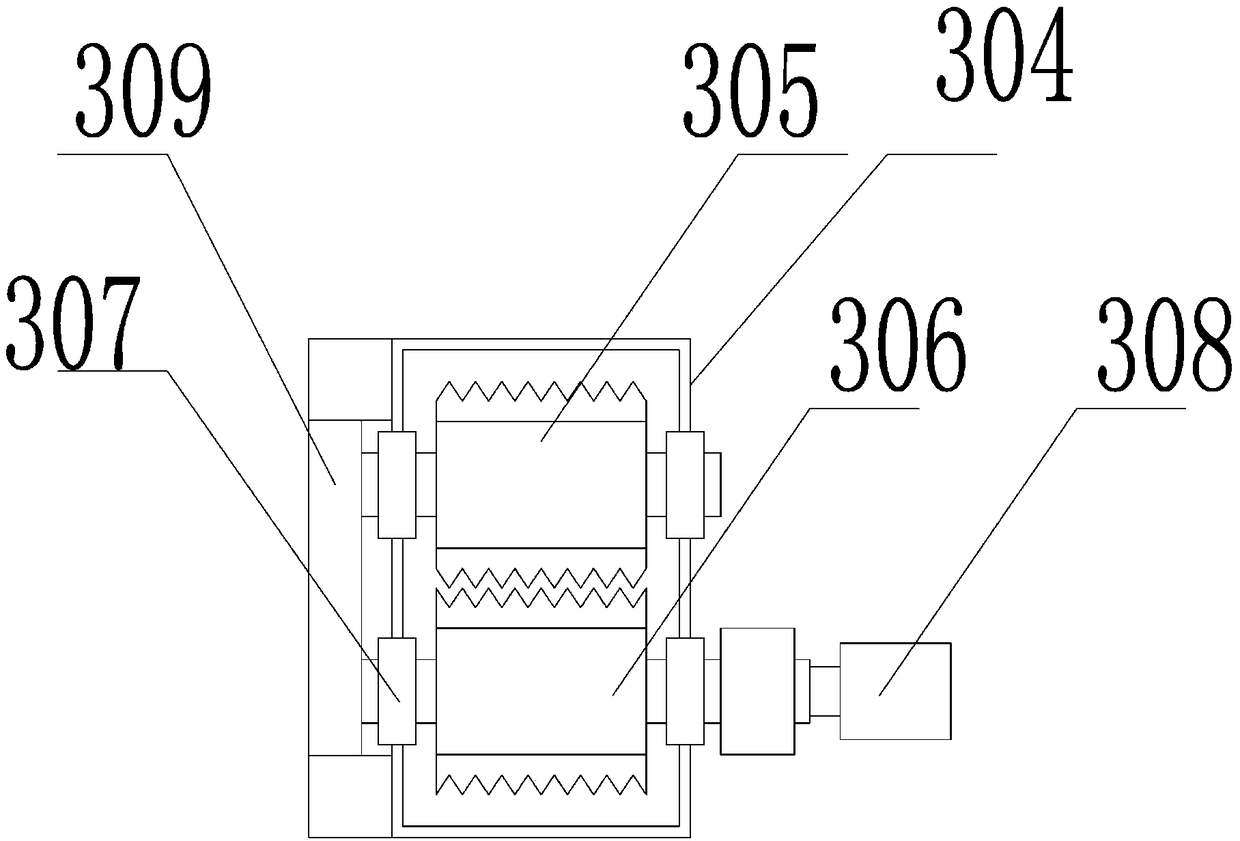

[0157] In order to increase the ability of the crushing roller surface to crush and cut metal, the crushing teeth provided on the outer circumference of the sleeve G2 of the moving roller 306 and the driven roller 305 are concave and convex crushing teeth (such as Figure 5-6 As shown), the sleeve roller G2 of the moving roller 306 and the concave-convex crushing teeth of the sleeve roller G2 of the driven roller 305 are engaged and connected to each other, which is beneficial for crushing and shredding materials.

[0158] The disposal method of the cement kiln co-processing waste lithium-ion battery system provided by the above-mentioned embodiment 1 and embodiment 2 includes: storage, classification and pretreatment of waste lithium-ion batteries; water-free and oxygen-free crushing and disintegration; evaporative decomposition and sintering; in flue gas With deacidification, solid mixed slag valuable eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com